sensor MITSUBISHI GALANT 1989 Service User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 110 of 1273

II-60ENGINE

(9) If a cylinder’s compression pressure or pressure differenceis outside the limit, fill a small amount of engine oil through

the spark plug hole and repeat Items (7) and (8) above.

@ If the compression is increased when the oil is filled, the piston

and/or cylinder wall may be worn or

damaged.

@ If the compression is not Increased even though the oil is filled, the valve may be thermally seized, the valve

contact may be improper or pressure may leak at the

gasket. (10)Connect the connector of the crankshaft position sensor.

(1l)lnstall

the spark plug and spark plug cable.

(12)Erase the diagnostic trouble code with the scan tool or re-

connect the battery (-)

cable 10 seconds or more after it

was disconnected.

NOTE

This will erase the memory of the diagnostic trouble code which resulted from disconnection of the crankshaft posi-

tion sensor connector.

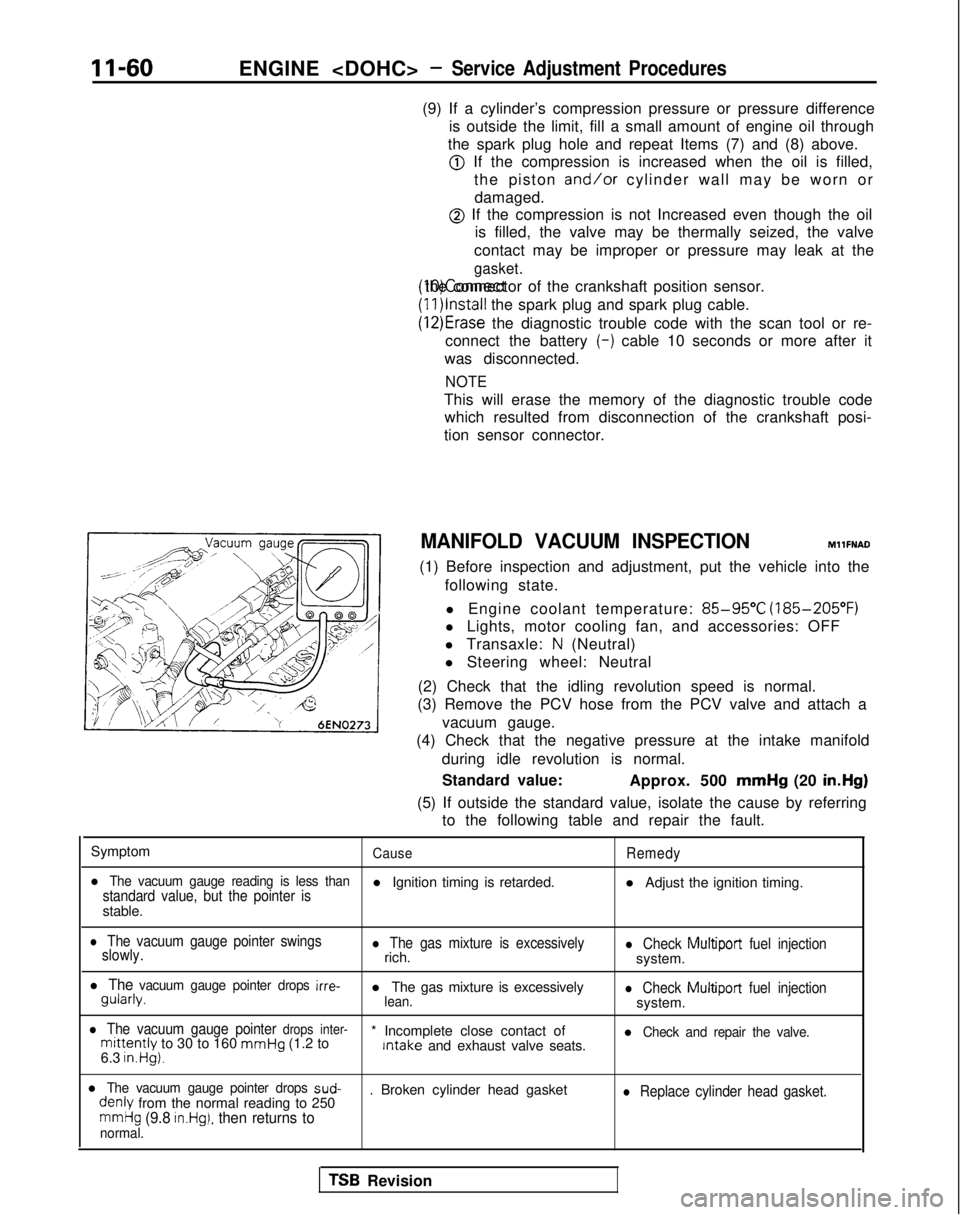

MANIFOLD VACUUM INSPECTION MllFNAD

(1) Before inspection and adjustment, put the vehicle into the following state.

l Engine coolant temperature:

85-95°C (185-205°F)

l Lights, motor cooling fan, and accessories: OFF

l Transaxle:

N (Neutral)

l Steering wheel: Neutral

(2) Check that the idling revolution speed is normal.

(3) Remove the PCV hose from the PCV valve and attach a

vacuum gauge.

(4) Check that the negative pressure at the intake manifold

during idle revolution is normal.

Standard value: Approx. 500 mmHg

(20 in.Hg)

(5) If outside the standard value, isolate the cause by referring to the following table and repair the fault.

Symptom

CauseRemedy

l The vacuum gauge reading is less thanstandard value, but the pointer isl Ignition timing is retarded. l Adjust the ignition timing.

stable.

l The vacuum gauge pointer swings

slowly.l The gas mixture is excessivelyrich.l Check Multiport fuel injectionsystem.

l The vacuum gauge pointer drops irre- gularly.

l The gas mixture is excessively

lean.l Check Multiport

fuel injectionsystem.

l The vacuum gauge pointer drops inter-mittently to 30 to 160 mmHg

(1.2 to * Incomplete close contact of Intake

and exhaust valve seats.l Check and repair the valve.

6.3 in.Hg).

l The vacuum gauge pointer drops sud- denly

from the normal reading to 250 . Broken cylinder head gasketl Replace cylinder head gasket.

mmHg (9.8 in.Hg), then returns tonormal.

TSB Revision

Page 115 of 1273

ENGINE

4-6

Nm

25

18

05AO196

I

23\il4-6 Nm3-4 ftlbs.

