MITSUBISHI GALANT 1989 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 341 of 1273

FUEL SYSTEM

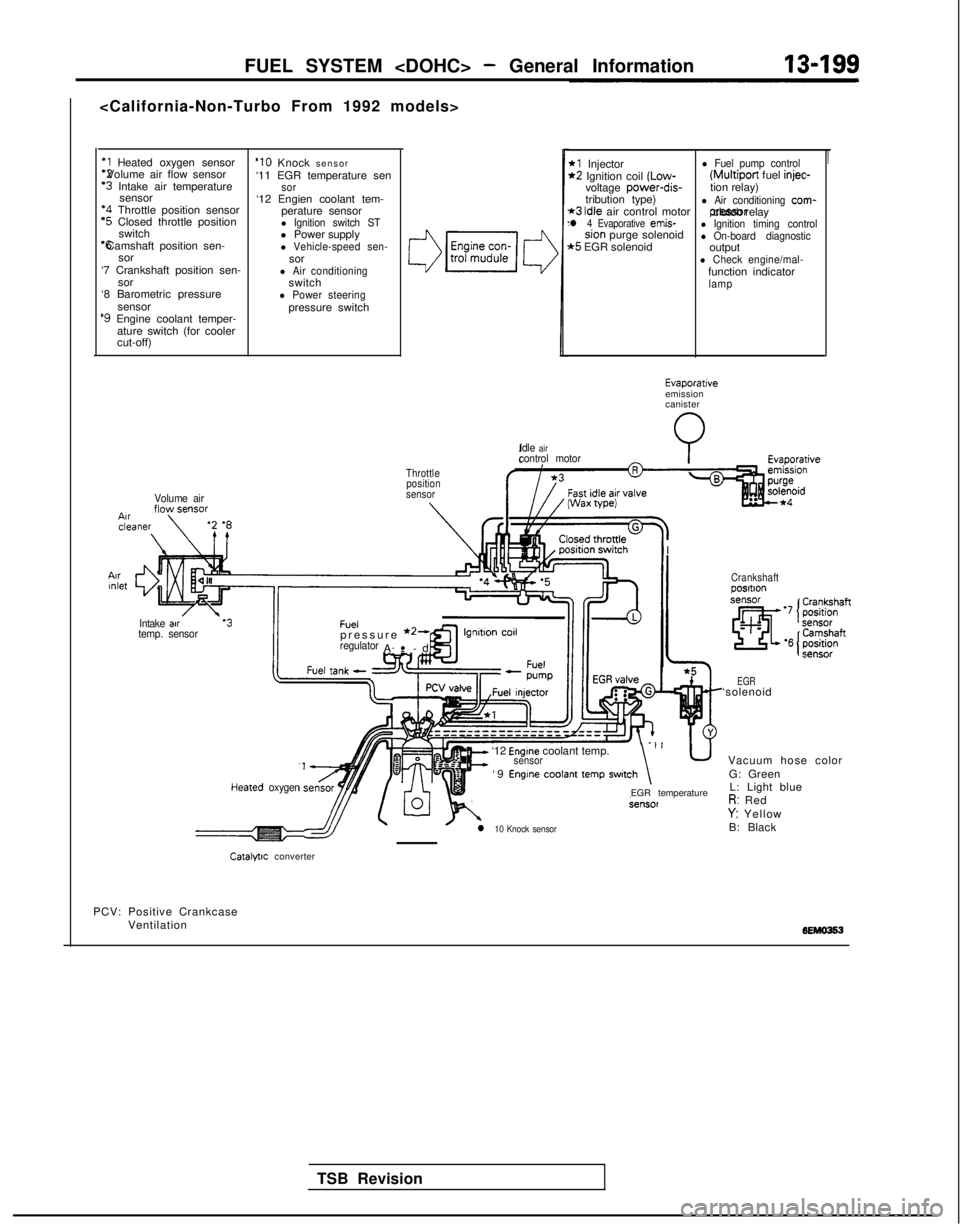

*1 Heated oxygen sensor *2 Volume air flow sensor

‘3 Intake air temperature

sensor *4

Throttle position sensor

‘5 Closed throttle position

switch *6 Camshaft position sen-

sor

‘7 Crankshaft position sen- sor

‘8 Barometric pressure

sensor

‘9 Engine coolant temper-ature switch (for cooler

cut-off)

Volume air

‘10 Knock sensor

‘11 EGR temperature sen

sor‘12 Engien coolant tem- perature sensor

l Ignition switch STl Power supplyl Vehicle-speed sen-sorl Air conditioningswitchl Power steeringpressure switch

3

Throttleposition

sensor

IIntake air.‘3Fueltemp. sensorpressure *2-regulatorA-

-

.

cd

’

*l Injectorl Fuel pump control*2 Ignition coil (Low- (Multiport

fuel injec-voltage power-dis-

tion relay)

tribution type)

*3 Idle air control motorl Air conditioning com-

l 4 Evaporative emis- pressor clutch relaysion purge solenoidl Ignition timing control

t5 EGR solenoidl On-board diagnosticoutputl Check engine/mal-function indicatorlamp

