MITSUBISHI GALANT 1989 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 381 of 1273

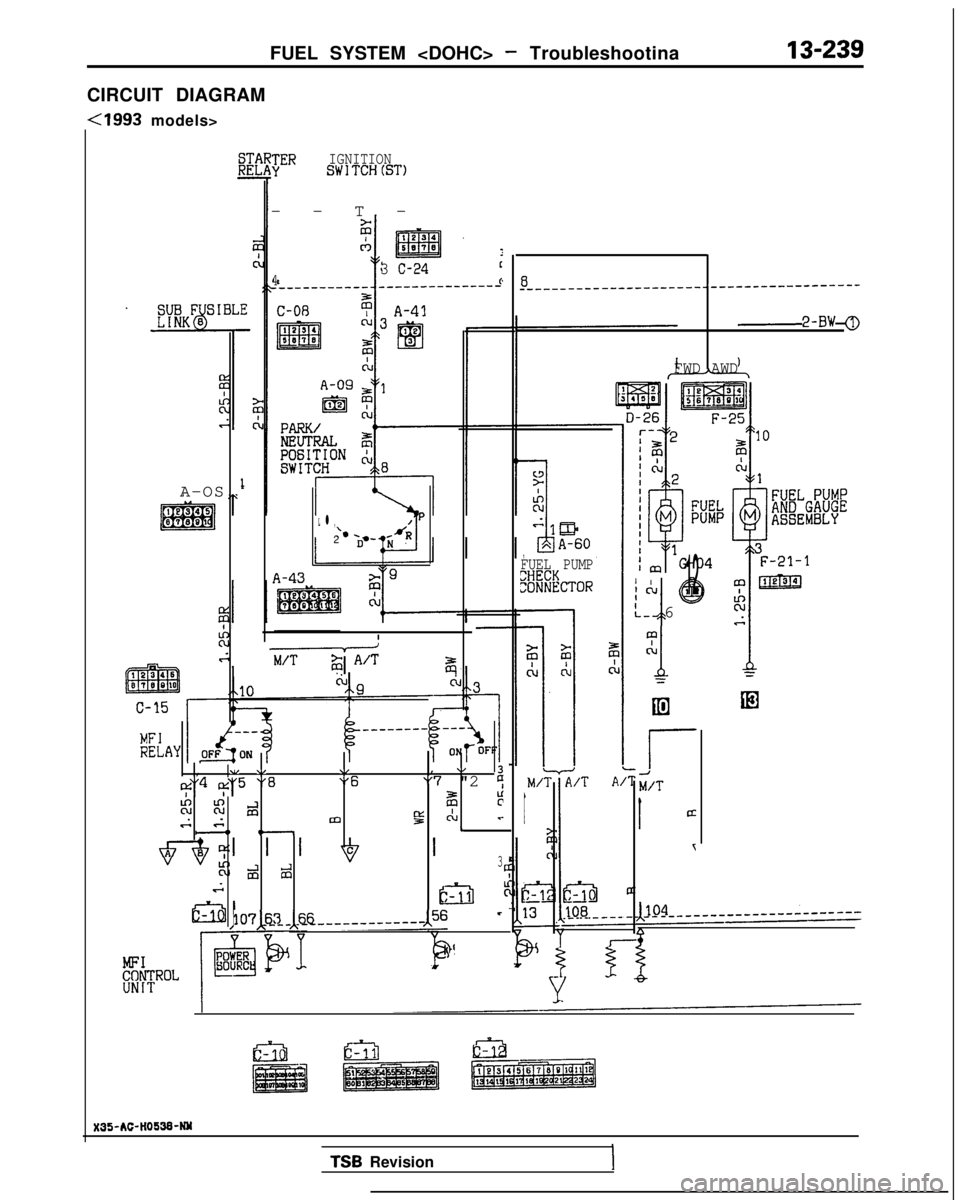

FUEL SYSTEM

CIRCUIT DIAGRAM

-Cl993 models>

A-OS

JER IGNITIONSWlTCH(ST)

--T

-

3 C-24c

4c

L l ,P

‘*2

A-43

+$1 A’Tz

, .I \/\,, \/3

I$'4 $'5 "8"6"7 "2 9

%Ki dF;rv,. 84m!z C-kJLc--o e-

d 23

2

107x~~-~~~______-------,56 -

I

&ROL

8_-____-___-_-__--___---------------------

2-BW

FWD AWD

FUEL PUMP

%#cT~RI I!”

J

@12

k. 6

m

cl

1

;

