sensor MITSUBISHI GALANT 1989 Service Manual PDF

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 207 of 1273

FUEL SYSTEM

(1) Improper adjustment of the basic idling speed.

(2) Deposits adhering to the ttirottle valve.

(3) Air being taken into the intake manifold due to a gasket leak, etc.

OPERATION

ISC motor position sensor is a variable resistor type,

and is integrated in the

ISC motor system. The slid-

ing pin of

ISC motor position sensor is in contact

with the end of the plunger. Therefore, as the plun- ger moves, the internal resistance of

ISC motor pos-

ition sensor varies. This leads to the variation of the (4) Improper seating of the EGR valve seat.

(5) lmcomplete combustion within a cylinder. (Mal-

function of spark plugs, ignition coil, injectors,

compression pressure, etc.)

the plunger position of the

ISC motor system, and

sends the signal to ECM. ECM processes the

ISC

motor position sensor signal, idle signal, coolant

temperature signal, load signal (A/T &

A/C) and ve-

hicle speed signal to control the opening angle of

the throttle valve and revolution speed during

en-

output voltage. ISC motor position sensor detects gine idling.

TROUBLESHOOTING HINTS

Since idling is not controlled when ISC motor posi-

tion sensor is troubled, idling may not be evenly

maintained.

INSPECTION

Using Scan tool

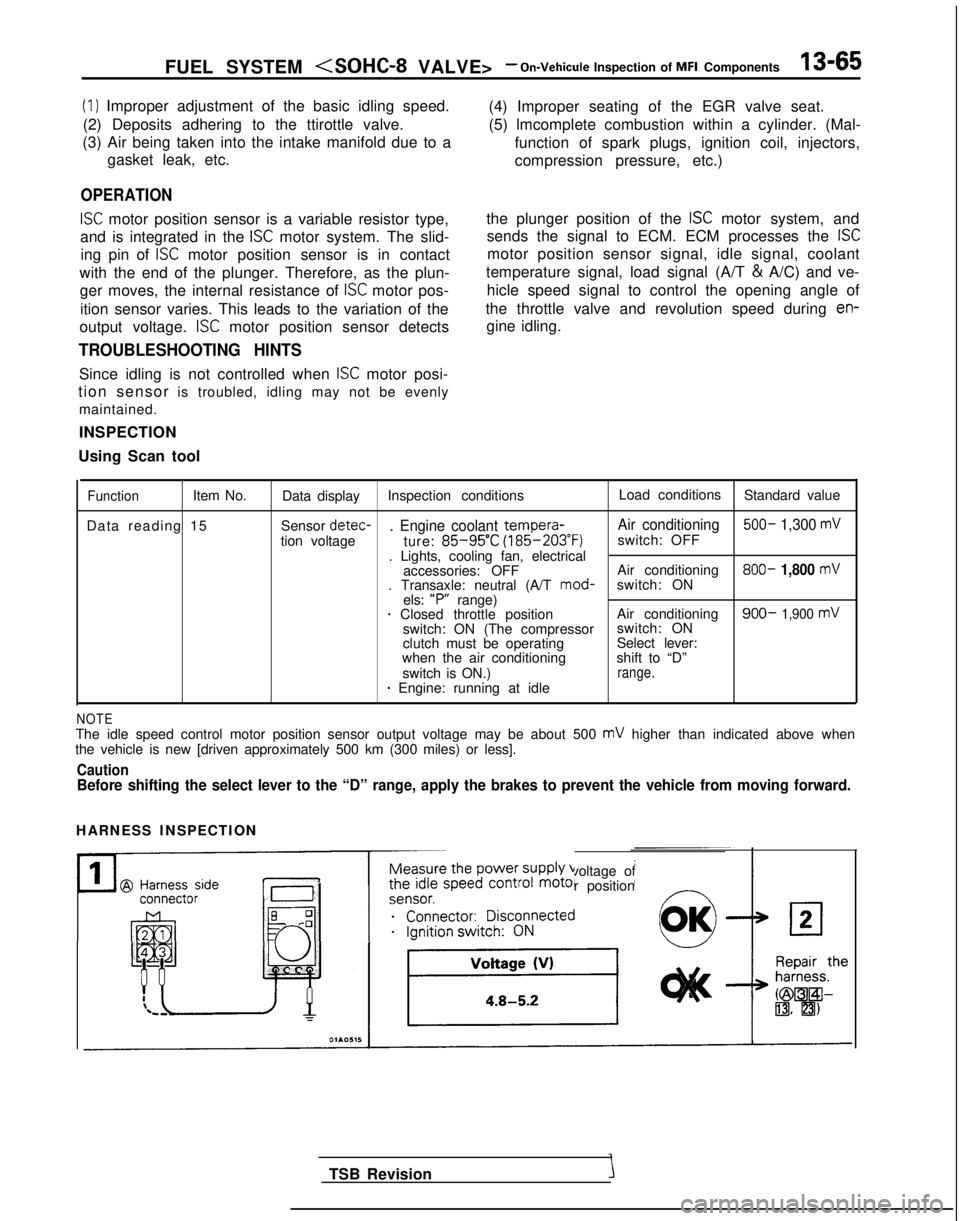

FunctionItem No. Data display Inspection conditions Load conditions

Standard value

Data reading 15 Sensor detec-

. Engine coolant tempera-

Air conditioning 500- 1,300 mV

tion voltage

ture: 85-95’C (185-203°F)

switch: OFF

. Lights, cooling fan, electrical accessories: OFF Air conditioning 800-

1,800 mV. Transaxle: neutral (A/T

mod-

switch: ON

els: “P”

range)

1 Closed throttle position Air conditioning900- 1,900 mVswitch: ON (The compressorswitch: ON

clutch must be operating Select lever:

when the air conditioning shift to “D”

switch is ON.)

range.* Engine: running at idle

NOTEThe idle speed control motor position sensor output voltage may be about\

500 mV higher than indicated above when

the vehicle is new [driven approximately 500 km (300 miles) or less].

CautionBefore shifting the select lever to the “D” range, apply the brake\

s to prevent the vehicle from moving forward.

