automatic MITSUBISHI GALANT 1989 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 812 of 1273

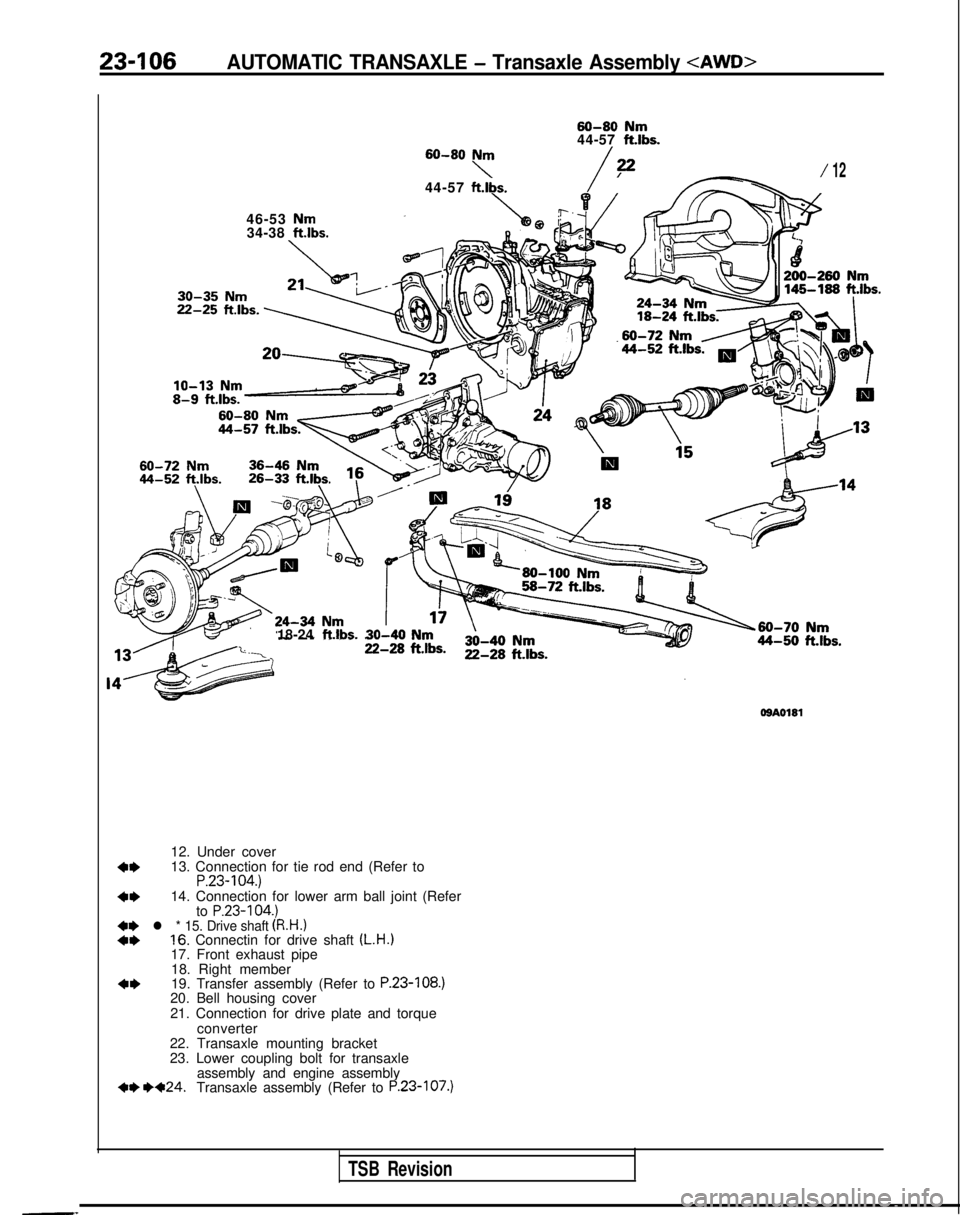

23-106AUTOMATIC TRANSAXLE - Transaxle Assembly

46-53 Nm34-38 ftlbs.

30-35 Nm

60-80 Nm44-57 ftlbs.60-80Nm

44-57ftlbs.\/,22/ 12

18-24

ftlbs.30-40

08AO181

4*

4*

12. Under cover

13. Connection for tie rod end (Refer to

P.23-104.)14. Connection for lower arm ball joint (Refer

to P.23-104.)~~ l * 15. Drive shaft (R.H.)4*16. Connectin for drive shaft (L.H.)17. Front exhaust pipe18. Right member

4*19. Transfer assembly (Refer to P.23-108.)20. Bell housing cover

21. Connection for drive plate and torque

converter

22. Transaxle mounting bracket

23. Lower coupling bolt for transaxle assembly and engine assembly

+O ++24.Transaxle assembly (Refer to P.23-107.)

