check engine MITSUBISHI GALANT 1989 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 322 of 1273

13-180FUEL SYSTEM

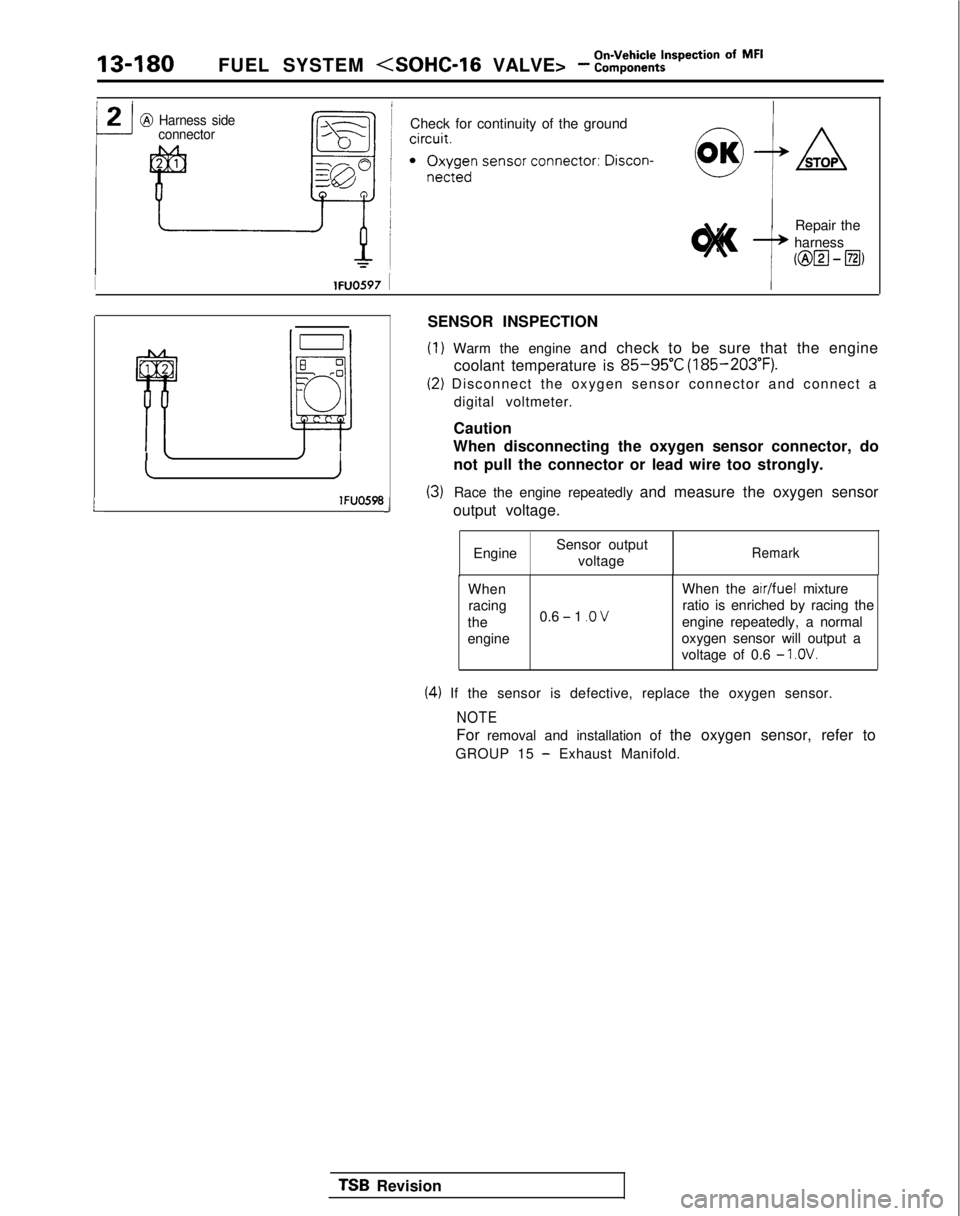

@ Harness sideconnectorCheck for continuity of the ground

Repair the

harness

(@lzl - El)

IlFUOS97 1I

L

G-lI’ ‘Ila

r rI L/I

IJ

lFUO598J

SENSOR INSPECTION

(I) Warm the engine and check to be sure that the engine

coolant temperature is

85-95°C (185-203°F).

(2) Disconnect the oxygen sensor connector and connect a

digital voltmeter.

Caution

When disconnecting the oxygen sensor connector, do

not pull the connector or lead wire too strongly.

(3)Race the engine repeatedly and measure the oxygen sensor

output voltage.

Engine Sensor output

voltage

Remark

When When the a/r/fuel

mixture

racing

the 0.6

- 1 .O Vratio is enriched by racing the

engine repeatedly, a normal

engine oxygen sensor will output a

voltage of 0.6

- 1 .OV.

(4) If the sensor is defective, replace the oxygen sensor.

NOTE

For removal and installation of the oxygen sensor, refer to

GROUP 15

- Exhaust Manifold.