HARNESS INSPECTION

Measure the power supply voltage of

the idle speed control motor position

ei;;;it;;sco$ected

__...._ -.-

TSB Revision

Page 208 of 1273

13-66 FUEL SYSTEM

Harness

sde

connectorI

OlAO362

@ Harness sideconnector

Engine control

module harnessside connector

I-

r

MD9984646FUO666

MD9984646FUo666

A

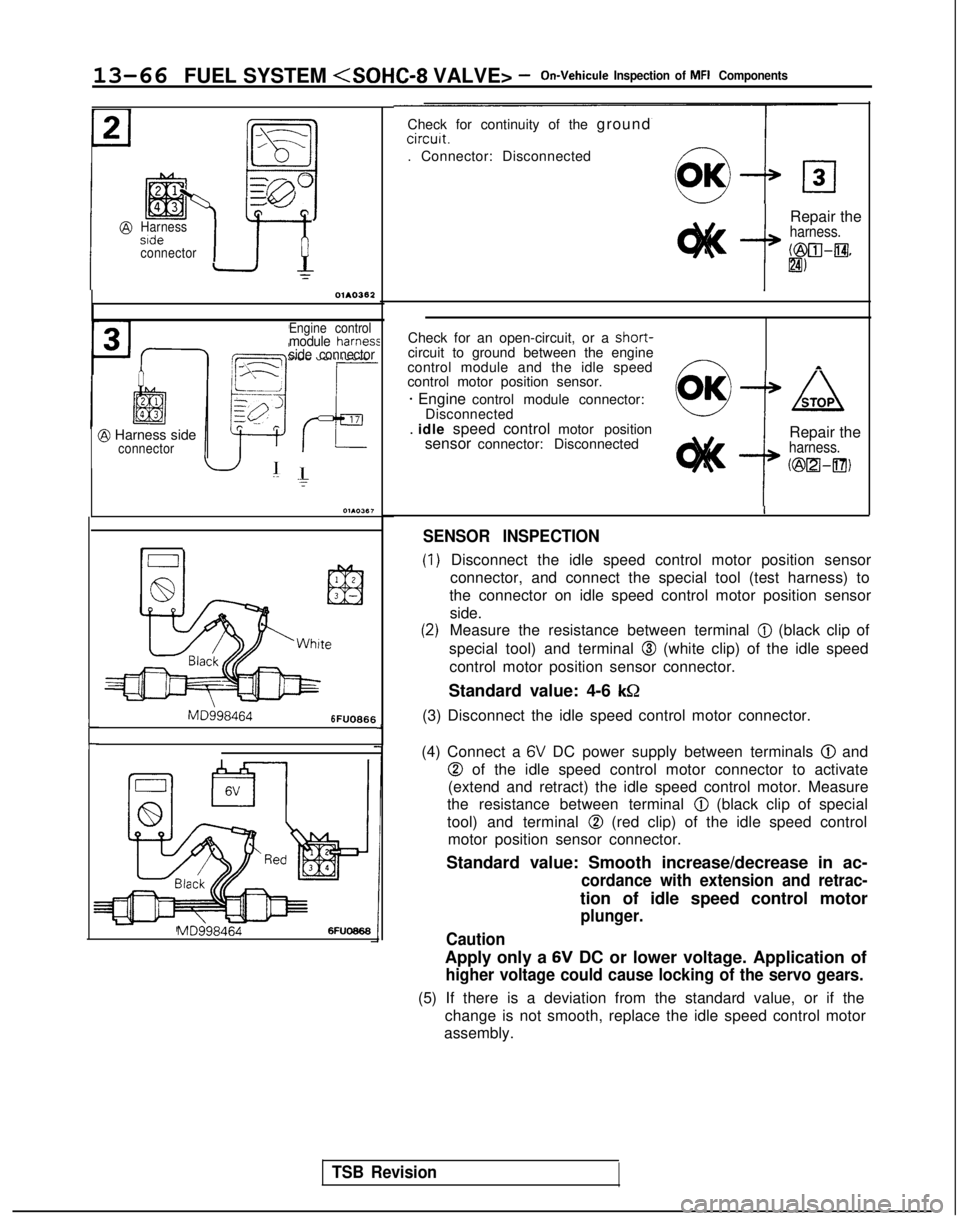

Check for continuity of the groundcircuit.

. Connector: Disconnected

t

Repair theharness.

l&l)

Check for an open-circuit, or a short-circuit to ground between the engine

control module and the idle speed

control motor position sensor.

* Engine control module connector:f-

A

1

Disconnected

. idle speed control motor position sensor connector: Disconnected Repair the

harness.

~@[z1-8)

I

SENSOR INSPECTION

Disconnect the idle speed control motor position sensor

connector, and connect the special tool (test harness) to

the connector on idle speed control motor position sensor side.

Measure the resistance between terminal

@ (black clip of

special tool) and terminal

0 (white clip) of the idle speed

control motor position sensor connector.

Standard value: 4-6

kS2

(3) Disconnect the idle speed control motor connector.

(4) Connect a

6V DC power supply between terminals 0 and

@ of the idle speed control motor connector to activate

(extend and retract) the idle speed control motor. Measure

the resistance between terminal

@ (black clip of special

tool) and terminal

0 (red clip) of the idle speed control

motor position sensor connector.

Standard value: Smooth increase/decrease in ac-

cordance with extension and retrac-

tion of idle speed control motor

plunger.

Caution

Apply only a 6V DC or lower voltage. Application of

higher voltage could cause locking of the servo gears.

(5) If there is a deviation from the standard value, or if the change is not smooth, replace the idle speed control motor

assembly.

