service MITSUBISHI GALANT 1989 Service Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 64 of 1273

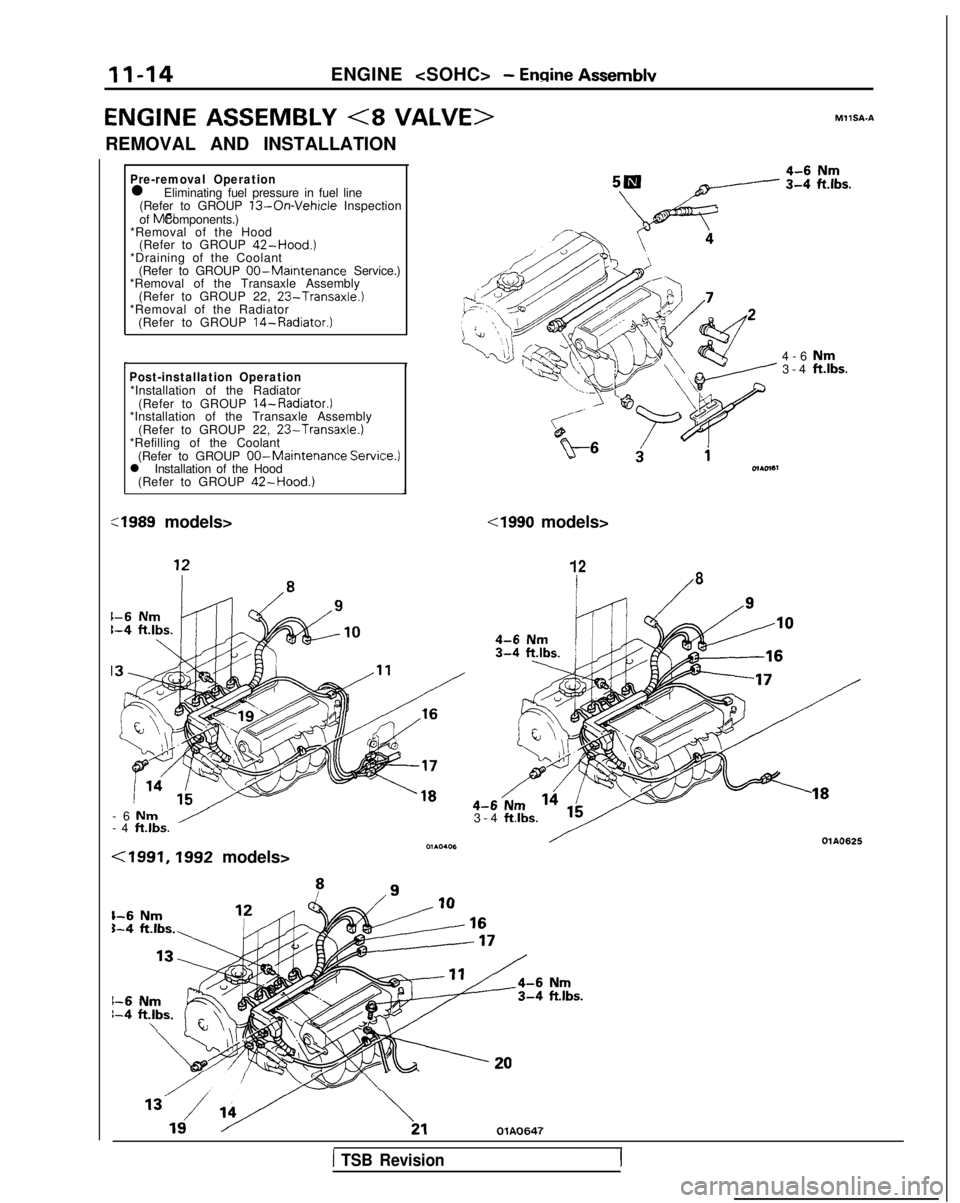

II-14ENGINE

ASSEMBLY

(8 VALVE>

REMOVAL AND INSTALLATION

Pre-removal Operationl Eliminating fuel pressure in fuel line

(Refer to GROUP 13-On-Vehicle Inspection

of MFI Components.)

*Removal of the Hood (Refer to GROUP

42-Hood.)*Draining of the Coolant

(Refer to GROUP OO-Maintenance Service.)

*Removal of the Transaxle Assembly

(Refer to GROUP 22,

23-Transaxle.)*Removal of the Radiator(Refer to GROUP 14-Radiator.)

I IPost-installation Operation*Installation of the Radiator

(Refer to GROUP 14-Radiator.)*Installation of the Transaxle Assembly (Refer to GROUP 22, 23-Transaxle.)*Refilling of the Coolant(Refer to GROUP 00-Maintenance Servic

l Installation of the Hood

(Refer to GROUP

42-Hood.)

:e.) :1989

models>

-6

Nm-4 ft.lbs./

4-6 Nm3-4 ft.lbs.

cl990 models>

128

3-4 ftlbs. MllSA-A

<1991,1992 models>

1-6 Nm5-4 ft.lbs.

1-6 Nm1-4 ft.lbs.\

OlAO625

\,,OlA0647

1 TSB Revision

Page 65 of 1273

ENGINE

35-4

5

25-33 35-45 Nm

25-33

ft.lbs.

24

35-45 N

m

25-33

ft.lbs.

23-2

7

250166309

I23

:l;nbs.

50-65 Nm

36-47 ft.lbs.

