sensor MITSUBISHI GALANT 1989 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 556 of 1273

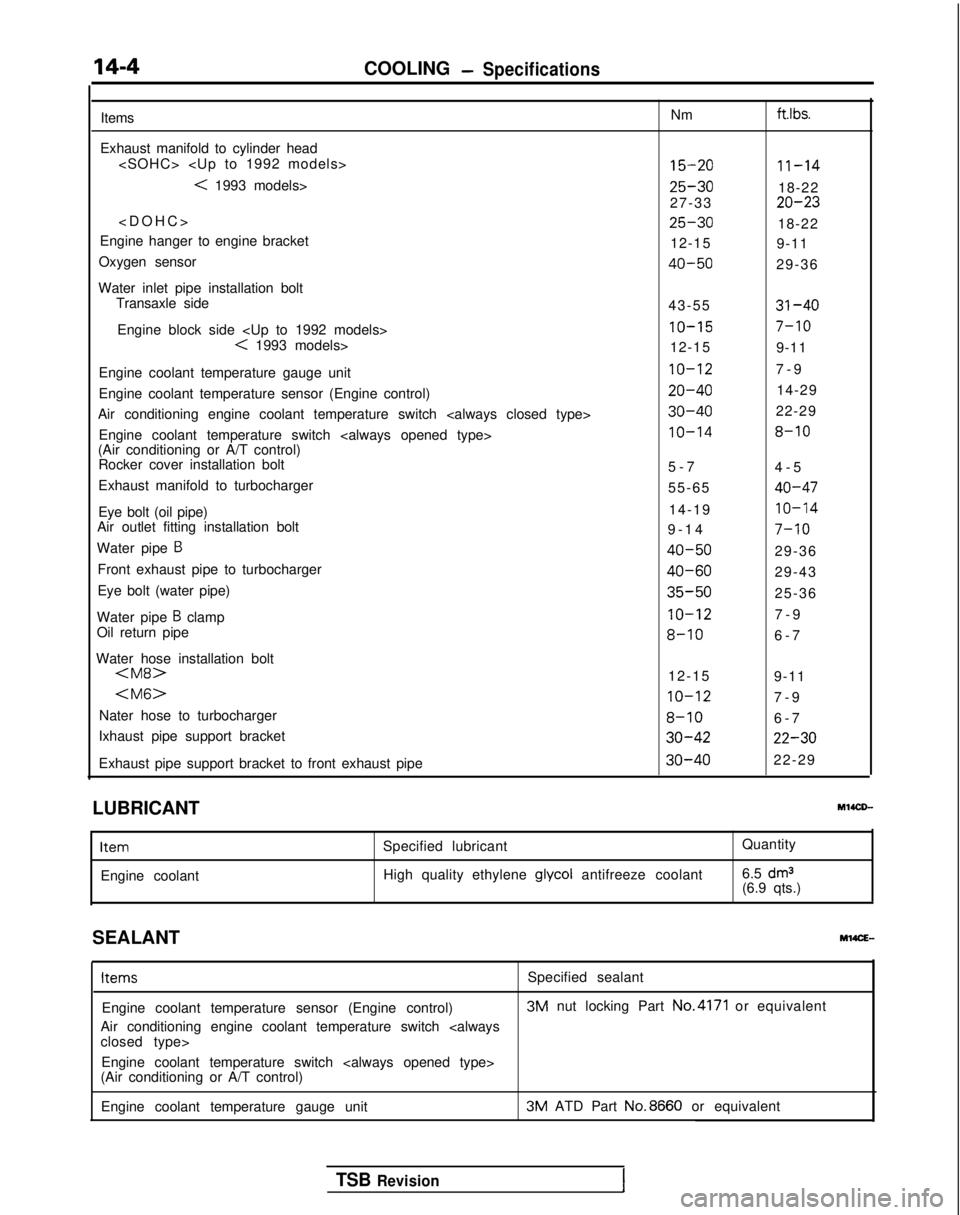

14-4COOLING-Specifications

Items

Exhaust manifold to cylinder head

< 1993 models>

Engine hanger to engine bracket

Oxygen sensor

Water inlet pipe installation bolt Transaxle side

Engine block side

< 1993 models>

Engine coolant temperature gauge unit

Engine coolant temperature sensor (Engine control)

Air conditioning engine coolant temperature switch

Engine coolant temperature switch

(Air conditioning or A/T control) Rocker cover installation bolt

Exhaust manifold to turbocharger

Eye bolt (oil pipe)

Air outlet fitting installation bolt

Water pipe

B

Front exhaust pipe to turbocharger

Eye bolt (water pipe)

Water pipe

B clamp

Oil return pipe

Water hose installation bolt

Nater hose to turbocharger

Ixhaust pipe support bracket

Exhaust pipe support bracket to front exhaust pipe Nm ft.lbs.

15-2011-14

25-3018-22

27-3320-23

25-3018-22

12-15 9-11

40-5029-36

43-55

31-40

IO-157-10

12-15 9-11

IO-127-

9

20-4014-29

30-4022-29

IO-148-10

5-

7

4-5

55-65

40-47

14-19IO-14

9-1

4

7-10

40-5029-36

40-6029-43

35-5025-36

IO-127-

9

8-106-

7

12-15 9-11

IO-127-

9

8-106-

7

30-4222-30

30-4022-29

LUBRICANT Ml4CD-

Item

Engine coolant

Specified lubricant

High quality ethylene glycol

antifreeze coolant Quantity

6.5

dm3(6.9 qts.)