TSB Revision

Page 209 of 1273

.-•r12-67FUEL SYSTEM

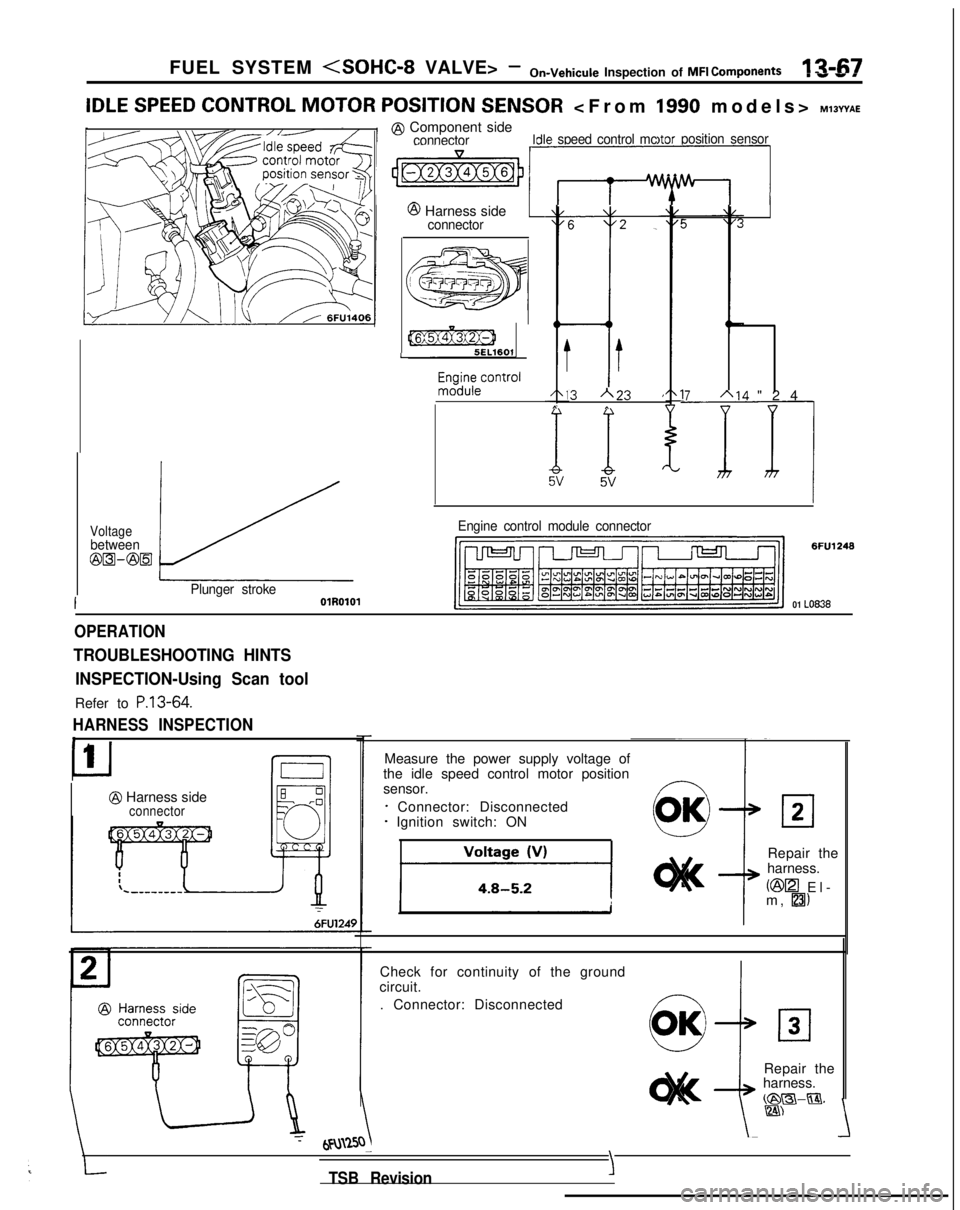

IDLE SPEED CONTROL

MOTOR POSiTiON SENSOR

@ Component sideconnectorIdle speed control mc)tor position sensor

‘{*q-r

T@ Harness sideLconnector

Voltagebetween

@n-@B

1.Plunger strokeI01R0101

I-@=%260jl

En$eecontrol

I3A23

’

A

L7A14 "2

4

I!-

Engine control module connector

6FU1246

01 LO838

OPERATION

TROUBLESHOOTING HINTS INSPECTION-Using Scan tool

Refer to P.13-64.

HARNESS INSPECTIONL

L-J1

@ Harness sideconnector

Measure the power supply voltage of

the idle speed control motor position

sensor.

* Connector: Disconnected- Ignition switch: ON

Check for continuity of the ground

circuit.

. Connector: Disconnected Repair the

harness.

@[zI El

-

m,

[231,

TSB Revision\

Repair the

harness.

