sensor MITSUBISHI GALANT 1989 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 522 of 1273

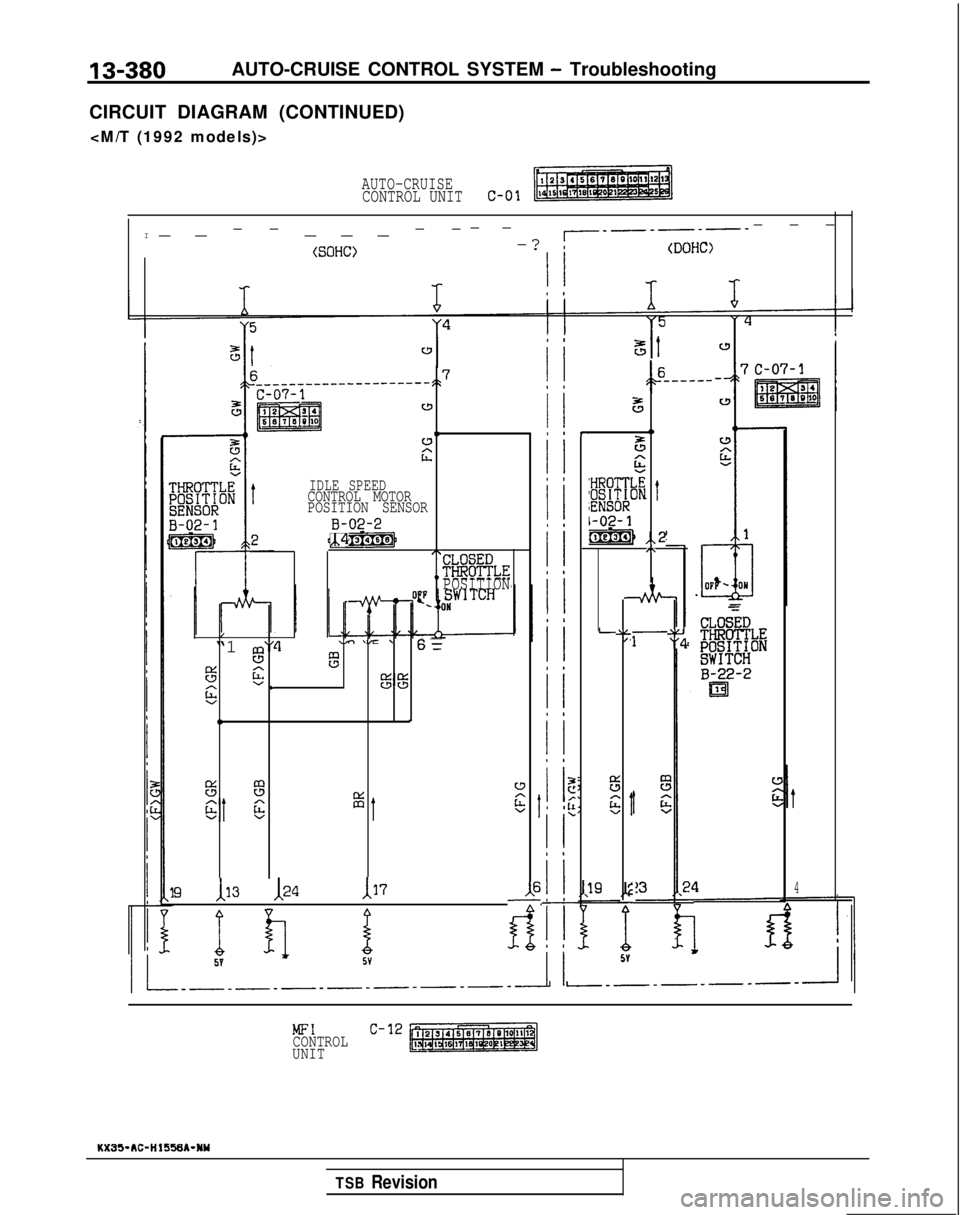

13-380AUTO-CRUISE CONTROL SYSTEM - Troubleshooting

CIRCUIT DIAGRAM (CONTINUED)

AUTO-CRUISECONTROL UNITc-01

--

-

I __--___--

--

(SOHC)-? r--------(DOHC>

I I

7---------------------,~

c3

c

6_--es-

0c3

I:

t-

IDLE SPEEDCONTROL MOTOR

POSITION SENSOR

B-02-2j-xeJjT4Tsfiiap,,4,.

,,&#%!LEPOSITION

I“1 "4k!3"' 6~

z+

G

G %cF5g

,IA

I I

I II I

I II I

I I4 I

I I, I

I II I

I II I

I II I

I II 6

I II I

! IF

,c

I I

\

I s

I I+

&La"4

-

FiELEFTITI+;~ON

B-22-2

ml

E58cI

$1

6 Etci t

9 113 124 117A

%fl!j f-iSV

5

0

5

G

jp~FFJi~ t

I-02-1

ttlm) ,,2I.

AL,.