SEALANT

M14CE- Items

Specified sealant

Engine coolant temperature sensor (Engine control) 3M

nut locking Part No.4171

or equivalent

Air conditioning engine coolant temperature switch

(Air conditioning or A/T control)

Engine coolant temperature gauge unit 3M

ATD Part No.8660

or equivalent

TSB Revision

Page 557 of 1273

COOLING - Special TooVTroubleshooting

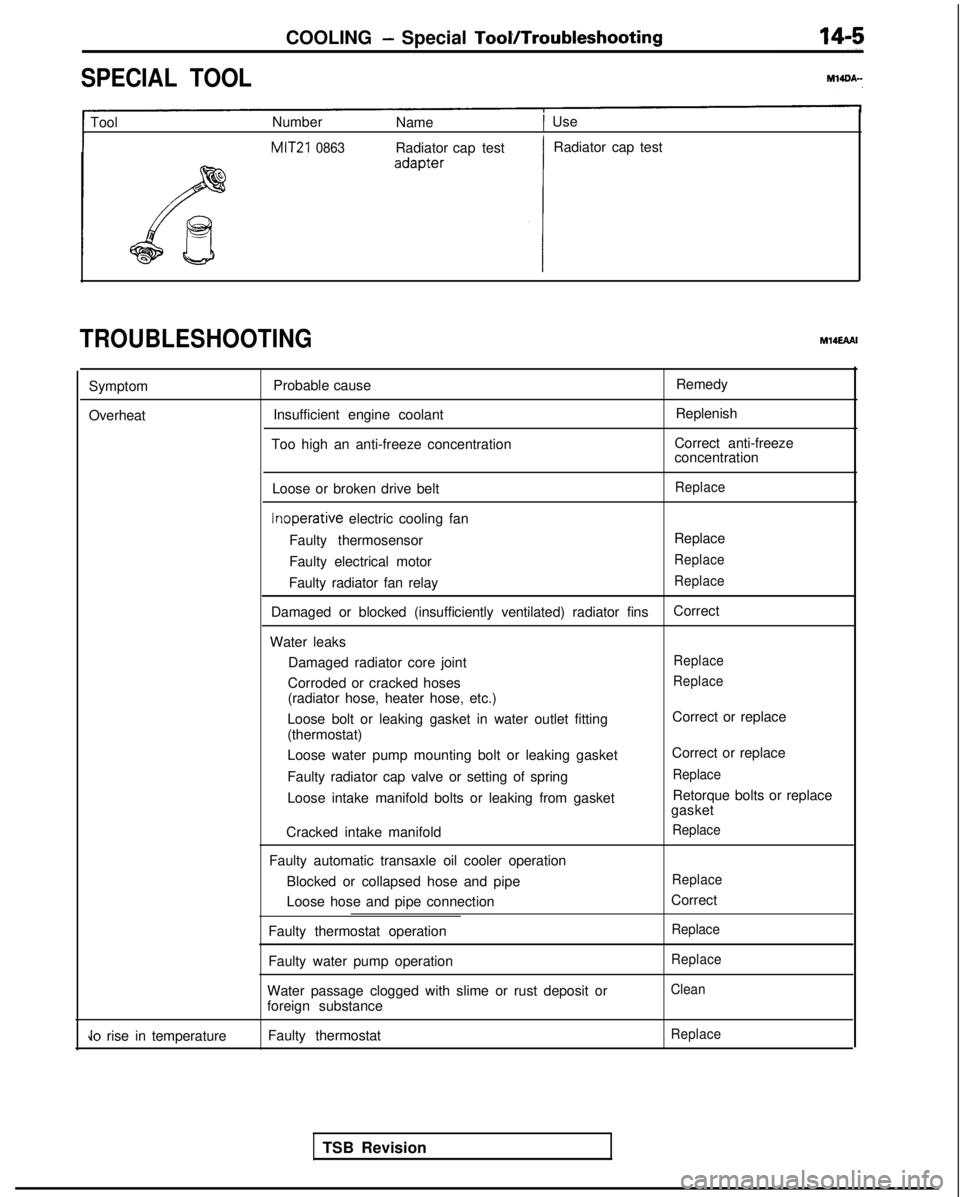

SPECIAL TOOL

1 Tool

Number

Name1 Use

MIT21 0863Radiator cap test Radiator cap test

TROUBLESHOOTINGM14EAAI

Symptom

Overheat Probable cause

Insufficient engine coolant

Too high an anti-freeze concentration Remedy

Replenish

Correct anti-freeze

concentration

Loose or broken drive belt

Replace Inoperative

electric cooling fan

Faulty thermosensor Replace

Faulty electrical motor

Replace

Faulty radiator fan relayReplace

Damaged or blocked (insufficiently ventilated) radiator fins Correct

Water leaks Damaged radiator core joint

Replace

Corroded or cracked hosesReplace

(radiator hose, heater hose, etc.)

Loose bolt or leaking gasket in water outlet fitting

(thermostat)

Loose water pump mounting bolt or leaking gasket

Faulty radiator cap valve or setting of spring

Loose intake manifold bolts or leaking from gasket

Cracked intake manifold

Faulty automatic transaxle oil cooler operation Blocked or collapsed hose and pipe

