jack points MITSUBISHI GALANT 1989 Service User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 1059 of 1273

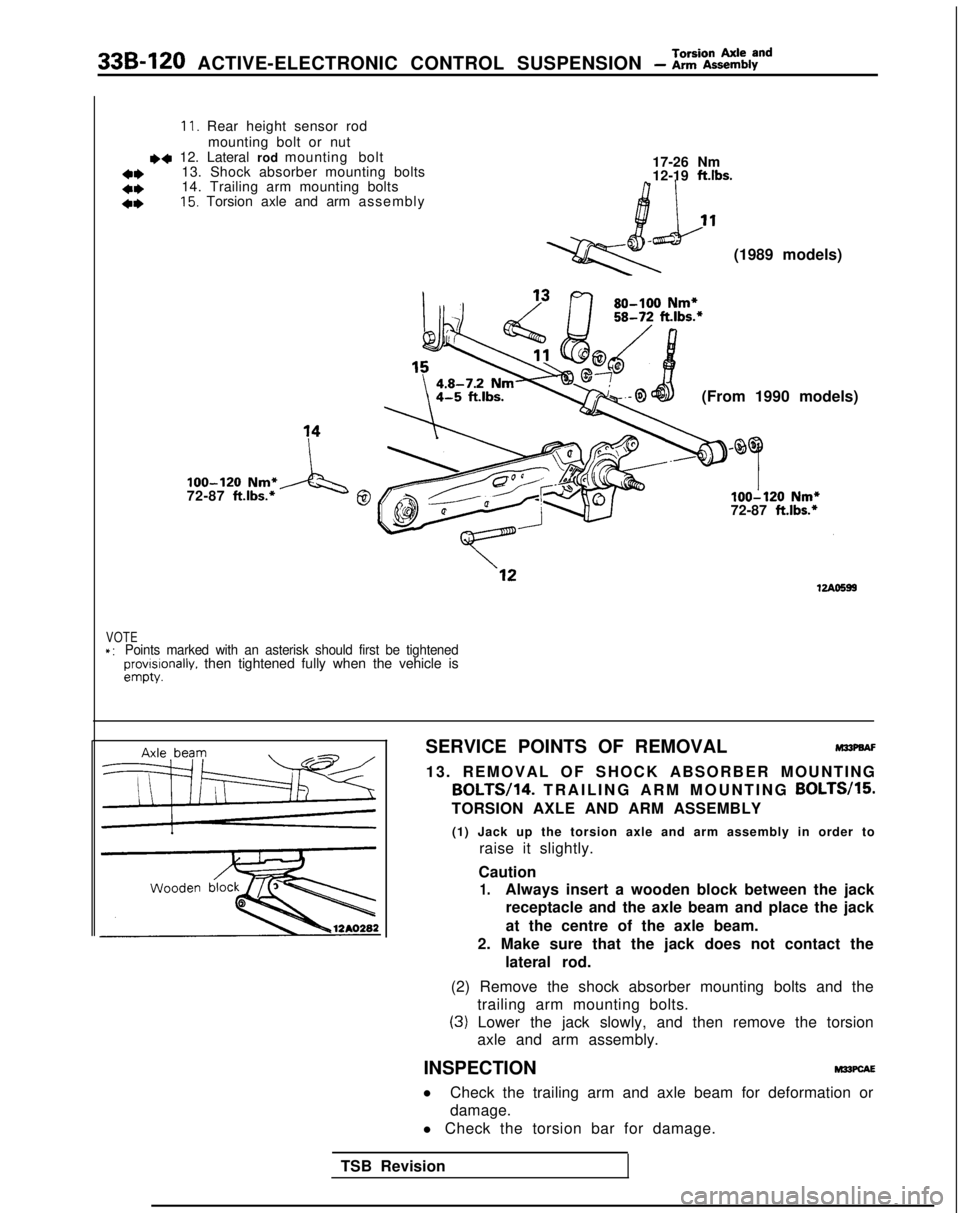

33B-120 ACTIVE-ELECTRONIC CONTROL SUSPENSION - Z%iZky8”d

11. Rear height sensor rodmounting bolt or nut

~~ 12. Lateral rod mounting bolt

13. Shock absorber mounting bolts 17-26 Nm

a*12-19 ftlbs.*I)14. Trailing arm mounting bolts

4*15. Torsion axle and arm assembl

y

(1989 models)

(From 1990 models)

loo-120 Nm*

72-87 ft.lbs.*A‘g0loo-120 Nm*

72-87 ft.lbs.*

VOTE*:Points marked with an asterisk should first be tightenedprovrslonally. then tightened fully when the vehicle isempty.

SERVICE POINTS OF REMOVALM33PaAF

13. REMOVAL OF SHOCK ABSORBER MOUNTING BOLTW14.

TRAILING ARM MOUNTING BOLTW15.

TORSION AXLE AND ARM ASSEMBLY

(1) Jack up the torsion axle and arm assembly in order to raise it slightly.

Caution

1.Always insert a wooden block between the jack receptacle and the axle beam and place the jack

at the centre of the axle beam.

2. Make sure that the jack does not contact the lateral rod.

(2) Remove the shock absorber mounting bolts and the trailing arm mounting bolts.

(3) Lower the jack slowly, and then remove the torsionaxle and arm assembly.

