Idle MITSUBISHI GALANT 1989 Service Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 158 of 1273

13-16

FUEL SYSTEM

FAILSAFE/BACK-UP FUNCTIONS LIST

If trouble with any major sensor is detected by the on-board diagnostic,\

the vehicle will be kept in the safe

driving conditions according to the preset control logic.

Trouble item Control content for trouble

Volume air flow Fuel injection timing and ignition timing are determined according to th\

e throttle position

sensor sensor

(TPS) and engine revolution speed signal (crankshaft position sensor signal)\

.

Intake air temperature The control is executed with the suction air temperature regarded as

25°C (77°F).

sensor

Throttle position The fuel injection rate is not increased for acceleration according to t\

he throttle position

sensor

(TPS)sensor signal.

Idle speed control After the idle speed control motor plunger is driven and contracted, the\

idle revolution speed

motor position sensor is not controlled.

Engine coolant The control is executed with the engine coolant temperature regarded as \

8OO.C (176°F).temperature sensor (Even if the sensor signal becomes normal again, the control is continued

until the ignltlon

switch is turned off.)

Camshaft position Simultaneous injection of fuel is executed for all cylinders. (In this \

case, the

No.1 cylinder top

sensor dead center is not detected at all after the ignition key is turned on.)\

Barometric pressure The control is executed with the pressure regarded as 760 mmHg

(30

in.Hg).

sensor

Oxygen sensor Closed loop control of the air/fuel mixture ratio is not executed.

i

READ OUT OF DIAGNOSTIC TROUBLE CODE

Precautions for operation

(1) When battery voltage is low, no detection of failure is possible. Be sure to check the battery for voltage and

other conditions before starting the test.

(2) On-board diagnostic item is erased if the battery or the engine control module connector is discon-

nected. Do not disconnect the battery before the di-

agnostic result is completely read.

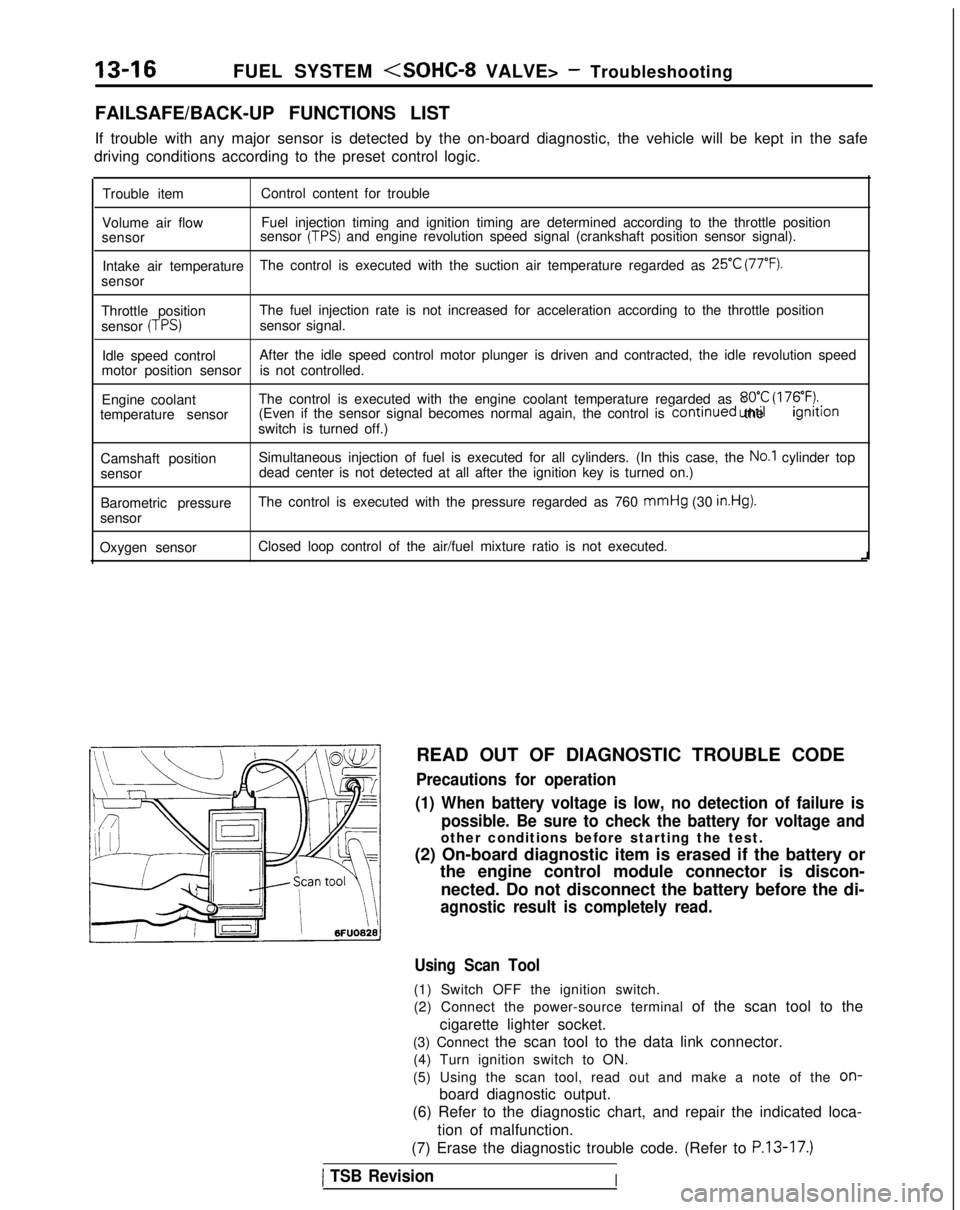

Using Scan Tool

(1) Switch OFF the ignition switch.

(2) Connect the power-source terminal of the scan tool to the

cigarette lighter socket.

(3) Connect the scan tool to the data link connector. (4) Turn ignition switch to ON.

(5) Using the scan tool, read out and make a note of the

on-

board diagnostic output.

(6) Refer to the diagnostic chart, and repair the indicated loca-

tion of malfunction.

(7) Erase the diagnostic trouble code. (Refer to

P.13-17.)

