check engine MITSUBISHI GALANT 1989 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 398 of 1273

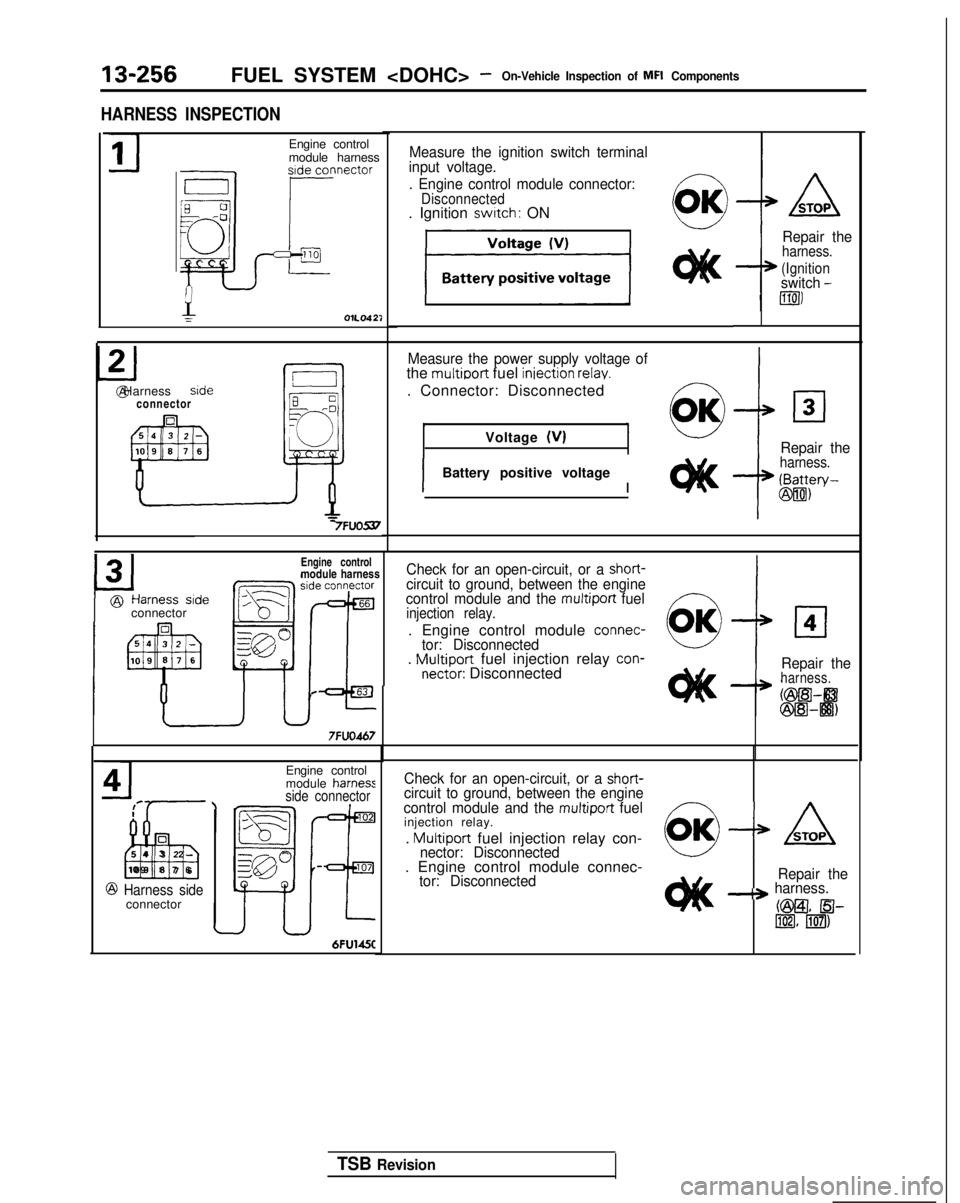

HARNESS INSPECTION

Engine control

module harness

1-OlLO421

Measure the ignition switch terminal

input voltage.

. Engine control module connector:

Disconnected. Ignition swatch: ON

13-256FUEL SYSTEM

Repair theharness.

(Ignition

switch -

Ilrol) @ Harness side

connector

Measure the power supply voltage ofthe multioort fuel iniection relav.

. Connector: Disconnected

Voltage (V)

IBattery positive voltageI

Repair theharness.

(Batter-y-

@@I)

connector

Engine controlmodule harnessCheck for an open-circuit, or a short-circuit to ground, between the engine

control module and the multiport fuelinjection relay.

. Engine control module connec-tor: Disconnected. Multiport fuel injection relay con-nectar: DisconnectedRepair theharness. 7FUO467

alJ*:

k!ii

054 3 2

-

109

9 7 6 Engine control

module

harnessside connector

@ Harness sideconnector

Check for an open-circuit, or a short-circuit to ground, between the engine

control module and the multiport fuelinjection relay.

.

Multiport fuel injection relay con-nector: Disconnected

@--A

. Engine control module connec-tor: Disconnected Repair the-+ harness.

@@I~ El-@?J. 11071)