TSB Revision

Page 324 of 1273

13-182FUEL SYSTEM

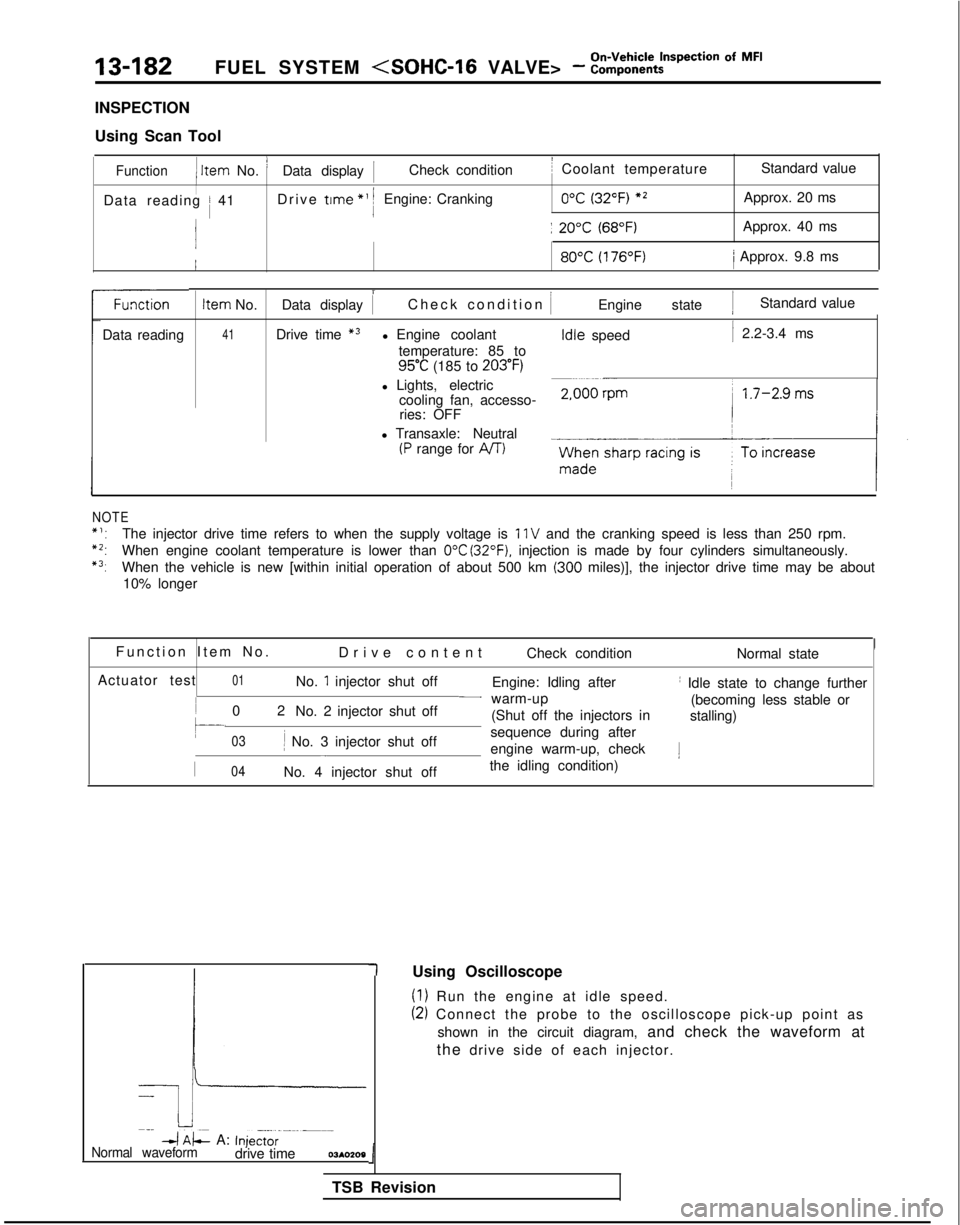

INSPECTION

Using Scan Tool

Function1 Item

No. ’Data display 1Check conditionI Coolant temperature Standard value

IData reading / 41Drive trme

*’ 1Engine: Cranking0°C (32°F) *2Approx. 20 ms

j: 20°C (68°F)Approx. 40 ms 80°C

(176°F)/ Approx. 9.8 ms

Data reading

NOTE Item

No.

41 i

Data display 1

Check condition

IEngine state 1Standard value

Drive time

*3l Engine coolant temperature: 85 to

95°C (185 to 203°F)

l Lights, electric cooling fan, accesso-ries: OFF

l Transaxle: Neutral

(P range for AIT) Idle

speed

1 2.2-3.4 ms

*‘:The injector drive time refers to when the supply voltage is 11 V and the cranking speed is less than 250 rpm.

*2:When engine coolant temperature is lower than 0°C (32°F). injection is made by four cylinders simultaneously.

*3:When the vehicle is new [within initial operation of about 500 km (300 miles)], the injector drive time may be about

10% longer

Function Item No

.

Drive content Check condition Normal state

Actuator test

01No. 1 injector shut off Engine: Idling afterI Idle state to change further

0

2

No. 2 injector shut off

- warm-up

(becoming less stable or

(Shut off the injectors in stalling)

03li No. 3 injector shut off sequence during after-engine warm-up, check1

I04No. 4 injector shut off

the idling condition)

-k

Imp

4 AL A: Inje,t,r--m--m-Normal waveformdrive time03*0209

(1) Run the engine at idle speed.

(2) Connect the probe to the oscilloscope pick-up point as

shown in the circuit diagram, and check the waveform at

the drive side of each injector.