dv--iu wm: ’22-29 ft.lbs. \ d.(,(I3L i‘9

50-65 Nm*Cb36-47 ft.lbs.* -

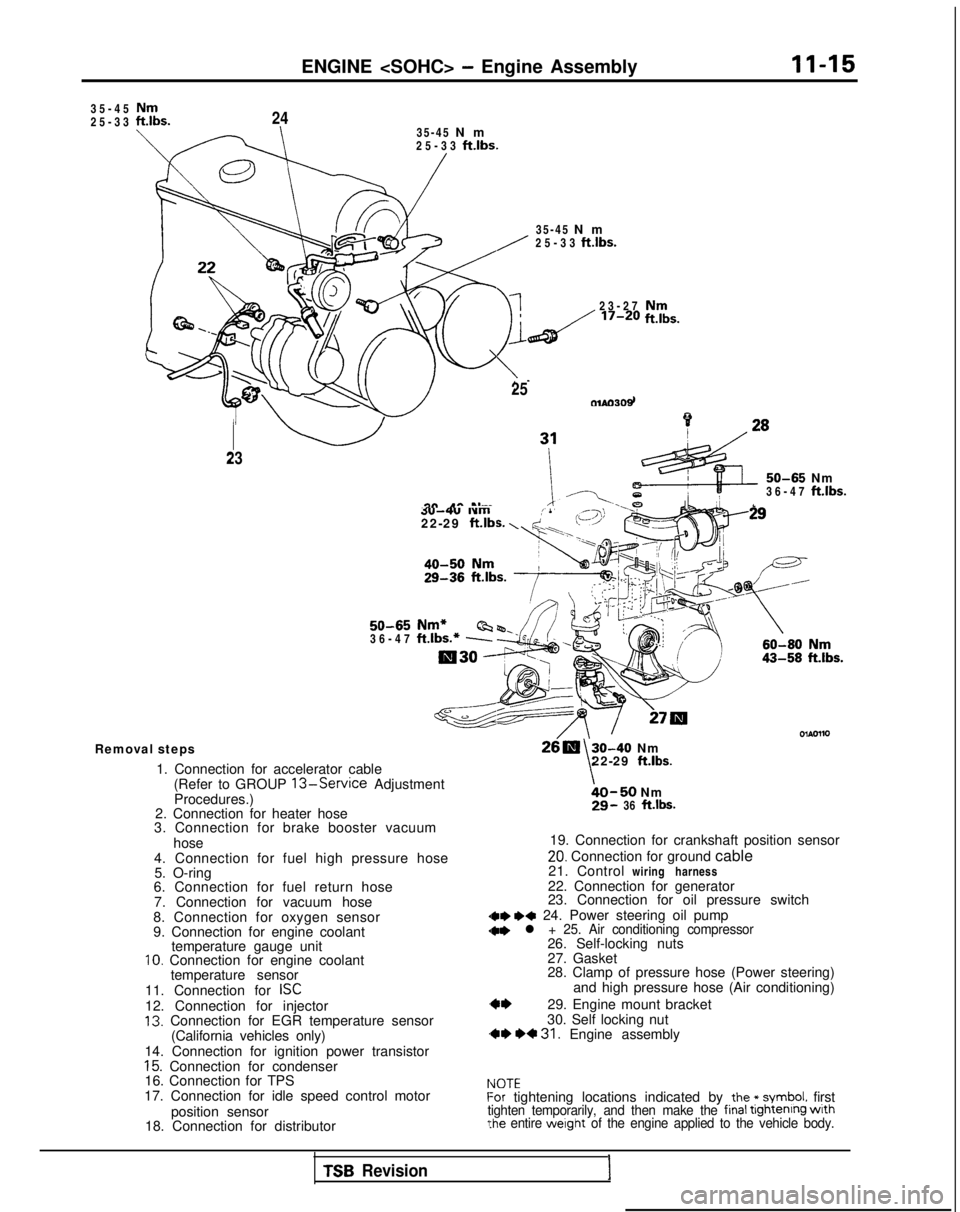

Removal steps

1. Connection for accelerator cable(Refer to GROUP

13-Service Adjustment

Procedures.)

2. Connection for heater hose

3. Connection for brake booster vacuum

hose

4. Connection for fuel high pressure hose 5. O-ring

6. Connection for fuel return hose

7. Connection for vacuum hose

8. Connection for oxygen sensor

9. Connection for engine coolant temperature gauge unit

10. Connection for engine coolant

temperature sensor

11. Connection for

ISC12. Connection for injector13. Connection for EGR temperature sensor (California vehicles only)

14. Connection for ignition power transistor

15. Connection for condenser

16. Connection for TPS

17. Connection for idle speed control motor

position sensor

18. Connection for distributor

30-40 Nm

\22-29 ft.lbs.

bO-50 Nm29- 36 ft.lbs.

19. Connection for crankshaft position sensor

20. Connection for ground cable

21. Control wiring harness

22. Connection for generator

23. Connection for oil pressure switch

dae I)* 24. Power steering oil pump

28. Clamp of pressure hose (Power steering) and high pressure hose (Air conditioning)

29. Engine mount bracket

30. Self locking nut

,** *+ 31. Engine assembly

IdOTEf-or tightening locations indicated by the * symbol. firsttighten temporarily, and then make the final tightenrng wrth?he entire werght of the engine applied to the vehicle body.