TSB Revision

Page 399 of 1273

FUEL SYSTEM

OlLO521

01

LO220

fx!l

.‘,~‘,_C;:i2J,‘:,

OlLO222

1J 7FUO470

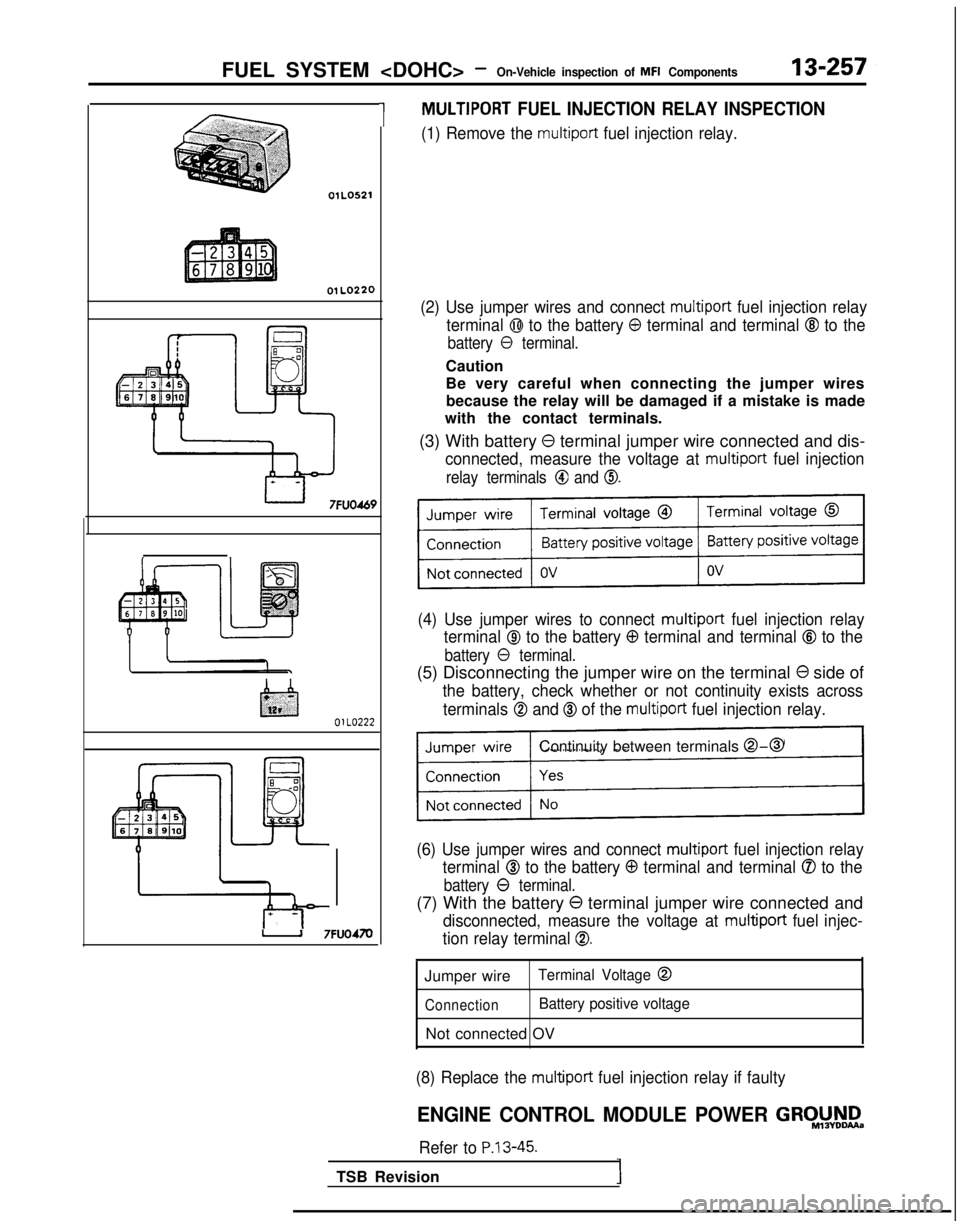

1MULTIPORT FUEL INJECTION RELAY INSPECTION

(1) Remove the multiport fuel injection relay.

(2) Use jumper wires and connect

multiport fuel injection relay

terminal

@I to the battery 0 terminal and terminal @I to the

battery 0 terminal.

Caution

Be very careful when connecting the jumper wires because the relay will be damaged if a mistake is made

with the contact terminals.

(3) With battery

0 terminal jumper wire connected and dis-

connected, measure the voltage at multiport fuel injection

relay terminals @ and 0.

(4) Use jumper wires to connect multiport fuel injection relay

terminal

@I to the battery 0 terminal and terminal @ to the

battery 0 terminal.

(5) Disconnecting the jumper wire on the terminal 0 side of

the battery, check whether or not continuity exists across

terminals

@ and @ of the multiport fuel injection relay.

Continuity between terminals 0-0

(6) Use jumper wires and connect multiport fuel injection relay

terminal

@ to the battery 0 terminal and terminal 0 to the

battery 0 terminal.

(7) With the battery 0 terminal jumper wire connected and

disconnected, measure the voltage at multiport fuel injec-

tion relay terminal

0.

Jumper wireTerminal Voltage @

ConnectionBattery positive voltage

Not connected OV

(8) Replace the multiport fuel injection relay if faulty

ENGINE CONTROL MODULE POWER GRtXJNla

Refer to P.13-45.

TSB Revision

Page 400 of 1273

k.