1 TSB RevisionI

Page 159 of 1273

FUEL SYSTEM

\ I\-\\\\\\6FUO807

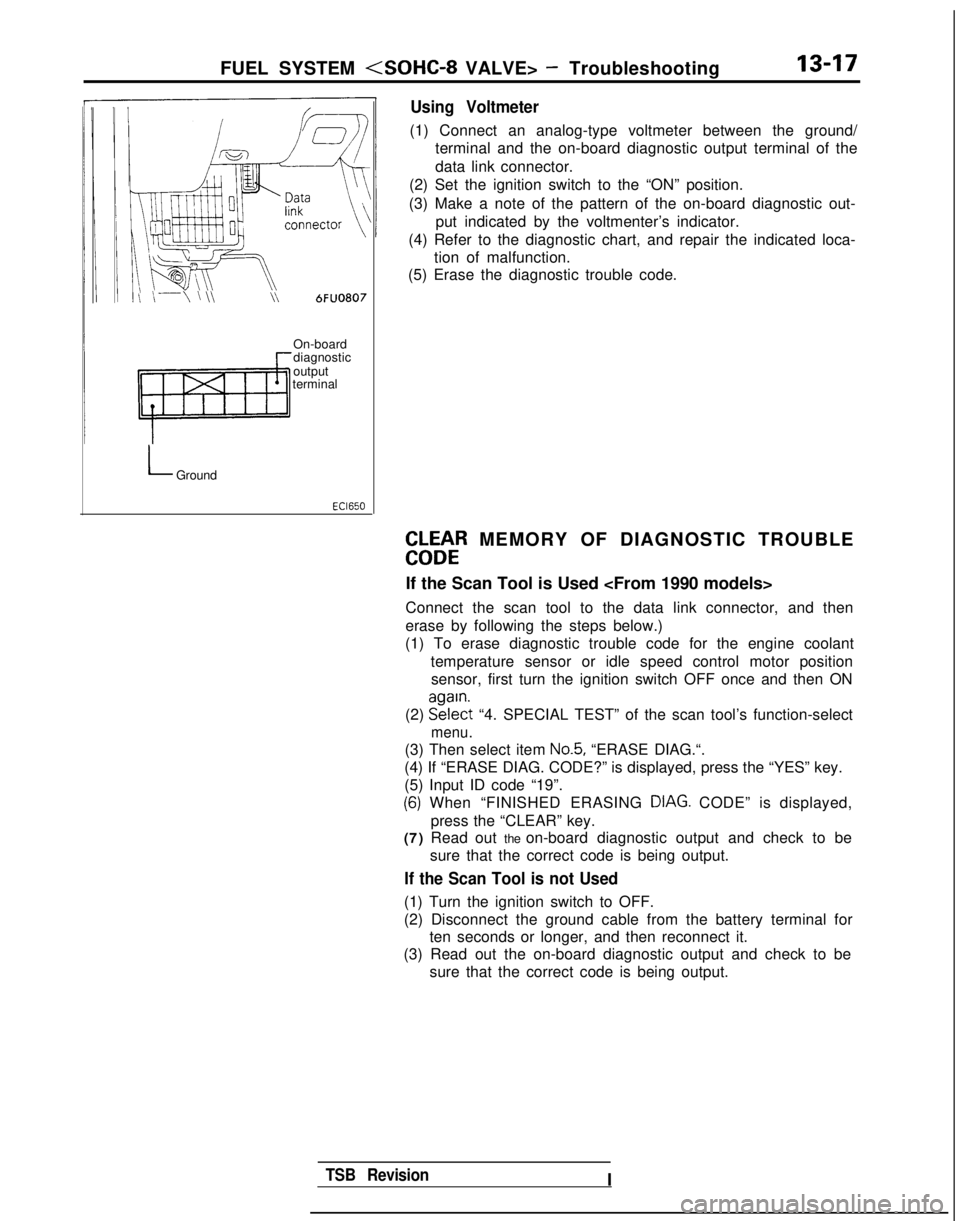

Using Voltmeter

(1) Connect an analog-type voltmeter between the ground/

terminal and the on-board diagnostic output terminal of the

data link connector.

(2) Set the ignition switch to the “ON” position.

(3) Make a note of the pattern of the on-board diagnostic out- put indicated by the voltmenter’s indicator.

(4) Refer to the diagnostic chart, and repair the indicated loca- tion of malfunction.

(5) Erase the diagnostic trouble code.

On-board

diagnostic

output

terminal

LGround

EbLbtR MEMORY OF DIAGNOSTIC TROUBLE

If the Scan Tool is Used

Connect the scan tool to the data link connector, and then

erase by following the steps below.)

(1) To erase diagnostic trouble code for the engine coolant

temperature sensor or idle speed control motor positionsensor, first turn the ignition switch OFF once and then ON

(2) EE?$t

“4. SPECIAL TEST” of the scan tool’s function-select

menu.

(3) Then select item No.5, “ERASE DIAG.“.

(4) If “ERASE DIAG. CODE?” is displayed, press the “YES” k\

ey.

(5) Input ID code “19”.

(6) When “FINISHED ERASING DIAG. CODE” is displayed,> Ipress the “CLEAR” key.

(7) Read out the on-board diagnostic output and check to be

sure that the correct code is being output.

If the Scan Tool is not Used

(1) Turn the ignition switch to OFF.

(2) Disconnect the ground cable from the battery terminal forten seconds or longer, and then reconnect it.

(3) Read out the on-board diagnostic output and check to be

sure that the correct code is being output.