TSB Revision

Page 813 of 1273

AUTOMATIC TRANSAXLE - Transaxle Assembly

OSAOl82

Hub

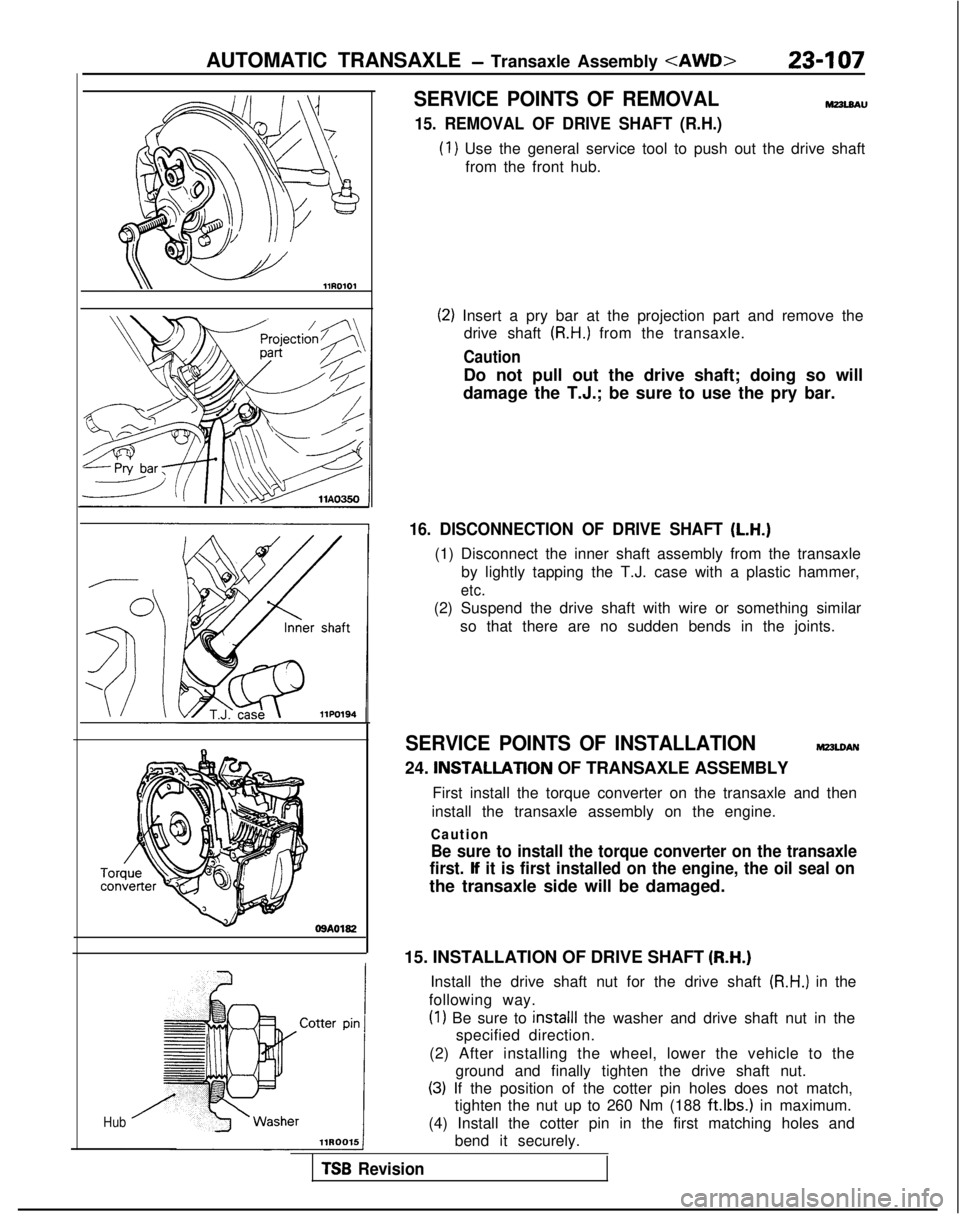

SERVICE POINTS OF REMOVAL MZ3LMU

15. REMOVAL OF DRIVE SHAFT (R.H.)

(1) Use the general service tool to push out the drive shaft

from the front hub.

(2) Insert a pry bar at the projection part and remove the drive shaft

(R.H.) from the transaxle.

Caution

Do not pull out the drive shaft; doing so will

damage the T.J.; be sure to use the pry bar.

16. DISCONNECTION OF DRIVE SHAFT (L.H.)

(1) Disconnect the inner shaft assembly from the transaxle

by lightly tapping the T.J. case with a plastic hammer,

etc.

(2) Suspend the drive shaft with wire or something similarso that there are no sudden bends in the joints.

SERVICE POINTS OF INSTALLATIONMZ3LOAN

24. INSTALLAnON OF TRANSAXLE ASSEMBLY

First install the torque converter on the transaxle and then

install the transaxle assembly on the engine.

Caution

Be sure to install the torque converter on the transaxle

first.

lf it is first installed on the engine, the oil seal on

the transaxle side will be damaged.

15. INSTALLATION OF DRIVE SHAFT

(R-H.)

Install the drive shaft nut for the drive shaft (R.H.) in the

following way.

(1) Be sure to install1 the washer and drive shaft nut in the

specified direction.

(2) After installing the wheel, lower the vehicle to the ground and finally tighten the drive shaft nut.

(3) If the position of the cotter pin holes does not match,tighten the nut up to 260 Nm (188

ft.lbs.1 in maximum.

(4) Install the cotter pin in the first matching holes and bend it securely.