13-258FUEL SYSTEM

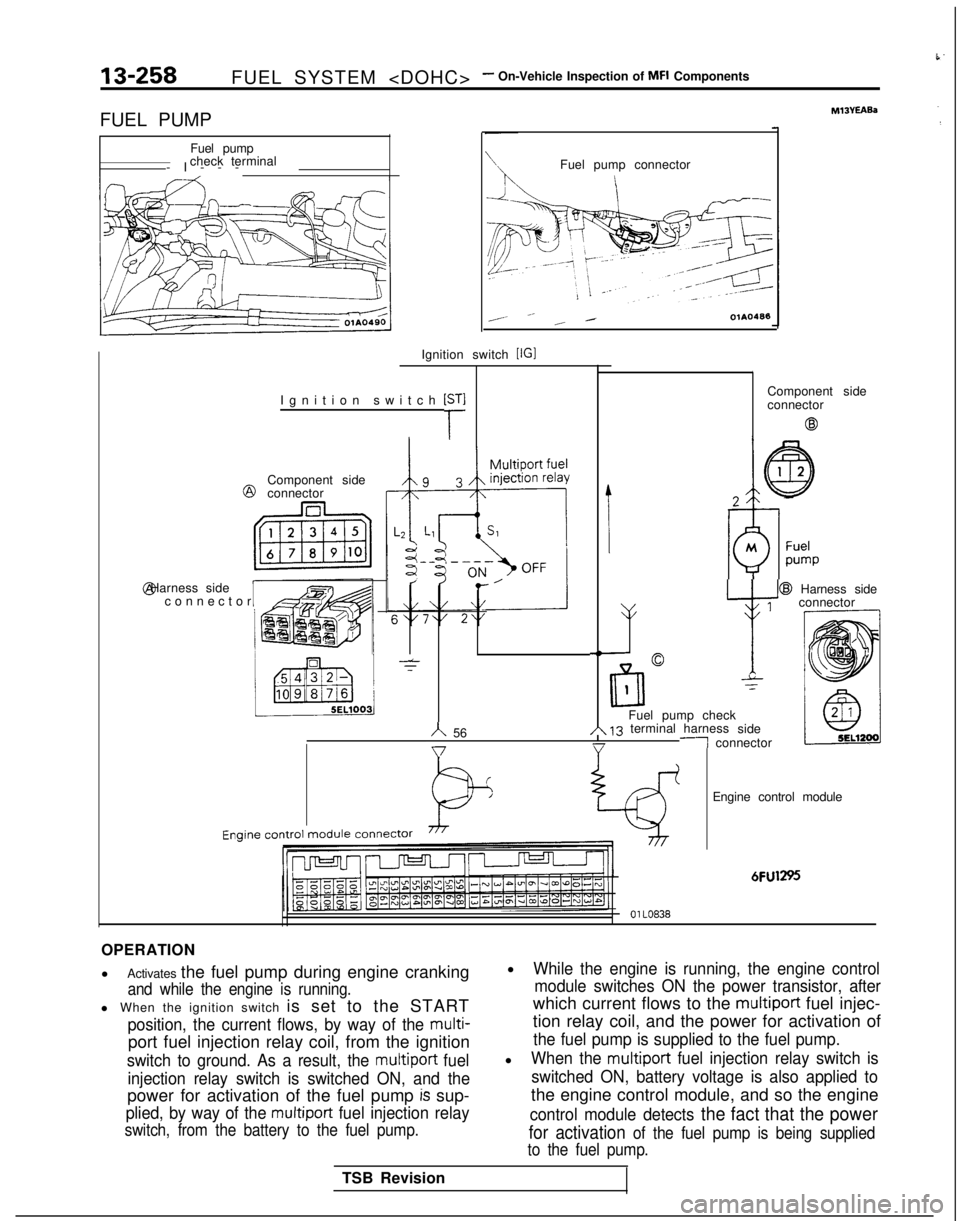

FUEL PUMP Fuel pump

check terminal

-I--

-

Ignition switch

[r

Ignition switch [IGI @

Component side

connector @ Harness side

Iconnecto

r

Fuel pump connector

I

,- __ _ /OlAO488

-T

IComponent side

connector

@

h 56 @

Harness side

1

v y

connector

-NC-

lrll

0

1-z

Fuel pump checkA 13 terminal harness

side-1 connector

I Engine

control

module

connector

Engine control module

6FU1295

01 LO838

OPERATION

l

Activates the fuel pump during engine cranking

and while the engine is running.

l When the ignition switch is set to the START

position, the current flows, by way of the multi-

port fuel injection relay coil, from the ignition

switch to ground. As a result, the multiport fuel

injection relay switch is switched ON, and the

power for activation of the fuel pump is sup-

plied, by way of the multiport fuel injection relay

switch, from the battery to the fuel pump.

lWhile the engine is running, the engine control module switches ON the power transistor, after

which current flows to the multiport fuel injec-

tion relay coil, and the power for activation of

the fuel pump is supplied to the fuel pump.

lWhen the multiport fuel injection relay switch is

switched ON, battery voltage is also applied to

the engine control module, and so the engine

control module detects the fact that the power

for activation of the fuel pump is being supplied

to the fuel pump.

TSB Revision

Page 401 of 1273

FUEL SYSTEM

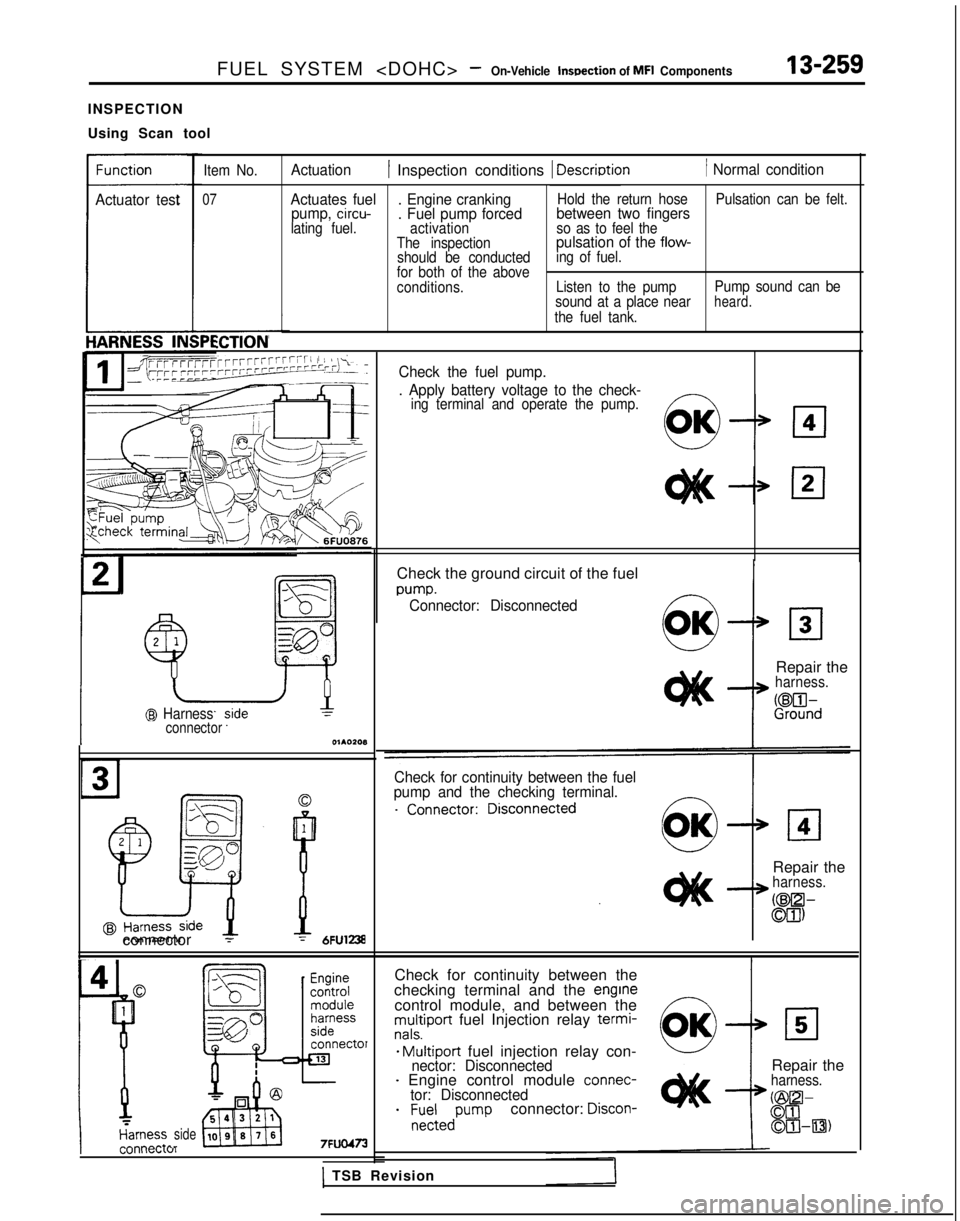

INSPECTION

Using Scan tool

Actuator test

Item No.