TSB RevisionI

Page 161 of 1273

FUEL SYSTEM

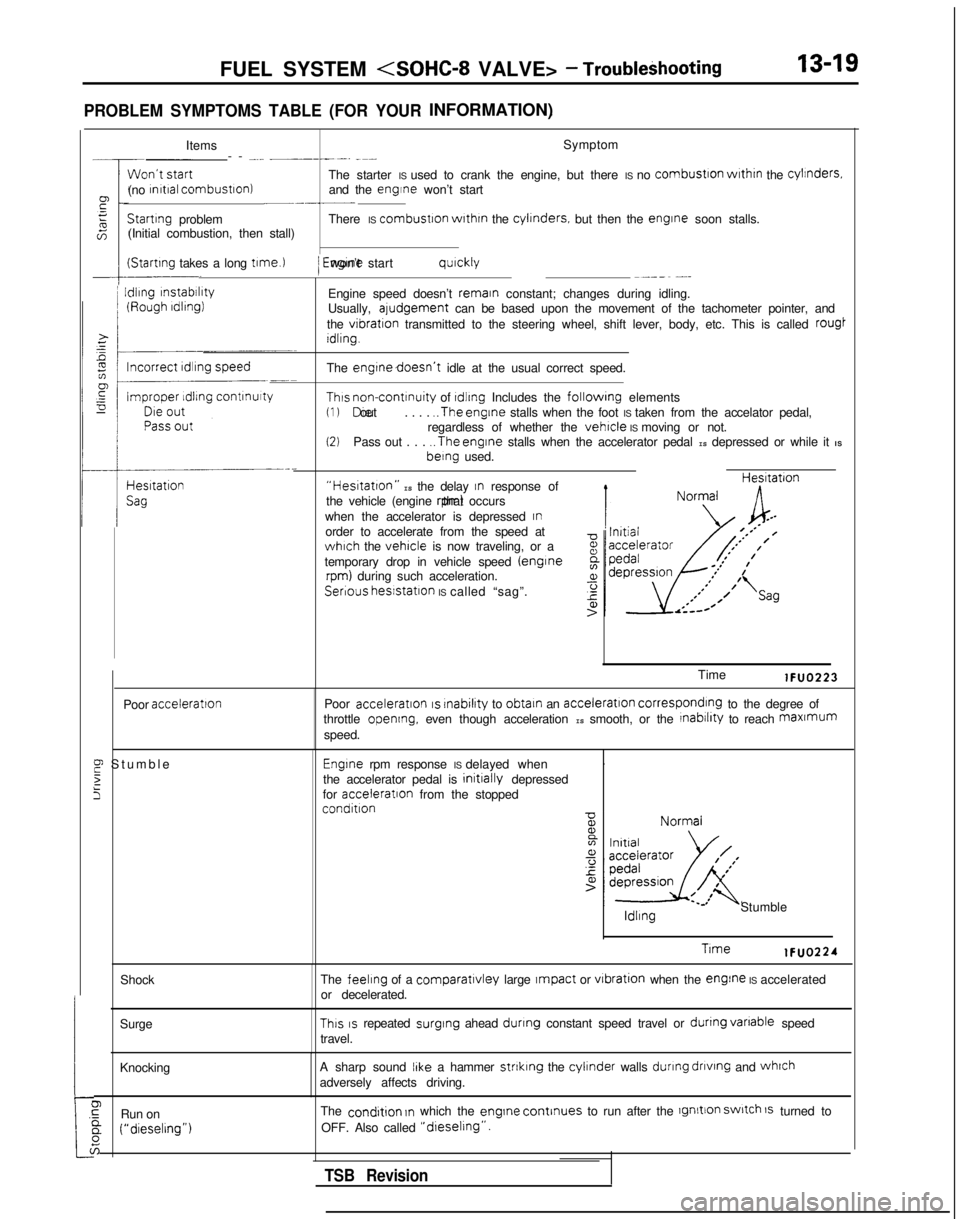

PROBLEM SYMPTOMS TABLE (FOR YOURINFORMATION)

:tShock

Surge

Knocking

0,GRun ona (“dieselrng”)

6

Items Symptom

-- -... __----. -~-

The starter IS used to crank the engine, but there IS no

combustron

wrthrn

the cylinders.

(no rnrtral combustron)

and the engine won’t start~-.-__Startrng

problem There IS combustron

wrthrn

the cylrnders.

but then the engrne

soon stalls.

(Initial combustion, then stall)

(Startrng takes a long t1me.l

I

Idling

rnstabrlrty

/ Engrne won’t start qurckly~--_~ -...

Engine speed doesn’t remain constant; changes during idling.

Usually, aludgement can be based upon the movement of the tachometer pointer, and

the

vibration transmitted to the steering wheel, shift lever, body, etc. This is call\

ed rougt

Idling.

The

engtnedoesn’t idle at the usual correct speed.

Thus non-contrnuity of rdlrng Includes the followrng elements(1) Die out

. . . . ..The

engine stalls when the foot IS taken from the accelator pedal,

regardless of whether the vehicle IS moving or not.(2)Pass out . . . ..The

engine stalls when the accelerator pedal IS depressed or while it IS berng

used.

“Hestatton” IS the delay In response of

the vehicle (engine rpm) that occurs

when the accelerator is depressed

Inorder to accelerate from the speed atwhich the vehicle is now traveling, or a

temporary drop in vehicle speed (enginerpm) during such acceleration. Hesltatron

Serious

hesstatlon IS called “sag”.

Poor

acceleration

E Stumbl

e

2

5

Time lFUO223

Poor

acceleration IS rnabilrty

to obtain an acceleration corresponding to the degree of

throttle opening, even though acceleration IS smooth, or the rnabrlrty to reach maxmum

speed.

Engrne rpm response IS delayed when .

the accelerator pedal is initrally

depressed

for acceleratron

from the stopped

condition ldllng

Stumble

Trme lFUO224

The

feeling of a comparatlvley large Impact or vrbration

when the engine IS accelerated

or decelerated.

This IS repeated surging

ahead dunng constant speed travel or dunng

vanable

speed

travel.

A sharp sound

IIke a hammer strtklng the cylinder walls during

dnvtng

and whrch

adversely affects driving.

The

condrtion In which the engrne

continues to run after the lgnltion switch 1s turned to

OFF. Also called

“dreselrng”.