K&y-m*

Page 210 of 1273

13-68 FUEL SYSTEM

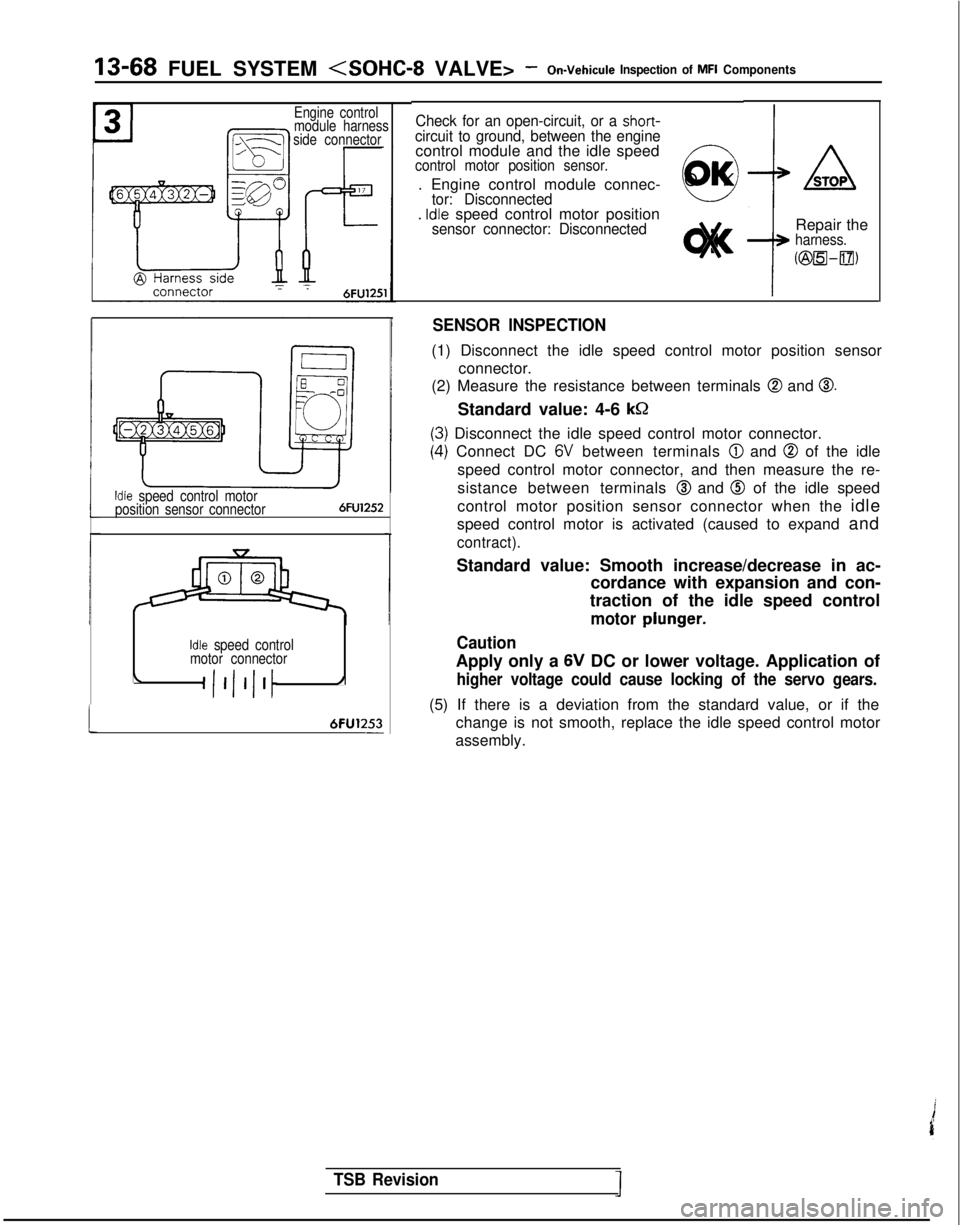

Engine control

module harness

side connectorCheck for an open-circuit, or a short-circuit to ground, between the enginecontrol module and the idle speedcontrol motor position sensor.

. Engine control module connec-tor: Disconnected. Idle speed control motor positionsensor connector: Disconnected

0

O

K

1

ASTOP

i

Repair theharness.

KzEwDlfl,

!

Idle speed control motor

position sensor connector6FU1252

Idle speed control

motor connector

\A 6FU1253

-

SENSOR INSPECTION

(1) Disconnect the idle speed control motor position sensor

connector.

(2) Measure the resistance between terminals

@ and 0.

Standard value: 4-6 k&2

I) Disconnect the idle speed control motor connector.

.) Connect DC 6V between terminals @ and @ of the idle

speed control motor connector, and then measure the re-

sistance between terminals

@ and @ of the idle speed

control motor position sensor connector when the idle

speed control motor is activated (caused to expand and

contract).

Standard value: Smooth increase/decrease in ac-

cordance with expansion and con-

traction of the idle speed control

motor plunger.

Caution

Apply only a 6V DC or lower voltage. Application of

higher voltage could cause locking of the servo gears.

(5) If there is a deviation from the standard value, or if the change is not smooth, replace the idle speed control motor

assembly.

TSB Revision

Page 211 of 1273

FUEL SYSTEM

of MFI Components13-69

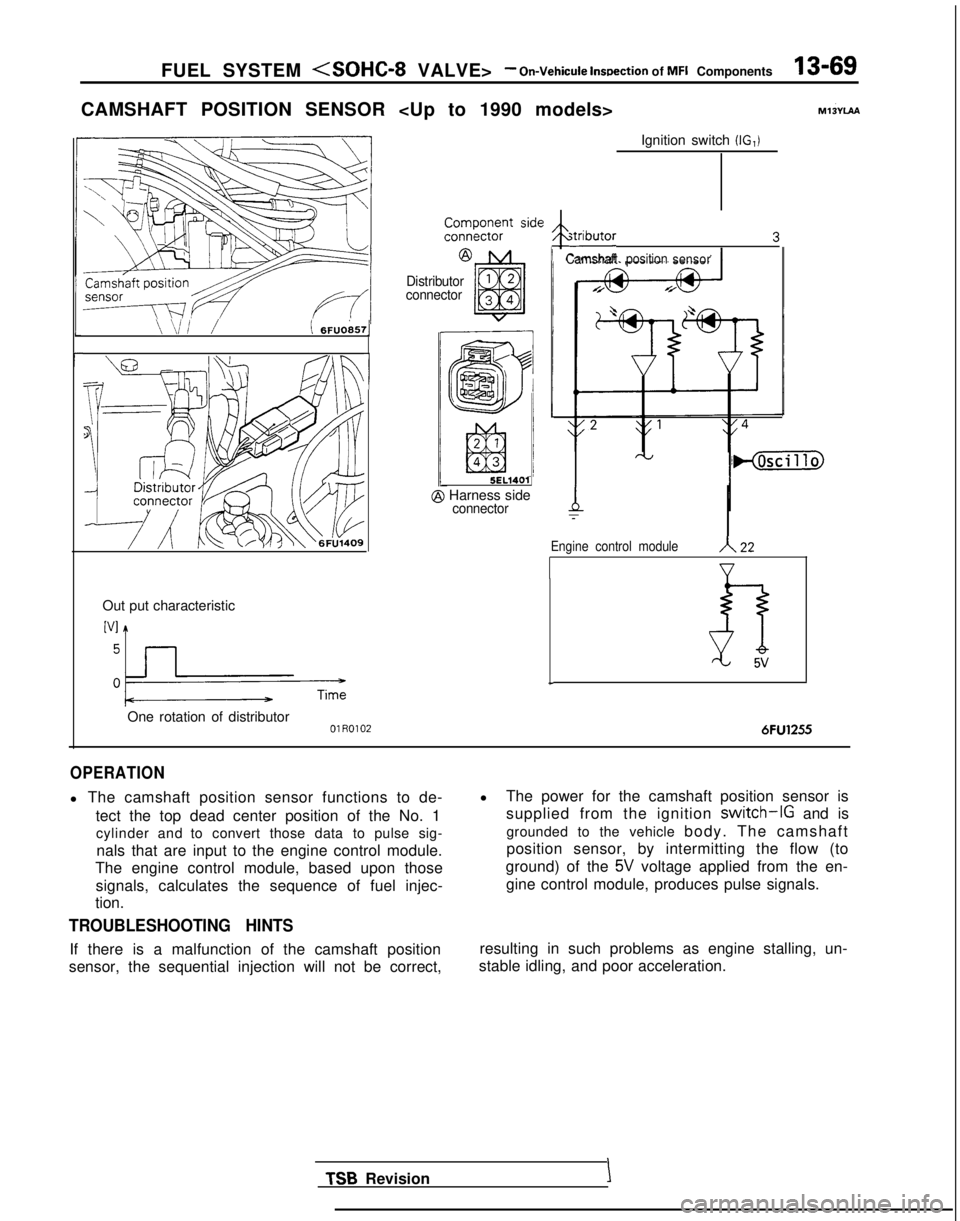

CAMSHAFT POSITION SENSOR

\ /‘4 iI ‘j6FUO857

r

1

Out put characteristic ‘“!I

pm

One rotation of distributorOlR0102

Ignition switch (IG,) ~~~!%k?nt

side ,Distributor4 3

Camshaft position

sensor

Distributor

connector 5EL1401

@ Harness sideconnectorT

Engine control moduleA22

V

L

6FU1255

OPERATION

l The camshaft position sensor functions to de-

tect the top dead center position of the No. 1cylinder and to convert those data to pulse sig-

nals that are input to the engine control module.

