sensor MITSUBISHI GALANT 1989 Service Owners Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 267 of 1273

FUEL SYSTEM

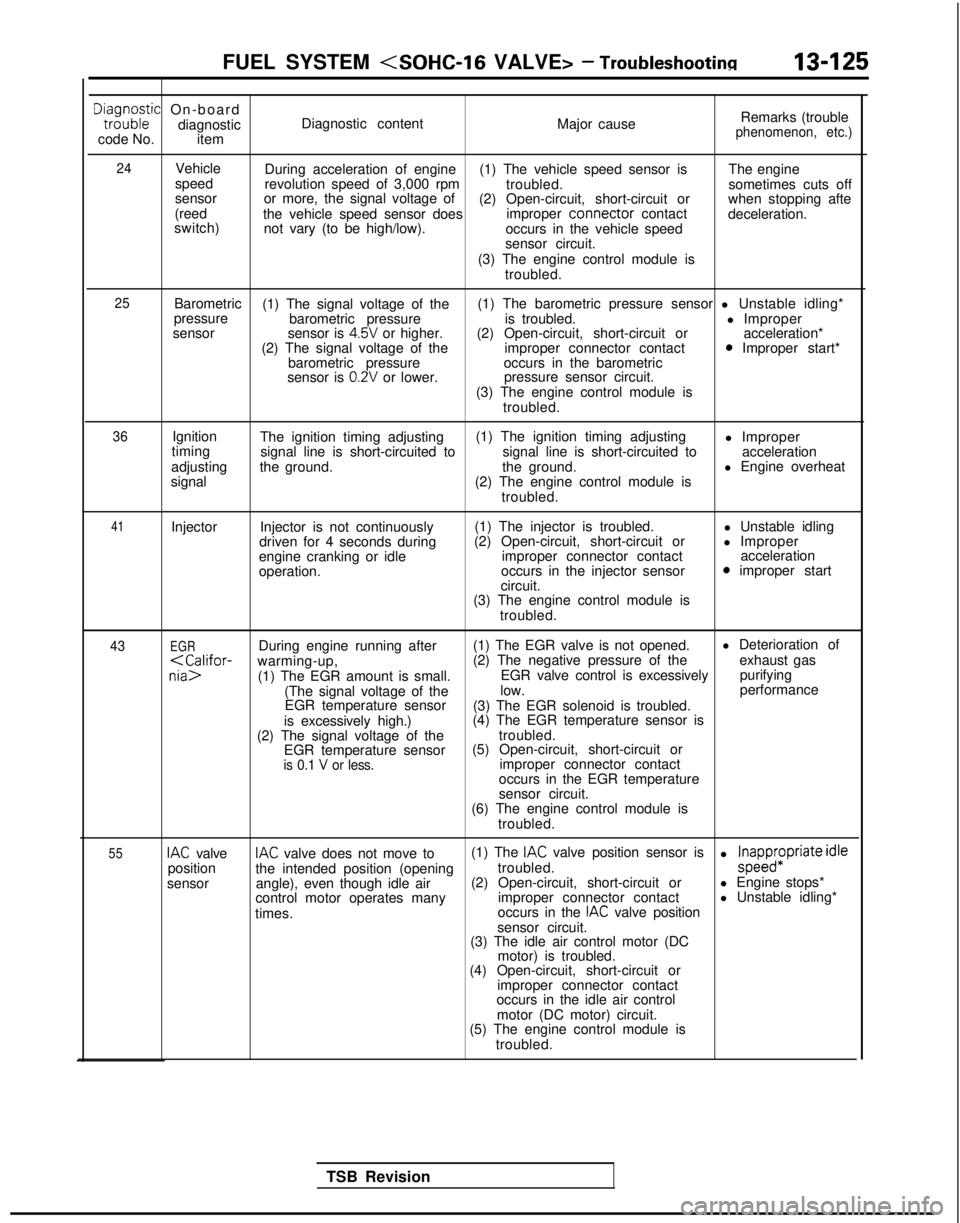

Dta,i;o;ic On-board

diagnostic

code No. item Diagnostic content

Major causeRemarks (trouble

phenomenon, etc.)

24

Vehicle

speed

sensor

(reed

switch) During acceleration of engine

(1) The vehicle speed sensor is The engine

revolution speed of 3,000 rpm troubled.sometimes cuts off

or more, the signal voltage of (2) Open-circuit, short-circuit or when stopping afte

the vehicle speed sensor does improper connector

contact

deceleration.

not vary (to be high/low). occurs in the vehicle speed

sensor circuit.

(3) The engine control module is troubled.

25Barometric (1) The signal voltage of the (1) The barometric pressure sensor l Unstable idling*

pressure barometric pressure is troubled. l Improper

sensor sensor is

4.5V or higher.(2) Open-circuit, short-circuit or acceleration*

(2) The signal voltage of the improper connector contact0 Improper start*

barometric pressure occurs in the barometric

sensor is

0.2V or lower. pressure sensor circuit.

(3) The engine control module is troubled.

36Ignition

timing

adjusting

signal The ignition timing adjusting

(1) The ignition timing adjusting

l Improper

signal line is short-circuited to signal line is short-circuited toacceleration

the ground. the ground.l Engine overheat

(2) The engine control module is troubled.

41Injector Injector is not continuously

driven for 4 seconds during

engine cranking or idle

operation. (1) The injector is troubled.

(2) Open-circuit, short-circuit or improper connector contact

occurs in the injector sensor

circuit. l Unstable idling

l Improper acceleration

0 improper start

(3) The engine control module is troubled.

43EGRDuring engine running after (1) The EGR valve is not opened. l Deterioration of

purifying

(The signal voltage of the low. performance

EGR temperature sensor (3) The EGR solenoid is troubled.

is excessively high.) (4) The EGR temperature sensor is

(2) The signal voltage of the troubled.

EGR temperature sensor (5) Open-circuit, short-circuit or

is 0.1 V or less.improper connector contact

occurs in the EGR temperature

sensor circuit.

(6) The engine control module is

troubled.

55IAC valveIAC valve does not move to (1) The IAC valve position sensor is

position the intended position (opening troubled.l ;papp$Priate idle

sensor angle), even though idle air (2) Open-circuit, short-circuit or

l Engine stops*

control motor operates many improper connector contactl Unstable idling*

times. occurs in the

IAC valve position

sensor circuit.

(3) The idle air control motor (DC

motor) is troubled.

(4) Open-circuit, short-circuit or

improper connector contact

occurs in the idle air control

motor (DC motor) circuit.

(5) The engine control module is

troubled.