r

M/T

1ci

T

X35-AC-HO!i3&NM

TSB

Revision

Page 382 of 1273

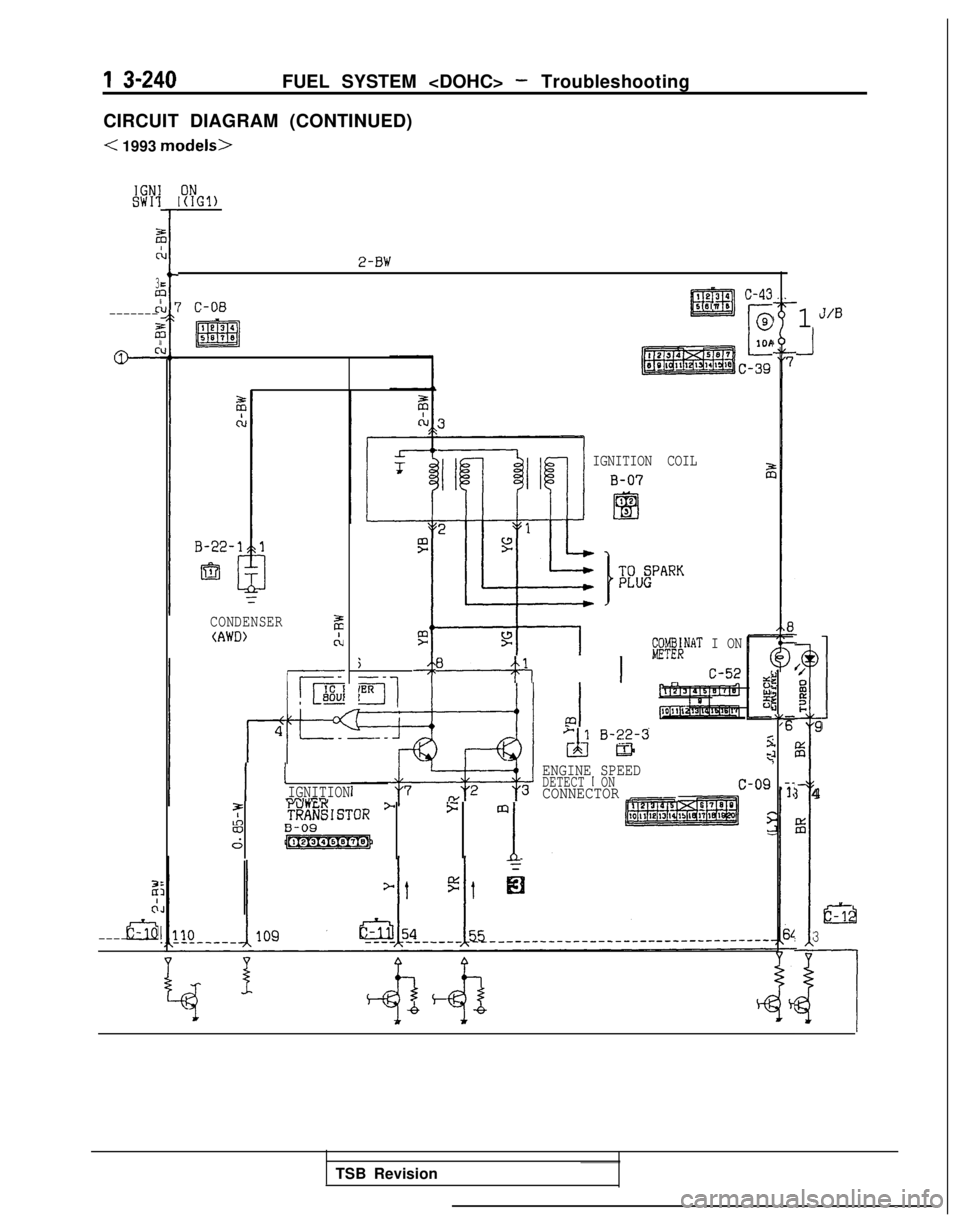

1 S-240FUEL SYSTEM

CIRCUIT DIAGRAM (CONTINUED)

< 1993 models>

IGNISW11

2

C

30

z’-------

2

ci+

21

&--------

I?YGl)

2-BW

7 C-08

1134

m5870

CONDENSERz(AWD)ct

j--

IER11

I ’IGNITIONnn3IIPl-,

I e3 4 c-43

ED507 5

C

@

1011

c-39

IGNITION COIL

iFZ;NAT I ON

w, 1 C-52

&) B-g-3

ENGINE SPEEDDETECT I ONCONNECTOR Irl

j:5 m

83B-09

61

4;5ALI.