TSB Revision

Page 164 of 1273

13-22

FUEL SYSTEM

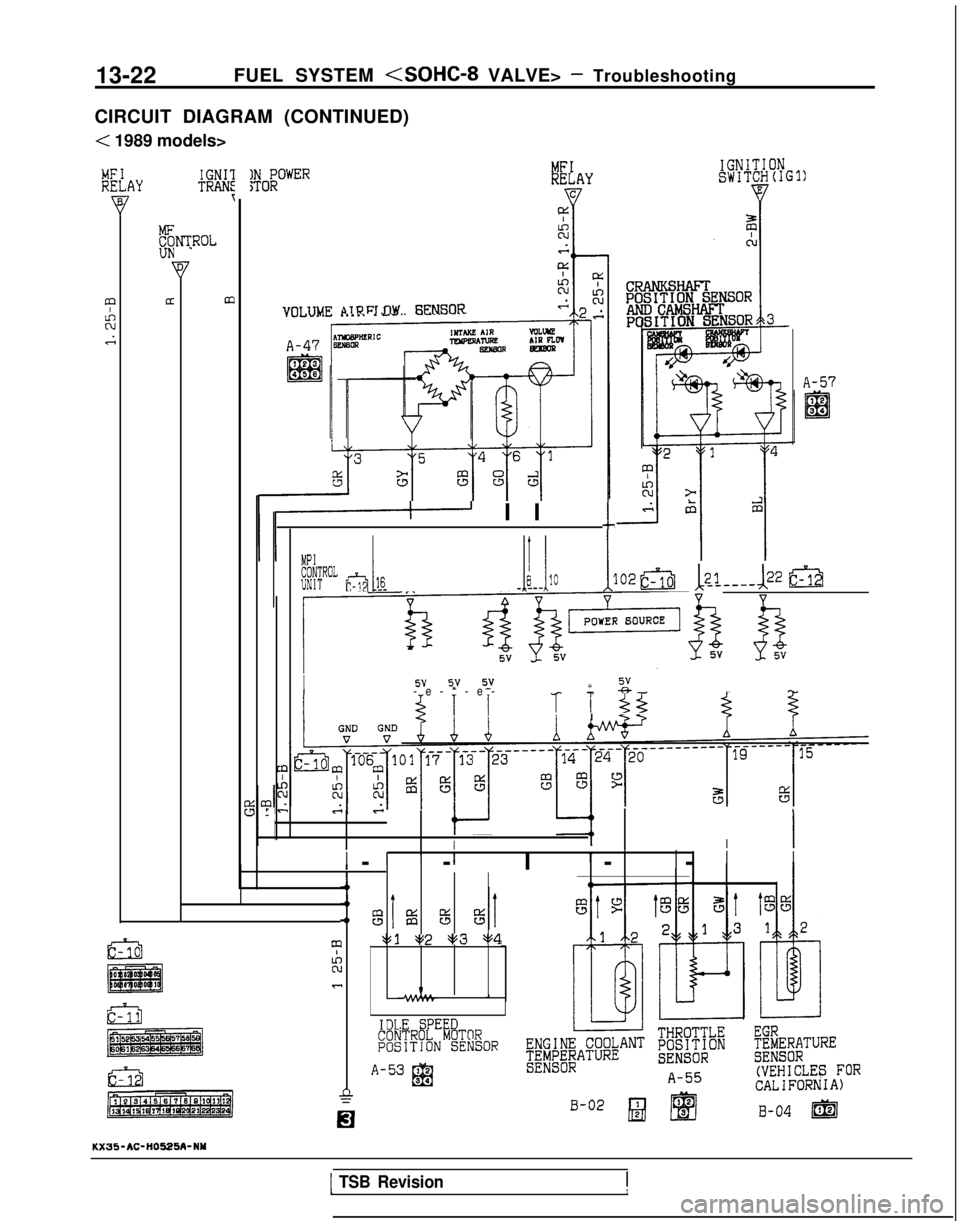

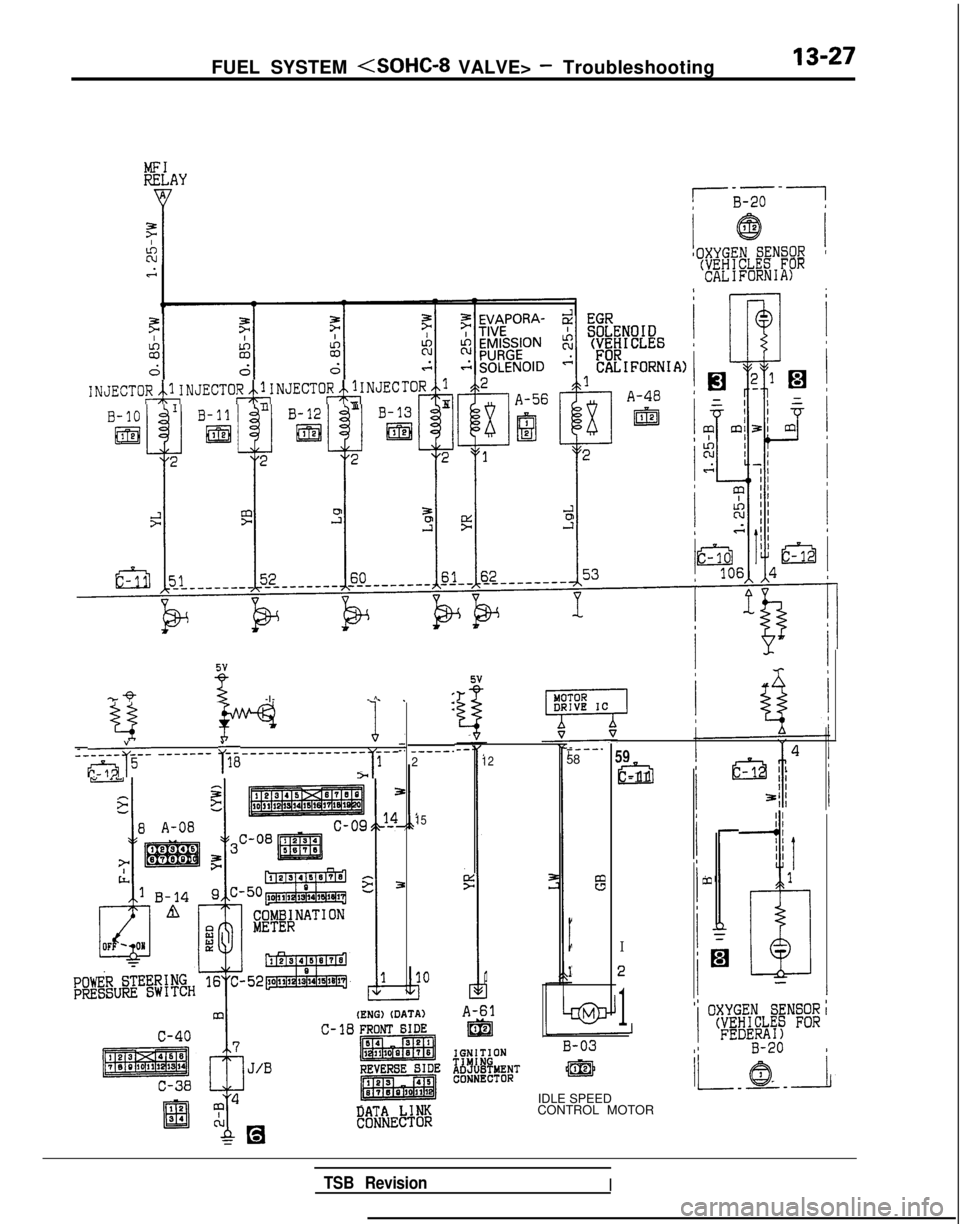

CIRCUIT DIAGRAM (CONTINUED)

< 1989 models>

IGNITIONSWITCHlIGl)#OF?OWERMFIRELAYIGNIlTRANf

;ROLKUN1

am\lR Fl.tlW i=XNSOR

A-57

II Il-

EF g?JEi _______ JLllOI:02&j12_1---& im

Y-+-I

k$$

Yh

I5VI I 5Y

syv s_v-e-*-e

-

“,

*-r

-5. IIII 5.5

c

L

III I

III1II --I-

-

I

II,---

1’ 8Iis%%

Gi3mv1 a+2 pg3 $14I

?Ic

IDLE SPEEDCONTROL MOTORPOSITJON SENSOR

A-53 12El(VEHICLES FOR94CALIFORNIA)

B-02 B @

KX35-AC-HO525A-NY

B-04 m

1 TSB Revision1I

Page 169 of 1273

FUEL SYSTEM (SOHC-8 VALVE> - Troubleshooting13-27

INJECTOR&INJECTOR&INJECTOR&NJEC

--

!-B-20 -7

!OXYGE!!ENSOR I'(VEHICLES FORCALIFORNIA)

5v

-w-Qz-I-

-

^

_____---______-_- ---____--&vs-- -__---- T18

I1

>

,..