The engine control module, based upon those

signals, calculates the sequence of fuel injec-

tion.

TROUBLESHOOTING HINTS

If there is a malfunction of the camshaft position

sensor, the sequential injection will not be correct, l

The power for the camshaft position sensor is

supplied from the ignition

switch-IG and is

grounded to the vehicle body. The camshaft

position sensor, by intermitting the flow (to

ground) of the

5V voltage applied from the en-

gine control module, produces pulse signals.

resulting in such problems as engine stalling, un-

stable idling, and poor acceleration.

TSB RevisionI

Page 213 of 1273

FUEL SYSTEM

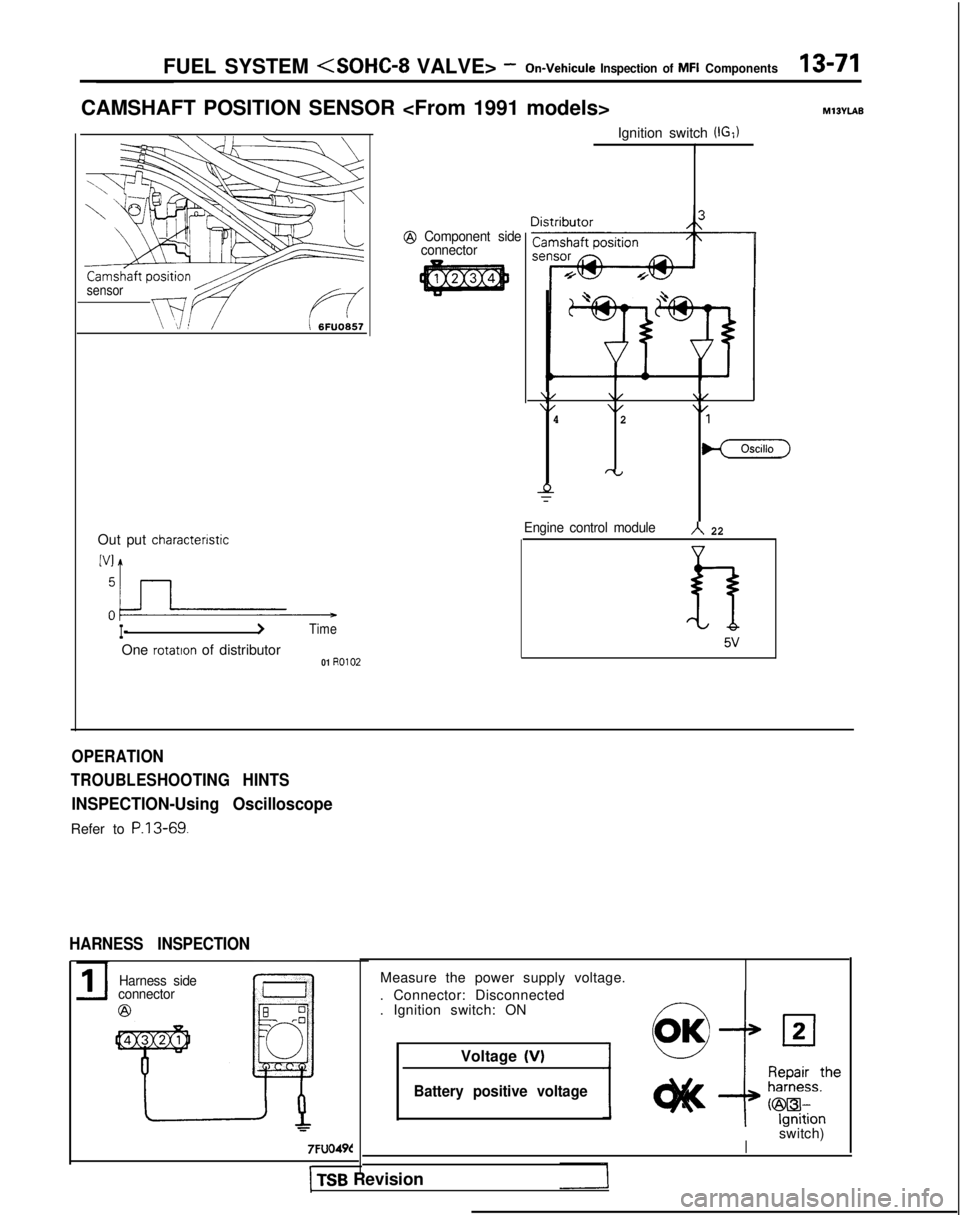

CAMSHAFT POSITION SENSOR

sensor/

WV?: (I 6FUO857

Out put charactenstic

I->Time

One rotatton of distributor01 R0102

@ Component side

connector

Ignition switch (IG,)

I

\/\/\/\/\/\/4 2

&T]

f-b

9r

Engine control moduleA 22

h

5v

OPERATION

TROUBLESHOOTING HINTS

INSPECTION-Using Oscilloscope

Refer to P.13-69.

HARNESS INSPECTION

Harness side

connector

@

7FUO49t

r1 TSB Revision Measure the power supply voltage.

. Connector: Disconnected

. Ignition switch: ON

Voltage

(V)

Battery positive voltage

Iswitch)