07

Actuation1 Inspection conditions 1 Descriotion1 Normal condition

Actuates fuel . Engine cranking

Hold the return hose Pulsation can be felt.pump, circu-. Fuel pump forcedbetween two fingerslating fuel.

activation so as to feel the

The inspectionpulsation of the flow-

should be conducted ing of fuel.

for both of the above

conditions. Listen to the pumpPump sound can be

sound at a place near

heard.the fuel tank.

iCTlON

TGrrW’-rTTrrrrrrrrrrrrrrrrrrri 1 SAL TCheck the fuel pump._---__. Apply battery voltage to the check-ing terminal and operate the pump.

@ Harnessconnector

connector 1

sideI_

Check the ground circuit of the fuel

m-m.Connector: Disconnected

Repair theharness.

if?%d

Check for continuity between the fuel

pump and the checking terminal.

Repair theharness.

CW-

Ml)

Check for continuity between the

checking terminal and the enginecontrol module, and between themultiport fuel Injection relay termi-nals.

* Multiport fuel injection relay con-nector: Disconnected- Engine control module connec-tor: Disconnected

- ;~-:edPumpconnector: Discon-

Repair theharness.

@O-00OIHl3)

1 TSB Revision

Page 402 of 1273

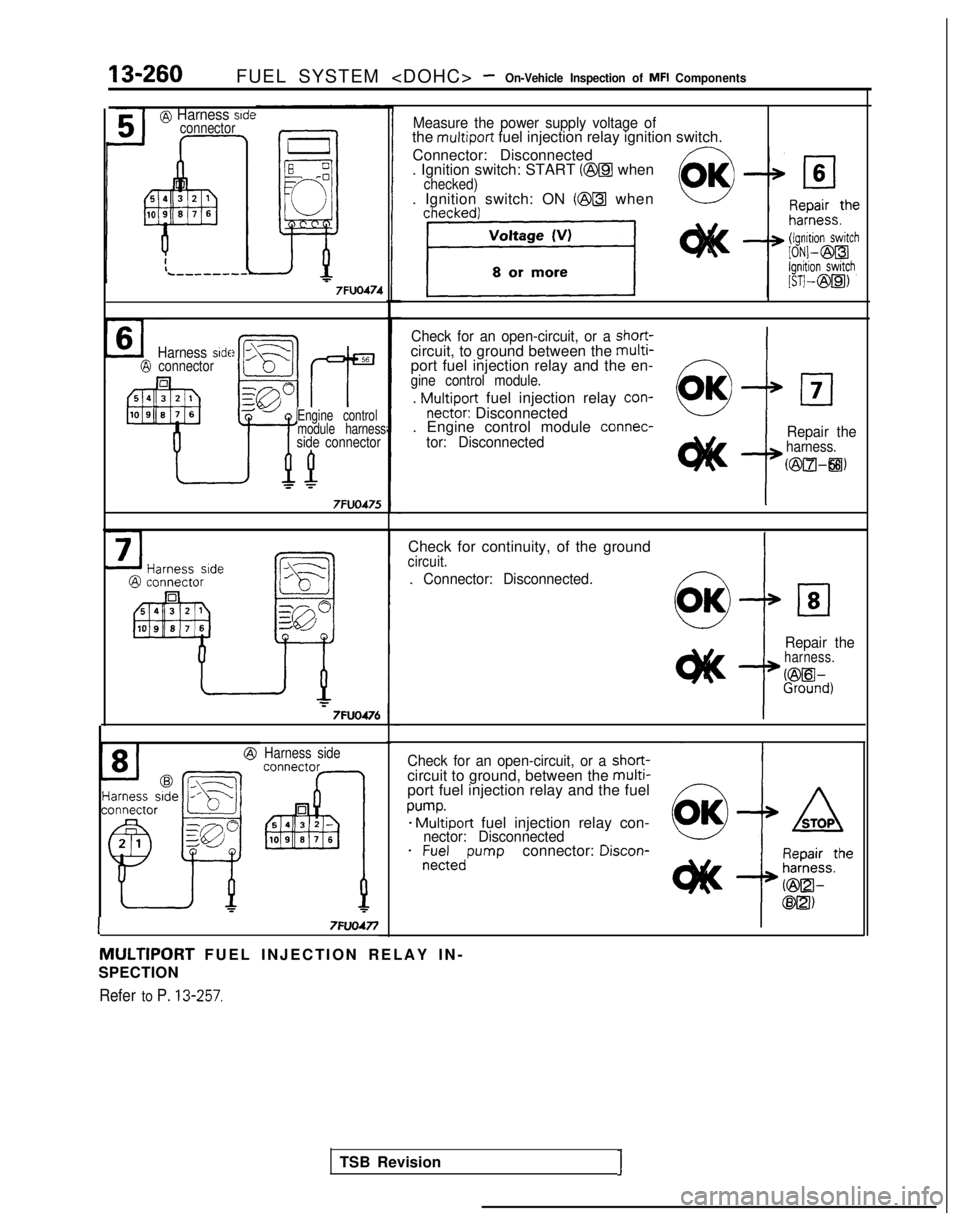

13-260FUEL SYSTEM

!5J

@ Harness srdeconnector

7FUO474

Harness srdc@ connector

Engine control

module harness

side connector

7FUO475

7FUO476

@Harness side

I7FllO477

Measure the power supply voltage ofthe multiport fuel injection relay ignition switch.

Connector: Disconnected

. Ignition switch: START

(@a whenchecked). Ignition switch: ON (@@ when

Check for an open-circuit, or a short-circuit, to ground between the multi-port fuel injection relay and the en-gine control module.

. Multiport fuel injection relay con-nectar: Disconnected

. Engine control module connec-

tor: Disconnected Repair the

harness.

uziul-8)

Check for continuity, of the groundcircuit.

. Connector: Disconnected.

cl8

Repair theharness.

%ih,

TSB RevisionJ

Check for an open-circuit, or a short-circuit to ground, between the multi-port fuel injection relay and the fuel

pump.- Multiport fuel injection relay con-nector: Disconnected

- nf;;;edw-wconnector: Discon-

MULTIPORT FUEL INJECTION RELAY IN

-

SPECTION

Refer to P. 13-257.