1

E-4

I II I

I I

KXSS-AC-Hl556A-NY

TSB

Revision WI

c-12CONTROL

UNIT

Page 535 of 1273

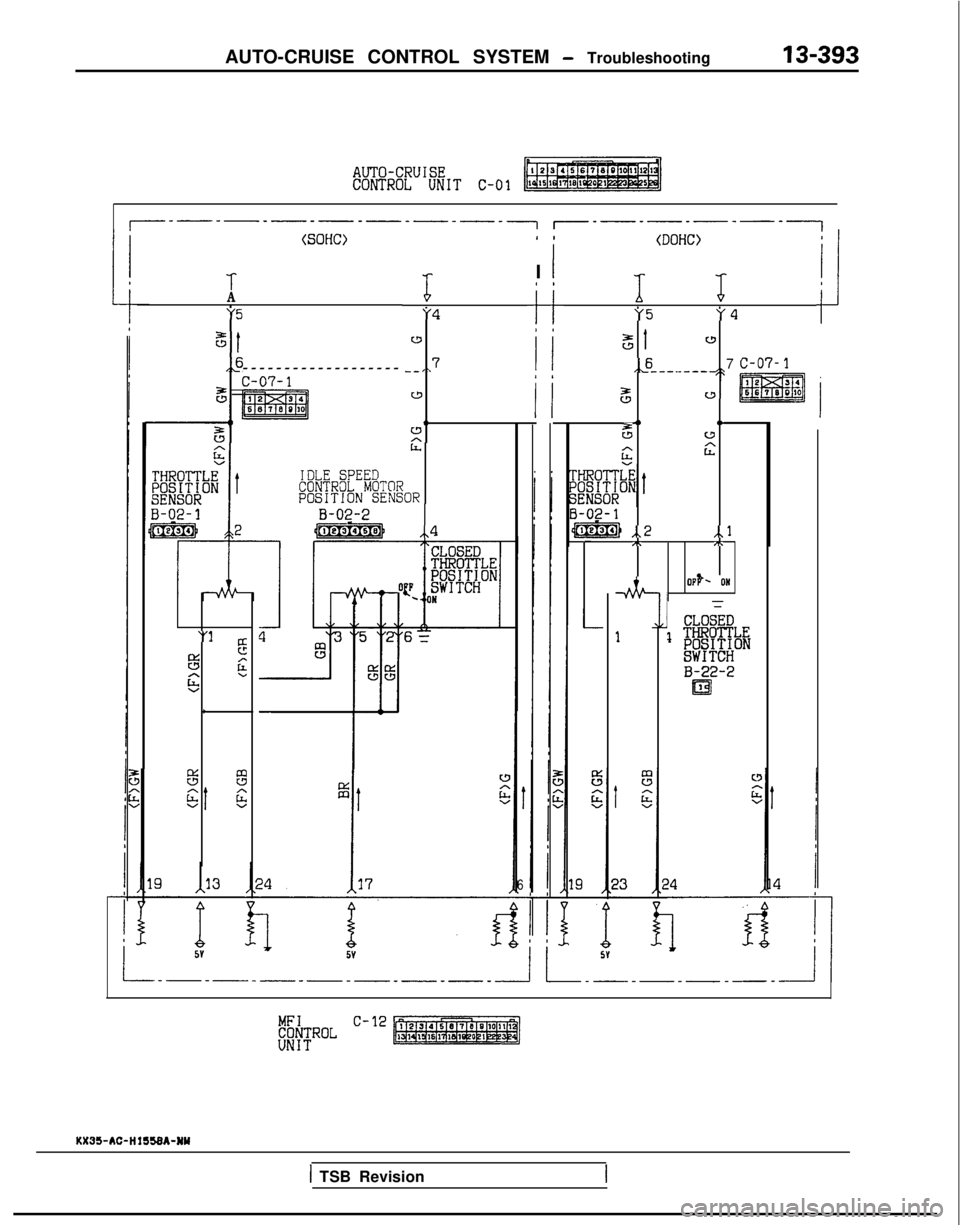

AUTO-CRUISE CONTROL SYSTEM - Troubleshooting

13-393

AUTO-CRUISECONTROL UNIT C-01

I__-_-_-____l-‘--------l(SOHC)I 0

-I-I I

(DOHC)

I I

A

v5

st,,s------------------

-

c-07-1

2

I1

i

‘6

"4

w

__I ,7

W

I,

wA

t-tI I

I II I

1 I

tx.