-----.2

15

12

I

----.58

8

I

1

IDLE SPEEDDATA LINKCONTROL MOTORCONNECTOR

59

cl-11

I

2

1

m

II

!II II1

ib -

I

' OXYGEN SENSOR'(VEHICLES FOR

FEDE89":;

i 63 i

TSB RevisionI

Page 174 of 1273

13-32

FUEL SYSTEM

FUEL TANK AND FUEL LINEMlBEAAA

Symptom Probable cause Remedy

Engtne malfunctions

Bent or kinked fuel pipe or hose Repair or replace3ue to insufficient fuel

SUPPlYClogged fuel pipe or hoseClean or replace

Clogged fuel filter or in-tank fuel filter Replace

Water in fuel filter Replace the fuel filter or clean the fuel tank

and fuel line

Dirty or rusted fuel tank interior Malfunctioning fuel pump

(Clogged filter in the pump) Clean or replace

Replace

Evaporative emission Mispiping of vapor line

Correct

control system malfunc-

tions (When fuel tank Disconnect vapor line piping joint Correct

filler tube cap is re- moved, pressure releas-

Folded, bent, cracked or clogged vapor line Replace

ng noise is heard) Faulty fuel tank filler tube cap

Malfunctioning fuel tank pressure control

valve Replace

Replace

LL

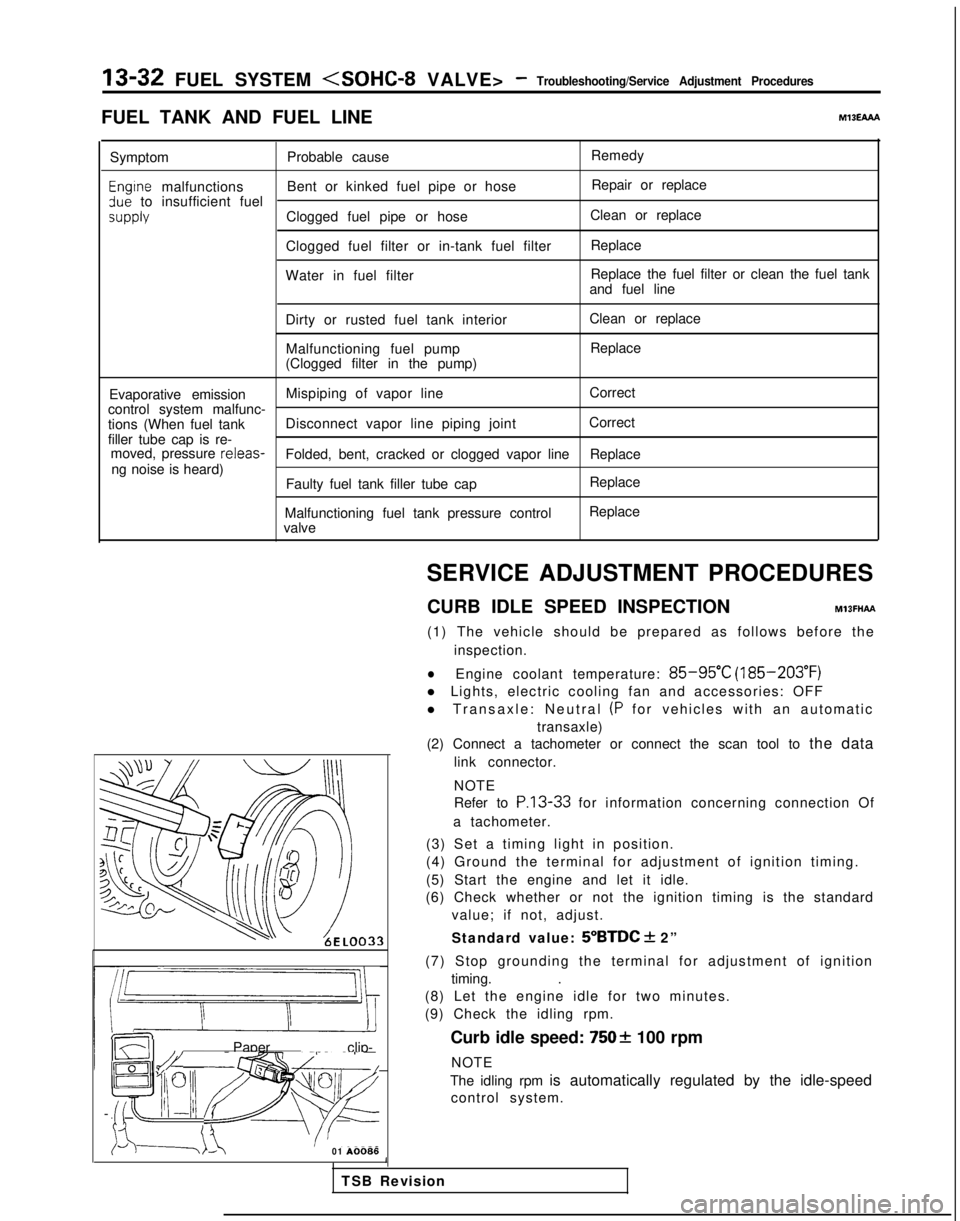

m ~~ : Paper clip-

F l!;“I /yFp- -

izd--_7-01

A0086SERVICE ADJUSTMENT PROCEDURES

CURB IDLE SPEED INSPECTION

MlBFHAFt

(1) The vehicle should be prepared as follows before the inspection.

lEngine coolant temperature: 85-95°C (185-203°F)

l Lights, electric cooling fan and accessories: OFF

l Transaxle: Neutral

(P for vehicles with an automatic

transaxle)

(2) Connect a tachometer or connect the scan tool to the data

link connector.

NOTE

Refer to

P.13-33 for information concerning connection Of

a tachometer.

(3) Set a timing light in position.

(4) Ground the terminal for adjustment of ignition timing.

(5) Start the engine and let it idle.

(6) Check whether or not the ignition timing is the standard

value; if not, adjust.

Standard value:

5”BTDC + 2”

(7) Stop grounding the terminal for adjustment of ignition timing. .

(8) Let the engine idle for two minutes.

(9) Check the idling rpm.

Curb idle speed:

7502 100 rpm

NOTE

The idling rpm is automatically regulated by the idle-speed control system.