Idle

aircontrol motorI Wax

wei

I

I

TSB Revision

Evaporativeemission

canister

Heared oxygen

It=

‘12 Engine coolant temp.sensor-‘I u

‘9 Engine coolant temp switch\

l 10 Knock sensor

EGR temperature

Crankshaftposltlon

EGR‘solenoid Vacuum hose colorG: GreenL: Light blue

R: RedY: Yellow

B: Black

Catalfllc converter

PCV: Positive Crankcase Ventilation

Page 342 of 1273

13-200FUEL SYSTEM

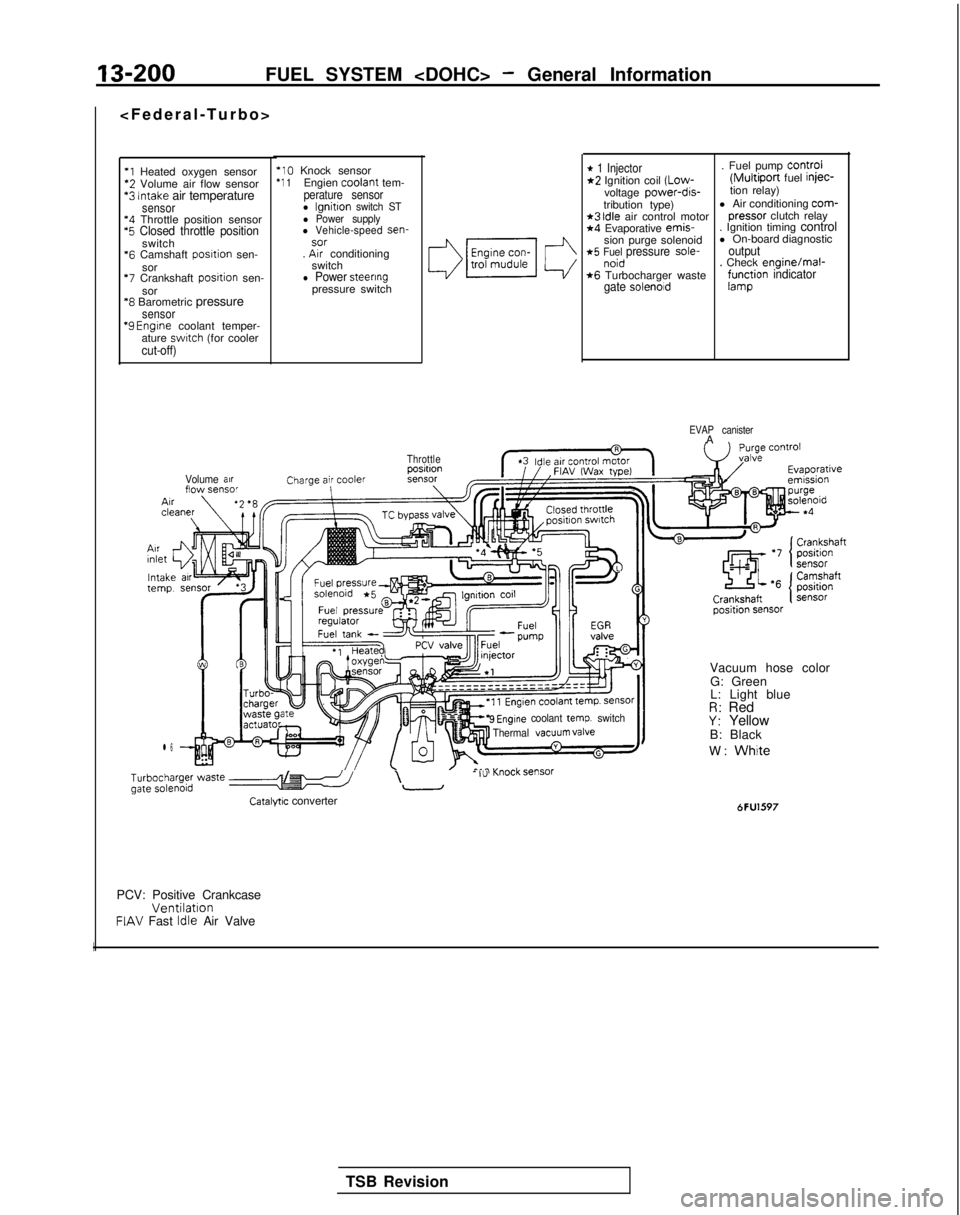

*l Heated oxygen sensor‘2 Volume air flow sensor*3 Intake air temperaturesensor‘4 Throttle position sensor‘5 Closed throttle positionswitch

*6

Camshaft posrtion sen-

sor

‘7 Crankshaft posrtion sen-

sor

‘8 Barometric pressuresensor “9

Engrne coolant temper-

ature swatch (for coolercut-off)

‘10 Knock sensor‘1 1Engien coolant

tem-perature sensorl lgnitton switch STl Power supplyl Vehicle-speed sen-sor. Arr conditioning

switch

l Power steeringpressure switch

Volume arrflow sensor

l 6

* 1 Injector. Fuel pump Control*2 Ignition coil (Low-(Multiport fuel injec-

voltage power-dis-tion relay)

tribution type) l Air conditioning com-

*3 Idle air control motor

pressor

clutch relay*4 Evaporative emis-

. Ignition timing control

sion purge solenoid l On-board diagnostic

*5 Fuel pressure sole-outputnoid. Check enginelmal-*6 Turbocharger wastegate solenoidf;r$ion indicator

EVAP canisterA

Throttle

9 Engine coolant temp. switch

Thermal VaCUUm valve

b;~ype; waste e-5 /I\- I”-

Catalyw converter

Vacuum hose color

G: Green

L: Light blue

R: RedY: Yellow

B: Black

W:

White

6FU1597

PCV: Positive CrankcaseVentilationFIAV Fast Idle Air Valve

I

TSB Revision

Page 343 of 1273

FUEL SYSTEM

I-

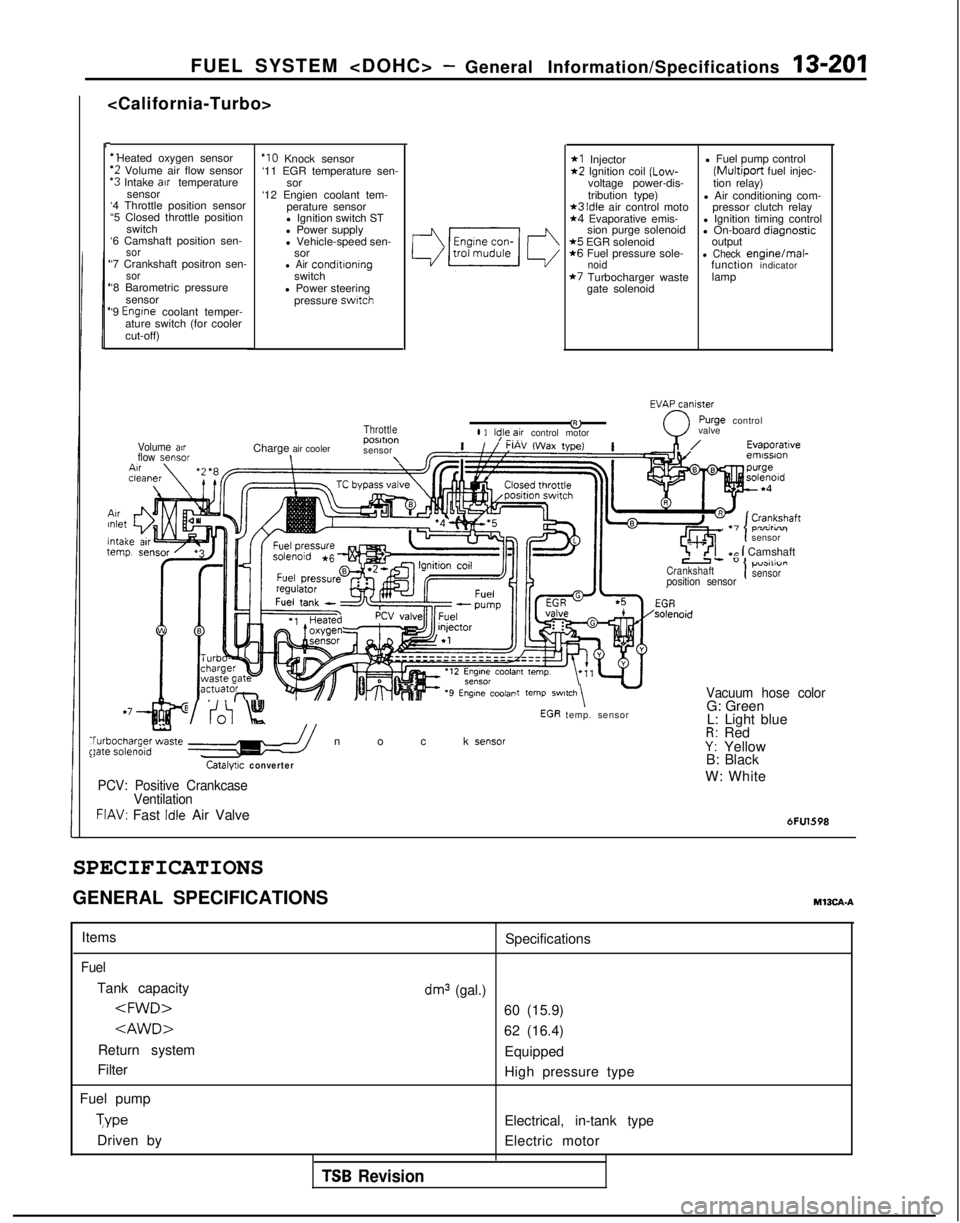

‘1 Heated oxygen sensor

‘2 Volume air flow sensor‘3 Intake arr temperature

sensor

‘4 Throttle position sensor

“5 Closed throttle position

switch

‘6 Camshaft position sen-

sor‘7 Crankshaft positron sen-sor‘8 Barometric pressure

sensor

‘9

Engrne coolant temper-

ature switch (for cooler

cut-off)

ArrInlet

lntaltern1

Volume airflow sensor

‘IO Knock sensor

‘11 EGR temperature sen- sor

‘12 Engien coolant tem- perature sensor

l Ignition switch ST

l Power supply

l Vehicle-speed sen- sor

l Air conditroningswitch

l Power steering pressure

swatch

Throttle

Charge air cooler posmon

sensor\\

*I Injector*2 Ignition coil (Low-

voltage power-dis-

tribution type)

*3 Idle air control moto*4 Evaporative emis- sion purge solenoid

*5 EGR solenoid*6 Fuel pressure sole-noid*7 Turbocharger waste

gate solenoid l Fuel pump control

(Multiport fuel injec-

tion relay)

l Air conditioning com- pressor clutch relay

l Ignition timing control

l On-board diaanostic

output

-l Check enginelmal-

function indicator

lamp

EVAxniy

&0

rurge controll 3ld,le,~ir control motor valve

,n/Evaporatrveemrssron

\tcln-^- temp. sensor

,Ir I-, . -,

sensor

7 ’ <‘I+c 1 Camshaft

Crankshaft1p”3111”I I

position sensorsensor

it

temp SWl,Ch\ -Vacuum hose color

t

WV:0 Knock sensor$bgha;ge;zte //

Catalyuc converter

G: Green

L: Light blue

R: RedY: Yellow

B: Black

PCV: Positive Crankcase

VentilationW: White

FIAV: Fast Idle Air Valve6FU1598

SPECIFICATIONS

GENERAL SPECIFICATIONSM13CA-A

Items

Fuel

Tank capacity

Return system

Filter

Fuel pump Type

Driven by Specifications

dm3 (gal.)

60 (15.9)

62 (16.4)

Equipped

High pressure type

Electrical, in-tank type

Electric motor

TSB Revision

Page 344 of 1273

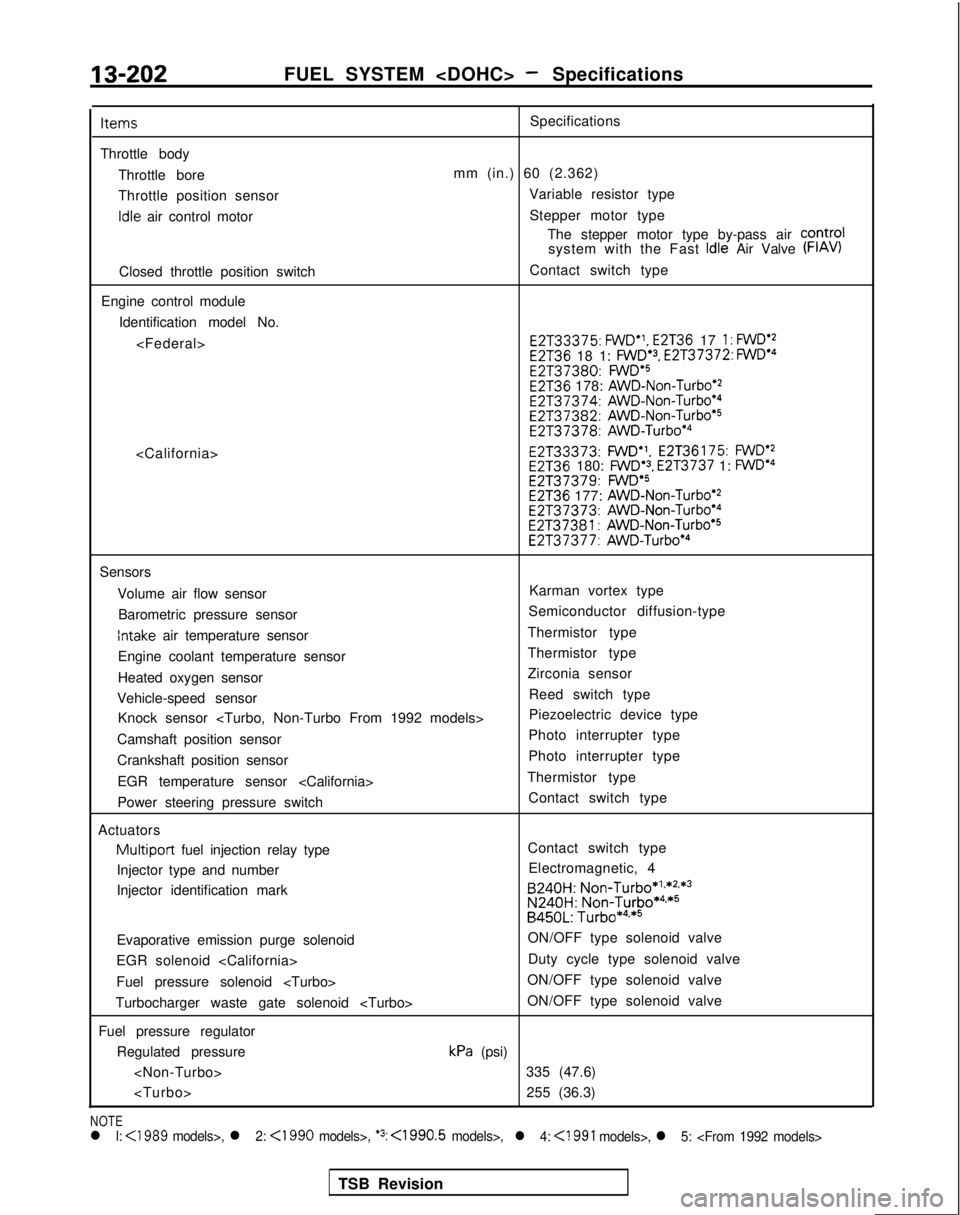

13-202FUEL SYSTEM

Throttle body Throttle bore

Throttle position sensor idle

air control motor

Closed throttle position switch

Engine control module Identification model No.

mm (in.) 60 (2.362) Variable resistor type

Stepper motor type The stepper motor type by-pass air COntrOl

system with the Fast

Idle Air Valve (FIAV)

Contact switch type E2T33375:

FWD”,

E2T36 17 1: FWD’2E2T36 18 1: FWD.3, E2T37372: FWDe4 E2137380:

FWDa5E2T36 178: AWD-Non-Turbo’2 E2T37374:

AWD-Non-Turboe4 E2T37382:

AWD-Non-Turbo*5 E2T37378:

AWD-Turbo’4 E2T33373:

FWD”.

