check engine MITSUBISHI GALANT 1989 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 350 of 1273

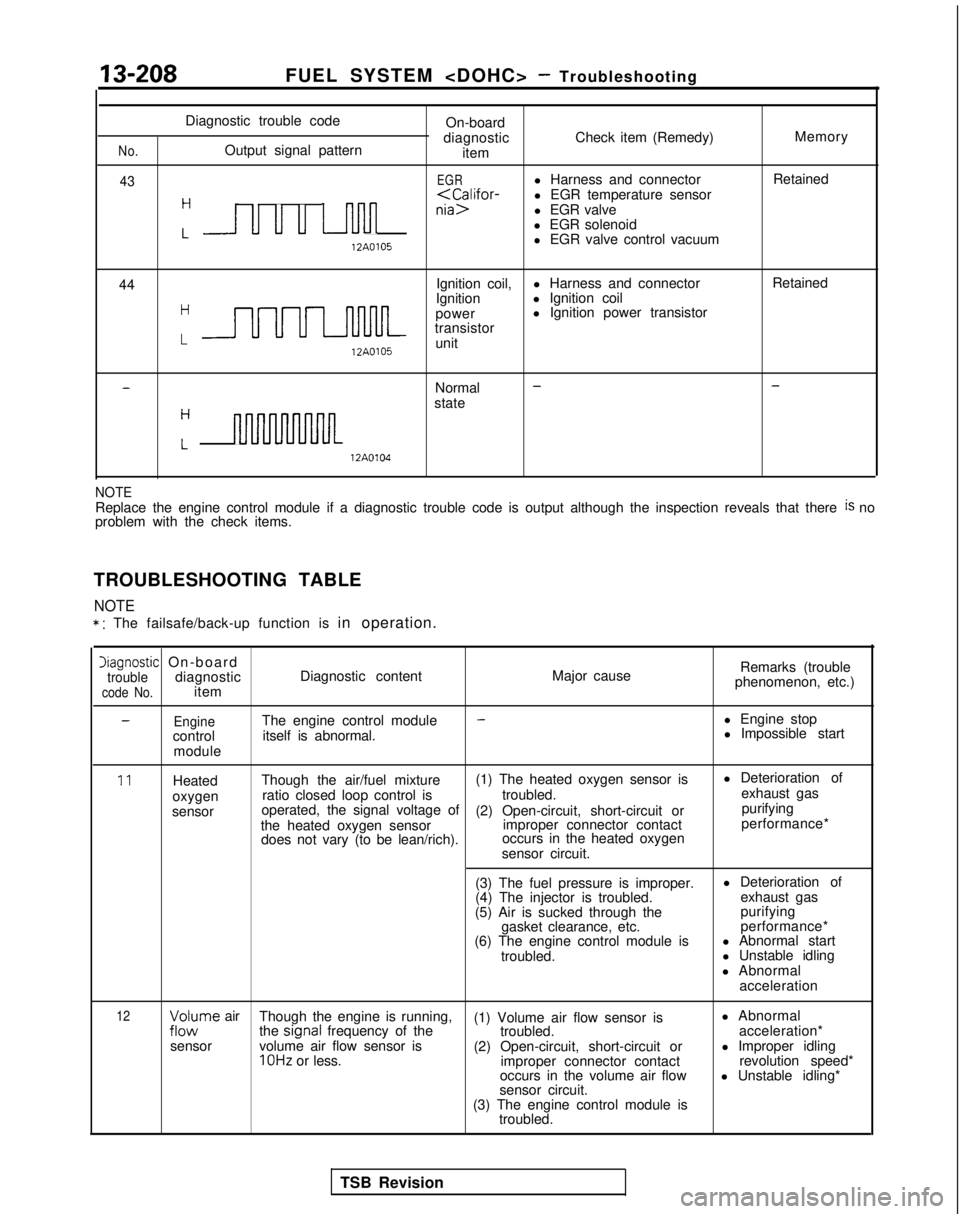

13-208FUEL SYSTEM

No.

43

Diagnostic trouble codeOn-board

diagnostic Check item (Remedy) Memory

Output signal pattern item

EGRl Harness and connector Retained

H

nia>l EGR valve

l EGR solenoid

L 12A0105

l EGR valve control vacuum

44 Ignition coil,

l Harness and connector Retained

Hl Ignition coil

LUUULnl-lM-

Ignition

power l Ignition power transistor

transistor 12A0105

unit

-Normal --

stateH

Lnm 12A0104

NOTEReplace the engine control module if a diagnostic trouble code is output\

although the inspection reveals that there is no

problem with the check items.

TROUBLESHOOTING TABLE

NOTE

* : The failsafe/back-up function is in operation.

Diagnostic On-boardtroublediagnosticcode No.itemDiagnostic content

Major causeRemarks (trouble

phenomenon, etc.)

-EngineThe engine control module-l Engine stop

control itself is abnormal. l Impossible start

module

11Heated Though the air/fuel mixture (1) The heated oxygen sensor is l Deterioration of

oxygen ratio closed loop control is

troubled.exhaust gas

sensor operated, the signal voltage of

(2) Open-circuit, short-circuit or purifying

the heated oxygen sensor improper connector contactperformance*

does not vary (to be lean/rich). occurs in the heated oxygen

sensor circuit.

(3) The fuel pressure is improper. l Deterioration of

(4) The injector is troubled. exhaust gas

(5) Air is sucked through the purifying

gasket clearance, etc. performance*

(6) The engine control module is l Abnormal start

troubled. l Unstable idling

l Abnormal acceleration

12;zc$rne air Though the engine is running,

(1) Volume air flow sensor is l Abnormal

the signal

frequency of the

troubled. acceleration*

sensor volume air flow sensor is

(2) Open-circuit, short-circuit or l Improper idling

1 OHz or less.

improper connector contact revolution speed*

occurs in the volume air flow l Unstable idling*

sensor circuit.

(3) The engine control module is troubled.

