sensor MITSUBISHI GALANT 1989 Service Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 157 of 1273

FUEL SYSTEM

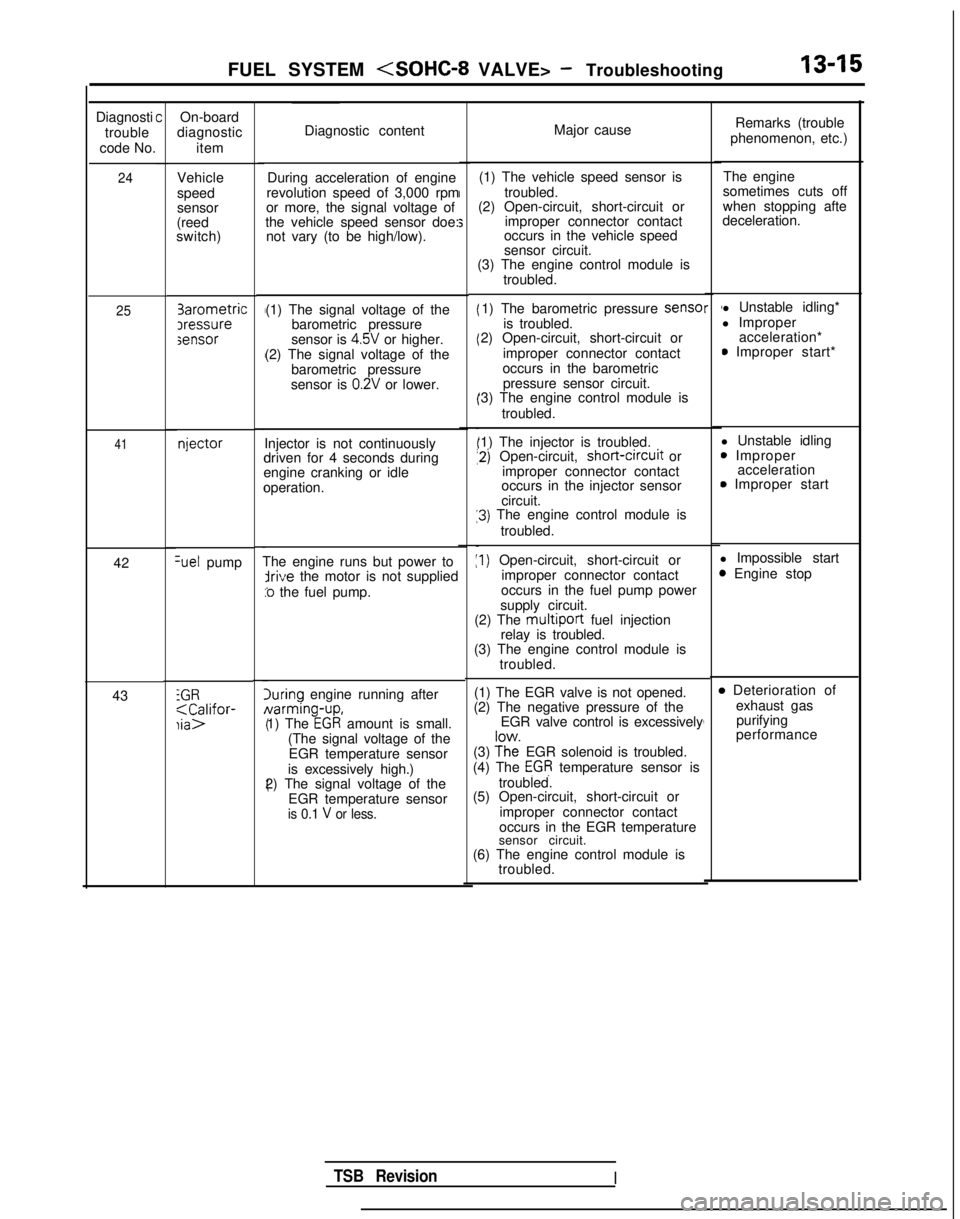

Diagnosti

trouble

code No.

24

25

41

42Set pump

43

iGR;aC;lifor-

COn-board

diagnostic

item

Vehicle

speed

sensor

(reed

switch) 3arometric

Iressuresensor

njector

Diagnostic content

Major cause

During acceleration of engine

revolution speed of 3,000 rpm

or more, the signal voltage of

the vehicle speed sensor doe: not vary (to be high/low). (1) The vehicle speed sensor is

troubled.

(2) Open-circuit, short-circuit or

improper connector contact

occurs in the vehicle speed

sensor circuit.

(1) The signal voltage of the barometric pressure

sensor is 4.5V or higher.

(2) The signal voltage of the barometric pressure

sensor is

0.2V or lower.

Injector is not continuously

driven for 4 seconds during

engine cranking or idle

operation.

The engine runs but power to

irive the motor is not supplied

:o the fuel pump.

luring engine running after Narming-up,

1) The

EGR amount is small.

(The signal voltage of the EGR temperature sensor

is excessively high.)

2) The signal voltage of the

EGR temperature sensor

is 0.1 V or less.

(3) The engine control module is troubled.

1) The barometric pressure sense

is troubled.

2) Open-circuit, short-circuit or

improper connector contact

occurs in the barometric pressure sensor circuit.

‘3) The engine control module is

troubled.

‘1) The injector is troubled.

12) Open-circuit, short-crrcuit

or

improper connector contact

occurs in the injector sensor

circuit.

13) The engine control module is

troubled.

:I) Open-circuit, short-circuit or improper connector contact

occurs in the fuel pump power

supply circuit.

(2) The

multiport fuel injection

relay is troubled.

(3) The engine control module is

troubled.

(1) The EGR valve is not opened.

(2) The negative pressure of the EGR valve control is excessively

(3)

?h”e EGR solenoid is troubled.

(4) The EGR temperature sensor is

troubled.

(5) Open-circuit, short-circuit or

improper connector contact

occurs in the EGR temperature

sensor circuit.

(6) The engine control module is troubled.

r 1l Unstable idling*

l Improper acceleration*

0 Improper start*

l Unstable idling

0 Improper acceleration

0 Improper start

l Impossible start

3 Engine stop4

4

,

B Deterioration of exhaust gaspurifying

performance

Remarks (trouble

phenomenon, etc.)

The engine

sometimes cuts off

when stopping afte

deceleration.

TSB RevisionI

Page 158 of 1273

13-16

FUEL SYSTEM

FAILSAFE/BACK-UP FUNCTIONS LIST

If trouble with any major sensor is detected by the on-board diagnostic,\

the vehicle will be kept in the safe

driving conditions according to the preset control logic.