IDLE SPEEDCONTROL MOTORPOSITION SENSOR

B-02-2(~@@zjijg# ,,4

1‘s

Y5Y4J

5 1cJ

,,s7

:>

c-07-1---._---

5p7zsq

0I.5w

si2

e-02-1

mfmj ,,2,.l,,,I\

OPV on

Ii

-A-

l

%

I g

!3

CLOsED3 THROTTLE;$W$AON

B-22-2

ia

“1

EsE

s

E

,

Fs8

GIG

6I

MFIc-12CONTROLUNIT

KX35-AC-HlSSW-NY

1 TSB Revision

Page 547 of 1273

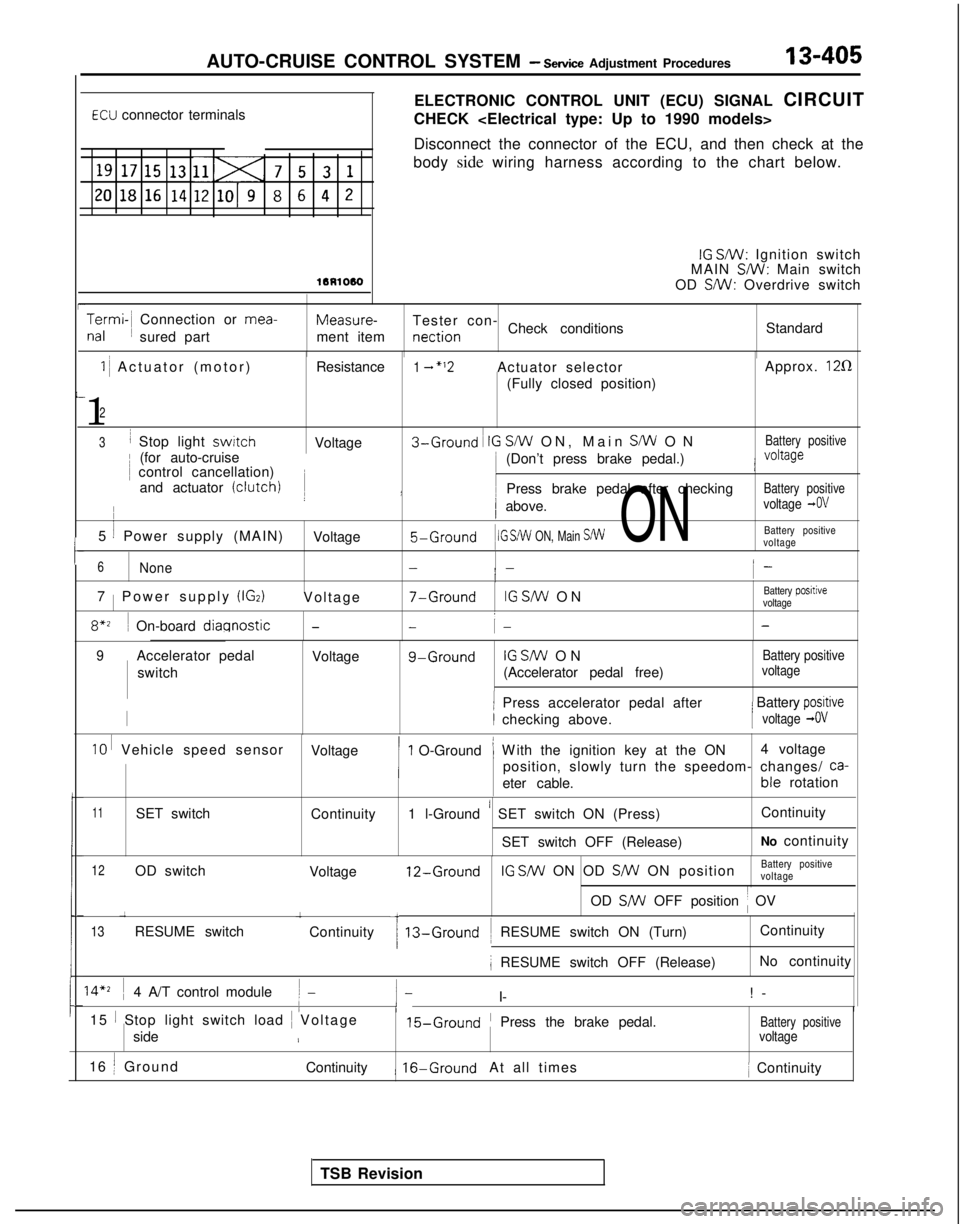

AUTO-CRUISE CONTROL SYSTEM - Sewice Adjustment Procedures

ECU connector terminals

19171513ll><7531

2018161412 101 98642

16A1060

ELECTRONIC CONTROL UNIT (ECU) SIGNAL CIRCUIT

CHECK

Disconnect the connector of the ECU, and then check at the

body side wiring harness according to the chart below.

IG SW: Ignition switch

MAIN SW: Main switch

OD SMI: Overdrive switch

Termi-~ Connection or mea-

nal

~

sured part Measure-

Tester con-

ment item nection

Check conditions

Standard

I-

I-

1 ~

Actuator (motor) Resistance1 - “‘2Actuator selector Approx. 120

(Fully closed position)

1

2

3I Stop light switchVoltage3-Ground ~

IG S/W ON, Main SW O

N

Battery positive

~

(for auto-cruise ~

control cancellation)

j )

i (Don’t press brake pedal.)j voltage

and actuator (clutch)I Press brake pedal after checkingBattery positive

5 1 Power supply (MAIN)

/ above.voltage -0V

Voltage5-Ground

1 IG S/W

ON, Main S/W ONBattery positive

voltage

6None-i -i-

7 1

Power supply (IGz)Voltag

e

7-GroundIG SfW O

N

Battery positive

voltage

8*z ~

On-board diagnostic--i- -

TSB Revision

9Accelerator pedal Voltageg-GroundIG SW O

N

Battery positive

switch

(Accelerator pedal free)voltage

1 Press accelerator pedal after/ Battery positive

II checking above.[voltage -0V

IO I Vehicle speed sensor

Voltage1 O-Ground’ W

ith the ignition key at the ON

’ ~

4 voltage

position, slowly turn the speedom- changes/

ca-

eter cable. ble

rotation

11SET switch

Continuity1 l-Ground ’ SET switch ON (Press) Continuity

SET switch OFF (Release) No continuity

12OD switch

13RESUME switch 1

Voltage

Continuity

12-GroundIG SNV ON OD SW ON position

Battery positive

voltage

OD

SW OFF position ~

OV

13-Ground ~

RESUME switch ON (Turn) Continuity

; RESUME switch OFF (Release)