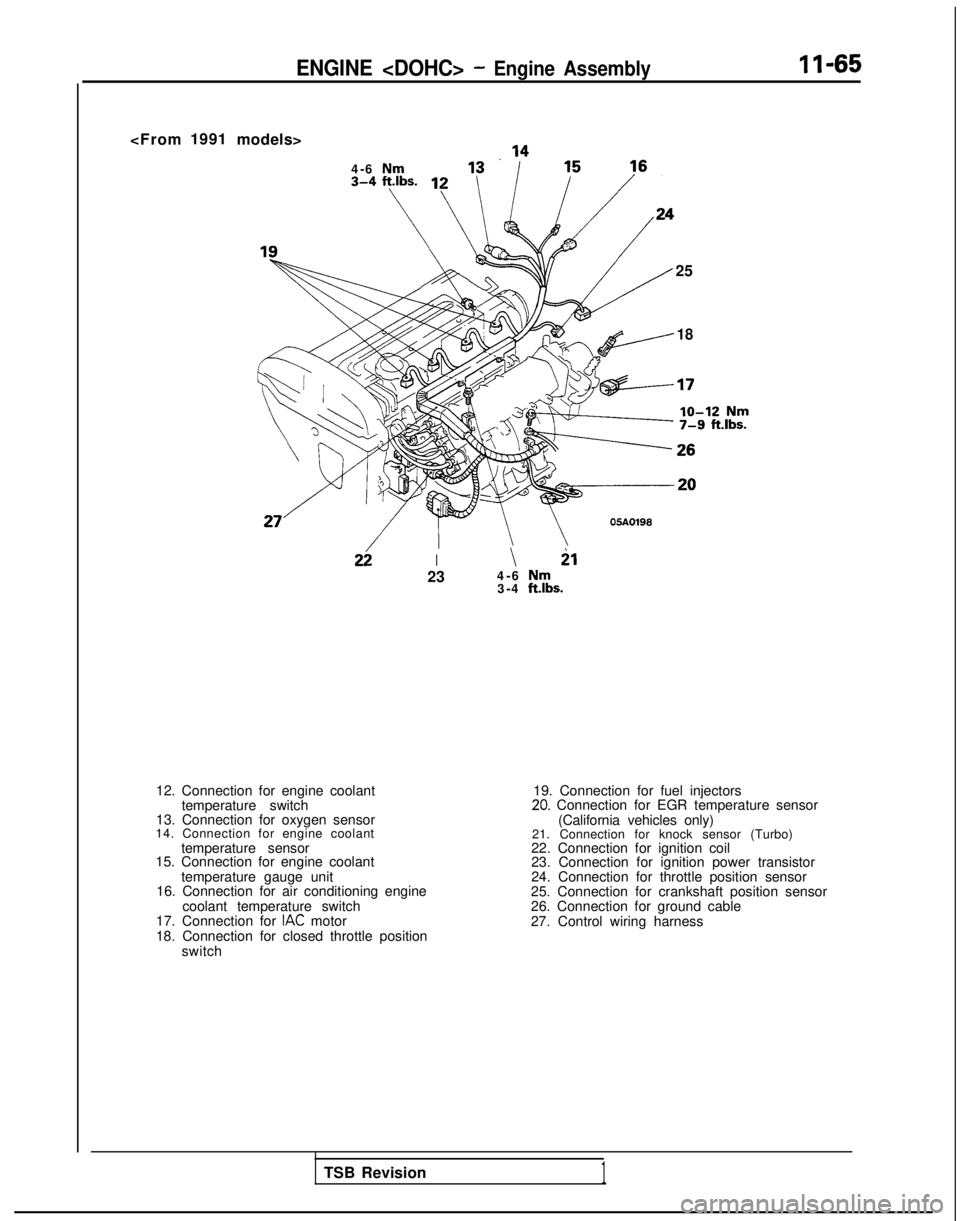

12. Connection for engine coolanttemperature switch

13. Connection for oxygen sensor

14. Connection for engine coolant

temperature sensor

15. Connection for engine coolant

temperature gauge unit

16. Connection for air conditioning engine

coolant temperature switch

17. Connection for

IAC motor

18. Connection for closed throttle position switch 19. Connection for fuel injectors

20. Connection for EGR temperature sensor

(California vehicles only)