1

TSB Revision 1

Using Oscilloscope

Page 325 of 1273

FUEL SYSTEM

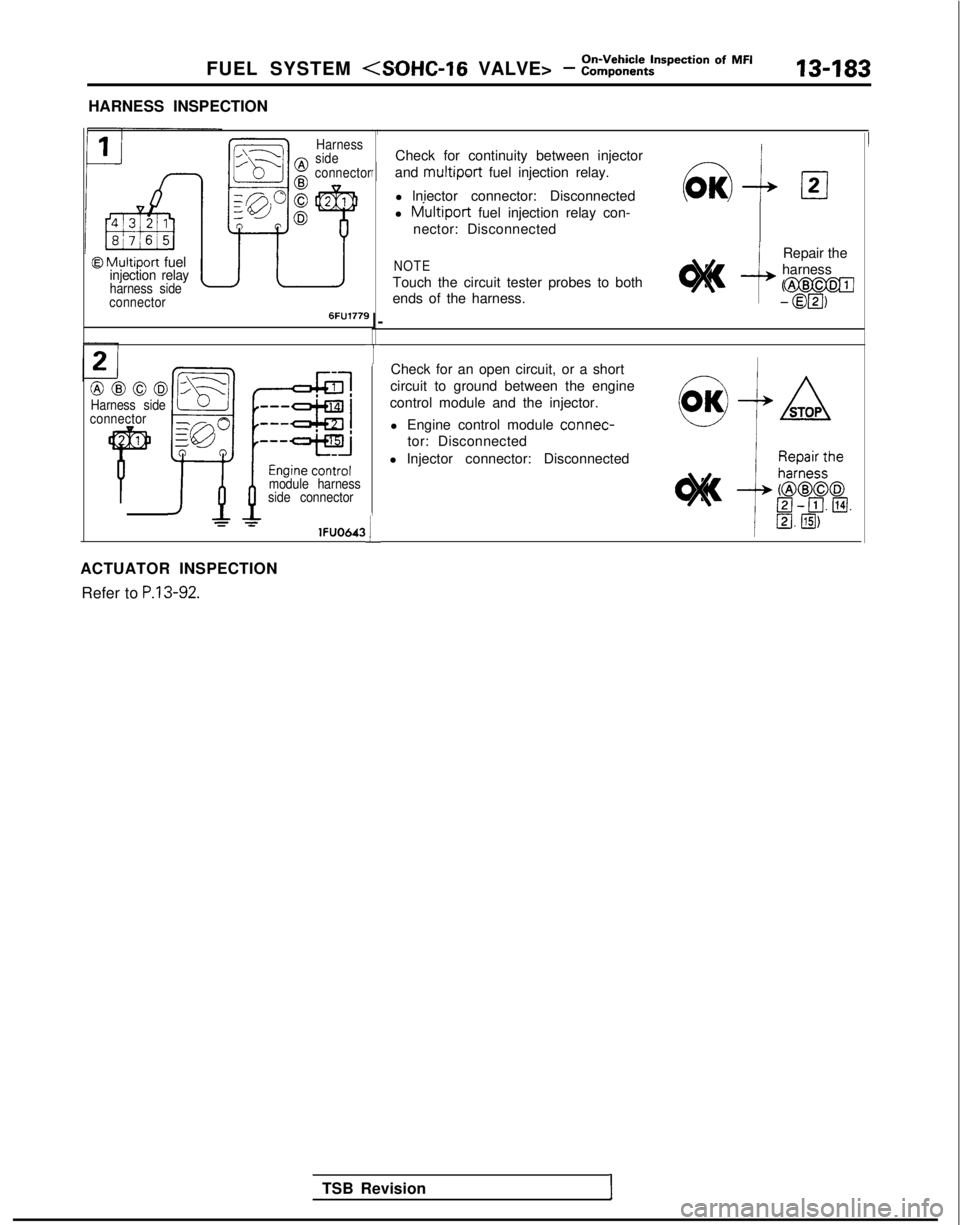

HARNESS INSPECTION

@ Multiport fuelinjection relayharness side

connector

,\---L

Ell---l0

!I?

pJ”

D

Harness

side

connector

6FU1779

@@@03Harness side

connector

1

Pmodule harness

side connector

=lFUO643

ACTUATOR INSPECTION

Refer to

P.13-92.

r I

I-

T

L

Check for continuity between injector

and

multiport fuel injection relay.

l lniector connector: Disconnected

l

tviultiport fuel injection relay con-

nector: Disconnected

NOTE

Touch the circuit tester probes to both

ends of the harness. Repair the

harnessCm

- 0@3,

Check for an open circuit, or a short

circuit to ground between the engine

control module and the injector.

l Engine control module connec-

tor: Disconnected

l Injector connector: Disconnected

TSB Revision

I

Page 327 of 1273

FUEL SYSTEM

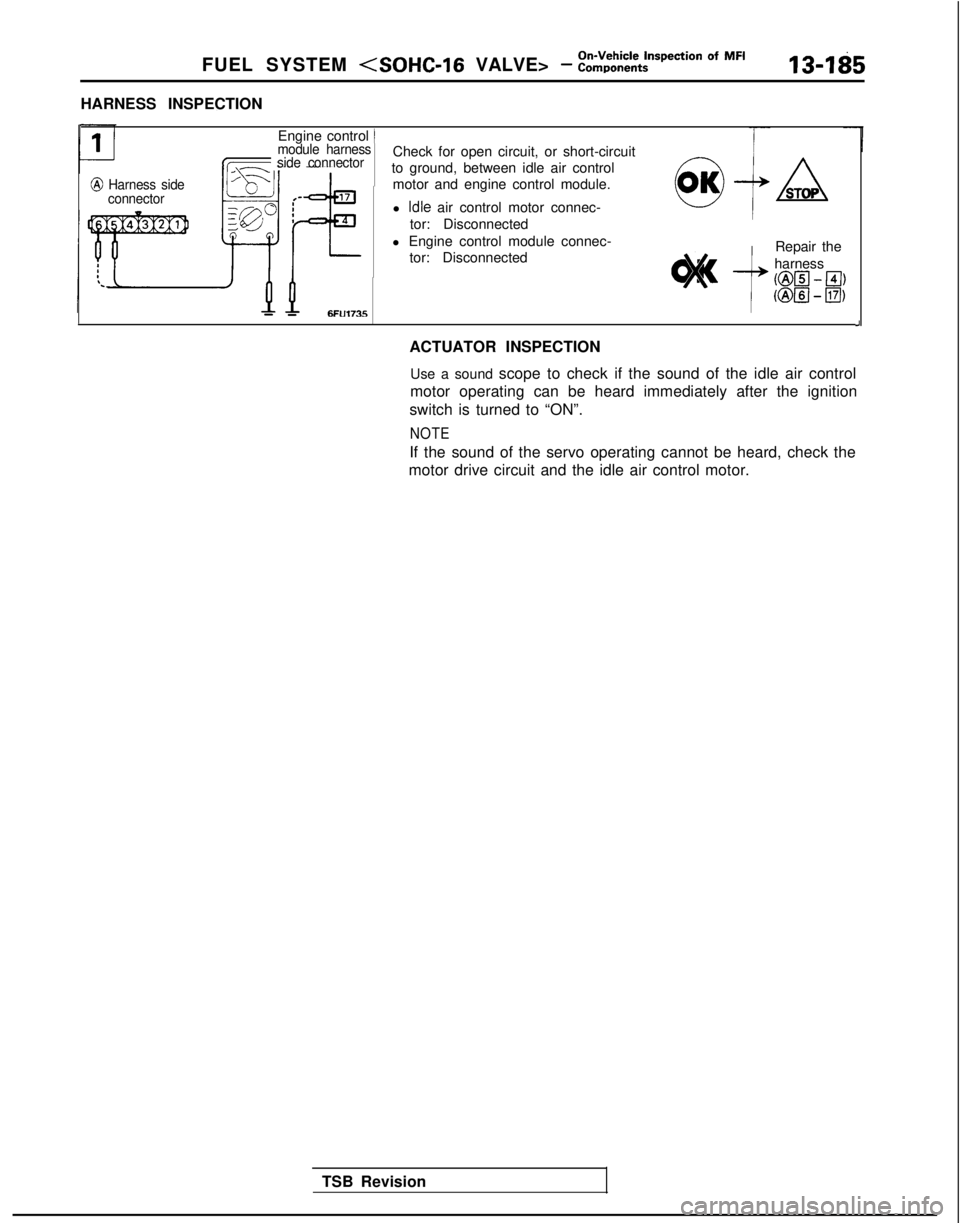

HARNESS INSPECTION

@ Harness side

connector

Engine control )module harness

side connector

- -6FU1735

Check for open circuit, or short-circuit

to ground, between idle air control motor and engine control module.

l

Idle air control motor connec-

tor: Disconnected

l Engine control module connec- tor: Disconnected0 OKSA

STOP

Repair the

harness

ml - El)

Km - El)

J

ACTUATOR INSPECTION

Use a sound scope to check if the sound of the idle air control

motor operating can be heard immediately after the ignition

switch is turned to “ON”.