TSB Revision1

Page 66 of 1273

11-16ENGINE

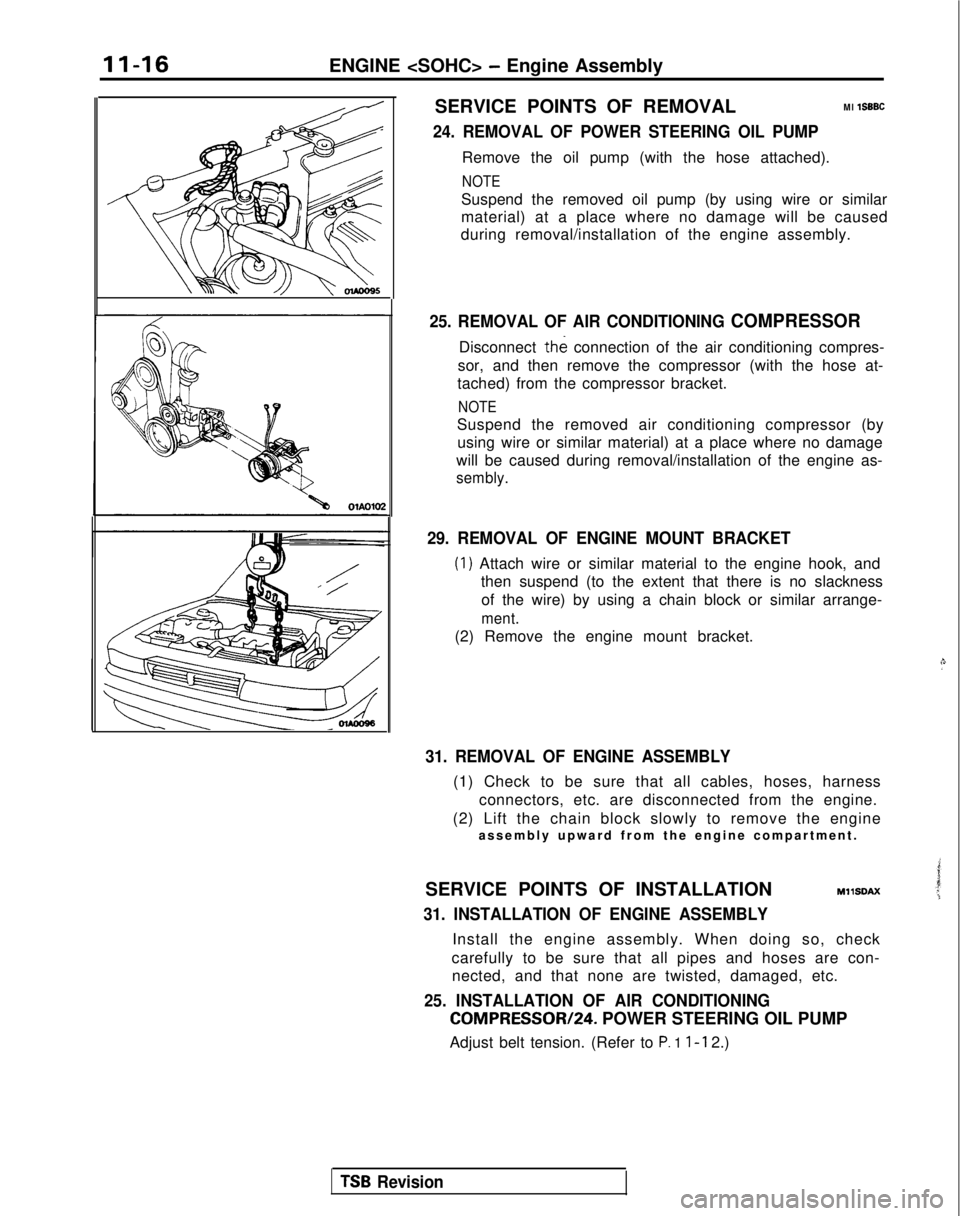

SERVICE POINTS OF REMOVAL

Ml 1SBBC

24. REMOVAL OF POWER STEERING OIL PUMP

Remove the oil pump (with the hose attached).

NOTE

Suspend the removed oil pump (by using wire or similar

material) at a place where no damage will be caused

during removal/installation of the engine assembly.

25. REMOVAL OF AIR CONDITIONING COMPRESSOR

Disconnect the

connection of the air conditioning compres-

sor, and then remove the compressor (with the hose at-

tached) from the compressor bracket.

NOTE

Suspend the removed air conditioning compressor (by using wire or similar material) at a place where no damage

will be caused during removal/installation of the engine as-

sembly.

29. REMOVAL OF ENGINE MOUNT BRACKET

(1) Attach wire or similar material to the engine hook, and then suspend (to the extent that there is no slackness

of the wire) by using a chain block or similar arrange-

ment.

(2) Remove the engine mount bracket.

31. REMOVAL OF ENGINE ASSEMBLY

(1) Check to be sure that all cables, hoses, harness connectors, etc. are disconnected from the engine.

(2) Lift the chain block slowly to remove the engine assembly upward from the engine compartment

.

SERVICE POINTS OF INSTALLATION

MllSDAX

31. INSTALLATION OF ENGINE ASSEMBLY

Install the engine assembly. When doing so, check

carefully to be sure that all pipes and hoses are con- nected, and that none are twisted, damaged, etc.