E2T36175: FWDe2E2T36 180: FWD’3, E2T3737 1: FWDa4 E2T37379:

FWD’SE2T36 177: AWD-Non-Turbo’2 E2T37373:

AWD-Non-Turbo’4 E2T37381:

AWD-Non-Turbo’5 E2T37377:

AWD-Turbo*4

Sensors

Volume air flow sensor Karman vortex type

Barometric pressure sensor Semiconductor diffusion-type

Intake air temperature sensor

Thermistor type

Engine coolant temperature sensor Thermistor type

Heated oxygen sensor Zirconia sensor

Vehicle-speed sensor Reed switch type

Knock sensor

Camshaft position sensor Photo interrupter type

Crankshaft position sensor Photo interrupter type

EGR temperature sensor

Power steering pressure switch Contact switch type

Actuators

Multiport fuel injection relay type Contact switch type

Injector type and number Electromagnetic, 4

Injector identification mark B240H:

Non-Turbo*1**2.*3

N240H:

Non-Turbo*4,*5B450L: Turbo*4**5

Evaporative emission purge solenoid ON/OFF type solenoid valve

EGR solenoid

Fuel pressure solenoid

Turbocharger waste gate solenoid

Fuel pressure regulator Regulated pressure

kPa (psi)

NOTEl l: <1989 models>, l 2: <1990 models>, ‘3: <1990.5 models>,l 4:

<1991 models>, l 5:

TSB Revision

Page 345 of 1273

FUEL SYSTEM

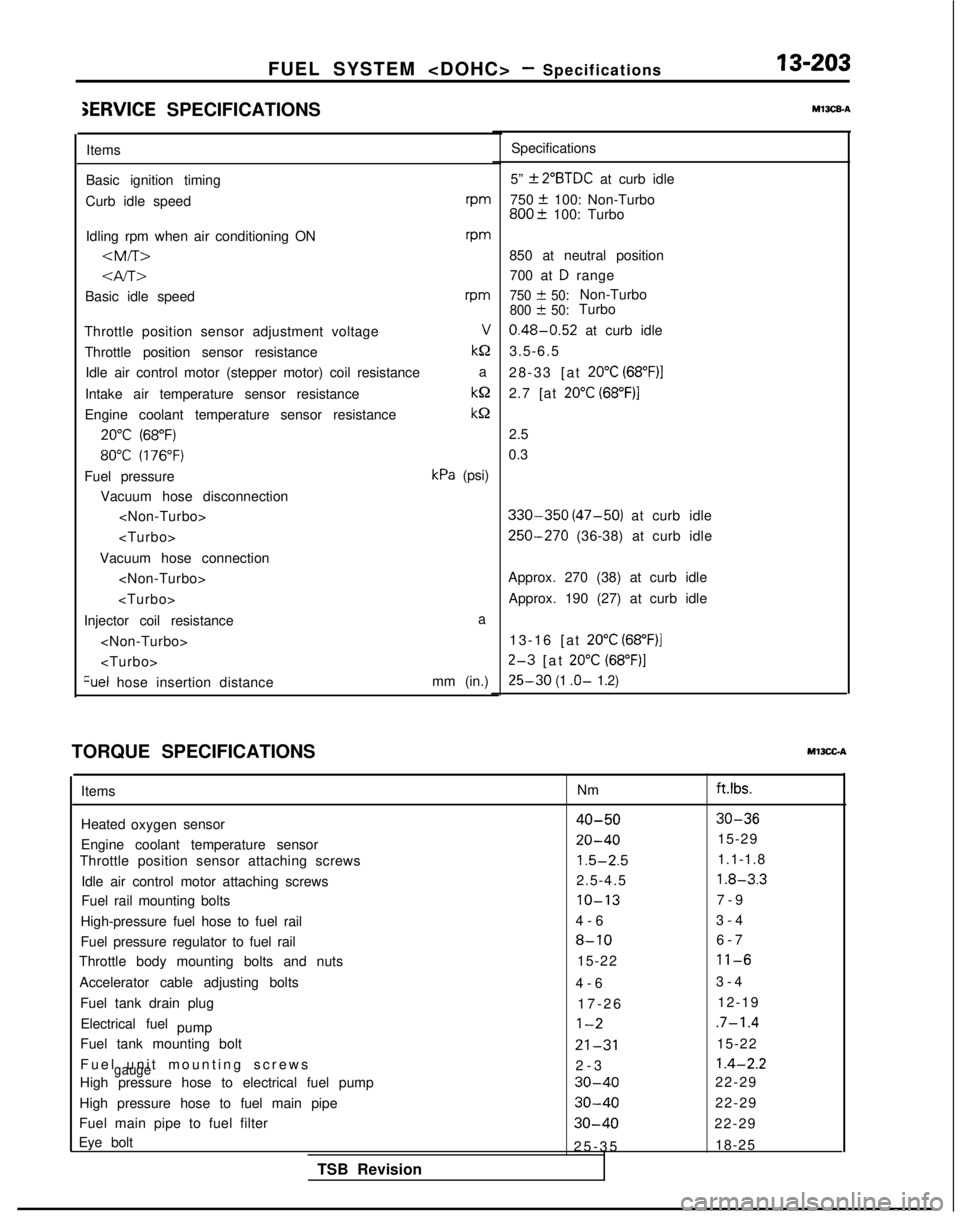

iERVlCE SPECIFICATIONS

Items

Basic ignition timing

Curb idle speed rpm

Idling rpm when air conditioning ON

vm

Basic idle speedrm

Throttle position sensor adjustment voltageV

Throttle position sensor resistance kQ

Idle air control motor (stepper motor) coil resistance a

Intake air temperature sensor resistance kQ

Engine coolant temperature sensor resistance

kS2

20°C (68°F)

80°C (176°F)

Fuel pressurekPa (psi)

Vacuum hose disconnection

Vacuum hose connection

Injector coil resistance a

Qel hose insertion distance mm (in.)

TORQUE SPECIFICATIONS

Ml3CGA

m13caA

Specifications

5”

f 2”BTDC at curb idle

750

+ 100: Non-Turbo800? 100: Turbo

850 at neutral position 700 at

D range

750 & 50:Non-Turbo800 + 50:Turbo

0.48-0.52 at curb idle

3.5-6.5

28-33 [at

20°C (68”F)l

2.7 [at 20°C (68”F)j

2.5

0.3

330-350 (47-50) at curb idle

250-270 (36-38) at curb idle

Approx. 270 (38) at curb idle Approx. 190 (27) at curb idle

13-16 [at

20°C (68”F)]

2-3 [at 20°C (68”F)]

25-30 (1 .o- 1.2)

Items

Heated sensor oxygen

Engine coolant temperature sensor

Throttle position sensor attaching screws

Idle air control motor attaching screws

Fuel rail mounting bolts

High-pressure fuel hose to fuel rail

Fuel pressure regulator to fuel rail

Throttle body mounting bolts and nuts

Accelerator cable adjusting bolts Fuel tank drain plugElectrical fuel pump

Fuel tank mounting bolt

Fuel unit mounting screw

s

gaugeHigh pressure hose to electrical fuel pump

High pressure hose to fuel main pipe

Fuel main pipe to fuel filter

Eye bolt

TSB Revision Nm

ft.lbs.