NOTE

If the sound of the servo operating cannot be heard, check the

motor drive circuit and the idle air control motor.

TSB Revision

Page 328 of 1273

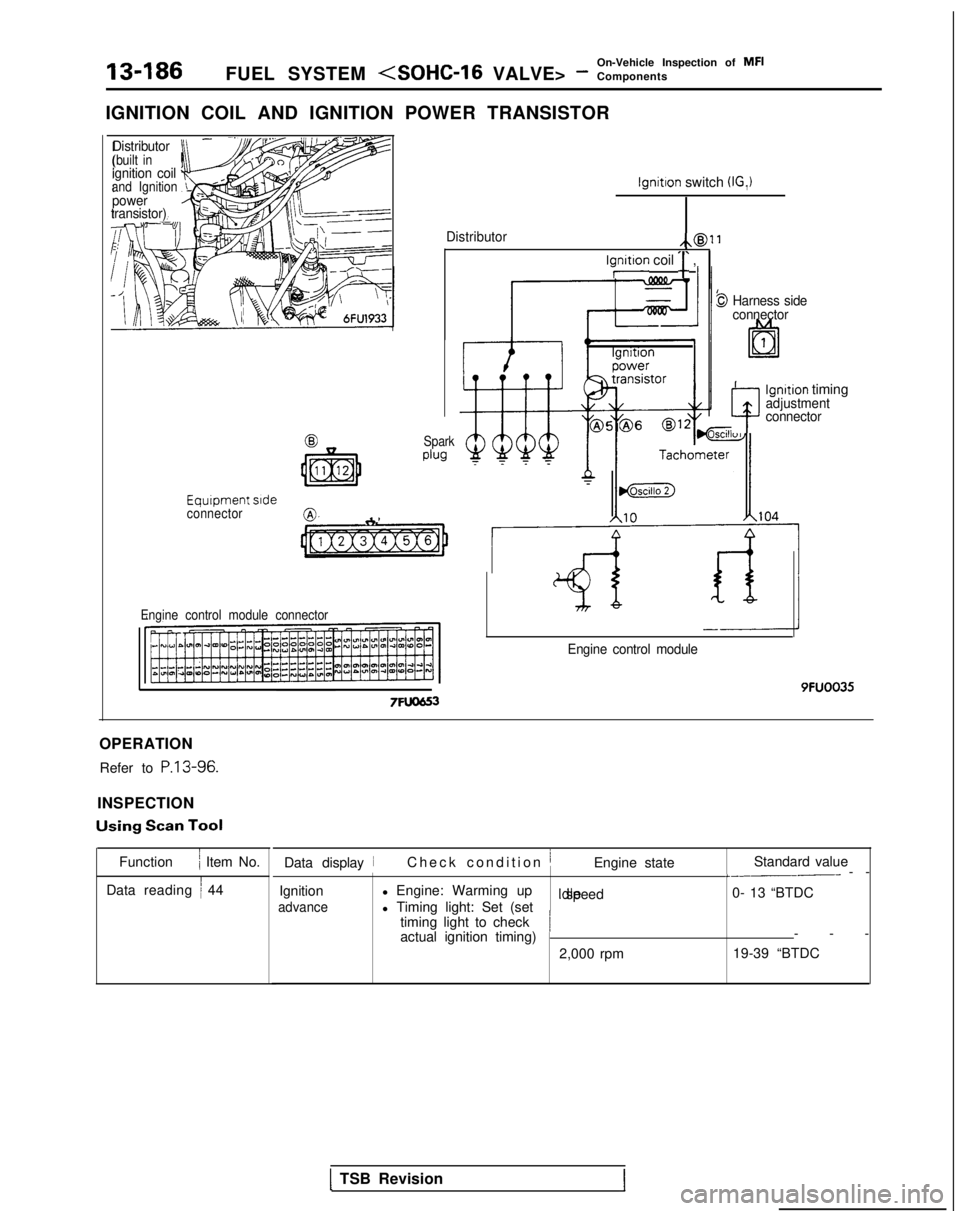

13-186On-Vehicle Inspection of MFI

FUEL SYSTEM

IGNITION COIL AND IGNITION POWER TRANSISTOR

-Distributor(built inignition coiland Ignitionpower

transistor)

Equrpment srdeconnector8”

Engine control module connector Spark

plug

Iynitron coil ‘r ,

lgnitron switch (IG,)

Distributor/,@)f1

9 Harness side

connector

4

lgnrtion timingadjustment

connector

7FU0653

Engine control module 9FUOO35

OPERATION Refer to

P.13-96.

INSPECTION Using

Scan Tool

Function

/ Item No.

Data reading

i 44 Data display

iCheck condition jEngine state

Standard value_.-___-- -

-

Ignition

advance

l Engine: Warming up Idle speed

0- 13 “BTDC

l Timing light: Set (set

timing light to check

actual ignition timing)