1

TSB Revision

Page 175 of 1273

FUEL SYSTEM

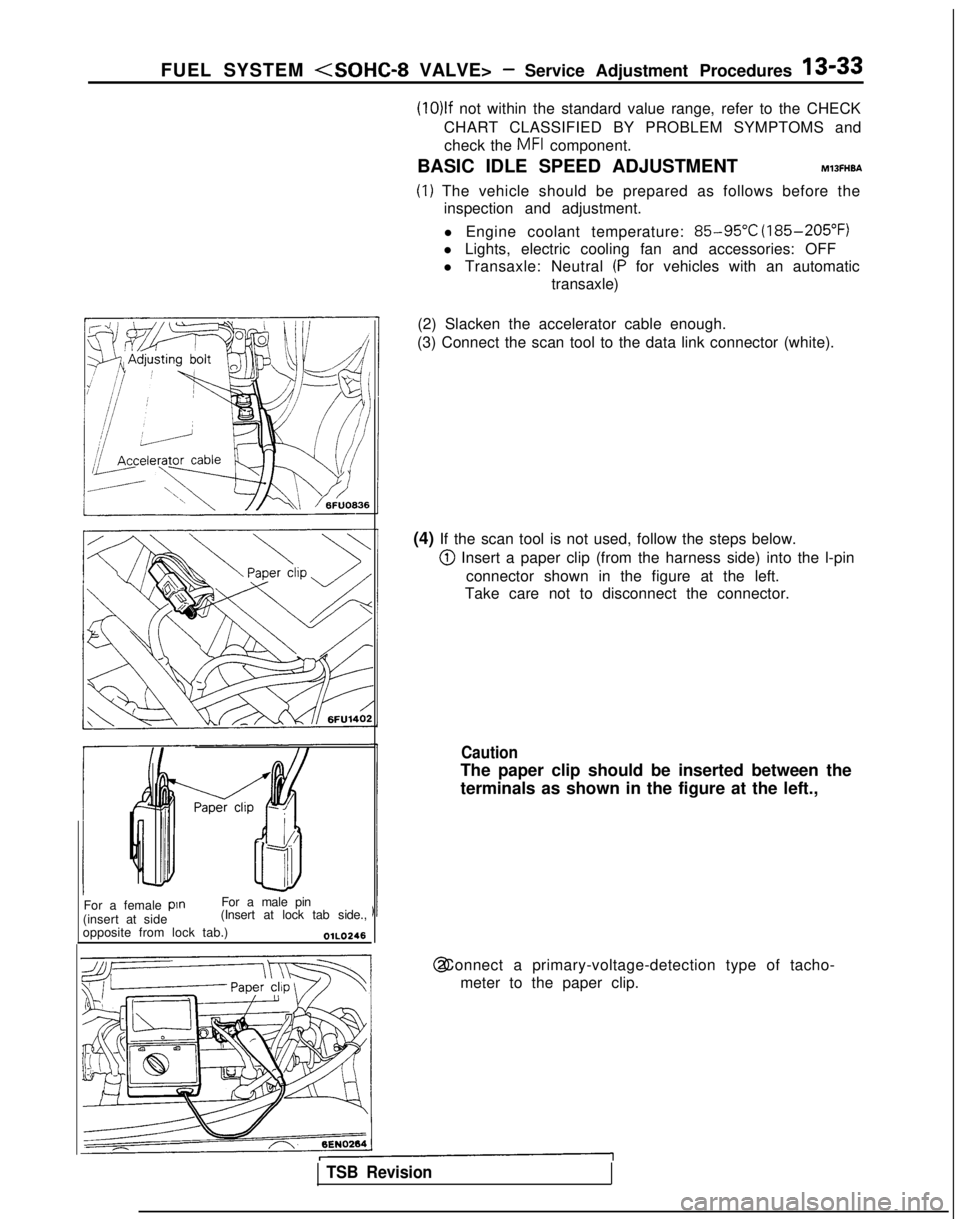

For a female

pin

For a male pin

(insert at side (Insert at lock tab side.,

opposite from lock tab.)

OlLO246

(10)lf not within the standard value range, refer to the CHECK

CHART CLASSIFIED BY PROBLEM SYMPTOMS and check the

MFI component.

BASIC IDLE SPEED ADJUSTMENT

MlBFHBA

(1) The vehicle should be prepared as follows before the inspection and adjustment.

l Engine coolant temperature:

85-95°C (185-205°F)

l Lights, electric cooling fan and accessories: OFF

l Transaxle: Neutral

(P for vehicles with an automatic

transaxle)

(2) Slacken the accelerator cable enough.

(3) Connect the scan tool to the data link connector (white).

(4) If the scan tool is not used, follow the steps below.

@I Insert a paper clip (from the harness side) into the l-pin connector shown in the figure at the left.

Take care not to disconnect the connector.

Caution

The paper clip should be inserted between the

terminals as shown in the figure at the left., @ Connect a primary-voltage-detection type of tacho-

meter to the paper clip.