INSPECTION

M22PcAE

l Check the trailing arm and axle beam for deformation or

damage.

l Check the torsion bar for damage.

TSB Revision

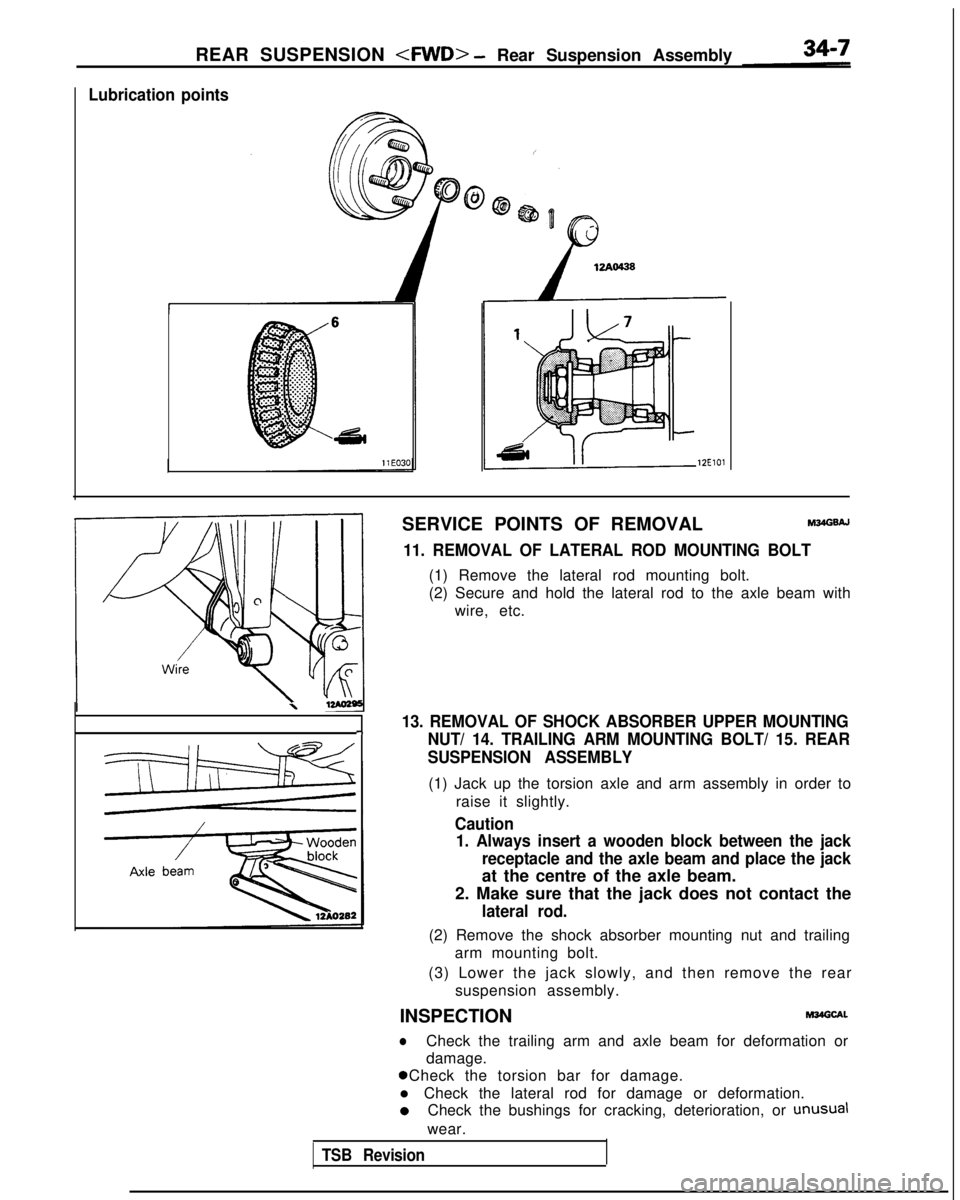

Page 1088 of 1273

REAR SUSPENSION

Lubrication points

12ElOl

SERVICE POINTS OF REMOVALM34GsAJ

11. REMOVAL OF LATERAL ROD MOUNTING BOLT

(1) Remove the lateral rod mounting bolt.

(2) Secure and hold the lateral rod to the axle beam with

wire, etc.

\

13. REMOVAL OF SHOCK ABSORBER UPPER MOUNTING-INUT/ 14. TRAILING ARM MOUNTING BOLT/ 15. REAR

SUSPENSION ASSEMBLY

(1) Jack up the torsion axle and arm assembly in order to

raise it slightly.

Caution1. Always insert a wooden block between the jack

receptacle and the axle beam and place the jack

at the centre of the axle beam.

2. Make sure that the jack does not contact the

lateral rod.

(2) Remove the shock absorber mounting nut and trailing arm mounting bolt.

(3) Lower the jack slowly, and then remove the rear suspension assembly.

INSPECTION

M34Glxl.

lCheck the trailing arm and axle beam for deformation or

damage. 0 Check the torsion bar for damage.

l Check the lateral rod for damage or deformation. 0

Check the bushings for cracking, deterioration, or

unusual

wear.