TSB Revision

Page 268 of 1273

13-126FUEL SYSTEM

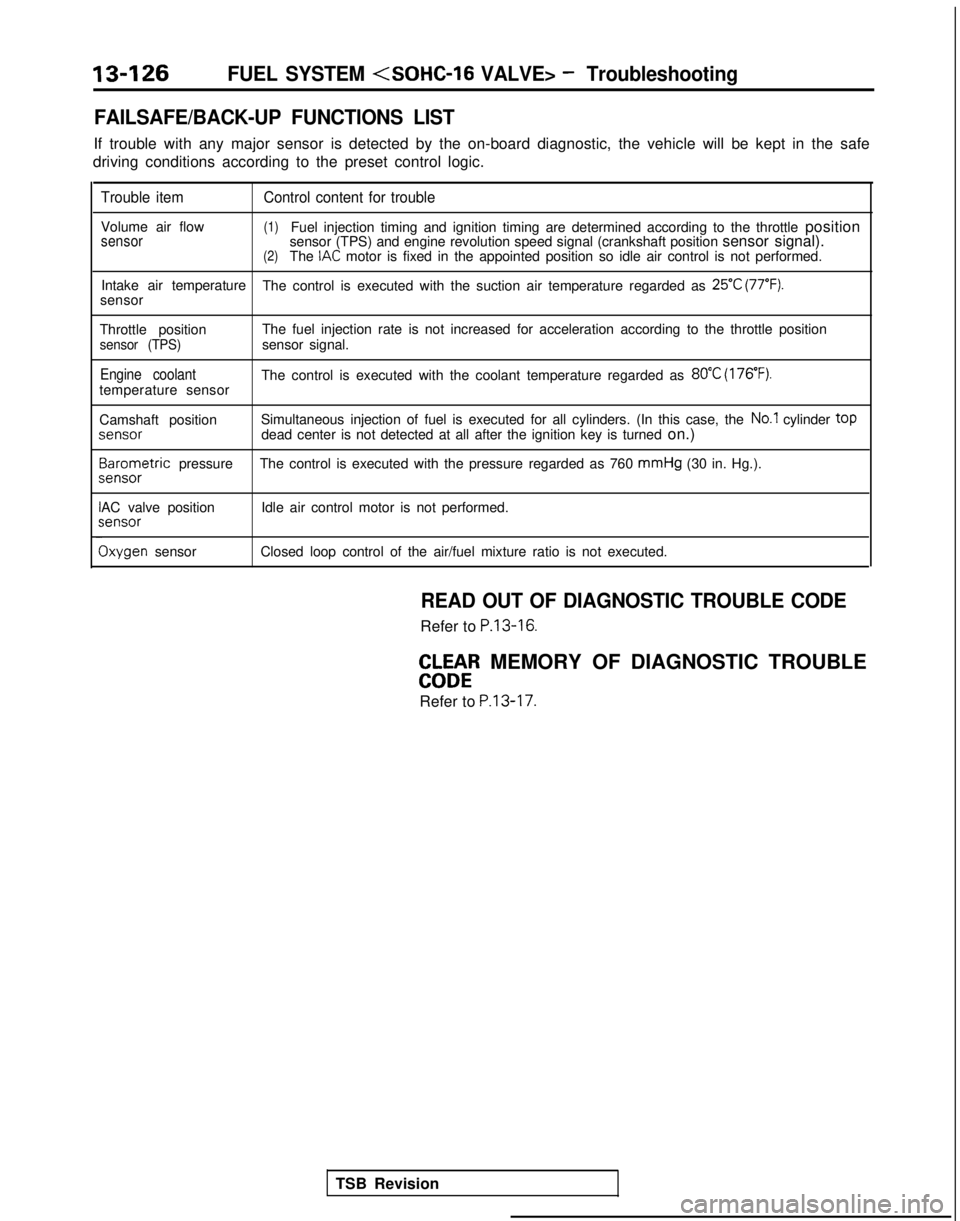

FAILSAFE/BACK-UP FUNCTIONS LIST

If trouble with any major sensor is detected by the on-board diagnostic,\

the vehicle will be kept in the safe

driving conditions according to the preset control logic.

Trouble item Control content for trouble

Volume air flow(1)Fuel injection timing and ignition timing are determined according to th\

e throttle positionsensorsensor (TPS) and engine revolution speed signal (crankshaft position \

sensor signal).(2)The IAC motor is fixed in the appointed position so idle air control is not per\

formed.

Intake air temperature The control is executed with the suction air temperature regarded as

25°C (77°F).sensor

Throttle position The fuel injection rate is not increased for acceleration according to t\

he throttle position

sensor (TPS)sensor signal.

Engine coolantThe control is executed with the coolant temperature regarded as 80°C (176’F).temperature sensor

Camshaft positionSimultaneous injection of fuel is executed for all cylinders. (In this \

case, the

No.1 cylinder top

jenS0r

dead center is not detected at all after the ignition key is turned

on.)3arometric

pressure The control is executed with the pressure regarded as 760 mmHg

(30 in. Hg.).

sensor

AC valve position Idle air control motor is not performed.;ensor

Ixygen sensor

Closed loop control of the air/fuel mixture ratio is not executed.

READ OUT OF DIAGNOSTIC TROUBLE CODE

Refer to P.13-16.

EbW&R MEMORY OF DIAGNOSTIC TROUBLE

Refer to

P.13-17.