Loose hose and pipe connection

Faulty thermostat operation

Faulty water pump operation

Water passage clogged with slime or rust deposit or

foreign substance Correct or replace

Correct or replace

Replace

Retorque bolts or replace

gasket

Replace

Replace

Correct

Replace

Replace

Clean

Jo rise in temperature Faulty thermostatReplace

TSB Revision

Page 558 of 1273

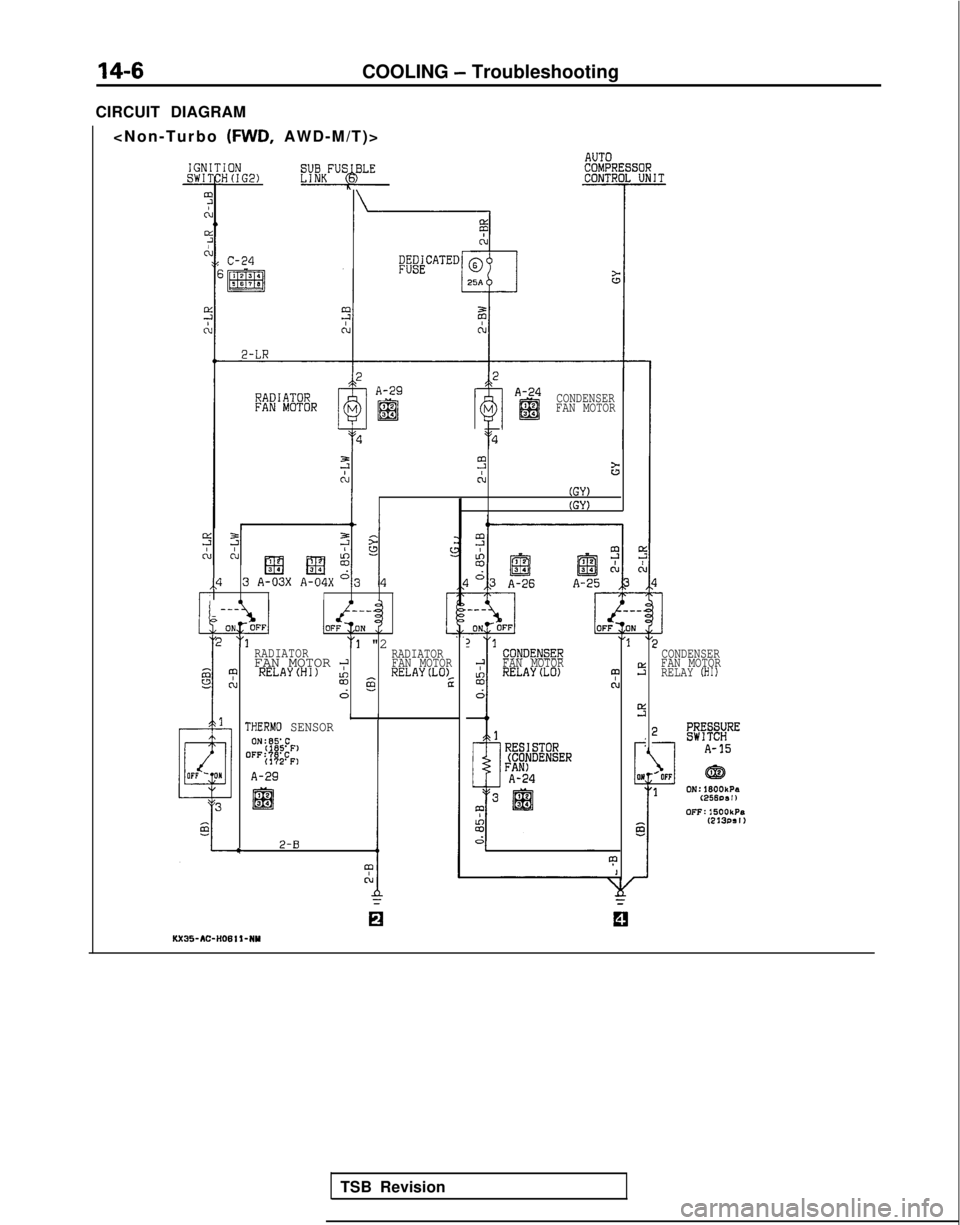

14-6COOLING - Troubleshooting

CIRCUIT DIAGRAM

IGNJvJc

c

c

c

IONH(IG2)W&FUj$?LE

C-24

3

CONDENSER

FAN MOTOR

5r; 5(GY)(GY)

,,43AExAy4x3,“4 s

[“1“1 "2RADIATOR

RADIATORFAN MOTOR +FAN MOTOR1 RELAYCHI) gRELAYCLO)J5Ed

I ITHERM0 SENSOR

ON:85’C

(185’F)OFF38 C(172’Fl

A-29

*2-E

40---4

g 51

Pu

411

d

i

FAN MOTOR

2CONDENSER

FAN MOTOR

RELAY

(HI)

&WE;""

A-15

a3 ON:1800kPa

e56Ds I )

OFF:1500kPe

(233DSl)

