sensor MITSUBISHI GALANT 1989 Service Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 146 of 1273

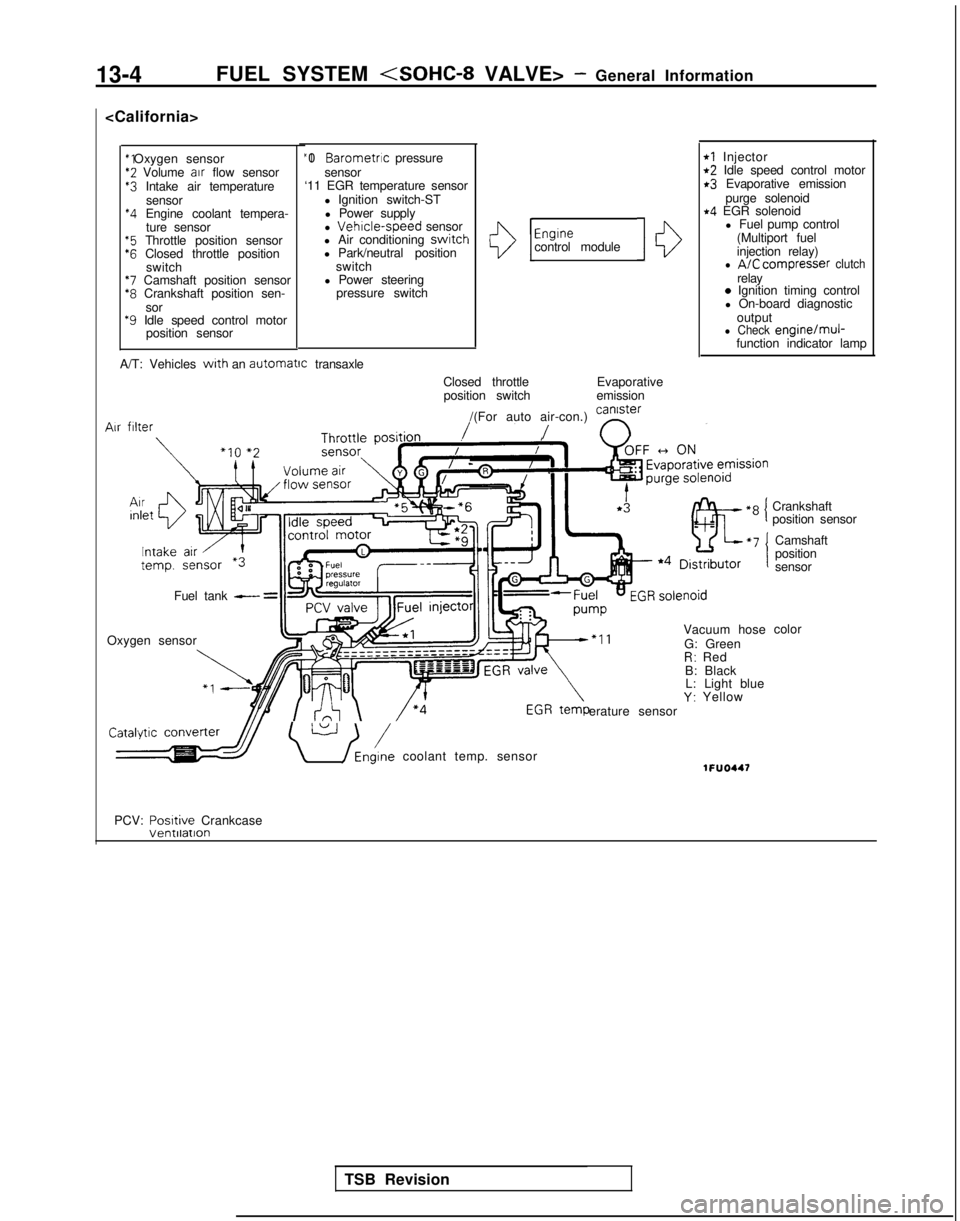

13-4FUEL SYSTEM

*2 Volume

air

flow sensor$3 Intake air temperature

sensor

*4 Engine coolant tempera-ture sensor

“5 Throttle position sensor‘6 Closed throttle position switch

*7 Camshaft position sensor*8 Crankshaft position sen-

sor

*9 Idle speed control motor position sensor “I 0

Barometric pressure

sensor

‘11 EGR temperature sensor

l Ignition switch-STl Power supply

l

Vehrcle-speed sensor

l Air conditioning switch

l Park/neutral position

switch

l Power steering pressure switchI13

Engrnecontrol module10

rl Injectort2 Idle speed control motorr3 Evaporative emission

purge solenoid

r4 EGR solenoidl Fuel pump control

(Multiport fuel

injection relay)