Trouble item Control content for trouble

Volume air flow Fuel injection timing and ignition timing are determined according to th\

e throttle position

sensor sensor

(TPS) and engine revolution speed signal (crankshaft position sensor signal)\

.

Intake air temperature The control is executed with the suction air temperature regarded as

25°C (77°F).

sensor

Throttle position The fuel injection rate is not increased for acceleration according to t\

he throttle position

sensor

(TPS)sensor signal.

Idle speed control After the idle speed control motor plunger is driven and contracted, the\

idle revolution speed

motor position sensor is not controlled.

Engine coolant The control is executed with the engine coolant temperature regarded as \

8OO.C (176°F).temperature sensor (Even if the sensor signal becomes normal again, the control is continued

until the ignltlon

switch is turned off.)

Camshaft position Simultaneous injection of fuel is executed for all cylinders. (In this \

case, the

No.1 cylinder top

sensor dead center is not detected at all after the ignition key is turned on.)\

Barometric pressure The control is executed with the pressure regarded as 760 mmHg

(30

in.Hg).

sensor

Oxygen sensor Closed loop control of the air/fuel mixture ratio is not executed.

i

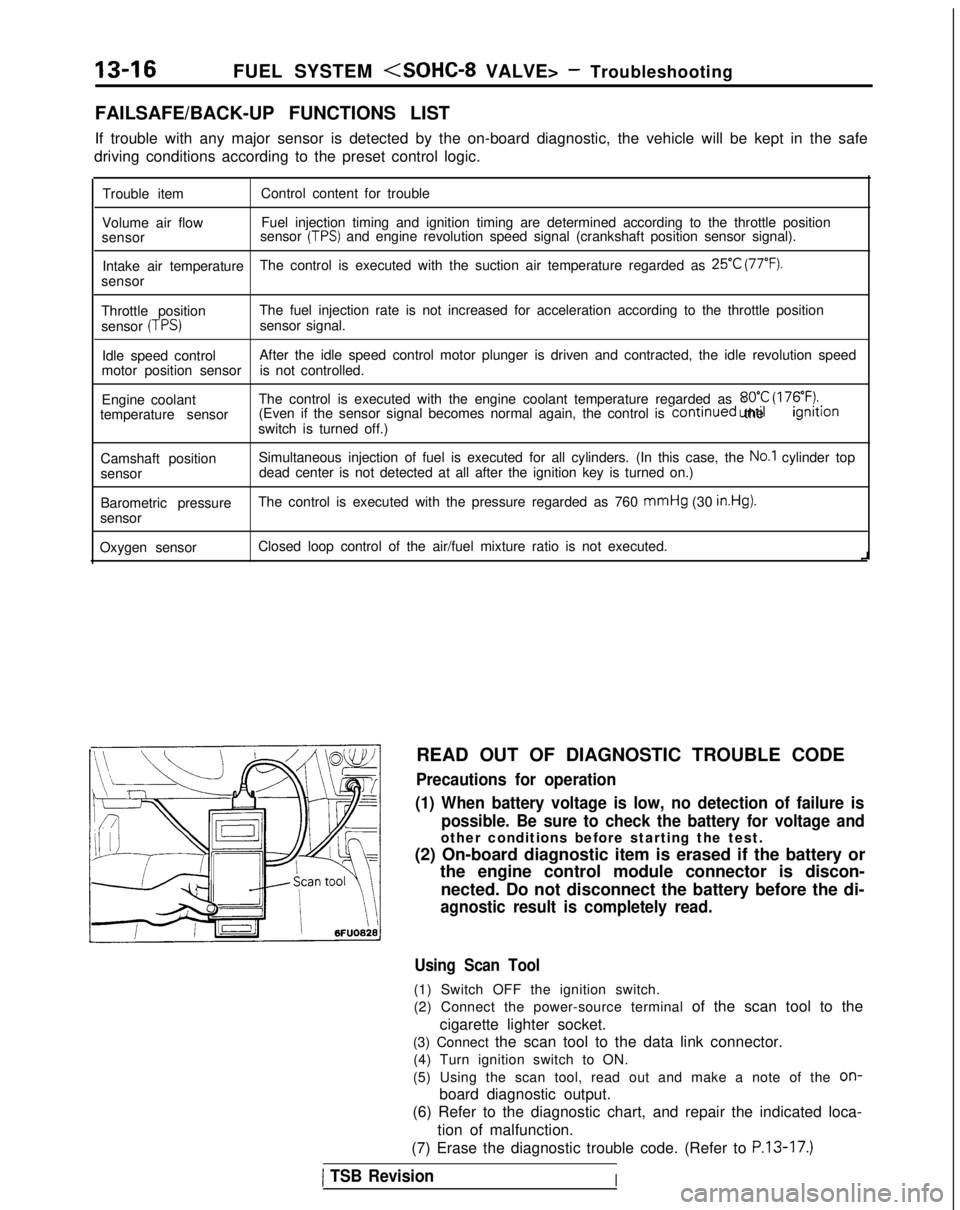

READ OUT OF DIAGNOSTIC TROUBLE CODE

Precautions for operation

(1) When battery voltage is low, no detection of failure is possible. Be sure to check the battery for voltage and

other conditions before starting the test.

(2) On-board diagnostic item is erased if the battery or the engine control module connector is discon-

nected. Do not disconnect the battery before the di-

agnostic result is completely read.

Using Scan Tool

(1) Switch OFF the ignition switch.

(2) Connect the power-source terminal of the scan tool to the

cigarette lighter socket.

(3) Connect the scan tool to the data link connector. (4) Turn ignition switch to ON.

(5) Using the scan tool, read out and make a note of the

on-

board diagnostic output.

(6) Refer to the diagnostic chart, and repair the indicated loca-

tion of malfunction.

(7) Erase the diagnostic trouble code. (Refer to

P.13-17.)

