check engine MITSUBISHI GALANT 1989 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 455 of 1273

FUEL SYSTEM

of MFI

Components13-313

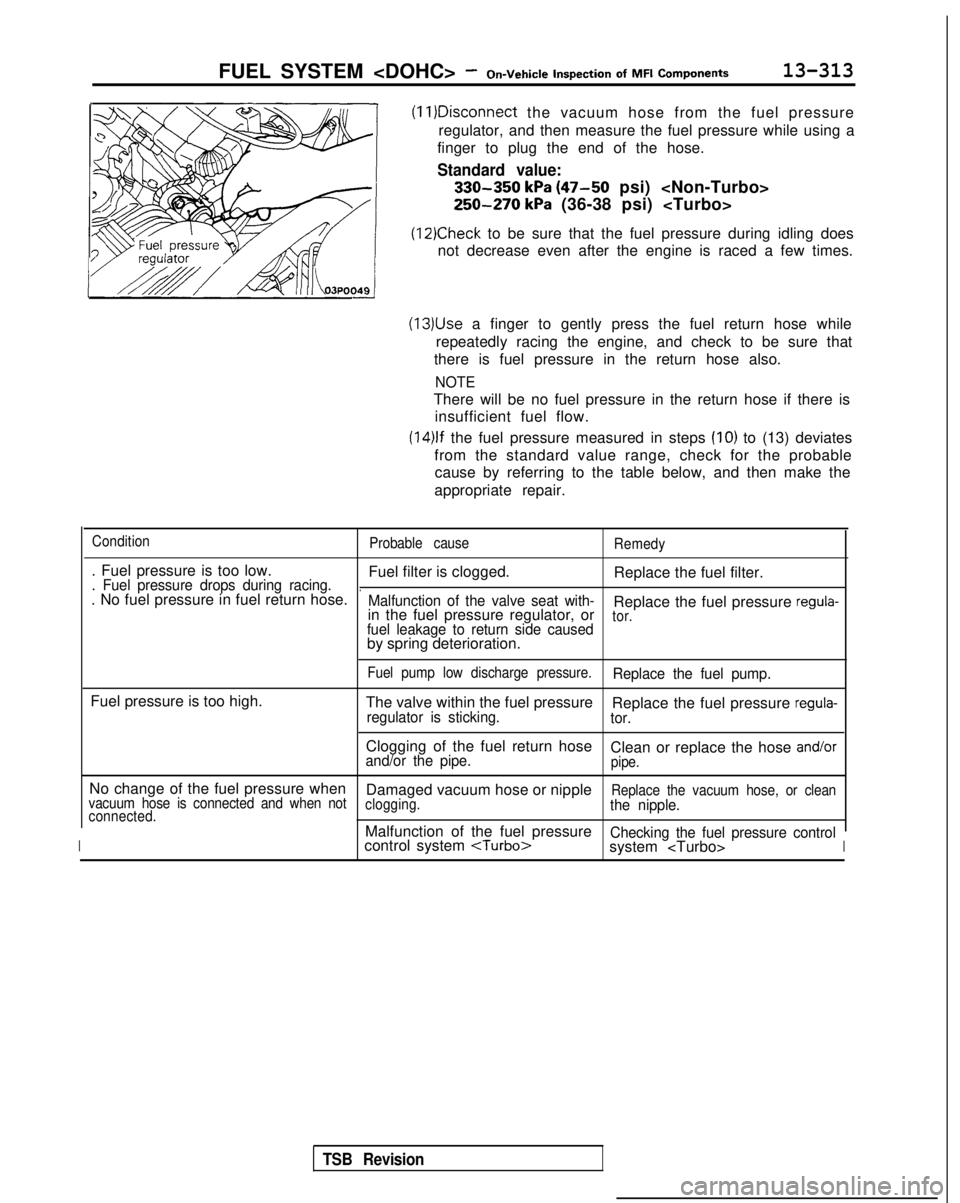

(11)Disconnect

the vacuum hose from the fuel pressure

regulator, and then measure the fuel pressure while using a

finger to plug the end of the hose.

Standard value:

330-350 kPa (47-50 psi)

250-270 kPa (36-38 psi)

(12)Check to be sure that the fuel pressure during idling does

not decrease even after the engine is raced a few times.

(13)Use a finger to gently press the fuel return hose while

repeatedly racing the engine, and check to be sure that

there is fuel pressure in the return hose also.

NOTE

There will be no fuel pressure in the return hose if there is insufficient fuel flow.

(14)lf the fuel pressure measured in steps (IO) to (13) deviates

from the standard value range, check for the probable cause by referring to the table below, and then make the

appropriate repair.

Condition Probable causeRemedy

. Fuel pressure is too low.

Fuel filter is clogged.Replace the fuel filter.. Fuel pressure drops during racing... No fuel pressure in fuel return hose.Malfunction of the valve seat with-Replace the fuel pressure regula-in the fuel pressure regulator, ortor.fuel leakage to return side causedby spring deterioration.

Fuel pump low discharge pressure.Replace the fuel pump.

Fuel pressure is too high.

The valve within the fuel pressureReplace the fuel pressure regula-regulator is sticking. tor.

Clogging of the fuel return hose

Clean or replace the hose and/orand/or the pipe.pipe.

No change of the fuel pressure when Damaged vacuum hose or nippleReplace the vacuum hose, or clean

vacuum hose is connected and when not clogging.the nipple.connected.

IMalfunction of the fuel pressureChecking the fuel pressure controlcontrol system

system

TSB Revision

Page 456 of 1273

13-314FUEL SYSTEM

of

MFI

Components

(15)Stop the engine and check for a change of the value

indicated by the fuel pressure gauge. The condition is

normal if there is no decrease of the indicated value within

two minutes.

If there is a decrease of the indicated value, monitor the

speed of the decrease, and, referring to the table below,

determine the cause of the problem and make the

appropriate repair.

ConditionProbable causeRemedy

After the engine is stopped, the fuel injector leakage pressure drops graudally.Replace the injector.

Leakage at the fuel pressure reg-ulator valve seat Replace the fuel pressure regula-tor.

There is a sudden sharp drop of the fuel

pressure immediately after the engine isThe check valve (within the fuel pump) is not closed.Replace the fuel pump.

stopped.

(16) Reduce the internal pressure of the fuel pipes and hoses.

(Refer to P. 13-l 02.)

(17) Disconnect the fuel pressure gauge and the special tools

from the fuel rail.