40-5030-36

20-4015-29

1.5-2.51.1-1.8

2.5-4.5

1.8-3.3

IO-137-

9

4-6 3-4

8-106-

7

15-22

11-6

4-

6

3-4

17-26 12-19

1-2.7-1.4

21-3115-22

2-

3

1.4-2.2

30-4022-29

30-4022-29

30-4022-29

25-3

5

18-25

Page 346 of 1273

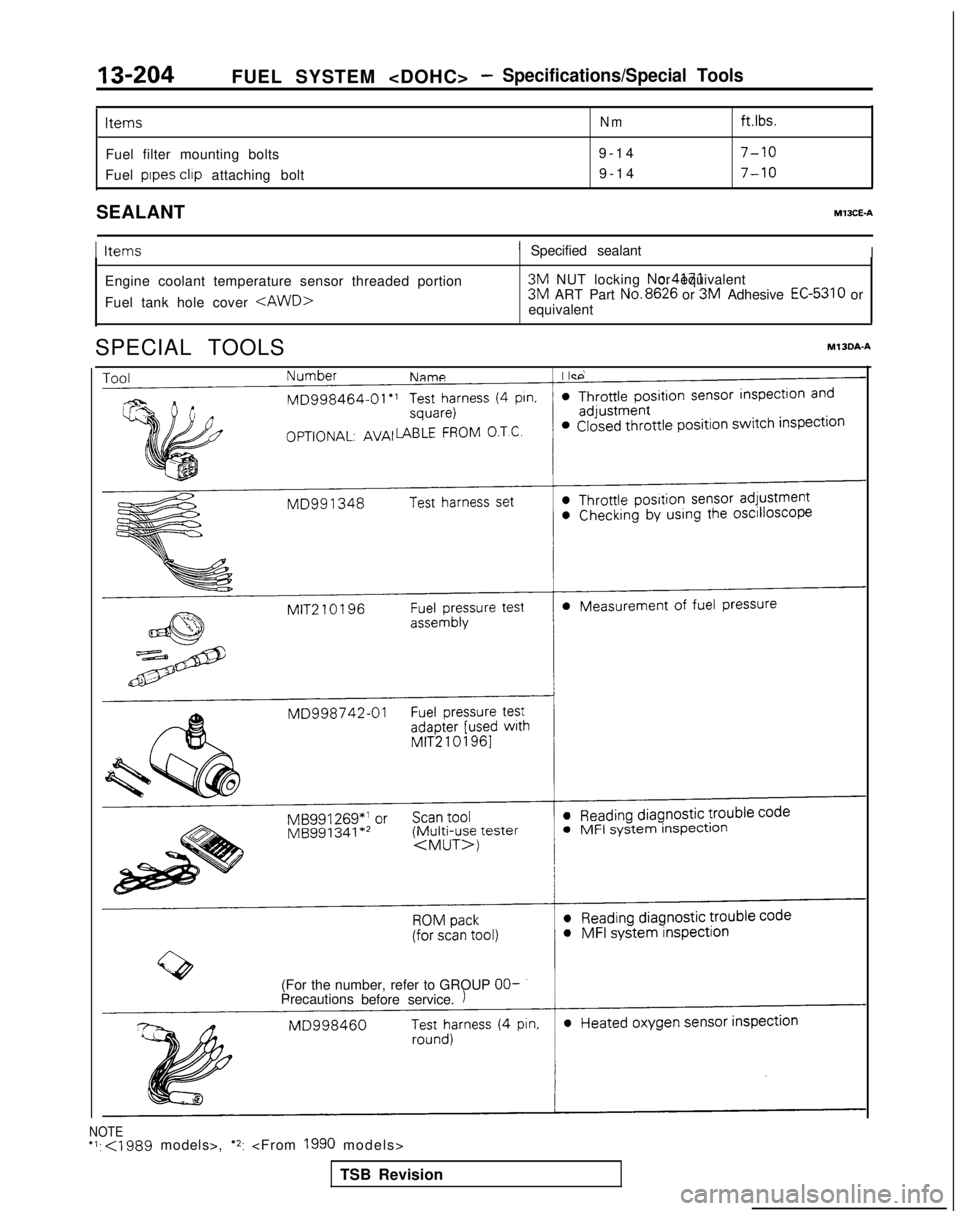

13-204FUEL SYSTEM

Items

Fuel filter mounting bolts

Fuel pipes

clip attaching bolt

Nmft.lbs.

9-1

4

7-10

9-1

4

7-10

SEALANTMlJCE-A

IItems1 Specified sealantI

Engine coolant temperature sensor threaded portion

Fuel tank hole cover

3M

NUT locking No.4171 or equivalent

3M

ART Part No.8626

or 3M

Adhesive EC-5310 or

equivalent

SPECIAL TOOLS

MlBDA-A

NameI IISP OPTIONAL:

AVAI

(For the number, refer to GROUP

OO-Precautions before service.

NOTE *I:

TSB Revision

Page 347 of 1273

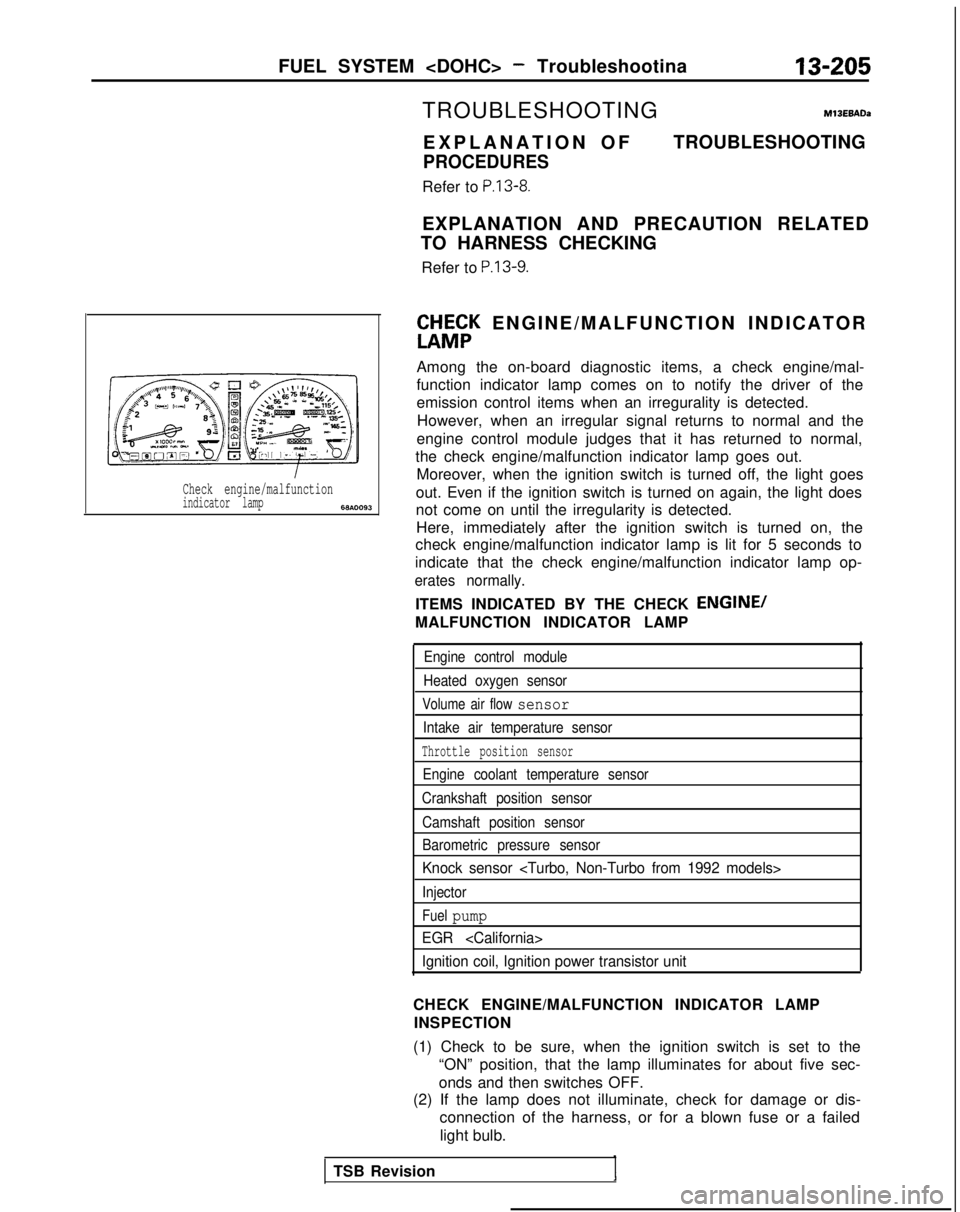

FUEL SYSTEM

Check engine/malfunctionindicator lamp6w.0093

TROUBLESHOOTINGM13EBADa

EXPLANATION O

F

PROCEDURES

Refer to P.13-8.

TROUBLESHOOTING

EXPLANATION AND PRECAUTION RELATED

TO HARNESS CHECKING

Refer to

P.13-9.

ft&;K ENGINE/MALFUNCTION INDICATO

R

Among the on-board diagnostic items, a check engine/mal-

function indicator lamp comes on to notify the driver of the

emission control items when an irregurality is detected. However, when an irregular signal returns to normal and the

engine control module judges that it has returned to normal,

the check engine/malfunction indicator lamp goes out. Moreover, when the ignition switch is turned off, the light goes

out. Even if the ignition switch is turned on again, the light does

not come on until the irregularity is detected. Here, immediately after the ignition switch is turned on, the

check engine/malfunction indicator lamp is lit for 5 seconds to

indicate that the check engine/malfunction indicator lamp op-

erates normally.

ITEMS INDICATED BY THE CHECK ENGINE/

MALFUNCTION INDICATOR LAMP

Engine control module

Heated oxygen sensor

Volume air flow sensor

Intake air temperature sensor

Throttle position sensor

Engine coolant temperature sensor

Crankshaft position sensor

Camshaft position sensor

Barometric pressure sensor

Knock sensor

Injector

Fuel pump

EGR

Ignition coil, Ignition power transistor unit

CHECK ENGINE/MALFUNCTION INDICATOR LAMP INSPECTION

(1) Check to be sure, when the ignition switch is set to the “ON” position, that the lamp illuminates for about five sec-

onds and then switches OFF.

(2) If the lamp does not illuminate, check for damage or dis-

connection of the harness, or for a blown fuse or a failed

light bulb.

TSB Revision

Page 348 of 1273

13-206FUEL SYSTEM

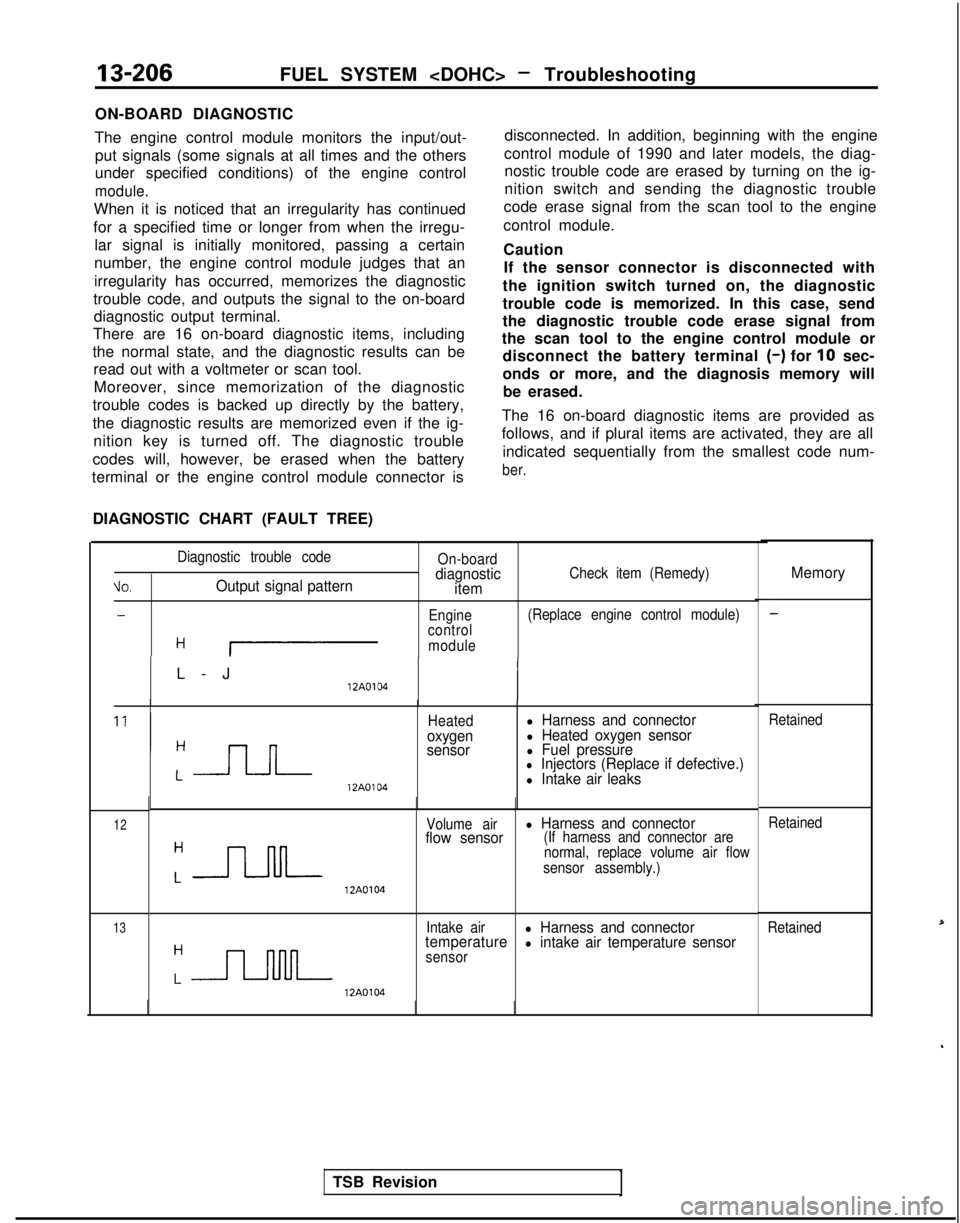

ON-BOARD DIAGNOSTIC

The engine control module monitors the input/out- put signals (some signals at all times and the others