No continuity

14’2 ~

4 A/T control module( -/- I- !

-

I/15 1 Stop light switch load

~

Voltage15-Ground’ Press the brake pedal.Battery positiveside/voltage

16 j Ground

Continuity1 16-GroundAt all times ~

Continuity

Page 548 of 1273

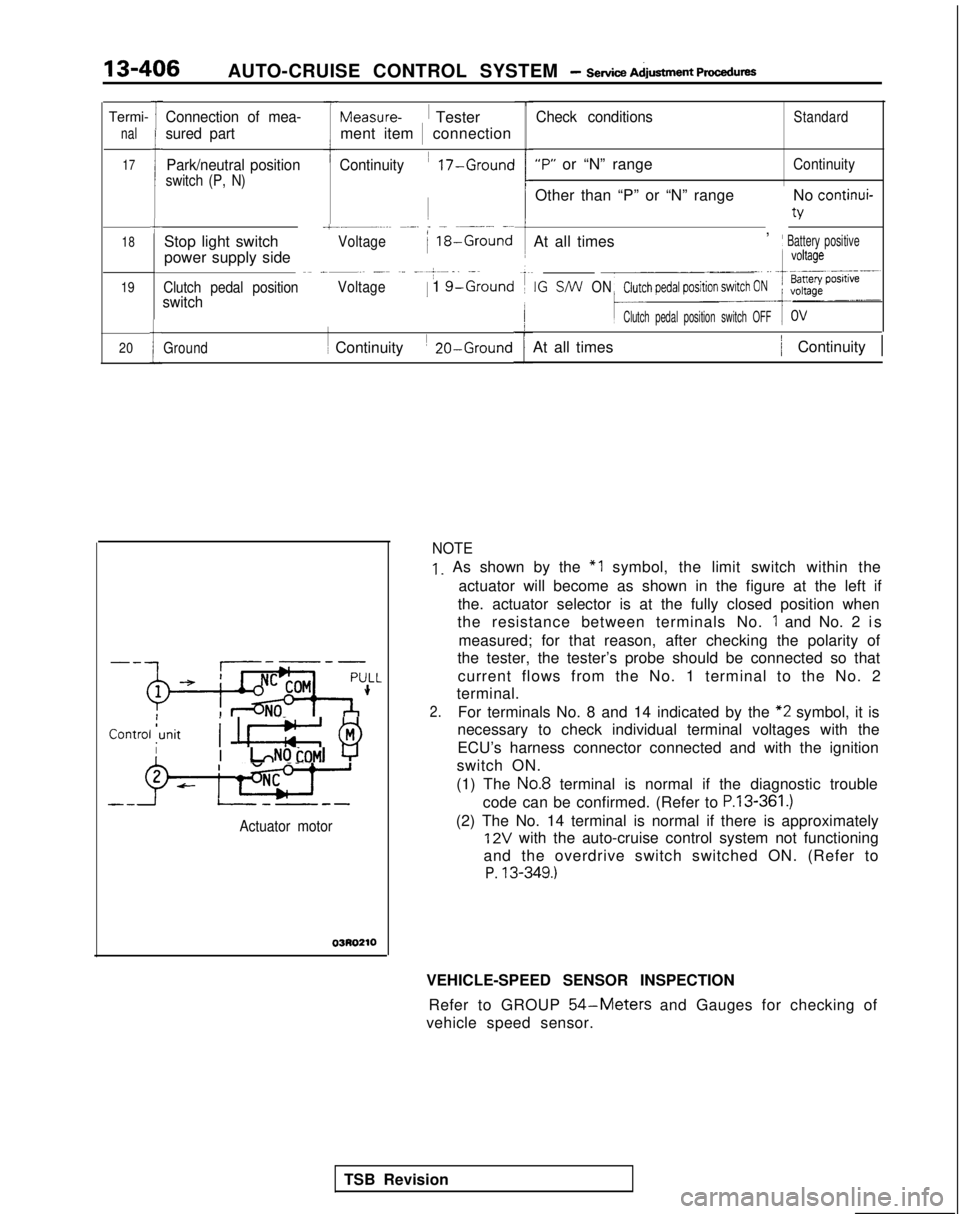

13-406AUTO-CRUISE CONTROL SYSTEM - Service A&tment ~mcec~ure~

Termi-

nal

17

18

19

20

l-

it

L

Connection of mea-

sured part Park/neutral position

switch (P, N)

T

f

+

Stop light switch

power supply side

Continuity ~

17-Ground

1

.~.~.~ ~.-. _ - ~~- -~/Voltage)

18-Ground

~~

____~ _~ ~.. ----+--.. .-~

Clutch pedal position

Voltage1 1 g-Groundswitch

Measure-1

Tester

ment item 1

connection

Ground

1 ~

Continuity ~

20-Ground

-Conrroljunitj I! @jIII LNOtOMl ‘-r’

+-j-

--J--L--

Actuator motor

03R0210

Check conditionsStandard

“P” or “N” rangeContinuity

Other than “P” or “N” range

,No continui-

v

At all timesj Battery positive

IG S/W

ON

Clutch pedal position switch OFF

At all times/ Continuity 1

NOTE

1. As shown by the “1 symbol, the limit switch within the

actuator will become as shown in the figure at the left if

the. actuator selector is at the fully closed position when

the resistance between terminals No.

1 and No. 2 i

s

measured; for that reason, after checking the polarity of

the tester, the tester’s probe should be connected so that

current flows from the No. 1 terminal to the No. 2

terminal.

2.For terminals No. 8 and 14 indicated by the “2

symbol, it is

necessary to check individual terminal voltages with the

ECU’s harness connector connected and with the ignition

switch ON.

(1) The

No.8 terminal is normal if the diagnostic trouble

code can be confirmed. (Refer to

P.13-361.)

(2) The No. 14 terminal is normal if there is approximately

12V with the auto-cruise control system not functioning

and the overdrive switch switched ON. (Refer to

P. 13-349.)

VEHICLE-SPEED SENSOR INSPECTION

Refer to GROUP

54-Meters and Gauges for checking of

vehicle speed sensor.

