sensor MITSUBISHI GALANT 1989 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 616 of 1273

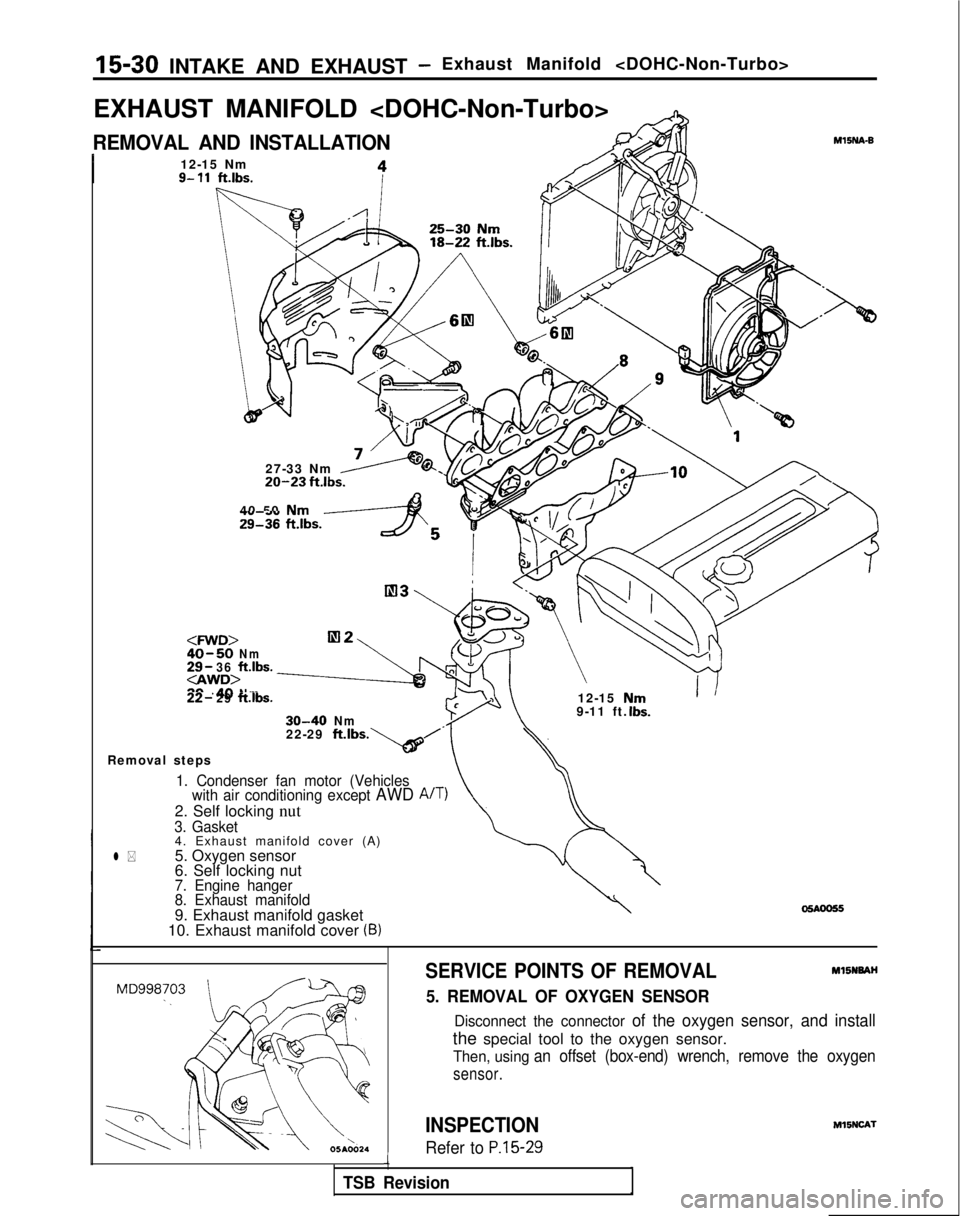

15-30 INTAKE AND EXHAUST -Exhaust Manifold

EXHAUST MANIFOLD

REMOVAL AND INSTALLATION

I12-15 Nm9- 11ft.lbs.

27-33 Nm20-23 fklbs.

40 50 Nm29136 ft.lbs.yAS

30-40Nm9-11 ft.

\

UrnIbs.

MlINA-B

22-29 ft.lbs

Removal steps*b’.