l A/C compresser clutchrelay0 Ignition timing control

l On-board diagnostic

output

l Check engine/muj-function indicator lamp

A/T: Vehicles

with an automatrc

transaxle

Closed throttleposition switch Evaporative

emission

/(For auto air-con.) can’ster

/ n

Vacuum hose

G: Green

R: Red

B: Black L: Light blue

Y: Yellow

erature sensor Air

filter

Fuel tank - =

Oxygen sensor

\ U /Eni coolant temp. sensor1FUO447

Crankshaft

position sensor

Camshaft

position

sensor

color

PCV: Posrtive

Crankcase

TSB Revision

Page 147 of 1273

FUEL SYSTEM

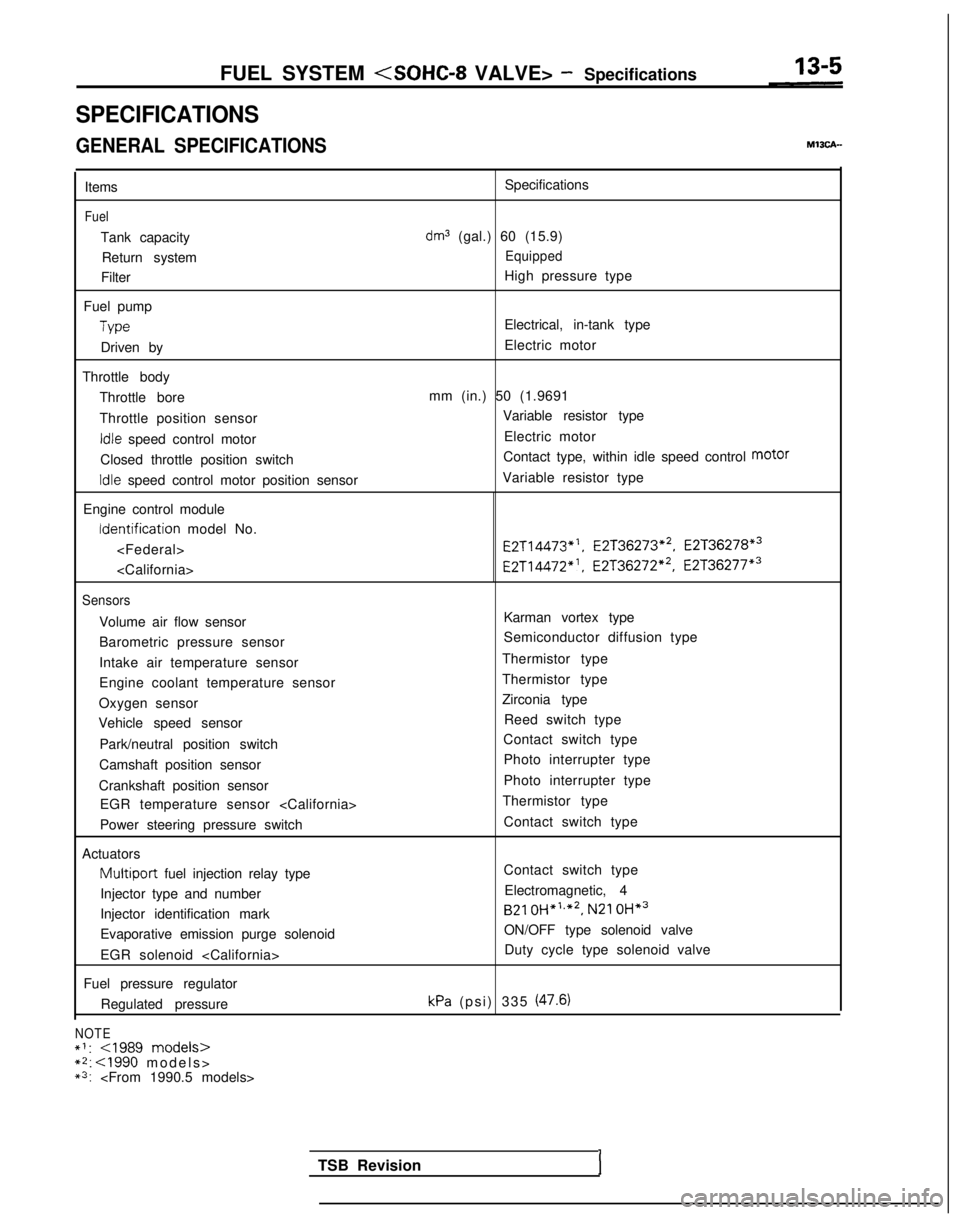

SPECIFICATIONS

GENERAL SPECIFICATIONS

Items

Fuel

Tank capacity

Return system

Filter

Fuel pump

Type

Driven by

Throttle body Throttle bore

Throttle position sensor

Idle speed control motor

Closed throttle position switch

Idle speed control motor position sensor

Engine control module Identification

model No.

Sensors

Volume air flow sensor

Barometric pressure sensor

Intake air temperature sensor

Engine coolant temperature sensor

Oxygen sensor

Vehicle speed sensor

Park/neutral position switch

Camshaft position sensor

Crankshaft position sensor EGR temperature sensor

Power steering pressure switch

Actuators

Multiport fuel injection relay type

Injector type and number

Injector identification mark

Evaporative emission purge solenoid

EGR solenoid

Fuel pressure regulator Regulated pressure

NOTE*I:

*3:

dm3 (gal.) 60 (15.9)

Equipped

High pressure type

Electrical, in-tank type

Electric motor

mm (in.) 50 (1.9691 Variable resistor type

Electric motor

Contact type, within idle speed control motor

Variable resistor type E2T14473*‘,

E2T36273*2, E2T36278*3

E2T14472”. E2T36272*2, E2T36277*3

Karman vortex type

Semiconductor diffusion type

Thermistor type

Thermistor type

Zirconia type Reed switch type

Contact switch type

Photo interrupter type

Photo interrupter type

Thermistor type

Contact switch type

Contact switch typeElectromagnetic, 4

B21 OH*‘,*2,

N21 OH*3

ON/OFF type solenoid valve

Duty cycle type solenoid valve

kPa (psi) 335 (47.6)

TSB RevisionI

Page 148 of 1273

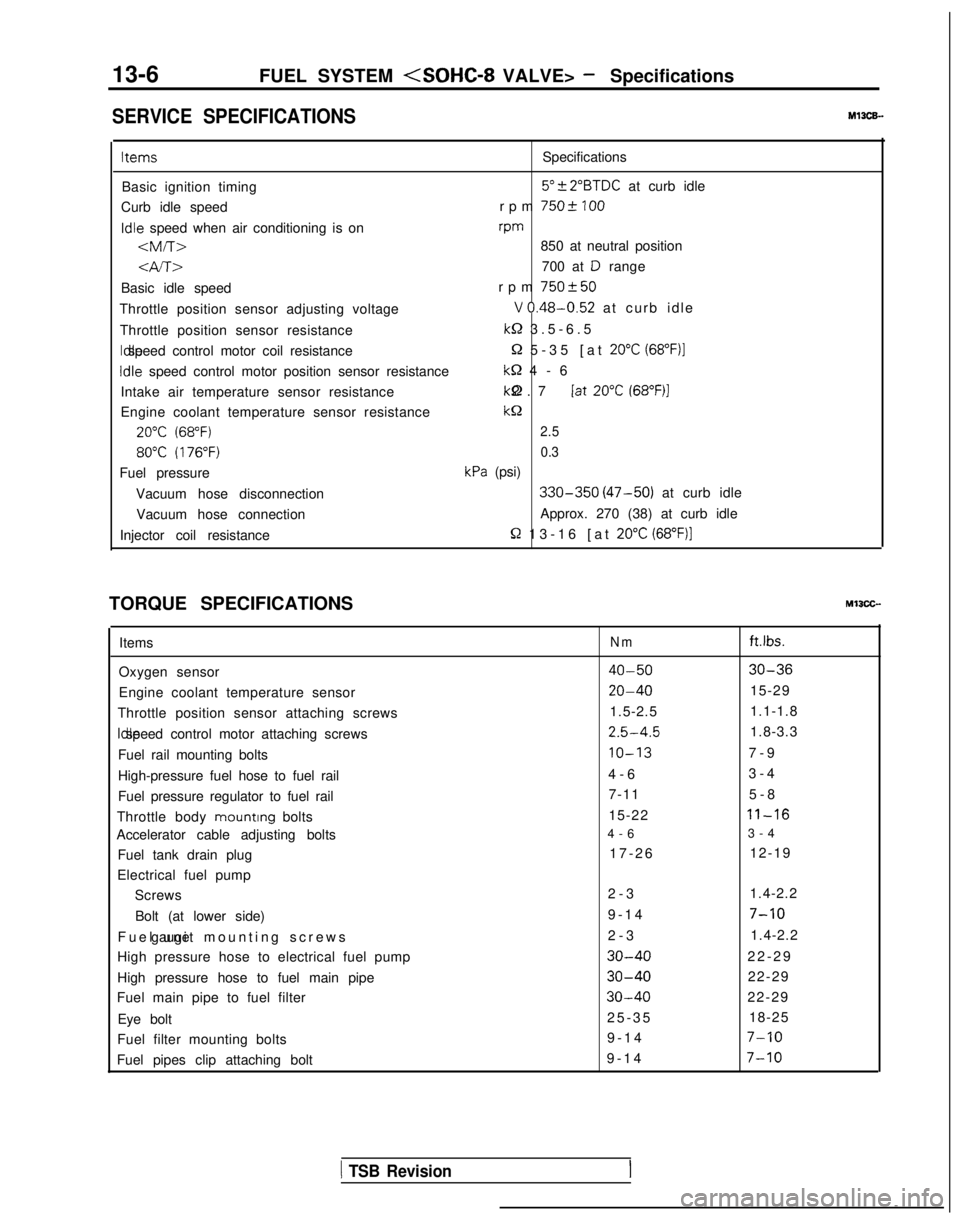

13-6

FUEL SYSTEM

SERVICE SPECIFICATIONSMl3CE.