TSB Revision

Page 549 of 1273

AUTO-CRUISE CONTROL SYSTEM - Setice Adjustment procedures13-407

=\

07A005.1

Controlvalve

L2

07AOO50

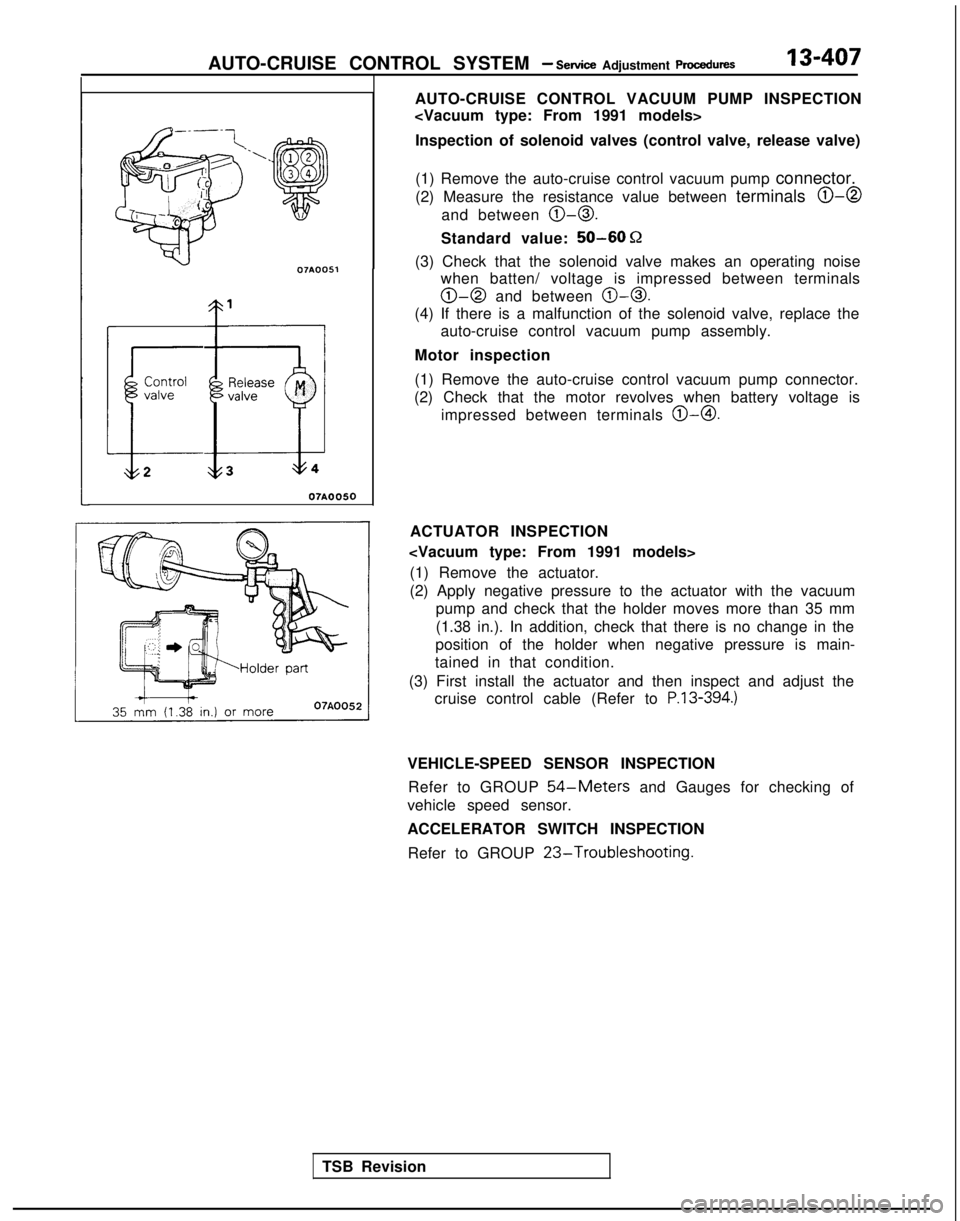

AUTO-CRUISE CONTROL VACUUM PUMP INSPECTION

Inspection of solenoid valves (control valve, release valve)

(1) Remove the auto-cruise control vacuum pump connector.

(2) Measure the resistance value between terminals

0-0

and between 0-0.

Standard value: 50-60 Q

(3) Check that the solenoid valve makes an operating noise

when batten/ voltage is impressed between terminals

0-0 and between 0-0.

(4) If there is a malfunction of the solenoid valve, replace the

auto-cruise control vacuum pump assembly.

Motor inspection

(1) Remove the auto-cruise control vacuum pump connector.

(2) Check that the motor revolves when battery voltage is impressed between terminals

@-0.

TSB Revision ACTUATOR INSPECTION

(1) Remove the actuator.

(2) Apply negative pressure to the actuator with the vacuum pump and check that the holder moves more than 35 mm

(1.38 in.). In addition, check that there is no change in the

position of the holder when negative pressure is main-

tained in that condition.

(3) First install the actuator and then inspect and adjust the cruise control cable (Refer to

P.13-394.)

VEHICLE-SPEED SENSOR INSPECTION

Refer to GROUP

54-Meters and Gauges for checking of

vehicle speed sensor.

ACCELERATOR SWITCH INSPECTION

Refer to GROUP

23-Troubleshooting.

Page 550 of 1273

13-408AUTO-CRUISE CONTROL SYSTEM - Auto-cruise Control

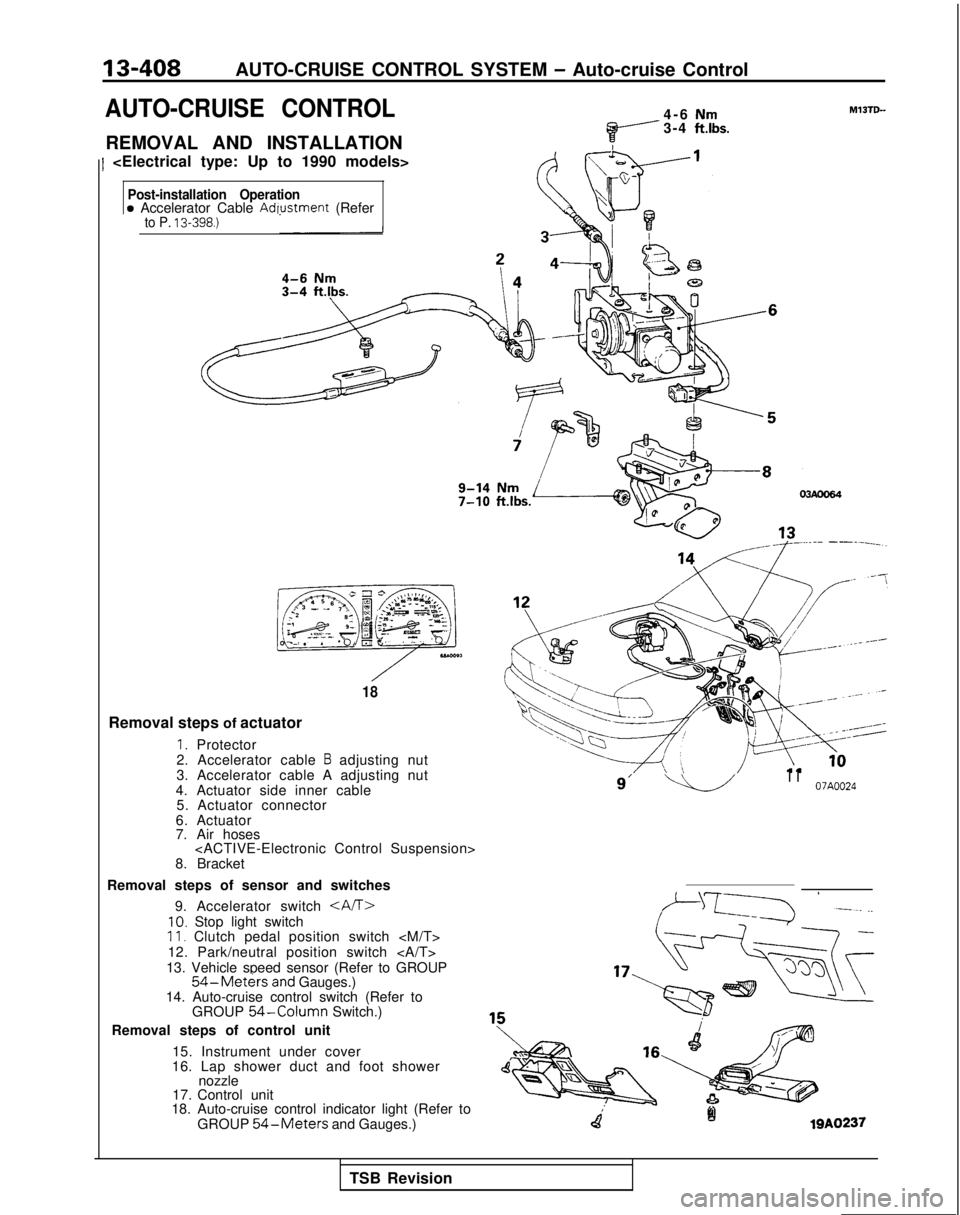

AUTO-CRUISE CONTROL

REMOVAL AND INSTALLATION

1

Nm3-4 ft.lbs.