TSB Revision

Page 269 of 1273

FUEL SYSTEM

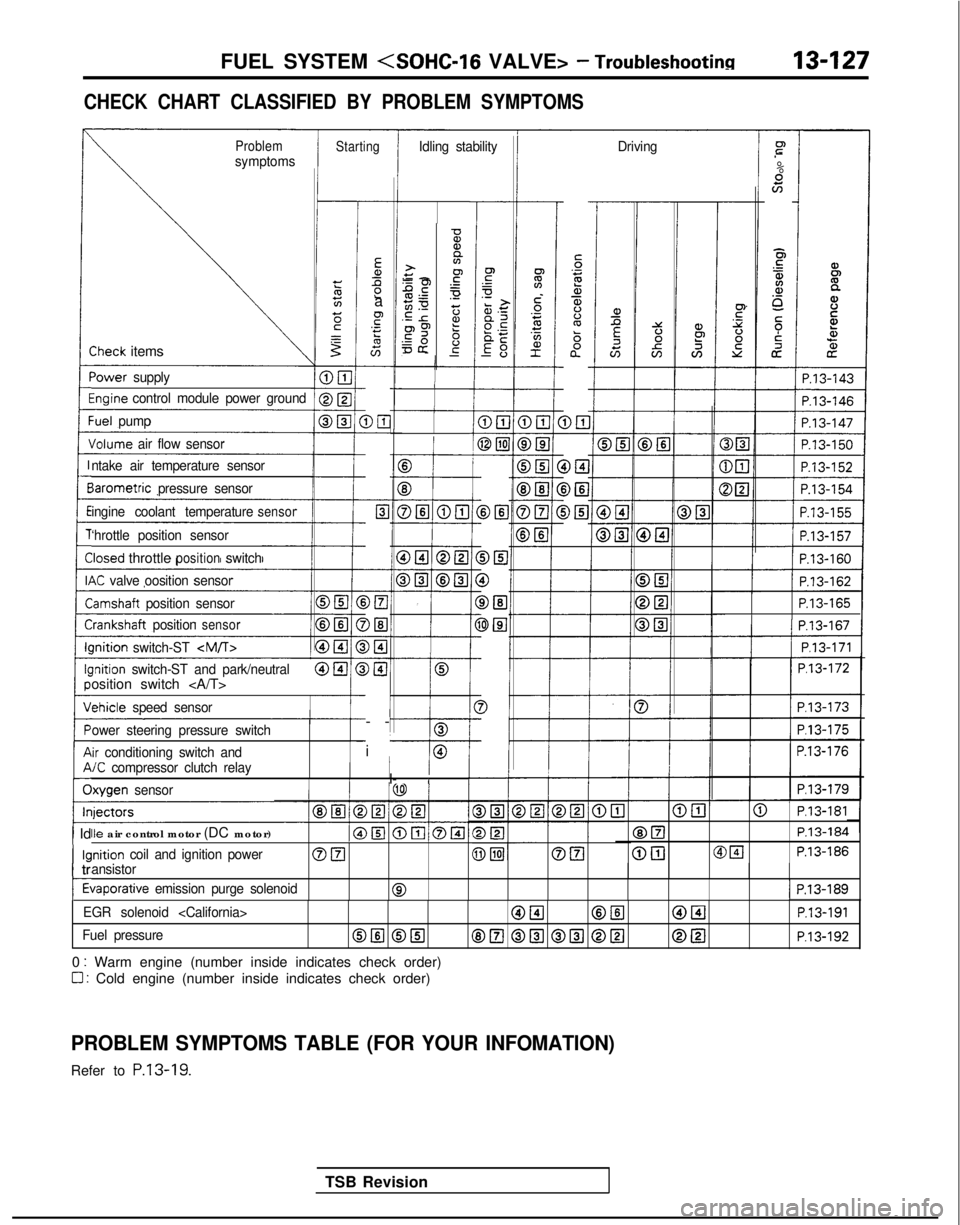

CHECK CHART CLASSIFIED BY PROBLEM SYMPTOMS

ProblemsymptomsStartingIdling stability Drivingr”

.-

%scn

E5

$4.a,o_

5;i

cz

iP.13-143

-

Ea,Ll2a

F.- s

G-

DE-

c-

Elc

-

-

>El

)El-

)I3-

)@I

I-

-

i

-

5‘32a,$%ba”

D&l DEI

i>El

-0%,a>+y -2.gPE.-50 z.E r2?p9 6=& g-

-

-Sheck items

‘ower

supply

%ginecontrol module power groundI

1 P.13-146

:uel pump

Jolume air flow sensor

B

f

E3

DELI @El

cP.13-162

P.13-165III P.13-167I

1/ P.l3-171 1

P.l3-172

P.l3-173

P.l3-175

P.13-176

P.l3-179

ntake air temperature sensor

BIB

DEI

0

DEl

3El

3

-I

iarometric

pressure sensor

ingine coolant temperature

sensor

‘hrottle position sensor

Iosed throttlepositionswitch

K valve oosition sensor

lamshaft position sensor

i-:rankshaft positionsensorIIlnition

switch-ST

-I---0lnition switch-ST and park/neutralosition switch

chicle

speed sensor

ower steering pressure switch

ir conditioning switch and/C compressor clutch relayI/I- IIlxygen sensor

@El@ P.l3-181

@ElP.13-184

@[email protected]

Ile air control motor (DC motor)

inition coil and ignition powerOFI@piJOEIansistor

tiaporative emission purge solenoid01 P.13-189

1 Id

kl

c

tr

t

EGR solenoid

Fuel pressureOIlI @El8E.l @El @El @[email protected]

0 : Warm engine (number inside indicates check order)

0 : Cold engine (number inside indicates check order)

PROBLEM SYMPTOMS TABLE (FOR YOUR INFOMATION)

Refer to P.13-19.