ItemsSpecifications

Basic ignition timing

5”?2”BTDC at curb idle

Curb idle speed rpm

7502 100Idle

speed when air conditioning is on rpm

-am-r>850 at neutral position

4A>700 at D range

Basic idle speed rpm

750+50

Throttle position sensor adjusting voltageV 0.48-0.52 at curb idl

e

Throttle position sensor resistance

k-2 3.5-6.

5

Idle speed control motor coil resistance

Q 5-35 [at 20°C (68”F)l

Idle

speed control motor position sensor resistance

M-2 4-

6

Intake air temperature sensor resistance kQ 2.7 [at

20°C (68”F)l

Engine coolant temperature sensor resistancekc2

20°C (68°F)2.5

80°C (176°F)0.3

Fuel pressurekPa (psi)

Vacuum hose disconnection

330-350 (47-50) at curb idle

Vacuum hose connection Approx. 270 (38) at curb idle

Injector coil resistance

R 13-16 [at 20°C (68”F)]

TORQUE SPECIFICATIONSMIICC-

Items

Oxygen sensor

Engine coolant temperature sensor

Throttle position sensor attaching screws Idle speed control motor attaching screws

Fuel rail mounting bolts

High-pressure fuel hose to fuel rail

Fuel pressure regulator to fuel rail

Throttle body mounting

bolts

Accelerator cable adjusting bolts

Fuel tank drain plug

Electrical fuel pump Screws

Bolt (at lower side)

Fuel unit mounting screws gauge

High pressure hose to electrical fuel pump

High pressure hose to fuel main pipe

Fuel main pipe to fuel filter

Eye bolt

Fuel filter mounting bolts

Fuel pipes clip attaching boltNmft.lbs.

40-5030-36

20-4015-29

1.5-2.5 1.1-1.8

2.5-4.51.8-3.3

IO-137-

9

4-6 3-4

7-11 5-8

15-22

11-16

4-

6

3-4

17-26 12-19

2-3 1.4-2.2

9-14

7-10

2-

3

1.4-2.2

30-4022-2

9

30-4022-29

30-4022-29

25-3

5

18-25

9-14

7-10

9-1

4

7-10

1 TSB Revision

Page 149 of 1273

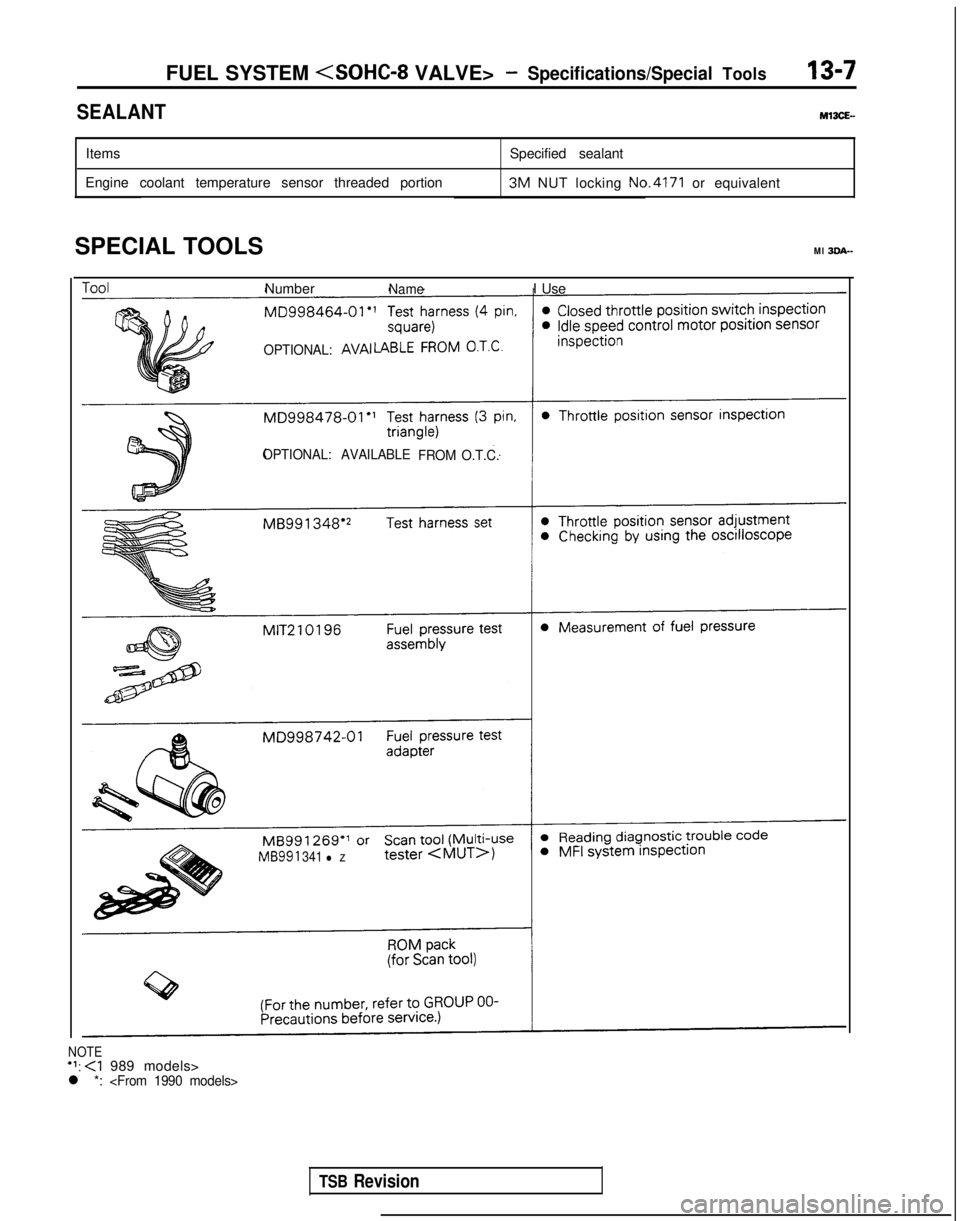

FUEL SYSTEM

SEALANTM13CE-

Items Specified sealant

Engine coolant temperature sensor threaded portion 3M

NUT locking

No.4171 or equivalent

SPECIAL TOOLS

Ml JDA-

Number

NameI Use

OPTIONAL: AVAI

OPTIONAL: AVAILABLE FROM O.T.C.