Post-installation Operationa Accelerator Cable Adwstment (Referto P. 13-398.)

,**.“qy “y ,,,,ezls:’ 3 -. .- ,*%L’J

01

,\@&&,

-<28- E+c- - - --.c,

T

$$y= *g i ;g+j$T

-3

18

Removal steps of actuator

1. Protector

2. Accelerator cable B adjusting nut

3. Accelerator cable A adjusting nut

4. Actuator side inner cable 5. Actuator connector

6. Actuator

7. Air hoses

8. Bracket

Removal steps of sensor and switches 9. Accelerator switch

10. Stop light switch11. Clutch pedal position switch

12. Park/neutral position switch

13. Vehicle speed sensor (Refer to GROUP

54-Met&sand Gauges.)

14. Auto-cruise control switch (Refer to GROUP

54-Column Switch.)

Removal steps of control unit

15. Instrument under cover

16. Lap shower duct and foot shower nozzle

17. Control unit

18. Auto-cruise control indicator light (Refer to

GROUP

54-Meters and Gauges.)

9’ -L.-lI I07A0024

falQA0237

TSB Revision

Page 551 of 1273

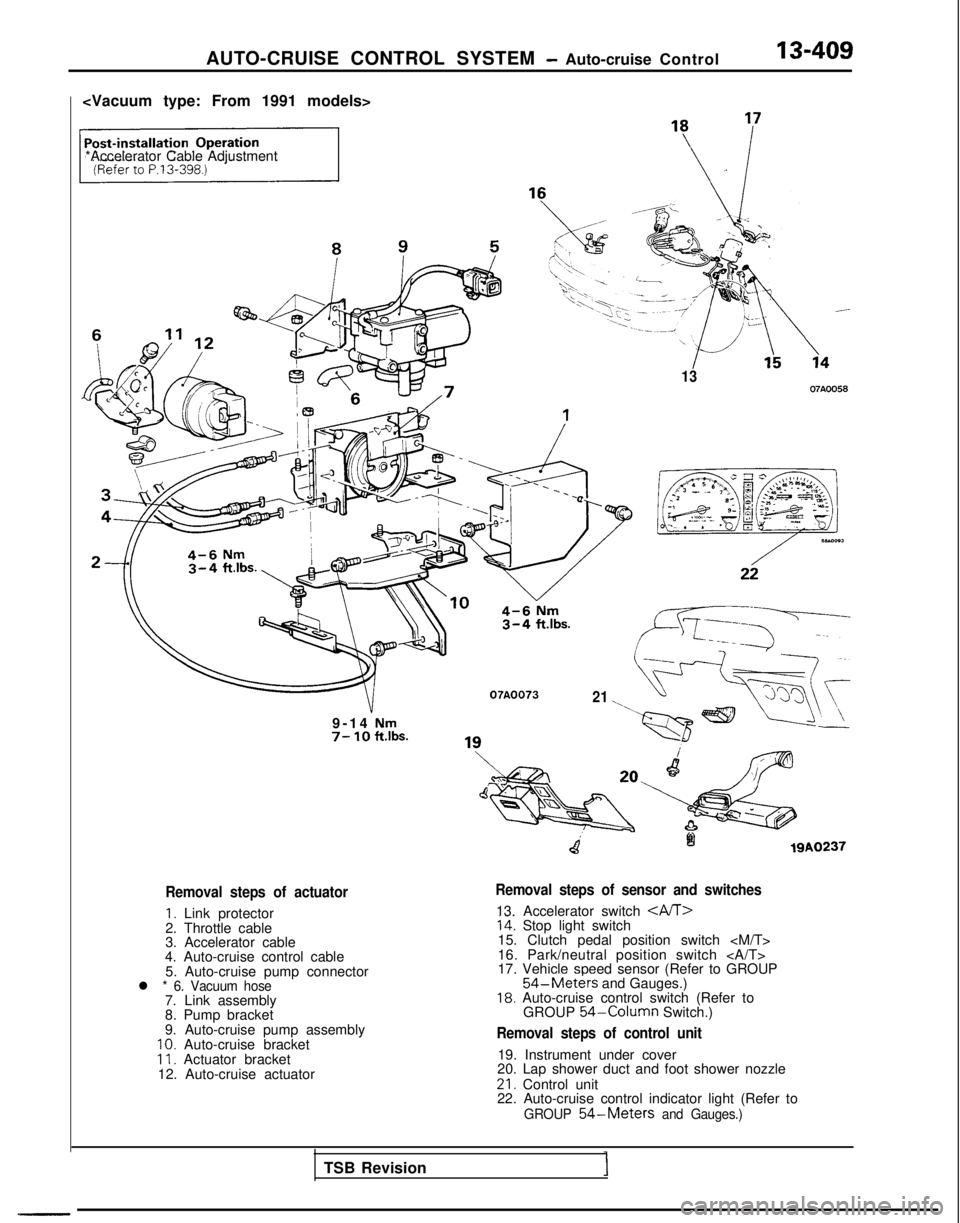

AUTO-CRUISE CONTROL SYSTEM - Auto-cruise Control

*Accelerator Cable Adjustment

Removal steps of actuator

1. Link protector

2. Throttle cable

3. Accelerator cable

4. Auto-cruise control cable

5. Auto-cruise pump connector

l * 6. Vacuum hose7. Link assembly

8. Pump bracket

9. Auto-cruise pump assembly

IO. Auto-cruise bracket11, Actuator bracket

12. Auto-cruise actuator

1307AOO58

9-14 Nm7- 10 ftlbs.

21

19AO237

Removal steps of sensor and switches

13. Accelerator switch

15. Clutch pedal position switch

16. Park/neutral position switch

17. Vehicle speed sensor (Refer to GROUP

54-Meters and Gauges.)18. Auto-cruise control switch (Refer to GROUP 54-Column Switch.)

Removal steps of control unit

19. Instrument under cover

20. Lap shower duct and foot shower nozzle

21. Control unit

22. Auto-cruise control indicator light (Refer to

GROUP 54-Meters and Gauges.)