TSB Revision

Page 354 of 1273

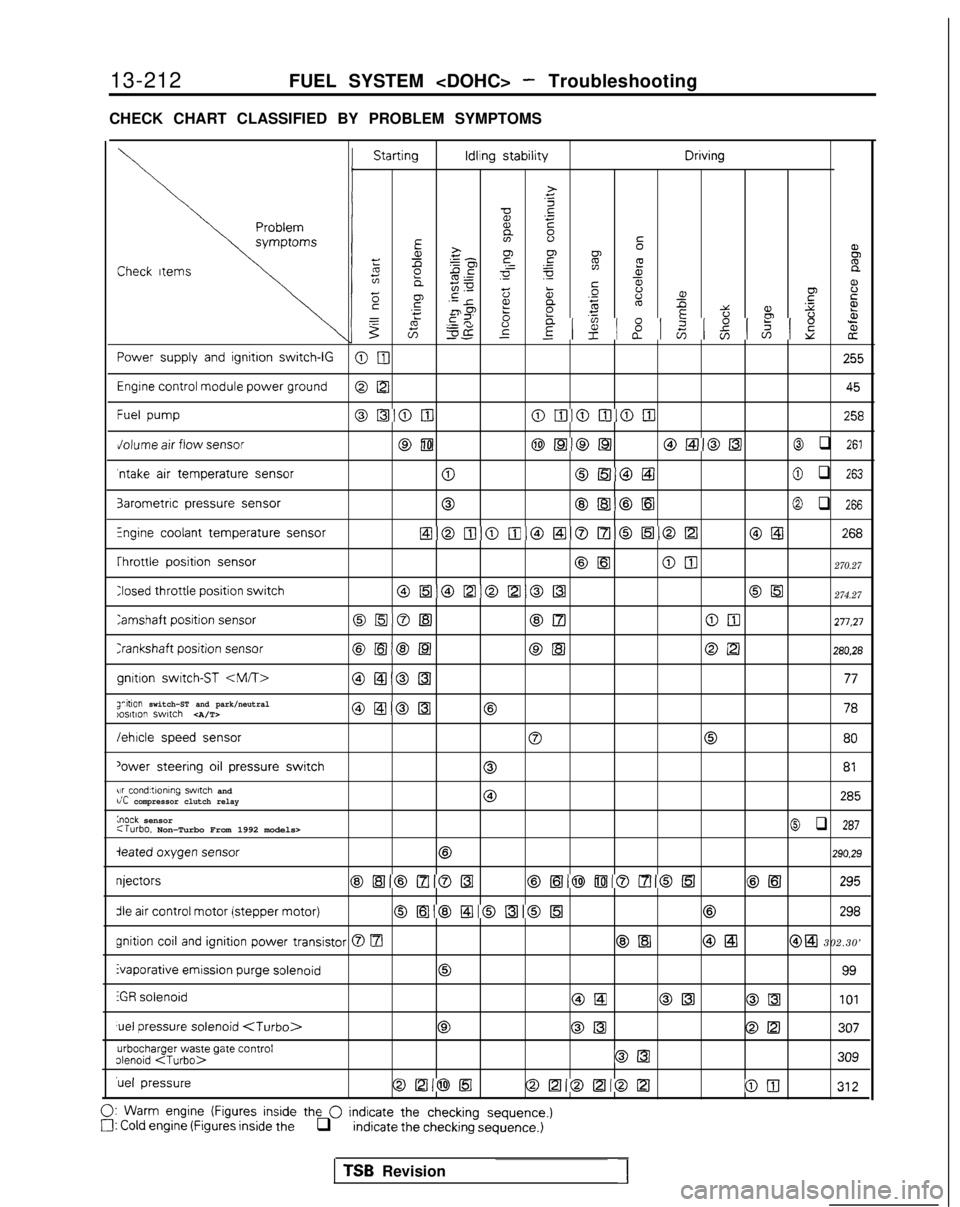

13-212

FUEL SYSTEM

CHECK CHART CLASSIFIED BY PROBLEM SYMPTOMS Starting Idling

stability Driving

>

.c

zx .-

E

EE 2-80’

52FCheck

Itemsz gp ~ =

gif8e

5;ms00 a,L%a‘;E

2

F5i5 .-

5scp ‘-re,t2aDo’6%.fP .xz YPfbz 2 ‘5 uE22

%il= 5

8

8 8gzzg-c$z8

z

Power

supply

and

ignition switch-IGOnI

255

Engine

control

module power ground

@ [ZI

45

Fuel

pumpoI51oulolIioDloiIl258

Jolume

air

flow sensorcam@Ea@@l@EilO[41@ q 261

‘ntake

air

temperature sensor0OlEiiOEtl@ q 263

3arometric

pressure

sensor0@lB@El@ q 266

Fngine coolant temperature sensorEloiIlomoaol7loEloDO@ 268

Throttle

position

sensor

@[email protected]

Closed throttle

position

switch0[51@D@D0[[email protected]

Tamshaft position

sensorOrnOlsl@Elam277,27

Crankshaft

position

sensor@El@[email protected]

gnltion

switch-ST

anitlon switch-ST and park/neutral)os,t,on switch @ElODl@ 78

/ehlcle

speed

sensor

00

80

‘ower

steering

oil

pressure

switch081

w conditlonlng swtch andr/C compressor clutch relay0285

knock sensor:Turbo. Non-Turbo From 1992 models>@ q 287

ieated oxygen

sensor

@290.29

njectors

@,[Hl@lzl@lz3@,161@Di080151@El

295

die air

control

motor (stepper

motor)0[63@!zl@al0863298 gnition

coil

and ignition

power transistor 0 m@El @El@ a 302.30’ Evaporative emission

purge

solenoid

0

99

iGR

solenoid@LaOK3@II3101

uel

pressure

solenoid

urbocharger waste gate contrololenoid

309

‘uel

pressureOD@l5l@D@D012100

312

0:

Warm

engine (Figures

inside

the 0 indicate the checking sequence.)a: Cold engine (Figures

inside

the q indicate

the checking

sequence.)