/--

-

2,000 rpm 19-39 “BTDC

1 TSB Revision1

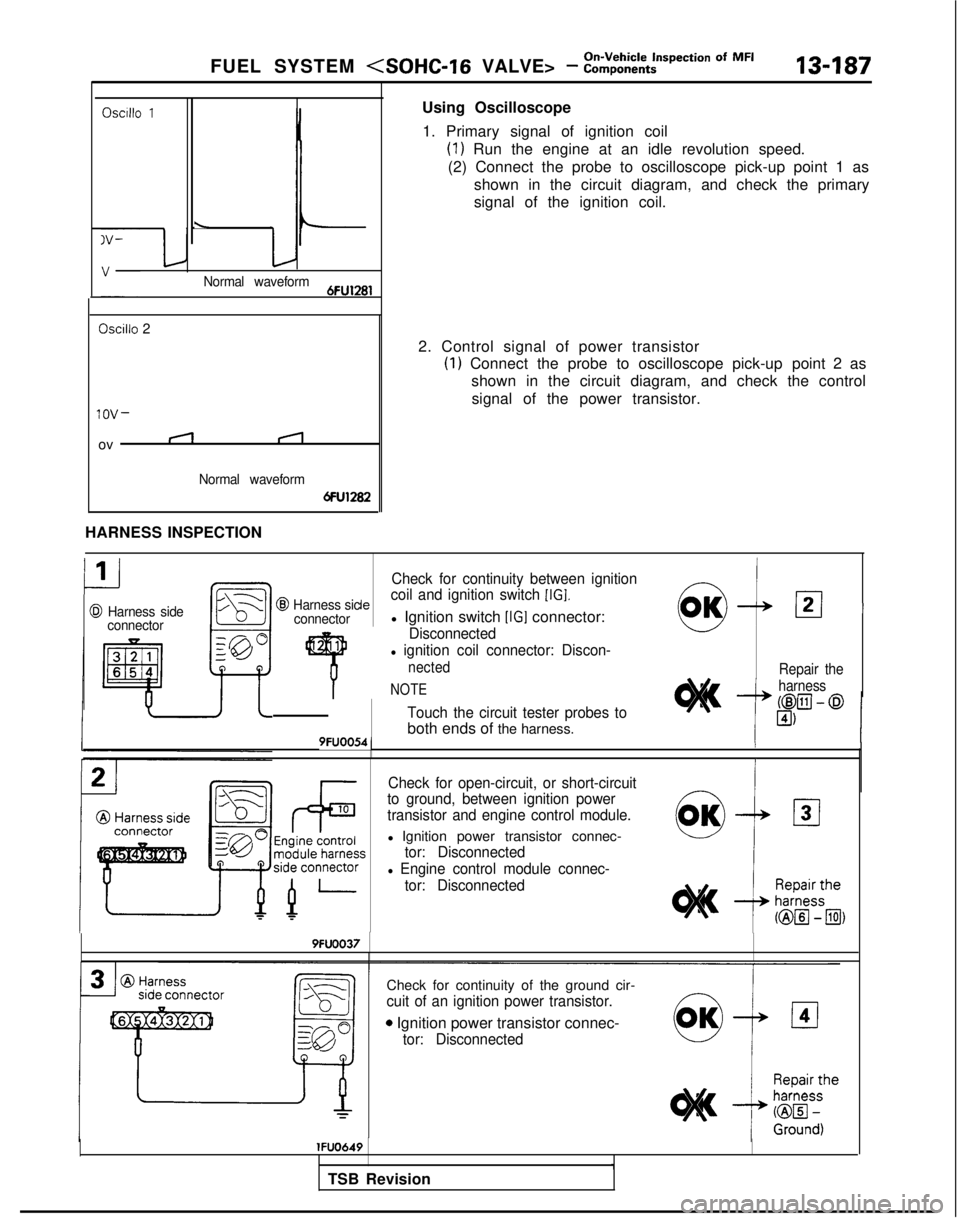

Page 329 of 1273

FUEL SYSTEM

\

Normal waveform6FU1281

Oscillo 2

lOV-

ovII

Normal waveform

6FU1282

HARNESS

INSPECTION Using Oscilloscope

1. Primary signal of ignition coil

(1) Run the engine at an idle revolution speed.

(2) Connect the probe to oscilloscope pick-up point 1 as shown in the circuit diagram, and check the primary

signal of the ignition coil.

2. Control signal of power transistor

(I) Connect the probe to oscilloscope pick-up point 2 as

shown in the circuit diagram, and check the control

signal of the power transistor.

CI1

@ Harness side connector

Check for continuity between ignition

‘R/4(21 I@I Harness siclecoil and ignition switch [IGI.

connectorl Ignition switch [IGI connector:/,‘\0”

Disconnected1

4

l ignition coil connector: Discon-

nected

NOTE

Touch the circuit tester probes to

both ends of the harness.19FUOO54,/I

Repair the

harness

_A- h

Check for open-circuit, or short-circuit

to ground, between ignition power

transistor and engine control module.

l Ignition power transistor connec-

tor: Disconnected

l Engine control module connec-

tor: Disconnected

9FUOO37

Check for continuity of the ground cir-

cuit of an ignition power transistor.