1 TSB RevisionI

Page 159 of 1273

FUEL SYSTEM

\ I\-\\\\\\6FUO807

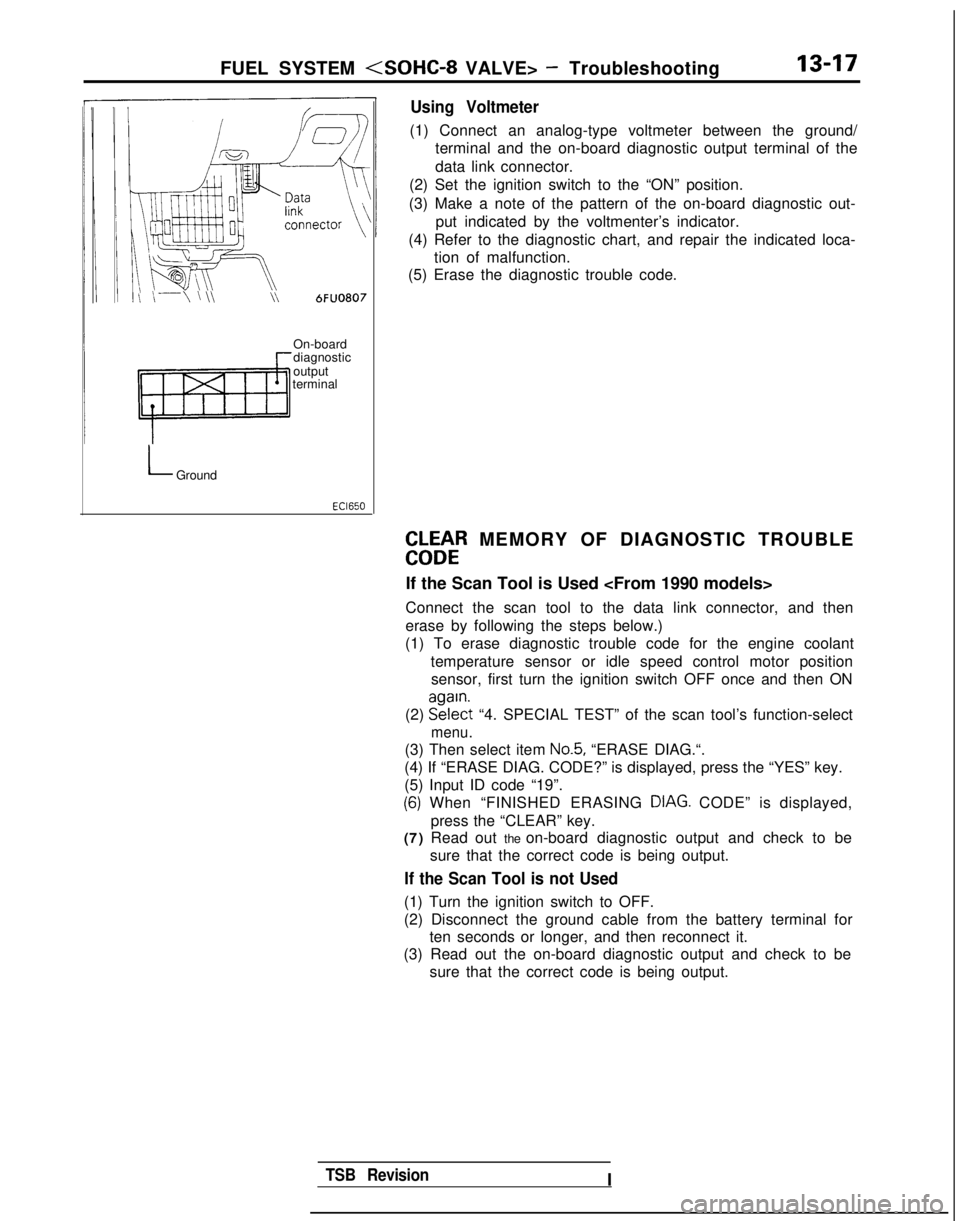

Using Voltmeter

(1) Connect an analog-type voltmeter between the ground/

terminal and the on-board diagnostic output terminal of the

data link connector.

(2) Set the ignition switch to the “ON” position.

(3) Make a note of the pattern of the on-board diagnostic out- put indicated by the voltmenter’s indicator.

(4) Refer to the diagnostic chart, and repair the indicated loca- tion of malfunction.

(5) Erase the diagnostic trouble code.

On-board

diagnostic

output

terminal

LGround

EbLbtR MEMORY OF DIAGNOSTIC TROUBLE

If the Scan Tool is Used

Connect the scan tool to the data link connector, and then

erase by following the steps below.)

(1) To erase diagnostic trouble code for the engine coolant

temperature sensor or idle speed control motor positionsensor, first turn the ignition switch OFF once and then ON

(2) EE?$t

“4. SPECIAL TEST” of the scan tool’s function-select

menu.

(3) Then select item No.5, “ERASE DIAG.“.

(4) If “ERASE DIAG. CODE?” is displayed, press the “YES” k\

ey.

(5) Input ID code “19”.

(6) When “FINISHED ERASING DIAG. CODE” is displayed,> Ipress the “CLEAR” key.

(7) Read out the on-board diagnostic output and check to be

sure that the correct code is being output.

If the Scan Tool is not Used

(1) Turn the ignition switch to OFF.

(2) Disconnect the ground cable from the battery terminal forten seconds or longer, and then reconnect it.

(3) Read out the on-board diagnostic output and check to be

sure that the correct code is being output.