1. Condenser fan motor (Vehicles with air conditioning except AWD A/T)

2. Self locking nut3. Gasket4. Exhaust manifold cover (A)

l *5. Oxygen sensor

6. Self locking nut

7. Engine hanger

8. Exhaust manifold

9. Exhaust manifold gasket

10. Exhaust manifold cover (B)

SERVICE POINTS OF REMOVALMl5NNAH

5. REMOVAL OF OXYGEN SENSOR

Disconnect the connector of the oxygen sensor, and install

the special tool to the oxygen sensor.

Then, using an offset (box-end) wrench, remove the oxygen

sensor.

INSPECTION

Refer to P.15-29i

TSB Revision M15NCA-l

Page 617 of 1273

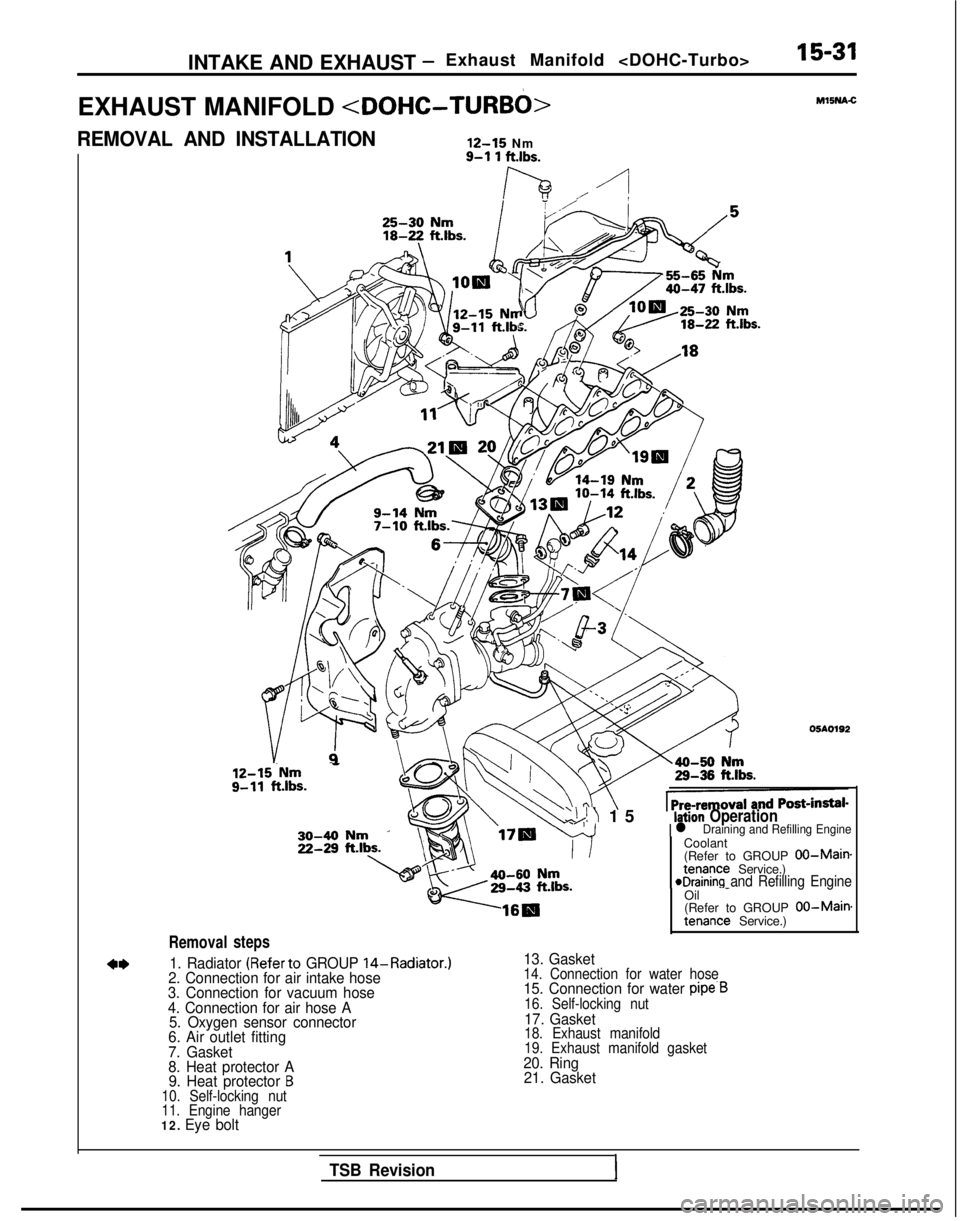

INTAKE AND EXHAUST -Exhaust Manifold

EXHAUST MANIFOLD

REMOVAL AND INSTALLATION

12-15

Nm

Removal

12-15.Nm - g-11

ft.lbs.