0 Ignition power transistor connec-

tor: Disconnected lFUO649

TSB Revision

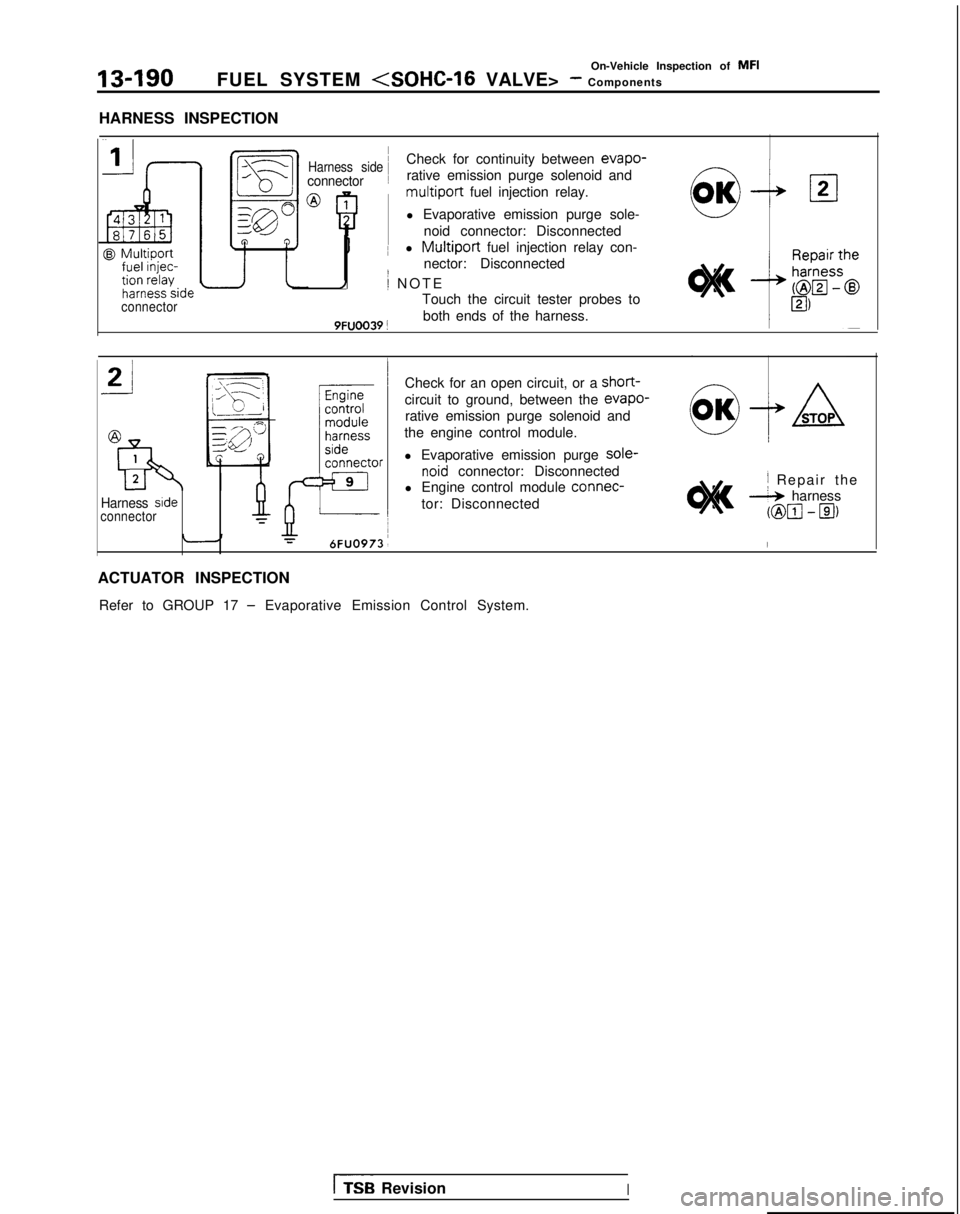

Page 332 of 1273

13-190

On-Vehicle Inspection of MFI

FUEL SYSTEM

HARNESS INSPECTION

@ Multiport

connector ~

Harness sideCheck for continuity between evapo-

connector

~

rative emission purge solenoid andmultiport fuel injection relay.

l Evaporative emission purge sole- noid connector: Disconnected

I ~

l Multiport fuel injection relay con-

nector: Disconnected

1; NOT

E

Touch the circuit tester probes to

9FUOO39 !both ends of the harness.

Check for an open circuit, or a

short-

circuit to ground, between the evapo-

rative emission purge solenoid and

the engine control module.

Harness srdeconnector

l Evaporative emission purge sole-

noid connector: Disconnected

l Engine control module connec-

tor: Disconnected,I Repair th

e

* harness

@m-El)

I

ACTUATOR INSPECTION

Refer to GROUP 17

- Evaporative Emission Control System.

I%% RevisionI

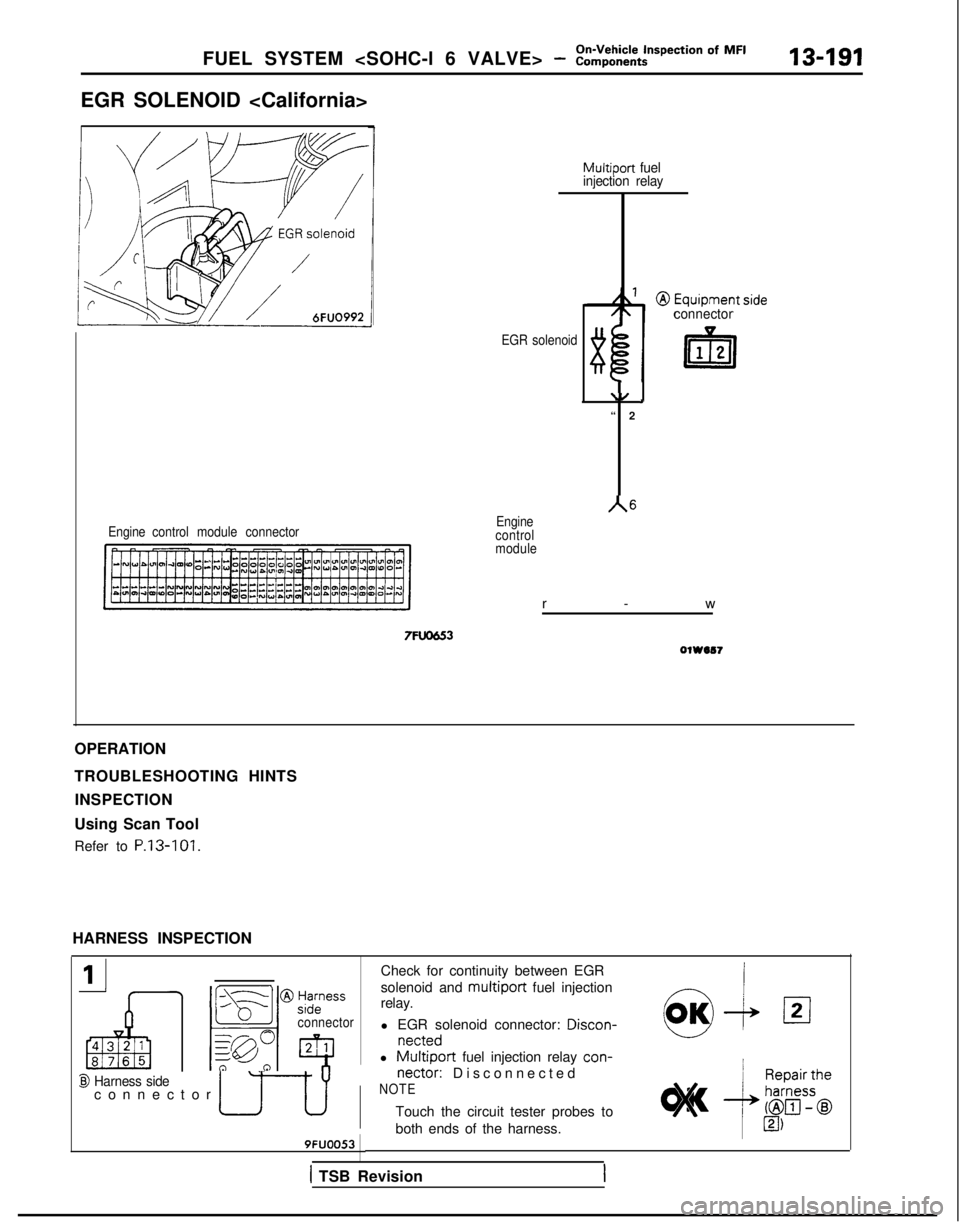

Page 333 of 1273

FUEL SYSTEM

EGR SOLENOID

I

Engine

control module connector

Multiport fuel

injection relay

EGR solenoid

connector

\/ ‘

“

2

A6Engine

control

module

r-

w

7FlJOU3OlWIS7

OPERATION

TROUBLESHOOTING HINTS

INSPECTION

Using Scan Tool

Refer to P.13-101.