TSB Revision

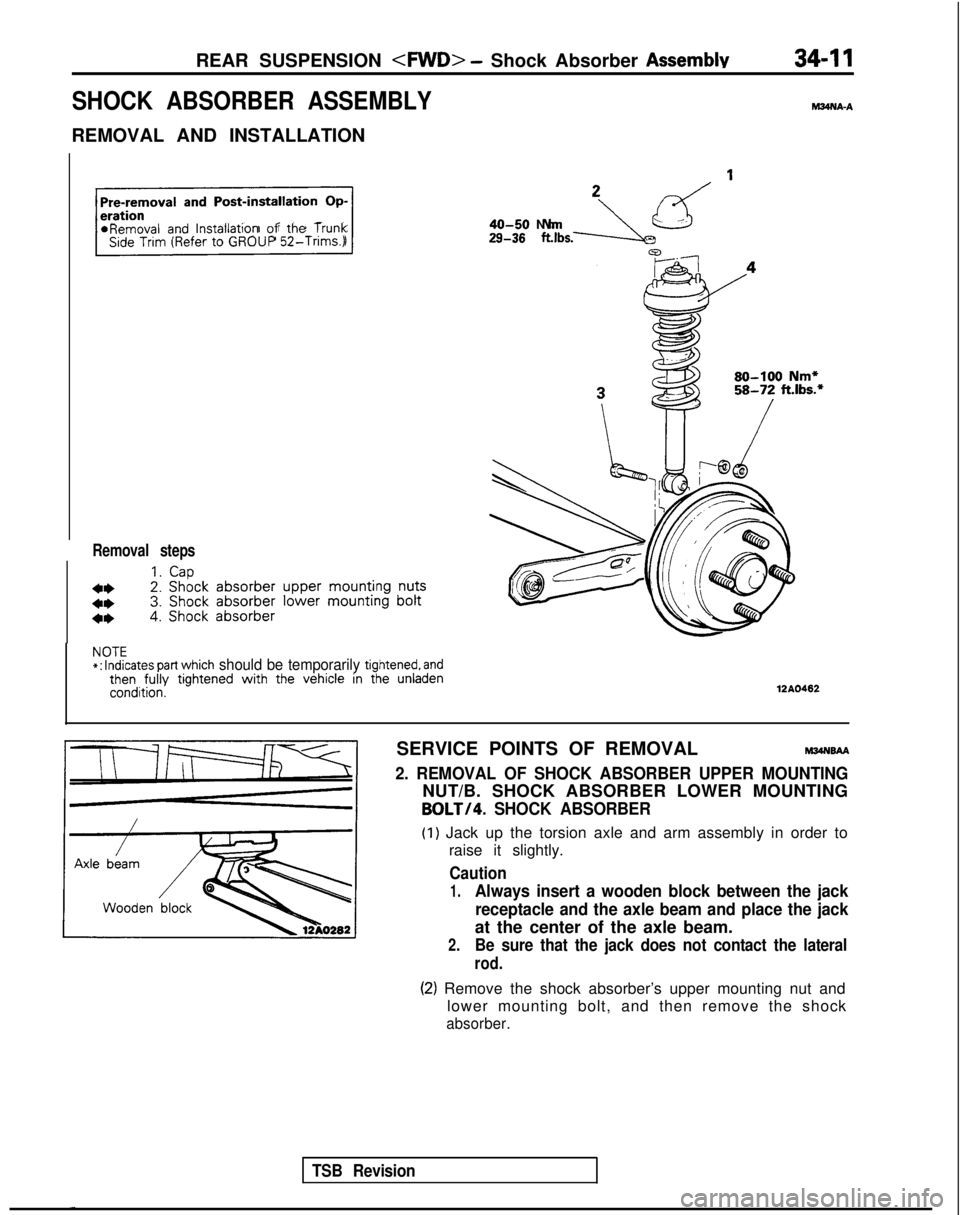

Page 1092 of 1273

REAR SUSPENSION

SHOCK ABSORBER ASSEMBLY

REMOVAL AND INSTALLATION

hl34NA-A

Pre-removal

and Post-installation Op-

r

*Removal and lnstallatlon of the TrunkSide Trim (Refer to GROUP

52-Trims.)

Removal steps

1.Cap

4*2. Shock

absorber

upper

mounting

nuts

4*3. Shock

absorber

lower mounting

bolt

4*4. Shock absorber

29-38 .,bs.-JLzd ’40-50 N

m

80-100 Nm*58-72 ft.lbs.*

NOTE*:

Indicates part which should be temporarily tightened, andthen fully

tightened with

the vehicle in the unladencondition.12AO462

TSB Revision

SERVICE POINTS OF REMOVALM34NsAA

2. REMOVAL OF SHOCK ABSORBER UPPER MOUNTING

NUT/B. SHOCK ABSORBER LOWER MOUNTING

BOLT/4. SHOCK ABSORBER

(1) Jack up the torsion axle and arm assembly in order to

raise it slightly.

Caution

1.Always insert a wooden block between the jack

receptacle and the axle beam and place the jack

at the center of the axle beam.

2.Be sure that the jack does not contact the lateral

rod.

(2) Remove the shock absorber’s upper mounting nut and lower mounting bolt, and then remove the shock

absorber.