steps

9-l 1 ftlbs.

lh ./-I

‘Uc Ml5NA.C

05AO192

Coolant

(Refer to GROUP

00-Maimtenance Service.)eDraining and Refilling Engine

1. Radiator (Referto GROUP 14-Radiator.)

2. Connection for air intake hose

3. Connection for vacuum hose

4. Connection for air hose A 5. Oxygen sensor connector

6. Air outlet fitting

7. Gasket

8. Heat protector A 9. Heat protector

B10. Self-locking nut

11. Engine hanger

12. Eye bolt

‘\!I 1

5

Ilation Operationl Draining and Refilling Engine

Oil

-

(Refer to GROUP 00-Main.tenance Service.)

13. Gasket14. Connection for water hose15. Connection for water pipe.B16. Self-locking nut17. Gasket18. Exhaust manifold

19. Exhaust manifold gasket

20. Ring

21. Gasket

TSB Revision1

Page 621 of 1273

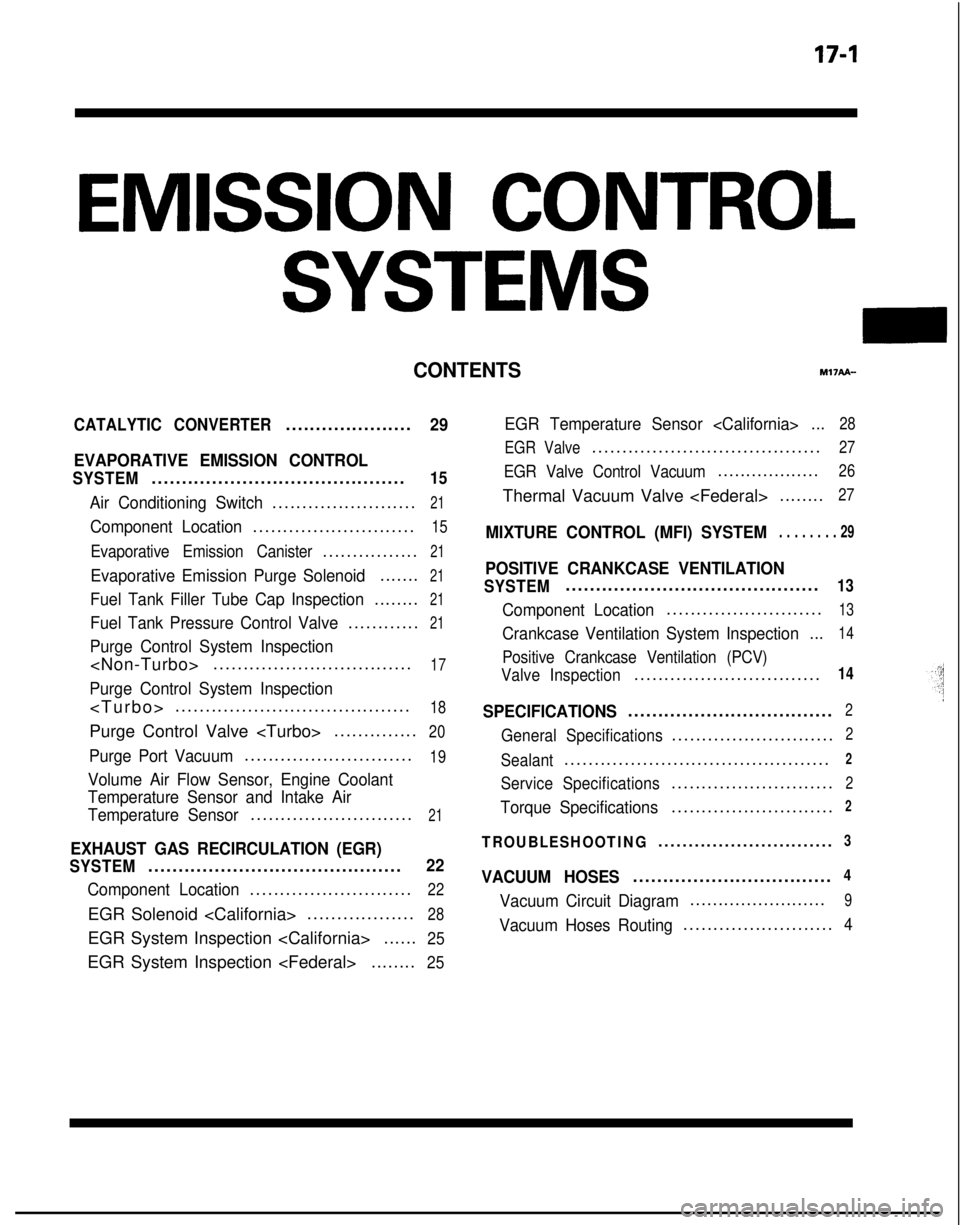

EMISSION CONTROL

SYSTEMS

CONTENTSr.w?API-

CATALYTIC CONVERTER.....................29

EVAPORATIVE EMISSION CONTROL

SYSTEM..........................................15

Air Conditioning Switch........................21

Component Location...........................15

Evaporative Emission Canister................21

Evaporative Emission Purge Solenoid.......21

Fuel Tank Filler Tube Cap Inspection........21

Fuel Tank Pressure Control Valve............21

Purge Control System Inspection

Purge Control System Inspection

.......................................

18

Purge Control Valve

..............20

Purge Port Vacuum............................19

Volume Air Flow Sensor, Engine Coolant

Temperature Sensor and Intake Air

Temperature Sensor

...........................21

EXHAUST GAS RECIRCULATION (EGR)

SYSTEM..........................................22

Component Location...........................22

EGR Solenoid

EGR System Inspection

......25

EGR System Inspection

EGR Temperature Sensor

EGR Valve

......................................27

EGR Valve Control Vacuum..................26

Thermal Vacuum Valve

MIXTURE CONTROL (MFI) SYSTEM. . . . . . . . 29

POSITIVE CRANKCASE VENTILATION

SYSTEM..........................................13

Component Location..........................13

Crankcase Ventilation System Inspection

...14

Positive Crankcase Ventilation (PCV)