HARNESS INSPECTION

_11

I IIF5

connector

@I Harness sideconnector ul[ J

9FUOO53

Check for continuity between EGR

solenoid and

multiport fuel injection-!relay.

l EGR solenoid connector: Discon-

nettedw

l Multiport fuel injection relay

con-I

nectar:

Disconnected

NOTE

Touch the circuit tester probes to

both ends of the harness. 1

MI,

1 TSB Revision

Page 334 of 1273

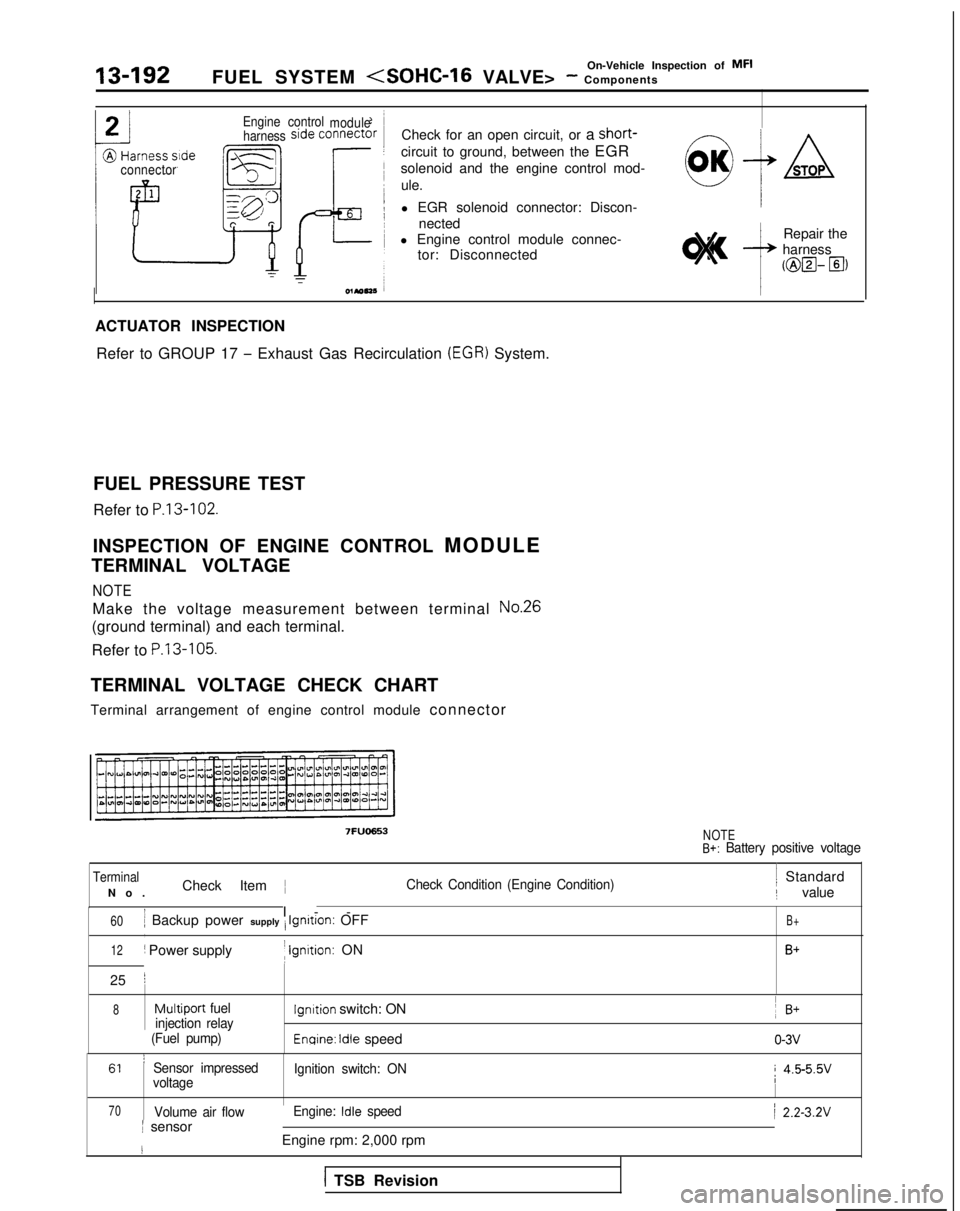

On-Vehicle Inspection of MFI13-192FUEL SYSTEM (SOHC-16 VALVE> - Components

connector

Engine control

module

harness

Check for an open circuit, or a short-

circuit to ground, between the EGR

solenoid and the engine control mod-

ule.

l EGR solenoid connector: Discon- nected

l Engine control module connec- tor: Disconnected

0OK+ASTOP

,

wsL

Repair the

harness

mzl- El)

ACTUATOR INSPECTION

Refer to GROUP 17

- Exhaust Gas Recirculation (EGR) System.

FUEL PRESSURE TEST

Refer to

P.13-102.

INSPECTION OF ENGINE CONTROL MODUL

E

TERMINAL VOLTAGE

NOTE

Make the voltage measurement between terminal No.26

(ground terminal) and each terminal.

Refer to

P.13-105.

TERMINAL VOLTAGE CHECK CHART

Terminal arrangement of engine control module connector

7FUQ653NOTEB+: Battery positive voltage

Terminal ~

No

.