Page 215 of 1273

FUEL SYSTEM

inspection of MFI Components13-73

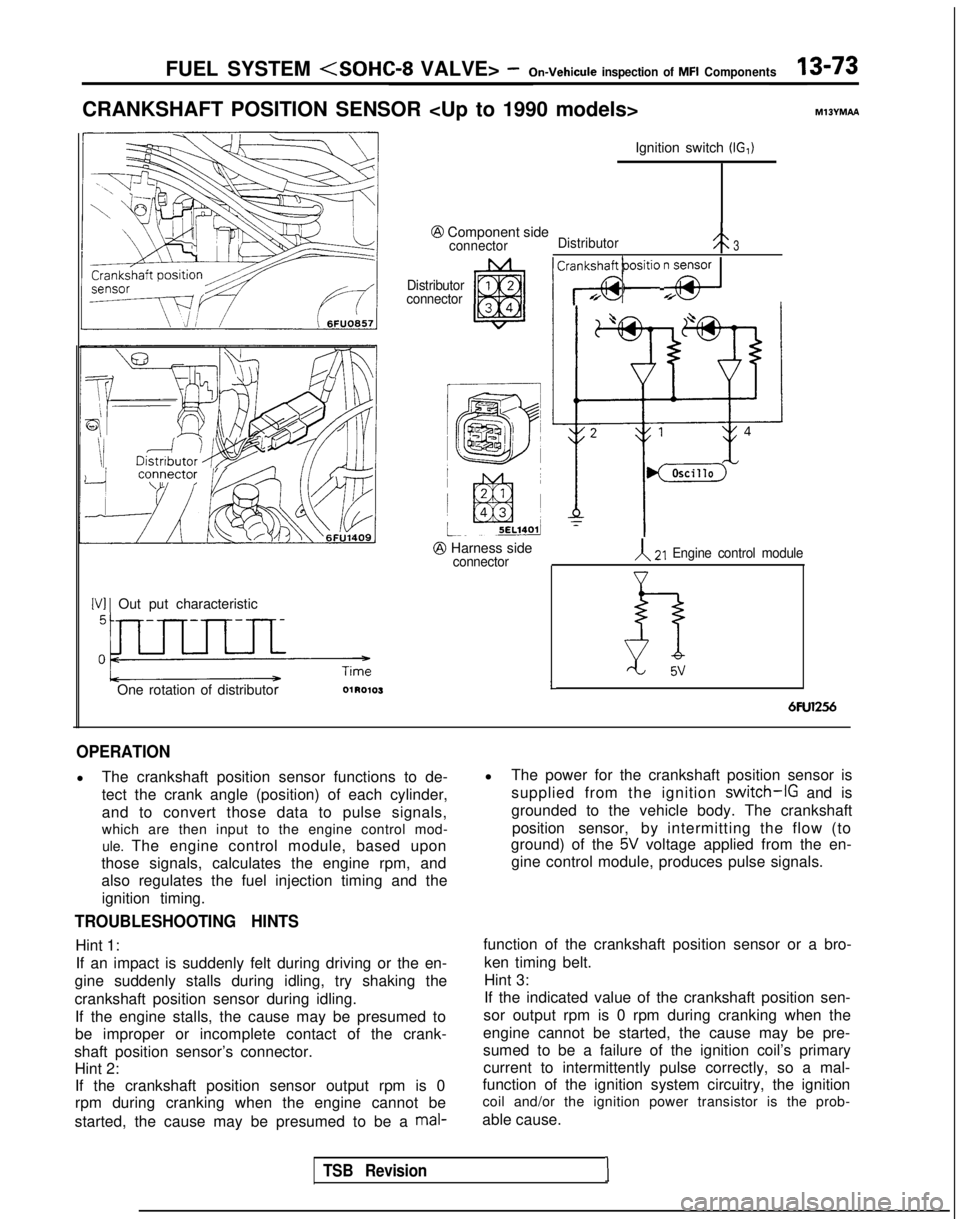

CRANKSHAFT POSITION SENSOR

\IDikZ!utoJP

[VI 1 Out put characteristic

One rotation of distributor Ignition switch

(IG,)

@ Component sideconnector

Distributor3

Distributor

connector

@ Harness sideconnector

/ CraTSiti0 y$/

A21 Engine control module

LD5vLI

6Fu1256

OPERATION

l The crankshaft position sensor functions to de-

tect the crank angle (position) of each cylinder,

and to convert those data to pulse signals,

which are then input to the engine control mod-

ule. The engine control module, based upon

those signals, calculates the engine rpm, and

also regulates the fuel injection timing and the

ignition timing.

TROUBLESHOOTING HINTS

Hint 1:If an impact is suddenly felt during driving or the en-

gine suddenly stalls during idling, try shaking the

crankshaft position sensor during idling. If the engine stalls, the cause may be presumed to

be improper or incomplete contact of the crank-

shaft position sensor’s connector. Hint 2:If the crankshaft position sensor output rpm is 0

rpm during cranking when the engine cannot be

started, the cause may be presumed to be a

mal-

l The power for the crankshaft position sensor is

supplied from the ignition

switch-IG and is

grounded to the vehicle body. The crankshaft position sensor, by intermitting the flow (to

ground) of the

5V voltage applied from the en-

gine control module, produces pulse signals.

function of the crankshaft position sensor or a bro- ken timing belt.

Hint 3:

If the indicated value of the crankshaft position sen-

sor output rpm is 0 rpm during cranking when the

engine cannot be started, the cause may be pre-

sumed to be a failure of the ignition coil’s primary current to intermittently pulse correctly, so a mal-

function of the ignition system circuitry, the ignition

coil and/or the ignition power transistor is the prob-

able cause.