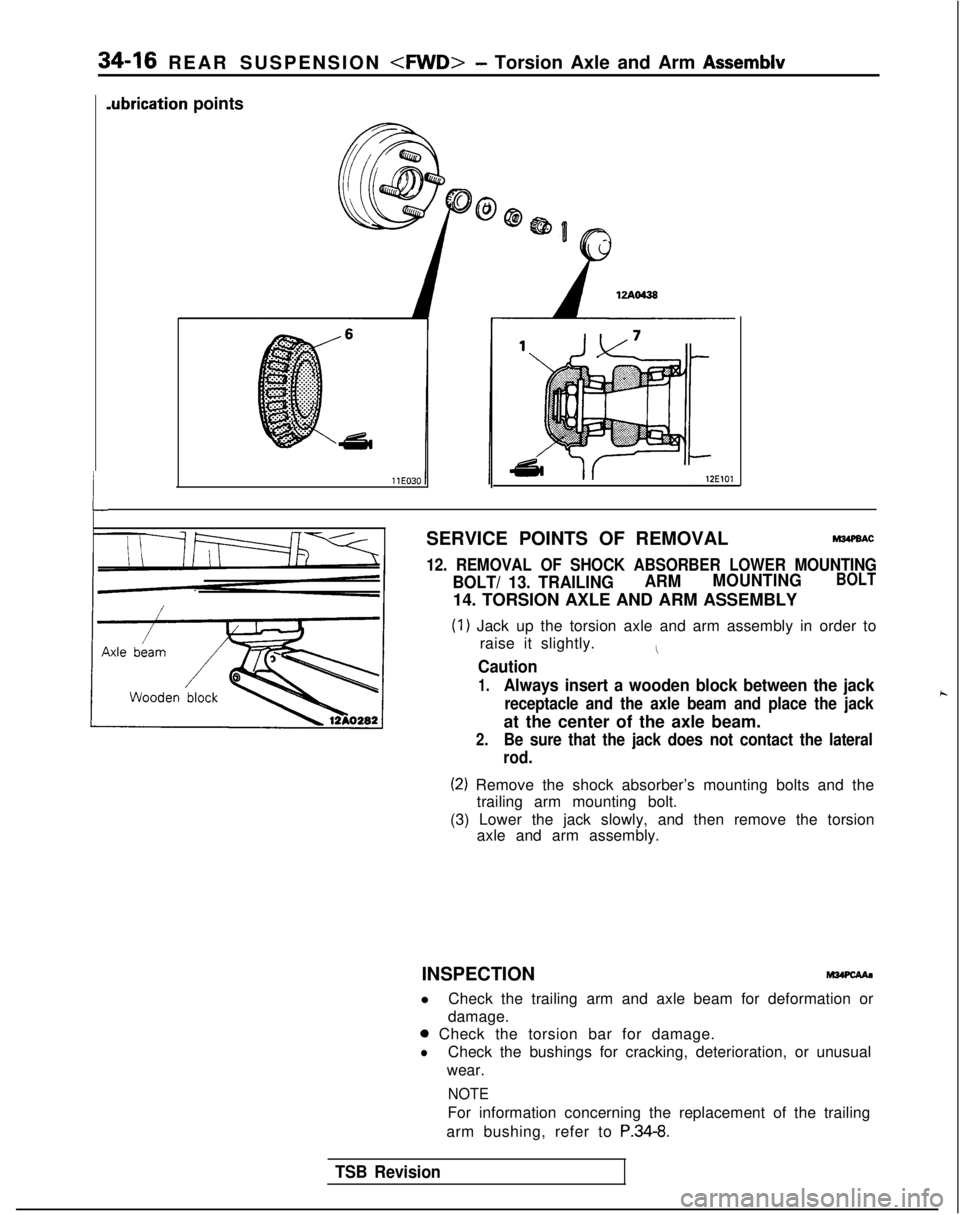

Page 1097 of 1273

34-16 REAR SUSPENSION

L

.ubrication points

12ElOl

SERVICE POINTS OF REMOVALM34PBAC

12. REMOVAL OF SHOCK ABSORBER LOWER MOUNTING

BOLT/ 13. TRAILINGARM

MOUNTINGBOLT

14. TORSION AXLE AND ARM ASSEMBLY

(1) Jack up the torsion axle and arm assembly in order to

raise it slightly.

I

Caution

1.Always insert a wooden block between the jack

receptacle and the axle beam and place the jackh

at the center of the axle beam.

2.Be sure that the jack does not contact the lateral

rod.

(2) Remove the shock absorber’s mounting bolts and the trailing arm mounting bolt.

(3) Lower the jack slowly, and then remove the torsion axle and arm assembly.

INSPECTION

l Check the trailing arm and axle beam for deformation or

damage.

0 Check the torsion bar for damage.

lCheck the bushings for cracking, deterioration, or unusual

wear.

NOTE

For information concerning the replacement of the trailing

arm bushing, refer to

P.34-8.