TSB Revision

Page 278 of 1273

13-136FUEL SYSTEM

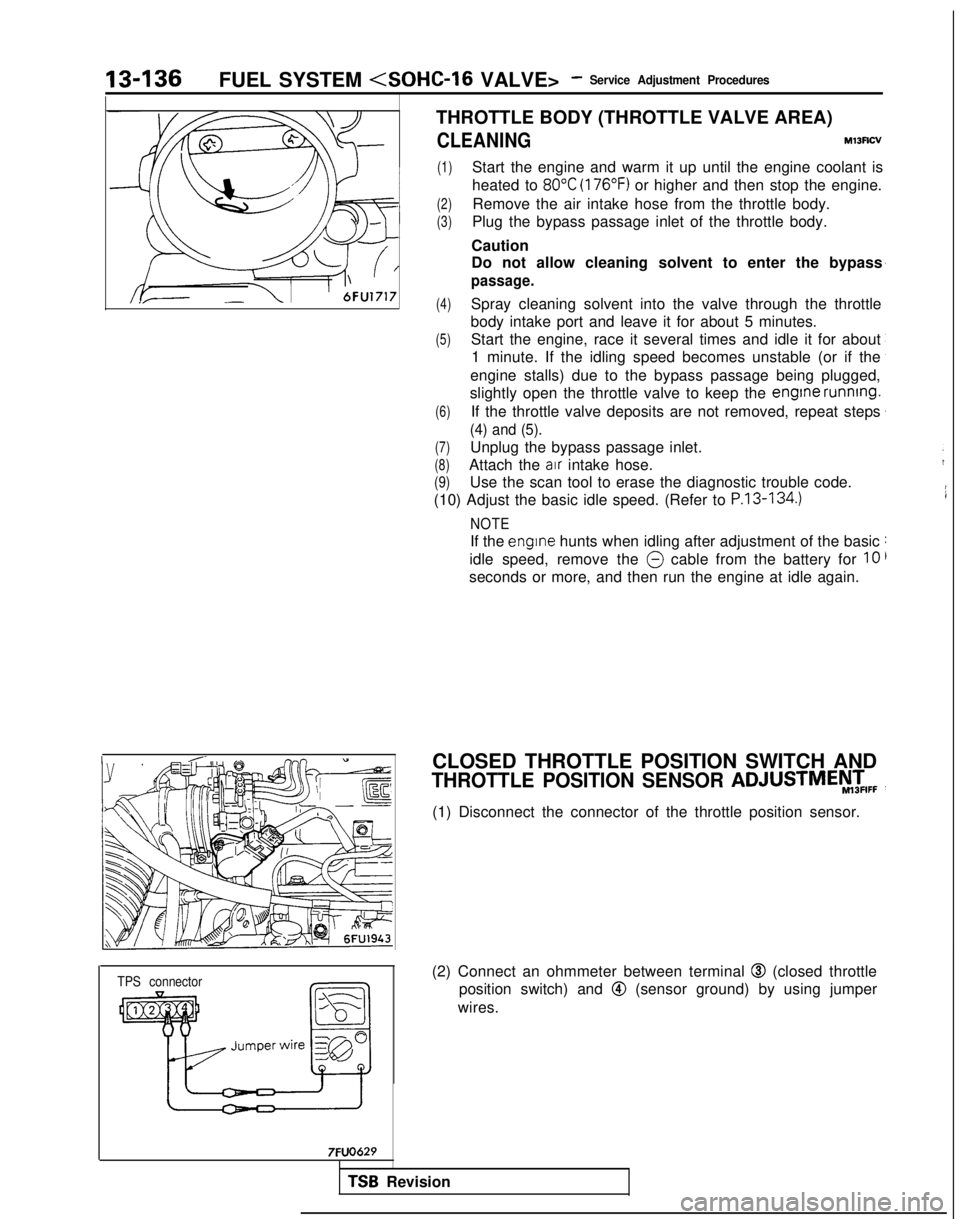

TPS connector

7FUO629

THROTTLE BODY (THROTTLE VALVE AREA)

CLEANINGMl3Rcv

(1)Start the engine and warm it up until the engine coolant is

heated to

80°C (176°F) or higher and then stop the engine.

(2)Remove the air intake hose from the throttle body.

(3)Plug the bypass passage inlet of the throttle body.

Caution

Do not allow cleaning solvent to enter the bypass

passage.

(4)Spray cleaning solvent into the valve through the throttle

body intake port and leave it for about 5 minutes.

(5)Start the engine, race it several times and idle it for about 1 minute. If the idling speed becomes unstable (or if the

engine stalls) due to the bypass passage being plugged,

slightly open the throttle valve to keep the engine

running.

(6)If the throttle valve deposits are not removed, repeat steps

(4) and (5).

(7)Unplug the bypass passage inlet.

(8)Attach the air intake hose.

(9)Use the scan tool to erase the diagnostic trouble code.

(10) Adjust the basic idle speed. (Refer to

P.13-134.)

NOTE

If the engrne hunts when idling after adjustment of the basic

idle speed, remove the

@ cable from the battery for 10

seconds or more, and then run the engine at idle again.

CLOSED THROTTLE POSITION SWITCH AND

THROTTLE POSITION SENSOR ADJUSTMEy,zIFF

(1) Disconnect the connector of the throttle position sensor.

(2) Connect an ohmmeter between terminal

@I (closed throttle

position switch) and

@ (sensor ground) by using jumper

wires.

TSB Revision

Page 279 of 1273

FUEL SYSTEM

I;gFixed SAS

Terminal @Terminal @(sensor output) (sensor ground) /

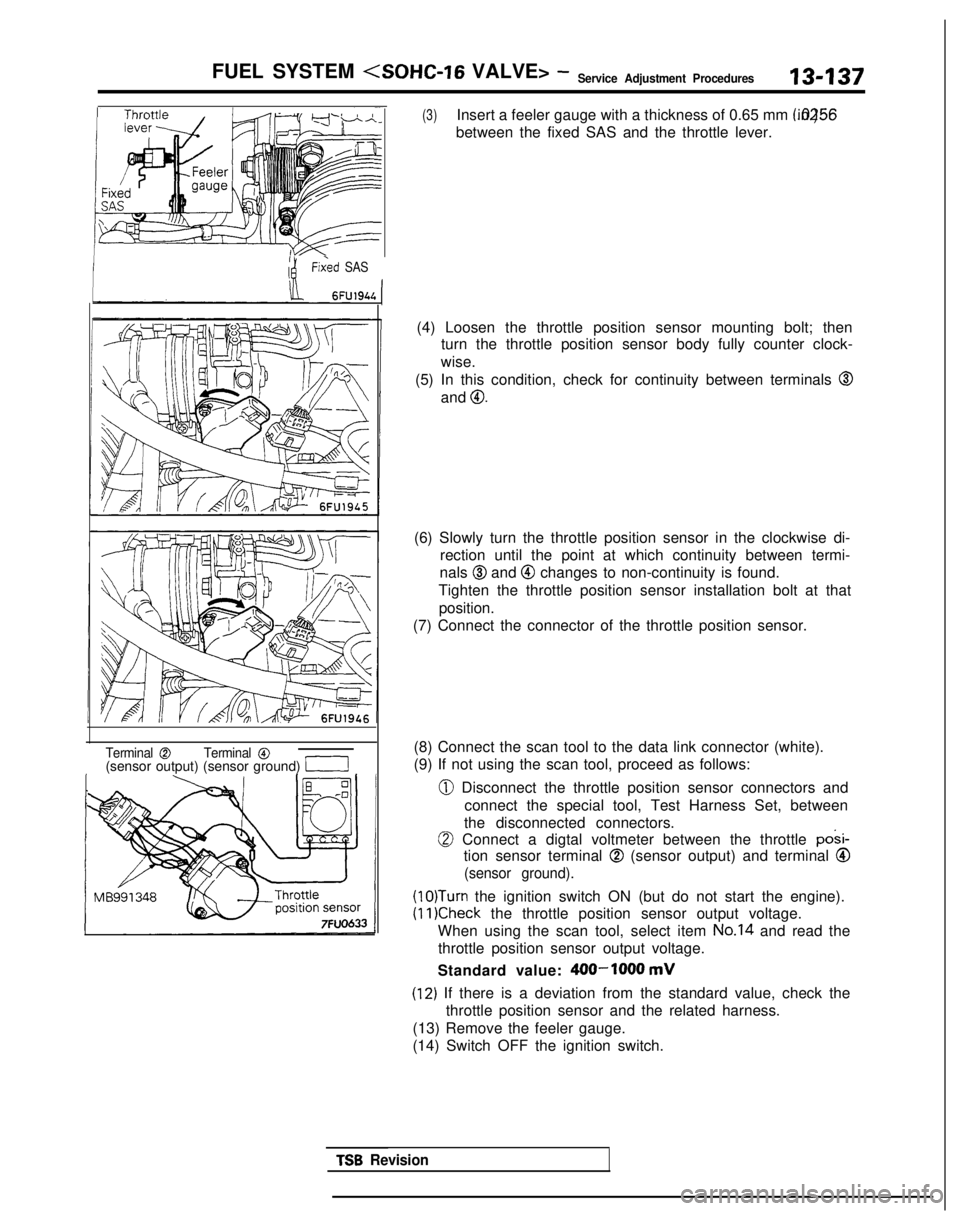

(3)Insert a feeler gauge with a thickness of 0.65 mm (.0256 in.)

between the fixed SAS and the throttle lever.