i,

,

1J/B

J

‘/0i?0I-]9

%

~

I 4

iz

:I

liEA

3

u

TSB Revision

Page 383 of 1273

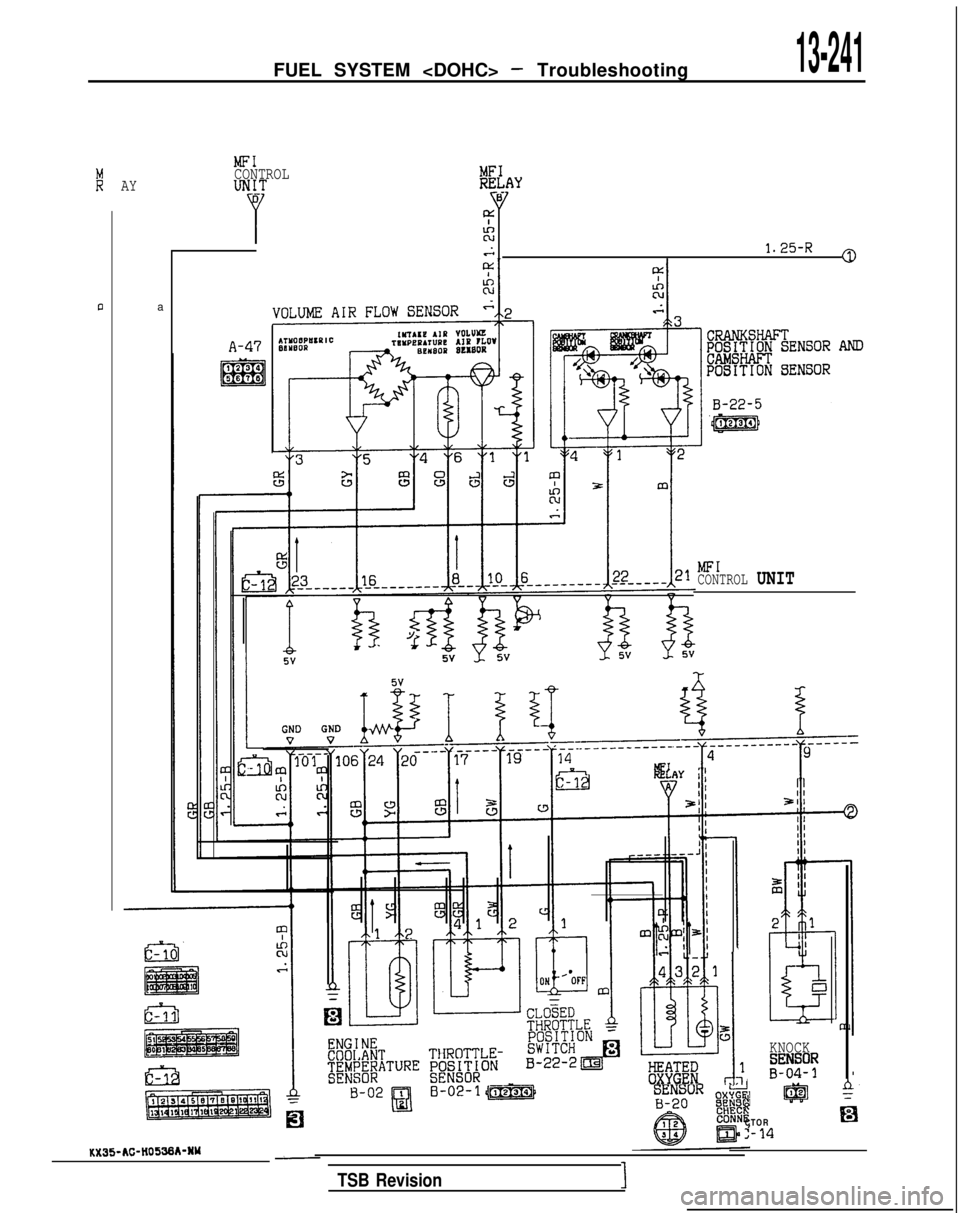

FUEL SYSTEM

MFICONTROLl&Y

lxlAcu.-i1.25-R0

AY

a

A-47

MFI

CONTROL UNIT

!z

&%R l.Tl

KNOCK

,"";y

I lg@l 42

CTOREl

2-14

TSB Revision1

KX35-AC-lt0536kNY

Page 384 of 1273

![MITSUBISHI GALANT 1989 Service Repair Manual 13-242FUEL SYSTEM <DOHC> - Troubleshooting

CIRCUIT DIAGRAM (CONTINUED)

< 1993 models>

sA-OB-

I

6

T

POWERSTEERINGgpX&RE

J/l3

\,\I4c-3

m

clLl

;

z

~~+l~:&--

*.z 3.

110+ v]

(CNG) (DATA

)

C- 18EFRONT SIDE MITSUBISHI GALANT 1989 Service Repair Manual 13-242FUEL SYSTEM <DOHC> - Troubleshooting

CIRCUIT DIAGRAM (CONTINUED)

< 1993 models>

sA-OB-

I

6

T

POWERSTEERINGgpX&RE

J/l3

\,\I4c-3

m

clLl

;

z

~~+l~:&--

*.z 3.

110+ v]

(CNG) (DATA

)

C- 18EFRONT SIDE](/img/19/57312/w960_57312-383.png)

13-242FUEL SYSTEM

CIRCUIT DIAGRAM (CONTINUED)

< 1993 models>

sA-OB-

I

6

T

POWERSTEERINGgpX&RE

J/l3

\,\I4c-3

m

clLl

;

z

~~+l~:&--

*.z 3.

110+ v]

(CNG) (DATA

)

C- 18EFRONT SIDE

5V

I

4%_-__-_-_________-----.--

11

r

12g 15g%

1

2

i

F

1

IGNITION

TIMING ADJUSTMENT

CONNECTOR

1

II

E

2 1

2

A-61

ml

%ES&$MERATURE

WEHI CLES FORCALIFORNIA)

E-04

Igig .