MB991 341 l z

NOTE

‘1: <1

989 models>l *:

TSB Revision

Page 150 of 1273

13-8

FUEL SYSTEM

TROUBLESHOOTING

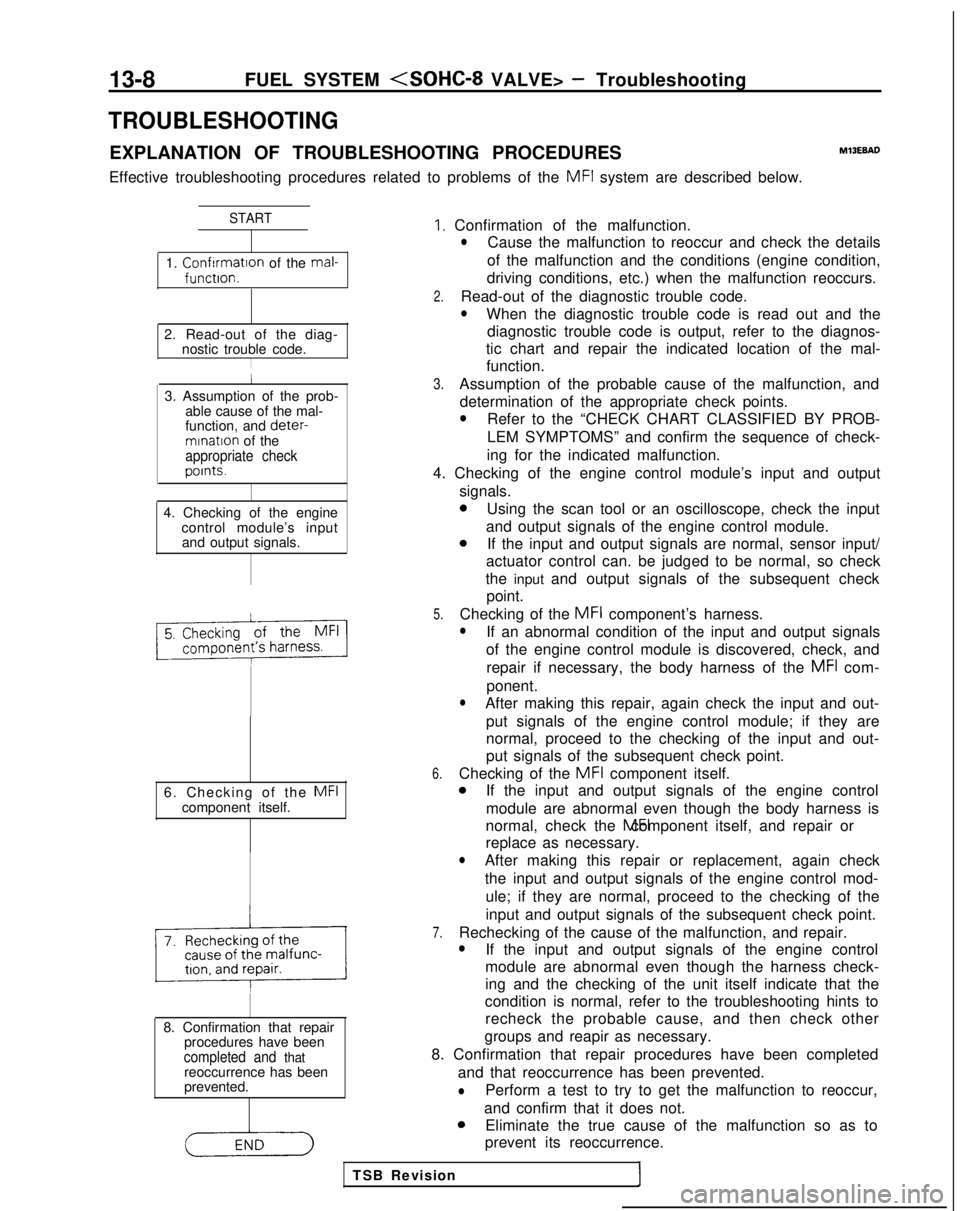

EXPLANATION OF TROUBLESHOOTING PROCEDURESMlBEBAD

Effective troubleshooting procedures related to problems of the MFI

system are described below.

START

1. Confrrmatron of the mal-functron.

2. Read-out of the diag-

nostic trouble code.

I

I

3. Assumption of the prob-

able cause of the mal-

function, and deter-

mrnatron of theappropriate checkpoints.

4. Checking of the engine

control module’s inputand output signals.

6. Checking of the

MFIcomponent itself.

8. Confirmation that repair procedures have been

completed and thatreoccurrence has been

prevented.

I. Confirmation of the malfunction.lCause the malfunction to reoccur and check the details

of the malfunction and the conditions (engine condition,

driving conditions, etc.) when the malfunction reoccurs.

2.Read-out of the diagnostic trouble code.

lWhen the diagnostic trouble code is read out and the diagnostic trouble code is output, refer to the diagnos-

tic chart and repair the indicated location of the mal- function.

3.Assumption of the probable cause of the malfunction, and

determination of the appropriate check points.

lRefer to the “CHECK CHART CLASSIFIED BY PROB-

LEM SYMPTOMS” and confirm the sequence of check-

ing for the indicated malfunction.

4. Checking of the engine control module’s input and output signals.

0Using the scan tool or an oscilloscope, check the input

and output signals of the engine control module.

aIf the input and output signals are normal, sensor input/

actuator control can. be judged to be normal, so check

the input and output signals of the subsequent check point.

5.Checking of the MFI

component’s harness.lIf an abnormal condition of the input and output signals

of the engine control module is discovered, check, and

repair if necessary, the body harness of the

MFI com-

ponent.

lAfter making this repair, again check the input and out- put signals of the engine control module; if they are

normal, proceed to the checking of the input and out-

put signals of the subsequent check point.

6.Checking of the MFI

component itself.aIf the input and output signals of the engine control

module are abnormal even though the body harness is

normal, check the MFI component itself, and repair or

replace as necessary.

lAfter making this repair or replacement, again check

the input and output signals of the engine control mod-

ule; if they are normal, proceed to the checking of the

input and output signals of the subsequent check point.

7.Rechecking of the cause of the malfunction, and repair.lIf the input and output signals of the engine control

module are abnormal even though the harness check-

ing and the checking of the unit itself indicate that the

condition is normal, refer to the troubleshooting hints to recheck the probable cause, and then check other

groups and reapir as necessary.

8. Confirmation that repair procedures have been completed and that reoccurrence has been prevented.

lPerform a test to try to get the malfunction to reoccur,

and confirm that it does not.

aEliminate the true cause of the malfunction so as to

prevent its reoccurrence.