TSB RevisionI

Page 164 of 1273

13-22

FUEL SYSTEM

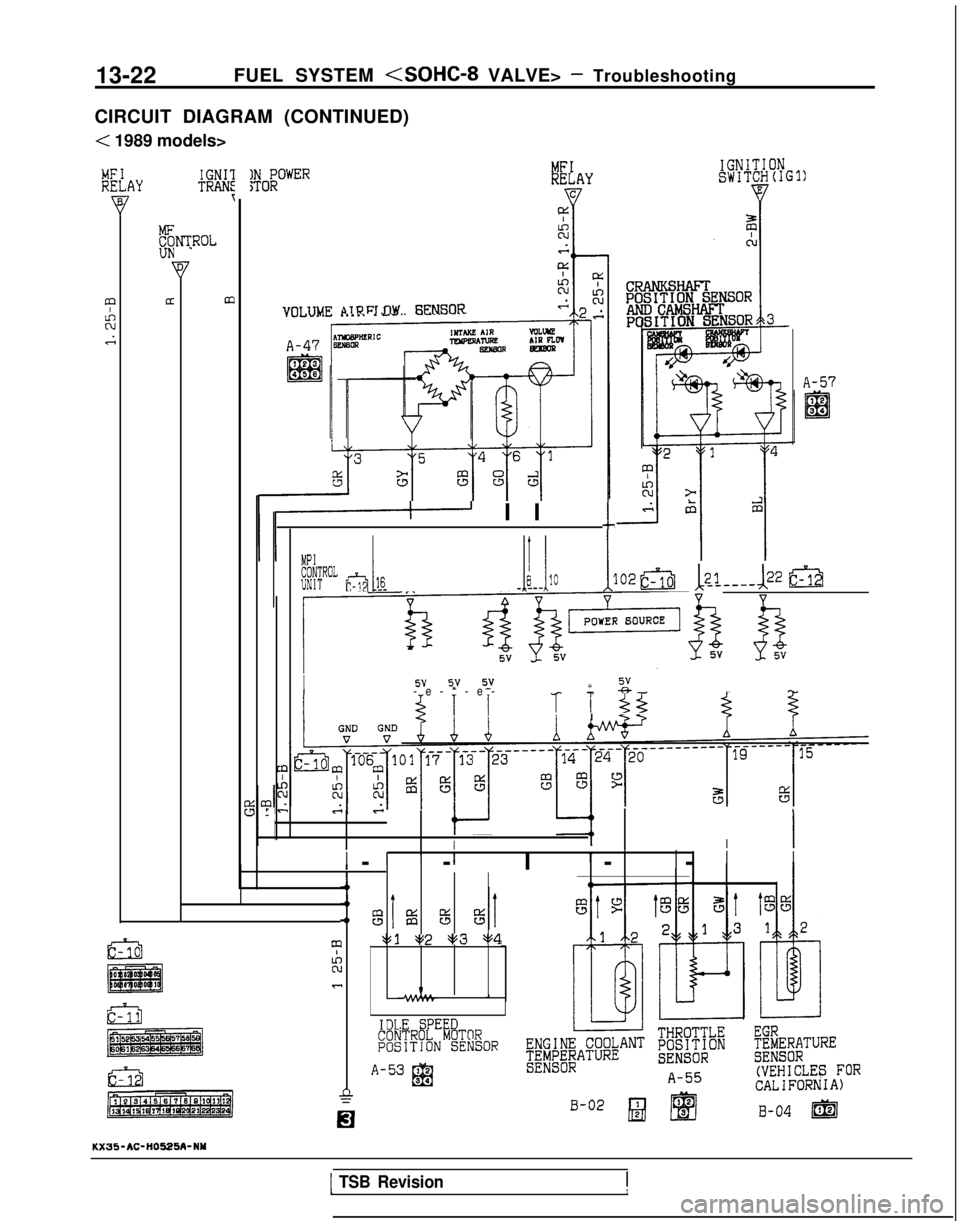

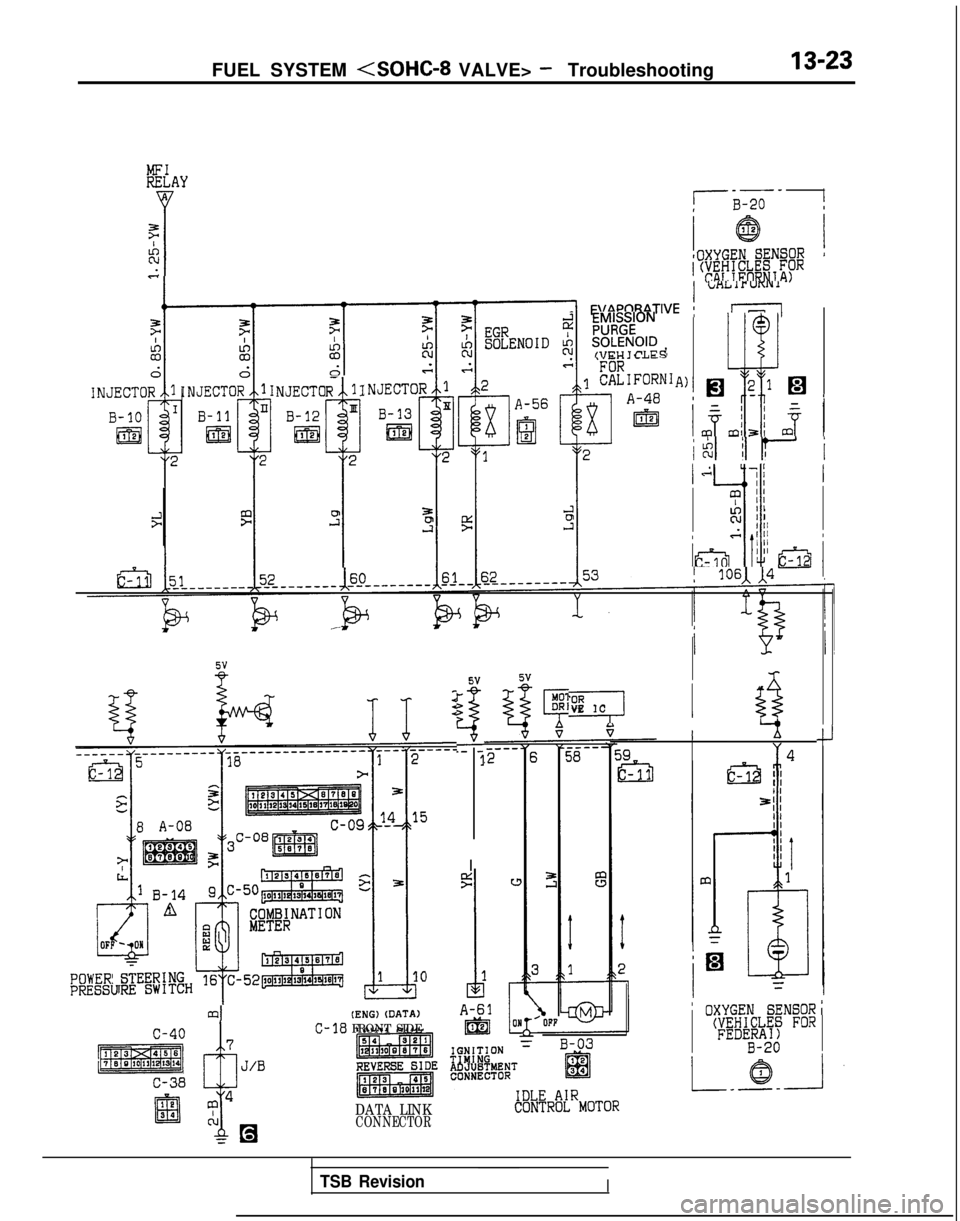

CIRCUIT DIAGRAM (CONTINUED)

< 1989 models>

IGNITIONSWITCHlIGl)#OF?OWERMFIRELAYIGNIlTRANf

;ROLKUN1

am\lR Fl.tlW i=XNSOR

A-57

II Il-

EF g?JEi _______ JLllOI:02&j12_1---& im

Y-+-I

k$$

Yh

I5VI I 5Y

syv s_v-e-*-e

-

“,

*-r

-5. IIII 5.5

c

L

III I

III1II --I-

-

I

II,---

1’ 8Iis%%

Gi3mv1 a+2 pg3 $14I

?Ic

IDLE SPEEDCONTROL MOTORPOSITJON SENSOR

A-53 12El(VEHICLES FOR94CALIFORNIA)