21. Connection for knock sensor (Turbo)

22. Connection for ignition coil

23. Connection for ignition power transistor

24. Connection for throttle position sensor

25. Connection for crankshaft position sensor

26. Connection for ground cable

27. Control wiring harness

TSB Revision

1

Page 118 of 1273

II-68ENGINE

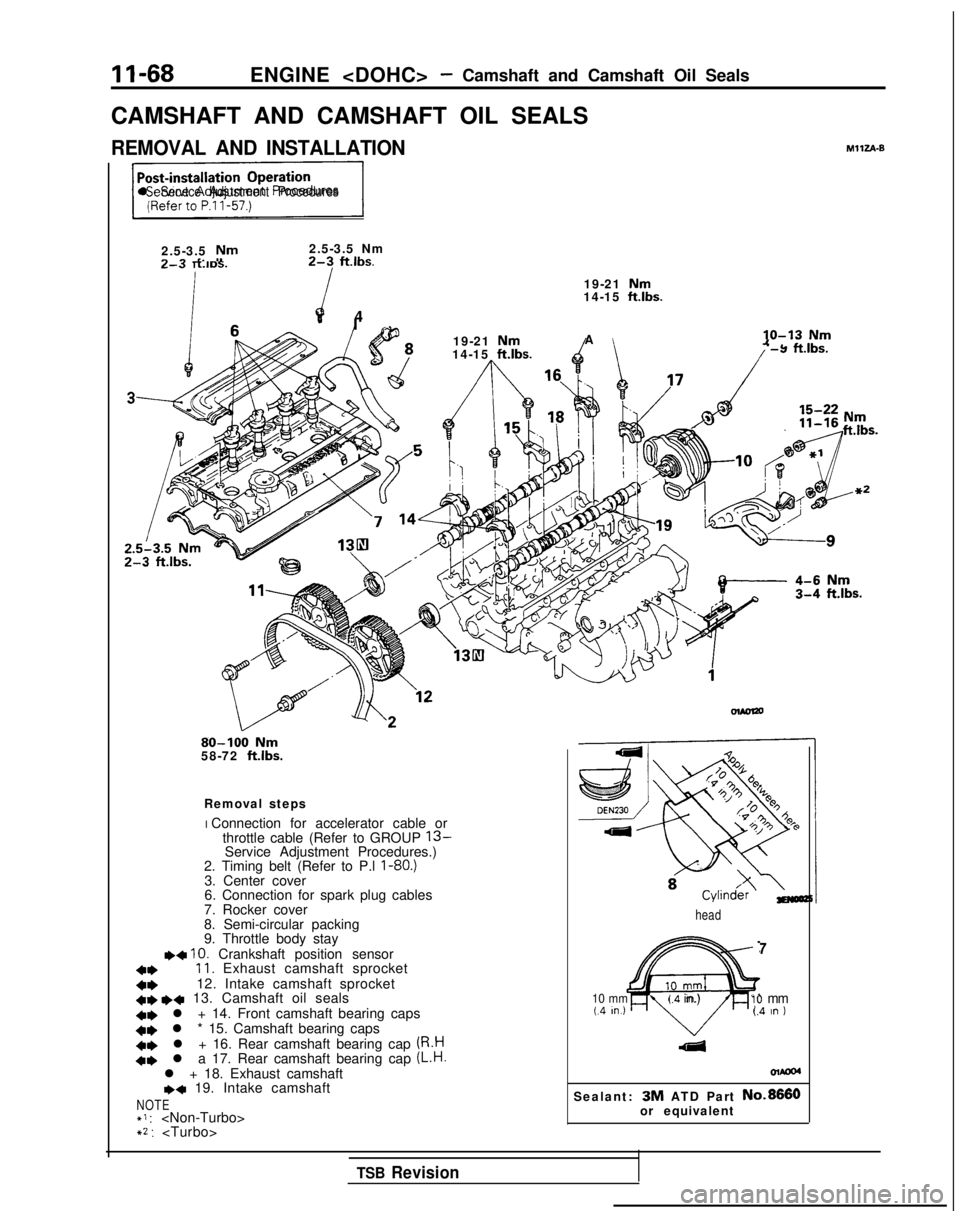

CAMSHAFT AND CAMSHAFT OIL SEALS

REMOVAL AND INSTALLATIONMIIZA-0

*Il Servtce Adjustment Procedures

2.5-3.5 Nm2.5-3.5 Nm^ ^ *. I.-3 -3YIL-L--J I-LIDS.L-S TLIDS.

19-21 Nm14-15 ft.lbs.

4

I ^

19-21 NmAlo-13 Nm-.. -IL-14-15 ft.lbs.-Y I-LIDS. 80-100

Nm58-72 ft.lbs.

Removal steps

I Connection for accelerator cable or throttle cable (Refer to GROUP

13-Service Adjustment Procedures.)

2. Timing belt (Refer to P.l I-80.)3. Center cover

6. Connection for spark plug cables

7. Rocker cover

8. Semi-circular packing

9. Throttle body stay

++ 10. Crankshaft position sensor

4,11. Exhaust camshaft sprocket

4*12. Intake camshaft sprocket+e I)+ 13. Camshaft oil seals 41)

l + 14. Front camshaft bearing caps

+e l * 15. Camshaft bearing caps+e l + 16. Rear camshaft bearing cap (R.H+e l a 17. Rear camshaft bearing cap (L.H.l + 18. Exhaust camshafte+ 19. Intake camshaft

NOTE+1 :

Nmft.lbs.

head

7

10 mm

@

10 mm(.4 in.)10 mmc.4 In.)(.4 In )

OlAca

Sealant: 3M ATD Part No.8880or equivalent

TSB Revision

Page 119 of 1273

ENGINE

11-69

SERVICE POINTS OF REMOVAL

MllZBAD

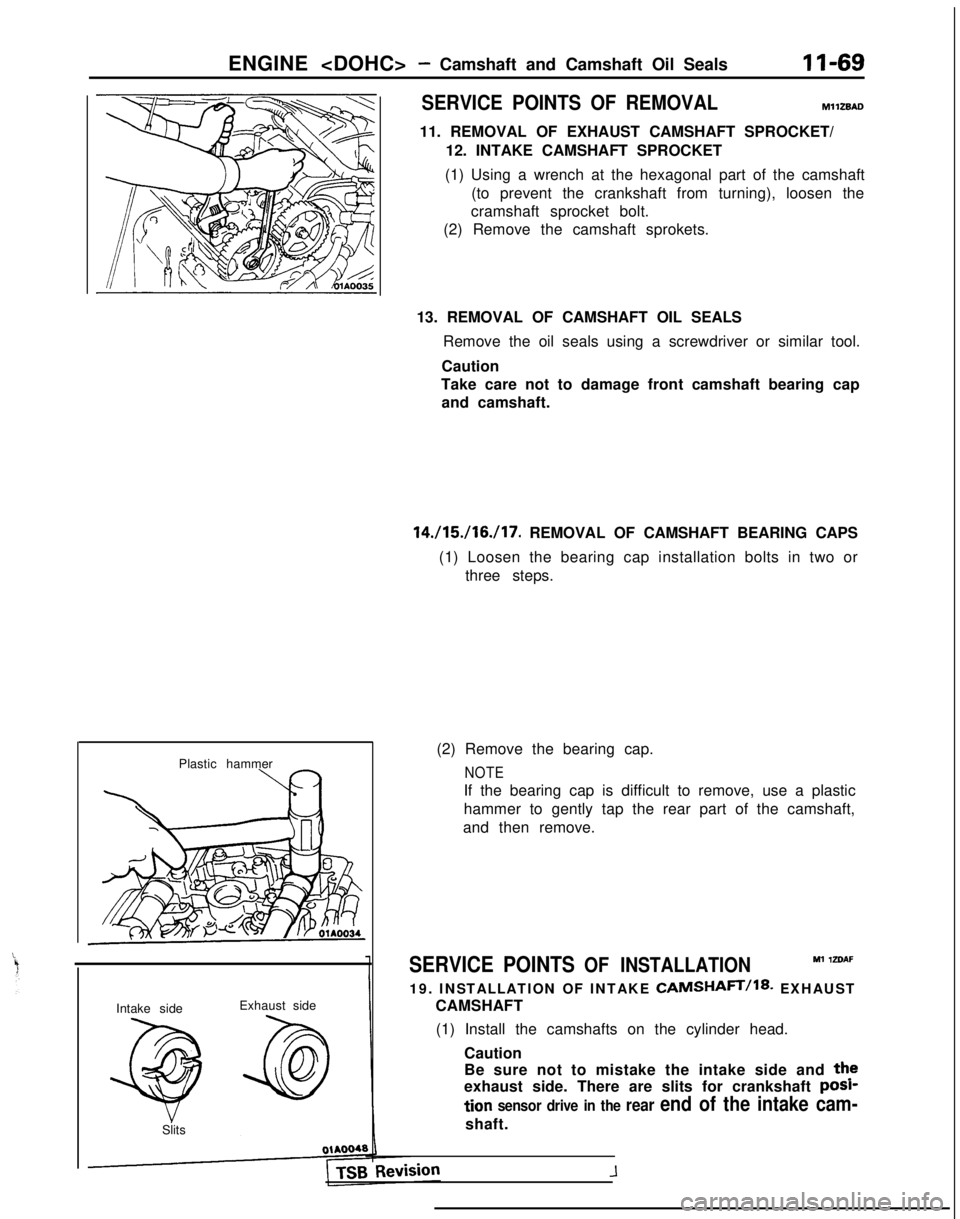

11. REMOVAL OF EXHAUST CAMSHAFT SPROCKET/ 12. INTAKE CAMSHAFT SPROCKET

(1) Using a wrench at the hexagonal part of the camshaft (to prevent the crankshaft from turning), loosen the

cramshaft sprocket bolt.

(2) Remove the camshaft sprokets.

Plastic hammer

Intake side Exhaust side

q 48

Slits 13. REMOVAL OF CAMSHAFT OIL SEALS

Remove the oil seals using a screwdriver or similar tool.

Caution

Take care not to damage front camshaft bearing cap and camshaft.

14./15./16./17. REMOVAL OF CAMSHAFT BEARING CAPS

(1) Loosen the bearing cap installation bolts in two or three steps.