TSB Revision

.-

Page 553 of 1273

14-1

COOLING

ENGINE COOLANT TEMPERATURE GAUGE

UNIT, ENGINE COOLANT

TEMPERATURE SENSOR AND ENGINE

COOLANT TEMPERATURE

SWITCH.............

31

RADIATOR ....................................................... 9

RADIATOR FAN MOTOR ASSEMBLY ..........

12

SERVICE ADJUSTMENT PROCEDURES..

.....

8

Engine Coolant Concentration Test .............

8

Engine Coolant LeakCheck

........................8

Engine Coolant

Replacement .......................

8

Radiator Cap Pressure Test .........................

8

SPECIAL TOOL................................................5

SPECIFICATIONS .............................................

2

General Specifications ..................................

2

Lubricant

....................................................... 4

CONTENTS

IM14AA-

Sealant. . . . . . . . . . . . . ..__...........’ . . . . . . . . . . . . . \

. . . . . .._.........4

ServiceSpecifications . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Torque

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

THERMOSTAT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . .13

TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. .5

No rise in temperature

Overheat

WATER HOSE AND WATER PIPE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

WATER HOSE AND WATER PIPE

WATER HOSE AND WATER PIPE

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..a.....23

WATER PUMP

WATER PUMP

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Page 554 of 1273

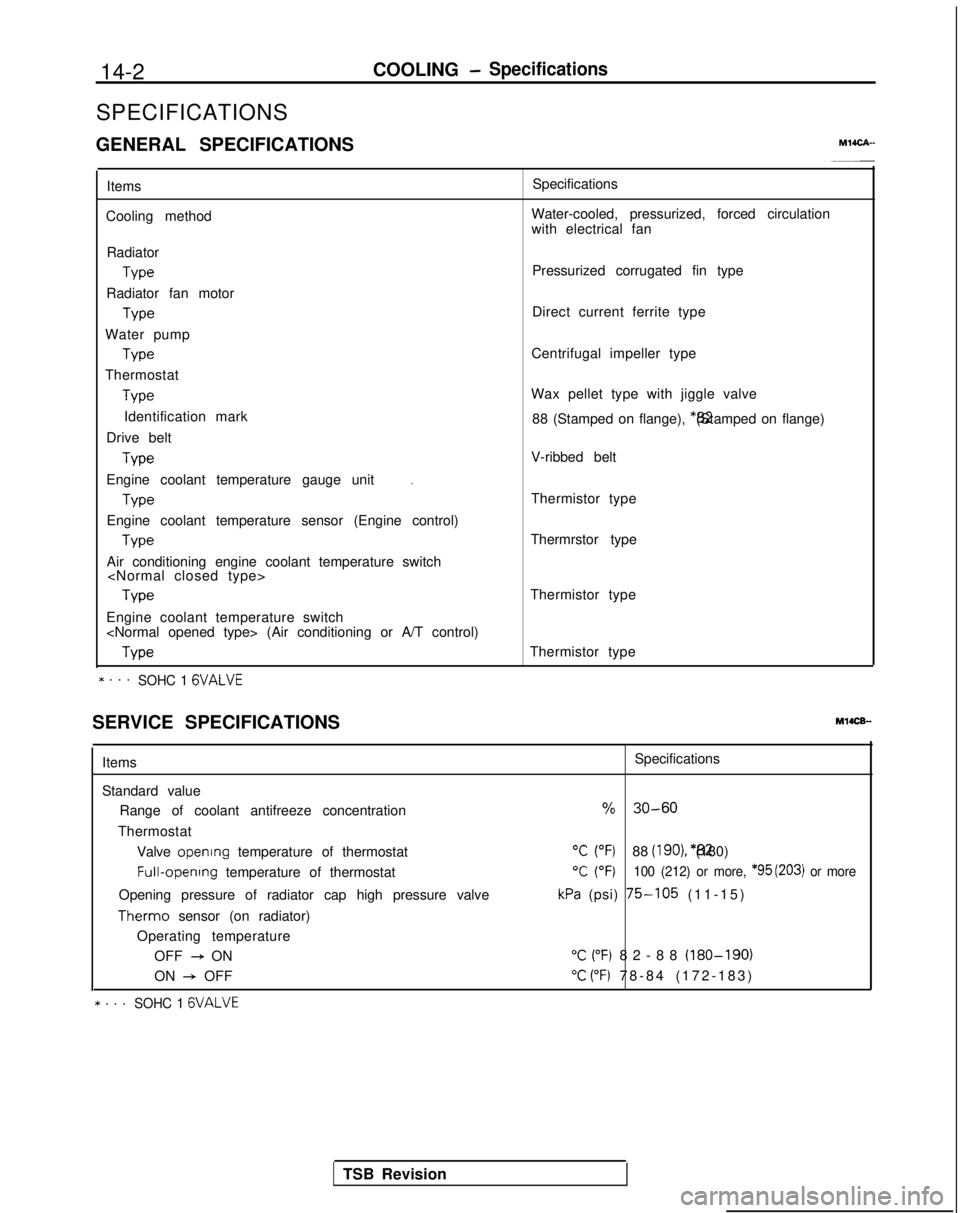

14-2

COOLING- Specifications

SPECIFICATIONS

GENERAL SPECIFICATIONS

MlICA-

Items

Cooling method Specifications

Water-cooled, pressurized, forced circulation

with electrical fan

Radiator Type

Radiator fan motor Type

Water pump Type

Thermostat Type

Identification mark

Drive belt Type

.Engine coolant temperature gauge unit

Type

Engine coolant temperature sensor (Engine control) Type

Air conditioning engine coolant temperature switch

Engine coolant temperature switch

* . . .SOHC 1 GVALVE

Pressurized corrugated fin type

Direct current ferrite type

Centrifugal impeller type

Wax pellet type with jiggle valve 88 (Stamped on flange), *82 (Stamped on flange)

V-ribbed belt

Thermistor type

Thermrstor type

Thermistor type

Thermistor type

SERVICE SPECIFICATIONS

MlOCB-

Items

Standard value Range of coolant antifreeze concentration

Thermostat Valve opening

temperature of thermostat Full-opening

temperature of thermostat

Opening pressure of radiator cap high pressure valve Therm0

sensor (on radiator)

Operating temperature OFF

+ ON

ON

+ OFF

* . . .SOHC 1 GVALVE

Specifications

% 30-60

“C (“F)88 (IgO), *82 (180)