B-02 B @

KX35-AC-HO525A-NY

B-04 m

1 TSB Revision1I

Page 165 of 1273

FUEL SYSTEM

--

r-B-20 I

LXYG~!tEN6OR 1

’I

W!E~W~,F;~R

-2 EVAPORATIVE ! ““L;,$ m&S-ON

h SOLENOID,\,C” 1 PI FR

*q

1:

2_1 El ,

Lk.i,i iiI

NJECTOi- 11

B-12 =

m

2

7'

2

A-56

IIQI2

/A T//

cpII

Ii

ime Ii i aI

%

i

‘OR

7VE

ICI A

I

“d

OT

4

-1 ;;I

I

5v

r5

s.- -

I

1

4J

POWERPRESSU

' OXYGEN SENSOR'(VEHICLES FOR

FEDE;zd

C-18 FRONT SIDE

DATA LINKCONNECTOR

4

IENG)

(DATA)

c-40

plqismq

C-38

7

F

J/B

cp4

", H

I e

Ell94

TSB RevisionI

Page 169 of 1273

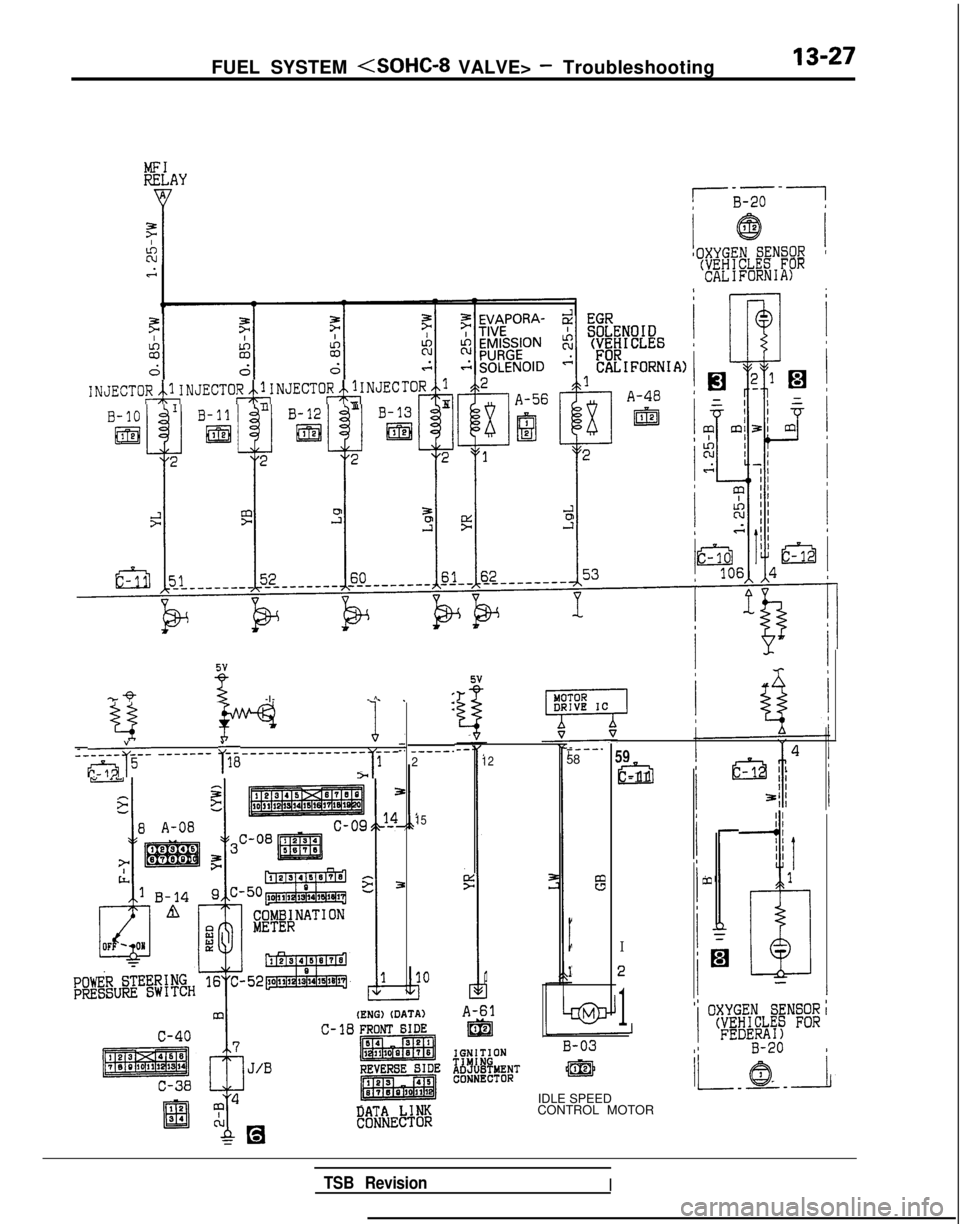

FUEL SYSTEM (SOHC-8 VALVE> - Troubleshooting13-27

INJECTOR&INJECTOR&INJECTOR&NJEC

--

!-B-20 -7

!OXYGE!!ENSOR I'(VEHICLES FORCALIFORNIA)

5v

-w-Qz-I-

-

^

_____---______-_- ---____--&vs-- -__---- T18

I1

>

,..

-----.2

15

12

I

----.58

8

I

1

IDLE SPEEDDATA LINKCONTROL MOTORCONNECTOR

59

cl-11

I

2

1

m

II

!II II1

ib -

I

' OXYGEN SENSOR'(VEHICLES FOR

FEDE89":;