(2) Remove the bearing cap.

NOTE

If the bearing cap is difficult to remove, use a plastic

hammer to gently tap the rear part of the camshaft,

and then remove.

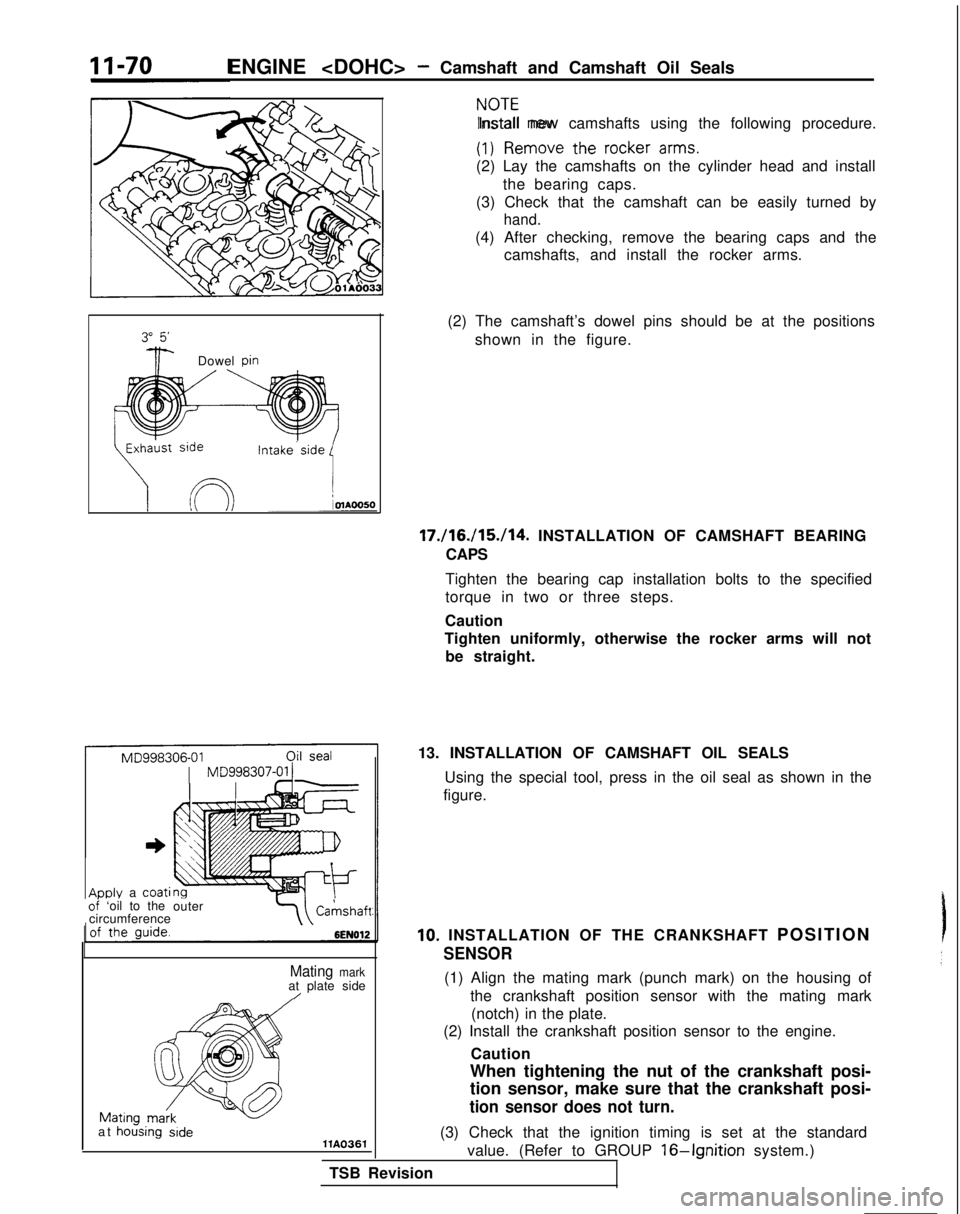

SERVICE POINTS OF INSTALLATION M, 1zDAF

19. INSTALLATION OF INTAKE

CAMSHAFT/18.

EXHAUST

CAMSHAFT

(1) Install the camshafts on the cylinder head.

Caution

Be sure not to mistake the intake side and

th!

exhaust side. There are slits for crankshaft posl-

tion sensor drive in the rear end of the intake cam-

shaft.

Page 120 of 1273

ENGINE

zI?mo”e the rocker arms.

Install new camshafts using the following procedure.

(2) Lay the camshafts on the cylinder head and install the bearing caps.

(3) Check that the camshaft can be easily turned by

hand.

(4) After checking, remove the bearing caps and the camshafts, and install the rocker arms.

3iF-Dowel Din

(2) The camshaft’s dowel pins should be at the positions

shown in the figure.

Intake.side

17./16./15./14. INSTALLATION OF CAMSHAFT BEARING

CAPS

Tighten the bearing cap installation bolts to the specified

torque in two or three steps.

Caution

Tighten uniformly, otherwise the rocker arms will not be straight.

ADDIY a coatioi ‘oil to the outer

circumferenceCahshaft

Mating markat plate side/

at hoising sidellA0361(3) Check that the ignition timing is set at the standard

value. (Refer to GROUP

16-Ignition system.)

TSB Revision 13. INSTALLATION OF CAMSHAFT OIL SEALS

Using the special tool, press in the oil seal as shown in the

figure.

10. INSTALLATION OF THE CRANKSHAFT POSITIO

N

SENSOR

(1) Align the mating mark (punch mark) on the housing of

the crankshaft position sensor with the mating mark(notch) in the plate.

(2) Install the crankshaft position sensor to the engine.

Caution

When tightening the nut of the crankshaft posi-

tion sensor, make sure that the crankshaft posi-

tion sensor does not turn.