TROLP(AWD>

1 TSB RevisionI

Page 385 of 1273

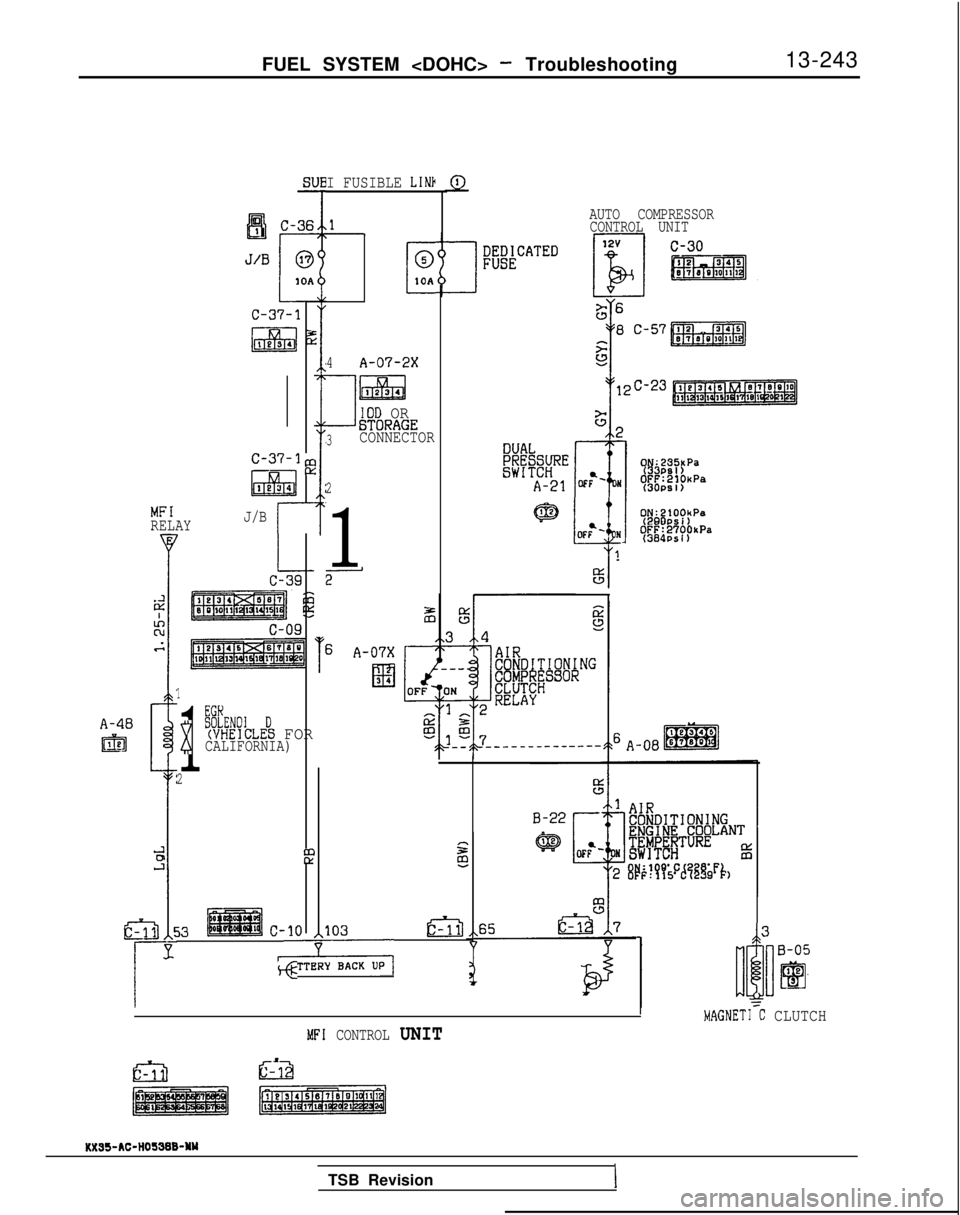

FUEL SYSTEM

13-243

A-48

IEEl

Sl-

c-37-3,:

l&l

lx

1e34

MFIRELAYJ/Br

1

1

x

BSLHENOI D(VHEICLES FORCALIFORNIA)

2

&

53c-10

-

103

, BAWL”‘,

E2-J

G

I FUSIBLE LINb

C

0

10A

4A-07-2X

1

liizEa1234

IOD ORGTORAGE3CONNECTOR

2

1

2

AUTO COMPRESSOR

CONTROL UNIT

OF? N

i

!

%

#j;;y;,

(3OPSl)

0N:ZlOOhPa(29DPSi)OFF:2’i’OOkPa(384PS I)

I

[

MAGNET1 C CLUTCH

3

lh

B-05

Elle.3

=

MFI CONTROL UNIT

TSB Revision

Page 386 of 1273

13-244FUEL SYSTEM

FUEL TANK AND FUEL LINE

MlBEAAh

Symptom Probable cause Remedy

Engine malfunctions Bent or kinked fuel pipe or hose Repair or replace

due to insufficient fuel supply

Clogged fuel pipe

or hose Clean or replace

Clogged fuel filter or in-tank fuel filter Replace

Water in fuel filter Replace the fuel filter or clean the fuel tank

and fuel line

Dirty or rested fuel tank interior

Malfunctioning fuel pump

(Clogged filter in the pump) Clean or replace

Replace Zvaporative

emission Mispiping of vapor line

Correct

:ontrol system malfunc-:ions (When fuel tank

Disconnect vapor line piping joint

Correct‘iller tube cap is re-noved, pressure releas-

Folded, bent, cracked or clogged vapor lineReplaceng noise is heard)