TSB Revision

Page 814 of 1273

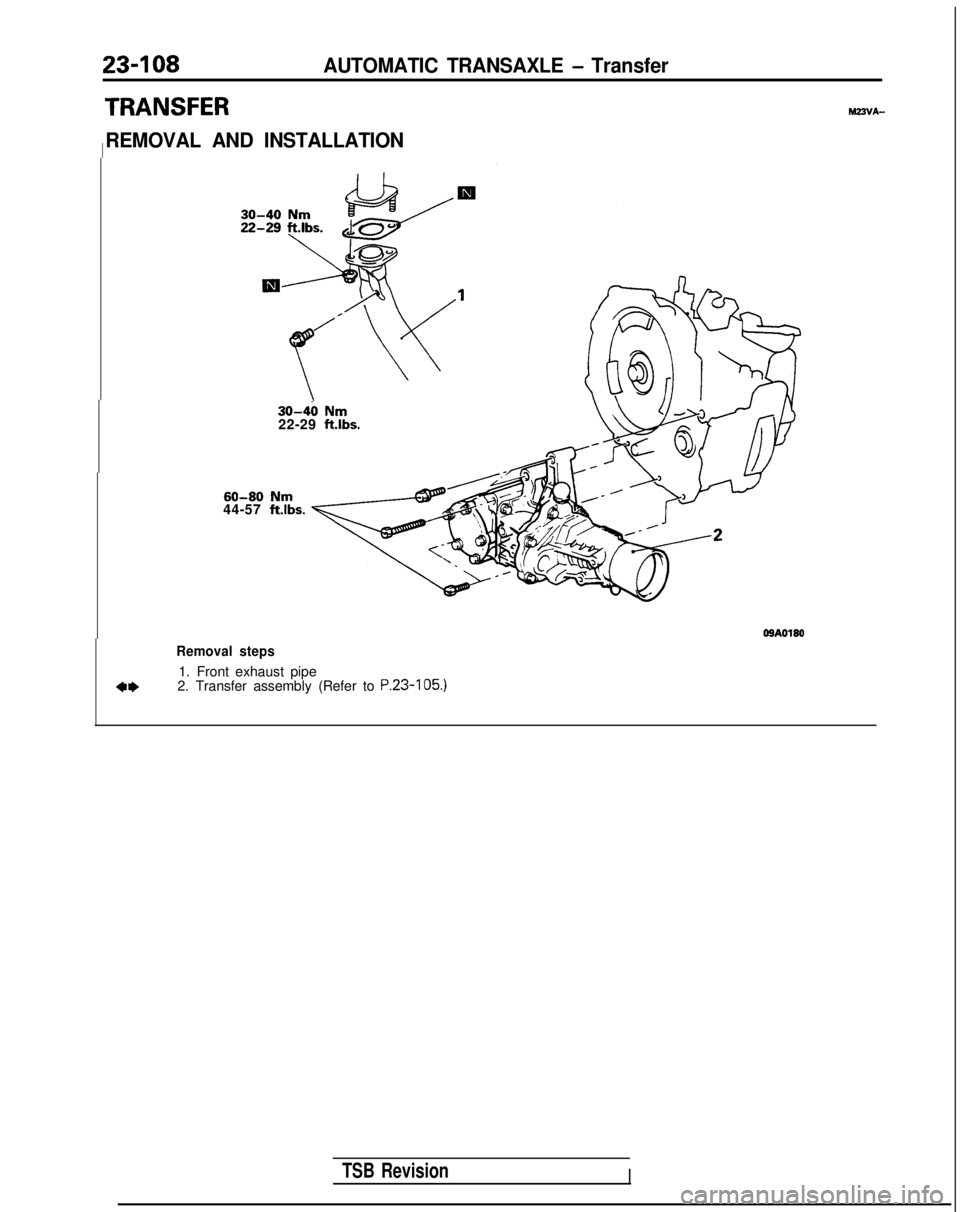

23-108AUTOMATIC TRANSAXLE - Transfer

TRANSFER

REMOVAL AND INSTALLATIONI

M23VA-

30-40 Nm22-29 ftlbs.

60-80 Nm44-57 ftlbs.O!IAOlSO

Removal steps

4*

1. Front exhaust pipe

2. Transfer assembly (Refer to P.23-105.)

TSB RevisionI

Page 905 of 1273

31-6WHEEL AND TIRE - Wheel and Tire

INSTRUCTIONS FOR ALUMINUM TYPE WHk&g

1. Aluminum is vulnerable to alkalies. If

a vehicle washing

detergent has been used, or salt from sea water or road

chemicals has adhered, wash the vehicle as soon as

possible. After washing the vehicle, apply body or wheel

wax to the aluminum type wheels to prevent corrosion.

2.When cleaning the vehicle with steam, do not direct steam

onto the aluminum type wheels.

When tightening nuts for aluminum type wheels, particular- ly observe the following:

(I) Clean the hub surface of aluminum type wheels.

(2) After finger-tightening wheel nuts, tighten them to specifications.

(3) Do not use an impact wrench or push the wrench by foot to tighten the wheel nuts.

(4) Do not apply oil to the threaded portions.

INSTRUCTIONS FOR TIRE CHAINS AND SNOW

TIRES M31GGbl

1.Use tire chains only on front wheels. Do not use tire chains

on rear wheels.

2. When using snow tires, use them on all four wheels for maneuverability and safety.

INSTRUCTIONS FOR COMPACT SPARE TlR,E,,,,

1. The compact spare tire is designed to save space in theluggage compartment, and its lighter weight makes it

easier to use if a flat tire occurs.

2.The following instructions for the compact spare tire should be observed.

(1) Check the inflation pressure after installing the spare, and adjust to the specified pressure.

(2) Avoid driving through automatic car washes and over obstacles that could possibly damage the vehicle’s

undercarriage. Because the tire is smaller than the

original tire, car ground clearance is slightly reduced.

(3) The compact spare tire should not be used on any other wheels, nor should standard tires, snow tires, wheel

covers or trim rings be used with the compact spare

wheel. If such use is attempted, damage to these items

or other vehicle components may occur.