Page 404 of 1273

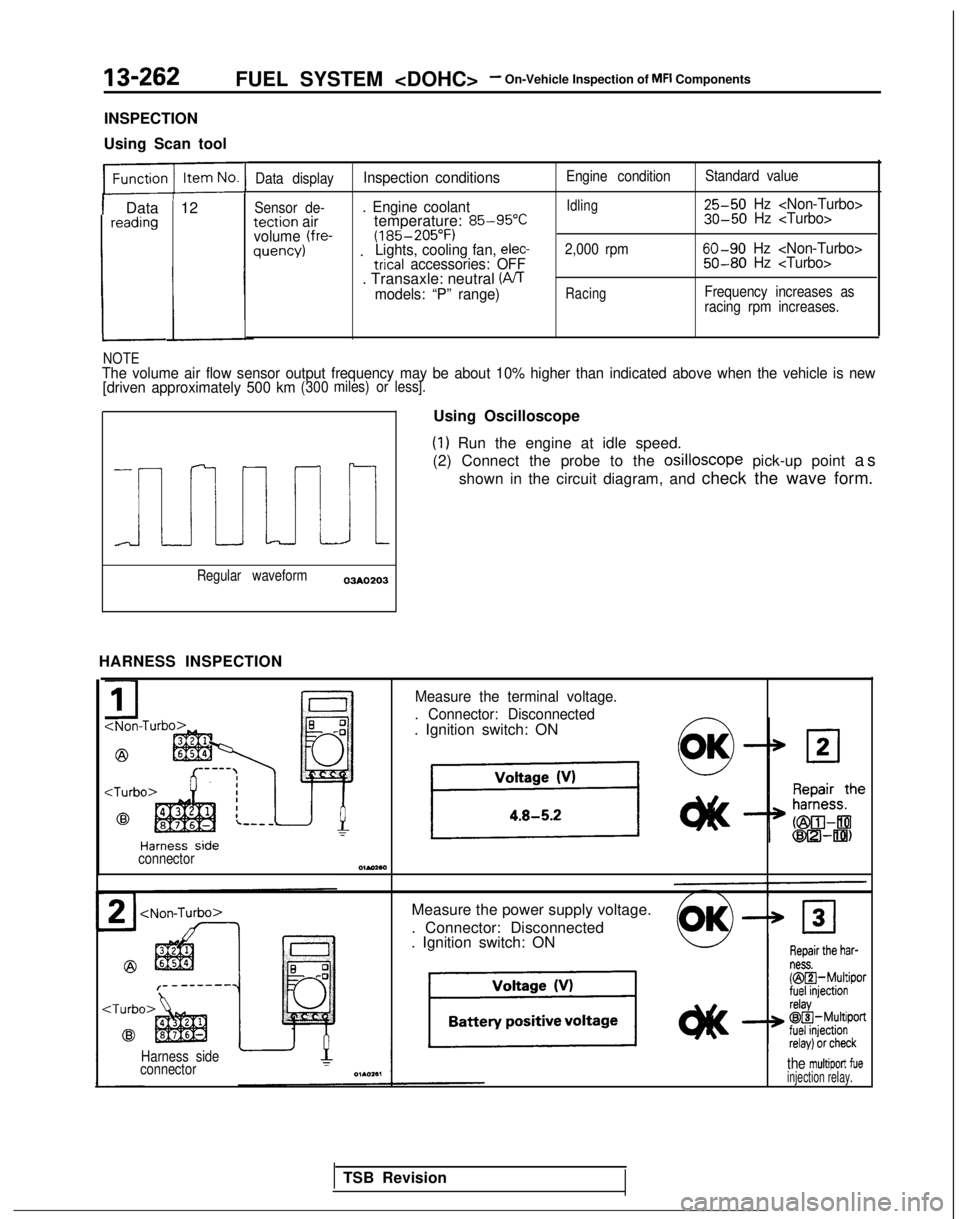

13-262FUEL SYSTEM

INSPECTION

Using Scan tool

1 Data 12reading

L

Data displayInspection conditions

Sensor de-. Engine coolanttection airtemperature: 85-95°Cvolume (fre-(185-205°F)quency) .Lights, cooling fan, elec-trical accessories: OFF. Transaxle: neutral (PJTmodels: “P” range)

Engine condition

Idling

2,000 rpm

Racing

Standard value 25-50

Hz

60-90 Hz

Frequency increases as

racing rpm increases.

NOTEThe volume air flow sensor output frequency may be about 10% higher than\

indicated above when the vehicle is new

[driven approximately 500 km(300 miles) or less].

i

Regular waveform03AO203

HARNESS INSPECTION Using Oscilloscope

(1) Run the engine at idle speed.

(2) Connect the probe to the osilloscope

pick-up point as

shown in the circuit diagram, and check the wave form.

Measure the terminal voltage.

. Connector: Disconnected

. Ignition switch: ON

connectorOlMaa

Measure the power supply voltage.

. Connector: Disconnected

. Ignition switch: ON

Harness side

connectorthe multiport fueinjection relay.