KXBS-AC-HOEIf-NY

TSB Revision

Page 559 of 1273

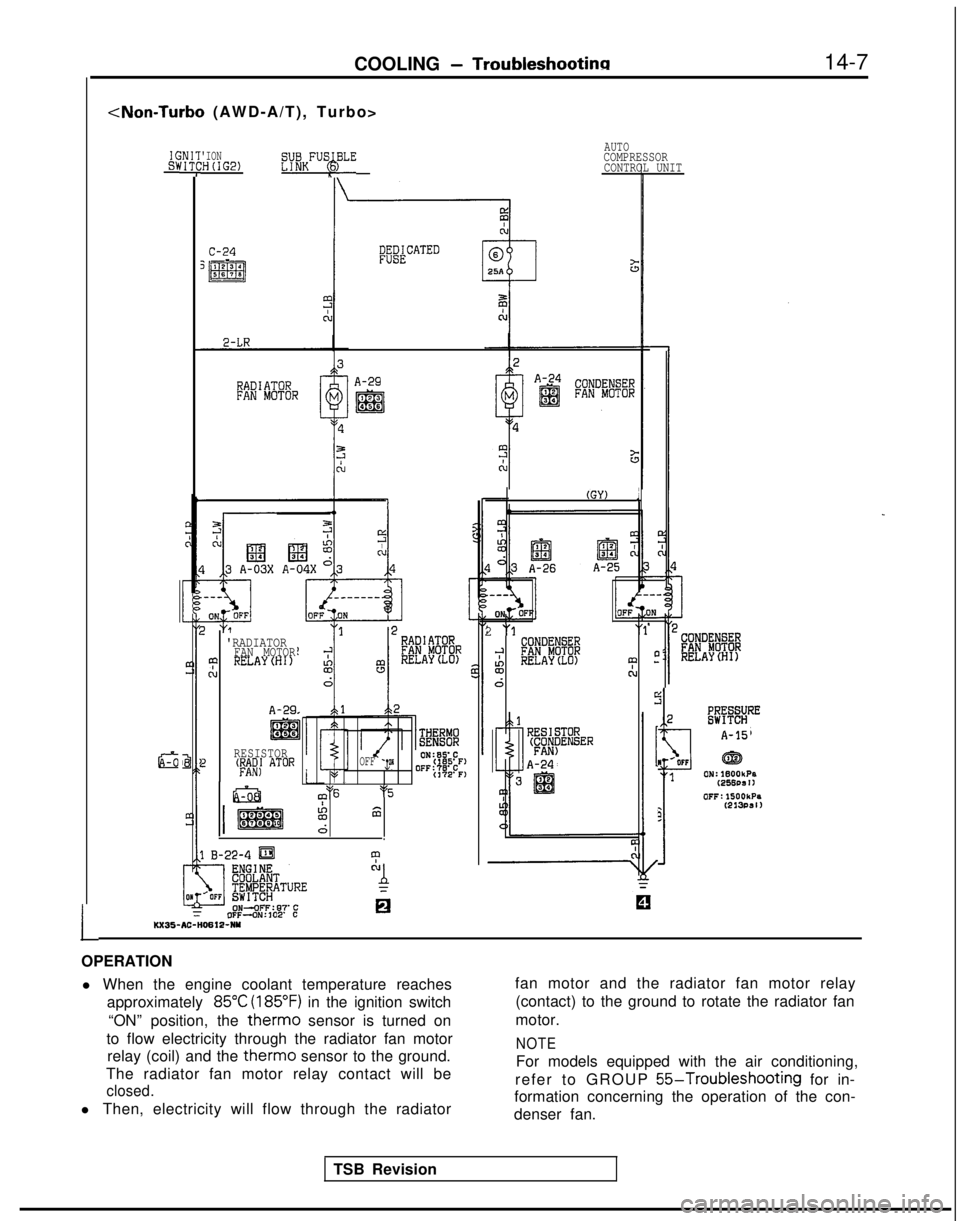

COOLING -Troubleshootina14-7

L

ICSk-iNIq

ci

'ION:H(IG2)

W&FUS$BLE

AUTOCOMPRESSOR

CONTROL UNIT

A-29

'RADIATORFAN MOTOR43 RELAYCHI)cu

A-29

RESISTOR

> 'Mf AToR

m ON:SSC

OFF -p(165'F)

OFF:?8’C(172’F)$5m6‘5I%

66.

B-22-4 m

?

"A

OFF-ON:

102’

C0 KX35-AC-H0612-NY

I(GY) ;

2 "1"1

;-'SX!D%% BRELAY(L0) 0? -

N

d

0-

A-24

2

f

A-15

I

/OFFGE3

1

0N:lBOOkPa(256DS

II 0FF:lSOOkPs

2

(213PSl)

OPERATION l When the engine coolant temperature reaches approximately

85°C (185°F) in the ignition switch

“ON” position, the

therm0 sensor is turned on

to flow electricity through the radiator fan motor relay (coil) and the

therm0 sensor to the ground.

The radiator fan motor relay contact will be

closed.

l Then, electricity will flow through the radiator fan motor and the radiator fan motor relay

(contact) to the ground to rotate the radiator fan

motor.

NOTE

For models equipped with the air conditioning,

refer to GROUP

55-Troubleshooting for in-

formation concerning the operation of the con-

denser fan.

TSB Revision

Page 561 of 1273

COOLING - Radiator

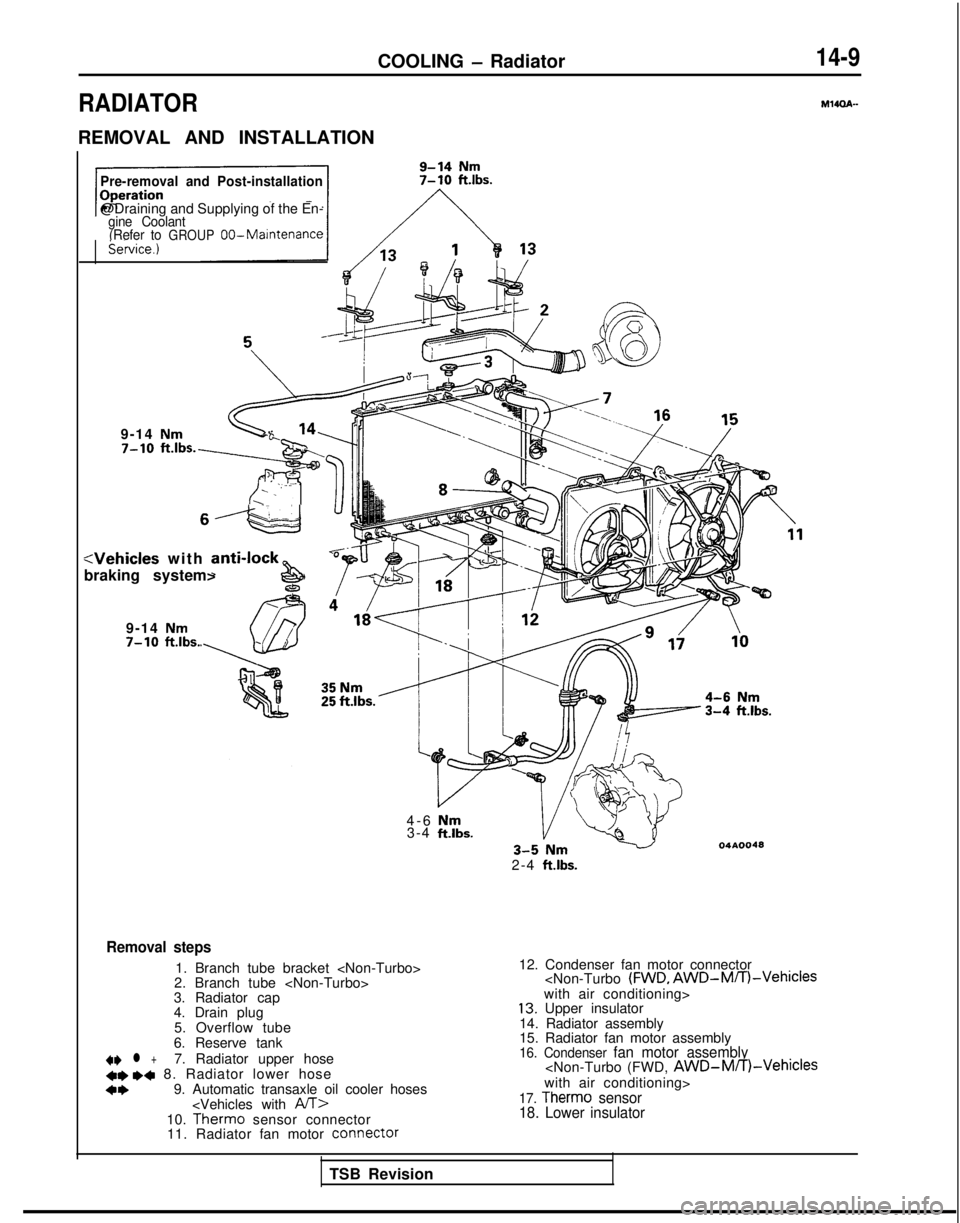

RADIATOR

REMOVAL AND INSTALLATION

14-9

M14OA-

Pre-removal and Post-installation

@Draining and Supplying of the En-gine Coolant

(Refer toGROUP 00-Maintenancekervice.)