TSB Revision1

Page 358 of 1273

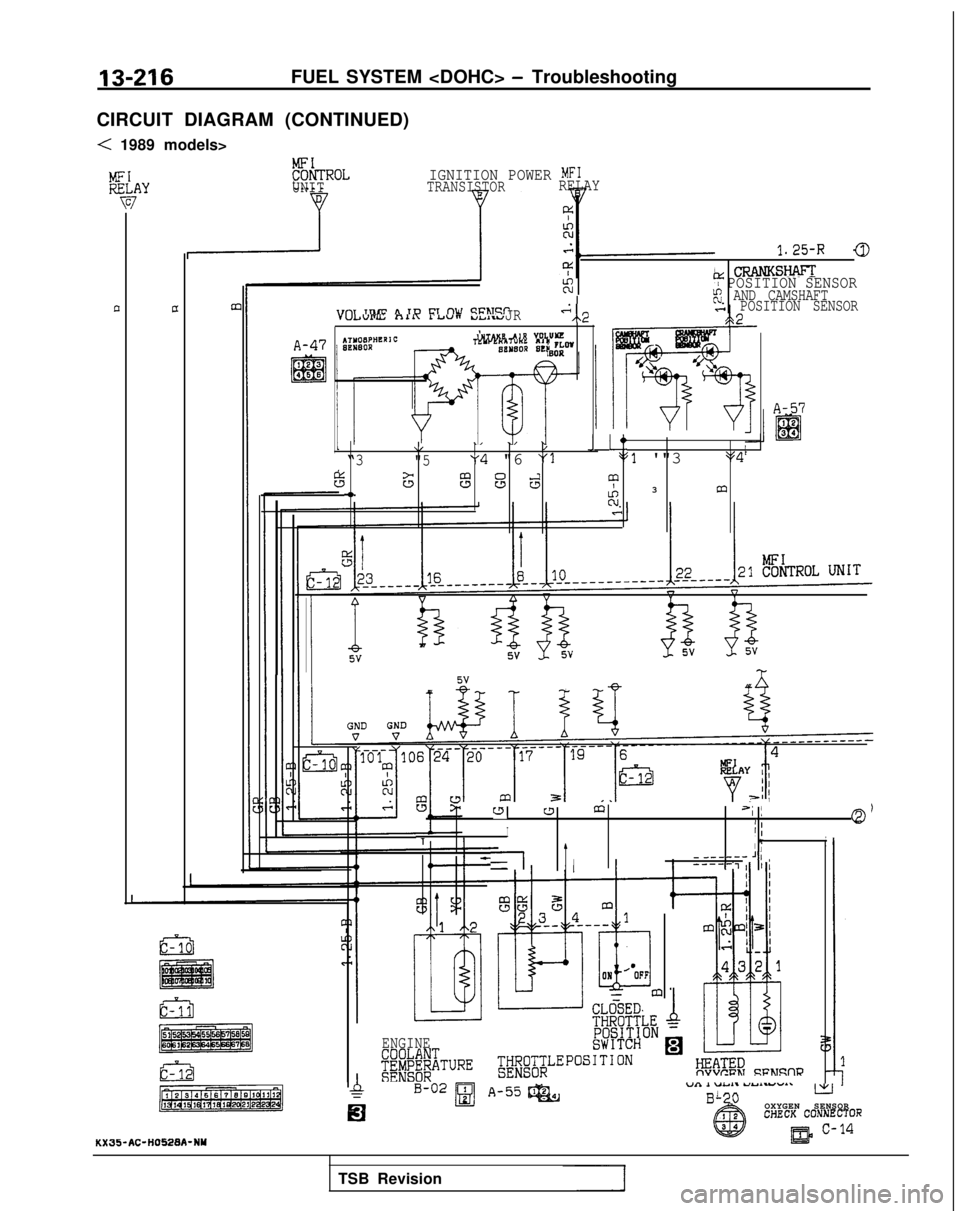

13216FUEL SYSTEM

CIRCUIT DIAGRAM (CONTINUED)

< 1989 models>

KTROLIGNITION POWER MFIUNIT TRANSISTORRELAY

,nr ,nrc n TD CT nv c!crw.fl\“l.I”mL c)I‘\ IAl””ULtll”JR"/\2

,PTAKB *,A VOLUkz! FLOWIBOR

1.25-R

LI: CRANKSHAFT1 POSITION SENSORg AND CAMSHAFT

. POSITION SENSORa

A-57

\//1 I,t“3"5"4 "6 "1‘$1 '"3*54

t5Gk3s 6mI

z3m1,

WI

wm=-i !QIIII1*I

z-l t

' I

- ____-- J,-----3 I

m

ENGINE

%%&TURE

A-55 m“‘3

1 “&a,. YYI..d”..73 nnLxD-C”OXYGEN SENSORCHECK CONNECTOR

B c-14KX35-AC-H052SA-NY

TSB Revision

Page 373 of 1273

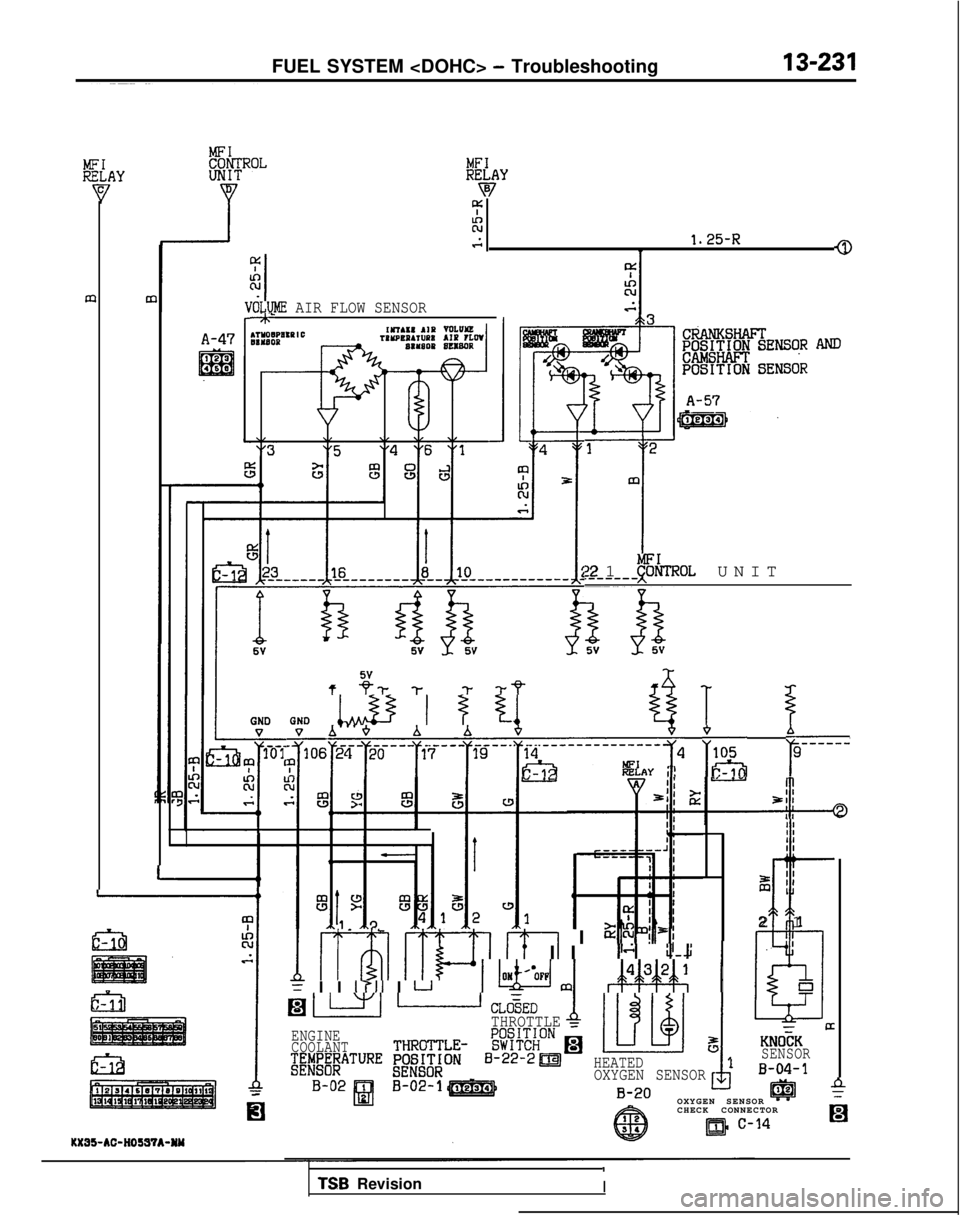

FUEL SYSTEM

4:

;zs1.25-R10

'1;rOLUK!Z AIR FLOW SENSOR

ANDA-47

12

m

I1221 t%TE!OL UNI

T

“? I@ 1 Yi Y

qEqsrp---~--~g---[~---------;;-~4 iuY&ii’------

1 mi mi E I

wT”ill’li

I II’-1 q-1’ I

f I I IT-11 I l-ijdrnl &$$$I I

i IIIII

z III

a

2 1

0

KNOCK

u

SENSOR

EII WI- CLiiEDdTHROTTLE =ENGINE

COOLANTTHROTTLE-l'#;&ON

##@ATURE @&ONB-22-2mEl %HEATED

OXYGEN SENSOR

1

1iB-04-1

B-02 Il!dB-02-1-B-20OXYGEN SENSORg@ e

CHECK CONNECTOR

m c-14H

l-

L

xX35-Ac-n0537wiu

,

TSB RevisionI

Page 387 of 1273

FUEL SYSTEM

cl989 models> -a’i\.-upI t

SERVICE ADJUSTMENT PROCEDURES

CURB IDLE SPEED INSPECTION

MlSFHAB

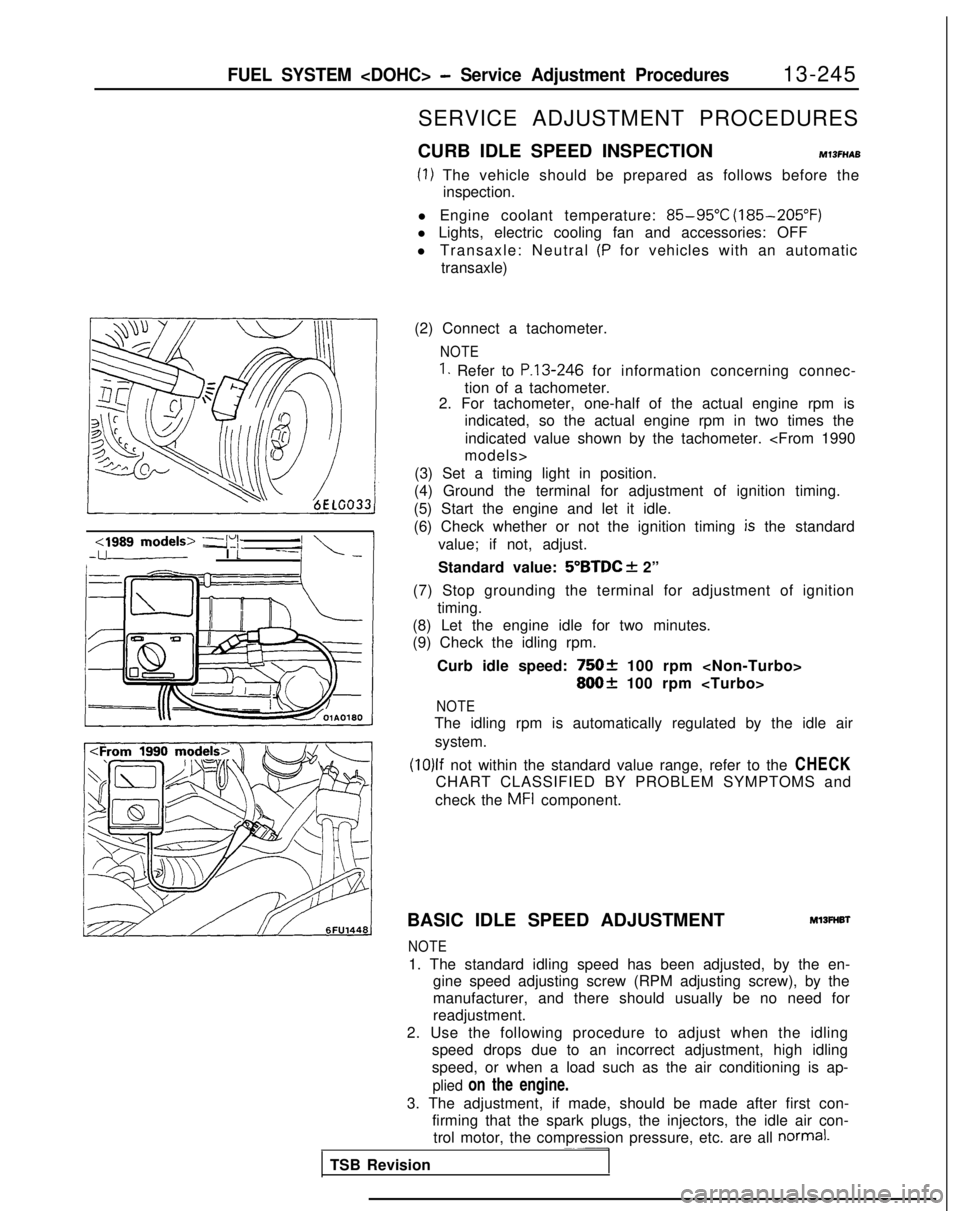

(1) The vehicle should be prepared as follows before the inspection.

l Engine coolant temperature:

85-95°C (185-205°F)

l Lights, electric cooling fan and accessories: OFF

l Transaxle: Neutral

(P for vehicles with an automatic

transaxle)

(2) Connect a tachometer.

NOTE

1. Refer to P.13-246 for information concerning connec-

tion of a tachometer.

2. For tachometer, one-half of the actual engine rpm is

indicated, so the actual engine rpm in two times the

indicated value shown by the tachometer.

(3) Set a timing light in position.

(4) Ground the terminal for adjustment of ignition timing.

(5) Start the engine and let it idle.

(6) Check whether or not the ignition timing

is the standard

value; if not, adjust.

Standard value:

5”BTDC f 2”

(7) Stop grounding the terminal for adjustment of ignition timing.

(8) Let the engine idle for two minutes.

(9) Check the idling rpm.

Curb idle speed:

75Ok 100 rpm

800+ 100 rpm

NOTE

The idling rpm is automatically regulated by the idle airsystem.