Faulty fuel tank filler tube cap

Malfunctioning fuel tank pressure control

valve Replace

Replace

TSB Revision

I

Page 387 of 1273

FUEL SYSTEM

cl989 models> -a’i\.-upI t

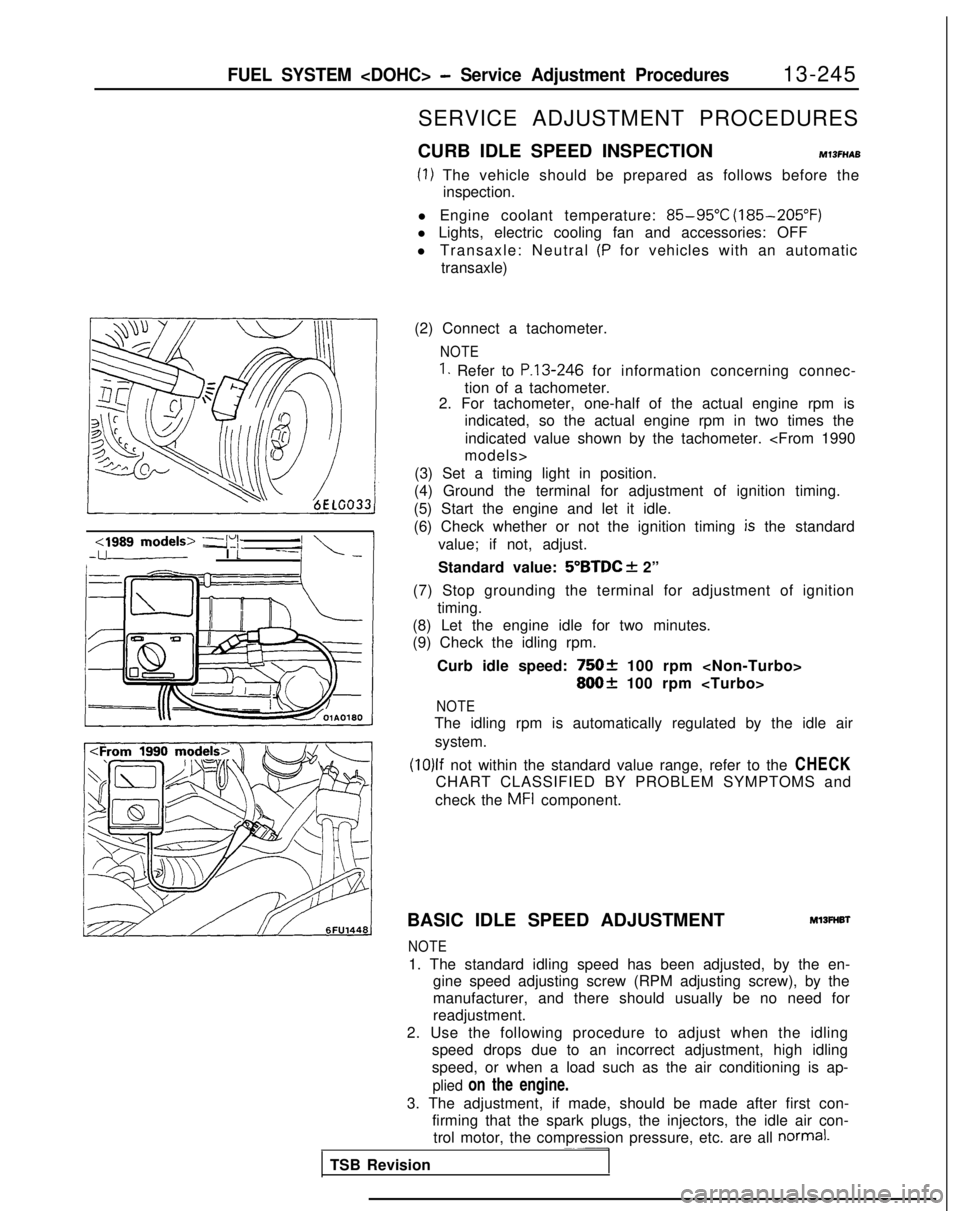

SERVICE ADJUSTMENT PROCEDURES

CURB IDLE SPEED INSPECTION

MlSFHAB

(1) The vehicle should be prepared as follows before the inspection.

l Engine coolant temperature:

85-95°C (185-205°F)

l Lights, electric cooling fan and accessories: OFF

l Transaxle: Neutral

(P for vehicles with an automatic

transaxle)

(2) Connect a tachometer.

NOTE

1. Refer to P.13-246 for information concerning connec-

tion of a tachometer.

2. For tachometer, one-half of the actual engine rpm is

indicated, so the actual engine rpm in two times the

indicated value shown by the tachometer.

(3) Set a timing light in position.

(4) Ground the terminal for adjustment of ignition timing.

(5) Start the engine and let it idle.

(6) Check whether or not the ignition timing

is the standard

value; if not, adjust.

Standard value:

5”BTDC f 2”

(7) Stop grounding the terminal for adjustment of ignition timing.

(8) Let the engine idle for two minutes.

(9) Check the idling rpm.

Curb idle speed:

75Ok 100 rpm

800+ 100 rpm

NOTE

The idling rpm is automatically regulated by the idle airsystem.

(10)lf not within the standard value range, refer to the CHECK

CHART CLASSIFIED BY PROBLEM SYMPTOMS and

check the

MFI component.

BASIC IDLE SPEED ADJUSTMENT

Ml3FHBl

NOTE

1. The standard idling speed has been adjusted, by the en- gine speed adjusting screw (RPM adjusting screw), by the

manufacturer, and there should usually be no need for

readjustment.

2. Use the following procedure to adjust when the idling speed drops due to an incorrect adjustment, high idling

speed, or when a load such as the air conditioning is ap-

plied on the engine.