9-14 Nm

(j/-&j

:Vehicles with anti-lock&

braking system>

9-14

Nm7-10 ft.lbs.

4-6 Nm3-4 ftlbs.04AOO48

2-4 ft.lbs.

Removal steps

1. Branch tube bracket

2. Branch tube

3. Radiator cap

4. Drain plug

5. Overflow tube

6. Reserve tank

41) l +7. Radiator upper hose+e ,+ 8. Radiator lower hose

a+9. Automatic transaxle oil cooler hoses

sensor connector

11. Radiator fan motor COnneCtOr12. Condenser fan motor connector

14. Radiator assembly

15. Radiator fan motor assembly

16. Condenser fan motor assembly

18. Lower insulator

TSB Revision

Page 563 of 1273

COOLING - Radiator14-11

04A0020

A

B’ -WaterI

423°C (725°F)temperature

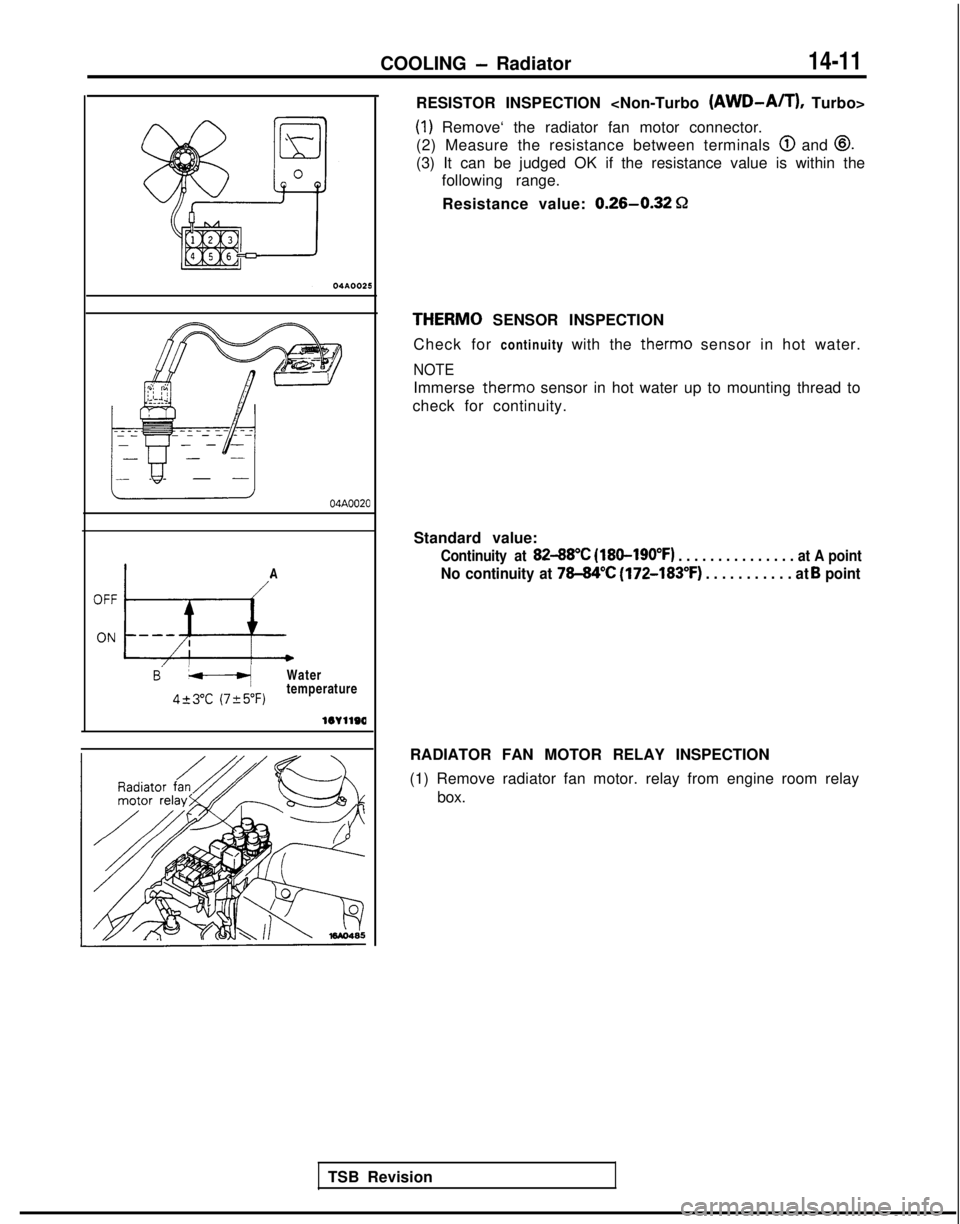

TSB Revision RESISTOR INSPECTION

(1) Remove‘ the radiator fan motor connector.

(2) Measure the resistance between terminals

0 and @.

(3) It can be judged OK if the resistance value is within the following range.

Resistance value:

0.26-0.32 Q

THERM0 SENSOR INSPECTION

Check for continuity with the therm0

sensor in hot water.

NOTE

Immerse therm0

sensor in hot water up to mounting thread to

check for continuity.

Standard value:

Continuity at 82-88”C (180-190°F) . . . . . . . . . . . . . . . at A point

No continuity at 7844°C (172-183°F) . . . . . . . . . . . at B point

RADIATOR FAN MOTOR RELAY INSPECTION

(1) Remove radiator fan motor. relay from engine room relay box.