TSB Revision

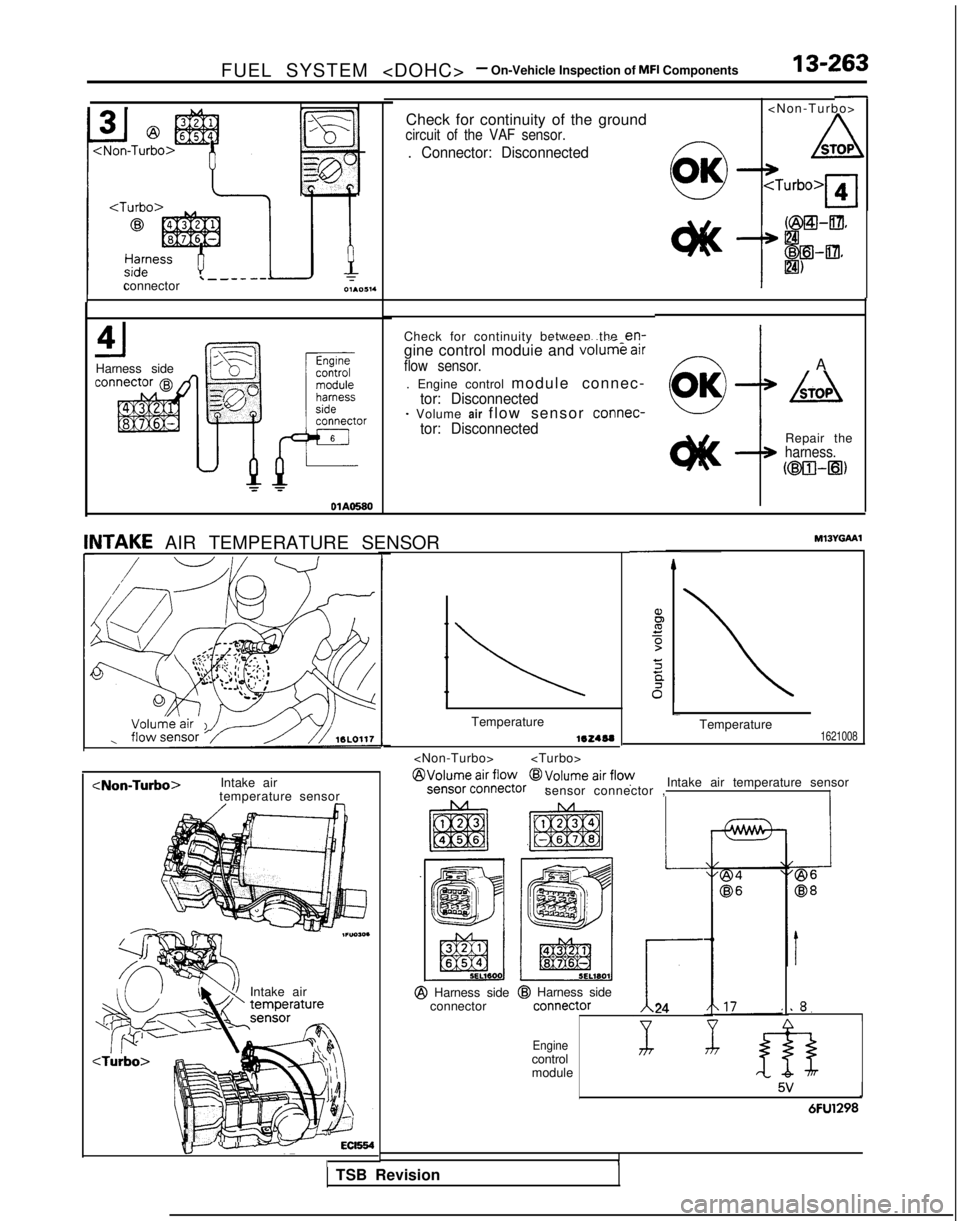

Page 405 of 1273

FUEL SYSTEM

Check for continuity of the ground

circuit of the VAF sensor.

. Connector: Disconnected

\--connector

4Harness side Check for continuity between the

en-3 air__.. --.. ..-gine control moduie and volumt

UIIflow sensor.Y---L1 A

. Engine control module connec-

tor: Disconnected- Volume air flow sensor connec-tor: Disconnected

kTOA

Repair theharness.

NliwHBl)