Valve Inspection

...............................14

SPECIFICATIONS..................................2

General Specifications...........................2

Sealant............................................2

Service Specifications...........................2

Torque Specifications...........................2

TROUBLESHOOTING.............................3

VACUUM HOSES.................................4

Vacuum Circuit Diagram........................9

Vacuum Hoses Routing.........................4

Page 622 of 1273

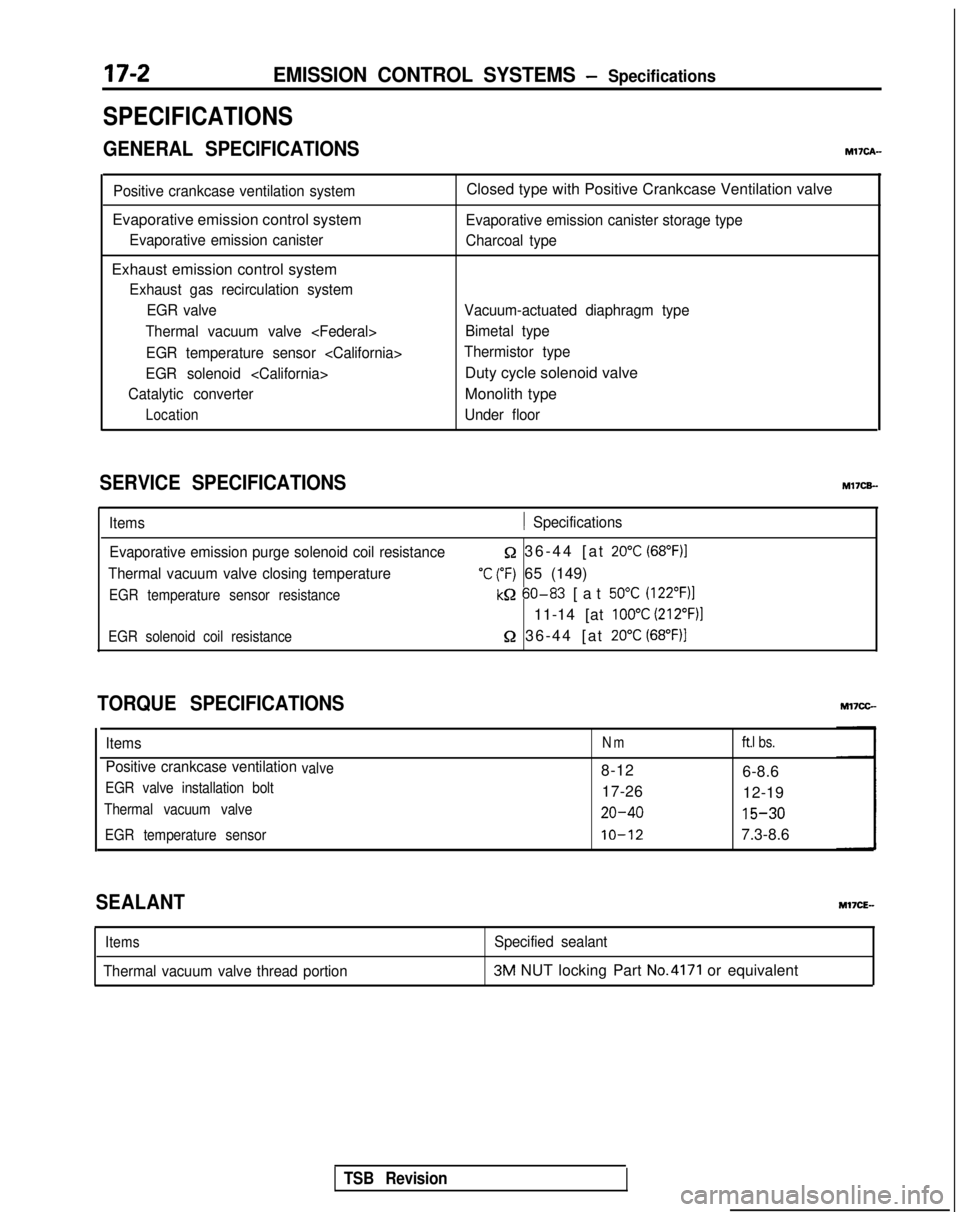

17-2EMISSION CONTROL SYSTEMS - Specifications

SPECIFICATIONS

GENERAL SPECIFICATIONSMl’IcA-

Positive crankcase ventilation system

Evaporative emission control system

Evaporative emission canister

Exhaust emission control system

Exhaust gas recirculation systemEGR valve

Thermal vacuum valve

EGR temperature sensor

EGR solenoid

Catalytic converter

Location

Closed type with Positive Crankcase Ventilation valve

Evaporative emission canister storage type

Charcoal type

Vacuum-actuated diaphragm type Bimetal type

Thermistor type

Duty cycle solenoid valve

Monolith type

Under floor

SERVICE SPECIFICATIONS M17CB-

Items1 Specifications

Evaporative emission purge solenoid coil resistance

Thermal vacuum valve closing temperature

EGR temperature sensor resistance

Q 36-44 [at 20°C (68”F)I

‘C (“F) 65 (149)

kQ 60-83

[at 50°C (122”F)l

11-14 [at 100°C (212”F)l

EGR solenoid coil resistance52 36-44 [at 20°C (68°F))

TORQUE SPECIFICATIONS

ItemsNmft.1 bs.