(10)lf not within the standard value range, refer to the CHECK

CHART CLASSIFIED BY PROBLEM SYMPTOMS and

check the

MFI component.

BASIC IDLE SPEED ADJUSTMENT

Ml3FHBl

NOTE

1. The standard idling speed has been adjusted, by the en- gine speed adjusting screw (RPM adjusting screw), by the

manufacturer, and there should usually be no need for

readjustment.

2. Use the following procedure to adjust when the idling speed drops due to an incorrect adjustment, high idling

speed, or when a load such as the air conditioning is ap-

plied on the engine.

3. The adjustment, if made, should be made after first con- firming that the spark plugs, the injectors, the idle air con-trol motor, the compression pressure, etc. are all

normal.~~-

TSB Revision

Page 389 of 1273

FUEL SYSTEM

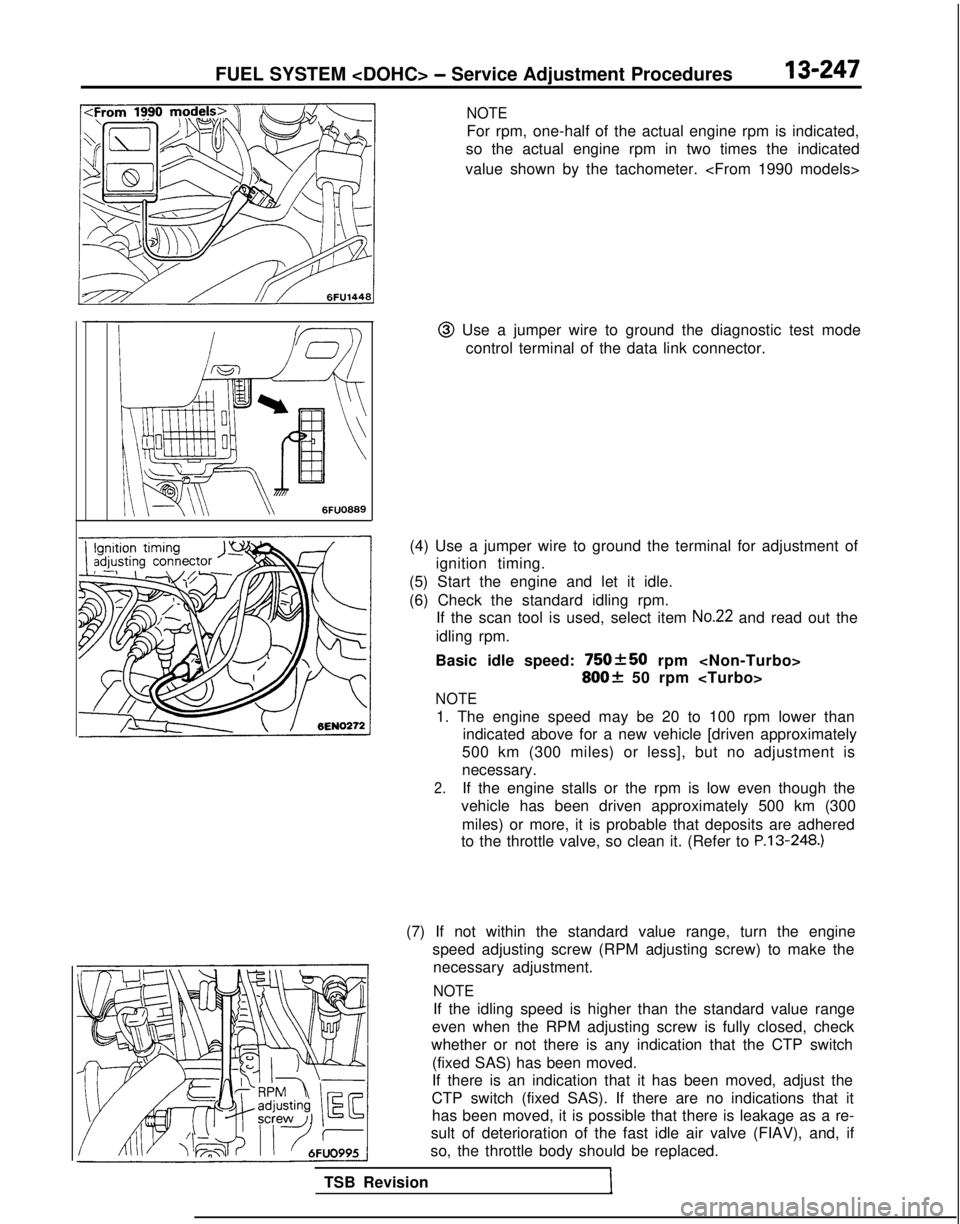

NOTE

For rpm, one-half of the actual engine rpm is indicated,

so the actual engine rpm in two times the indicated

value shown by the tachometer.

@I Use a jumper wire to ground the diagnostic test mode control terminal of the data link connector.

(4) Use a jumper wire to ground the terminal for adjustment of ignition timing.

(5) Start the engine and let it idle.

(6) Check the standard idling rpm. If the scan tool is used, select item

No.22 and read out the

idling rpm.

Basic idle speed:

750+50 rpm

800f 50 rpm

NOTE

1. The engine speed may be 20 to 100 rpm lower than indicated above for a new vehicle [driven approximately

500 km (300 miles) or less], but no adjustment is

necessary.

2.If the engine stalls or the rpm is low even though the

vehicle has been driven approximately 500 km (300

miles) or more, it is probable that deposits are adhered

to the throttle valve, so clean it. (Refer to P.13-248.)

TSB Revision

1

(7) If not within the standard value range, turn the engine speed adjusting screw (RPM adjusting screw) to make thenecessary adjustment.

NOTE

If the idling speed is higher than the standard value range

even when the RPM adjusting screw is fully closed, check

whether or not there is any indication that the CTP switch

(fixed SAS) has been moved.

If there is an indication that it has been moved, adjust the

CTP switch (fixed SAS). If there are no indications that it has been moved, it is possible that there is leakage as a re-

sult of deterioration of the fast idle air valve (FIAV), and, if

so, the throttle body should be replaced.

Page 390 of 1273

13-248FUEL SYSTEM

(8) Switch OFF the ignition switch.

(9) If the scan tool was not used, disconnect the jumper wire from the diagnostic test mode control terminal. (10)Disconnect

the jumper wire from the terminal for adjust-

ment of ignition timing, and return the connector to its

original condition.

(11

)Start the engine again and let it run at idle speed for about

ten minutes; check to be sure that the idling condition is

normal.