TSB Revision

Page 1123 of 1273

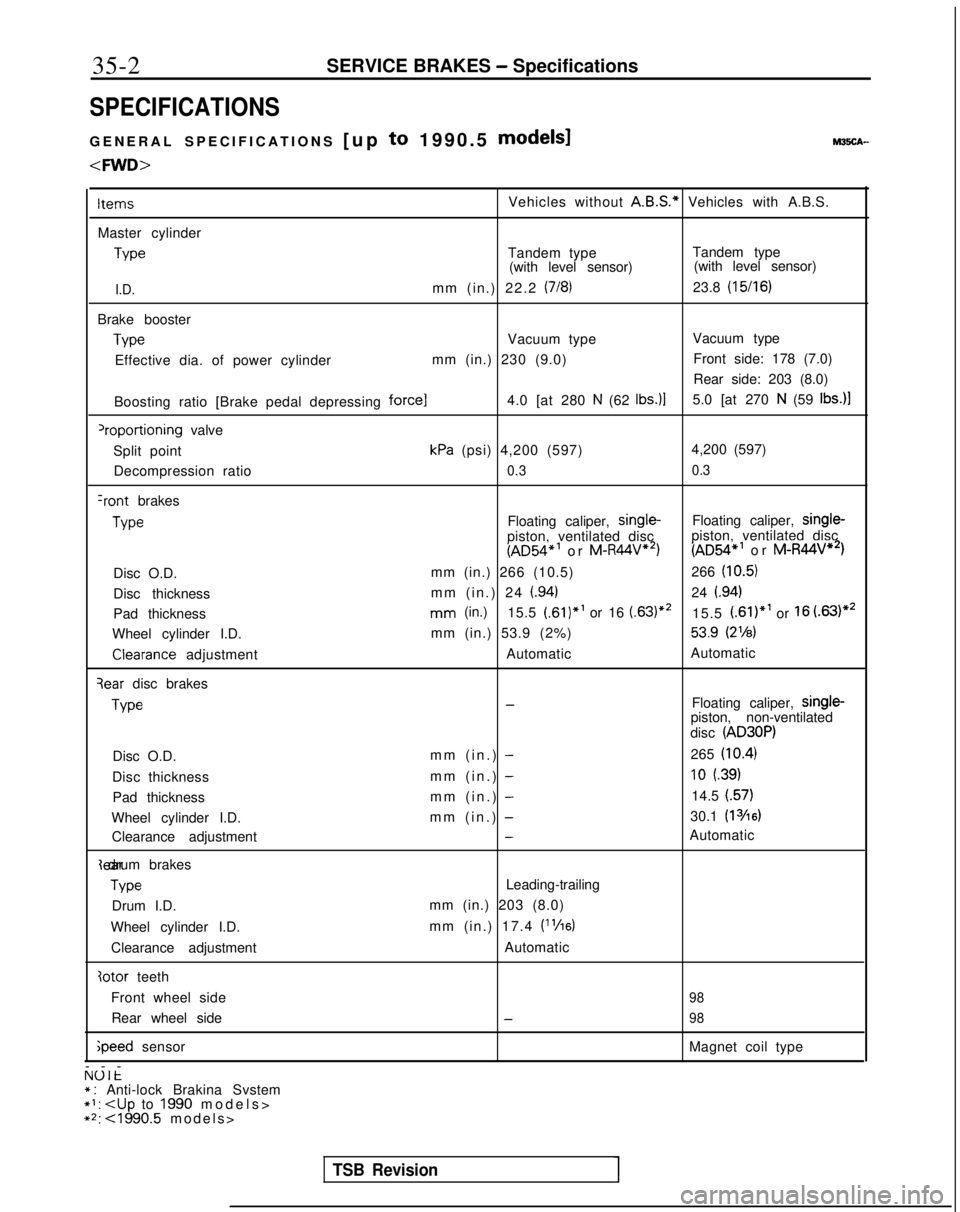

35-2

SERVICE BRAKES - Specifications

SPECIFICATIONS

GENERAL SPECIFICATIONS

[up to 1990.5 models1 M3!iCA-

ItemsVehicles without

A.B.S.*

Vehicles with A.B.S.

Master cylinder Type

Tandem type

Tandem type

(with level sensor) (with level sensor)

I.D.mm (in.) 22.2 (718)23.8 (15/16)

Brake boosterType

Vacuum type

Vacuum type

Effective dia. of power cylinder mm (in.) 230 (9.0)Front side: 178 (7.0)

Rear side: 203 (8.0)

Boosting ratio [Brake pedal depressing

force14.0 [at 280 N (62 tbs.)]5.0 [at 270 N (59 Ibs.)l

‘roportioning valve

Split point

kPa (psi) 4,200 (597) 4,200 (597)

Decompression ratio

0.3 0.3

Iront brakesType

Floating caliper, single-

Floating caliper, single-

piston, ventilated disc

(AD54*’ or M-R44V”‘)piston, ventilated disc (AD54*’

or M-R44V**)

Disc O.D. mm (in.) 266 (10.5)

266

(10.5)

Disc thickness mm (in.) 24 (.94)24 i.94)

Pad thicknessmm (in.)

15.5 (.61)*’ or 16 (63)“’15.5 (.61)*’ or 16 (.63)**

Wheel cylinder I.D. mm (in.) 53.9 (2%)

53.9 (2’/8)Clearance

adjustment AutomaticAutomatic

qear disc brakesType

-Floating caliper, single-

piston, non-ventilated

disc

(AD30P)

Disc O.D. mm (in.) -265 (10.4)

Disc thickness

mm (in.) -10 (.39)

Pad thicknessmm (in.) -14.5 (.57)

Wheel cylinder I.D. mm (in.) -30.1 (13/16)

Clearance adjustment-Automatic{ear drum brakes

Type

Leading-trailing

Drum I.D. mm (in.) 203 (8.0)

Wheel cylinder I.D. mm (in.) 17.4

V’/16)

Clearance adjustment

Automatic

Iotor teeth

Front wheel side

98

Rear wheel side-98 ;peed

sensor Magnet coil type

---

NUlt* : Anti-lock Brakina Svstem*I:

+2: ~1990.5 models

>

TSB RevisionI

Page 1124 of 1273

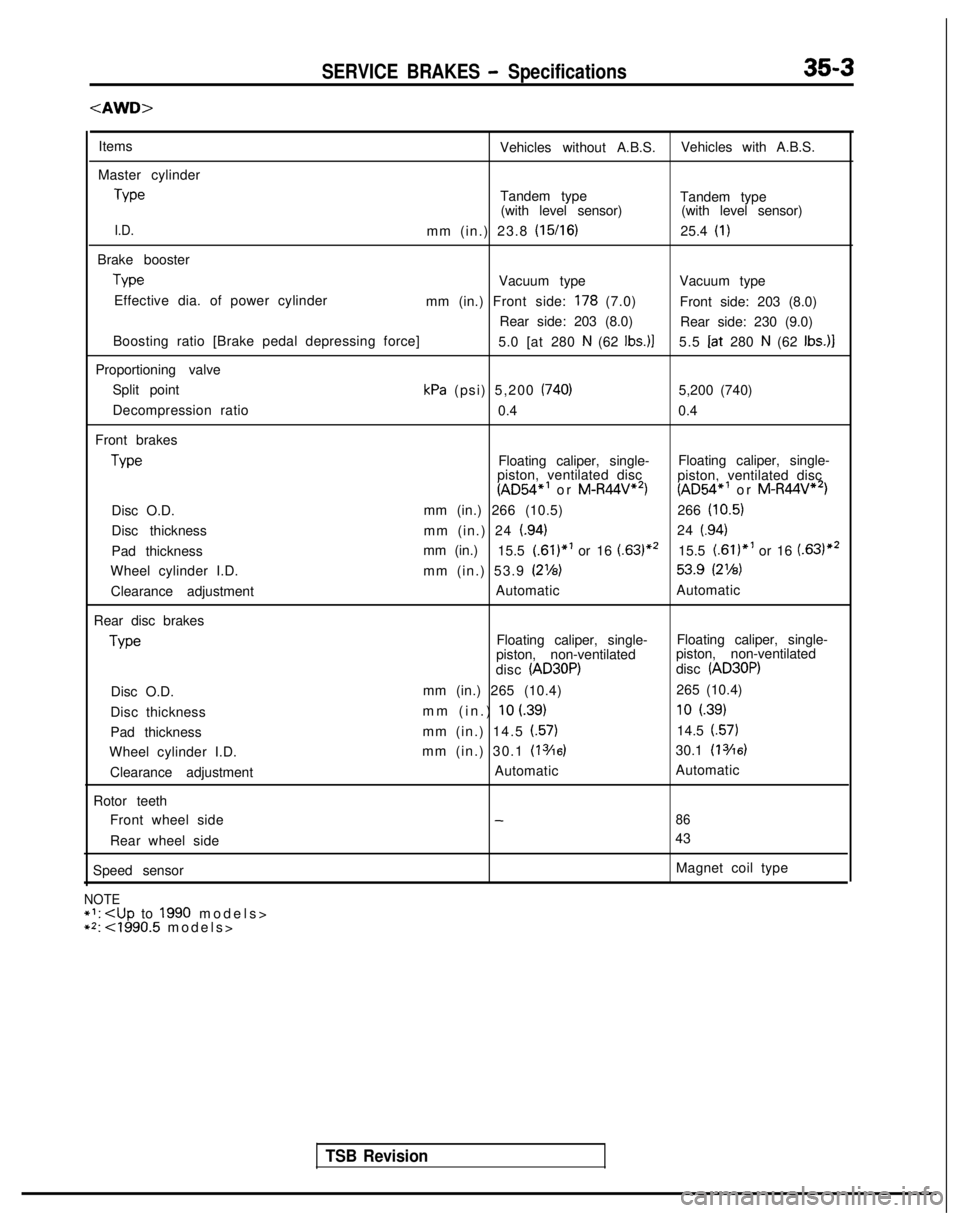

SERVICE BRAKES - Specifications35-3

Items

Vehicles without A.B.S.Vehicles with A.B.S.

Master cylinder Type

Tandem type

Tandem type

(with level sensor) (with level sensor)

I.D.mm (in.) 23.8 (15/16)25.4 (I)

Brake boosterType

Vacuum type

Vacuum type

Effective dia. of power cylinder mm (in.) Front side:

178 (7.0)Front side: 203 (8.0)

Rear side: 203 (8.0) Rear side: 230 (9.0)

Boosting ratio [Brake pedal depressing force] 5.0 [at 280

N (62 Ibs.)]5.5 Iat

280 N (62 Ibs.)]

Proportioning valve Split point

kPa (psi) 5,200 (740)5,200 (740)

Decompression ratio 0.40.4

Front brakes Type

Floating caliper, single-

Floating caliper, single-

piston, ventilated disc

(AD54”’ or M-R44V**)

piston, ventilated disc(AD54*’ or M-R44V**)

Disc O.D. mm (in.) 266 (10.5)

266

(10.5)

Disc thickness mm (in.) 24 (.94)24 (.94)

Pad thicknessmm (in.)

15.5 (.61)*’ or 16 (.63)*’15.5 f.61)“’ or 16 (.63)*2

Wheel cylinder I.D. mm (in.) 53.9 (2%) 53.9

(2%)

Clearance adjustment

Automatic

Automatic

Rear disc brakes Type

Floating caliper, single-

Floating caliper, single-

piston, non-ventilated piston, non-ventilated

disc

(AD30P)disc (AD30P)

Disc O.D. mm (in.) 265 (10.4)

265 (10.4)

Disc thickness mm (in.)

10 L39)10 (.39)

Pad thickness

mm (in.) 14.5 f.57)14.5 (.57)

Wheel cylinder I.D. mm (in.) 30.1 (13/16)30.1 (13/16)

Clearance adjustment Automatic

Automatic

Rotor teeth Front wheel side

-86

Rear wheel side 43

Speed sensor Magnet coil type

NOTE+‘:

**: <1990.5 models

>

TSB Revision

Page 1125 of 1273

![MITSUBISHI GALANT 1989 Service Repair Manual 35-4SERVICE BRAKES - Specifications

GENERAL SPECIFICATIONS [Up to 1992 models]

<fYVD>

Vehicles without A.B.S.

ItemsVehicles with A.B.S.SOHCDOHC

Master cylinderType

Tandem type

Tandem type

Tandem type

MITSUBISHI GALANT 1989 Service Repair Manual 35-4SERVICE BRAKES - Specifications

GENERAL SPECIFICATIONS [Up to 1992 models]

<fYVD>

Vehicles without A.B.S.

ItemsVehicles with A.B.S.SOHCDOHC

Master cylinderType

Tandem type

Tandem type

Tandem type](/img/19/57312/w960_57312-1124.png)

35-4SERVICE BRAKES - Specifications

GENERAL SPECIFICATIONS [Up to 1992 models]

Vehicles without A.B.S.