TSB Revision

Page 1107 of 1273

34-26REAR SUSPENSION

I 412AOlOS

J

TSB Revision

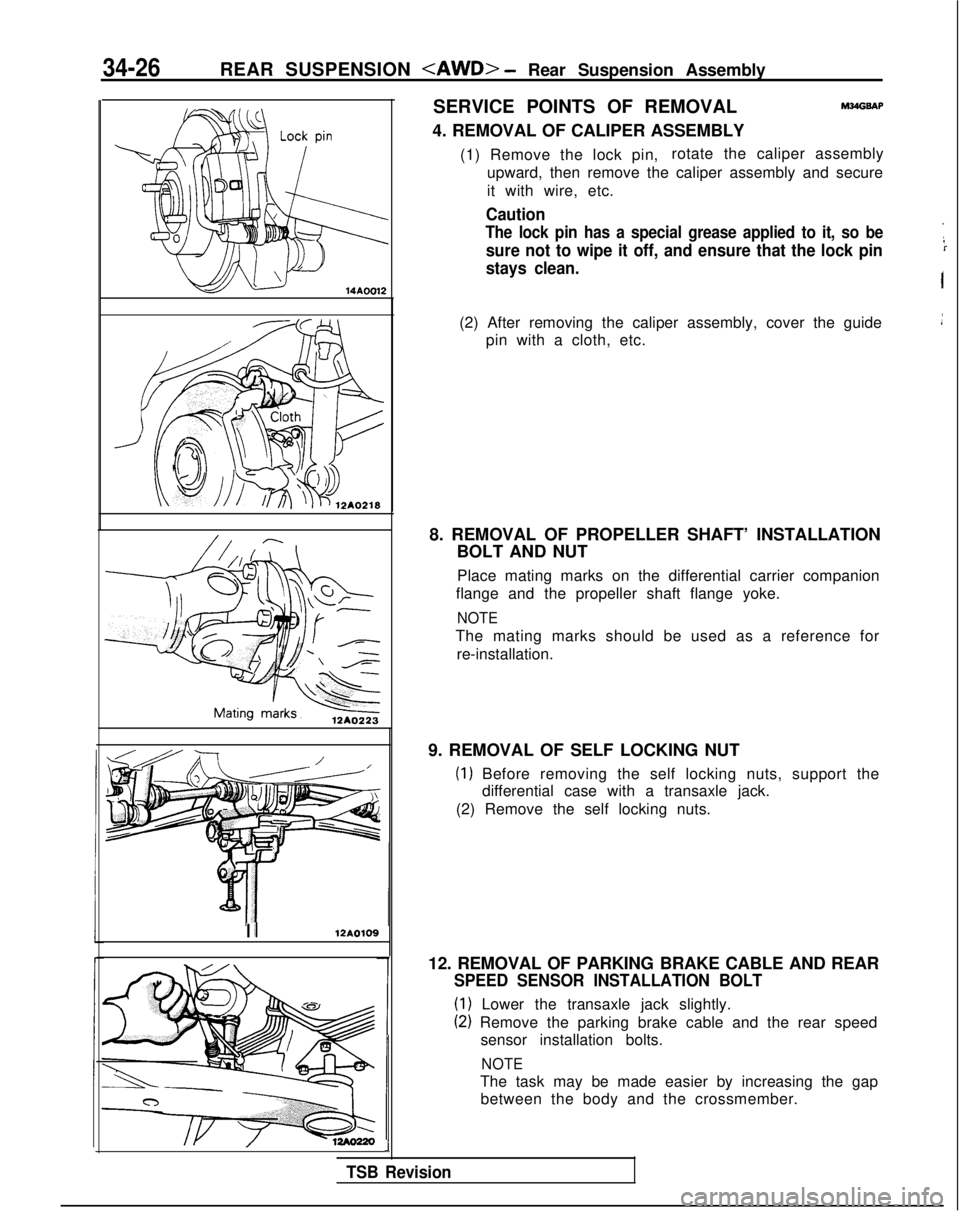

SERVICE POINTS OF REMOVAL

4. REMOVAL OF CALIPER ASSEMBLYM?dGSAP

(1) Remove the lock pin, rotate the caliper assembly

upward, then remove the caliper assembly and secure

it with wire, etc.

Caution

The lock pin has a special grease applied to it, so be

sure not to wipe it off, and ensure that the lock pin

stays clean.

I

(2) After removing the caliper assembly, cover the guide pin with a cloth, etc.

8. REMOVAL OF PROPELLER SHAFT’ INSTALLATION BOLT AND NUT

Place mating marks on the differential carrier companion

flange and the propeller shaft flange yoke.

NOTE

The mating marks should be used as a reference for

re-installation.

9. REMOVAL OF SELF LOCKING NUT

(1) Before removing the self locking nuts, support the differential case with a transaxle jack.

(2) Remove the self locking nuts.

12. REMOVAL OF PARKING BRAKE CABLE AND REAR

SPEED SENSOR INSTALLATION BOLT

(1) Lower the transaxle jack slightly.

(2) Remove the parking brake cable and the rear speed sensor installation bolts.

NOTE

The task may be made easier by increasing the gapbetween the body and the crossmember.