TSB Revision

Page 152 of 1273

13-10

FUEL SYSTEM

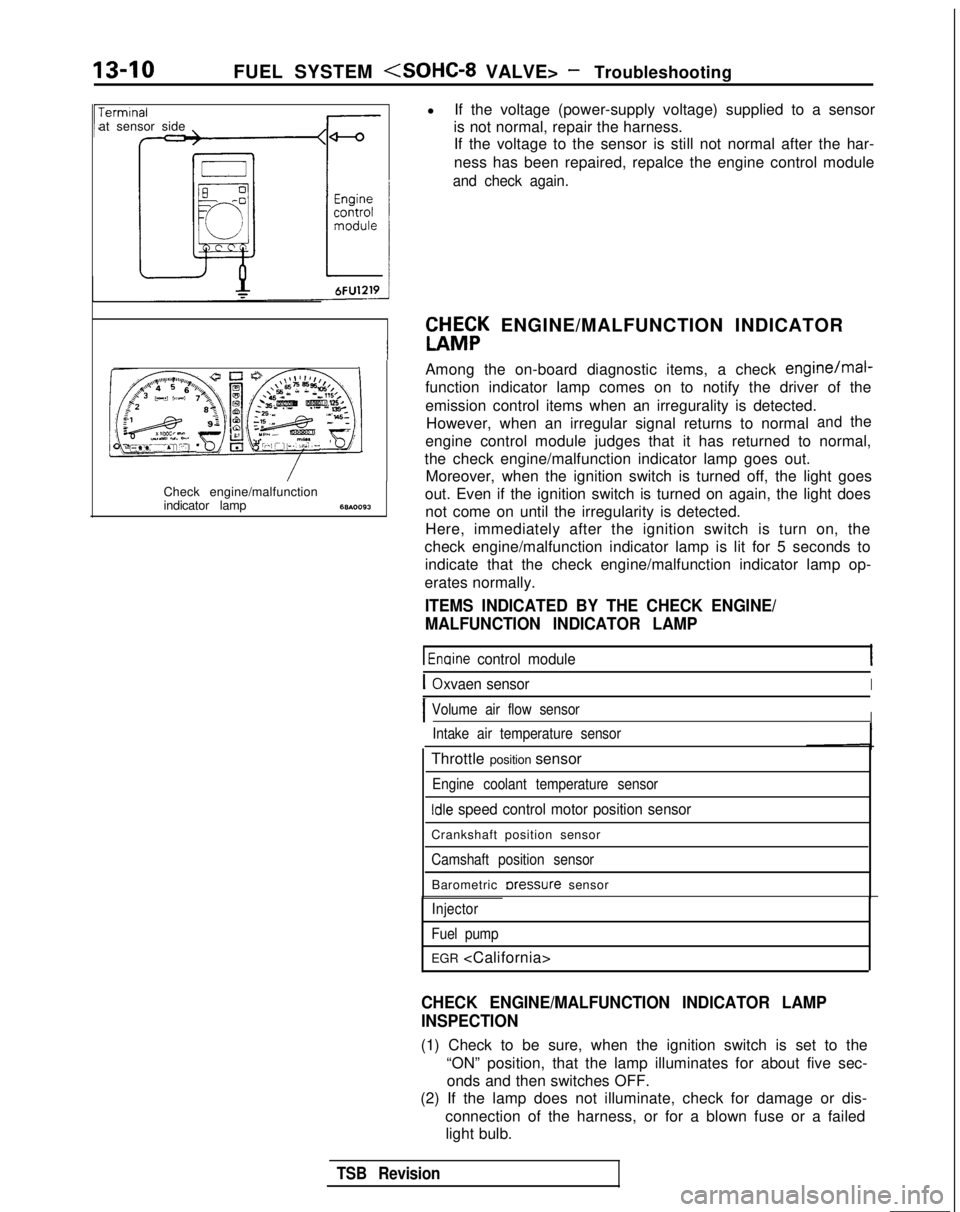

at sensor side

1\~“‘,““W,O,’ ‘\*N 4-cnDQ5a,, \llllf,,

c 3 c-11 ‘.<-!

( .[&

;%* \ g ~ &.$$~&%,;

0%: E

.Oj-,,

giI lOWI -,n

/ ~ ( ~~‘-~~~

-.mo .u. m,.0 - rj*> ;;

indicator lamp68AOO93

l

If the voltage (power-supply voltage) supplied to a sensor

is not normal, repair the harness. If the voltage to the sensor is still not normal after the har-

ness has been repaired, repalce the engine control module

and check again.

W&K ENGINE/MALFUNCTION INDICATOR

Among the on-board diagnostic items, a check

engine/mal-

function indicator lamp comes on to notify the driver of the

emission control items when an irregurality is detected. However, when an irregular signal returns to normal

andthe

engine control module judges that it has returned to normal,

the check engine/malfunction indicator lamp goes out. Moreover, when the ignition switch is turned off, the light goes

out. Even if the ignition switch is turned on again, the light does not come on until the irregularity is detected.

Here, immediately after the ignition switch is turn on, the

check engine/malfunction indicator lamp is lit for 5 seconds to indicate that the check engine/malfunction indicator lamp op-

erates normally.

ITEMS INDICATED BY THE CHECK ENGINE/

MALFUNCTION INDICATOR LAMP

1 Enaine control module

IOxvaen sensorI

IVolume air flow sensorIIntake air temperature sensor

Throttle position sensor

Engine coolant temperature sensor

Idle speed control motor position sensor

Crankshaft position sensor

Camshaft position sensor

Barometric rxessure sensor

Injector

Fuel pump

EGR

CHECK ENGINE/MALFUNCTION INDICATOR LAMP

INSPECTION

(1) Check to be sure, when the ignition switch is set to the “ON” position, that the lamp illuminates for about five sec-onds and then switches OFF.

(2) If the lamp does not illuminate, check for damage or dis-

connection of the harness, or for a blown fuse or a failedlight bulb.