ItemsVehicles with A.B.S.SOHCDOHC

Master cylinderType

Tandem type

Tandem type

Tandem type

(with level sensor) (with level sensor)(with level sensor)

I.D.mm (in.) 22.2 (7/8)23.8 (15/l 6)

25.4 (I)

Brake booster Type

Vacuum type

Vacuum type

Vacuum type

Effective dia. of power cylinder Front side: 178

(7.0)mm (in.) 230 (9.0)230 (9.0)

Rear side: 203 (8.0)

Boosting ratio 4.05.05.5[Brake pedal depressing force]

[at 280 N (62 Ibs.)][at 220 N (48 Ibs.)][at 250 N (55 Ibs.11

Proportioning valve

Split point

kPa (psi) 4,200 (597)3,700 (526) 3,700 (526)

Decompression ratio0.4 0.30.3

Front brakes Type

Floating caliper, single-

Floating caliper, single-

F!oating caliper, single

piston, ventilated disc y$or&entrlated disc

r;;;6ventrlated drsc(MR44V)

Disc O.D. mm (in.) 256 (10.1)256 (10.1)256 (10.1)

Disc thickness mm (in.) 24

(.94)24 (.94)24 (.94)

Pad thicknessmm (in.) 16 (.63)16 (63)16 (.63)

Wheel cylinder I.D.

mm (in.) 53.9 (2%)60.3 (z3/8)60.3 (23/8)

Clearance adjustment AutomaticAutomatic

Automatic

Rear disc brakes Type

-Floating caliper, single-

piston, non-ventilated Floating caliper, single

piston, non-ventilated

disc

(AD35P)disc (AD35P)

Disc O.D. mm (in.) -265 (10.4)265 (10.4)

Disc thickness mm (in.)

- IO

i.39)

10 (.39)

Pad thickness

mm (in.) -14.5 (57)14.5 (.57)

Wheel cylinder I.D. mm (in.) - 34.9

u3h)34.9 (1%)

Clearance adjustment-Automatic Automatic

Rear drum brakes Type

Leading-trailing

-

Drum I.D.

mm (in.) 203 (8.0)

Wheel cylinder I.D.

mm (in.) 17.4 (‘l/16)--

Clearance adjustment Automatic--3otor

teeth

Front wheel side

98”. 43’2

Rear wheel side--98”. 43’2

speed sensor--Magnet coil type

NOTEl l: 1991 modelsl ? 1992 models

TSB Revision

Page 1126 of 1273

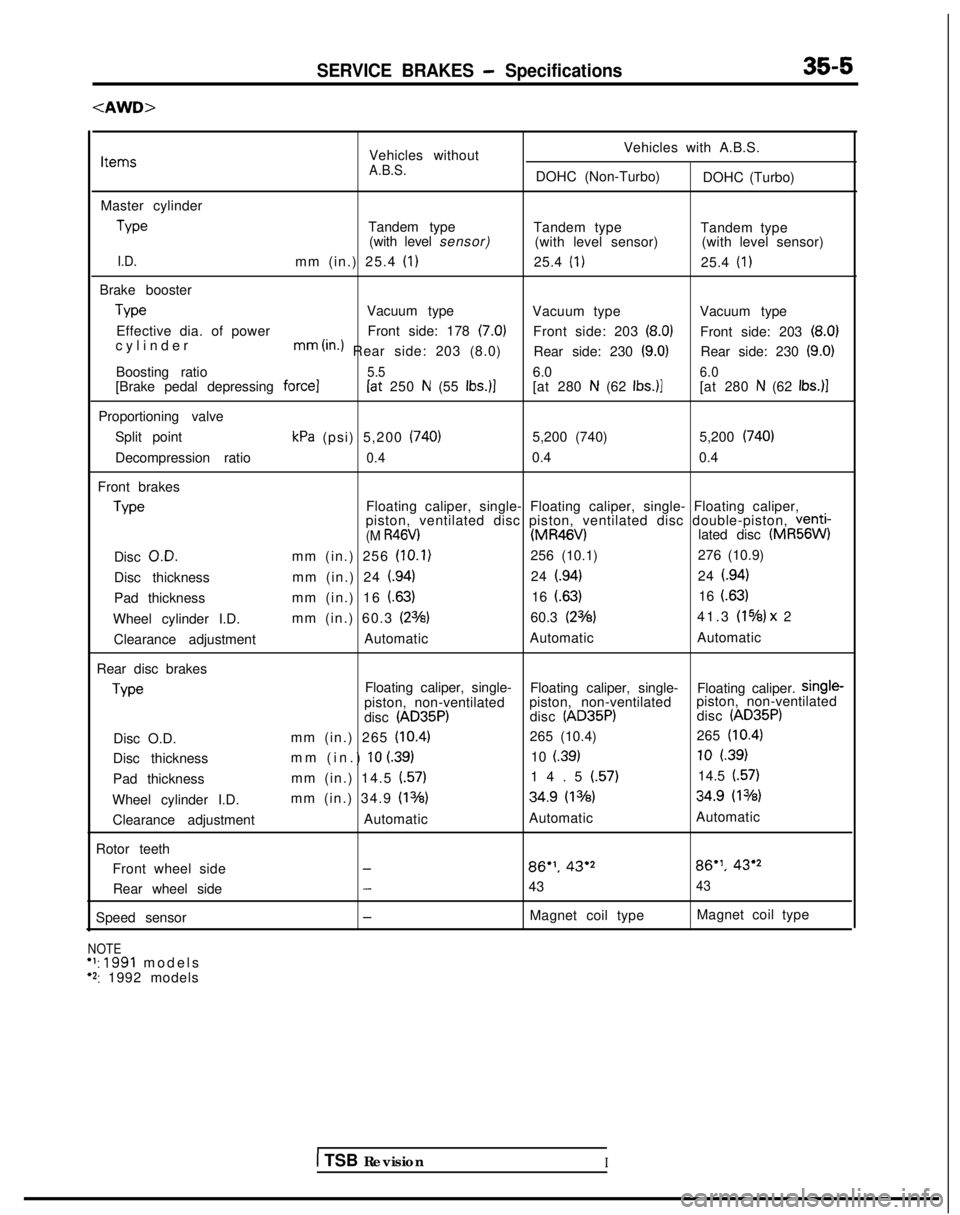

SERVICE BRAKES - Specifications35-5

Vehicles withoutVehicles with A.B.S.ItemsA.B.S.DOHC (Non-Turbo)

DOHC (Turbo)