Check Item ~

Check Condition (Engine Condition)/ Standard

/ value

60j Backup power supply i Ignrtron: OFF

I-

-

,

12/ Power supplyI Ignrtion: ON

25

j

B+

B+

8

Multiport fuellgnrtion switch: ON ~

B+injection relay~ (Fuel pump)Enqine: Idle speedo-3v

61 ’Sensor impressed

Ignition switch: ONi 4.5-5.5v

voltage

70Volume air flow Engine: Idle speed/ 2.2-3.2Vj sensor

IEngine rpm: 2,000 rpm

1 TSB Revision

Page 335 of 1273

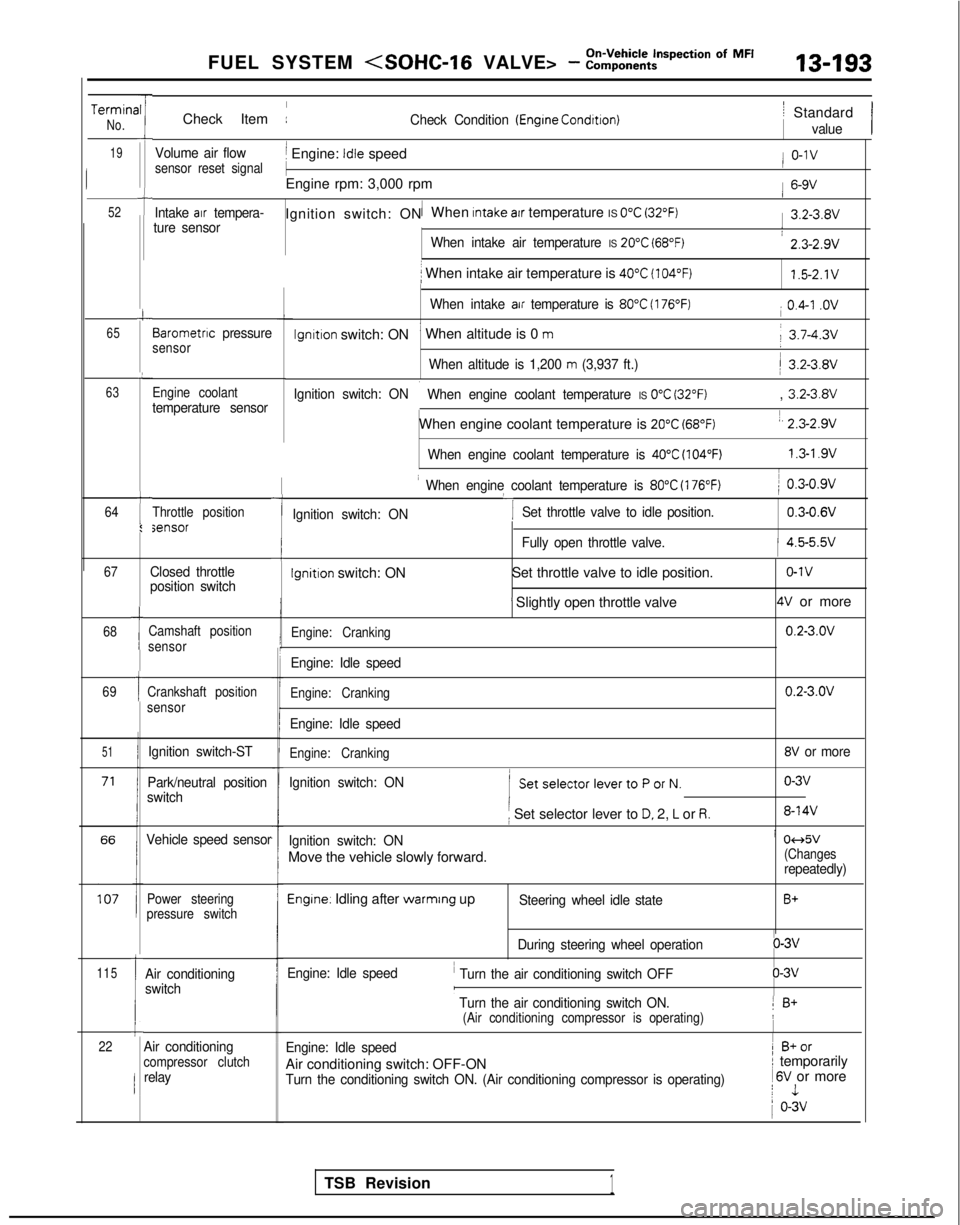

FUEL SYSTEM

TerminaNo.

19

52

-rII

i

t

c

65

L

63

64t

I:

I

Check Item :Check Condition (Engrne Condrtron)

Volume air flowj Engine: Idle speedsensor reset signal

1

Engine rpm: 3,000 rpm

Intake air tempera-1Ignition switch: ON When Intake atr temperature IS 0°C (32°F)ture sensor

When intake air temperature IS 20°C (68°F)

i When intake air temperature is 40°C (104°F)

When intake air temperature is 80°C (176°F)

lgnltlon switch: ON’ When altitude is 0 m

When altitude is 1,200 m (3,937 ft.)

Ignition switch: ON

i When engine coolant temperature IS 0°C (32°F)

When engine coolant temperature is 20°C (68°F)

When engine coolant temperature is 40°C (104°F)

Barometnc pressuresensor

Engine coolant

temperature sensor

Throttle positionsensor

67

68

69

51

115

1

1

Ic22

Closed throttle

position switch

Camshaft position

sensor

Crankshaft position

sensor

Ignition switch-ST

Park/neutral position

switch

Vehicle speed sensor

Power steering

pressure switch

Air conditioning

switch

-I

I When engine coolant temperature is 80°C (176°F)

‘I

) 0.3-0.9v

Ignition switch: ON Set throttle valve to idle position.

0.3-0.6V

iFully open throttle valve.1 4.5-5.5v

Ignition switch: ON

Set throttle valve to idle position.o-1v

’ Slightly open throttle valve4V or more

Engine: Cranking0.2-3.OV

Engine: Idle speed

Engine: Cranking0.2-3.OV

Engine: Idle speed

Engine: Cranking8V or more

Ignition switch: ON

( SetselectorlevertoPorN.o-3v

i Set selector lever to D. 2, L or R.8-14V

Ignition switch: ONi 04d5v

Move the vehicle slowly forward.(Changesrepeatedly)

Engine. Idling after warmrng upSteering wheel idle stateB+

During steering wheel operationo-3v

Engine: Idle speed

’ Turn the air conditioning switch OFFo-3vI

’ Turn the air conditioning switch ON.1 B+(Air conditioning compressor is operating)!

Engine: Idle speed1 B+or

Air conditioning switch: OFF-ONI temporarily

Turn the conditioning switch ON. (Air conditioning compressor is operat\

ing) 1

6V or morej 1

1 o-3v

/ Standard

value

/ o-1v

1 6-9V

1 3.2-3.8V

: 2.3-2.9v

1.5-2.1V

i 0.4-I .ov

j 3.7-4.3v

/ 3.2-3.8V

, 3.2-3.8V

1, 2.3-2.9v

1.3-l .9vI

Air conditioningcompressor clutchrelay

TSB Revision1