TSB Revision

Page 176 of 1273

13-34 FUEL SYSTEM

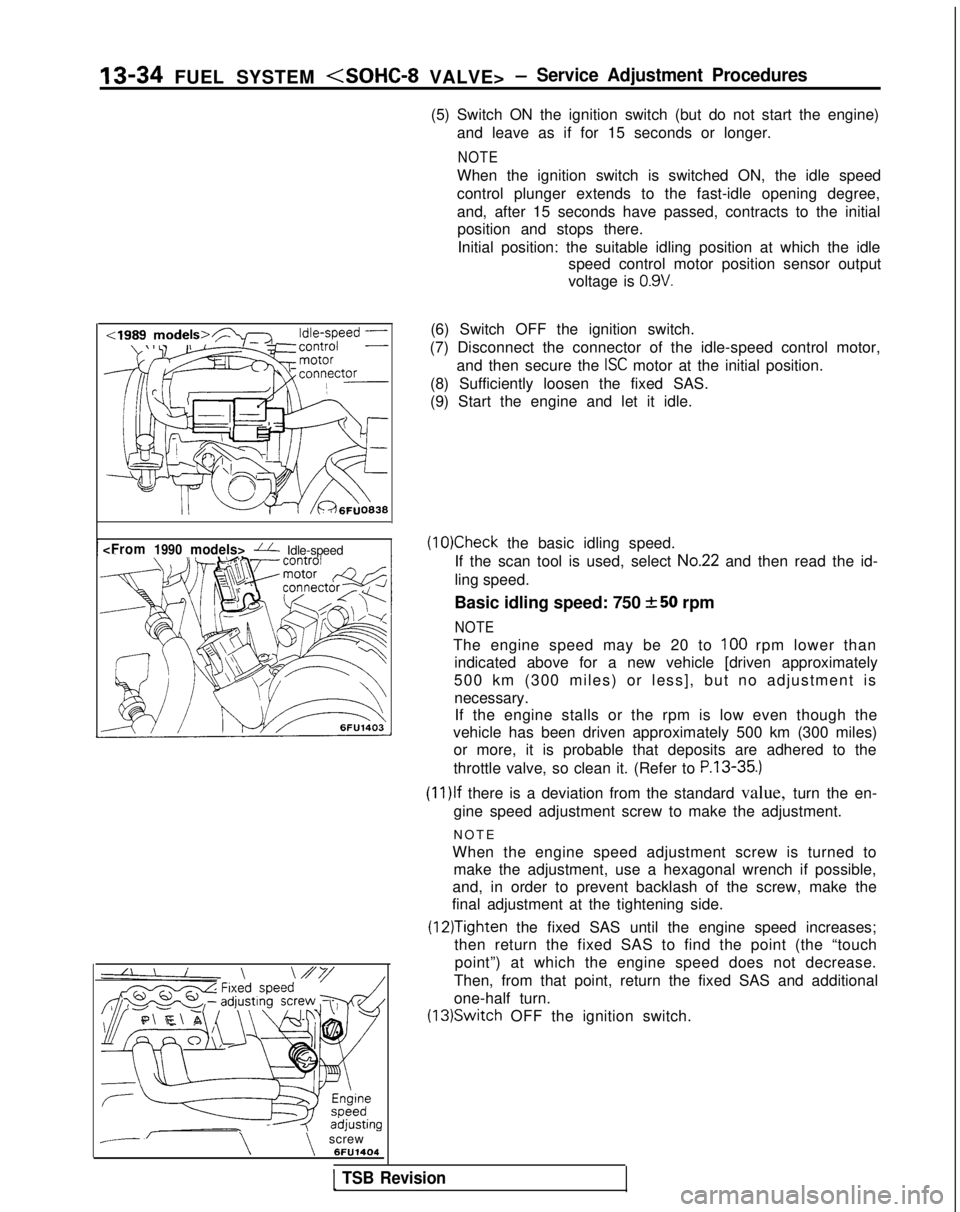

(5) Switch ON the ignition switch (but do not start the engine)and leave as if for 15 seconds or longer.

NOTE

When the ignition switch is switched ON, the idle speed

control plunger extends to the fast-idle opening degree,

and, after 15 seconds have passed, contracts to the initialposition and stops there.

Initial position: the suitable idling position at which the idle speed control motor position sensor output

voltage is

0.9V.

--\\screw 6FU1404(6) Switch OFF the ignition switch.

(7) Disconnect the connector of the idle-speed control motor, and then secure the

ISC motor at the initial position.

(8) Sufficiently loosen the fixed SAS.

(9) Start the engine and let it idle.

(10)Check the basic idling speed.

If the scan tool is used, select

No.22 and then read the id-

ling speed.

Basic idling speed: 750

+-50 rpm

NOTE

The engine speed may be 20 to 100 rpm lower than

indicated above for a new vehicle [driven approximately

500 km (300 miles) or less], but no adjustment is necessary.If the engine stalls or the rpm is low even though the

vehicle has been driven approximately 500 km (300 miles) or more, it is probable that deposits are adhered to the

throttle valve, so clean it. (Refer to

P.13-35.)

(1l)lf there is a deviation from the standard value, turn the en-

gine speed adjustment screw to make the adjustment.

NOT

E

When the engine speed adjustment screw is turned to make the adjustment, use a hexagonal wrench if possible,

and, in order to prevent backlash of the screw, make the

final adjustment at the tightening side.

(12)Tighten the fixed SAS until the engine speed increases;

then return the fixed SAS to find the point (the “touch

point”) at which the engine speed does not decrease.

Then, from that point, return the fixed SAS and additional

one-half turn. (13)Switch

OFF the ignition switch.

1 TSB Revision

Page 177 of 1273

FUEL SYSTEM

(14)Adjust the play of the accelerator cable. (Refer to P.13-

329.)

(15)Connect the idle-speed control motor’s connector.

(16)Adjust the throttle-position sensor.

(17)Start the engine again and let it run at idle speed for about

ten minutes; check to be sure that the idling condition is

normal.

THROTTLE BODY (THROTTLE VALVE AREA)

CLEANING

MllFlCK

(1)Start the engine and warm it up until the temperature of the

engine coolant reaches

80°C (176°F) or higher; then stop

the engine.

(2) Disconnect the air intake hose at the throttle body side.

(3) Spray cleaning liquid (from the intake port of the throttle body) onto the valve, and then leave as is for about fiveminutes.

(4) Start the engine and race it a few times; then let it run at idle speed for about one minute.

NOTE

If the engine idling speed is unstable (or the engine stalls),

let the engine run with the throttle valve slightly open.

(5) If deposits are not removed from the throttle valve, repeat steps (3) and (4).

(6) Connect the air intake hose.

(7) Using the scan tool, erase the diagnostic trouble code, or disconnect the battery’s ground cable for ten seconds orlonger and then reconnect it.

(8) Adjust the basic idle speed (engine speed adjusting screw). (Refer to

P.13-33.)

(9) Adjust the throttle position sensor.