T (OF)100 (212) or more, *95 (203) or more

kPa (psi) 75-105 (11-15

)

“C (“F) 82-88 (180-190)

“C (“F) 78-84 (172-183

)

TSB Revision

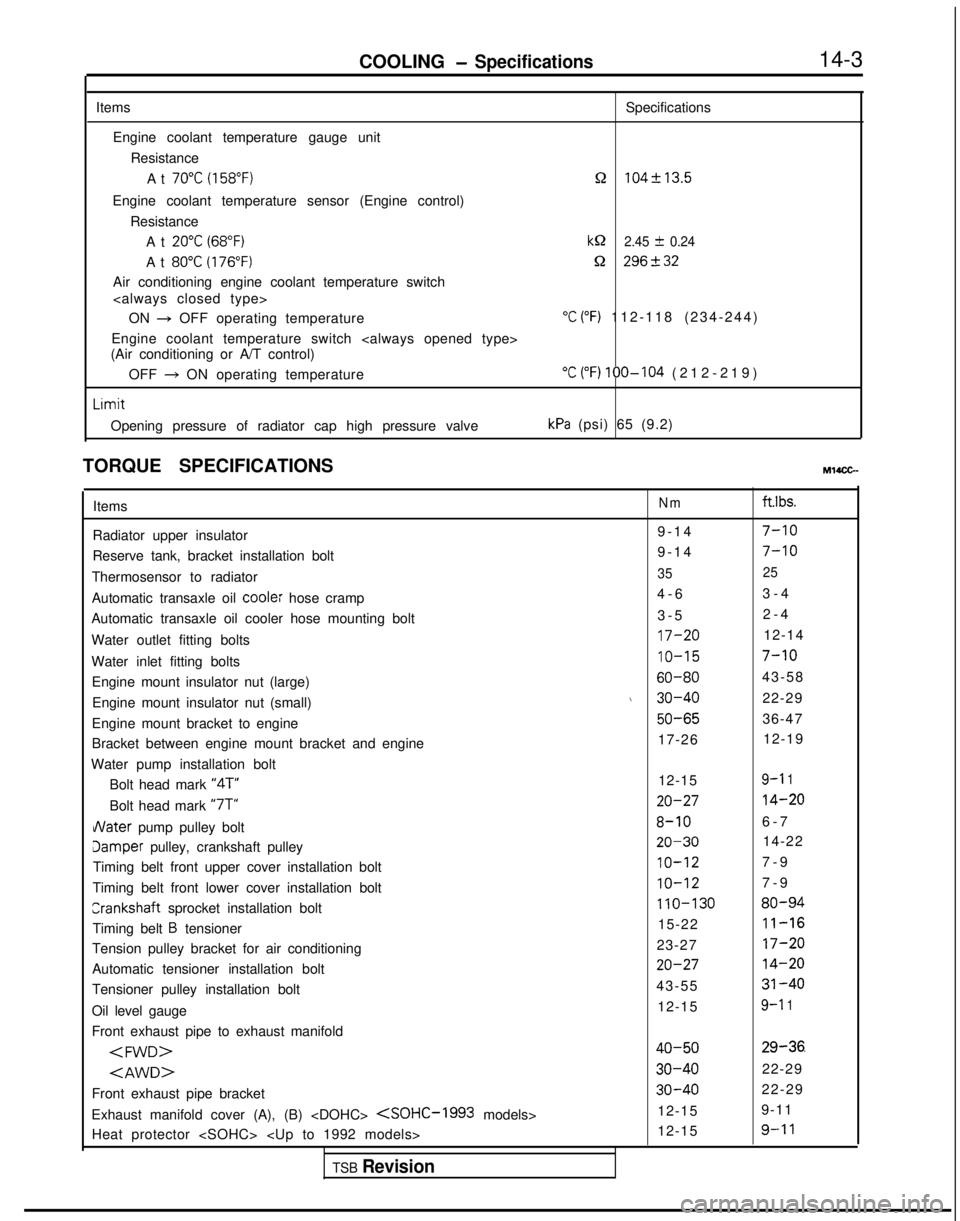

Page 555 of 1273

COOLING- Specifications14-3

Items Specifications

Engine coolant temperature gauge unit ResistanceAt

70°C (158°F)n 104f13.5

Engine coolant temperature sensor (Engine control) ResistanceAt

20°C (68°F)kQ 2.45 f 0.24

At 80°C (176°F)Q 296+32

Air conditioning engine coolant temperature switch

ON

+ OFF operating temperature“C (“F) 112-118 (234-244

)

Engine coolant temperature switch

(Air conditioning or A/T control)

OFF

+ ON operating temperature“C (“F) 100-104 (212-219

)

Limit

Opening pressure of radiator cap high pressure valvekPa (psi) 65 (9.2)

TORQUE SPECIFICATIONS

MWCG-

ItemsNm ft.lbs.

Radiator upper insulator 9-14

7-10

Reserve tank, bracket installation bolt9-1

4

7-10

Thermosensor to radiator35

25

Automatic transaxle oil coole: hose cramp 4-

6

3-4

Automatic transaxle oil cooler hose mounting bolt 3-5

2-4

Water outlet fitting bolts

17-2012-14

Water inlet fitting bolts

IO-157-10

Engine mount insulator nut (large)60-8043-58

Engine mount insulator nut (small)

\ 30-4022-29

Engine mount bracket to engine

50-6536-47

Bracket between engine mount bracket and engine 17-26

12-19

Water pump installation bolt Bolt head mark “4T”

12-15

9-l 1

Bolt head mark “7T”20-2714-20

dater pump pulley bolt8-106-

7

Jamper pulley, crankshaft pulley20-3014-22

Timing belt front upper cover installation bolt

IO-127-

9

Timing belt front lower cover installation bolt

IO-127-

9

Crankshaft

sprocket installation bolt

110-13080-94

Timing belt B tensioner 15-2211-16

Tension pulley bracket for air conditioning

23-2717-20

Automatic tensioner installation bolt20-2714-20

Tensioner pulley installation bolt43-5531-40

Oil level gauge 12-159-l 1

Front exhaust pipe to exhaust manifold

Front exhaust pipe bracket

30-4022-29

Exhaust manifold cover (A), (B)

9-11

Heat protector

TSB Revision