3. The adjustment, if made, should be made after first con- firming that the spark plugs, the injectors, the idle air con-trol motor, the compression pressure, etc. are all

normal.~~-

TSB Revision

Page 388 of 1273

13-246FUEL SYSTEM

17k&---,!E~,~~/iY I

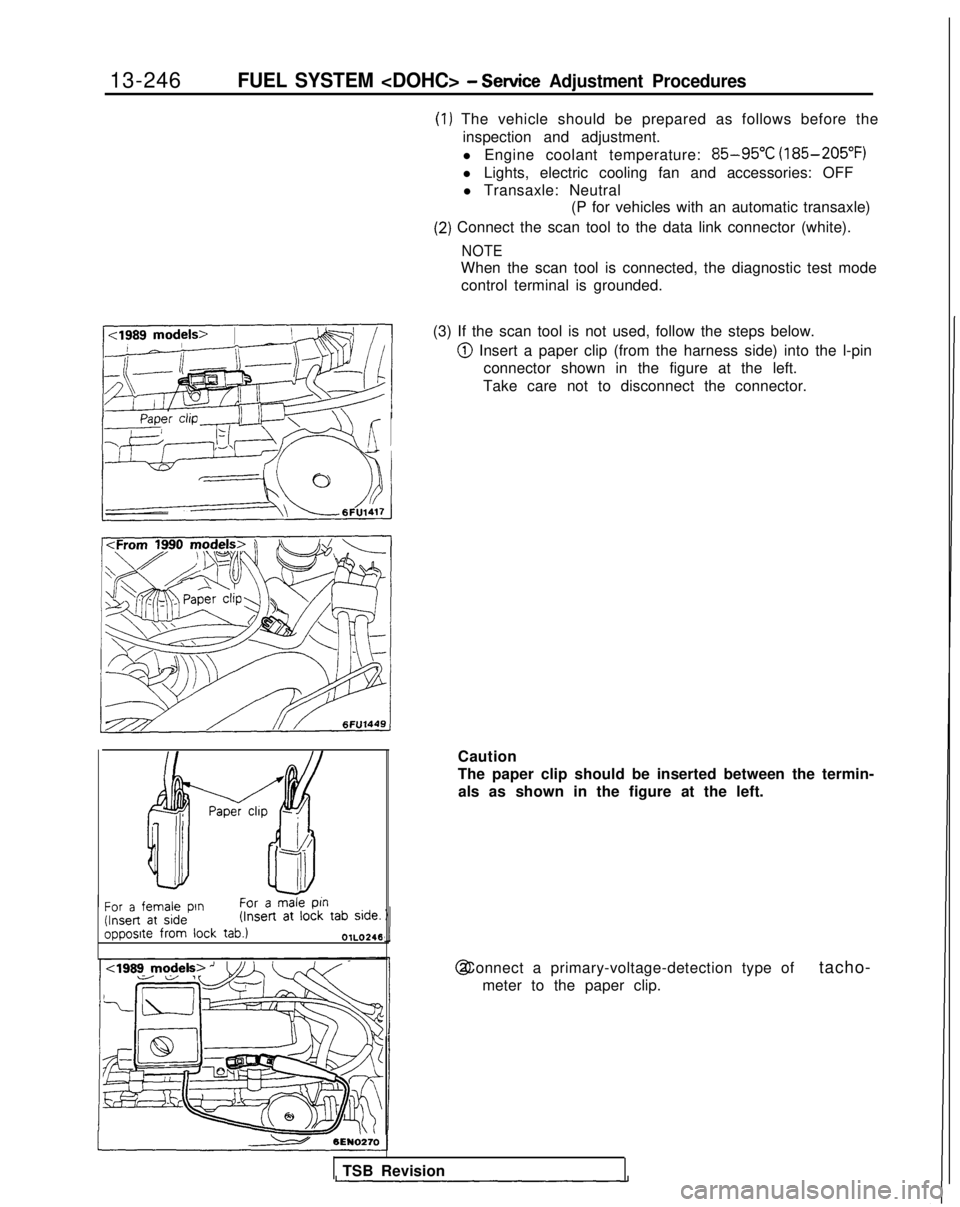

(1) The vehicle should be prepared as follows before the

inspection and adjustment.

l Engine coolant temperature:

85-95°C (185-205°F)

l Lights, electric cooling fan and accessories: OFF l Transaxle: Neutral (P for vehicles with an automatic transaxle)

(2) Connect the scan tool to the data link connector (white).

NOTE

When the scan tool is connected, the diagnostic test mode

control terminal is grounded.

(3) If the scan tool is not used, follow the steps below.

@ Insert a paper clip (from the harness side) into the l-pin connector shown in the figure at the left.

Take care not to disconnect the connector.

/ Paper chp -

f!f--i!t

Ah

-II

For a female pin

For a male

ptn (Insert

at side (Insert

at

lock tab side.

opposite from

lock

tab.)OlL0246

Caution

The paper clip should be inserted between the termin-

als as shown in the figure at the left. @ Connect a primary-voltage-detection type of

tacho-

meter to the paper clip.