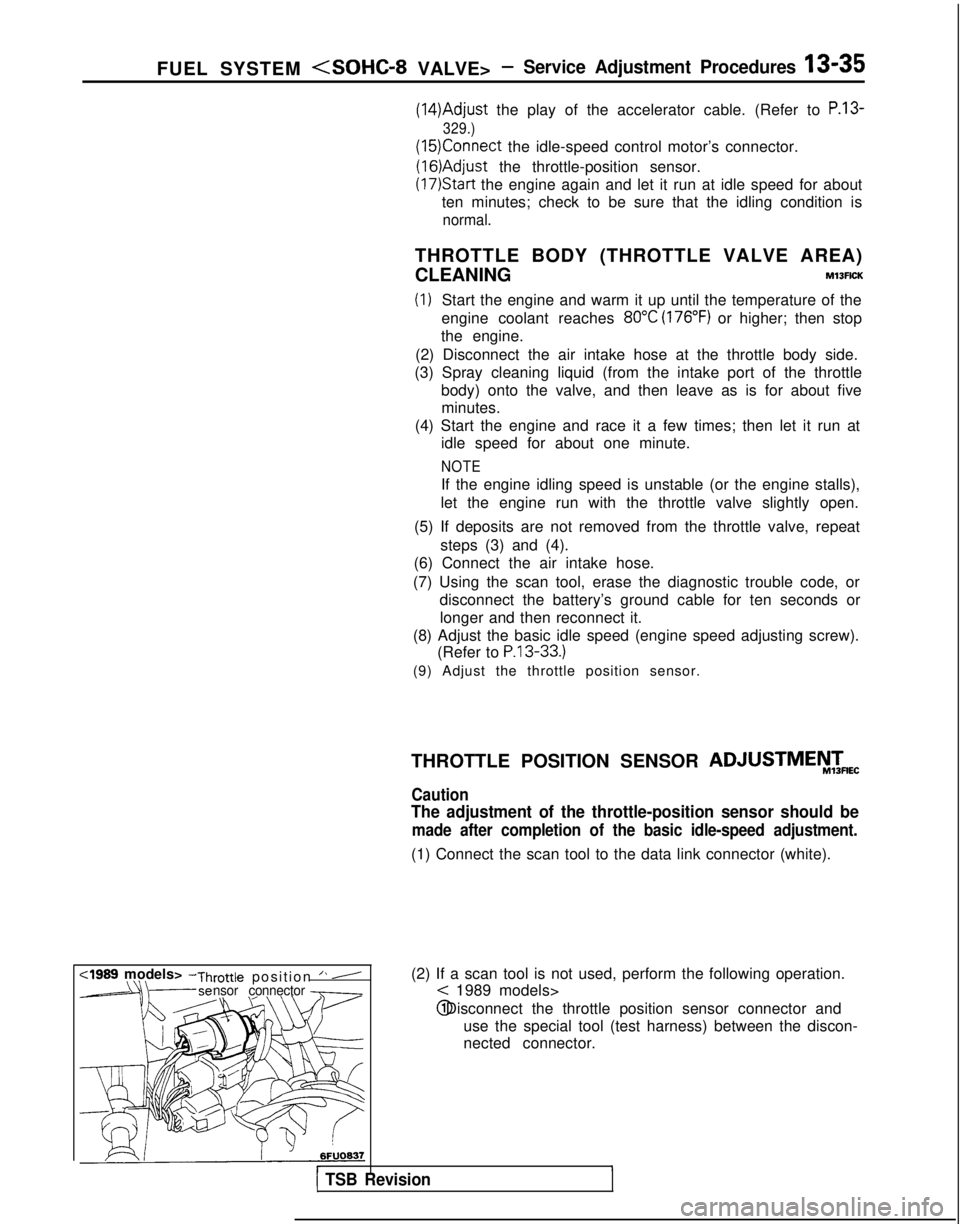

(2) If a scan tool is not used, perform the following operation.

< 1989 models> @ Disconnect the throttle position sensor connector and

use the special tool (test harness) between the discon-

nected connector.

r1 TSB Revision

THROTTLE POSITION SENSOR ADJUSTMEiW&

Caution

The adjustment of the throttle-position sensor should be

made after completion of the basic idle-speed adjustment.

(1) Connect the scan tool to the data link connector (white).

,

Page 178 of 1273

13-36 FUEL SYSTEM

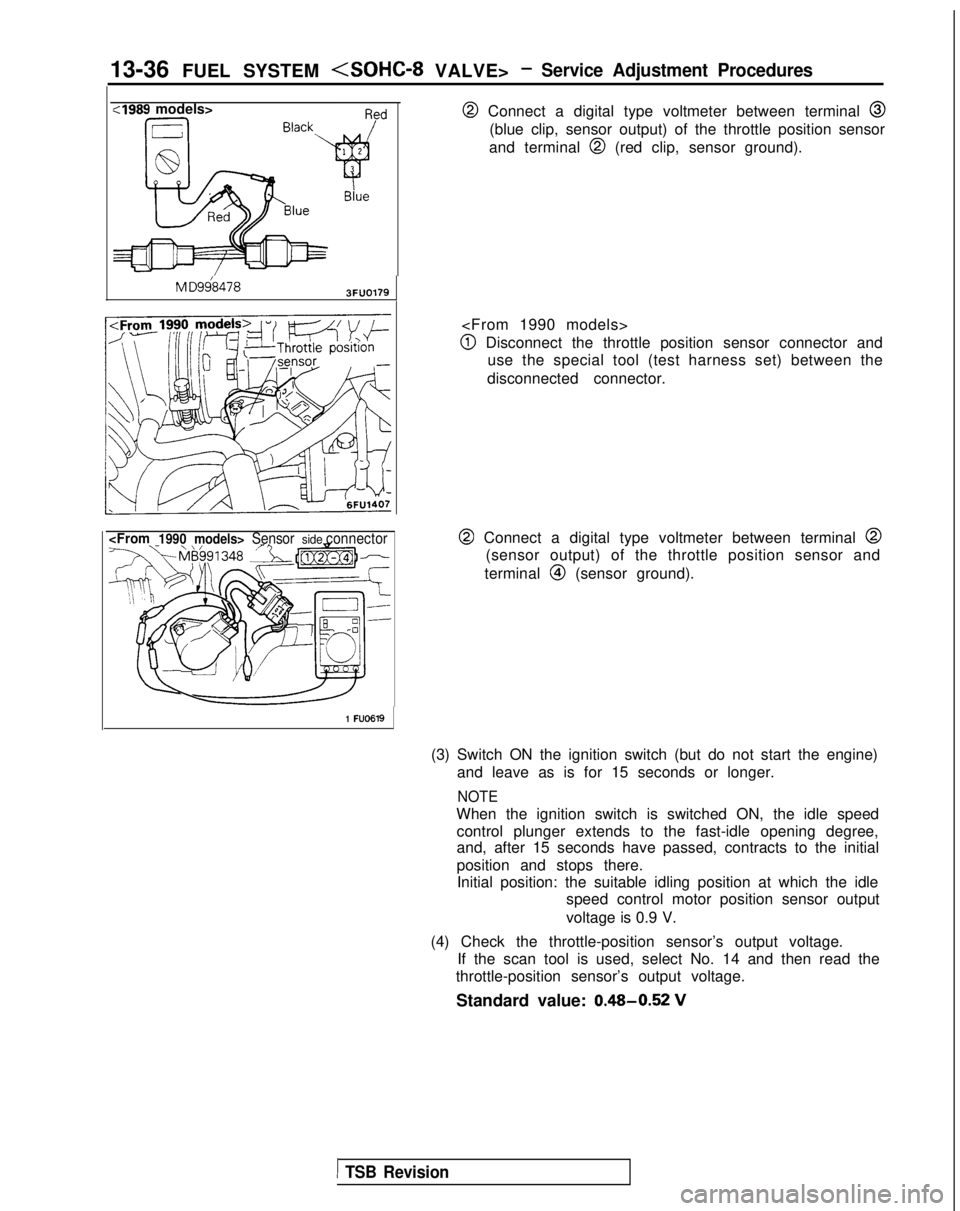

:I989 models>

M

D9684783FUO179

@ Connect a digital type voltmeter between terminal @

(blue clip, sensor output) of the throttle position sensor

and terminal

@I (red clip, sensor ground).

@I Disconnect the throttle position sensor connector and use the special tool (test harness set) between the

disconnected connector.

@ Connect a digital type voltmeter between terminal @

(sensor output) of the throttle position sensor and

terminal

@I (sensor ground).

1 FU0619

(3) Switch ON the ignition switch (but do not start the engine) and leave as is for 15 seconds or longer.

NOTE

When the ignition switch is switched ON, the idle speedcontrol plunger extends to the fast-idle opening degree,

and, after 15 seconds have passed, contracts to the initial

position and stops there.Initial position: the suitable idling position at which the idle speed control motor position sensor output

voltage is 0.9 V.

(4) Check the throttle-position sensor’s output voltage. If the scan tool is used, select No. 14 and then read the

throttle-position sensor’s output voltage.

Standard value: 0.48-0.52

V

1 TSB Revision