Caution

Because there will be a some residual pressure in the

fuel pipe line, use a shop towel to cover so that fuel

doesn’t splatter.

(18)Replace the O-ring at the end of the fuel high-pressure

hose with a new one. (19)After

connecting the fuel high-pressure hose to the fuel

rail, tighten the installation bolt.

(20)Check to be sure that there is no fuel leakage. @ Apply battery voltage to the terminal for activation of

@

the fuel pump so as to activate the fuel pump.

With fuel pressure applied, check for leakage of the fuel

line.

TSB Revision1

Page 457 of 1273

FUEL SYSTEM

On-Vehicle

Inwection of MFI

ComDonents13-315

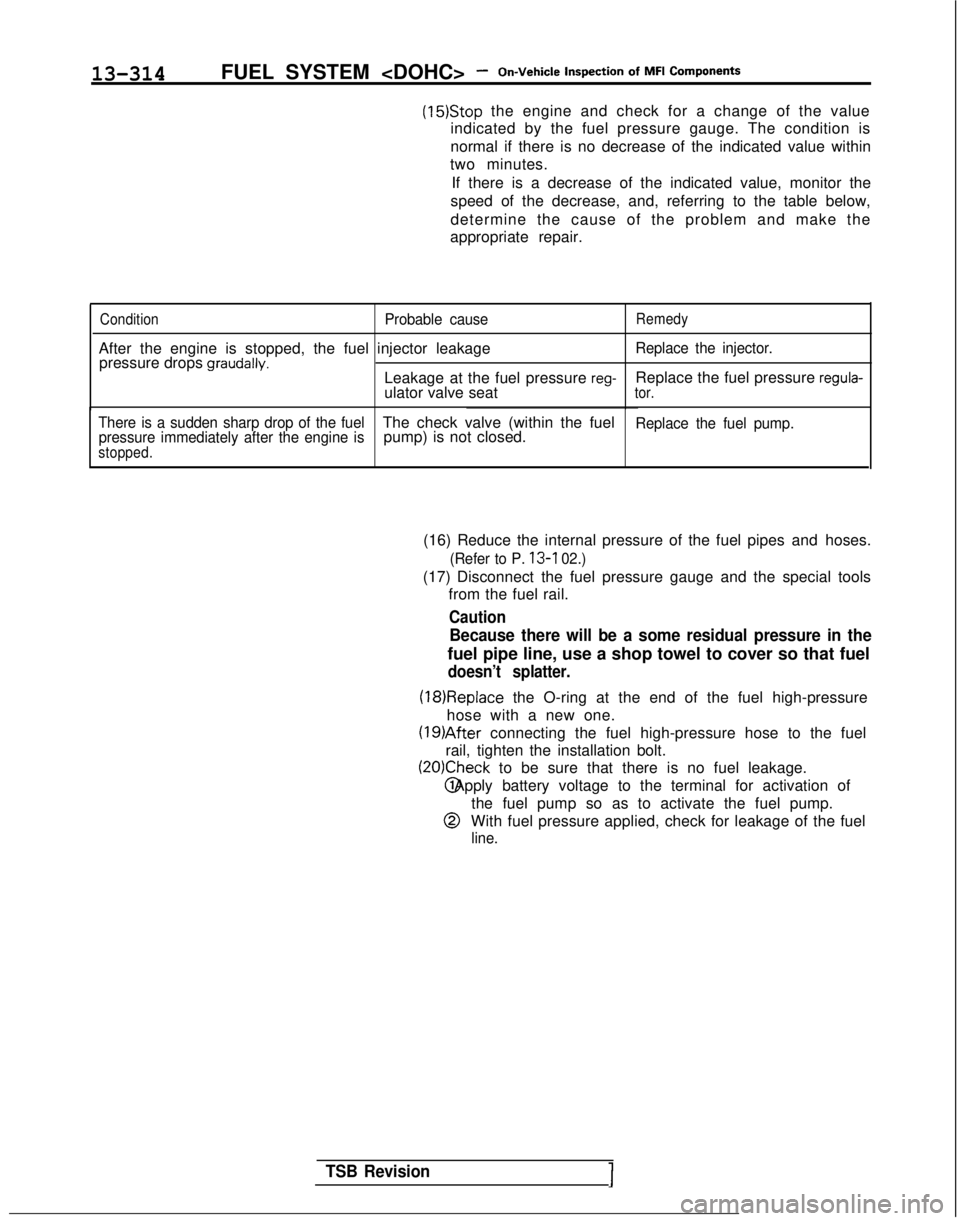

INSPECTION OF ENGINE CONTROL MODULE

TERMINAL VOLTAGEM13zALCa

Refer to P.13-105.

TERMINAL VOLTAGE CHECK CHART

Terminal arrangement of engine control module connector

l!m n-J-J-l-II

NOTE:B+: Battery

positive voltage

TerminalCheck item Check condition (Engine state)Standardvalu

e

Remarks

No.

103

102

107

Backup power

SUPPlY

Power supply

Ignition switch: OFFB+

Ignition switch: ONB+

110

13

63

66 56

23

Ignition switch-IGIgnition switch: ON

Fuel pump Engine: Cranking

drive signal Engine: Idling

Multiport fuel Ignition switch: OFFinjection relay

(Power supply)Ignition switch: ON

Multiport fuel Ignition switch: ON

injection relay

(Fuel pump) Engine: Idling

Sensor impressed Ignition switch: ONvoltage

B+

8V or higher

B+

B+

o-3v

B+

o-3v

4.5- 5.w

10

8

16

20

Volume air flowsensor

Ax intaketemperature

sensor

Barometric

pressure sensor

Engine coolant

temperature sensor Engine: Idling

2.2-3.2V

Engine speed: 2,000 rpm

IgnitionAir Intake temperature of 0°C (32°F)3.2- 3.8V

switch:

ONAir intake temperature of 20°C (68°F)2.3- 2.9V

Air intake temperature of 40°C (104°F) 1.5-2.1V

Air intake temperature of 80°C (176°F)0.4- 1 .OV

Ignition Altitude of 0 m (0 ft.)3.7-4.3v

switch

:

ONAltitude of 1,200 m (3,937 ft.)3.2-3.8V

IgnitionCoolant temperature of 0°C (32’F)3.2-

3.Wswitch:ONCoolant temperature of 20°C (68°F)2.3- 2.9V

Coolant temperature of 40°C (104°F)1.3- 1.9V

Coolant temperature of 80°C (176°F) 0.3-0.9V

TSB Revision

Page 458 of 1273

13-316FUEL SYSTEM

Inspection

of

MFI

Components

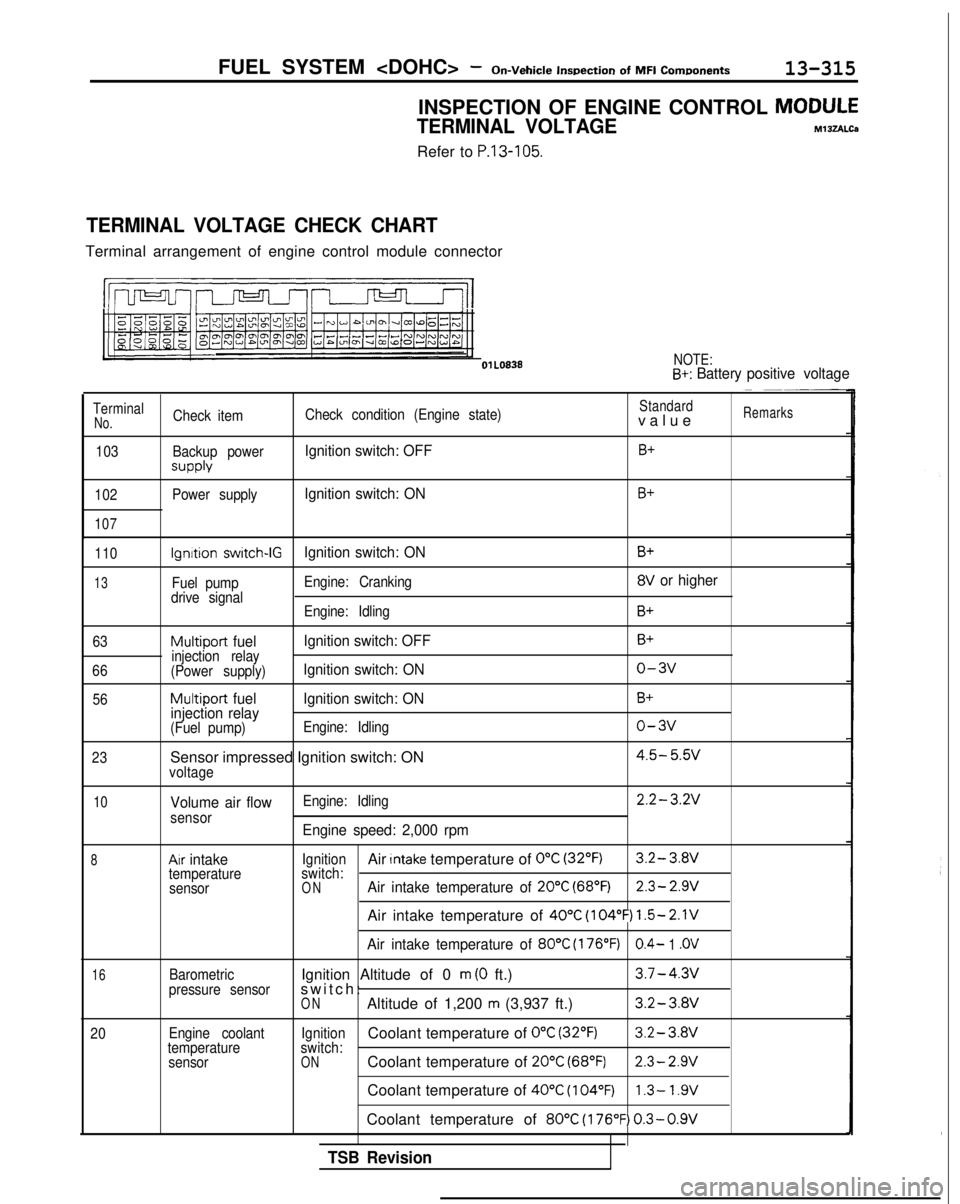

TerminalNo.Check itemCheck condition (Engine state)Standardvalue

Remarks

19Throttle positronIgnition switch: ItSet the throttle valve to the0.4- 0.wsensorIS kept ON for 15seconds or moreidlrng position.

Fully open the throttle valve.4.5- 5.5v

14

Closed throttlelgnrtrono-1vposition switchswitch:Set the throttle valve to the idling

position.

ONSlightly open the throttle valve.4V or higher

22Camshaft posi-tion sensorEngine: Cranking0.2- 3.ov

Engine: ldlrng

21

Crankshfat posi-tion sensor Engine: Cranking0.2- 3.ov

Engine: Idling

108lgnrtion switch-STEngine: Cranking8V or higher

104

Park/neutral

pos-ition switchIgnitionSet the selector lever to P or N.o-3vswitch:ONSet the selector lever to D, 2, L or R.8- 14V

18Vehicle speedl Ignition switch: ON

sensorl Slowly run the vehicle forward0 - 5v(Repeat the

variation.)

5Power steering

pressure switchEngine:Idling opera-Steering wheel idle stateB+

tion afterwarming-upDuring steering wheel operationo-3v

7A&;;;ditioningEngine:Idling _Turn OFF the air conditioning switch.o-3v

Turn ON the air conditioning switch.B+

(The air conditioning compressor is in

the drive state.)

35Air conditioningl Engine: IdlingB+ orcompressor

clutch relayl Air conditioning switch: OFF -, ON(The air conditioning compressor is in the

temporarily

drive state.)6V or higher o’-

3v

1Heated oxygen

sensorEngine: Keep the engrne speed at 2.000 rpmafter warming up.

(For checking, use a digital voltmeter.)ke;atoZivariation.)

51No. 1 InjectorEngine: After warming up, rapidly press the

52No. 2 Injector accelerator pedal from the idlrng state,Voltage

temporarily

drops slightly

30No. 3 Injectorfrom 14V to1 IV.

51No. 4 Injector

j8

Stepper motorcoil

i9

Stepper motor0%

coil

variation.)