25. INSTALLATION OF AIR CONDITIONING

COMPRESSORI24. POWER STEERING OIL PUMP

Adjust belt tension. (Refer to

P. 1 1-l 2.)

TSB Revision

Page 67 of 1273

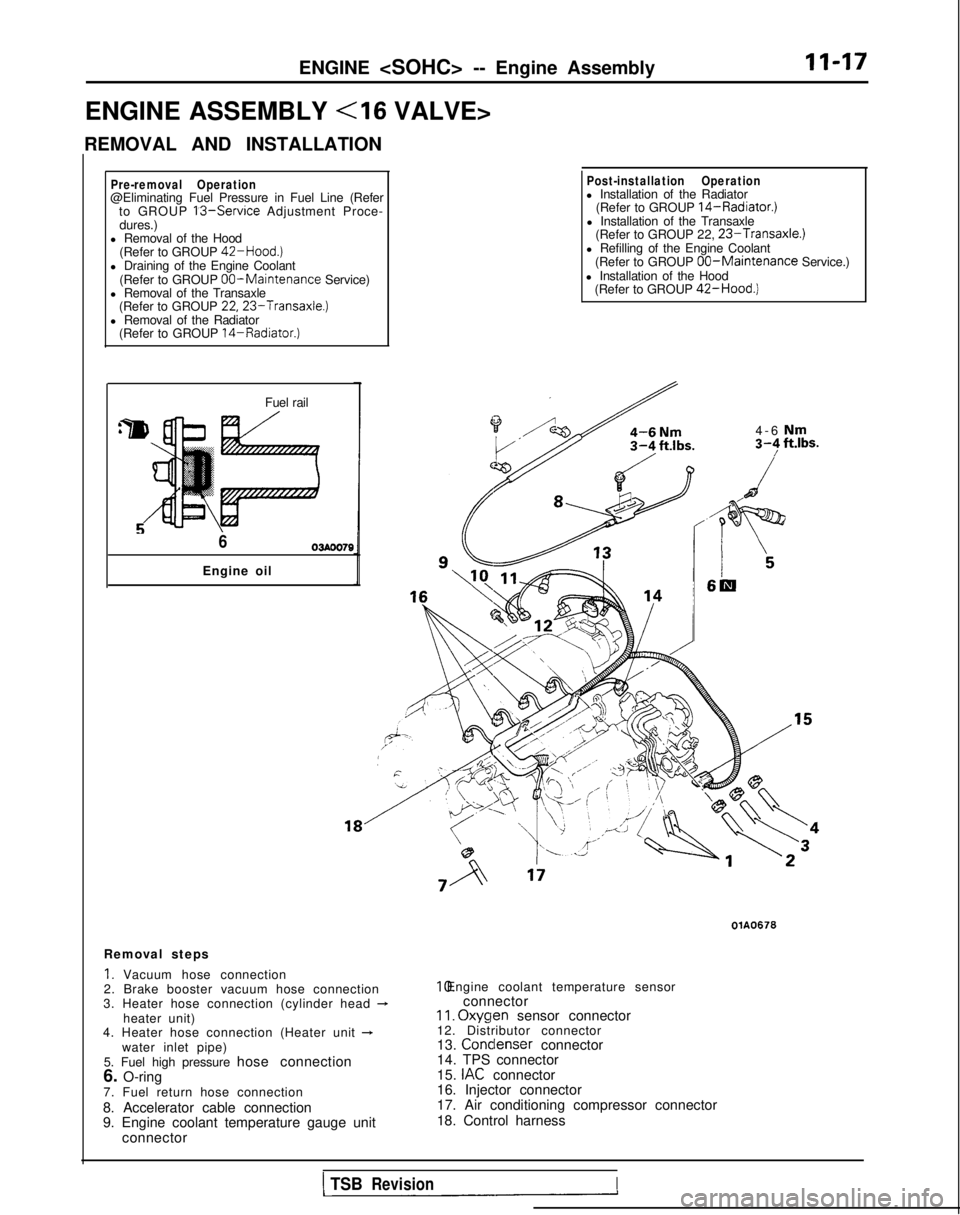

ENGINE

ENGINE ASSEMBLY

REMOVAL AND INSTALLATION

II-17

Pre-removal Operation@Eliminating Fuel Pressure in Fuel Line (Refer to GROUP 13-Service Adjustment Proce-

dures.)

l Removal of the Hood

(Refer to GROUP

42-Hood.)l Draining of the Engine Coolant

(Refer to GROUP 00-Maintenance Service)

l Removal of the Transaxle (Refer to GROUP

22,23-Transaxle.)l Removal of the Radiator(Refer to GROUP 14-Radiator.)

Fuel rail

603AOO70

Engine oil

Post-installation Operationl Installation of the Radiator (Refer to GROUP 14-Radiator.)l Installation of the Transaxle(Refer to GROUP 22, 23-Transaxle.)l Refilling of the Engine Coolant

(Refer to GROUP 00-Maintenance Service.)

l Installation of the Hood (Refer to GROUP

42-Hood.)

4-6 Nm3-F ft.lbs.

I6m

Removal steps

1. Vacuum hose connection

2. Brake booster vacuum hose connection

3. Heater hose connection (cylinder head

-heater unit)

4. Heater hose connection (Heater unit +water inlet pipe)

5. Fuel high pressure hose connection

6. O-ring

7. Fuel return hose connection

8. Accelerator cable connection

9. Engine coolant temperature gauge unit connector

OlA0676 10. Engine coolant temperature sensor

connector

II. Oxyqen

sensor connector

12. Distributor connector

13. Condenser

connector

14. TPS connector

15.

IAC connector

16. Injector connector

17. Air conditioning compressor connector

18. Control harness

1 TSBRevisionI

Page 70 of 1273

II-20ENGINE

MD998443-011

6EN245

Oil seal

MD998307-01 1

MD99

CaAshaft6ENOlZ

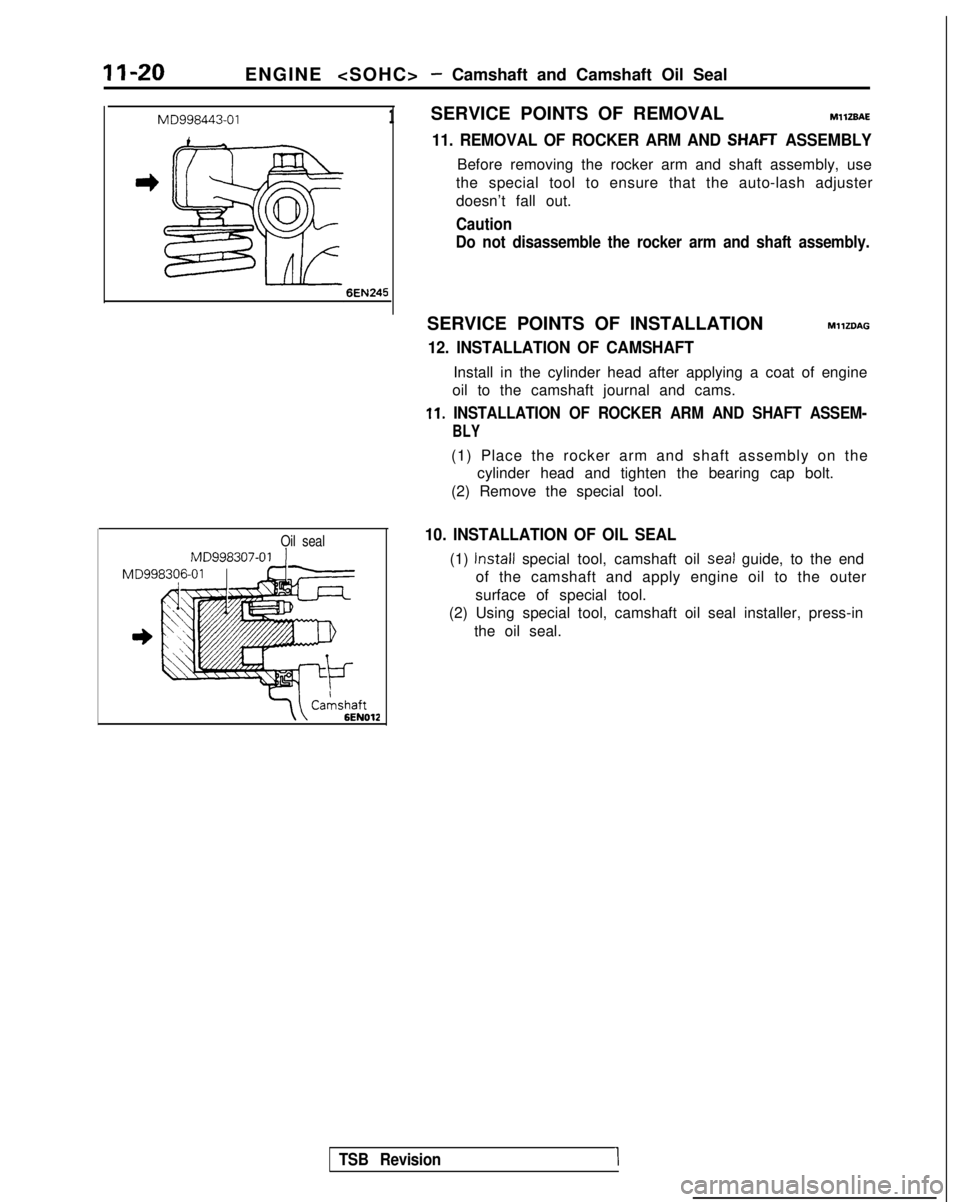

SERVICE POINTS OF REMOVALMllZBAE

11. REMOVAL OF ROCKER ARM AND SHAFr ASSEMBLY

Before removing the rocker arm and shaft assembly, use

the special tool to ensure that the auto-lash adjuster

doesn’t fall out.