Page 123 of 1273

ENGINE

CYLINDER HEAD GASKET

MllJA-9

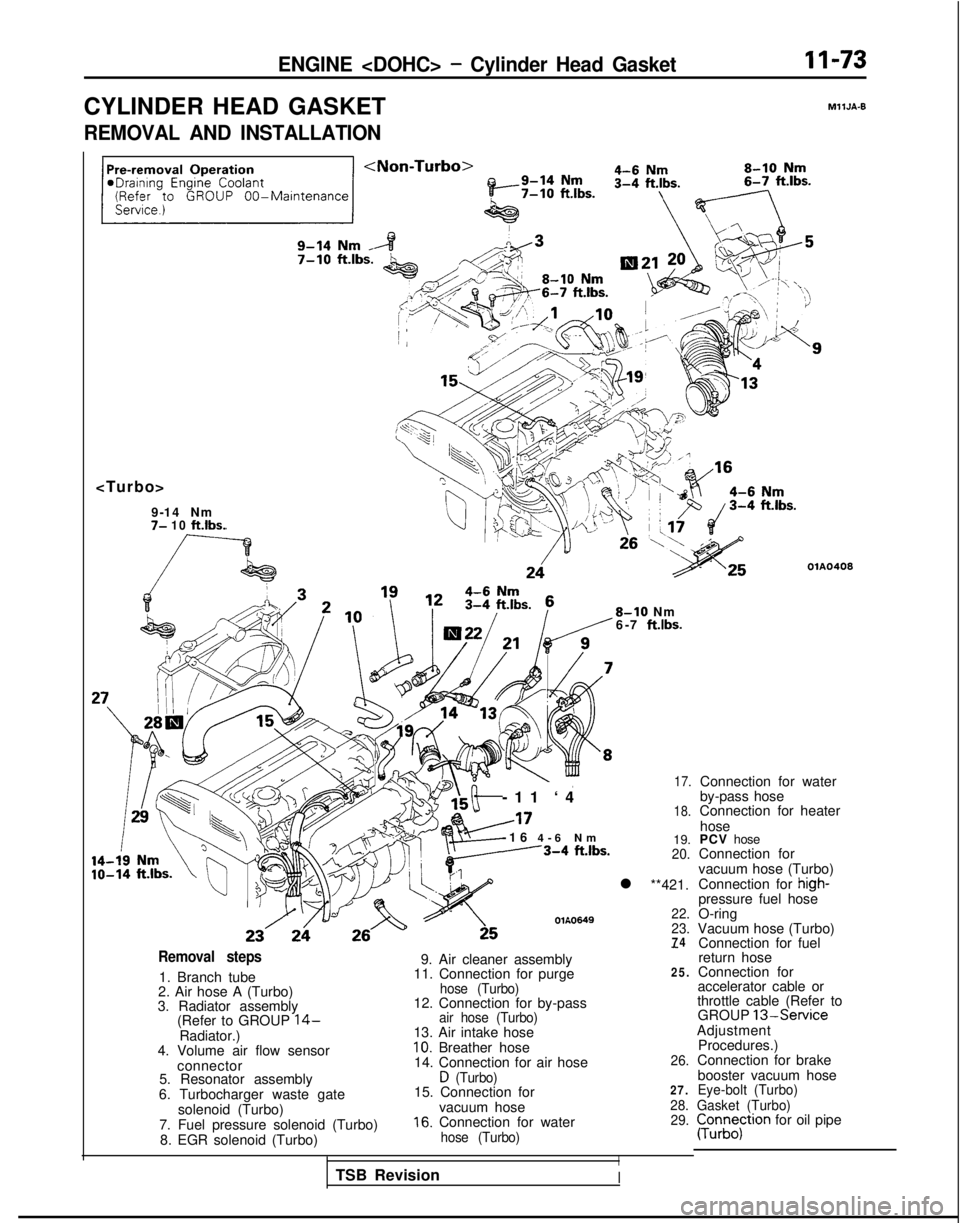

REMOVAL AND INSTALLATION

7- 10 ft.lbs.

OlA0408

8-10 Nm

6-7 ft.lbs.

-11 ‘

4

A17

-16

4-6 N

m

---3-4

ftlbs.

OlA0649

17.

18.

19.20.

l **421.

22.

23.

74Removal steps

1. Branch tube

2. Air hose A (Turbo)

3. Radiator assembly (Refer to GROUP

14-Radiator.)

4. Volume air flow sensor

connector

5. Resonator assembly

6. Turbocharger waste gate solenoid (Turbo)

7. Fuel pressure solenoid (Turbo) 8. EGR solenoid (Turbo)

-

9. Air cleaner assembly

11. Connection for purge25.

hose (Turbo)12. Connection for by-passair hose (Turbo)13. Air intake hose10. Breather hose

14. Connection for air hose26.

D (Turbo)15. Connection for27.

vacuum hose28.

16. Connection for water29.

hose (Turbo)

I

Connection for water

by-pass hose

Connection for heater

hose

PCV hose

Connection for

vacuum hose (Turbo)

Connection for

high-pressure fuel hose

O-ring

Vacuum hose (Turbo) Connection for fuel

return hose

Connection for

accelerator cable or

throttle cable (Refer to GROUP

13-ServiceAdjustment

Procedures.)

Connection for brake

booster vacuum hose

Eye-bolt (Turbo)

Gasket (Turbo)

pun;;;tron for oil pipe

TSB Revision

I

Page 125 of 1273

ENGINE

Z&-y,bfm

‘\ .

,,\:.,.s.

46

4-6

‘Nm $7

3-4 ftlbs.

41

43

42

IO-12 Nm

7-9 ft.lbs.