Page 575 of 1273

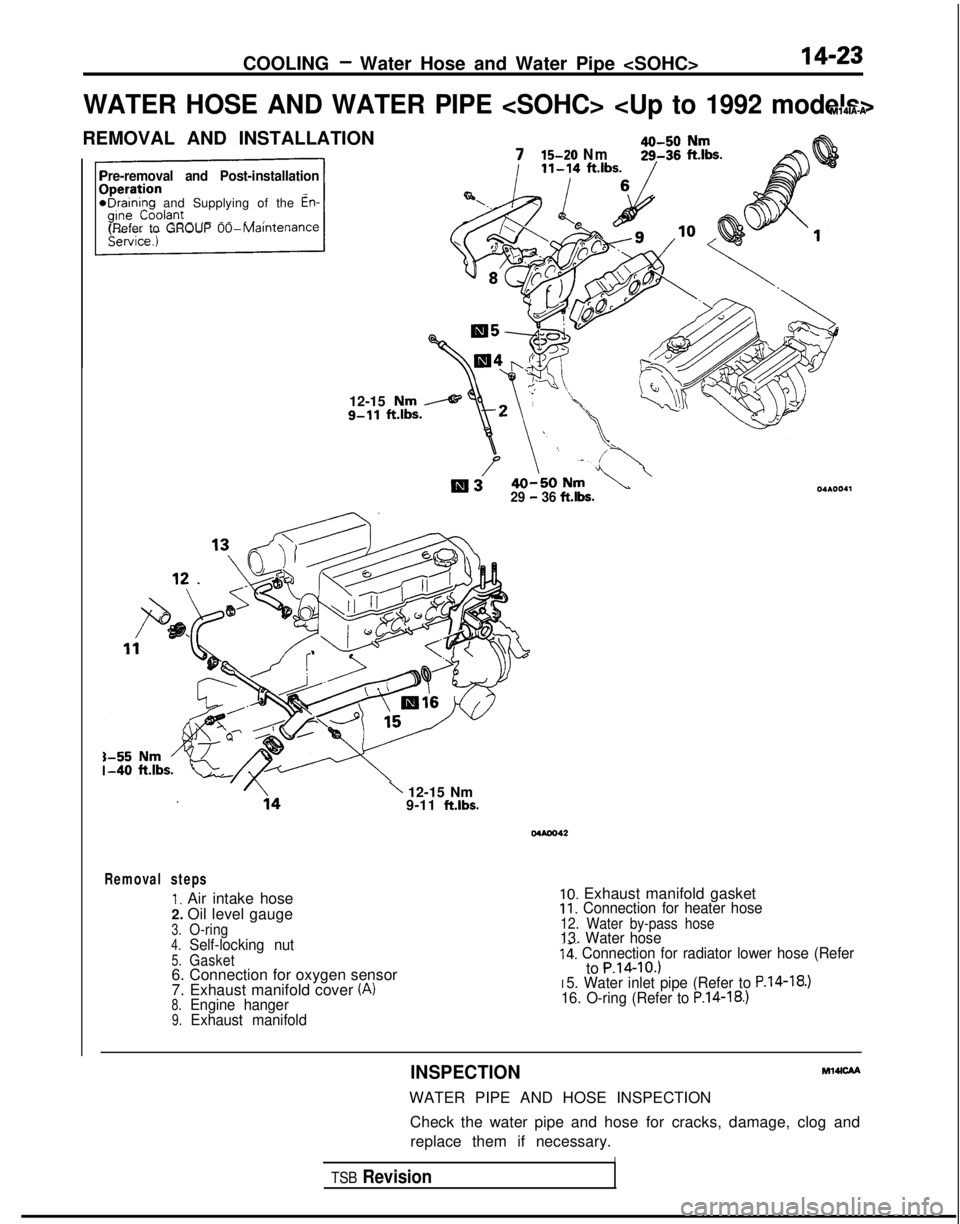

COOLING - Water Hose and Water Pipe

WATER HOSE AND WATER PIPE

REMOVAL AND INSTALLATION

Pre-removal and Post-installation

*Draining and Supplying of the En-

(Refer to GROUP 00-Maintenance

12-15 Nm

g-11

ft.lbs.

715-20 Nm

Ill329 - 36 fths.

\ 12-15 Nm

9-11 ft.lbs.

Mbm42

Removal steps

1. Air intake hose

2. Oil level gauge

3.O-ring4.Self-locking nut5.Gasket6. Connection for oxygen sensor

7. Exhaust manifold cover (A)

8.Engine hanger9.Exhaust manifold

10. Exhaust manifold gasket11. Connection for heater hose12. Water by-pass hose13. Water hosei41 Connection for radiator lower hose (Referto P.14-IO.)I 5. Water inlet pipe (Refer to P.14-18.)16. O-ring (Refer to P.14-18.)

INSPECTIONMl4lcAA

WATER PIPE AND HOSE INSPECTION

Check the water pipe and hose for cracks, damage, clog andreplace them if necessary.