Page 1108 of 1273

REAR SUSPENSION

12A0222

12A.0221

,

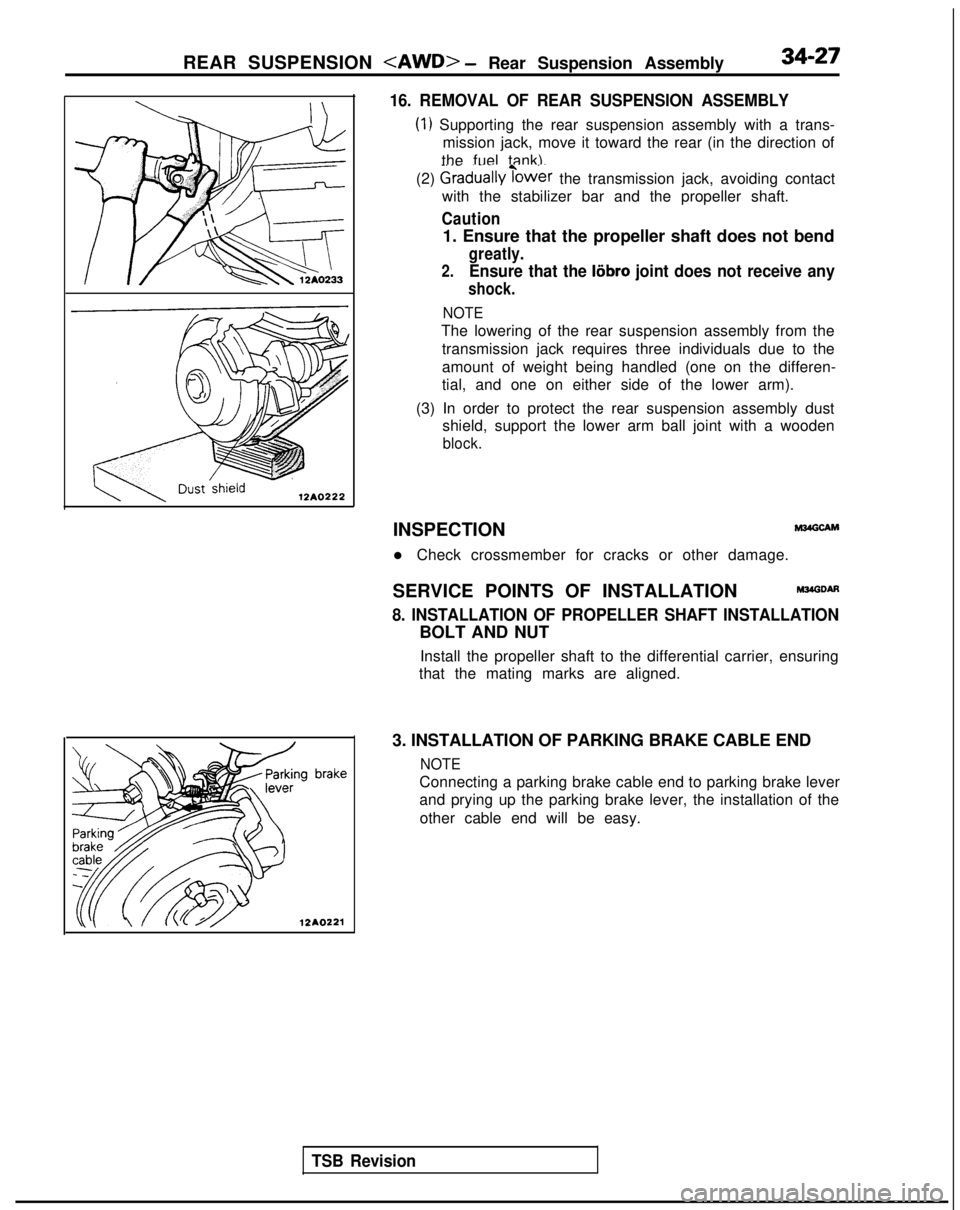

16. REMOVAL OF REAR SUSPENSION ASSEMBLY

(1) Supporting the rear suspension assembly with a trans-

mission jack, move it toward the rear (in the direction of

the fuel tank).

(2)

Graduallyibwer the transmission jack, avoiding contact

with the stabilizer bar and the propeller shaft.

Caution

1. Ensure that the propeller shaft does not bend

greatly.

2.Ensure that the liibro joint does not receive any

shock.

NOTE

The lowering of the rear suspension assembly from the

transmission jack requires three individuals due to the

amount of weight being handled (one on the differen-

tial, and one on either side of the lower arm).

(3) In order to protect the rear suspension assembly dust shield, support the lower arm ball joint with a wooden

block.

TSB Revision

INSPECTIONM24GCAM

l Check crossmember for cracks or other damage.

SERVICE POINTS OF INSTALLATION

M34GDAfl

8. INSTALLATION OF PROPELLER SHAFT INSTALLATION

BOLT AND NUT Install the propeller shaft to the differential carrier, ensuring

that the mating marks are aligned.

3. INSTALLATION OF PARKING BRAKE CABLE END

NOTE

Connecting a parking brake cable end to parking brake lever

and prying up the parking brake lever, the installation of the other cable end will be easy.