05A0199

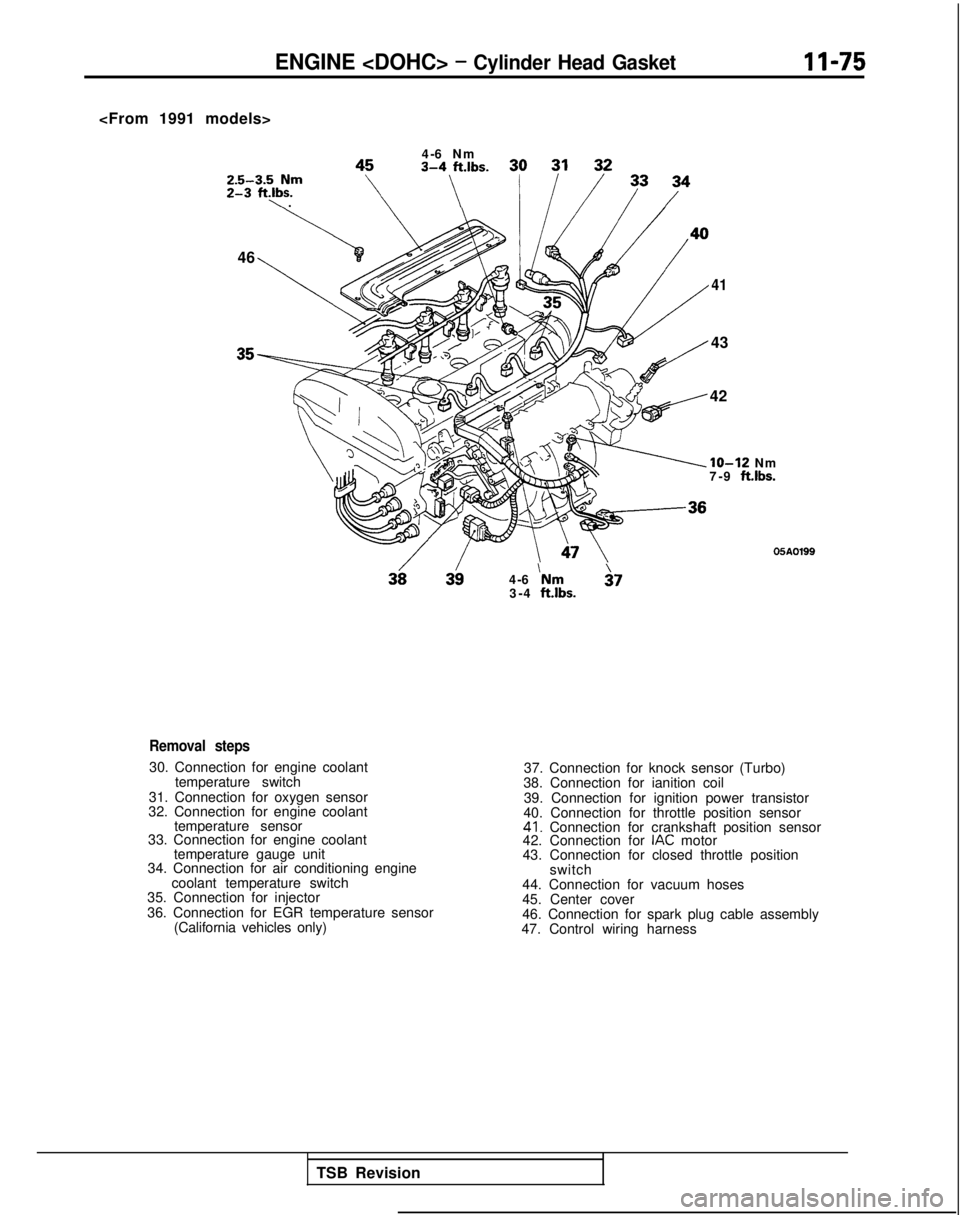

Removal steps

30. Connection for engine coolant

temperature switch

31. Connection for oxygen sensor

32. Connection for engine coolant temperature sensor

33. Connection for engine coolant

temperature gauge unit

34. Connection for air conditioning engine

coolant temperature switch

35. Connection for injector

36. Connection for EGR temperature sensor

(California vehicles only) 37. Connection for knock sensor (Turbo)

38. Connection for ianition coil

39. Connection for ignition power transistor

40. Connection for throttle position sensor

41. Connection for crankshaft position sensor

42. Connection for IAC motor

43. Connection for closed throttle position

switch

44. Connection for vacuum hoses

45. Center cover

46. Connection for spark plug cable assembly

47. Control wiring harness

TSB Revision

Page 143 of 1273

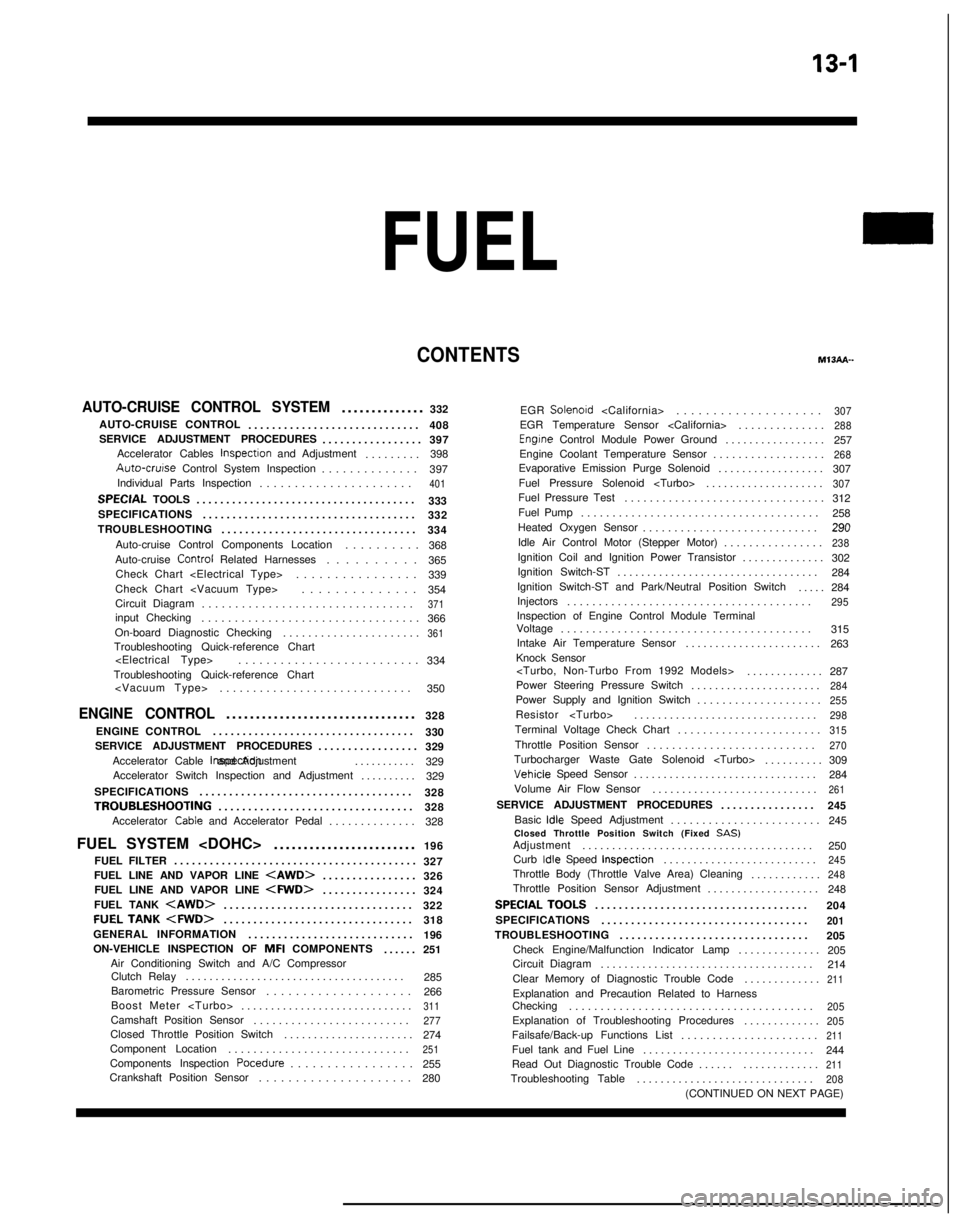

13-1

FUEL

CONTENTSM’ISAA--

AUTO-CRUISE CONTROL SYSTEM.............

.

332

AUTO-CRUISE CONTROL ............................. 408

SERVICE ADJUSTMENT PROCEDURES .................397

Accelerator Cables

inspectron and Adjustment ........

.

398 Auto-cruise

Control System Inspection

..............397

Individual Parts Inspection ......................

401SPECfAL

TOOLS

.....................................

333

SPECIFICATIONS .................................... 332

TROUBLESHOOTING ................................. 334

Auto-cruise Control Components Location ..........368

Auto-cruise Control

Related Harnesses

..........365

Check Chart

Check Chart

Circuit Diagram ................................

371input Checking................................

.

366

On-board Diagnostic Checking ......................

361Troubleshooting Quick-reference Chart

.

334

Troubleshooting Quick-reference Chart

ENGINE CONTROL...............................

.