Positive crankcase ventilationvalve8-12

6-8.6

EGR valve installation bolt17-2612-19

Thermal vacuum valve20-40 15-30

EGR temperature sensorIO-127.3-8.6

SEALANT

Items

Thermal vacuum valve thread portion

Specified sealant3M NUT locking Part No.4171 or equivalent

TSB Revision

Page 638 of 1273

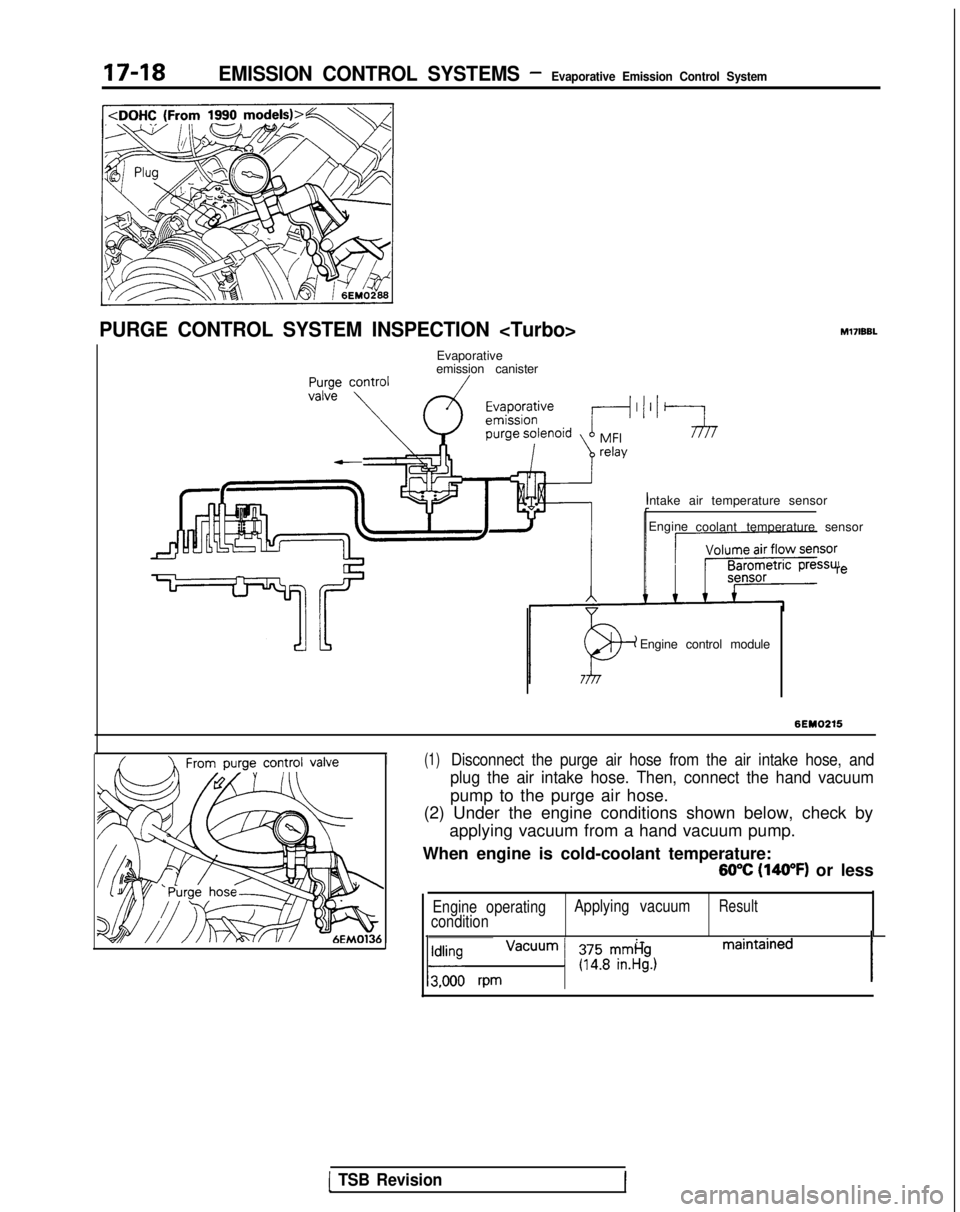

EMISSION CONTROL SYSTEMS -Evaporative Emission Control System

PURGE CONTROL SYSTEM INSPECTION

Evaporative

emission canister

Intake air temperature sensorEngine coolant temperature sensor re

Engine control module

I(1)Disconnect the purge air hose from the air intake hose, and

plug the air intake hose. Then, connect the hand vacuum

pump to the purge air hose.

(2) Under the engine conditions shown below, check by

applying vacuum from a hand vacuum pump.

When engine is cold-coolant temperature:

60°C (140°F) or less

Engine operating Applying vacuumResultcondition

1 vacuum is maintained 1ldldl rpm1 gy?r$y)

[ TSB Revision

Page 641 of 1273

EMISSION CONTROL SYSTEMS -Evaporative Emission Control System17-21EC1510

6EM137

EVAPORATIVE EMlS$lON

PURGE SOLENOID

INSPECTIONM17lBFD

NOTE

When disconnecting the vacuum hose, make an identification

mark on it so that it can be reconnected to the original posi-

tion.

(1) Disconnect the vacuum hoses (non stripe and red stripe

hoses) from the solenoid valve

(2) Disconnect the harness connector from solenoid valve.