Master cylinder Type

Tandem type

Tandem type Tandem type

(with level sensor) (with level sensor) (with level sensor)

I.D.mm (in.) 25.4 (1)25.4 (I)25.4 (I)

Brake boosterType

Vacuum type

Vacuum type Vacuum type

Effective dia. of power Front side: 178

(7.0)Front side: 203 (8.0)Front side: 203 (8.0)cylinde

r

mm

(in.) Rear side: 203 (8.0)

Rear side: 230 (9.0)Rear side: 230 (9.0)

Boosting ratio5.56.06.0[Brake pedal depressing force](at 250 N (55 Ibs.)][at 280 N (62 Ibs.)][at 280 N (62 Ibs.)l

Proportioning valve Split point

kPa (psi) 5,200 (740)5,200 (740) 5,200 (740)

Decompression ratio0.40.40.4

Front brakes Type

Floating caliper, single- Floating caliper, single- Floating caliper,

piston, ventilated disc piston, ventilated disc double-piston,

venti-(M R46V) (MR46V)

lated disc (MR56W)

Disc O.D.

mm (in.) 256

(10.1)256 (10.1)

276 (10.9)

Disc thickness mm (in.) 24

(.94)24 (.94)24 l.94)

Pad thickness mm (in.) 16

(.63)16 (.63)16 (63)

Wheel cylinder I.D. mm (in.) 60.3 (23/s)60.3 (23/8)41.3 (1%) x

2

Clearance adjustment AutomaticAutomatic

Automatic

Rear disc brakes Type

Floating caliper, single-

Floating caliper, single- Floating caliper.

Single-piston, non-ventilatedpiston, non-ventilated piston, non-ventilated

disc (AD35P)disc (AD35P)disc (AD35P)

Disc O.D. mm (in.) 265 (10.4)265 (10.4)

265 (10.4)

Disc thickness mm (in.) 10 (.39)10 l.39)10 l.39)

Pad thickness mm (in.) 14.5

(.57)14.5 (.57)14.5 (57)

Wheel cylinder I.D. mm (in.) 34.9 (13/8) 34.9

(13h) 34.9

(1%8)

Clearance adjustment AutomaticAutomatic Automatic

Rotor teeth Front wheel side

-86”. 43’286”‘. 43’2

Rear wheel side

-4343

Speed sensor-Magnet coil type Magnet coil type

NOTE+I: 1991 model

s

‘2: 1992 models

1 TSB RevisionI

Page 1127 of 1273

![MITSUBISHI GALANT 1989 Service Repair Manual 35-6SERVICE BRAKES - Specifications

3ENERAL SPECIFICATIONS [1993 models]

Items

Master cylinder Type

I.D.mm (in.1

Brake booster

Type

Effective dia. of power cylinder mm (in.)

Boosting ratio

[Brake peda MITSUBISHI GALANT 1989 Service Repair Manual 35-6SERVICE BRAKES - Specifications

3ENERAL SPECIFICATIONS [1993 models]

Items

Master cylinder Type

I.D.mm (in.1

Brake booster

Type

Effective dia. of power cylinder mm (in.)

Boosting ratio

[Brake peda](/img/19/57312/w960_57312-1126.png)

35-6SERVICE BRAKES - Specifications

3ENERAL SPECIFICATIONS [1993 models]

Items

Master cylinder Type

I.D.mm (in.1

Brake booster

Type

Effective dia. of power cylinder mm (in.)

Boosting ratio

[Brake pedal depressing

force1

Proportioning valve Split

point

kPa (psi)

Decompression ratio

Front brakes Type

Disc O.D.

Disc thickness

Pad thickness

Wheel cylinder I.D. Clearance adjustment

Rear disc brakes Type

mm (in.)

mm (in.)

mm (in.)

mm (in.)

Disc O.D.

Disc thickness Pad thickness

Wheel cylinder I.D. Clearance adjustment mm (in.)

mm (in.)

mm (in.)

mm (in.) {ear

drum brakes Type

Drum I.D.

Wheel cylinder I.D. Clearance adjustment

jotor teeth

Front wheel side Rear wheel side mm (in.)

mm (in.)ipeed

sensor

TL

I

Tandem type

(with level sensor)

22.2

(718)

Vacuum type

230

(9.0)

4.0 [at 280 N (62 Ibs.11

4,200 (597)

0.4

Floating caliper, single-

piston, ventilated disc

(M R44V)

256 (10.1)

24

f.94)

16 (.63) 53.9

(2’/8)

Automatic

-

-

-

-

-

I

-eading-trailing

I

SOHC1DOHC1

Vehicles without A.B.S.

Tandem type (with level sensor)

23.8 (15/I

6)

Vacuum type

230

(9.0)

5.0

[at 220 N (48 Ibs.11

3,700 (526)

0.3

Floating caliper, single-

piston, ventilated disc

(MR46V)

256 (10.1)

24 l.94)

16

(.63)

60.3 (23/8)

Automatic

Floating caliper, single-

piston, non-ventilated

disc

(AD35P)

265 (10.4)

10

(.39)

14.5 (.57)

34.9 (1 3/8)

Automatic

TSB Revision

7

Vehicles with A.B.S.