328

ENGINE CONTROL ..................................

330

SERVICE ADJUSTMENT PROCEDURES .................329

Accelerator Cable inspectron and Adjustment

...........329

Accelerator Switch Inspection and Adjustment ..........329

SPECIFICATIONS ....................................

328

TROUBLESHOOTlNG................................

.

328

Accelerator

Cable and Accelerator Pedal .............

.

328

FUEL SYSTEM

FUEL FILTER .........................................

327

FUEL LINE AND VAPOR LINE

.

326

FUEL LINE AND VAPOR LINE

.

324

FUEL TANK

.

322

FUELTANK

.

318

GENERAL INFORMATION ............................ 196

ON-VEHICLE INSPECTION OF MFI

COMPONENTS

......251

Air Conditioning Switch and A/C Compressor Clutch Relay .....................................

285

Barometric Pressure Sensor .................... 266

Boost Meter

311Camshaft Position Sensor ........................

.

277Closed Throttle Position Switch

.....................

.

274

Component Location .............................

251Components Inspection Pocedure

................. 255

Crankshaft Position Sensor ..................... 280EGR

Solenord

...................

.

307EGR Temperature Sensor

.............

.

288Engrne Control Module Power Ground

................

.

257

Engine Coolant Temperature Sensor ..................

268Evaporative Emission Purge Solenoid .................

.

307

Fuel Pressure Solenoid

307Fuel Pressure Test...............................

.

312

Fuel Pump ...................................... 258

Heated Oxygen Sensor ............................ 290

Idle Air Control Motor (Stepper Motor) ................

238Ignition Coil and Ignition Power Transistor .............

.

302

Ignition Switch-ST .................................. 284

Ignition Switch-ST and Park/Neutral Position Switch .....284

Injectors .......................................

295Inspection of Engine Control Module Terminal

Voltage .......................................

.

315

Intake Air Temperature Sensor .......................263

Knock Sensor

Power Steering Pressure Switch ......................

284Power Supply and Ignition Switch ...................

.

255Resistor

..............................

.

298Terminal Voltage Check Chart

......................

.

315Throttle Position Sensor

..........................

.

270Turbocharger Waste Gate Solenoid

.........

.

309 Vehicle

Speed Sensor

............................... 284

Volume Air Flow Sensor ............................

261SERVICE ADJUSTMENT PROCEDURES ...............

.

245

Basic

idle Speed Adjustment .......................

.

245

Closed Throttle Position Switch (Fixed

SAS)Adjustment ......................................

.

250

Curb

Idle Speed Inspection

..........................245Throttle Body (Throttle Valve Area) Cleaning

...........

.

248Throttle Position Sensor Adjustment

..................

.

248

SPECIALTOOLS...................................

.

204

SPECIFICATIONS ...................................

201TROUBLESHOOTING ...............................

.

205

Check Engine/Malfunction Indicator Lamp ..............205

Circuit Diagram .................................... 214

Clear Memory of Diagnostic Trouble Code .............

211Explanation and Precaution Related to Harness

Checking ......................................

.

205Explanation of Troubleshooting Procedures

............

.

205Failsafe/Back-up Functions List

.....................

.

211Fuel tank and Fuel Line

............................

.

244

Read Out Diagnostic Trouble Code ...................

211Troubleshooting Table

.............................

.

208(CONTINUED ON NEXT PAGE)

Page 144 of 1273

13-2

FUEL SYSTEM

..........

FUEL FILTER ....................................

FUEL LINE AND VAPOR LINE .....................FUELTANK....................................

.

GENERAL INFORMATION ........................

ON-VEHICLE INSPECTION OF MFI

COMPONENTS . .

Air

Conditionrng Switch and A/C CompressorClutch Relay ......

.

.............

Barometric Pressure Sensor .........

Camshaft Position Sensor ...........

Closed Throttle Position Switch ...........

Component Location .............

Components

Inspectron Procedure .......

.

Crankshaft Positron Sensor ............

EGR Solenoid

. . .3. .

115..,.113

. 109

. . 3

. . . 38

83

536961384173101EGR Temperature Sensor

.

85

Enqine Control Module Power Ground ......

.

....

45

Engine Coolant Temperature Sensor ...............

55Evaporative Emission Purge Solenord..............

.

99

Fuel Pressure ...............................

102Fuel Pump

...................................

.

46

Idle Speed Control Motor (DC Motor) ................

.

93

Idle Speed Control Motor Positron Sensor ............

.

64

lgnitron Co11 and Ignition Power Transistor .........

.

96

Ignition Switch-ST ..........................

77Ignition Switch-ST and Park/Neutral Position Switch

...78

Injectors..................................

.

90

Inspection of

Engrne Control Module Terminal

Voltage .........

.

..........................

105Intake Air Temperature Sensor ..................

.

51Oxygen Sensor

............................

.

87Power Steering Pressure Switch

..................

.

81Power Supply

.........................

.

42

Terminal Voltage Check Chart ......................

106Throttle Positron Sensor.....................

.

57Vehicle Speed Sensor

.........................

.

80

Volume Air Flow Sensor .........................

49

SERVICE ADJUSTMENT PROCEDURES .................

32

Basic

Idle Speed Adjustment ...................

.

33

Curb Idle Speed Inspection ..........................

32Throttle Body (Throttle Valve Area) Cleaning........

.

35

Throttle Positron Sensor Adjustment ................

35

SPECIAL TOOLS 7

.................

...................

SPECIFICATIONS ....................................

5

TROUBLESHOOTING .................................

8

Check Engine/Malfunction Indicator Lamp ..............

10Crrcuit Diagram.................................

.

20

Clear Memory of Diagnostic Trouble Code ............

17Explanation and Precaution Related to HarnessChecking......................................

.

9Explanation of Troubleshooting Procedures

...........

.

8

Failsafe/Back-up Functions List ....................

16Fuel Tank and Fuel Lrne.........................

.

32Read Out of Diagnostic Trouble Code

...............

.

16Troubleshooting Table

.........................

.

13

FUEL SYSTEM

116

FUEL FILTER .......................................

195

FUEL LINE AND VAPOR LINE ........................

195

FUEL TANK ........................................ 195

GENERAL INFORMATION ............................

116

ON-VEHICLE INSPECTION OF MFI

COMPONENTS

Air Conditioning Switch and A/C Compressor Clutch Relay .............................

Barometric Pressure Sensor .................

Camshaft Position Sensor ....................

Closed Throttle Position Switch ................

Component Location .......................

Components Inspectron Pocedure

..............

Crankshaft Position Sensor .................

EGR Solenoid

EGR Temperature Sensor

Engine Control Module Power Ground ..........

Engine Coolant Temperature Sensor .............

Evaporative Emission Purge Solenoid ............

Fuel Pressure Test ...........................

Fuel Pump ..................................

IAC Valve Positon Sensor

......................

Idle Air Control Motor (DC Motor) ..............

lgnrtion Coil and Ignition Power Transistor

.......

.

Ignition Switch-ST ...........................