(4) Loosen the throttle position sensor mounting bolt; then turn the throttle position sensor body fully counter clock-

wise.

(5) In this condition, check for continuity between terminals

@

and 0.

(6) Slowly turn the throttle position sensor in the clockwise di- rection until the point at which continuity between termi-

nals

@I and @ changes to non-continuity is found.

Tighten the throttle position sensor installation bolt at that position.

(7) Connect the connector of the throttle position sensor.

(8) Connect the scan tool to the data link connector (white).

(9) If not using the scan tool, proceed as follows:

0 Disconnect the throttle position sensor connectors and connect the special tool, Test Harness Set, between

the disconnected connectors.

0 Connect a digtal voltmeter between the throttle posi-

tion sensor terminal

@ (sensor output) and terminal Q

(sensor ground).

(lO)Turn the ignition switch ON (but do not start the engine).

(11)Check the throttle position sensor output voltage.

When using the scan tool, select item

No.14 and read the

throttle position sensor output voltage.

Standard value:

400-1000 mV

(12) If there is a deviation from the standard value, check the throttle position sensor and the related harness.

(13) Remove the feeler gauge.

(14) Switch OFF the ignition switch.

TSB Revision

Page 280 of 1273

13-138

FUEL SYSTEM (SOHC-16 VALVE>- Service Adjustment Procedures

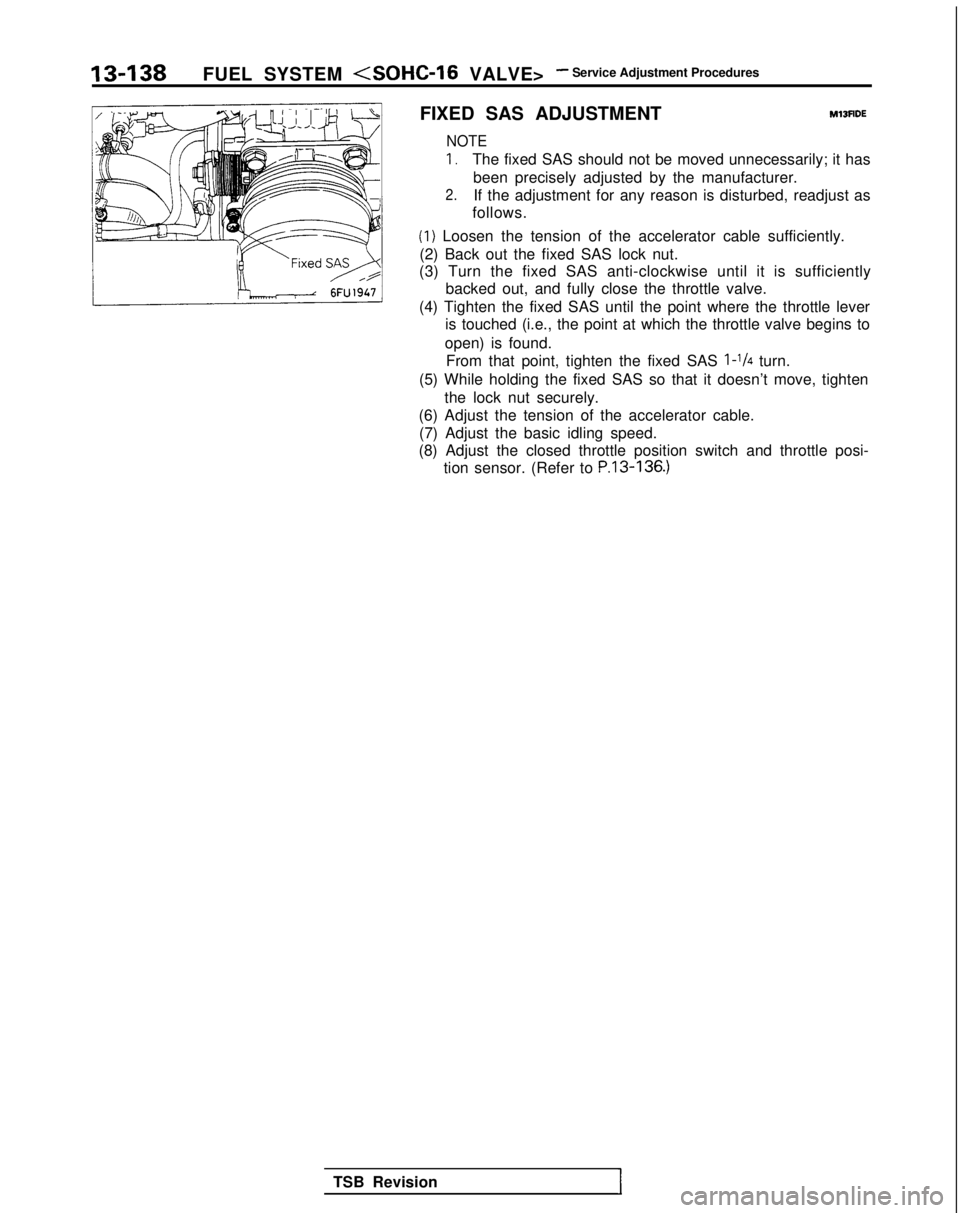

FIXED SAS ADJUSTMENT

M13FlDE

NOTE

I,The fixed SAS should not be moved unnecessarily; it has been precisely adjusted by the manufacturer.

2.If the adjustment for any reason is disturbed, readjust as

follows.

(1) Loosen the tension of the accelerator cable sufficiently.

(2) Back out the fixed SAS lock nut.

(3) Turn the fixed SAS anti-clockwise until it is sufficiently

backed out, and fully close the throttle valve.

(4) Tighten the fixed SAS until the point where the throttle lever is touched (i.e., the point at which the throttle valve begins to

open) is found. From that point, tighten the fixed SAS

l-1/4 turn.

(5) While holding the fixed SAS so that it doesn’t move, tighten the lock nut securely.

(6) Adjust the tension of the accelerator cable. (7) Adjust the basic idling speed.

(8) Adjust the closed throttle position switch and throttle posi- tion sensor. (Refer to

P.13-136.)