TSB Revision

Page 389 of 1273

FUEL SYSTEM

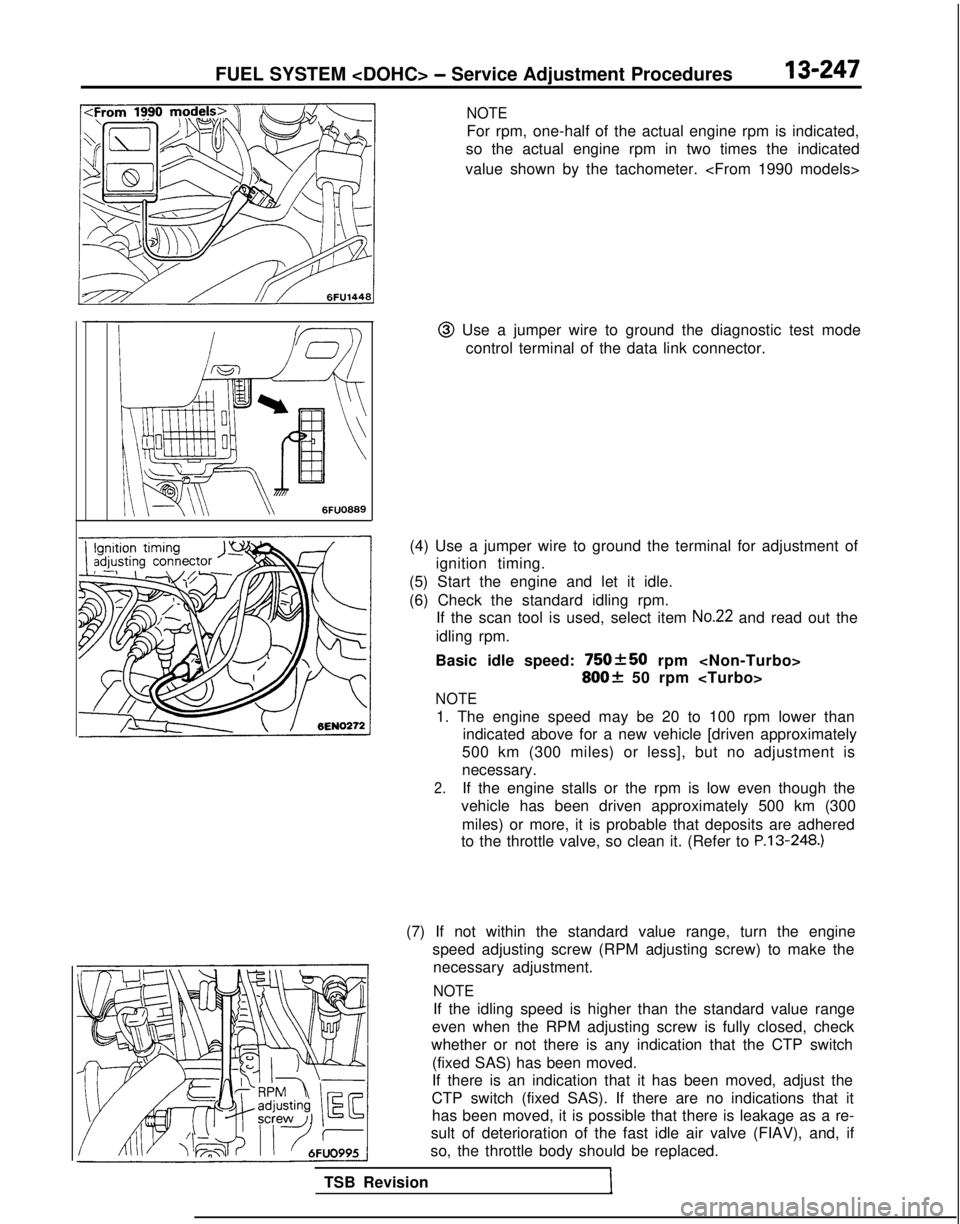

NOTE

For rpm, one-half of the actual engine rpm is indicated,

so the actual engine rpm in two times the indicated

value shown by the tachometer.

@I Use a jumper wire to ground the diagnostic test mode control terminal of the data link connector.

(4) Use a jumper wire to ground the terminal for adjustment of ignition timing.

(5) Start the engine and let it idle.

(6) Check the standard idling rpm. If the scan tool is used, select item

No.22 and read out the

idling rpm.

Basic idle speed:

750+50 rpm

800f 50 rpm

NOTE

1. The engine speed may be 20 to 100 rpm lower than indicated above for a new vehicle [driven approximately

500 km (300 miles) or less], but no adjustment is

necessary.

2.If the engine stalls or the rpm is low even though the

vehicle has been driven approximately 500 km (300

miles) or more, it is probable that deposits are adhered

to the throttle valve, so clean it. (Refer to P.13-248.)

TSB Revision

1

(7) If not within the standard value range, turn the engine speed adjusting screw (RPM adjusting screw) to make thenecessary adjustment.

NOTE

If the idling speed is higher than the standard value range

even when the RPM adjusting screw is fully closed, check

whether or not there is any indication that the CTP switch

(fixed SAS) has been moved.

If there is an indication that it has been moved, adjust the

CTP switch (fixed SAS). If there are no indications that it has been moved, it is possible that there is leakage as a re-

sult of deterioration of the fast idle air valve (FIAV), and, if

so, the throttle body should be replaced.

Page 390 of 1273

13-248FUEL SYSTEM

(8) Switch OFF the ignition switch.

(9) If the scan tool was not used, disconnect the jumper wire from the diagnostic test mode control terminal. (10)Disconnect

the jumper wire from the terminal for adjust-

ment of ignition timing, and return the connector to its

original condition.