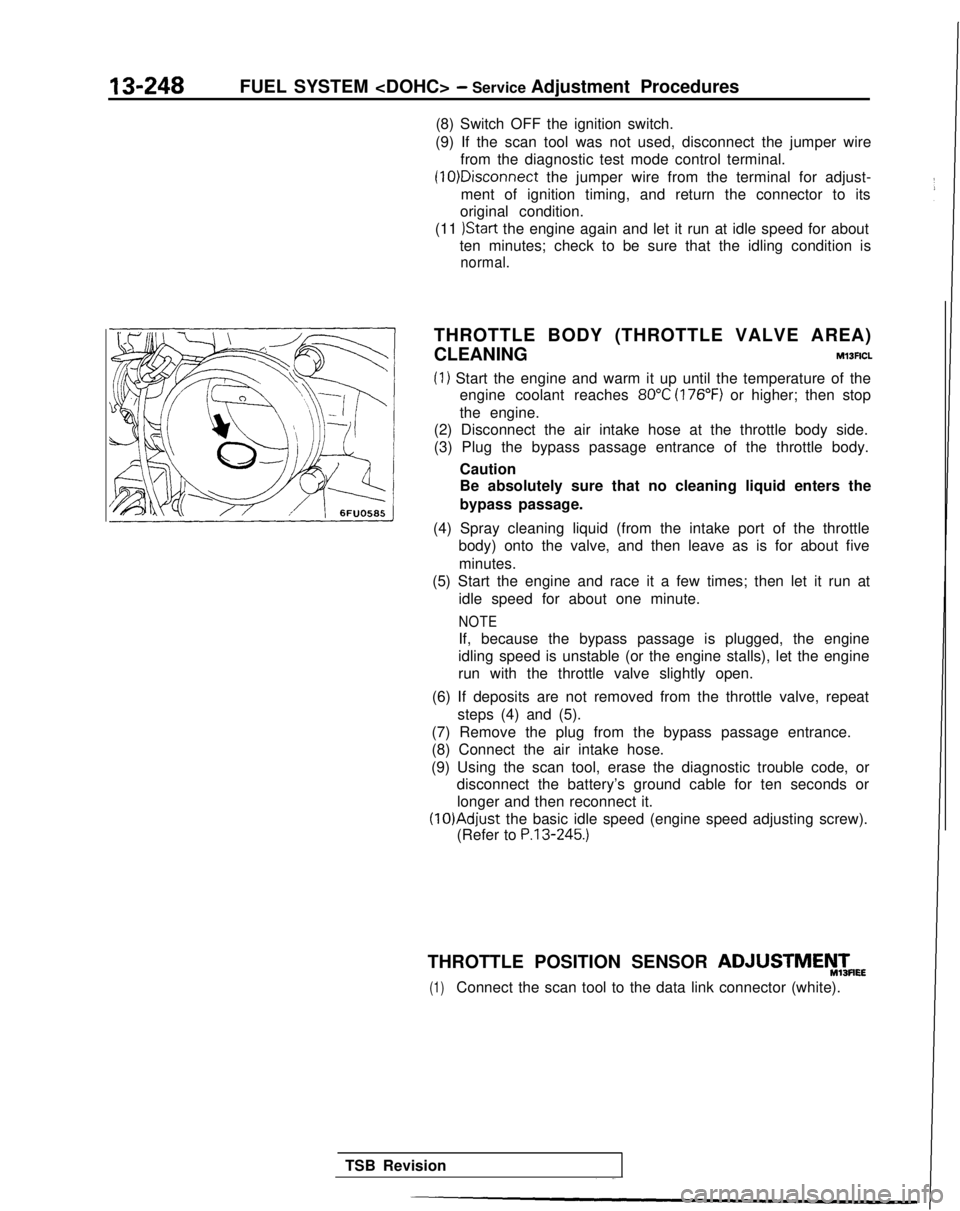

THROTTLE BODY (THROTTLE VALVE AREA)

CLEANING

Ml3ACL

(1) Start the engine and warm it up until the temperature of the engine coolant reaches

80°C (176°F) or higher; then stop

the engine.

(2) Disconnect the air intake hose at the throttle body side.

(3) Plug the bypass passage entrance of the throttle body.

Caution

Be absolutely sure that no cleaning liquid enters the

bypass passage.

(4) Spray cleaning liquid (from the intake port of the throttle body) onto the valve, and then leave as is for about five

minutes.

(5) Start the engine and race it a few times; then let it run at

idle speed for about one minute.

NOTE

If, because the bypass passage is plugged, the engine

idling speed is unstable (or the engine stalls), let the engine

run with the throttle valve slightly open.

(6) If deposits are not removed from the throttle valve, repeat steps (4) and (5).

(7) Remove the plug from the bypass passage entrance.

(8) Connect the air intake hose.

(9) Using the scan tool, erase the diagnostic trouble code, or disconnect the battery’s ground cable for ten seconds or

longer and then reconnect it. (lO)Adjust

the basic idle speed (engine speed adjusting screw).

(Refer to

P.13-245.)

THROTTLE POSITION SENSOR ADJUSTMEyTmEE

(1)Connect the scan tool to the data link connector (white).