TSB RevisionI

Page 281 of 1273

FUEL SYSTEM

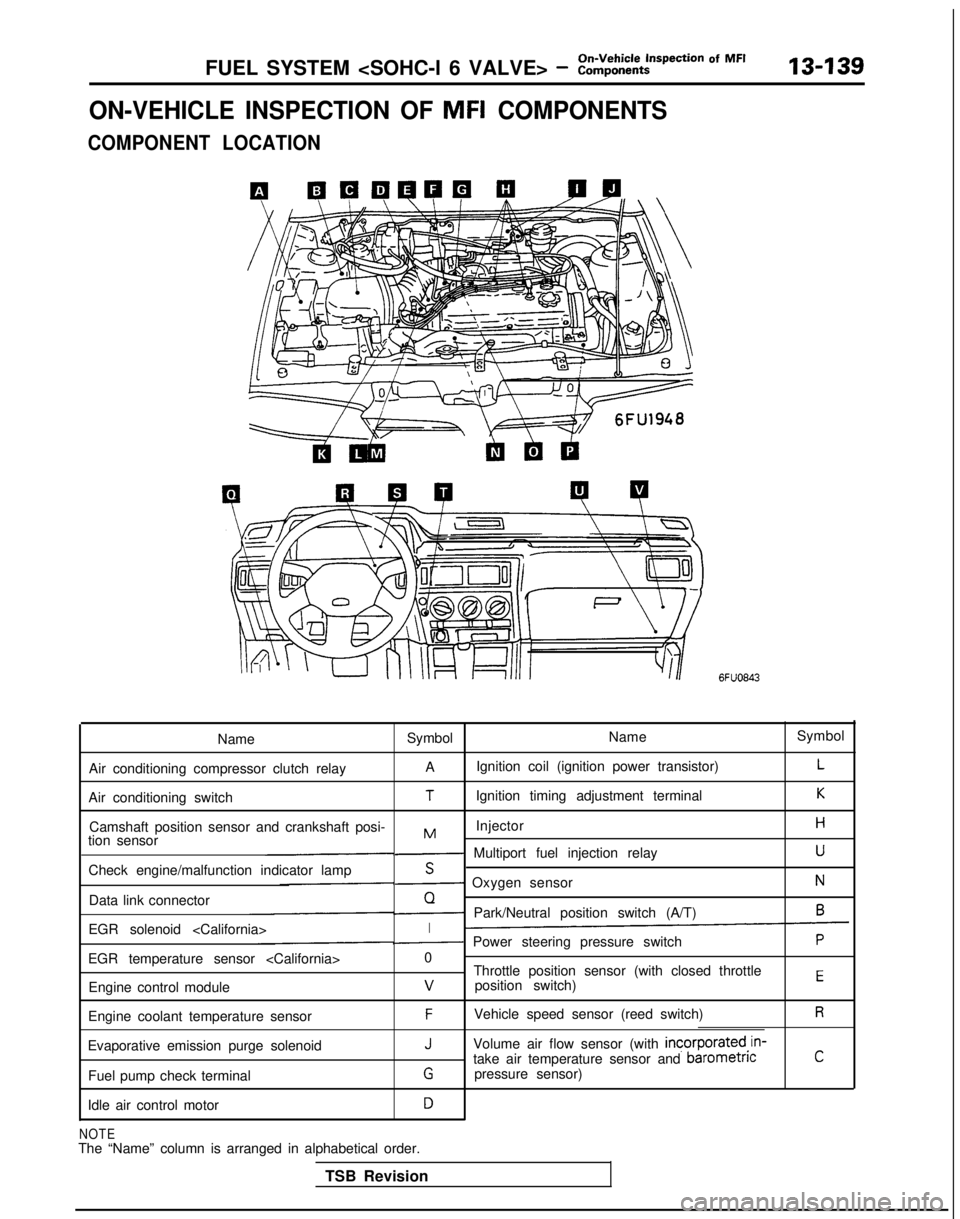

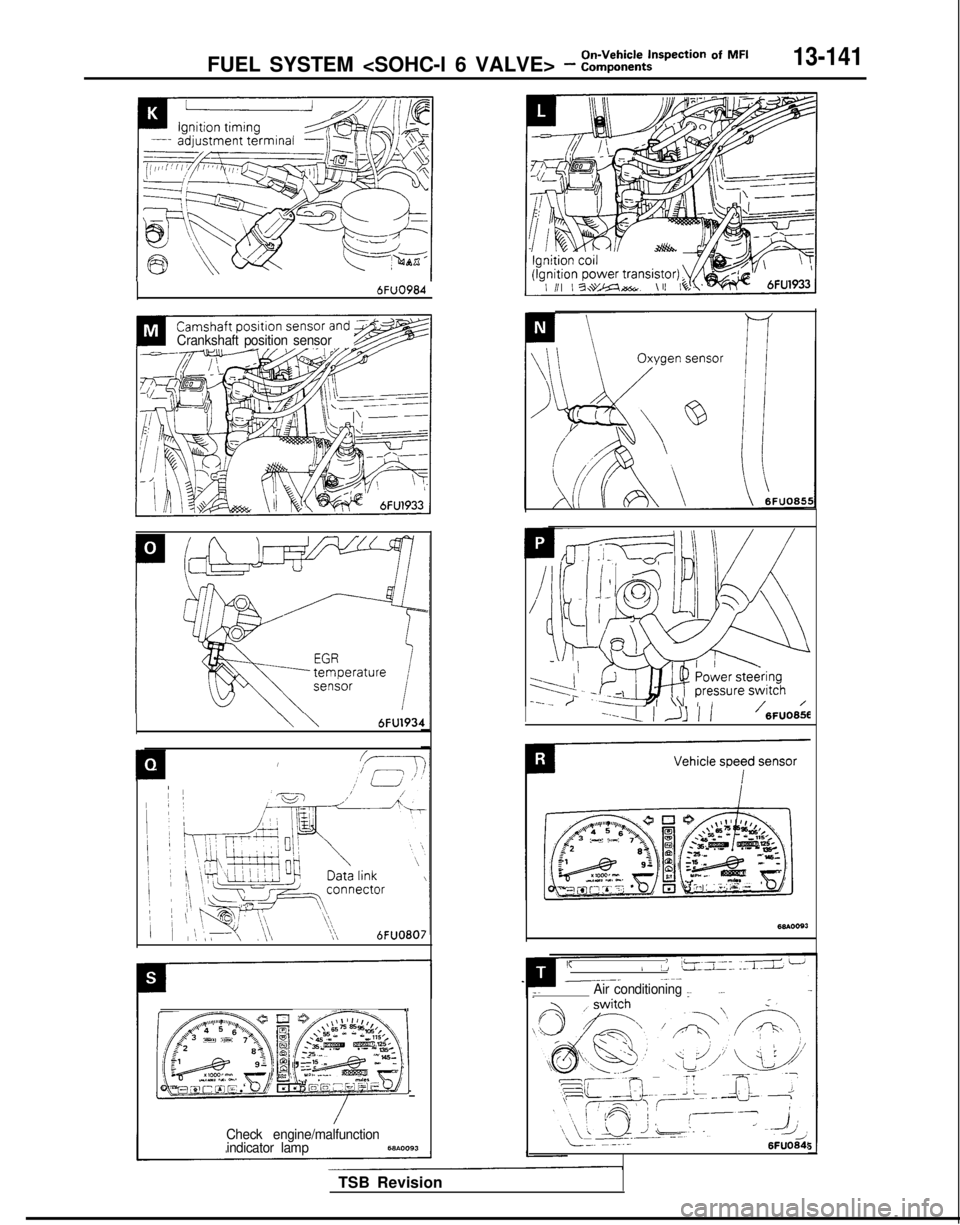

ON-VEHICLE INSPECTION OF MFI COMPONENTS

COMPONENT LOCATION

6FUO843

Name Symbol NameSymbol

Air conditioning compressor clutch relay A

Ignition coil (ignition power transistor)

L

Air conditioning switchTIgnition timing adjustment terminalK

Camshaft position sensor and crankshaft posi- InjectorHMtion sensor- Multiport fuel injection relayU

Check engine/malfunction indicator lampS- Oxygen sensorN

Data link connectorQ- Park/Neutral position switch (A/T)6

EGR solenoid

EGR temperature sensor

Throttle position sensor (with closed throttle

position switch)

EEngine control modulev

Engine coolant temperature sensorFVehicle speed sensor (reed switch)R

Evaporative emission purge solenoidJVolume air flow sensor (with incorporated,in-

take air temperature sensor and barometncC

Fuel pump check terminalGpressure sensor)

Idle air control motor

D