TSB Revision1

Page 216 of 1273

13-74 FUEL SYSTEM

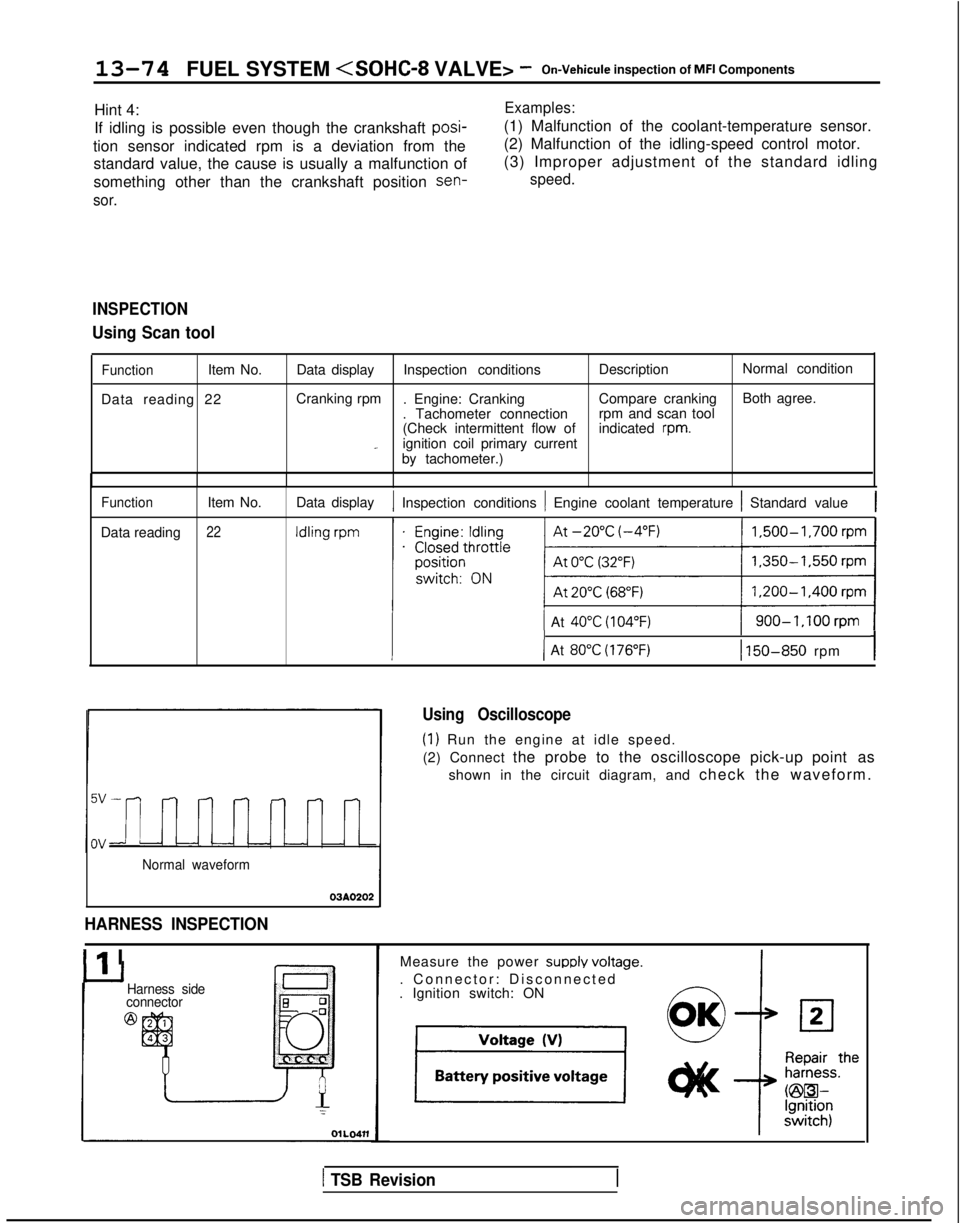

Hint 4:

If idling is possible even though the crankshaft posi-

tion sensor indicated rpm is a deviation from the standard value, the cause is usually a malfunction of

something other than the crankshaft position sen-

sor.

Examples:

(1) Malfunction of the coolant-temperature sensor.

(2) Malfunction of the idling-speed control motor.

(3) Improper adjustment of the standard idling

speed.

INSPECTION

Using Scan tool

FunctionItem No.

Data reading 22 Data display

Inspection conditions DescriptionNormal condition

Cranking rpm . Engine: Cranking Compare crankingBoth agree.

. Tachometer connection rpm and scan tool

(Check intermittent flow of indicated

rpm._ignition coil primary current

by tachometer.)

Function

Data reading Item No.22

Data display1 Inspection conditions 1 Engine coolant temperature 1 Standard value1

1 At 40°C (104°F)1 900-1,100rpm 1

III-I( At 80°C (176°F)1 150-850 rpm

Normal waveform

03AO202

HARNESS INSPECTION

Ilr I

Using Oscilloscope

(1) Run the engine at idle speed.

(2) Connect the probe to the oscilloscope pick-up point as

shown in the circuit diagram, and check the waveform.

Harness side

connector

@

Measure the power SUPPIY voltaoe.

. Connector: Disconnected

-. Ignition switch: ON

1 TSB Revision

Page 217 of 1273

FUEL SYSTEM

@ Harness srdeconnector

@ Harness sideconnector

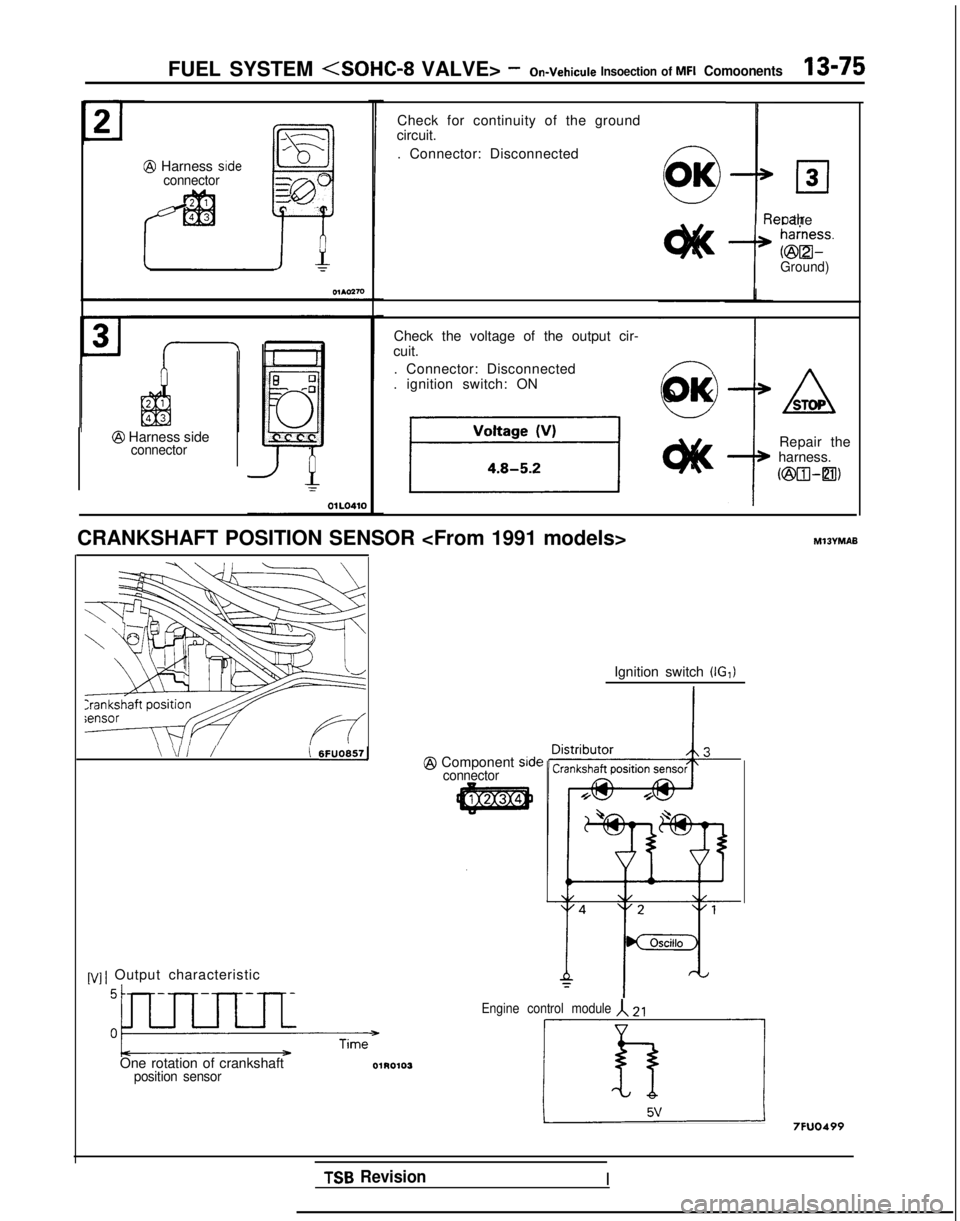

Check for continuity of the ground

circuit.