‘7Stepper motorcoil

8Stepper motorco11

TSB Revision

Page 459 of 1273

FUEL SYSTEM

Inspection

of MFI

Components13-317

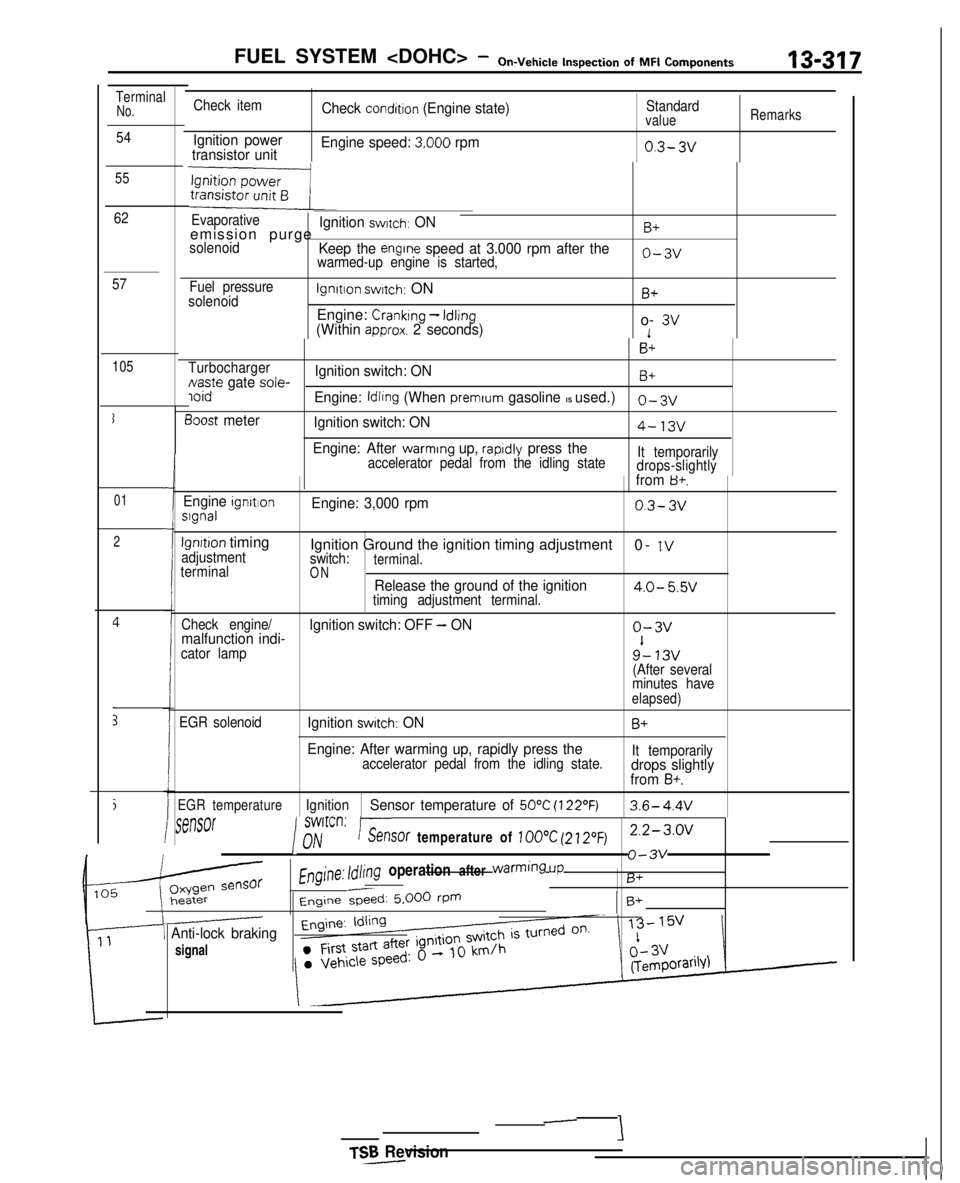

TerminalNo.

54

55

62

57

105

I

01

2

i

E

Check item

Ignition power

transistor unit Check

condition (Engine state)

Engine speed:

3.000 rpm

Standardvalue

0.3- 3v

Remarks

Evaporativeemission purgeIgnition switch: ONB+

solenoidKeep the engrne speed at 3.000 rpm after thewarmed-up engine is started,o-3v

Fuel pressure

solenoidlgnltlon switch: ON

Engine:

Cranking - Idling(Within approx. 2 seconds)

B+

o- 3v1

B+

TurbochargerNaste gate sole-Ignition switch: ONB+ ioid

Engine: Idling (When premrum gasoline IS used.)0-3~

3oost meter

Ignition switch: ON4-13v

Engine: After warming up, rapldly press theaccelerator pedal from the idling state It temporarily

drops-slightlyIfrom B+.

Engine ignrtlonslgnalEngine: 3,000 rpm0.3-3v

lgnrtion timingadjustment

terminalIgnition Ground the ignition timing adjustment 0- 1Vswitch:terminal.ONRelease the ground of the ignition4.0- 5.5vtiming adjustment terminal.

Check engine/

malfunction indi- Ignition switch: OFF - ONo-3v

cator lamp9’- 13v(After several

minutes have

elapsed)

EGR solenoidIgnition switch: ONB+

Engine: After warming up, rapidly press theaccelerator pedal from the idling state. It temporarilydrops slightly

from B+.