under specified conditions) of the engine control

module.

When it is noticed that an irregularity has continued

for a specified time or longer from when the irregu- lar signal is initially monitored, passing a certain

number, the engine control module judges that an

irregularity has occurred, memorizes the diagnostic

trouble code, and outputs the signal to the on-board diagnostic output terminal.

There are 16 on-board diagnostic items, including

the normal state, and the diagnostic results can be read out with a voltmeter or scan tool.

Moreover, since memorization of the diagnostic

trouble codes is backed up directly by the battery,

the diagnostic results are memorized even if the ig- nition key is turned off. The diagnostic trouble

codes will, however, be erased when the battery

terminal or the engine control module connector is

DIAGNOSTIC CHART (FAULT TREE) disconnected. In addition, beginning with the engine

control module of 1990 and later models, the diag- nostic trouble code are erased by turning on the ig-

nition switch and sending the diagnostic trouble

code erase signal from the scan tool to the engine

control module.

Caution If the sensor connector is disconnected with

the ignition switch turned on, the diagnostic

trouble code is memorized. In this case, send

the diagnostic trouble code erase signal from

the scan tool to the engine control module or disconnect the battery terminal

(-) for 10 sec-

onds or more, and the diagnosis memory will be erased.

The 16 on-board diagnostic items are provided as

follows, and if plural items are activated, they are all indicated sequentially from the smallest code num-

ber. ti0.

Diagnostic trouble code

Output signal pattern

On-boarddiagnostic

itemCheck item (Remedy)

-Engine (Replace engine control module)

control

H Imodule

L-

J

12A0104

Heatedoxygen

sensor

l Harness and connectorl Heated oxygen sensorl Fuel pressurel Injectors (Replace if defective.) 12A0104l Intake air leaks

12

13 12A0104Volume airl Harness and connector

flow sensor(If harness and connector are

normal, replace volume air flow

sensor assembly.)

Intake air

l Harness and connector

temperaturel intake air temperature sensorsensor 12A0104

Memory

Retained

Retained

Retained

TSB Revision

Page 349 of 1273

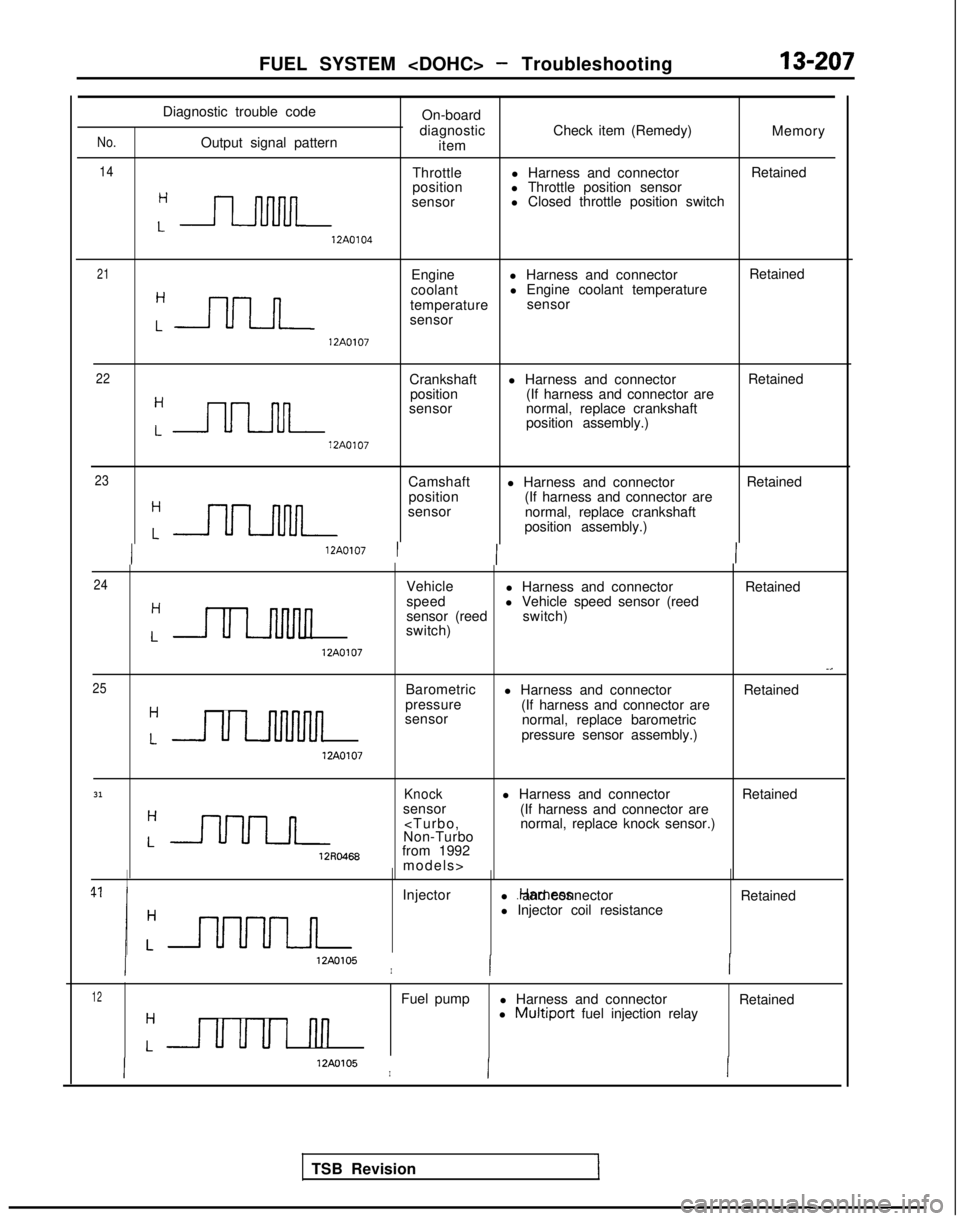

FUEL SYSTEM

No.