Caution

Do not disassemble the rocker arm and shaft assembly.

SERVICE POINTS OF INSTALLATIONMllZOAG

12. INSTALLATION OF CAMSHAFT

Install in the cylinder head after applying a coat of engine

oil to the camshaft journal and cams.

11. INSTALLATION OF ROCKER ARM AND SHAFT ASSEM-

BLY

(1) Place the rocker arm and shaft assembly on the cylinder head and tighten the bearing cap bolt.

(2) Remove the special tool.

10. INSTALLATION OF OIL SEAL

(1) Install special tool, camshaft oil sea) guide, to the end

of the camshaft and apply engine oil to the outer

surface of special tool.

(2) Using special tool, camshaft oil seal installer, press-in

the oil seal.

TSB Revision1

Page 71 of 1273

ENGINE

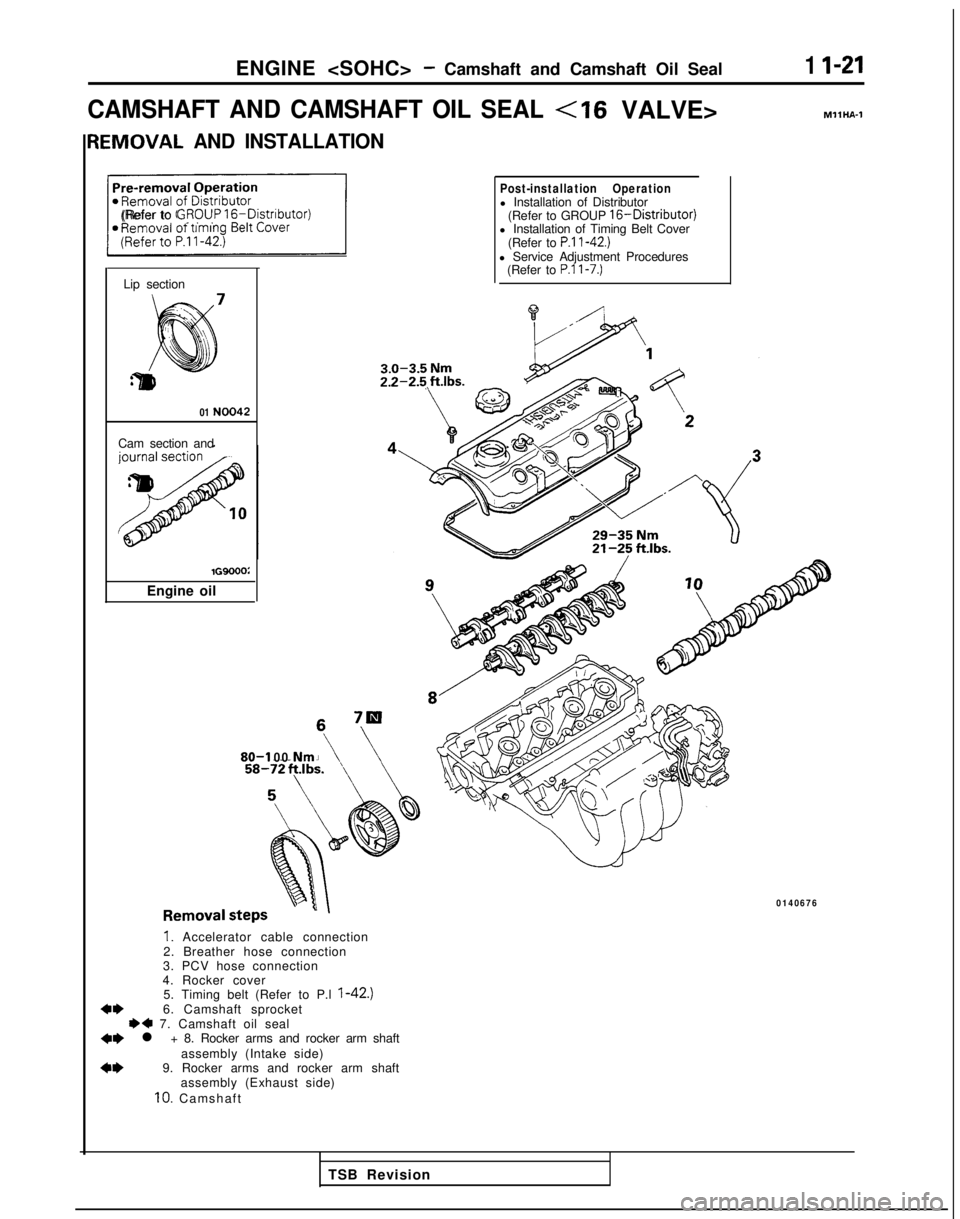

CAMSHAFT AND CAMSHAFT OIL SEAL

IEMOVAL AND INSTALLATION

1(Refer to GRPUP 16-Distnbutor)

Lip section

01

NO042

Cam section and lG9000:

Engine oil

Post-installation Operationl Installation of Distributor (Refer to GROUP 16-Distributor)l Installation of Timing Belt Cover

(Refer to P.l l-42.)l Service Adjustment Procedures(Refer to P.l l-7.)

3.0-3.5 Nm2.2-2.5 ft.lbs.