Ignition Switch-ST and Park/Neutral Position Switch

Injectors ....................................

Inspection of Engine Control Module Terminal

Voltage .....................................

Intake Air Temperature Sensor .................

Oxygen Sensor .............................

Power Steering Pressure

Swatch..............

.

Power Supply ...............................

Terminal Voltage Check Chart ..................

Throttle Position Sensor .......................

Vehicle Speed Sensor ......................... . . . . 139

176

154

165

16013914216

7

..,_ 191177146

155

189192

147

162

184

186

171172181

192152

179

175

143

192

157

173

Volume Air Flow Sensor ...........................

.

150

SERVICE ADJUSTMENT PROCEDURES

...............

.

133

Basic Idle Speed Adjustment 133

Closed Throttle Position Switch and Throttle Position

Sensor Adjustment .................................

136Curb Idle Speed Inspection

.........................

.

133Fixed SAS Adjustment

.............................

.

138Throttle Body (Throttle Valve Area) Cleaning

...........

.

136

SPECIAL TOOLS

...................................

.

119

SPECIFICATIONS 118

.... ..............................

TROUBLESHOOTING ..................

.............

119

Check Engine/Malfunction Indicator Lamp ..............

120Circuit Diagram...................................

.

128Clear Memory of Diagnostic Trouble Code

............

.

126Explanation and Precaution Related to Harness

Checking ........................................

.

119Explanation of Troubleshooting Procedures

............

.

119Failsafe/Back-up

Fuctions List

........................

126

Fuel Tank and Fuel Line .............................

133Read Out of Diagnostic Trouble Code ................

.

126

Troubleshooting Table ..............................

123

Page 145 of 1273

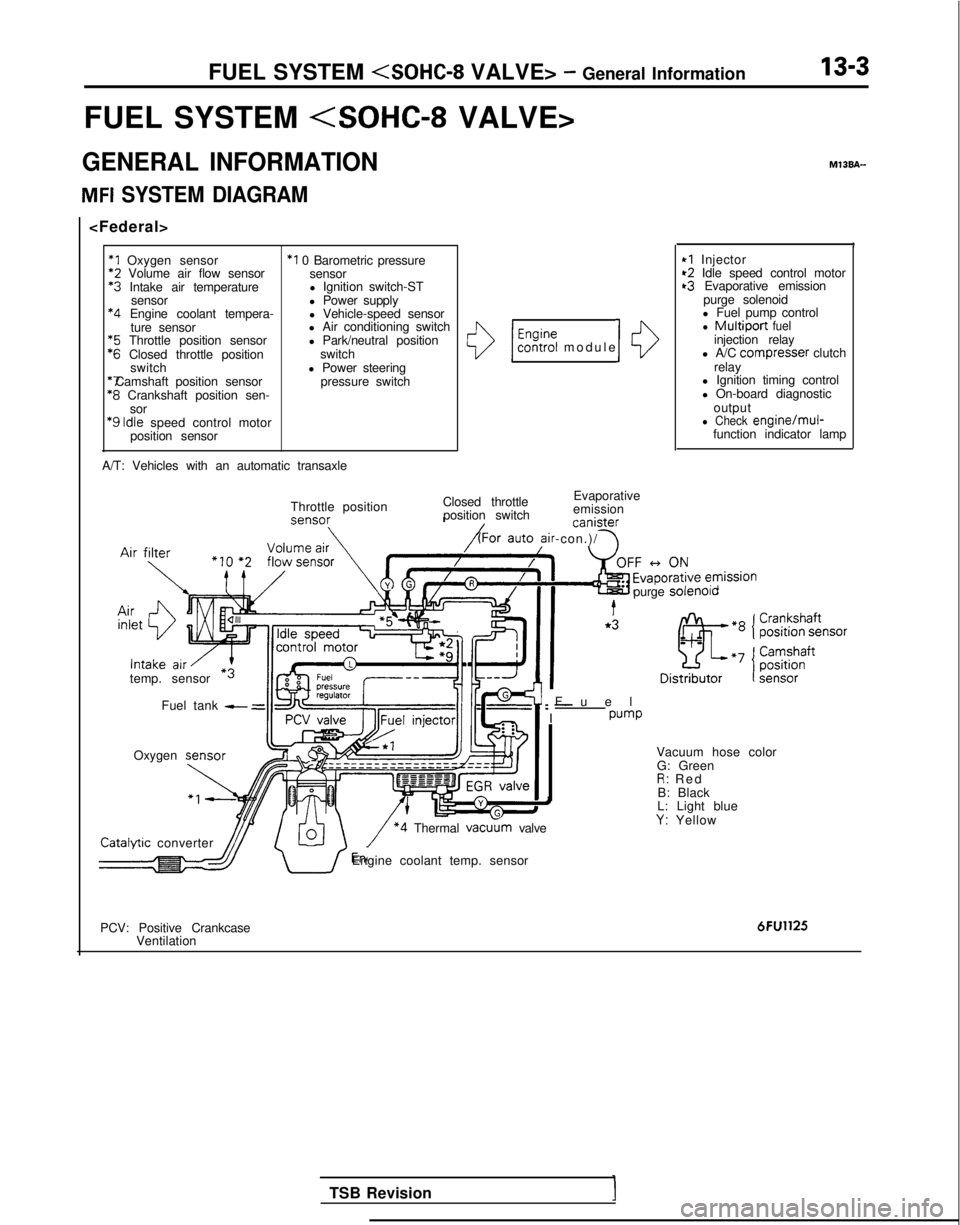

FUEL SYSTEM

FUEL SYSTEM

GENERAL INFORMATION

MFI SYSTEM DIAGRAM

*1 Oxygen sensor

*2

Volume air flow sensor *3

Intake air temperature

sensor *4

Engine coolant tempera-

ture sensor *5

Throttle position sensor *6

Closed throttle position

switch *7 Camshaft position sensor

*8

Crankshaft position sen-

sor

‘9 Idle

speed control motor

position sensor

*I 0 Barometric pressure sensor

l Ignition switch-ST

l Power supply

l Vehicle-speed sensor

l Air conditioning switch

l Park/neutral position

switch

l Power steering pressure switch

A/T: Vehicles with an automatic transaxle

()/ $%?i modul

e

Closed throttle Evaporative

position switch emission canister

ir-con.)/ \

10

Throttle position

temp. sensor Fuel tank

- =

Oxygen M13BA-

I

*I Injector~2 Idle speed control motort3 Evaporative emission

purge solenoid

l Fuel pump control

l Multiport fuelinjection relay

l A/C compresser clutch

relay

l Ignition timing control

l On-board diagnostic

output

l Check engine/mul-function indicator lamp

Fue

l

: -

I

pump

purge

solenolo Catalvtic

converter

\/ *4 Thermal vacu

G: Green

R: Re

d

B: Black

L: Light blue

Y: Yellow

dJJ/ U’Engine coolant temp. sensor

PCV: Positive Crankcase Ventilation

6FU1125

TSB Revision