EGR temperatureIgnitionSensor temperature of 50°C (122’F)3.6- 4.4V

rSt?MX

I

swlrcrl:nhir--.%?nY/V-_. ..sof temperature of 100°C (21.20~)2.2-3.0~

Engine: Idling operation after warming

UP

o-3v

B+

Engine &ed: 5.000 rPmB+

\ Anti-lock braking

signal

TSR Revision-

-

‘i

Page 465 of 1273

FUEL SYSTEM

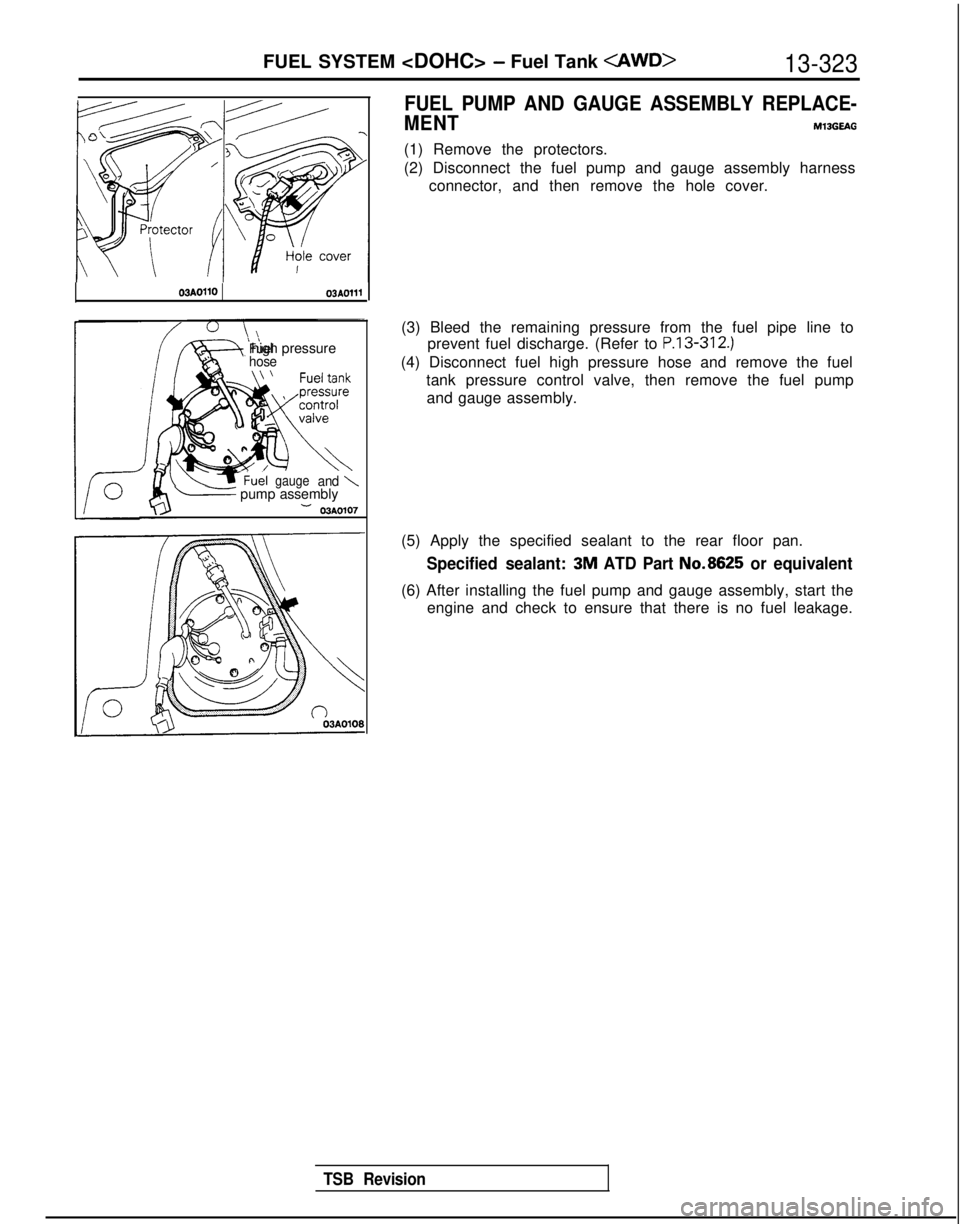

03AOllO03AOlll

f%? hose

‘F;el high pressure

-Fuelgaugeand \n pump assembly- 03AO107

TSB Revision

FUEL PUMP AND GAUGE ASSEMBLY REPLACE-

MENT

MlBGEAG

(1) Remove the protectors.

(2) Disconnect the fuel pump and gauge assembly harness connector, and then remove the hole cover.

(3) Bleed the remaining pressure from the fuel pipe line to prevent fuel discharge. (Refer to

P.13-312.)

(4) Disconnect fuel high pressure hose and remove the fuel

tank pressure control valve, then remove the fuel pumpand gauge assembly.

(5) Apply the specified sealant to the rear floor pan.

Specified sealant: 3M ATD Part No.8625 or equivalent

(6) After installing the fuel pump and gauge assembly, start the

engine and check to ensure that there is no fuel leakage.