80-l 00 Nm

0140676Removalsteps

I. Accelerator cable connection

2. Breather hose connection

3. PCV hose connection

4. Rocker cover 5. Timing belt (Refer to P.l

l-42.)4*6. Camshaft sprocketI)+ 7. Camshaft oil seal*e l + 8. Rocker arms and rocker arm shaft

assembly (Intake side)

**9. Rocker arms and rocker arm shaftassembly (Exhaust side) 10.

Camshaft

TSB Revision

Page 72 of 1273

ENGINE

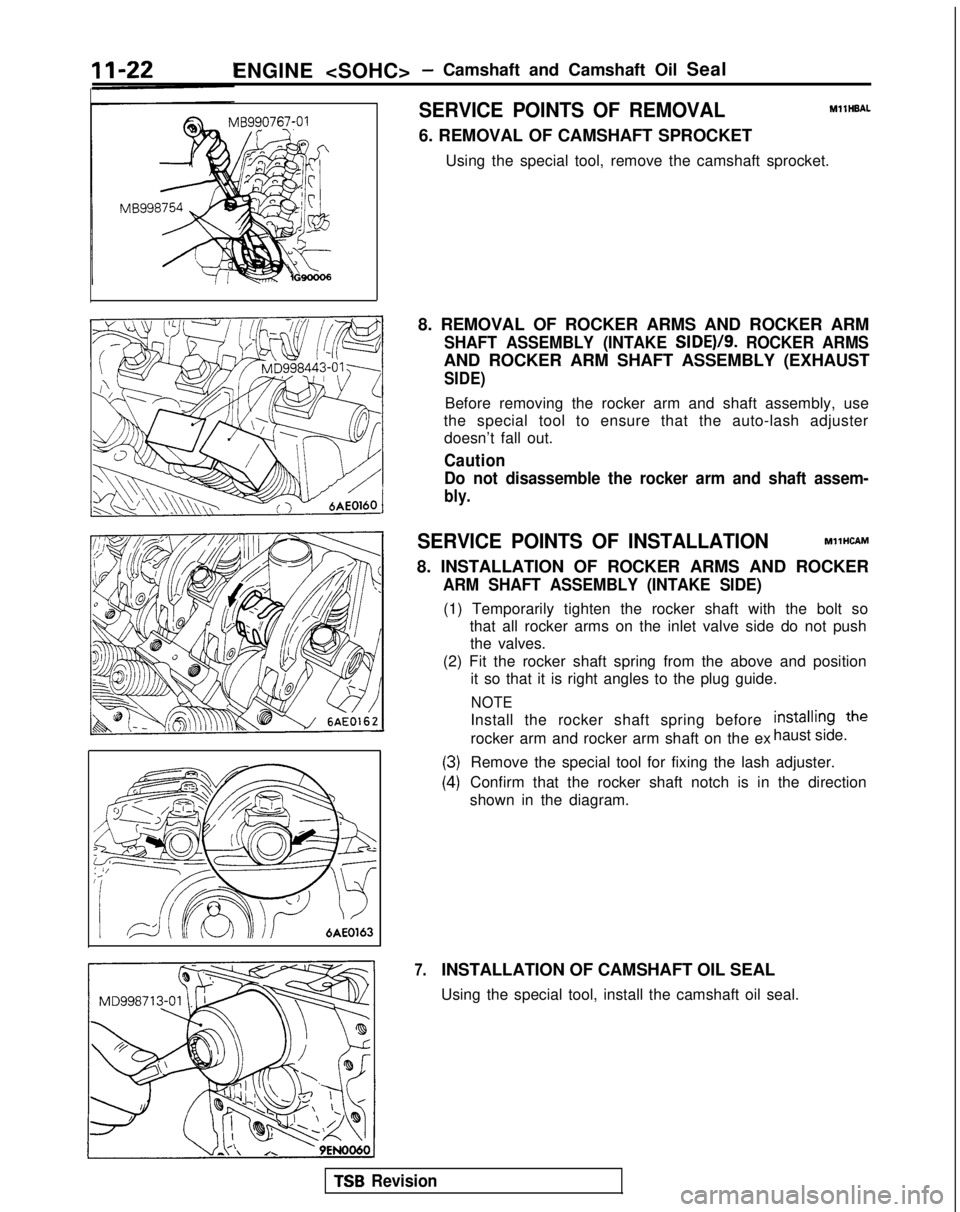

SERVICE POINTS OF REMOVALMllHBAL

6. REMOVAL OF CAMSHAFT SPROCKET

Using the special tool, remove the camshaft sprocket.

8. REMOVAL OF ROCKER ARMS AND ROCKER ARM

SHAFT ASSEMBLY (INTAKE SIDE)/S. ROCKER ARMS

AND ROCKER ARM SHAFT ASSEMBLY (EXHAUST

SIDE)

Before removing the rocker arm and shaft assembly, use

the special tool to ensure that the auto-lash adjuster doesn’t fall out.

Caution

Do not disassemble the rocker arm and shaft assem-

bly.

SERVICE POINTS OF INSTALLATIONMllHCAM

8. INSTALLATION OF ROCKER ARMS AND ROCKER

ARM SHAFT ASSEMBLY (INTAKE SIDE)

(1) Temporarily tighten the rocker shaft with the bolt so that all rocker arms on the inlet valve side do not pushthe valves.

(2) Fit the rocker shaft spring from the above and position it so that it is right angles to the plug guide.

NOTE

Install the rocker shaft spring before installinn the

rocker arm and rocker arm shaft on the ex haust side.

7.

(3)

(4)

Remove the special tool for fixing the lash adjuster.

Confirm that the rocker shaft notch is in the direction

shown in the diagram.

INSTALLATION OF CAMSHAFT OIL SEAL

Using the special tool, install the camshaft oil seal.