TSB Revision

Page 391 of 1273

FUEL SYSTEM

13-249

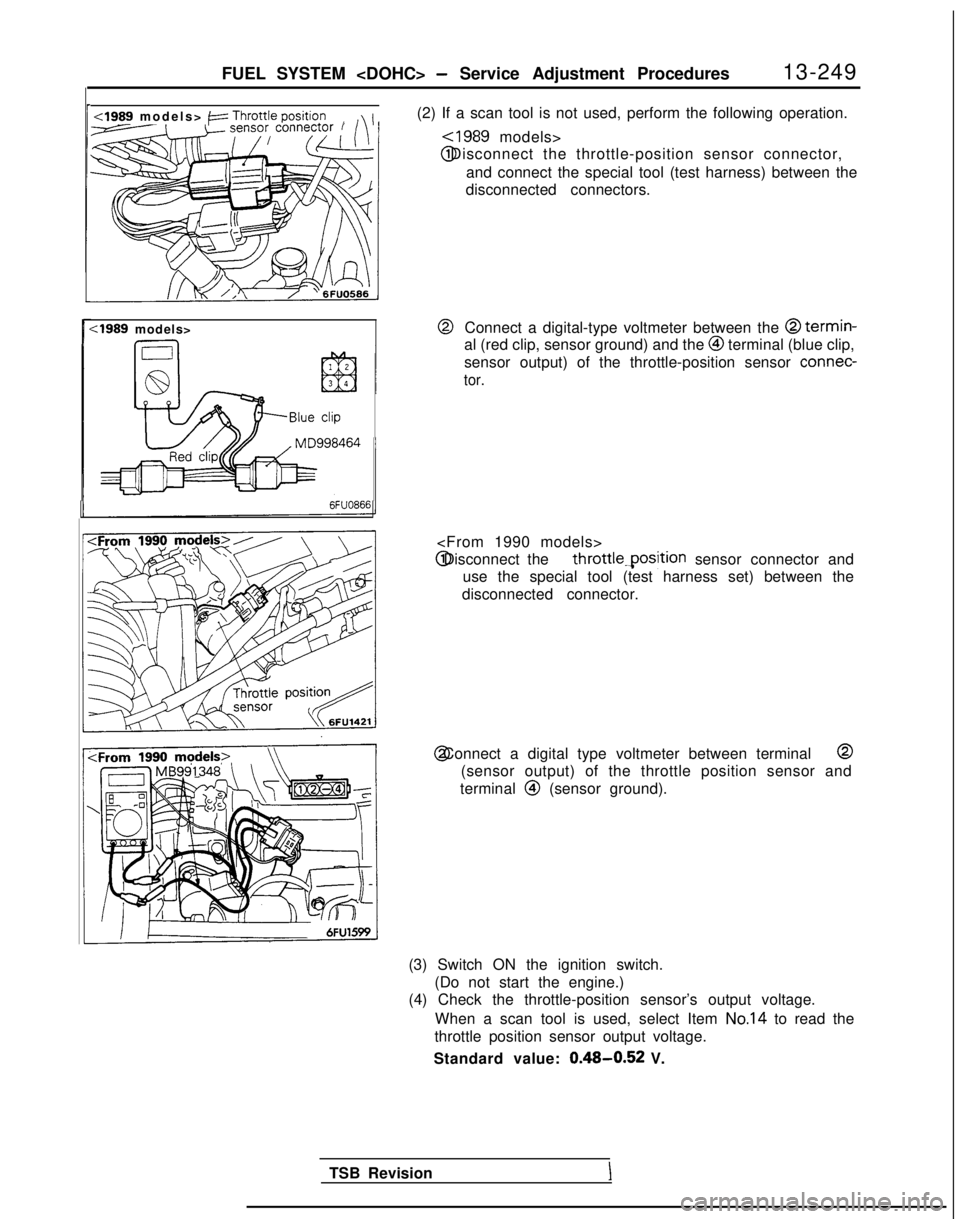

<1989 models> /zz Throttle position

(2) If a scan tool is not used, perform the following operation.,-

~1989 models> @ Disconnect the throttle-position sensor connector,

and connect the special tool (test harness) between the

disconnected connectors.

:1989 models>@Connect a digital-type voltmeter between the @ termin-

al (red clip, sensor ground) and the @I terminal (blue clip,

sensor output) of the throttle-position sensor connec-

tor.

Blue

clip

throttle.position sensor connector and

use the special tool (test harness set) between the

disconnected connector. @ Connect a digital type voltmeter between terminal @

(sensor output) of the throttle position sensor and

terminal

@ (sensor ground).

(3) Switch ON the ignition switch. (Do not start the engine.)

(4) Check the throttle-position sensor’s output voltage.

When a scan tool is used, select Item

No.14 to read the

throttle position sensor output voltage.

Standard value:

0.48-0.52 V.

TSB Revision

I

Page 393 of 1273

FUEL SYSTEM

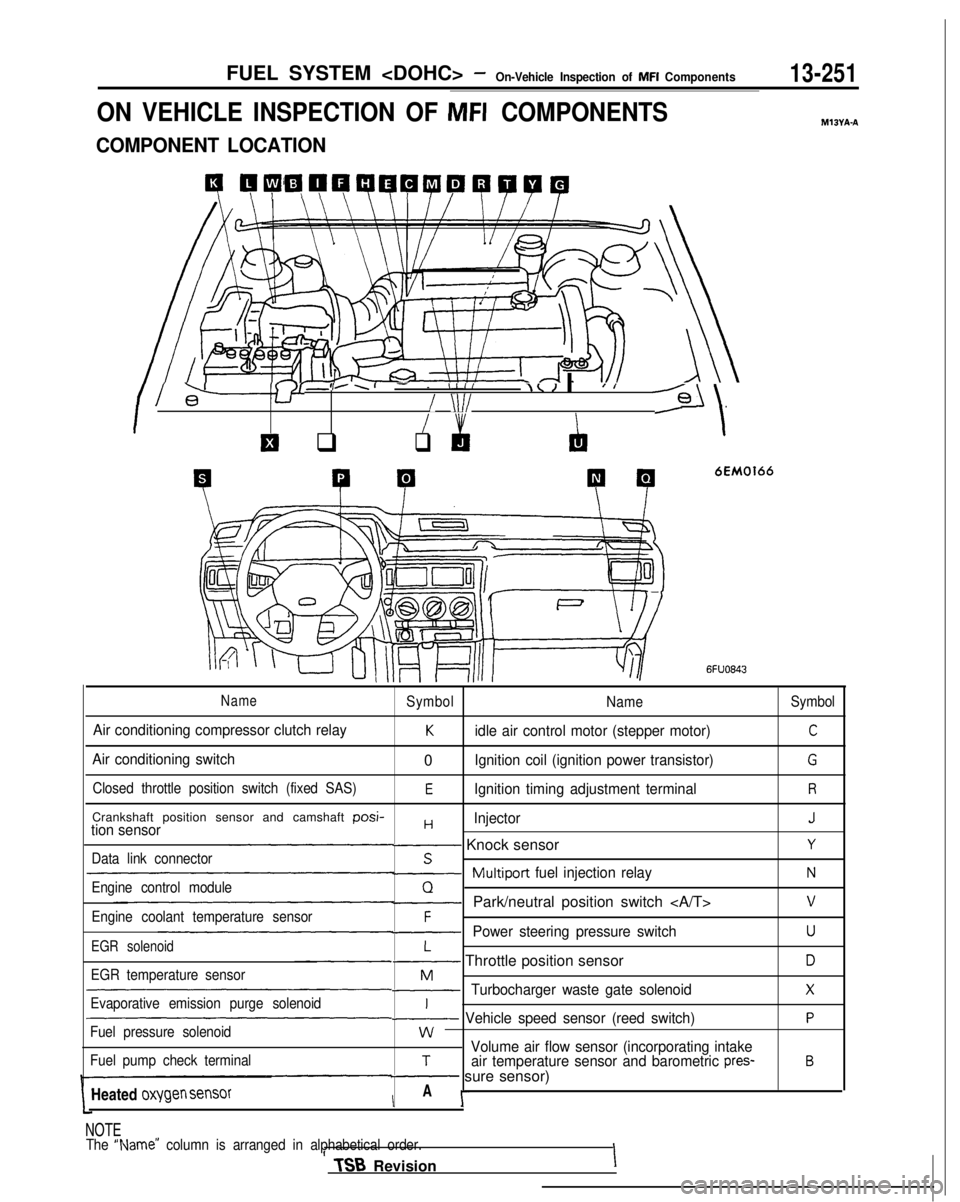

ON VEHICLE INSPECTION OF MFI COMPONENTS

COMPONENT LOCATION

4 QCiW41QQWPQWQ

I l-+-Y8’