TSB Revision

Page 153 of 1273

FUEL SYSTEM

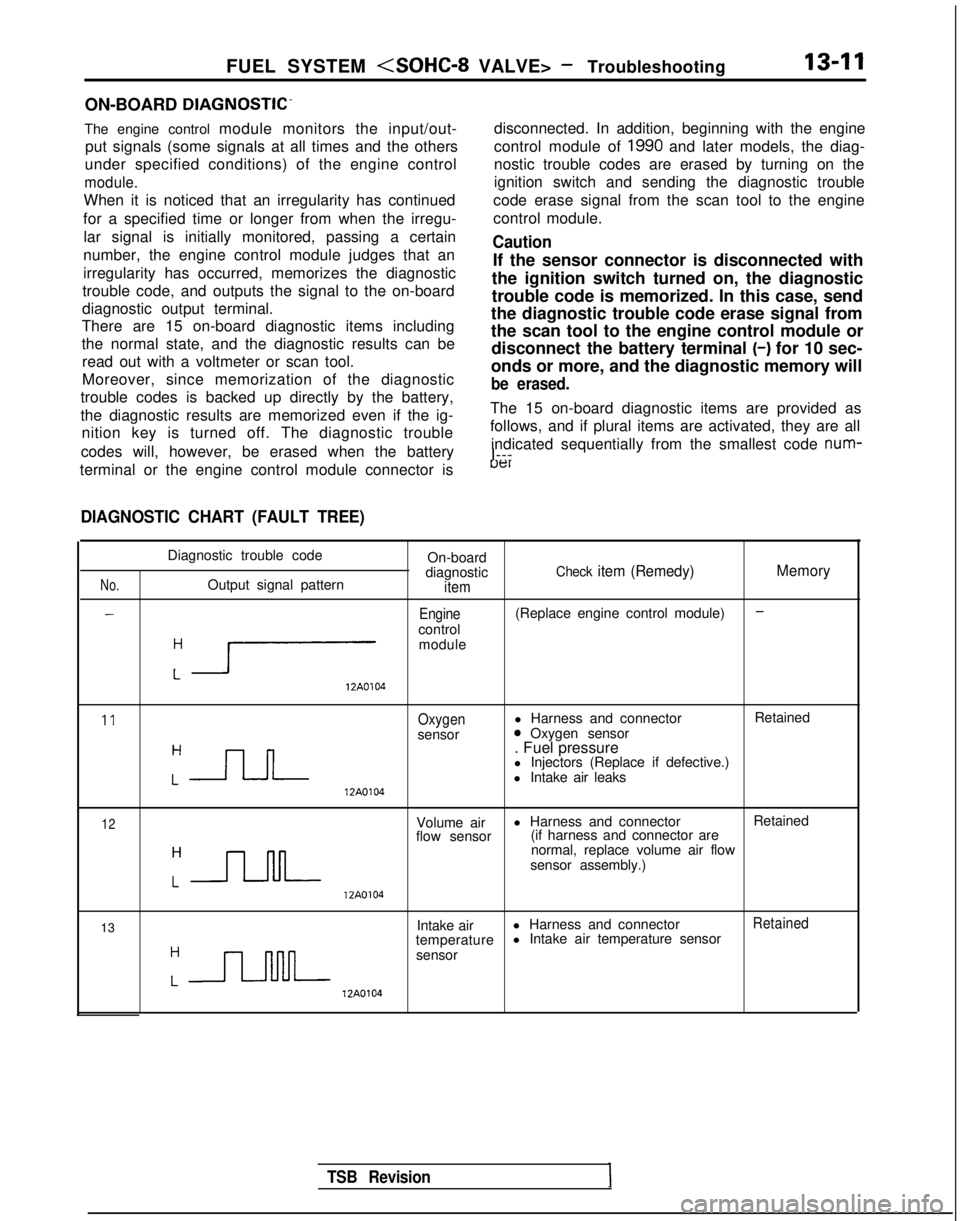

ON-BOARD DIAGNOSTIC-

The engine control module monitors the input/out-

put signals (some signals at all times and the others

under specified conditions) of the engine control

module.

When it is noticed that an irregularity has continued

for a specified time or longer from when the irregu- lar signal is initially monitored, passing a certain

number, the engine control module judges that an

irregularity has occurred, memorizes the diagnostic

trouble code, and outputs the signal to the on-board

diagnostic output terminal.

There are 15 on-board diagnostic items including

the normal state, and the diagnostic results can be

read out with a voltmeter or scan tool.

Moreover, since memorization of the diagnostic

trouble codes is backed up directly by the battery,

the diagnostic results are memorized even if the ig- nition key is turned off. The diagnostic trouble

codes will, however, be erased when the battery disconnected. In addition, beginning with the engine

control module of

1990 and later models, the diag-

nostic trouble codes are erased by turning on the

ignition switch and sending the diagnostic trouble

code erase signal from the scan tool to the engine

control module.

Caution

If the sensor connector is disconnected with

the ignition switch turned on, the diagnostic

trouble code is memorized. In this case, send

the diagnostic trouble code erase signal from

the scan tool to the engine control module or disconnect the battery terminal (-)

for 10 sec-

onds or more, and the diagnostic memory will

be erased.

The 15 on-board diagnostic items are provided as

follows, and if plural items are activated, they are all

indicated sequentially from the smallest code num-

I---

terminal or the engine control module connector is

uer

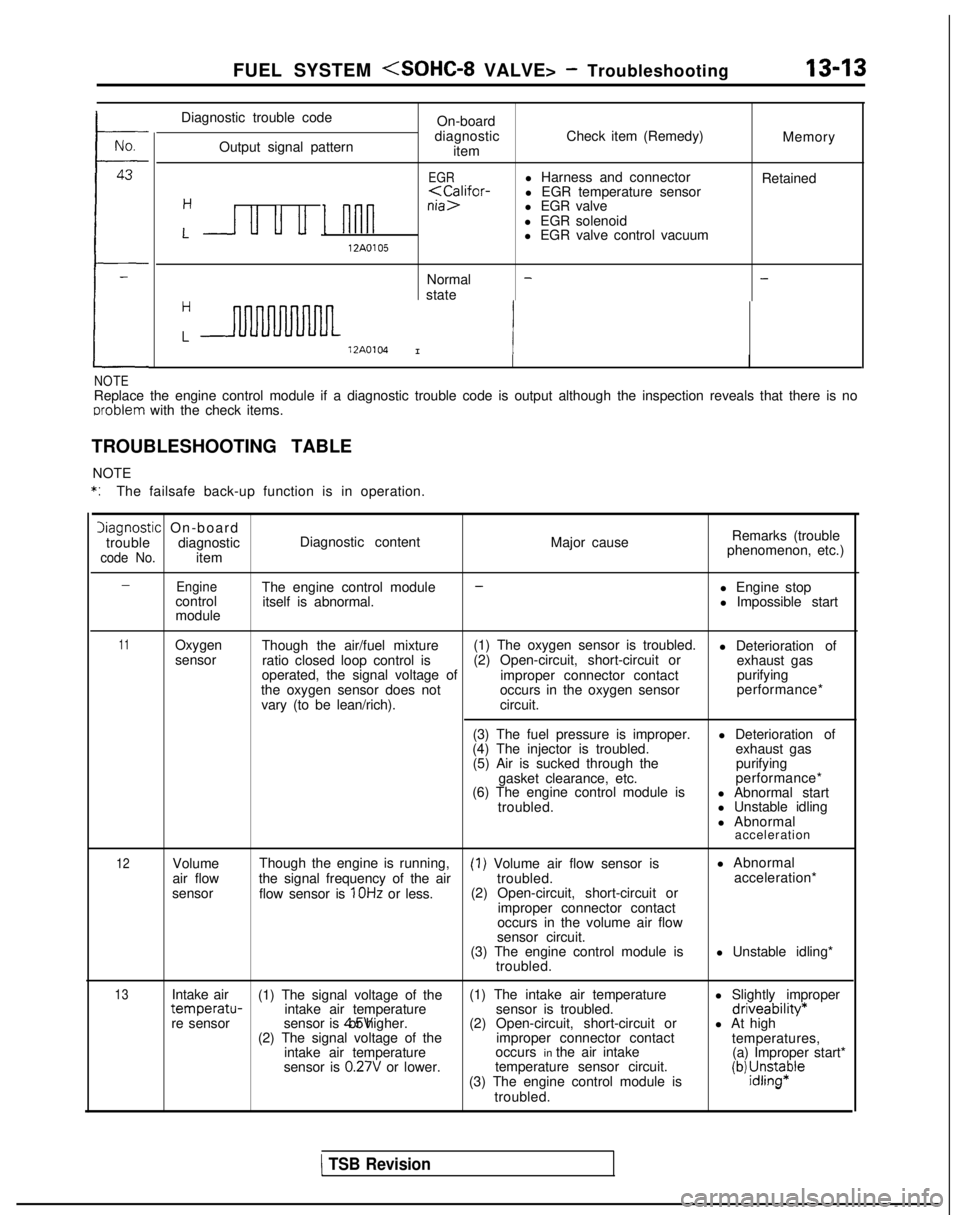

DIAGNOSTIC CHART (FAULT TREE)

No.