i 63 i

TSB RevisionI

Page 172 of 1273

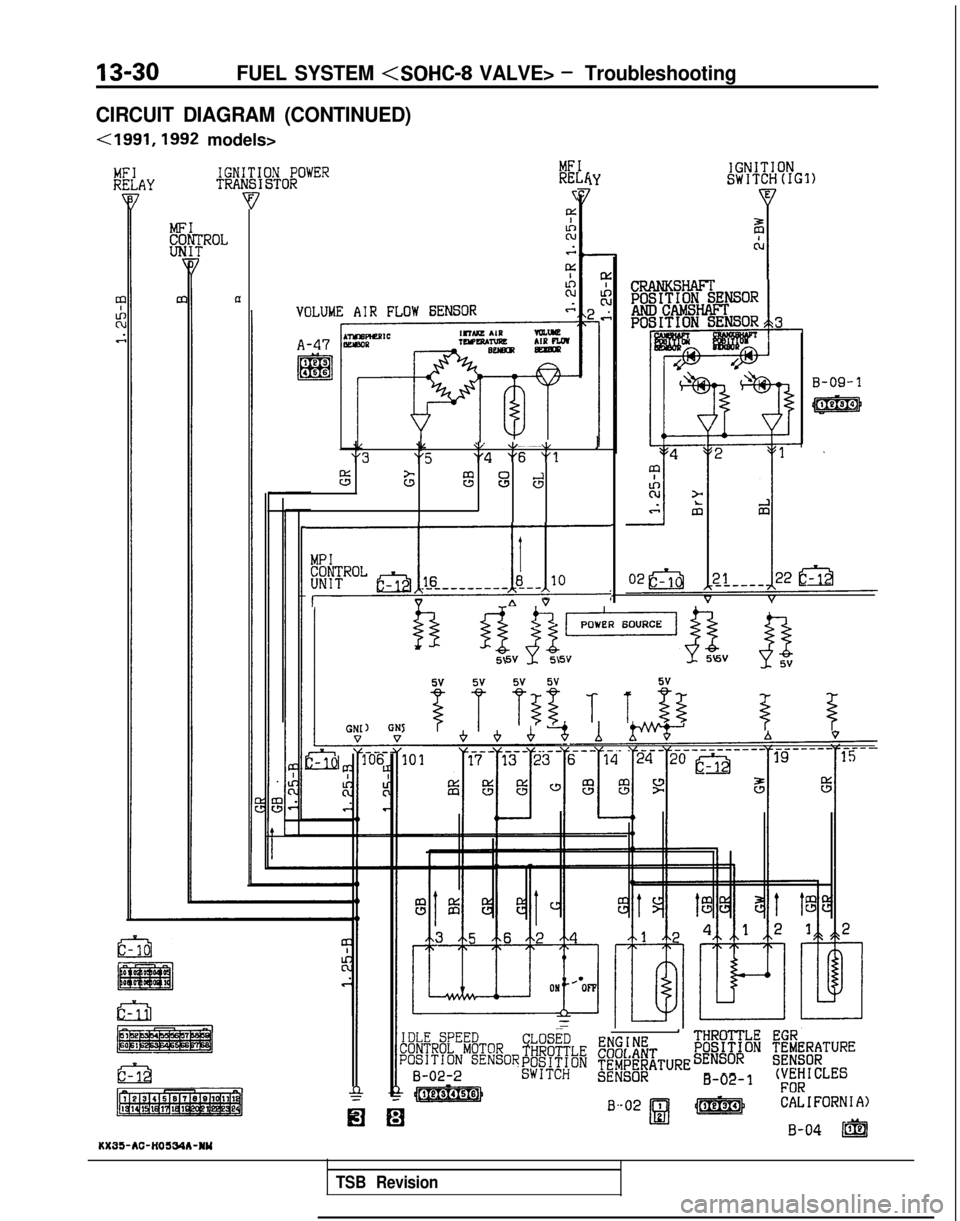

13-30FUEL SYSTEM

CIRCUIT DIAGRAM (CONTINUED)

<1991,1992 models>

IGNITIONSWITCH(IG1)IGNITION POWERTRANSISTOR

FROL

91

\lxI

z;.

F

R

VOLUME AIR FLOW SENSORs

LYAYE

z m

1

rl

\I\I/ ,,I"3"5"4 "6 "1

E

stz

8

d

j,

Y4Y (

gj ~~p=q~ @

5v5v5v

) f $ T$z T T $5$ $GNI

CLOSED'

THROTTLE :;:/,fT

THROTTLE EGRPOSITION ;;;;!;TURE

@~#ON ~&~~~~ATUREsENSoRB-02-1(VEHICLESFOR

B-02

1 4-1RI

CALIFORNIA)