TSB Revision

Page 73 of 1273

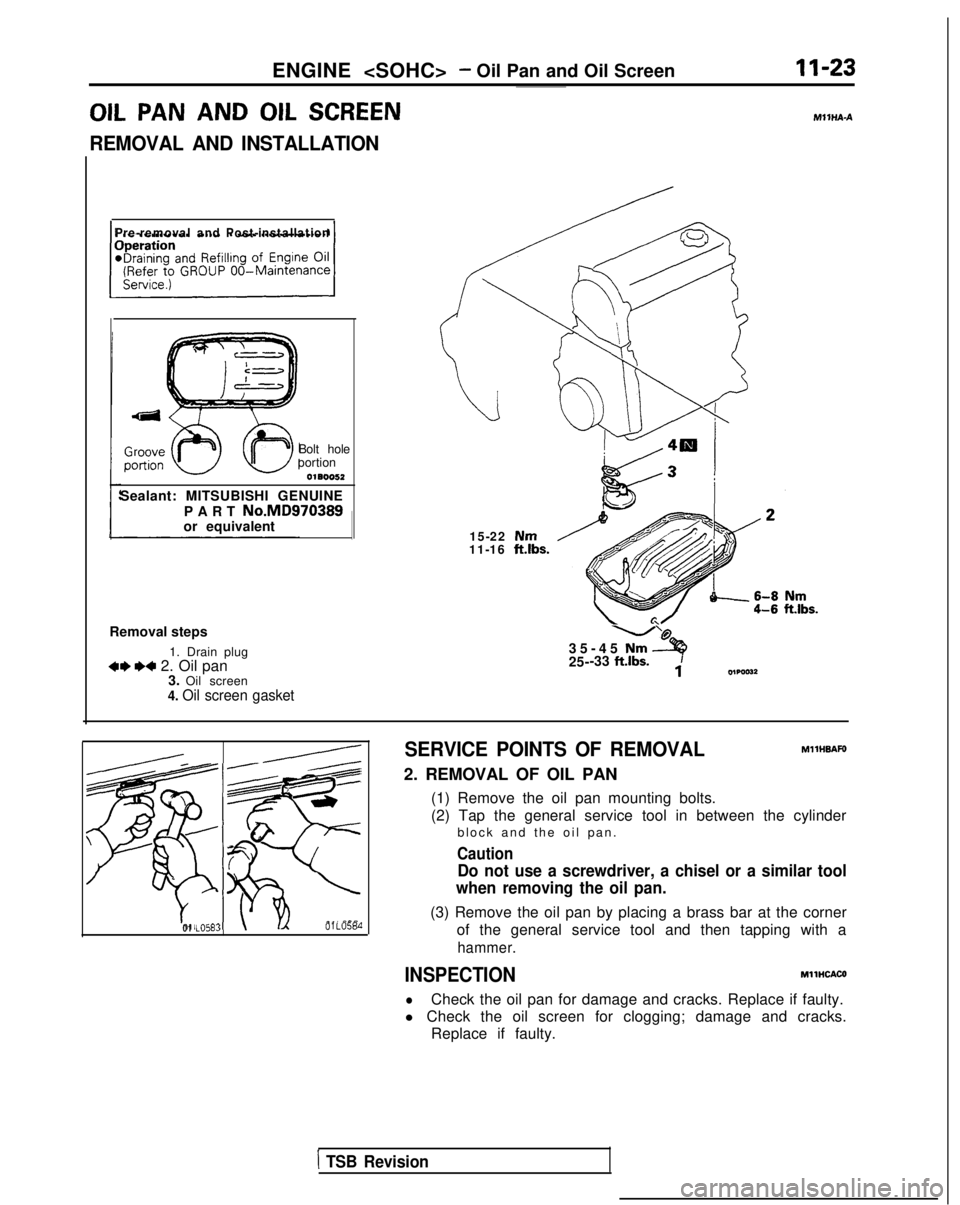

ENGINE

OIL PAN

AND

OIL SCREENMllHA-A

REMOVAL AND INSTALLATION

Pre-removal and Post-installation

Bolt hole

portion

0180052

Sealant: MITSUBISHI GENUINE

PART

No.MD970389or equivalent

Removal steps 1. Drain plug

4**4 2. Oil pan3. Oil screen

4. Oil screen gasket

15-22 Nm11-16 ft.lbs.

U’@

35-45 Nm a25- -33 ft.lbs.iowaI32

d- -<

--,\9 -

\’ 63

%e

;

01 LO583\01 LO584

SERVICE POINTS OF REMOVALMllHBAFO

2. REMOVAL OF OIL PAN

(1) Remove the oil pan mounting bolts.

(2) Tap the general service tool in between the cylinderblock and the oil pan

.

Caution

Do not use a screwdriver, a chisel or a similar tool

when removing the oil pan.

(3) Remove the oil pan by placing a brass bar at the corner

of the general service tool and then tapping with a

hammer.

INSPECTIONMllHCACO

lCheck the oil pan for damage and cracks. Replace if faulty.

l Check the oil screen for clogging; damage and cracks. Replace if faulty.