(11

)Start the engine again and let it run at idle speed for about

ten minutes; check to be sure that the idling condition is

normal.

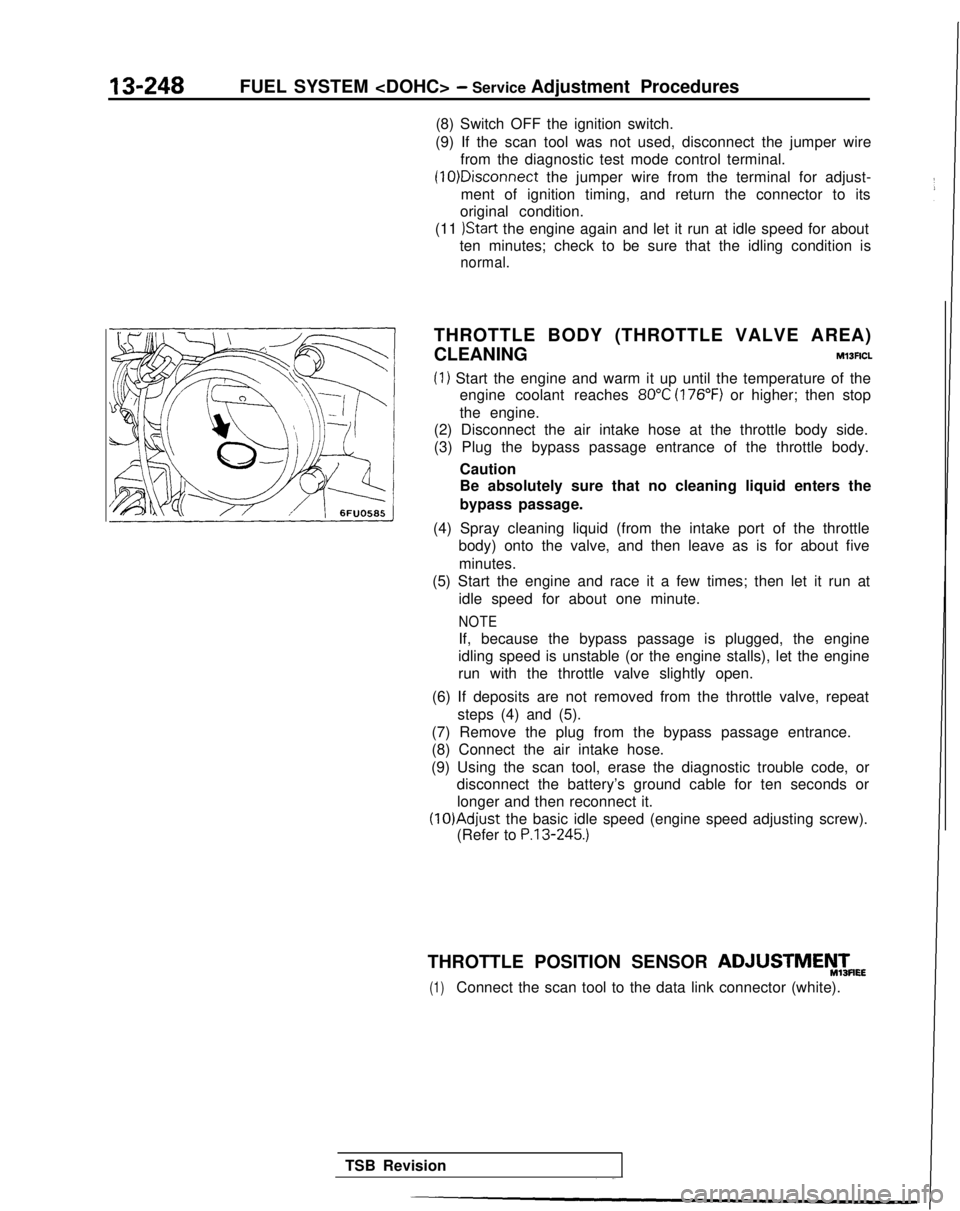

THROTTLE BODY (THROTTLE VALVE AREA)

CLEANING

Ml3ACL

(1) Start the engine and warm it up until the temperature of the engine coolant reaches

80°C (176°F) or higher; then stop

the engine.

(2) Disconnect the air intake hose at the throttle body side.

(3) Plug the bypass passage entrance of the throttle body.

Caution

Be absolutely sure that no cleaning liquid enters the

bypass passage.

(4) Spray cleaning liquid (from the intake port of the throttle body) onto the valve, and then leave as is for about five

minutes.

(5) Start the engine and race it a few times; then let it run at

idle speed for about one minute.

NOTE

If, because the bypass passage is plugged, the engine

idling speed is unstable (or the engine stalls), let the engine

run with the throttle valve slightly open.

(6) If deposits are not removed from the throttle valve, repeat steps (4) and (5).

(7) Remove the plug from the bypass passage entrance.

(8) Connect the air intake hose.

(9) Using the scan tool, erase the diagnostic trouble code, or disconnect the battery’s ground cable for ten seconds or

longer and then reconnect it. (lO)Adjust

the basic idle speed (engine speed adjusting screw).

(Refer to

P.13-245.)

THROTTLE POSITION SENSOR ADJUSTMEyTmEE

(1)Connect the scan tool to the data link connector (white).

TSB Revision