Tandem type (with level sensor)

25.4

(1)

Vacuum type

Front side: 178 (7.0) Rear side: 203 (8.0)

5.5[at 250 N (55 Ibs.11

3,700 (526)

0.3

Floating caliper, single-

piston, ventilated disc

(MR46V)

256 (10.1)

24

(.94)

16 (.63)

60.3 (23/8)

Automatic

Floating caliper, single-

piston, non-ventilated

disc

(AD35P)

265 (10.4)

10 i.39)

14.5

(.57)

34.9 (13/8)

%tomatic

13

I3 dagnet

coil type

Page 1231 of 1273

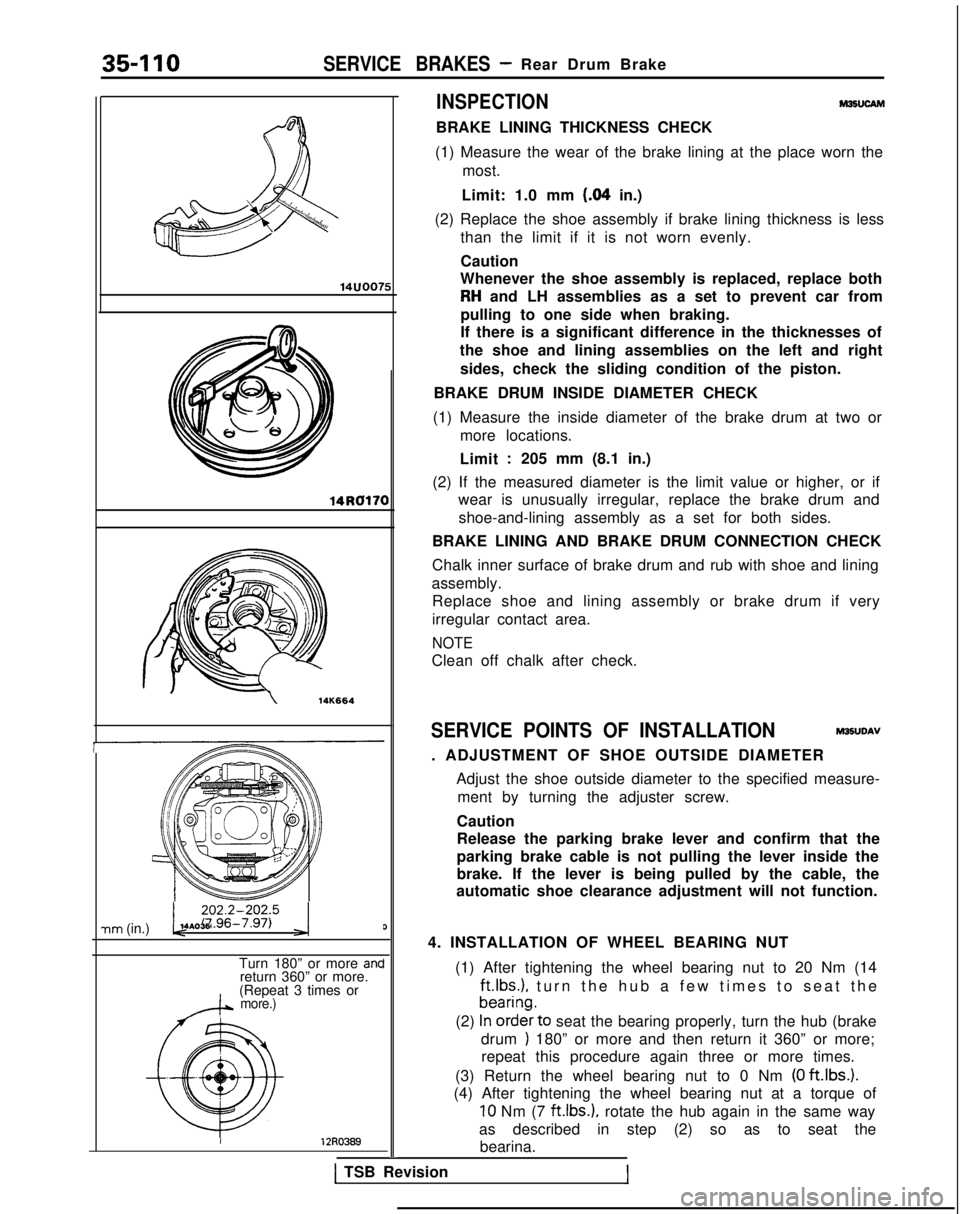

35-110SERVICE BRAKES- Rear Drum Brake

14uoo75

14R0170

14K664r

nm (in.)G $%?-7?~i” >1,4A0361

Turn 180” or more anoreturn 360” or more.

(Repeat 3 times or

> more.)

D

I

-

INSPECTIONM36UCAM

BRAKE LINING THICKNESS CHECK

(1) Measure the wear of the brake lining at the place worn the most.

Limit: 1.0 mm

(84 in.)

(2) Replace the shoe assembly if brake lining thickness is less than the limit if it is not worn evenly.

Caution

Whenever the shoe assembly is replaced, replace both

RH and LH assemblies as a set to prevent car from

pulling to one side when braking.

If there is a significant difference in the thicknesses of

the shoe and lining assemblies on the left and right

sides, check the sliding condition of the piston.

BRAKE DRUM INSIDE DIAMETER CHECK

(1) Measure the inside diameter of the brake drum at two or more locations.

Limit

:205 mm (8.1 in.)

(2) If the measured diameter is the limit value or higher, or if wear is unusually irregular, replace the brake drum and

shoe-and-lining assembly as a set for both sides.

BRAKE LINING AND BRAKE DRUM CONNECTION CHECK

Chalk inner surface of brake drum and rub with shoe and lining

assembly. Replace shoe and lining assembly or brake drum if very

irregular contact area.

NOTE

Clean off chalk after check.

SERVICE POINTS OF INSTALLATION M35UDAV

. ADJUSTMENT OF SHOE OUTSIDE DIAMETER Adjust the shoe outside diameter to the specified measure-ment by turning the adjuster screw.

Caution

Release the parking brake lever and confirm that the

parking brake cable is not pulling the lever inside the

brake. If the lever is being pulled by the cable, the

automatic shoe clearance adjustment will not function.

4. INSTALLATION OF WHEEL BEARING NUT (1) After tightening the wheel bearing nut to 20 Nm (14 ft.lbs.),

turn the hub a few times to seat the

(2)

~~~~~‘to seat the bearing properly, turn the hub (brake

drum

) 180” or more and then return it 360” or more;

repeat this procedure again three or more times.

(3) Return the wheel bearing nut to 0 Nm

(0 ftlbs.).

(4) After tightening the wheel bearing nut at a torque of

10 Nm (7 ft.1b.s.). rotate the hub again in the same way

as described in step (2) so as to seat the bearina.

1 TSB Revision