NOTEThe “Name” column is arranged in alphabetical order. TSB Revision

Page 283 of 1273

FUEL SYSTEM

6FuO984

Crankshaft position sensor

\\6FU193~

I(7-T

I;.’ E

,/ii

;

i

; ~&qqLk~

)

’ [,,“\,k@$&b;,,,“\

I’

/ \, pQi, >{,

1; /

‘\l>,

/\\\6FUO8Oi

,<,$+$GgT

z Jp$j&& ‘\

,

“2$---8%\.35 Fqp2; ,I <,, cLTgg.&~.

,D~~,

1sl ) g , a&&iI& I.“: :

(;-omd!gs?~ 5, gt : .“*I-- L l2,, m ‘IFiTb;qF

/Check engine/malfunction

indicator lamp68b.0093

B :iG i 1

,i mIl-

11

’ 0_;

3

(1P

I”;l-i-yCL, ,\i / ,---_ /

’ - ’ +-+j$p2E~~;:c9h

/ /I----4 ) Jj 1 1’ 6FU0656

68mosJ

I(>/

!,ij”_II. .:a L-2__--. ~-~-Air conditioning I~.~ ~..

LT. --..-6FUO64!

TSB Revision

Page 292 of 1273

On-Vehicle Inspection of MFI

13450FUEL SYSTEM

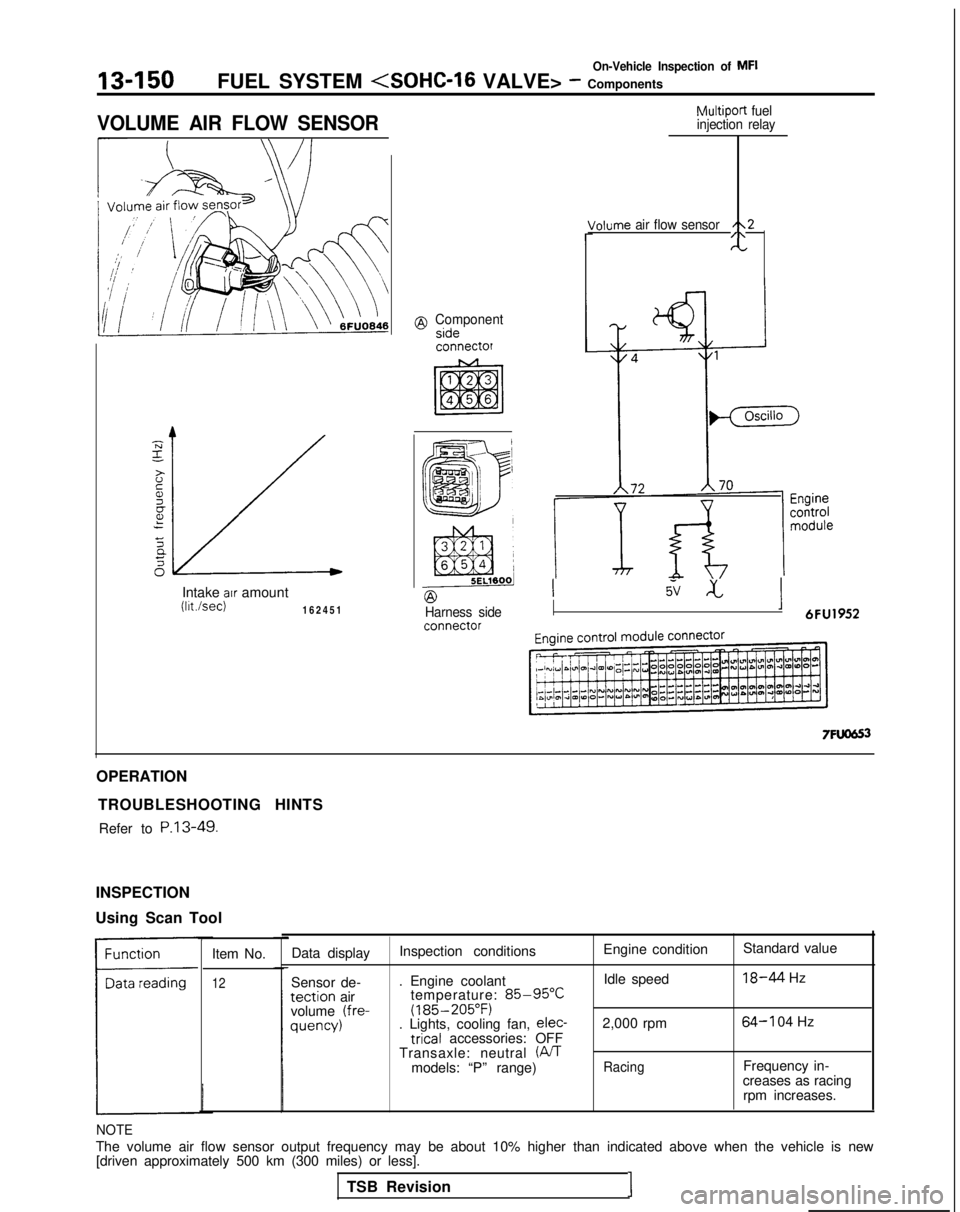

VOLUME AIR FLOW SENSOR

Intake air amountWsec)16245

1

@ Componentsideconnectof

Multiport

fuel

injection relay

/ohme air flow sensor/\2/\-

@Harness side

Isv xI 6FU1952

OPERATION TROUBLESHOOTING HINTSRefer to

P.13-49.