-

Diagnostic trouble code On-board

diagnostic

Check item (Remedy) MemoryOutput signal patternitem

-Engine(Replace engine control module)

control

:r

module 12A0104

11Oxygenl Harness and connector

Retained

sensor0 Oxygen sensor

:-JLJ--

. Fuel pressure

l Injectors (Replace if defective.)

l Intake air leaks 12A0104

12Volume air

l Harness and connector

Retained

flow sensor (if harness and connector are

:-JJ-M-

normal, replace volume air flow

sensor assembly.) 12A0104

13 Intake air

l Harness and connector

Retained

temperature l Intake air temperature sensor

:n

sensor 12A0104

TSB Revision

Page 154 of 1273

13-12

FUEL SYSTEM

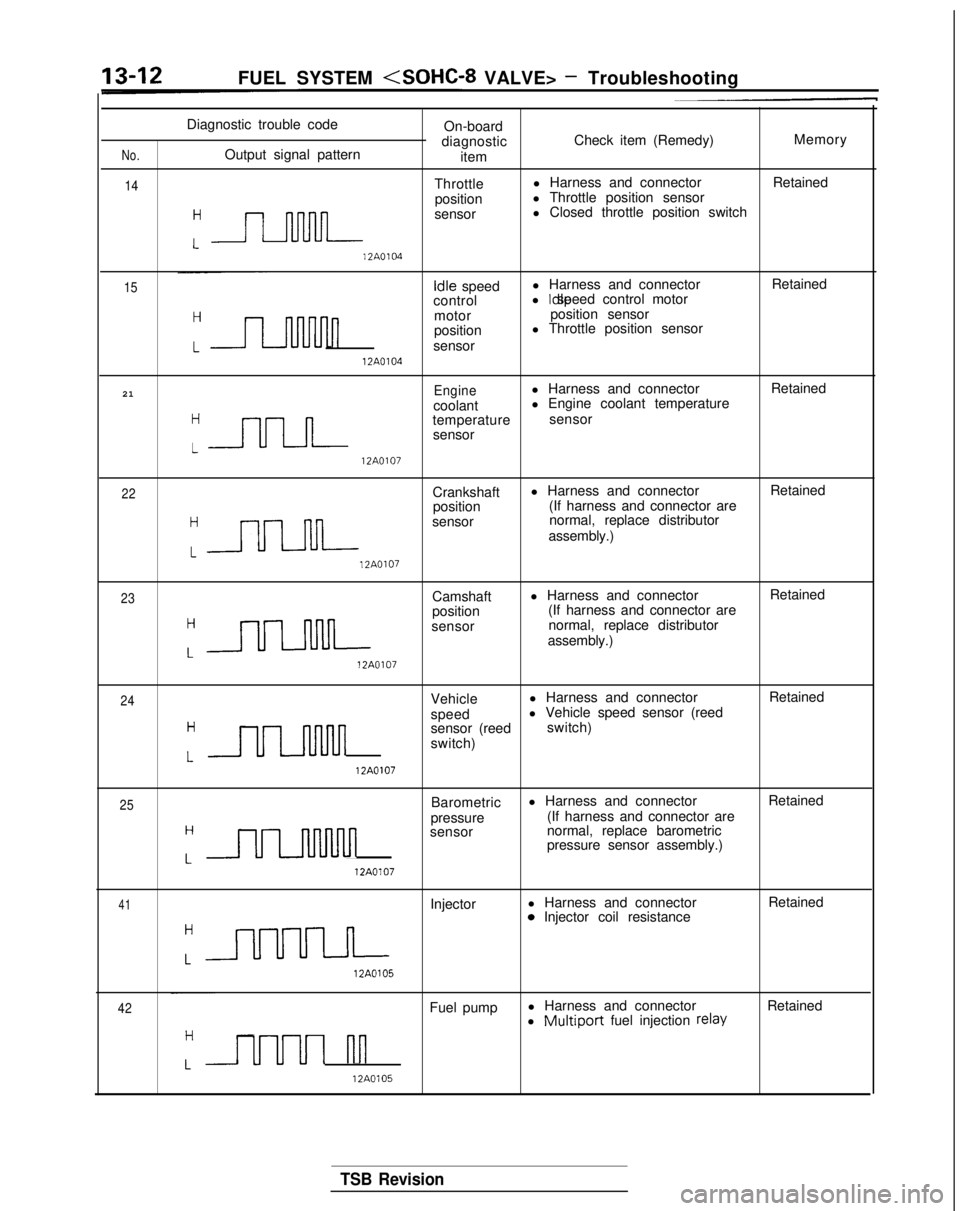

No.

14

Diagnostic trouble code

On-board

diagnostic Check item (Remedy)

Memory

Output signal pattern item

Throttle l Harness and connector

Retained

position l Throttle position sensor

:-

sensor l Closed throttle position switch 12A0104

15

Idle

speed l Harness and connector

Retained

control l Idle speed control motor

n

motor

position sensor

position l Throttle position sensor

sensor 12A0104

21

Enginel Harness and connector Retained

coolant l Engine coolant temperature

“=

temperature

sensor

sensor 12A0107

22Crankshaft

l Harness and connector

Retained

position (If harness and connector are

:-

sensor normal, replace distributor

assembly.) 12A0107

23Camshaft

l Harness and connector

Retained

position (If harness and connector are

:=

sensor normal, replace distributor

assembly.) 12A0107

24Vehicle

l Harness and connector

Retained

speed l Vehicle speed sensor (reed

H

uulnnn

sensor (reed

switch)

switch)

L 12A0107

25Barometric

l Harness and connector

Retained

pressure (If harness and connector are

H

ULnMnn

sensor

normal, replace barometric

pressure sensor assembly.)

L 12A0107

41Injector

l Harness and connector

Retained0 Injector coil resistance

:a 12A0105

42Fuel pump

l Harness and connector

Retained

l Multiport fuel injection relay

Luuul nn

12A0105

TSB Revision

Page 155 of 1273

FUEL SYSTEM

No.

43

4

-

Diagnostic trouble code

Output signal pattern On-board

diagnostic item Check item (Remedy)

Memory

EGRl Harness and connector

Retained

l EGR solenoid

L u u u I nnnl EGR valve control vacuum12A0105

Normal -state

-

H

L12A0104I 1

NOTEReplace the engine control module if a diagnostic trouble code is output\

although the inspection reveals that there is no

oroblem

with the check items.

TROUBLESHOOTING TABLE NOTE

*:The failsafe back-up function is in operation.

Diagnostic On-board

trouble diagnostic Diagnostic content

code No.item Major cause

Remarks (trouble

phenomenon, etc.)

-EngineThe engine control module-l Engine stop

control itself is abnormal. l Impossible start

module

11Oxygen Though the air/fuel mixture (1) The oxygen sensor is troubled.

l Deterioration of

sensor ratio closed loop control is (2) Open-circuit, short-circuit or

exhaust gas

operated, the signal voltage of improper connector contactpurifying

the oxygen sensor does not occurs in the oxygen sensorperformance*

vary (to be lean/rich). circuit.

(3) The fuel pressure is improper. l Deterioration of

(4) The injector is troubled. exhaust gas

(5) Air is sucked through the purifying

gasket clearance, etc. performance*

(6) The engine control module is l Abnormal start

troubled. l Unstable idling

l Abnormal

acceleration

12Volume

air flow

sensor Though the engine is running,(I) Volume air flow sensor is

l Abnormal

the signal frequency of the air troubled.acceleration*

flow sensor is

1 OHz or less. (2) Open-circuit, short-circuit or

improper connector contact

occurs in the volume air flow

sensor circuit.

(3) The engine control module is l Unstable idling*

troubled.