Page 467 of 1273

FUEL SYSTEM

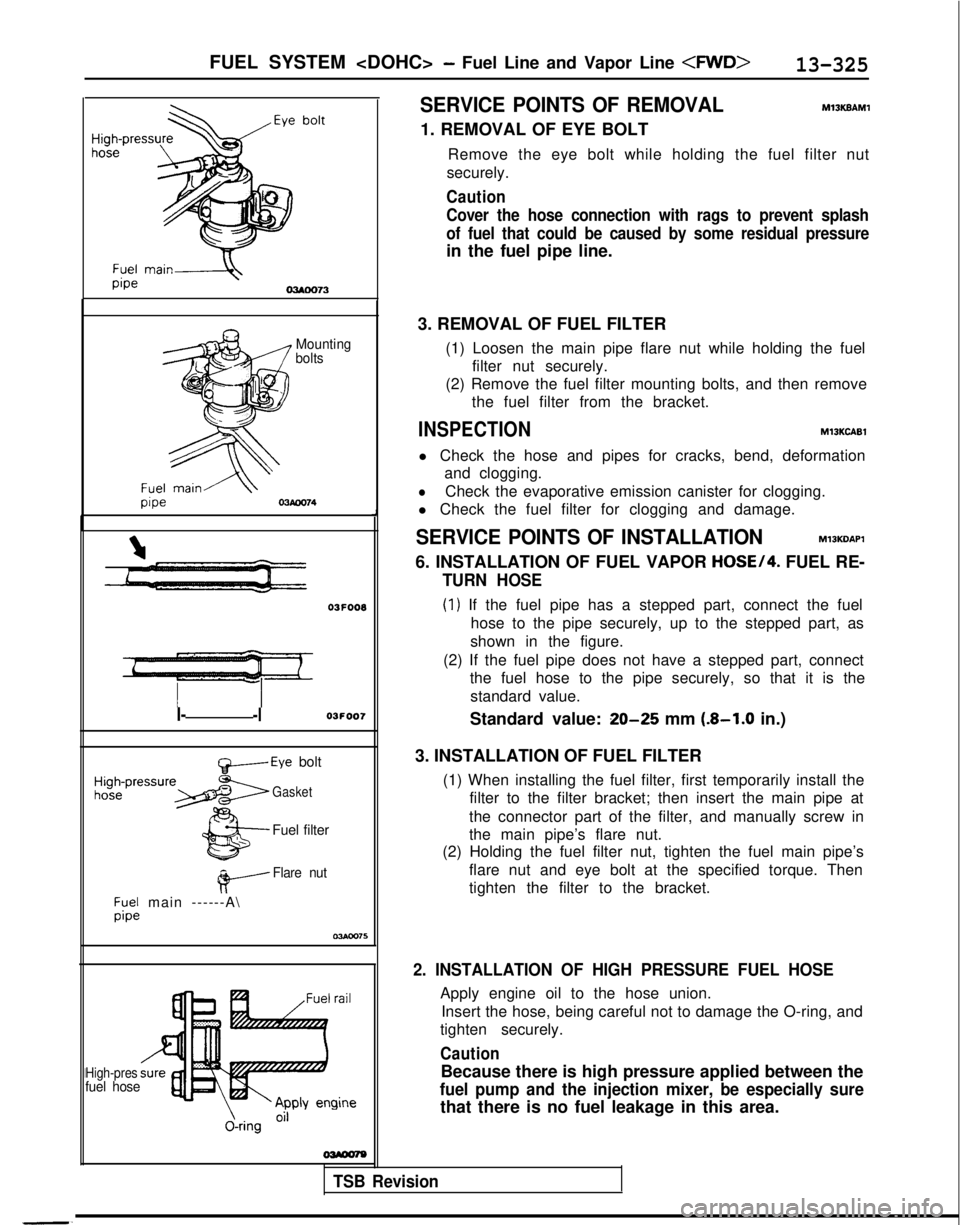

Mounting

bolts 03F008

I--l03FOO7Standard value: 20-25 mm (8-1.0 in.)

t&-----Eye bolt

Gasket

Fuel filter

#-----

Flare nut

;y;; main ------A\

J

I

-.

High-presfuel hose

J-ring

O”

SERVICE POINTS OF REMOVALMlSKBAMl

1. REMOVAL OF EYE BOLT

Remove the eye bolt while holding the fuel filter nut

securely.

Caution

Cover the hose connection with rags to prevent splash

of fuel that could be caused by some residual pressure

in the fuel pipe line.

3. REMOVAL OF FUEL FILTER (1) Loosen the main pipe flare nut while holding the fuelfilter nut securely.

(2) Remove the fuel filter mounting bolts, and then remove the fuel filter from the bracket.

INSPECTIONMlOKCABl

l Check the hose and pipes for cracks, bend, deformationand clogging.

lCheck the evaporative emission canister for clogging.

l Check the fuel filter for clogging and damage.

SERVICE POINTS OF INSTALLATIONMlJKDAPl

6. INSTALLATION OF FUEL VAPOR HOSE/4. FUEL RE-

TURN HOSE

(1) If the fuel pipe has a stepped part, connect the fuel

hose to the pipe securely, up to the stepped part, as

shown in the figure.

(2) If the fuel pipe does not have a stepped part, connect the fuel hose to the pipe securely, so that it is the

standard value.

3. INSTALLATION OF FUEL FILTER (1) When installing the fuel filter, first temporarily install thefilter to the filter bracket; then insert the main pipe at

the connector part of the filter, and manually screw in

the main pipe’s flare nut.

(2) Holding the fuel filter nut, tighten the fuel main pipe’s

flare nut and eye bolt at the specified torque. Then

tighten the filter to the bracket.

TSB Revision 2. INSTALLATION OF HIGH PRESSURE FUEL HOSE

Apply engine oil to the hose union.

Insert the hose, being careful not to damage the O-ring, and

tighten securely.

Caution

Because there is high pressure applied between the

fuel pump and the injection mixer, be especially sure

that there is no fuel leakage in this area.