DlAO!XO

MlJYGAAlUTAKE AIR TEMPERATURE SENSORI

I

Temperature-Temperature1621008

sensor connector , Intake air temperature sensor

temperature sensor

I24

Intake air

@I Harness side

connector@I Harness side

.8.I

4Enginecontrol

module 5V

I1

6FU1298

Iv---I1 TSB Revision

Page 406 of 1273

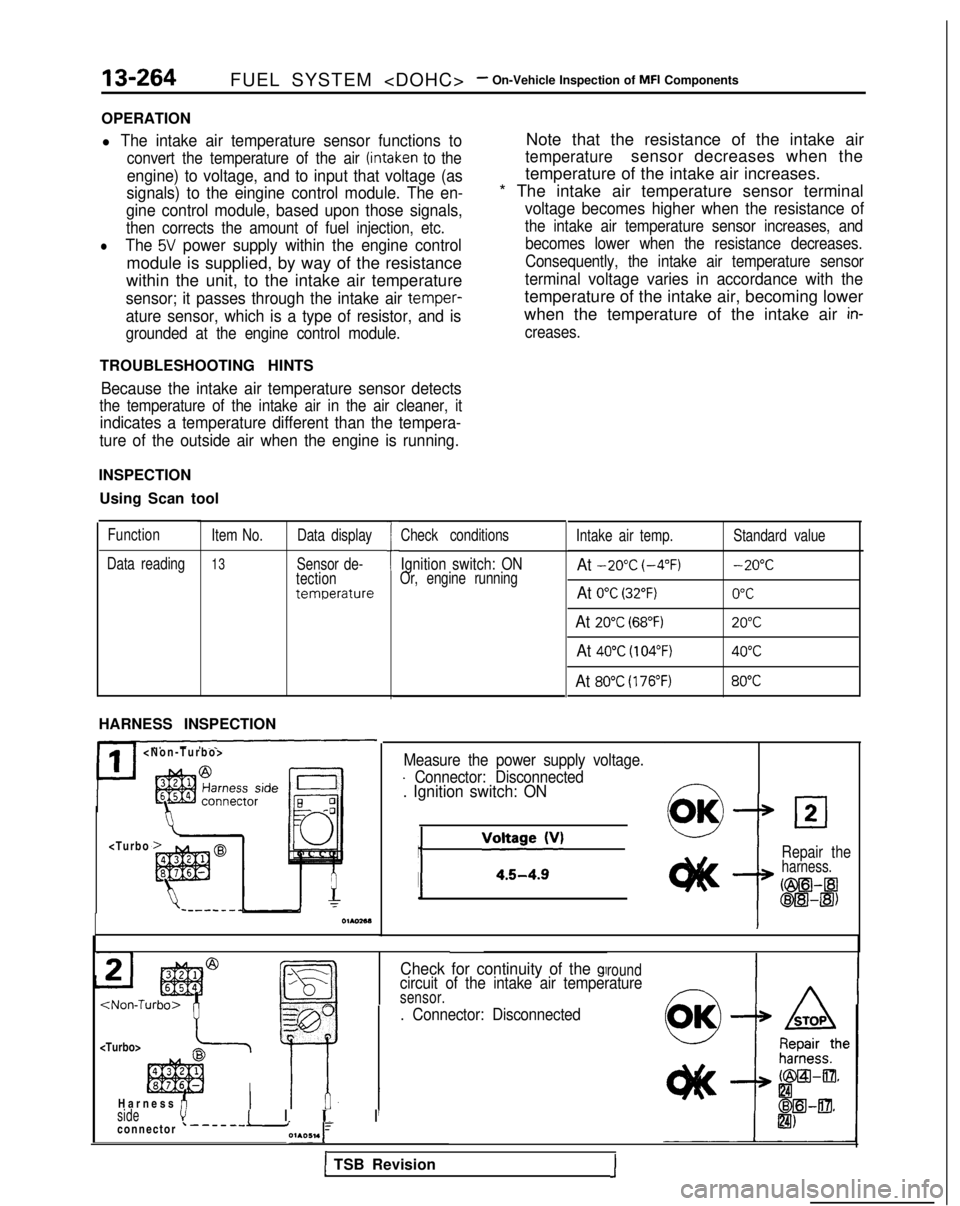

13-264FUEL SYSTEM

OPERATION

l The intake air temperature sensor functions to

convert the temperature of the air (intaken to the

engine) to voltage, and to input that voltage (as

signals) to the eingine control module. The en-

gine control module, based upon those signals,

then corrects the amount of fuel injection, etc.

lThe 5V power supply within the engine control

module is supplied, by way of the resistance

within the unit, to the intake air temperature

sensor; it passes through the intake air temper-

ature sensor, which is a type of resistor, and is

grounded at the engine control module.

Note that the resistance of the intake air

temperaturesensor decreases when the

temperature of the intake air increases.

* The intake air temperature sensor terminal

voltage becomes higher when the resistance of

the intake air temperature sensor increases, and becomes lower when the resistance decreases.

Consequently, the intake air temperature sensor

terminal voltage varies in accordance with the

temperature of the intake air, becoming lower

when the temperature of the intake air

in-

creases.

TROUBLESHOOTING HINTS

Because the intake air temperature sensor detects

the temperature of the intake air in the air cleaner, it

indicates a temperature different than the tempera-

ture of the outside air when the engine is running.

INSPECTION

Using Scan tool

Function

Data reading Item No.

13

Data display

Sensor de-

tection

temperature

HARNESS INSPECTION

II

I

Check conditions

Ignition switch: ONOr, engine running

Intake air temp.At -20°C (-4°F)

At 0°C (32°F)

At 20°C (68°F)

At 40°C (104°F)

At 80°C (176°F)

Standard value -20°C

0°C

20°C

40°C

80°C

Measure the power supply voltage.

- Connector: Disconnected. Ignition switch: ON

j

/‘“:;~~~v’0OKLl2

Repair theharness.

Cm--a

oE!l-@)

Check for continuity of the glroundcircuit of the intake air temperaturesensor.

. Connector: Disconnected

I

sidevI I 1~ I

I

Harness fi

connector ‘-------i01A051.1

1 TSB Revision1

Page 408 of 1273

13-266FUEL SYSTEM

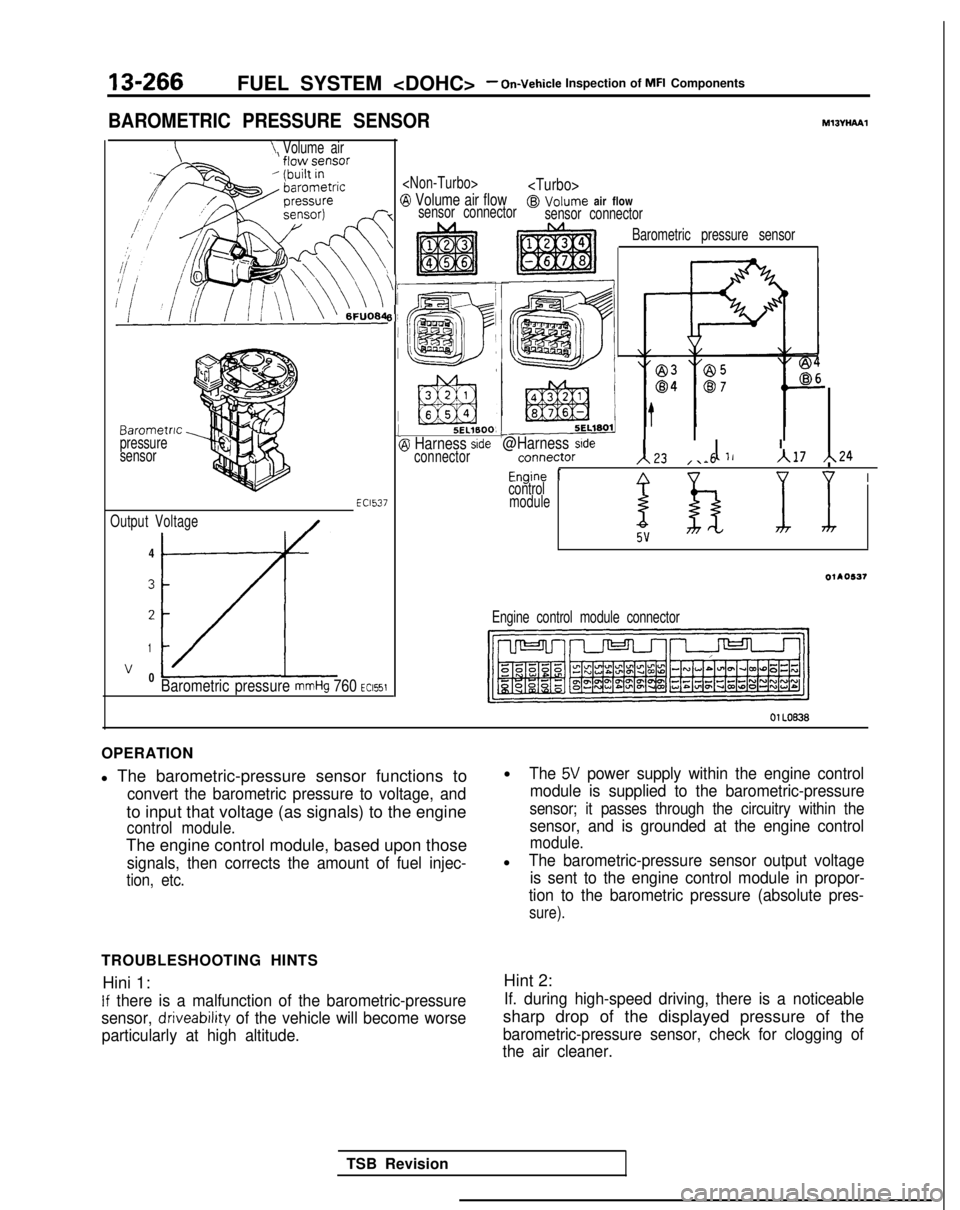

BAROMETRIC PRESSURE SENSORMl3VHPYPl

\ Volume air

Barometric

pressure

sensor

Output Voltage

/-4

3

2

1

v 0LzLBarometric pressure mmHg 760 ~~1551

EC1537

(

7

\

‘i

6!