Page 1119 of 1273

34-38

REAR SUSPENSION

II12AO109

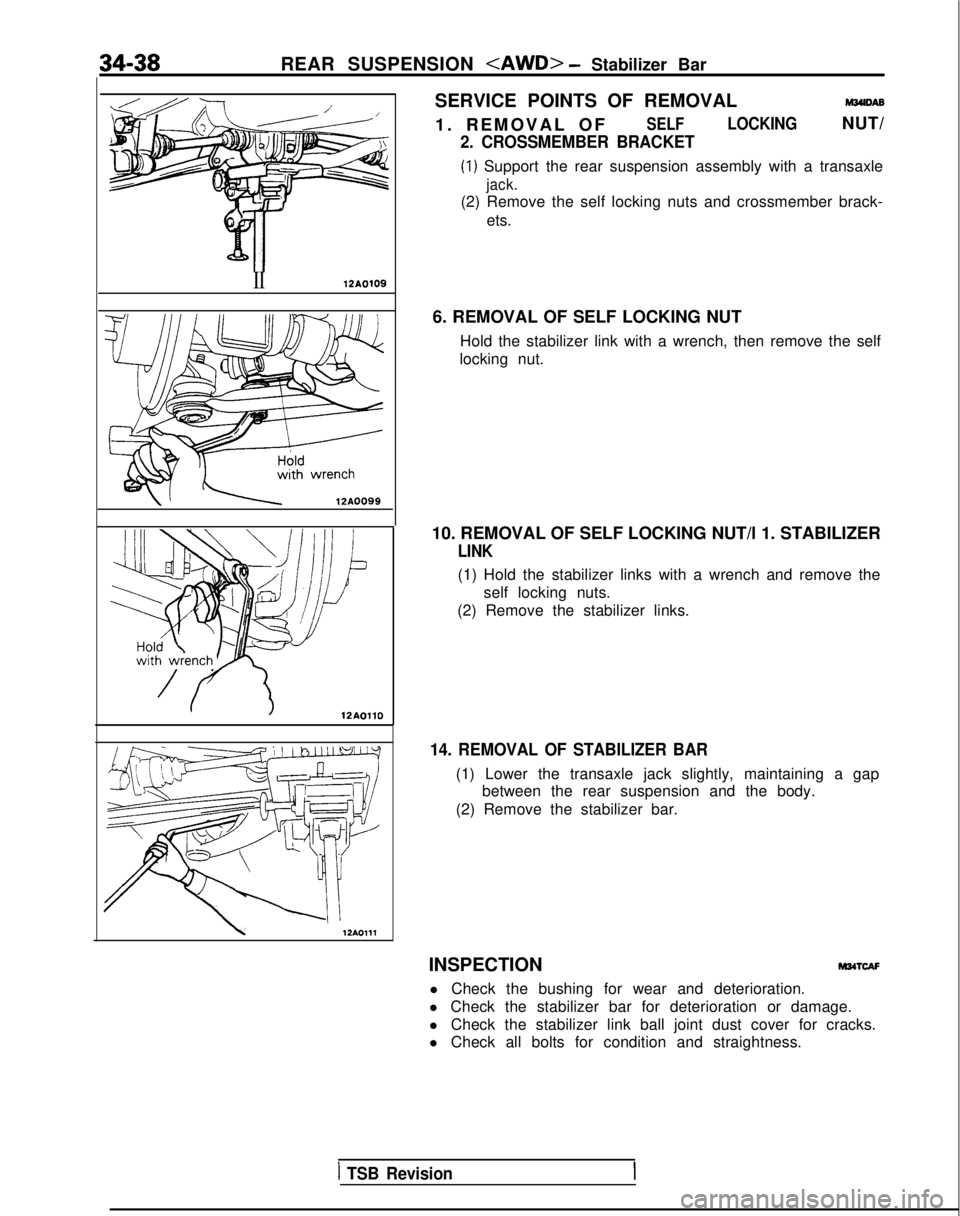

/ 12AOllOSERVICE POINTS OF REMOVAL

M34lDAB

1. REMOVAL O

F

SELFLOCKINGNUT/

2. CROSSMEMBER BRACKET

(1) Support the rear suspension assembly with a transaxle

jack.

(2) Remove the self locking nuts and crossmember brack-

ets.

6. REMOVAL OF SELF LOCKING NUT Hold the stabilizer link with a wrench, then remove the self

locking nut.

10. REMOVAL OF SELF LOCKING NUT/l 1. STABILIZER

LINK

(1) Hold the stabilizer links with a wrench and remove the self locking nuts.

(2) Remove the stabilizer links.

14. REMOVAL OF STABILIZER BAR

(1) Lower the transaxle jack slightly, maintaining a gap between the rear suspension and the body.

(2) Remove the stabilizer bar.

INSPECTION

M34TcAF

l Check the bushing for wear and deterioration.

l Check the stabilizer bar for deterioration or damage.

l Check the stabilizer link ball joint dust cover for cracks.

l Check all bolts for condition and straightness.