B-04 /@KX35-AC-HOSWA-NY

TSB Revision

Page 173 of 1273

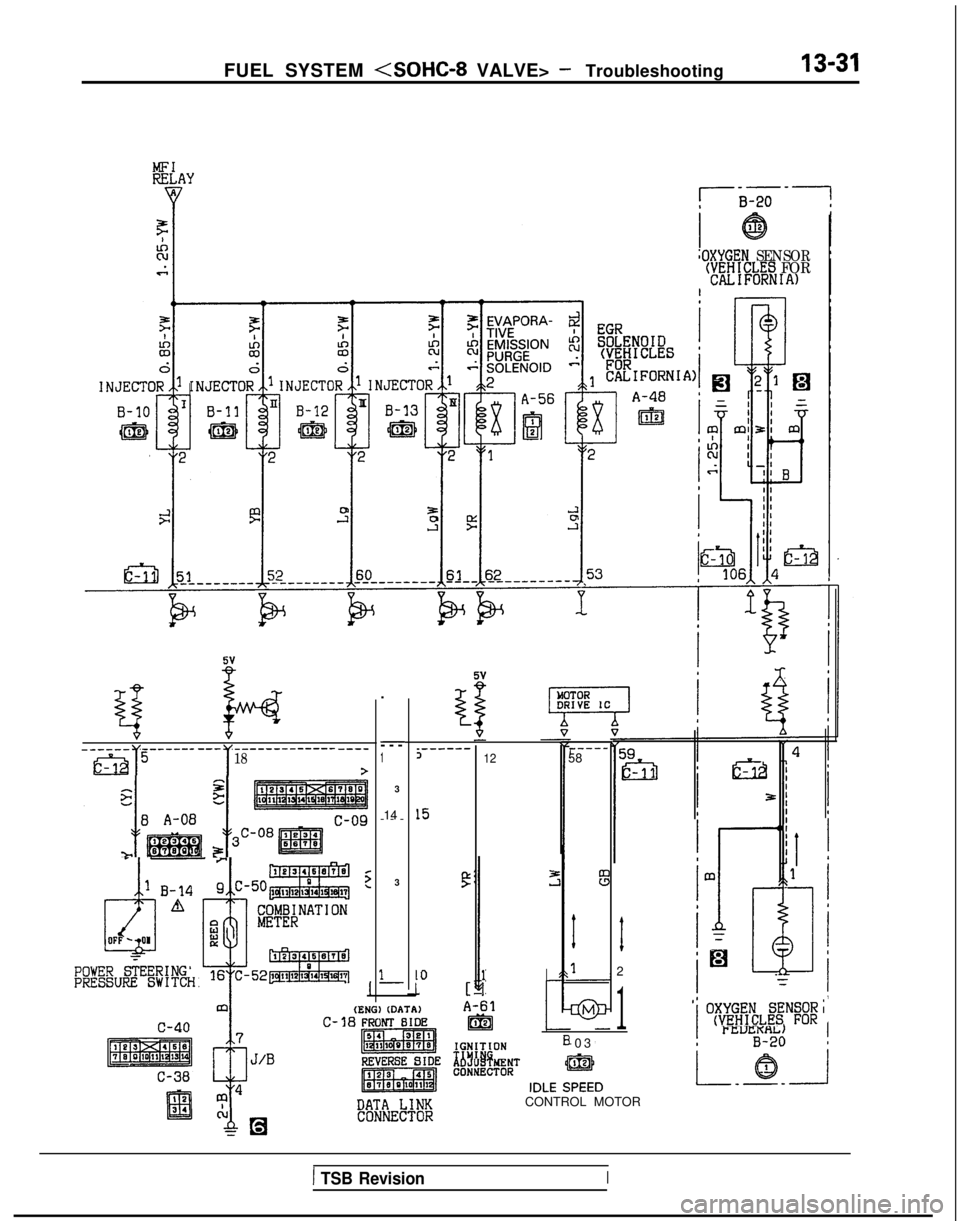

FUEL SYSTEM

MFIRELAY

IIOXYGEN SENSOR(VEHICLES FORCALIFORNIA)

g k______ -___----__ -------------

mlI

----518>

EF

!, -I

s A-08c-09

f@p&g~,,-yg@

POWER STEERINGPRESSURE SWITCH

.

---

-

1

3

14

--

-

3

1-

I

_------3

15

P

10

I [

12 t-----58

(ENG)

(DATA)

c-40-0

3

1

2

1

C-38

DATA LINKCONTROL MOTORCONNECTOR

' OXYGEN SENSOR'(VEHICLES FOR

1 TSB RevisionI

Page 176 of 1273

13-34 FUEL SYSTEM

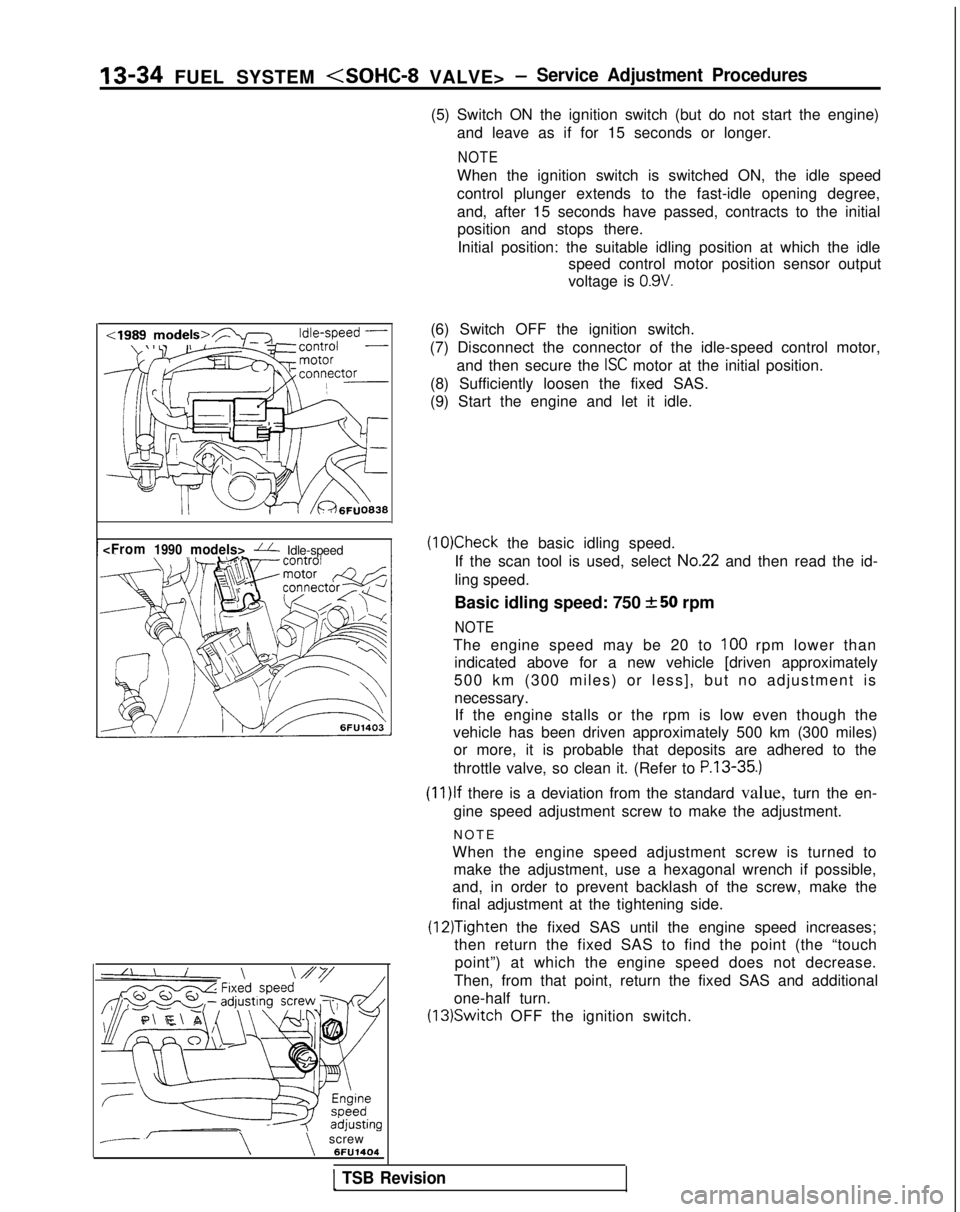

(5) Switch ON the ignition switch (but do not start the engine)and leave as if for 15 seconds or longer.

NOTE

When the ignition switch is switched ON, the idle speed

control plunger extends to the fast-idle opening degree,

and, after 15 seconds have passed, contracts to the initialposition and stops there.

Initial position: the suitable idling position at which the idle speed control motor position sensor output

voltage is

0.9V.

--\\screw 6FU1404(6) Switch OFF the ignition switch.

(7) Disconnect the connector of the idle-speed control motor, and then secure the

ISC motor at the initial position.

(8) Sufficiently loosen the fixed SAS.

(9) Start the engine and let it idle.

(10)Check the basic idling speed.

If the scan tool is used, select

No.22 and then read the id-

ling speed.