Page 471 of 1273

ENGINE CONTROL - Service Adjustment Procedures13-329

SERVICE ADJUSTMENT PROCEDW,E,t&

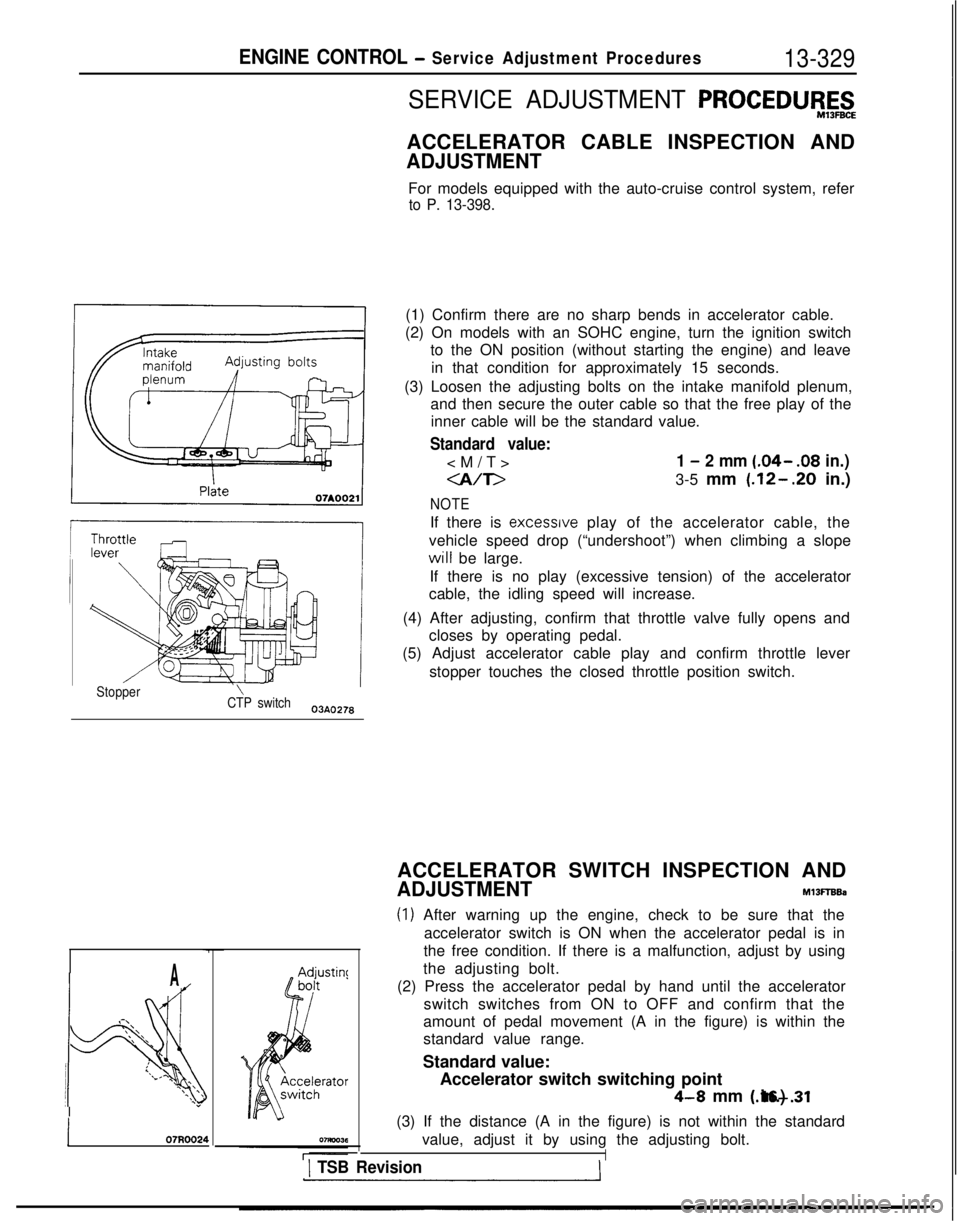

ACCELERATOR CABLE INSPECTION AND

ADJUSTMENT

For models equipped with the auto-cruise control system, refer

to P. 13-398.

(1) Confirm there are no sharp bends in accelerator cable.

(2) On models with an SOHC engine, turn the ignition switch to the ON position (without starting the engine) and leave

in that condition for approximately 15 seconds.

(3) Loosen the adjusting bolts on the intake manifold plenum, and then secure the outer cable so that the free play of theinner cable will be the standard value.

Standard value:

1 - 2 mm (.04- .08

in.)

-a/T>3-5 mm (.12-.20 in.)

NOTE

If there is excessrve play of the accelerator cable, the

vehicle speed drop (“undershoot”) when climbing a slope will

be large.

If there is no play (excessive tension) of the accelerator

cable, the idling speed will increase.

(4) After adjusting, confirm that throttle valve fully opens and closes by operating pedal.

(5) Adjust accelerator cable play and confirm throttle lever

stopper touches the closed throttle position switch.

Stopper\CTP switch03AO278

A

.-\\‘\.\ ‘\

!4

:l/.\\ \\‘\ I\*\\”

j 07R0024

ACCELERATOR SWITCH INSPECTION AND

ADJUSTMENTM13FTBBa

(1) After warning up the engine, check to be sure that theaccelerator switch is ON when the accelerator pedal is in

the free condition. If there is a malfunction, adjust by using

the adjusting bolt.

(2) Press the accelerator pedal by hand until the accelerator switch switches from ON to OFF and confirm that the

amount of pedal movement (A in the figure) is within the

standard value range.

Standard value: Accelerator switch switching point

4-8 mm (.16-.31 in.)

(3) If the distance (A in the figure) is not within the standard value, adjust it by using the adjusting bolt.

I1 TSB Revision

Page 473 of 1273

ENGINE CONTROL - Engine Control13-331

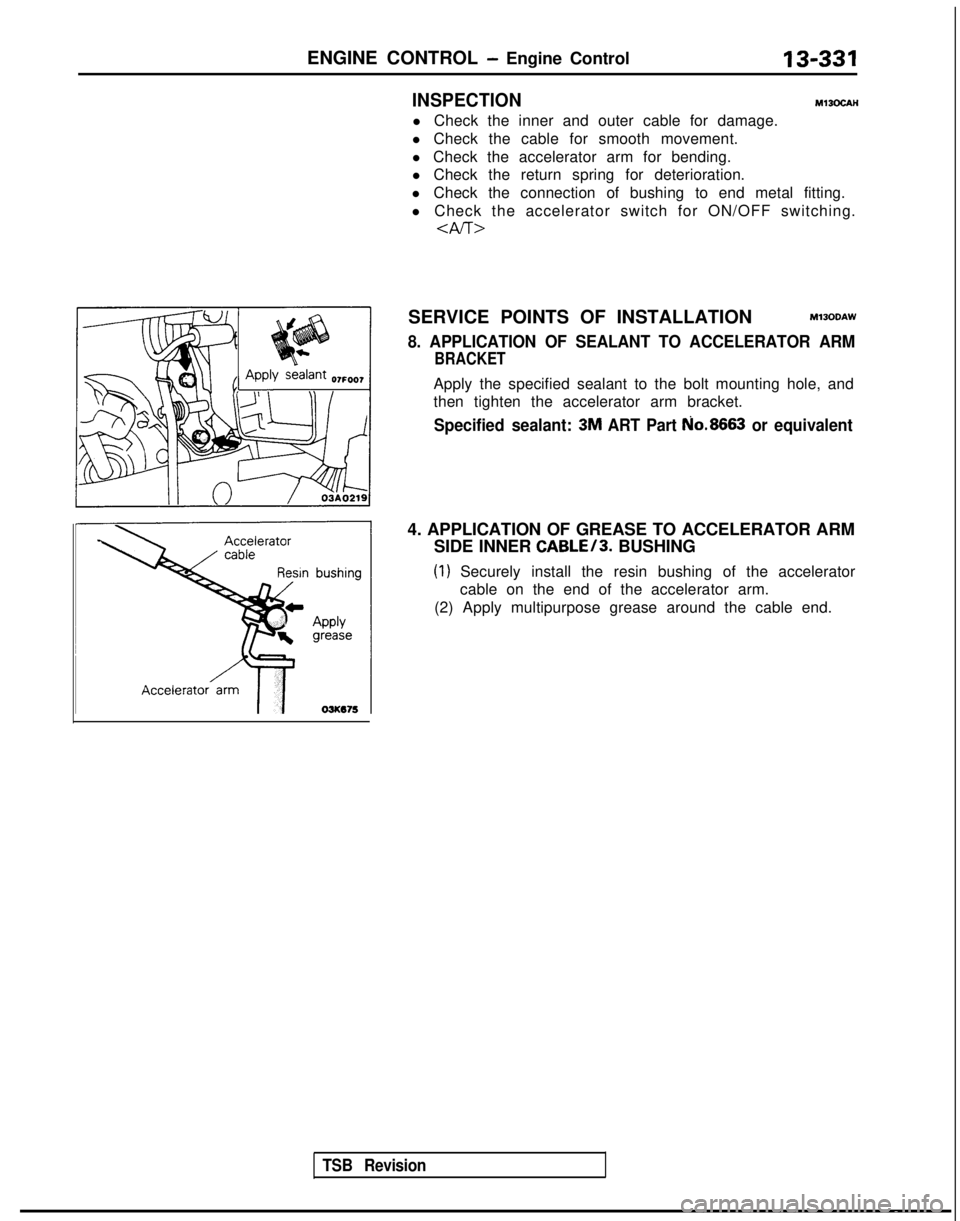

4. APPLICATION OF GREASE TO ACCELERATOR ARM

SIDE INNER

CABLE/3. BUSHING

(1) Securely install the resin bushing of the accelerator

cable on the end of the accelerator arm.