I

I1(

5EL1600, L-@I Harness sideconnector@Harness sidernnn~rtnr131 11, I ’““, ,. Iv-.-.,\L4 ,\-5A17 h24

Fnnine 1Anv uI

Barometric pressure sensor

-“J -control

module

I

OllO537

Engine control module connector

01 LOB38

OPERATION

l The barometric-pressure sensor functions to

convert the barometric pressure to voltage, and

to input that voltage (as signals) to the engine

control module.

The engine control module, based upon those

signals, then corrects the amount of fuel injec-

tion, etc.

TROUBLESHOOTING HINTS Hini 1:

If there is a malfunction of the barometric-pressure

sensor,

driveability of the vehicle will become worse

particularly at high altitude.

lThe 5V power supply within the engine control

module is supplied to the barometric-pressure

sensor; it passes through the circuitry within the

sensor, and is grounded at the engine control

module.

lThe barometric-pressure sensor output voltage is sent to the engine control module in propor-

tion to the barometric pressure (absolute pres-

sure).

Hint 2:

If. during high-speed driving, there is a noticeable

sharp drop of the displayed pressure of the

barometric-pressure sensor, check for clogging of

the air cleaner.

TSB Revision

Page 409 of 1273

FUEL SYSTEM

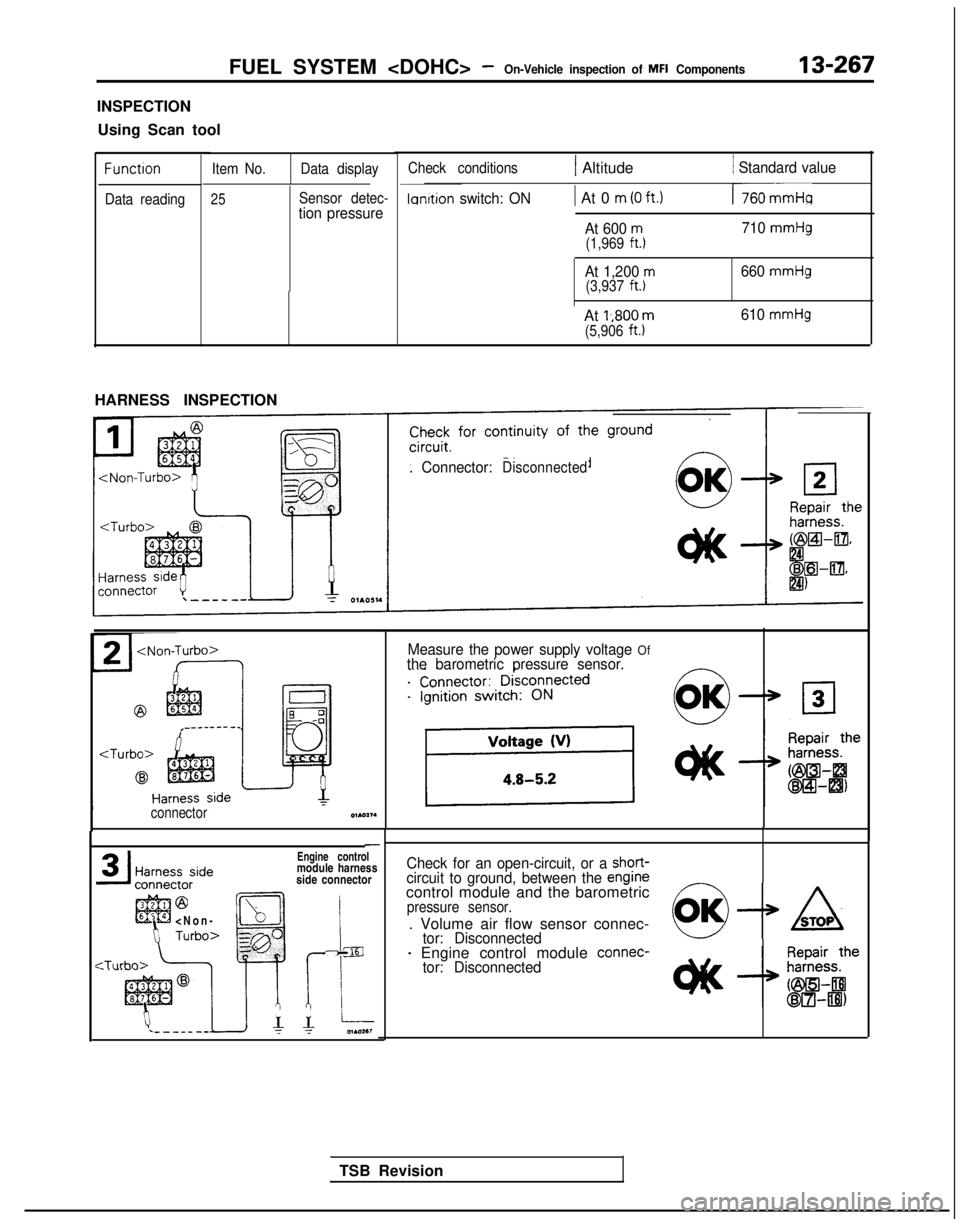

INSPECTION

Using Scan tool

Function Item No.

Data display

Data reading

25Sensor detec-tion pressure

HARNESS INSPECTION

Check conditions1 Altitude1 Standard value

lanltion switch: ON1 At 0 m (0 ft.)LrnmmHq

At 600 m(1,969 ft.)710 mmHg

At 1,200 m660 mmHg(3,937 ft.)

At I:800

m610 mmHg

(5,906 ft.)

. Connector:Disconnected

Measure the power supply voltage Ofthe barometric pressure sensor.

connector

TSB Revision

-Engine controlmodule harness

side connector

6%

Check for an open-circuit, or a shqrt-circuit to ground, between the enginecontrol module and the barometricpressure sensor.

. Volume air flow sensor connec-tor: Disconnected@--/LA

- Engine control module connec-tor: Disconnected