13Intake air (1) The signal voltage of the (1) The intake air temperature

l Slightly impropertemperatu-intake air temperaturesensor is troubled.driveability*re sensorsensor is 4.5V or higher.

(2) Open-circuit, short-circuit or l At high

(2) The signal voltage of the improper connector contact

temperatures,

intake air temperature occurs in the air intake

(a) Improper start*

sensor is

0.27V or lower. temperature sensor circuit.

(3) The engine control module is(b) ;J;pe

troubled.

1 TSB Revision

Page 156 of 1273

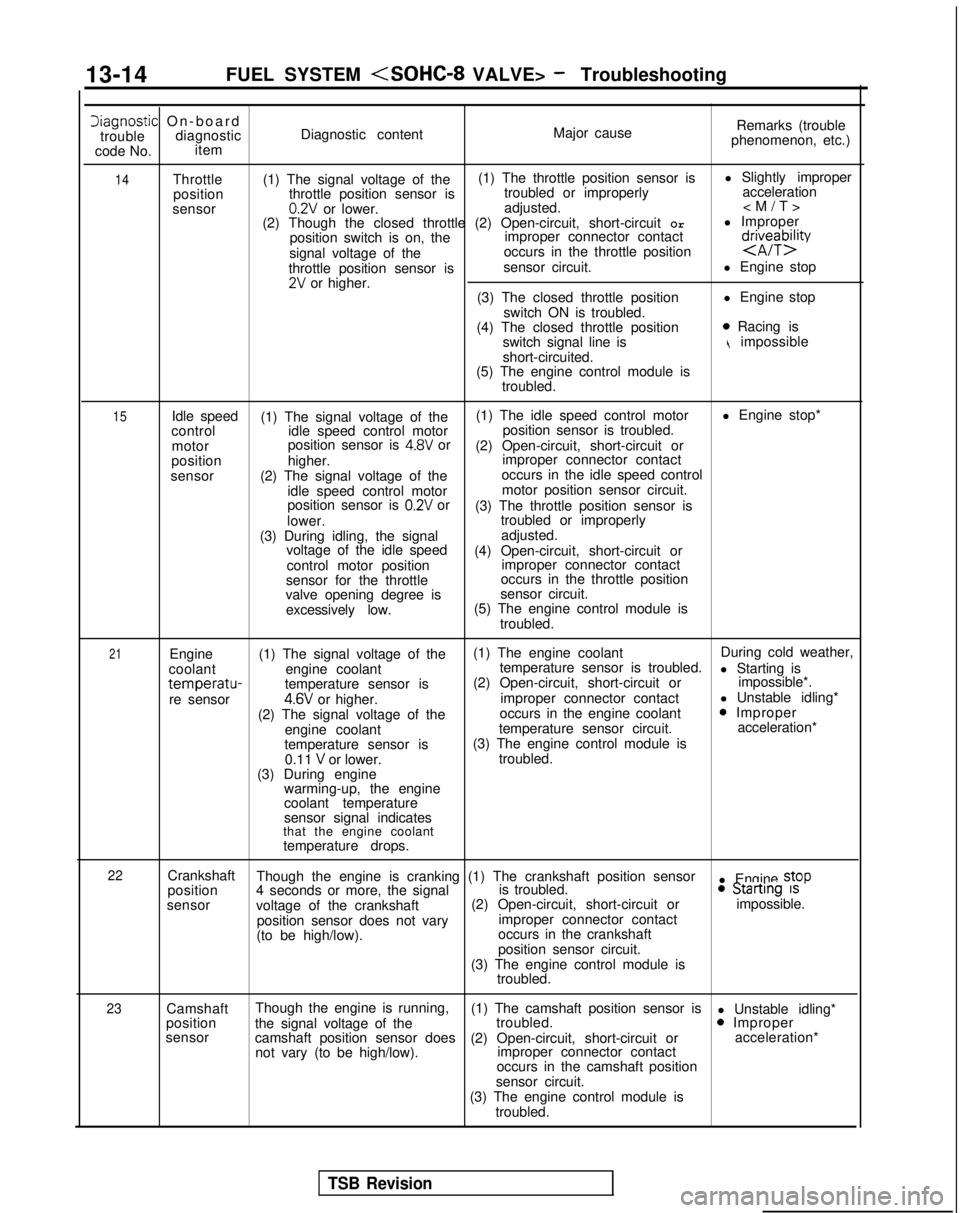

13-14

FUEL SYSTEM

Iiagnostic On-boar

d

trouble diagnostic Diagnostic content Major causeRemarks (trouble

phenomenon, etc.)

code No. item

14Throttle

(1) The signal voltage of the (1) The throttle position sensor is

l Slightly improper

position throttle position sensor is troubled or improperly

acceleration

sensor

0.2V or lower. adjusted.

(2) Though the closed throttle (2) Open-circuit, short-circuit Orl Improper

position switch is on, the improper connector contact

signal voltage of the occurs in the throttle position

d$eybzty

throttle position sensor is

sensor circuit.

l Engine stop2V or higher.

(3) The closed throttle position l Engine stop

switch ON is troubled.

(4) The closed throttle position

0 Racing is

switch signal line ist impossible

short-circuited.

(5) The engine control module is

troubled.

15Idle speed (1) The signal voltage of the (1) The idle speed control motor

l Engine stop*

control idle speed control motor position sensor is troubled.

motor position sensor is

4.8V or

(2) Open-circuit, short-circuit or

position higher. improper connector contact

sensor (2) The signal voltage of the occurs in the idle speed control

idle speed control motor motor position sensor circuit.

position sensor is

0.2V or (3) The throttle position sensor is

lower. troubled or improperly

(3) During idling, the signal adjusted.

voltage of the idle speed (4) Open-circuit, short-circuit or

control motor position improper connector contact

sensor for the throttle occurs in the throttle position

valve opening degree is sensor circuit.

excessively low. (5) The engine control module is

troubled.

21Engine (1) The signal voltage of the (1) The engine coolant

During cold weather,

coolant engine coolant temperature sensor is troubled.

l Starting is

temperatu-temperature sensor is(2) Open-circuit, short-circuit or

impossible*.

re sensor4.6V or higher. improper connector contact

l Unstable idling*

(2) The signal voltage of the occurs in the engine coolant0 Improper

engine coolant temperature sensor circuit. acceleration*

temperature sensor is (3) The engine control module is

0.11

V or lower. troubled.

(3) During engine warming-up, the engine

coolant temperature

sensor signal indicates

that the engine coolant

temperature drops.

22Crankshaft Though the engine is cranking (1) The crankshaft position sensor

l Engine stop

position 4 seconds or more, the signal is troubled.0 Startrng 1s

sensor

voltage of the crankshaft (2) Open-circuit, short-circuit or

impossible.

position sensor does not vary improper connector contact

(to be high/low). occurs in the crankshaft

position sensor circuit.

(3) The engine control module is troubled.

23Camshaft Though the engine is running,

(1) The camshaft position sensor is

l Unstable idling*

position the signal voltage of the troubled.0 Improper

sensor camshaft position sensor does (2) Open-circuit, short-circuit or acceleration*

not vary (to be high/low). improper connector contact

occurs in the camshaft position

sensor circuit.

(3) The engine control module is troubled.

TSB Revision