1 TSB Revision

Page 74 of 1273

11-24ENGINE

2 roove

1 EN227

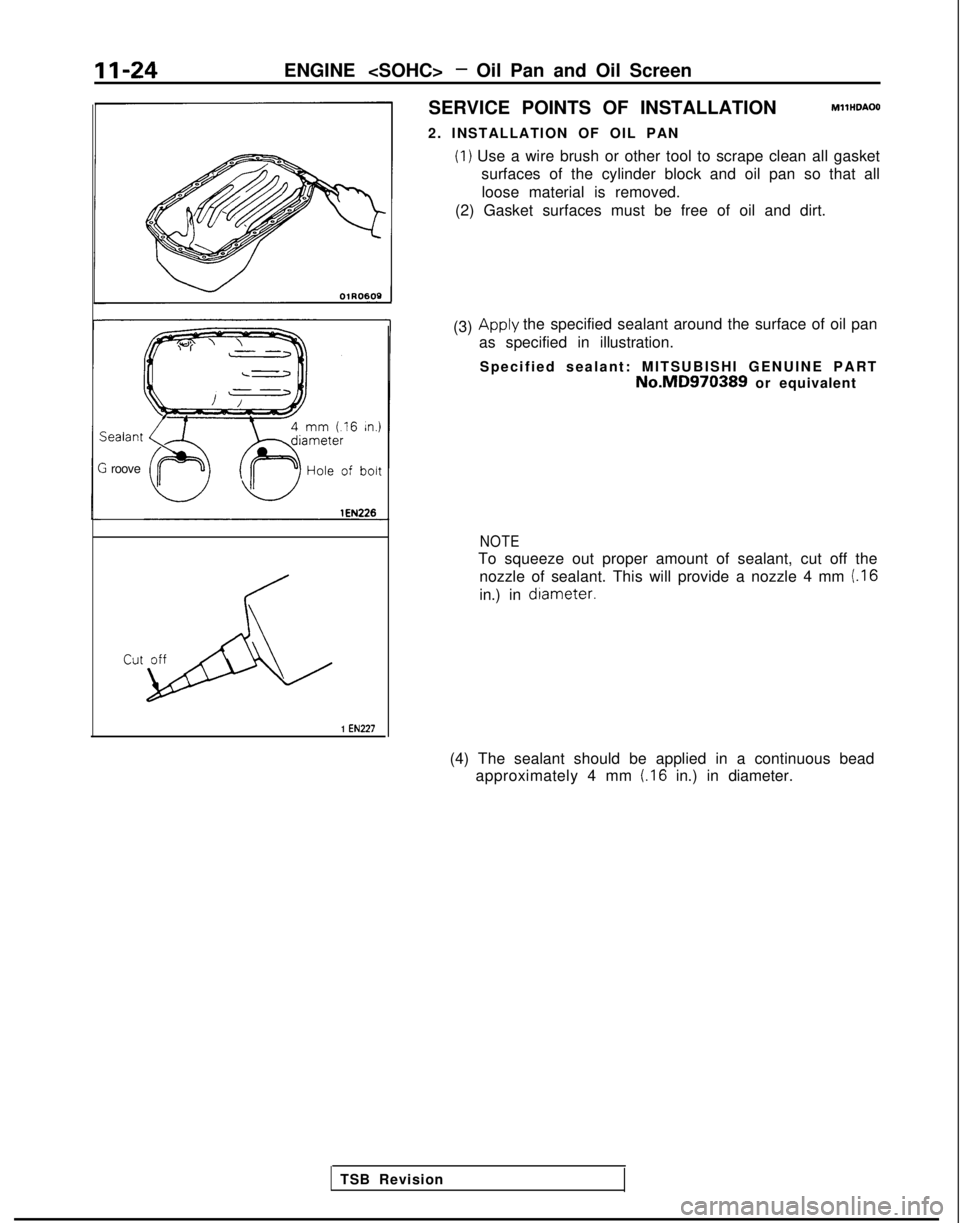

SERVICE POINTS OF INSTALLATIONMllHDAOO

2. INSTALLATION OF OIL PAN

(1) Use a wire brush or other tool to scrape clean all gasket

surfaces of the cylinder block and oil pan so that all

loose material is removed.

(2) Gasket surfaces must be free of oil and dirt.

(3)

APP~the specified sealant around the surface of oil pan

as specified in illustration.

Specified sealant: MITSUBISHI GENUINE PART

No.MD970389 or equivalent

NOTE

To squeeze out proper amount of sealant, cut off the nozzle of sealant. This will provide a nozzle 4 mm

1.16

in.) in drameter.

(4) The sealant should be applied in a continuous bead approximately 4 mm

(.I6 in.) in diameter.

TSB Revision

Page 75 of 1273

ENGINE

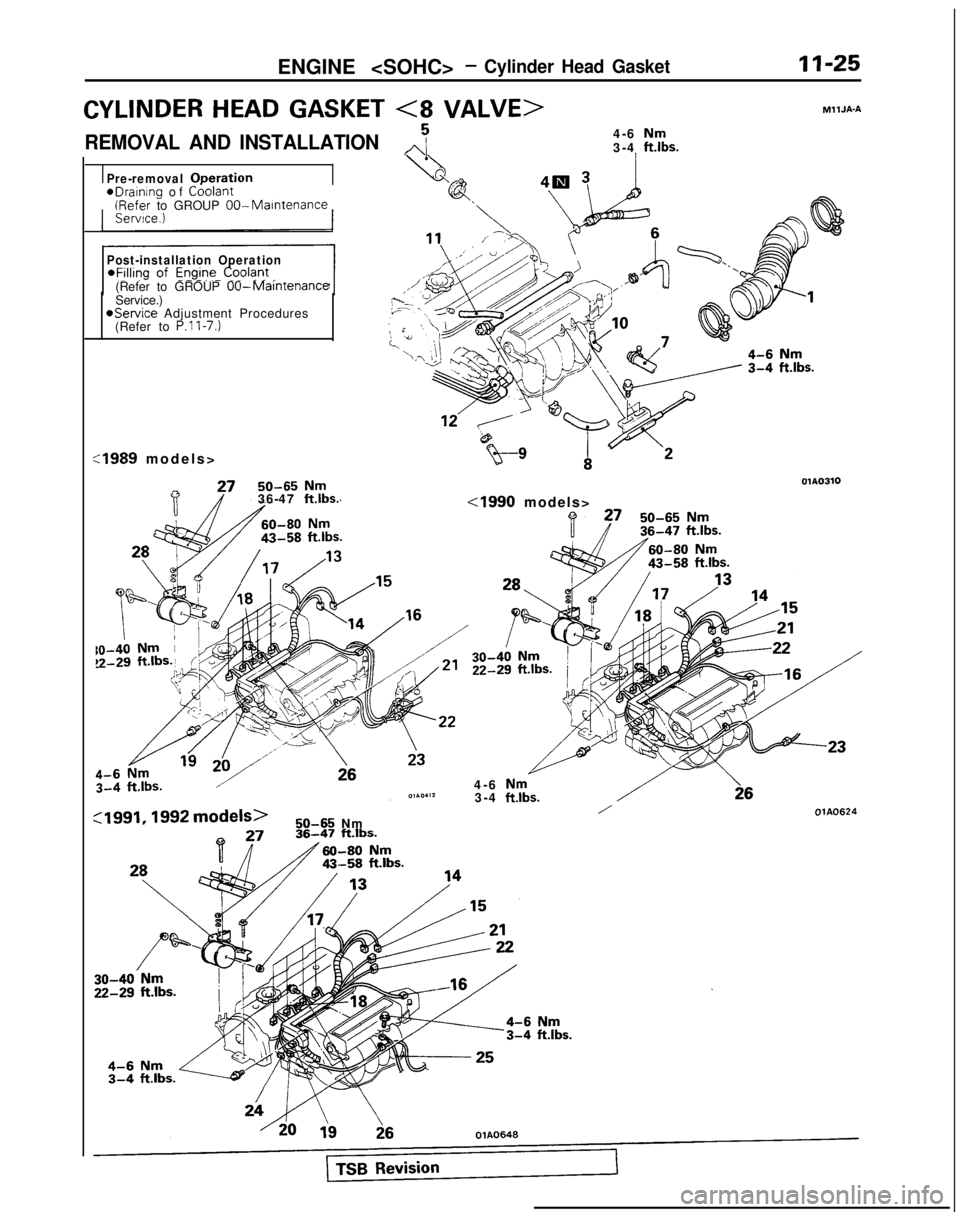

CYLINDER HEAD GASKET <8 VALVE>

REMOVAL AND INSTALLATION,,j4-6 Nm3-4 ft.lbs.

MllJA-A

Pre-removal ODeration

eDraInIng

of Coolant (Refer

to GROUP OO-Maintenance

Post-installation Operation

(Refer to GROUP 00-MaintenanceService.)@Service Adjustment Procedures

(Refer to P.ll-7.)

:1989 models

>

50-65

Nm36-47 ftlbs.

OlAO310

cl990 models>

4-6

Nm3-4 ftlbs.

:1991,1992 models>/OlA0624 50-65

Nm