INSPECTION

Using Scan Tool

Item No.

12

Data displayInspection conditions Engine condition

Standard value

Sensor de- . Engine coolant Idle speed

18-44 Hz

tection airtemperature: 85-95°C

volume (fre- (185-205°F)

quency)

. Lights, cooling fan, elec-

2,000 rpm64-l 04 Hz tricaI

accessories: OFF

Transaxle: neutral

(PJTmodels: “P” range)RacingFrequency in-

creases as racing rpm increases.

NOTE

The volume air flow sensor output frequency may be about 10% higher than\

indicated above when the vehicle is new[driven approximately 500 km (300 miles) or less].

TSB Revision

1

Page 293 of 1273

On-Vehicle Inspection of MFIFUEL SYSTEM

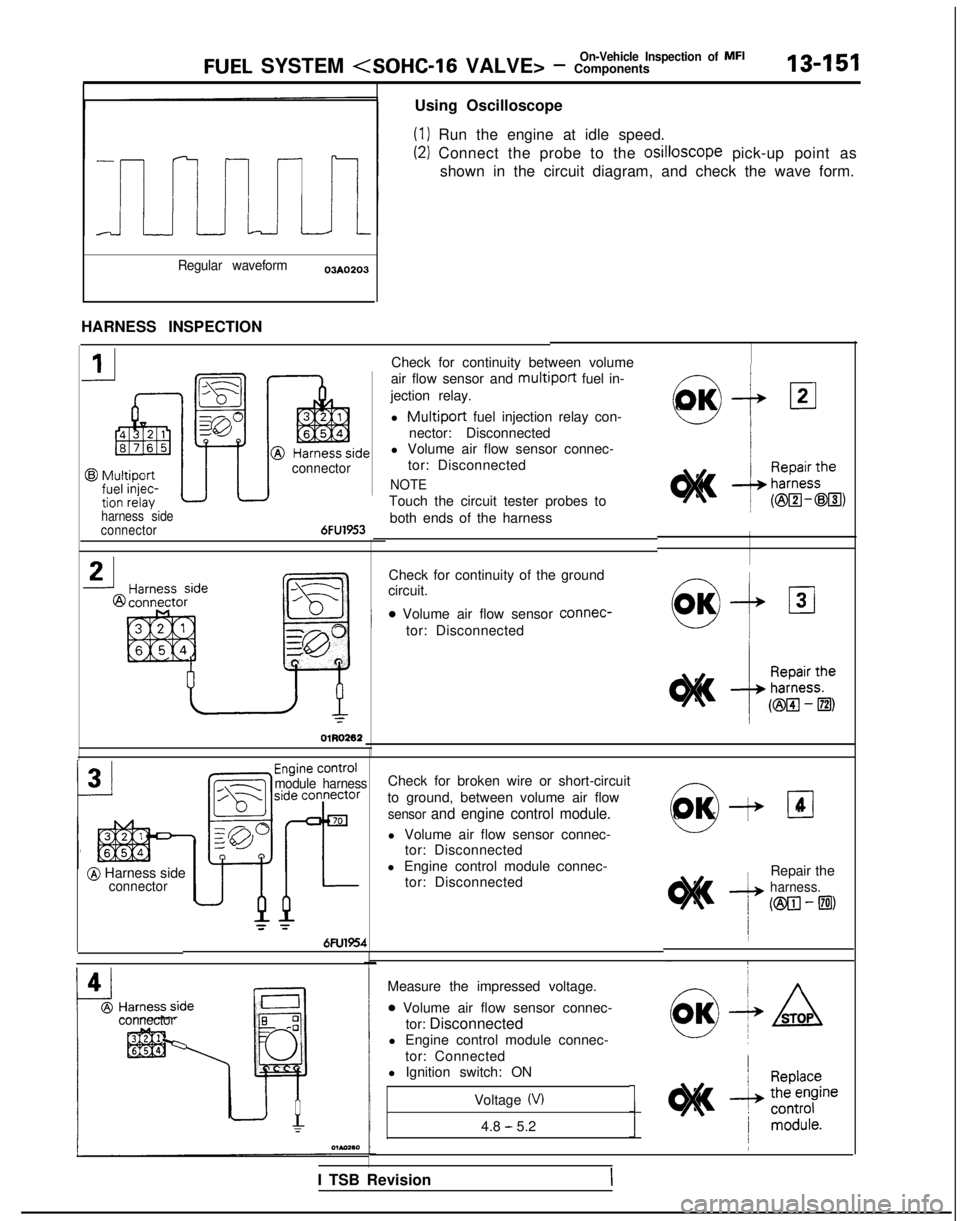

Using Oscilloscope

(1) Run the engine at idle speed.

(2) Connect the probe to the osilloscope

pick-up point as

shown in the circuit diagram, and check the wave form.

Regular waveform03AO203

HARNESS INSPECTION

Check for continuity between volume

air flow sensor and

multiport fuel in-

jection relay.

l

Multiport fuel injection relay con-

nector: Disconnected

l Volume air flow sensor connec-

tor: Disconnected

NOTE

Touch the circuit tester probes to

both ends of the harness

a+

OK 121

harness side

connector6FU1953

connector

Check for continuity of the ground-Icircuit.

0 Volume air flow sensor connec-WI+ 131tor: DisconnectedL-l I

OlR0262

/I

module harness

@ Harness sideconnector

= =

6FU1954

0O

K

-I+

Check for broken wire or short-circuit

to ground, between volume air flow

sensor and engine control module.

l Volume air flow sensor connec- tor: Disconnected

l Engine control module connec- tor: Disconnected

El4

Repair the

harness.

(ml-El)

Measure the impressed voltage.

0 Volume air flow sensor connec- tor: Disconnected

l Engine control module connec-

tor: Connected

l Ignition switch: ONconnector

Voltage (V)

4.8 - 5.2

I TSB Revision