14

Diagnostic trouble code On-board

Output signal pattern diagnostic

item Check item (Remedy)

Memory

Throttle l Harness and connector Retained

:-

position

l Throttle position sensor

sensor l Closed throttle position switch

12A0104

21Engine

l Harness and connector Retained

:nn

coolant

l Engine coolant temperature

temperature sensor

sensor 12A0107

22Crankshaft

l Harness and connector Retained

:nn

position

(If harness and connector are

sensor normal, replace crankshaft

position assembly.) 12A0107

23Camshaft

position

sensor l Harness and connector

(If harness and connector are

normal, replace crankshaft

position assembly.) Retained 12A0107

I

24

25Vehicle l Harness and connector Retained

Hspeed

sensor (reedl Vehicle speed sensor (reed

Lswitch)

switch)

12A0107-.

Barometric

l Harness and connector Retained

H

ULJuuuvl

pressure

(If harness and connector are

sensor normal, replace barometric

Lpressure sensor assembly.) 12A0107

31Knockl Harness and connector

Retained

:-

sensor

12RO468from 1992

models>

Injector l .Harness and connector

l Injector coil resistance Retained

12AO105I

12Fuel pump

l Harness and connector Retained

Hl Multiport fuel injection relay

Luuul I-Ill

12AO105I

TSB Revision

Page 350 of 1273

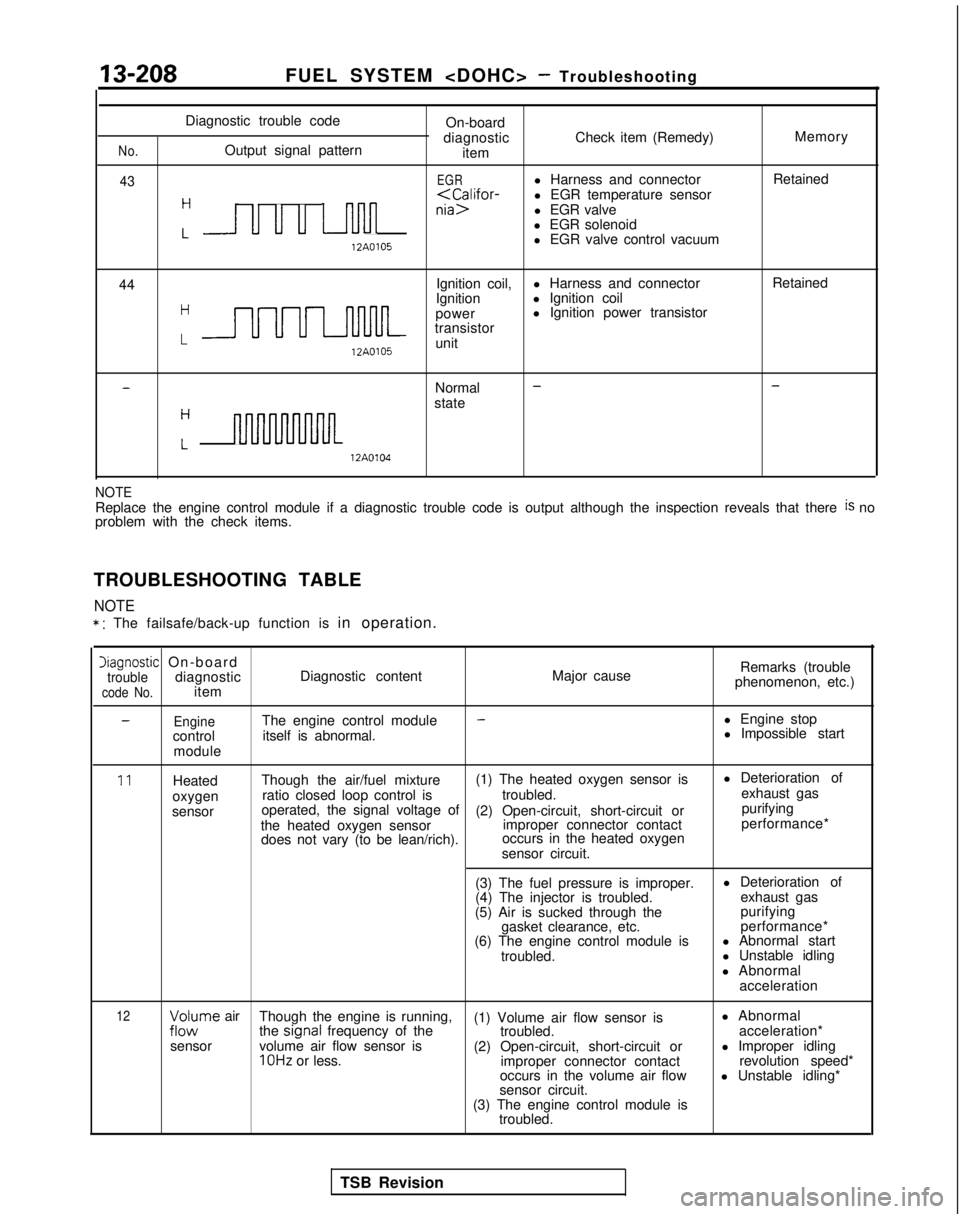

13-208FUEL SYSTEM

No.

43

Diagnostic trouble codeOn-board

diagnostic Check item (Remedy) Memory

Output signal pattern item

EGRl Harness and connector Retained

H

nia>l EGR valve

l EGR solenoid

L 12A0105

l EGR valve control vacuum

44 Ignition coil,

l Harness and connector Retained

Hl Ignition coil

LUUULnl-lM-

Ignition

power l Ignition power transistor

transistor 12A0105

unit

-Normal --

stateH

Lnm 12A0104

NOTEReplace the engine control module if a diagnostic trouble code is output\

although the inspection reveals that there is no

problem with the check items.

TROUBLESHOOTING TABLE

NOTE

* : The failsafe/back-up function is in operation.

Diagnostic On-boardtroublediagnosticcode No.itemDiagnostic content

Major causeRemarks (trouble

phenomenon, etc.)

-EngineThe engine control module-l Engine stop

control itself is abnormal. l Impossible start

module

11Heated Though the air/fuel mixture (1) The heated oxygen sensor is l Deterioration of

oxygen ratio closed loop control is

troubled.exhaust gas

sensor operated, the signal voltage of

(2) Open-circuit, short-circuit or purifying

the heated oxygen sensor improper connector contactperformance*

does not vary (to be lean/rich). occurs in the heated oxygen

sensor circuit.

(3) The fuel pressure is improper. l Deterioration of

(4) The injector is troubled. exhaust gas

(5) Air is sucked through the purifying

gasket clearance, etc. performance*

(6) The engine control module is l Abnormal start

troubled. l Unstable idling

l Abnormal acceleration

12;zc$rne air Though the engine is running,

(1) Volume air flow sensor is l Abnormal

the signal

frequency of the

troubled. acceleration*

sensor volume air flow sensor is

(2) Open-circuit, short-circuit or l Improper idling

1 OHz or less.

improper connector contact revolution speed*

occurs in the volume air flow l Unstable idling*

sensor circuit.

(3) The engine control module is troubled.

TSB Revision