Basic idling speed: 750

+-50 rpm

NOTE

The engine speed may be 20 to 100 rpm lower than

indicated above for a new vehicle [driven approximately

500 km (300 miles) or less], but no adjustment is necessary.If the engine stalls or the rpm is low even though the

vehicle has been driven approximately 500 km (300 miles) or more, it is probable that deposits are adhered to the

throttle valve, so clean it. (Refer to

P.13-35.)

(1l)lf there is a deviation from the standard value, turn the en-

gine speed adjustment screw to make the adjustment.

NOT

E

When the engine speed adjustment screw is turned to make the adjustment, use a hexagonal wrench if possible,

and, in order to prevent backlash of the screw, make the

final adjustment at the tightening side.

(12)Tighten the fixed SAS until the engine speed increases;

then return the fixed SAS to find the point (the “touch

point”) at which the engine speed does not decrease.

Then, from that point, return the fixed SAS and additional

one-half turn. (13)Switch

OFF the ignition switch.

1 TSB Revision

Page 177 of 1273

FUEL SYSTEM

(14)Adjust the play of the accelerator cable. (Refer to P.13-

329.)

(15)Connect the idle-speed control motor’s connector.

(16)Adjust the throttle-position sensor.

(17)Start the engine again and let it run at idle speed for about

ten minutes; check to be sure that the idling condition is

normal.

THROTTLE BODY (THROTTLE VALVE AREA)

CLEANING

MllFlCK

(1)Start the engine and warm it up until the temperature of the

engine coolant reaches

80°C (176°F) or higher; then stop

the engine.

(2) Disconnect the air intake hose at the throttle body side.

(3) Spray cleaning liquid (from the intake port of the throttle body) onto the valve, and then leave as is for about fiveminutes.

(4) Start the engine and race it a few times; then let it run at idle speed for about one minute.

NOTE

If the engine idling speed is unstable (or the engine stalls),

let the engine run with the throttle valve slightly open.

(5) If deposits are not removed from the throttle valve, repeat steps (3) and (4).

(6) Connect the air intake hose.

(7) Using the scan tool, erase the diagnostic trouble code, or disconnect the battery’s ground cable for ten seconds orlonger and then reconnect it.

(8) Adjust the basic idle speed (engine speed adjusting screw). (Refer to

P.13-33.)

(9) Adjust the throttle position sensor.

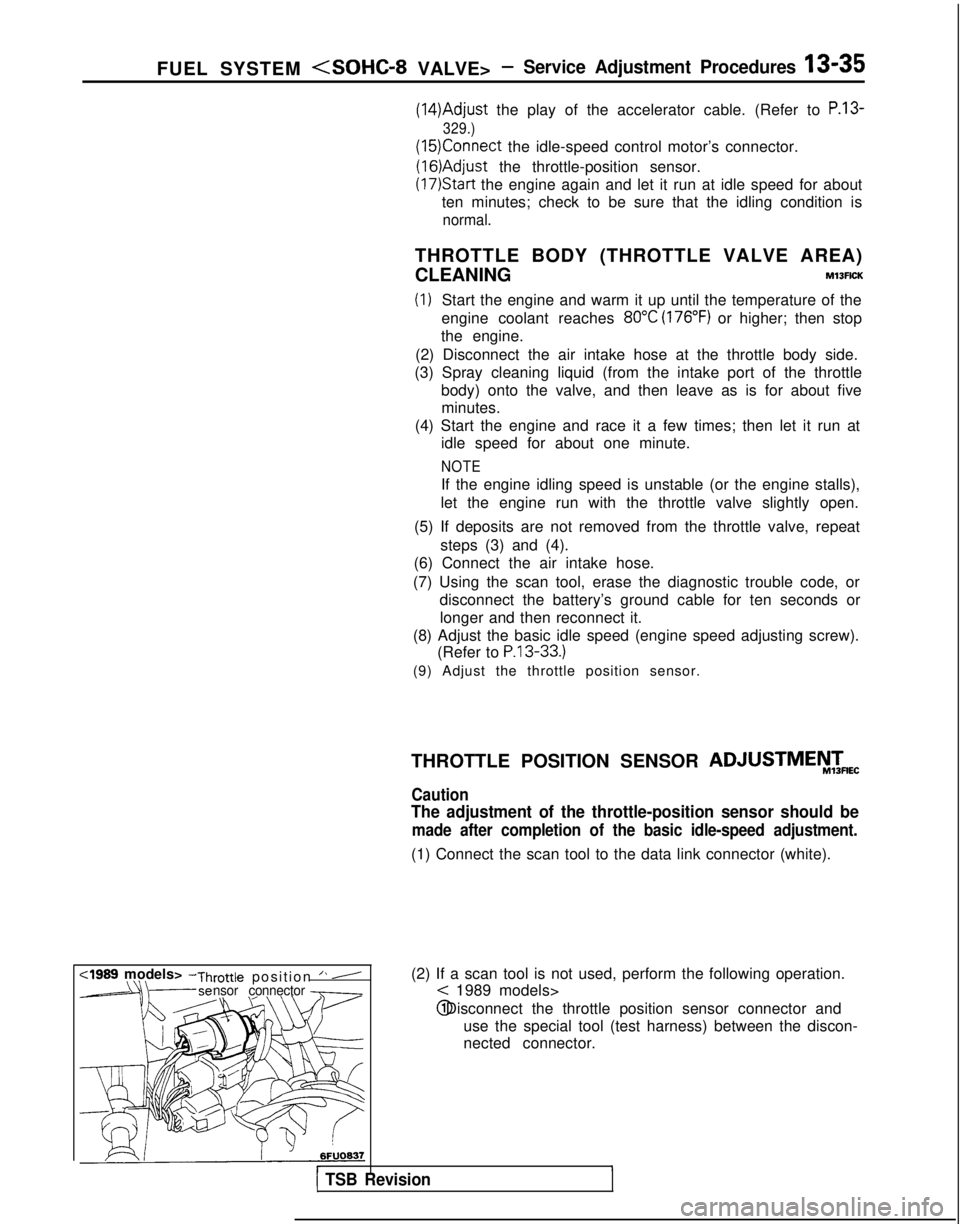

(2) If a scan tool is not used, perform the following operation.

< 1989 models> @ Disconnect the throttle position sensor connector and

use the special tool (test harness) between the discon-

nected connector.

r1 TSB Revision

THROTTLE POSITION SENSOR ADJUSTMEiW&

Caution

The adjustment of the throttle-position sensor should be

made after completion of the basic idle-speed adjustment.

(1) Connect the scan tool to the data link connector (white).

,