(3) Connect a hand vacuum pump to the nipple to which the red-striped vacuum hose was connected.

(4) Apply a vacuum and check for air-tightness when voltage applied directly to the evaporative emission purge solenoid

when the voltage is discontinued.

Battery voltageResult

Non-Turbo When appliedVacuum leaks

When discontinued Vacuum is maintained

TurboWhen appliedVacuum is maintained

When discontinued Vacuum leaks

(5) Measure the resistance between the terminals of the sole-

noid valve.

Standard value: 36-44 Q [at 20°C (68”F)l

VOLUME AIR FLOW SENSOR, ENGINE

COOLANT TEMPERATURE SENSOR AND

INTAKE AIR TEMPERATURE SENSOR

M17IBGB

To inspect these parts, refer to GROUP 13-On-Vehicle Inspec-

tion of

MFI Components.

AIR CONDITIONING SWITCH Ml7IBHB

To inspect the air conditioning switch, refer to GROUP

55-Air

Conditioning Switch.

FUEL TANK PRESSURE CONTROL VALVE MI’IIBEB

To inspect the fuel tank pressure control valve, refer to GROUP

13-Fuel

Tank.

EVAPORATIVE EMISSION CANISTERM17lBlB

To inspect the evaporative emission canister, refer to GROUP

13-Fuel Line and Vapor Line.

FUEL TANK FILLER TUBE CAP INSPECTIONM,7,w~

Check the gasket of the fuel tank filler tube cap, and the filler

cap itself, for damage or deformation; replace the

cap if neces-

sary.

TSB RevisionI

Page 642 of 1273

17-22EMISSION CONTROL SYSTEMS -Exhaust Gas Recirculation (EGR) System

EXHAUST GAS RECIRCULATION (EGR) SYSTEM

COMPONENT LOCATION

Name

EGR solenoid

EGR valve

EGR temperature sensor

Thermal vacuum valve

Symbol

D

B

C

A

\ temperature

-, ‘F-$

3

i

bEM0148

1 TSB Revision

Page 643 of 1273

EMISSION CONTROL SYSTEMS -Exhaust Gas Recirculation (EGR) System17-23

INameISymbol 1

IEGR solenoid

EGR valve

EGR temperature sensor

B

C

1 Thermal vacuum valve

\

. ,6FUl93~

I

TSB Revision\i

Page 644 of 1273

17-24EMISSION CONTROL SYSTEMS- Exhaust Gas Recirculation (EGR) System

Name

EGR solenoid

EGR valve

EGR temperature sensor

Thermal vacuum valve

Symbol

D

B

C

A

6EM0166

TSB Revision

Page 648 of 1273

17-28EMISSION CONTROL SYSTEMS -Exhaust Gas Recirculation (EGR) Svstem

n

7@

REMOVAL

(1) When removing the thermal vacuum valve, do not use

wrenches or other tools on the resin part.

(2) When disconnecting the vacuum hose, put a mark on thehose so that it may be reconnected at original position.

INSTALLATION

(1) Apply specified sealant to the threads of thermal vacuumvalve and tighten to specified torque. When installing the

thermal vacuum valve, do not use wrenches or other tools

on the resin part.

Specified sealant: 3M

NUT Locking Part

No.4171 or equivalent

Specified torque:

20-40 Nm (15-30 ft.lbs.)

(2) Reconnect the vacuum hose as it was before.

EGR TEMPERATURE SENSOR

INSPECTION

(1) Remove the EGR temperature sensor.

(2) Place the EGR temperature sensor in water, and then

measure the resistance value between terminals 1 and 2

while increasing the water’s temperature.

Replace the EGR temperature sensor if there is a signifi-

cant deviation from the standard value.

INSTALLATION

(1) Install the EGR temperature sensor, tighten to specified

torque.

Specified tightening torque:

lo-12 Nm (7.3-8.6 ft.lbs.1

EGR SOLENOID

INSPECTION

NOTE

Ml7ICRB

When disconnecting the vacuum hose, make an identification

mark on it so that it can be reconnected to the original posi-

tion.

(1) Disconnect the vacuum hoses (yellow and green stripe)

from the solenoid valve.

(2) Disconnect the harness connector.

(3) Connect a hand vacuum pump to the nipple to which the

green-striped vacuum hose was connected.

TSB Revision