. Connector: Disconnected

1 Reoair the

t

hainess.

(@B-Ground)

Check the voltage of the output cir-

cuit.

. Connector: Disconnected

. ignition switch: ON

u

O

K

ASTOP

Repair the

harness.

(@m-m)

CRANKSHAFT POSITION SENSOR

m/i /i 6FUO6571

[VI 1 Output characteristic

@ Component sideconnector

Ignition switch (IG1)

One rotation of crankshaftposition sensor

01R0’05

TSB Revision

Engine control module,( 21

m---l 7F”04pp

I

Page 222 of 1273

13-80 FUEL SYSTEM

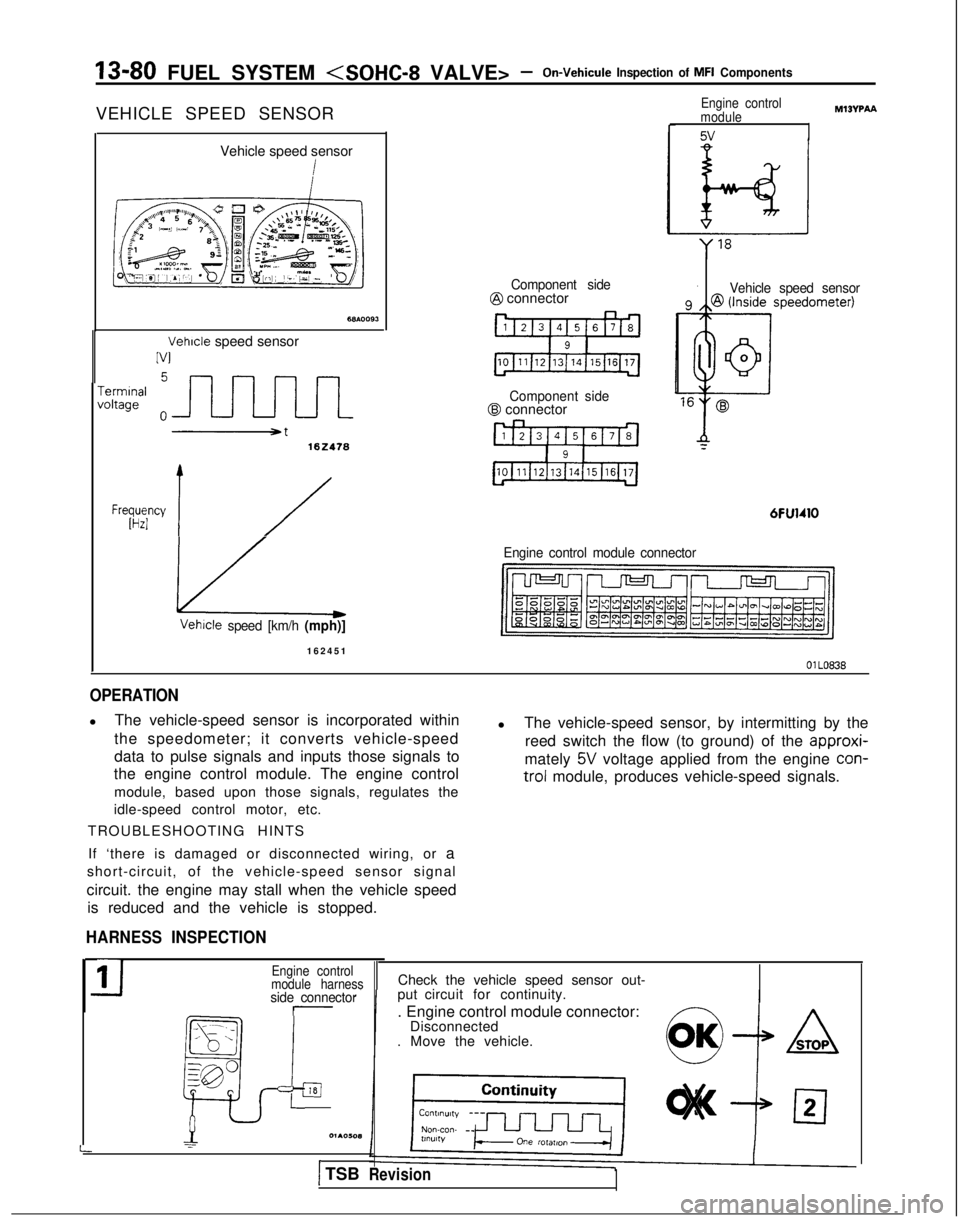

VEHICLE SPEED SENSOR

Vehicle speed sensor

Vehicle speed sensor

IV1

-errnInafoltage

102418

Frwyy 1/

Component side@ connector

Component side@ connector

6FU1410

Engine control

module

5v

MIBVPAA

Vehicle speed sensor

Engine control module connector Vetwle

speed [km/h (mph)]

16245

1

OlLO838

OPERATION

l

The vehicle-speed sensor is incorporated within

the speedometer; it converts vehicle-speed

data to pulse signals and inputs those signals to

the engine control module. The engine control

module, based upon those signals, regulates the

idle-speed control motor, etc.

TROUBLESHOOTING HINTS l

The vehicle-speed sensor, by intermitting by the

reed switch the flow (to ground) of the approxi-

mately

5V voltage applied from the engine con-

trol

module, produces vehicle-speed signals.

If ‘there is damaged or disconnected wiring, or a

short-circuit, of the vehicle-speed sensor signal

circuit. the engine may stall when the vehicle speed is reduced and the vehicle is stopped.

HARNESS INSPECTION

-side connector

_--- _

ia

_, - .,

:_--

gp

p

L

11Engine control

module harness

=l01AOW(1

I

Check the vehicle speed sensor out-

put circuit for continuity.

. Engine control module connector: Disconnected

. Move the vehicle.

) TSBRevision