-,..I- - IIII\< I IJ I

/ \lI/--Gl/

El q

I &

q

‘\

P P

6EM0166

MIBYA-A

6FUO843

NameSymbol

NameSymbol

Air conditioning compressor clutch relayKidle air control motor (stepper motor)C

Air conditioning switch0Ignition coil (ignition power transistor)G

Closed throttle position switch (fixed SAS)EIgnition timing adjustment terminalR

Crankshaft position sensor and camshaft posi-HInjectorJtion sensor- Knock sensorYData link connectorS~Multiport

fuel injection relayNEngine control moduleQ-Park/neutral position switch vEngine coolant temperature sensorF-Power steering pressure switchUEGR solenoidL- Throttle position sensorDEGR temperature sensorM-Turbocharger waste gate solenoidXEvaporative emission purge solenoidI~ Vehicle speed sensor (reed switch)PFuel pressure solenoidwVolume air flow sensor (incorporating intakeFuel pump check terminalTair temperature sensor and barometric pres-B- sure sensor)

Heated

oxygen sensorIA I-

NOTE

The “Name” column is arranged in alphabetical order.II TSB

RevisionI

Page 397 of 1273

FUEL SYSTEM

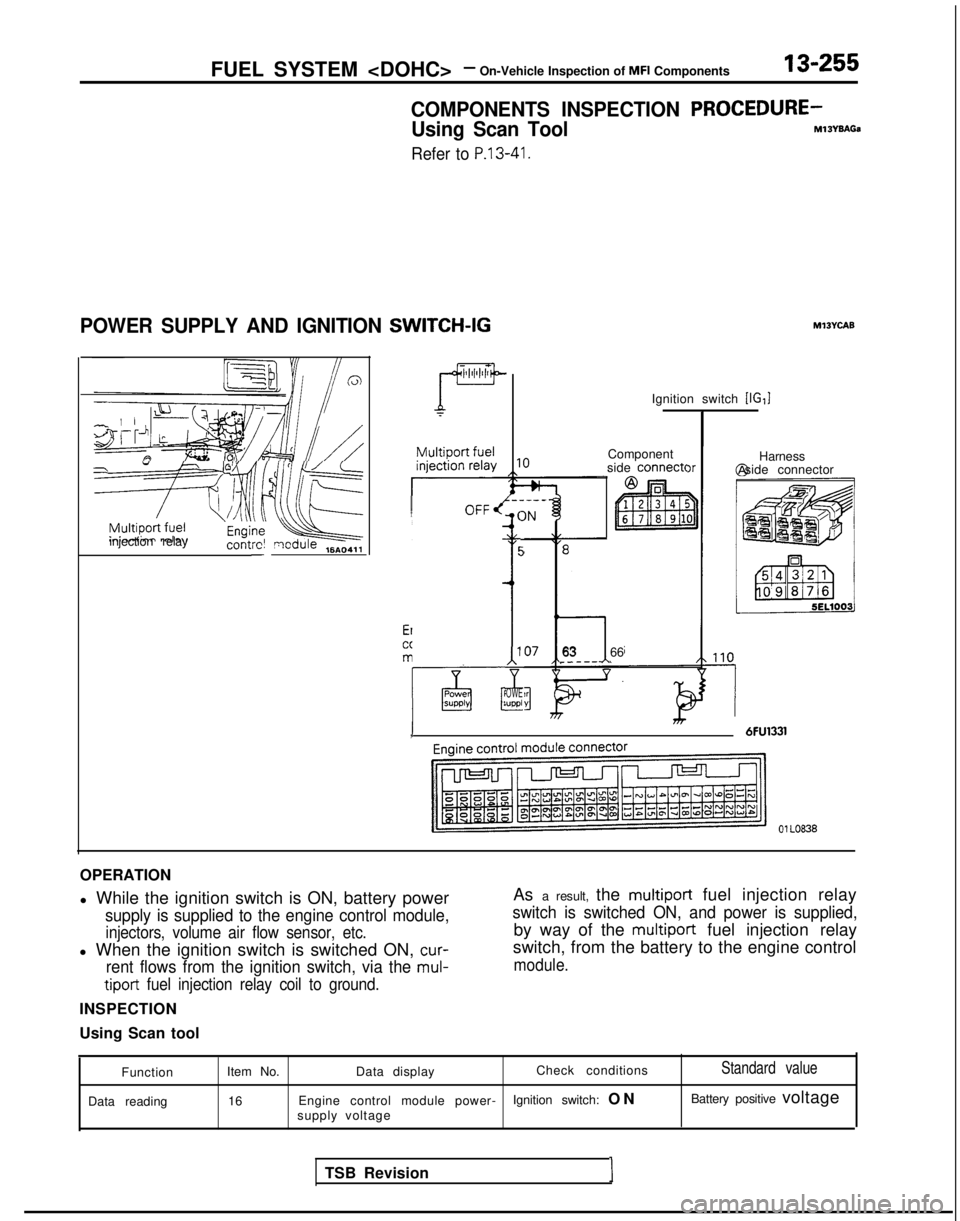

COMPONENTS INSPECTION PROCEDURE-

Using Scan ToolMlsYsAGa

Refer to P.13-41.

POWER SUPPLY AND IGNITION SWITCH-IG

zT=f?Qjkeinjection relay

contrc! qcdule ,6A04,,-

----_OFF/ (IN

t5

’ i

4

-

‘OWE;uppl-

Ignition switch [IG,]

Component

side

connect<

763 66.----

1 6FU1331, )r

Ml3YcAB

Harness

@ side connector

01 LO838

OPERATION

l While the ignition switch is ON, battery power

supply is supplied to the engine control module,

injectors, volume air flow sensor, etc.

l When the ignition switch is switched ON, cur-

rent flows from the ignition switch, via the mul-

tiport

fuel injection relay coil to ground.

INSPECTION

Using Scan tool As a result, the

multiport fuel injection relay

switch is switched ON, and power is supplied,

by way of the multiport fuel injection relay

switch, from the battery to the engine control

module.

Function

Data reading Item No.

Data display Check conditionsStandard value

16

Engine control module power- Ignition switch: O

N

Battery positive voltage

supply voltage

TSB Revision I