ITSB Revision

Page 576 of 1273

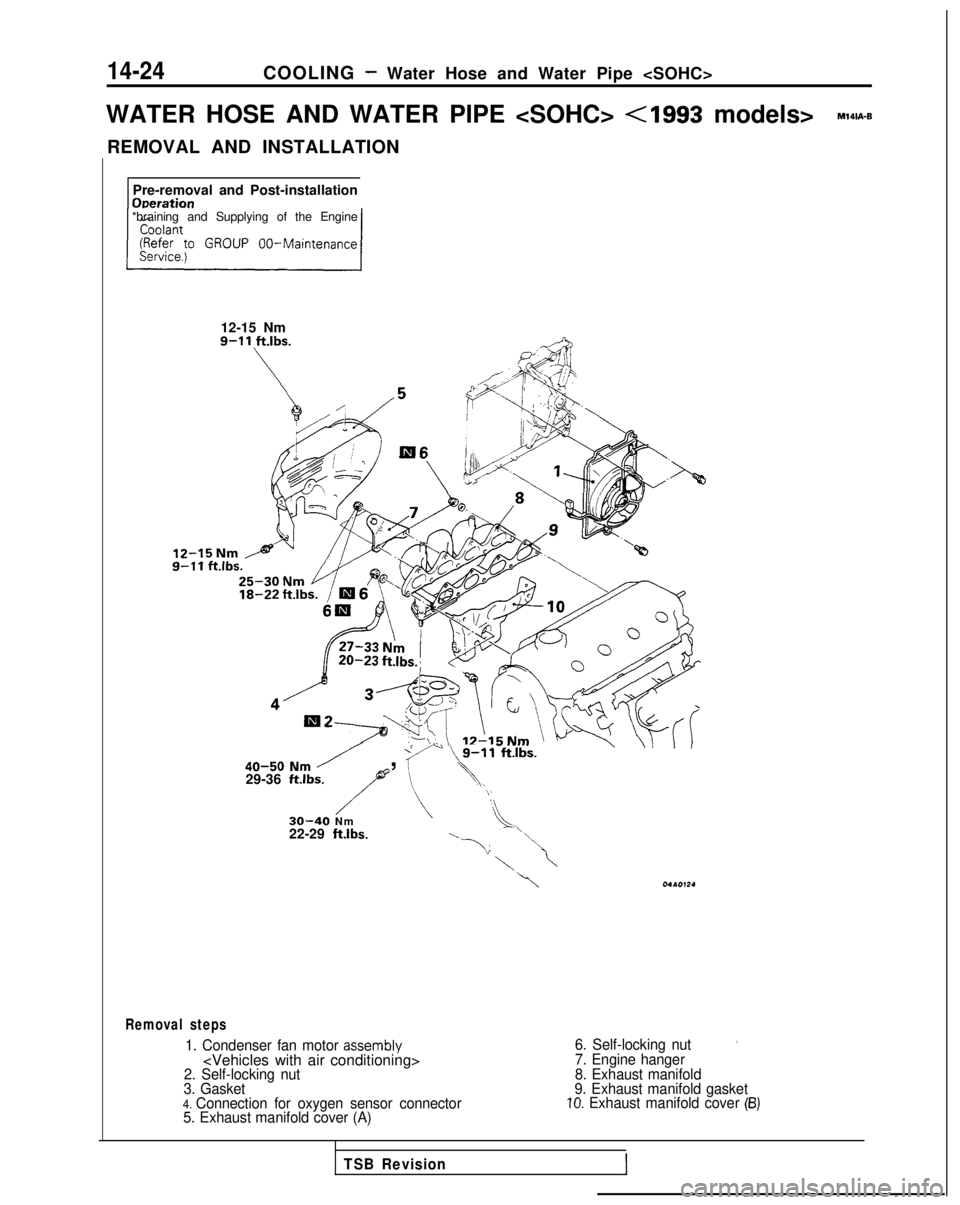

14-24COOLING - Water Hose and Water Pipe

WATER HOSE AND WATER PIPE

REMOVAL AND INSTALLATION

Pre-removal and Post-installation

ODeration*braining and Supplying of the Engine

12-15 Nm

4(,-s‘, ,,,,,, /

29-36 ftlbs.

/

, ‘r- y’ ft”bs.

\.

30-40 Nm\

22-29 ft.lbs.‘,L.\

‘7;

\“.‘i

\

Removal steps

1. Condenser fan motor assembly

3. Gasket 6. Self-locking nut

’