(2) Apply multipurpose grease around the cable end.

INSPECTIONMl3ocAH

l Check the inner and outer cable for damage.

l Check the cable for smooth movement.

l Check the accelerator arm for bending.

l Check the return spring for deterioration.

l Check the connection of bushing to end metal fitting.

l Check the accelerator switch for ON/OFF switching.

SERVICE POINTS OF INSTALLATIONMlJODAW

8. APPLICATION OF SEALANT TO ACCELERATOR ARM

BRACKET

Apply the specified sealant to the bolt mounting hole, and

then tighten the accelerator arm bracket.

Specified sealant: 3M ART Part No.8663 or equivalent

TSB Revision

Page 476 of 1273

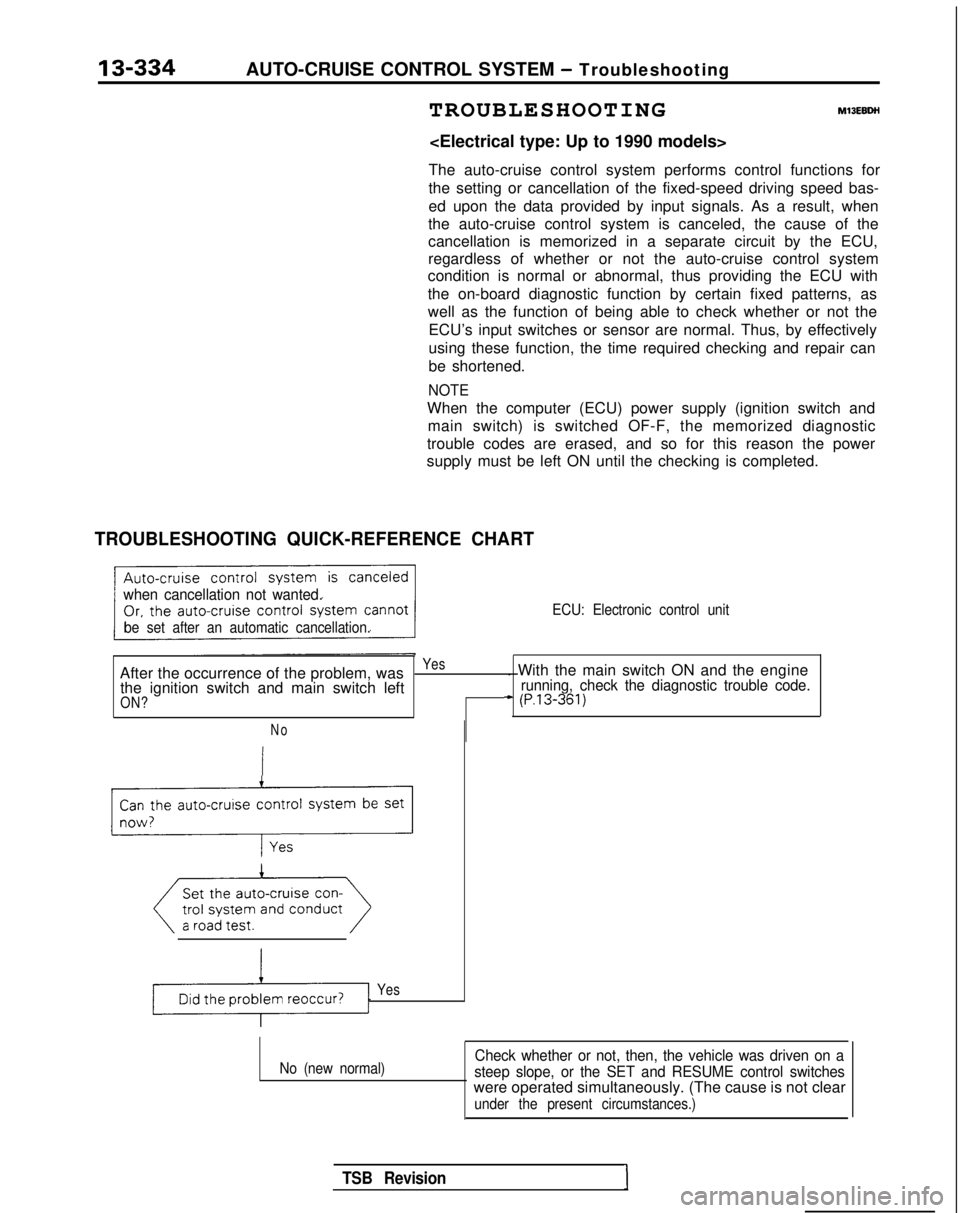

13-334AUTO-CRUISE CONTROL SYSTEM - Troubleshooting

TROUBLESHOOTIN

G

MlJEBDH

The auto-cruise control system performs control functions for

the setting or cancellation of the fixed-speed driving speed bas-

ed upon the data provided by input signals. As a result, when

the auto-cruise control system is canceled, the cause of the

cancellation is memorized in a separate circuit by the ECU,

regardless of whether or not the auto-cruise control system

condition is normal or abnormal, thus providing the ECU with

the on-board diagnostic function by certain fixed patterns, as

well as the function of being able to check whether or not the

ECU’s input switches or sensor are normal. Thus, by effectively

using these function, the time required checking and repair can

be shortened.

NOTE

When the computer (ECU) power supply (ignition switch andmain switch) is switched OF-F, the memorized diagnostic

trouble codes are erased, and so for this reason the power

supply must be left ON until the checking is completed.

TROUBLESHOOTING QUICK-REFERENCE CHART

when cancellation not wanted.

be set after an automatic cancellation. ECU: Electronic control unit

After the occurrence of the problem, wasYes. With the main switch ON and the engine

the ignition switch and main switch leftrunning, check the diagnostic trouble code.

ON?+ (P.13-361)

No

Can the auto-cruise control system be set

_r-l;

Yes

No (new normal)Check whether or not, then, the vehicle was driven on a

steep slope, or the SET and RESUME control switches

were operated simultaneously. (The cause is not clear

under the present circumstances.)

TSB RevisionI