1 TSB Revision

Page 1191 of 1273

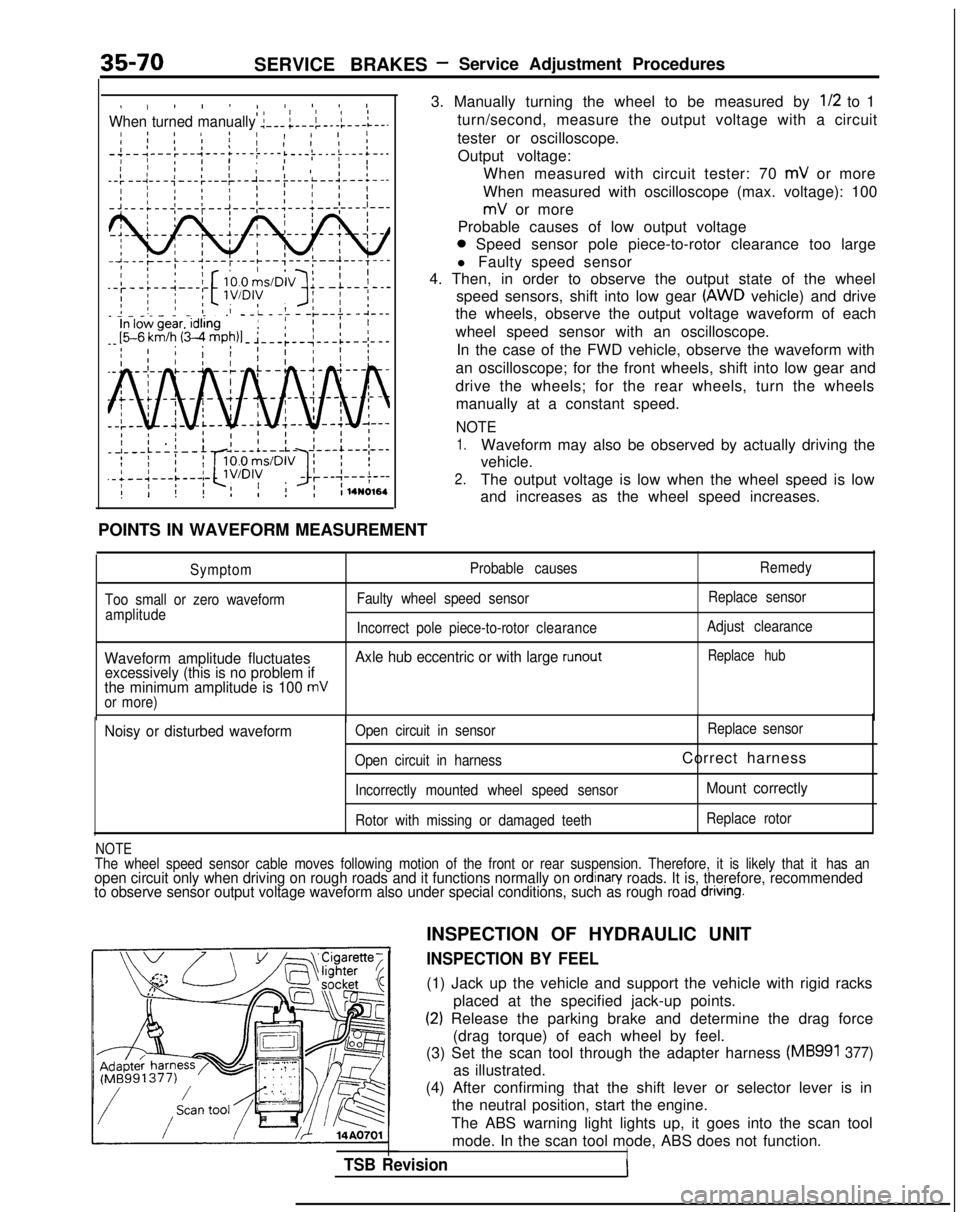

35-70SERVICE BRAKES- Service Adjustment Procedures

I, ! I ! I4 IO II IIWhen turned manually :---;---i-.-l---L--.I 8 ! IaI 1 11 1 II ’I 1’ I I I;-;--1---:--‘---+---t---i ’I IL---)-.-i---+--.II ’ I I 1 , 1 ,I

--:--~---;---:---~--~--

POINTS IN WAVEFORM MEASUREMENT

3. Manually turning the wheel to be measured by

l/2 to 1

turn/second, measure the output voltage with a circuit

tester or oscilloscope. Output voltage: When measured with circuit tester: 70

mV or more

When measured with oscilloscope (max. voltage): 100

mV or more

Probable causes of low output voltage

0 Speed sensor pole piece-to-rotor clearance too large

l Faulty speed sensor

4. Then, in order to observe the output state of the wheel

speed sensors, shift into low gear

(AWD vehicle) and drive

the wheels, observe the output voltage waveform of each

wheel speed sensor with an oscilloscope.

In the case of the FWD vehicle, observe the waveform with

an oscilloscope; for the front wheels, shift into low gear and

drive the wheels; for the rear wheels, turn the wheels manually at a constant speed.

NOTE

1.Waveform may also be observed by actually driving the

vehicle.

2.The output voltage is low when the wheel speed is low

and increases as the wheel speed increases.

Symptom

Too small or zero waveform amplitude Probable causes

Faulty wheel speed sensor Remedy

Replace sensor

Incorrect pole piece-to-rotor clearanceAdjust clearance

Waveform amplitude fluctuates Axle hub eccentric or with large runoutReplace hub

excessively (this is no problem if

the minimum amplitude is 100 mVor more)

Noisy or disturbed waveformOpen circuit in sensor Replace

sensor

Open circuit in harness

Correct harness

Incorrectly mounted wheel speed sensorMount correctly

Rotor with missing or damaged teeth Replace rotor

NOTEThe wheel speed sensor cable moves following motion of the front or rear\

suspension. Therefore, it is likely that it

has anopen circuit only when driving on rough roads and it functions normally \

on ordinan/ roads. It is, therefore, recommended

to observe sensor output voltage waveform also under special conditions,\

such as rough road dnvlng.

TSB Revision

INSPECTION OF HYDRAULIC UNIT

INSPECTION BY FEEL

(1) Jack up the vehicle and support the vehicle with rigid racks

placed at the specified jack-up points.

(2) Release the parking brake and determine the drag force(drag torque) of each wheel by feel.

(3) Set the scan tool through the adapter harness

(MB991 377)

as illustrated.

(4) After confirming that the shift lever or selector lever is in the neutral position, start the engine.

The ABS warning light lights up, it goes into the scan tool mode. In the scan tool mode, ABS does not function.

I