7. Engine hanger

8. Exhaust manifold

9. Exhaust manifold gasket

10. Exhaust manifold cover (6)4. Connection for oxygen sensor connector

5. Exhaust manifold cover (A)

TSB Revision

Page 578 of 1273

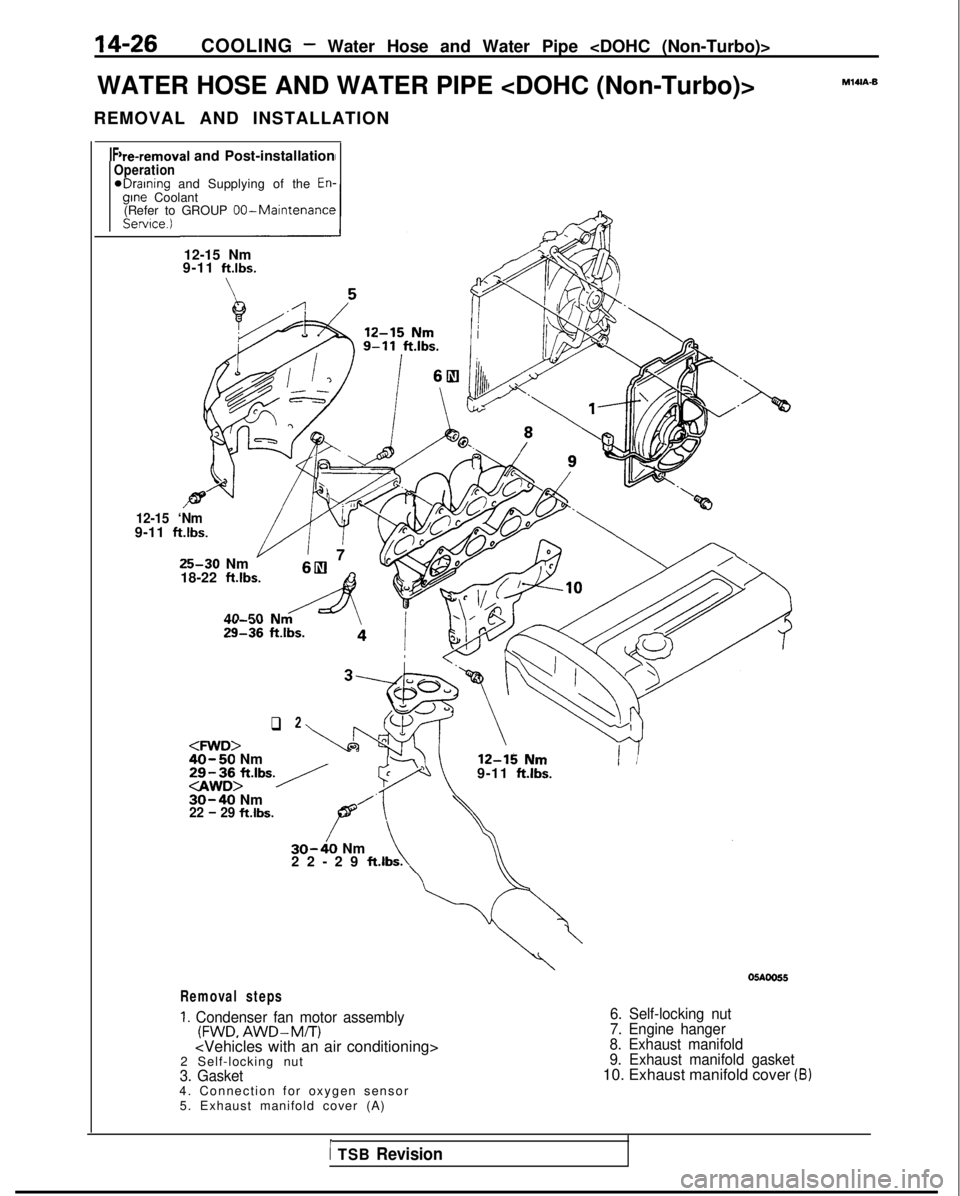

14-26COOLING - Water Hose and Water Pipe

WATER HOSE AND WATER PIPE

REMOVAL AND INSTALLATION

MlUA-B

IF‘re-removal and Post-installationOperation eDraIning

and Supplying of the En- glne

Coolant

(Refer to GROUP

00-Maintenance Service.)

12-15 Nm

9-11 ftlbs.

12-15 ‘Nm9-11 ft.lbs.

25-30 Nm’ 7

18-22

ft.lbs.68

A

40 50 Nm’&\29136 ft.lbs.4Ib.

q 2,h

40-50 Nm

9-11 ft.lbs.

30-40 Nm22 - 29 ft.lbs.

30-40 Nm\22-29 ft.lbs. \ OSAOOSS

Removal steps

1. Condenser fan motor assembly(FWD,

AWD-M/T)

2 Self-locking nut

3. Gasket4. Connection for oxygen sensor

5. Exhaust manifold cover (A)

6. Self-locking nut

7. Engine hanger

8. Exhaust manifold

9. Exhaust manifold gasket

10. Exhaust manifold cover (B)

1 TSB Revision

Page 579 of 1273

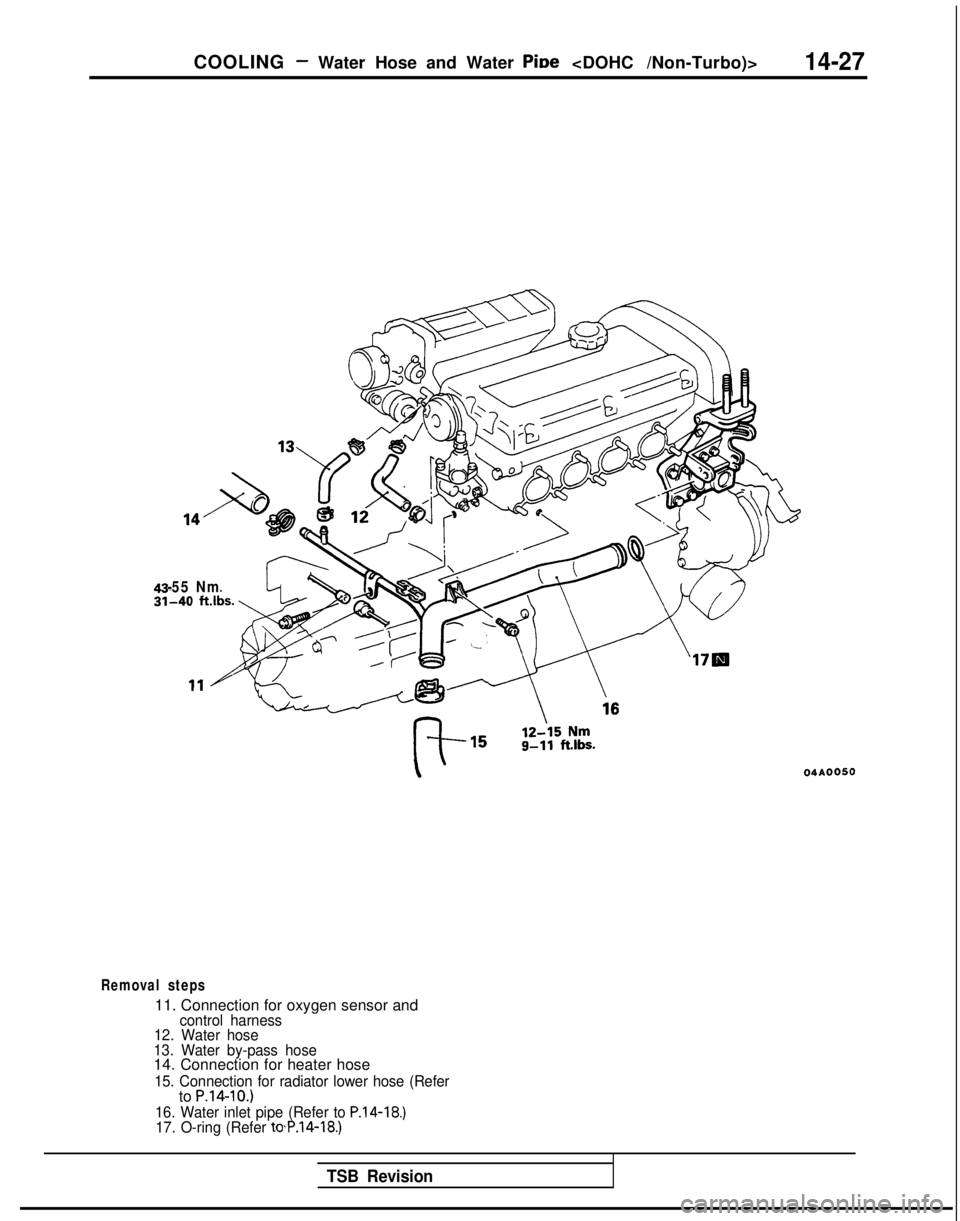

COOLING - Water Hose and Water PiDe

-55 Nm

Removal steps

11. Connection for oxygen sensor andcontrol harness

12. Water hose

13. Water by-pass hose

14. Connection for heater hose

15. Connection for radiator lower hose (Referto P.14-10.)

16. Water inlet pipe (Refer to P.14-18.)17. O-ring (Refer toP.14-18.)

04A0050

TSB Revision