relay MITSUBISHI GALANT 1989 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 9 of 1273

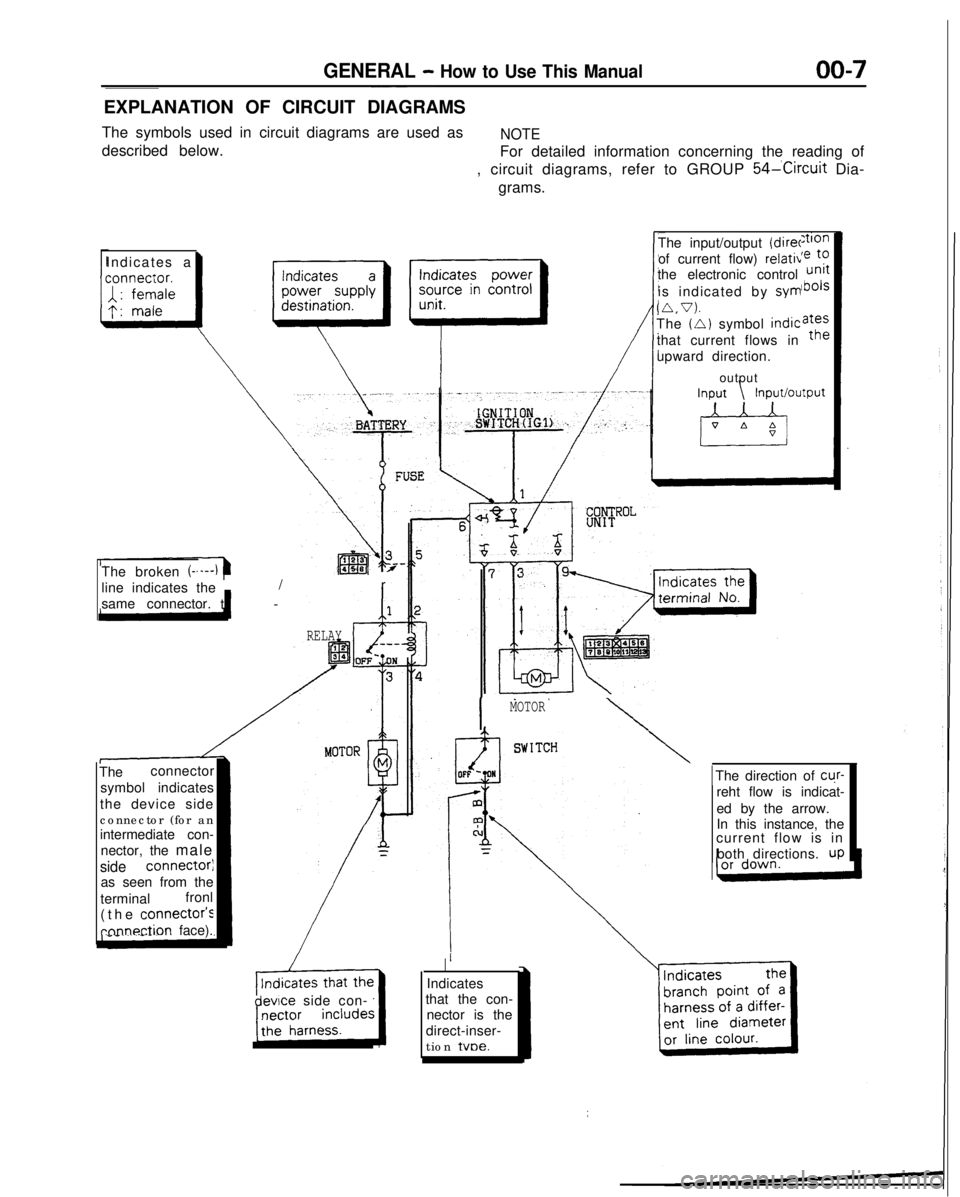

GENERAL - How to Use This Manual00-7

EXPLANATION OF CIRCUIT DIAGRAMS

The symbols used in circuit diagrams are used as

NOTE

described below. For detailed information concerning the reading of

, circuit diagrams, refer to GROUP

54lCircuit Dia-

grams.

Indicates

a

I

The input/output (direr

of current flow) relativ

the electronic control

is indicated by sym

(A.V).The (A) symbol

indic

that current flows in

upward direction.

output

The broken

(-.

line indicates the t

-

/r

same connector.

The connector

symbol indicates

the device side

connector (for an

intermediate con- nector, the male

side connectorj

as seen from the

terminal fronl

(the

connectois

rnnnection face).

RELAY

devce side con-

I

MOTOR

\

\

Indicates

that the con- nector is the

direct-inser-

tion tvoe.The direction of

cu.r-

reht flow is indicat-

ed by the arrow.

In this instance, the

current flow is in

both directions.

UP

Page 143 of 1273

13-1

FUEL

CONTENTSM’ISAA--

AUTO-CRUISE CONTROL SYSTEM.............

.

332

AUTO-CRUISE CONTROL ............................. 408

SERVICE ADJUSTMENT PROCEDURES .................397

Accelerator Cables

inspectron and Adjustment ........

.

398 Auto-cruise

Control System Inspection

..............397

Individual Parts Inspection ......................

401SPECfAL

TOOLS

.....................................

333

SPECIFICATIONS .................................... 332

TROUBLESHOOTING ................................. 334

Auto-cruise Control Components Location ..........368

Auto-cruise Control

Related Harnesses

..........365

Check Chart

Check Chart

Circuit Diagram ................................

371input Checking................................

.

366

On-board Diagnostic Checking ......................

361Troubleshooting Quick-reference Chart

.

334

Troubleshooting Quick-reference Chart

ENGINE CONTROL...............................

.

328

ENGINE CONTROL ..................................

330

SERVICE ADJUSTMENT PROCEDURES .................329

Accelerator Cable inspectron and Adjustment

...........329

Accelerator Switch Inspection and Adjustment ..........329

SPECIFICATIONS ....................................

328

TROUBLESHOOTlNG................................

.

328

Accelerator

Cable and Accelerator Pedal .............

.

328

FUEL SYSTEM

FUEL FILTER .........................................

327

FUEL LINE AND VAPOR LINE

.

326

FUEL LINE AND VAPOR LINE

.

324

FUEL TANK

.

322

FUELTANK

.

318

GENERAL INFORMATION ............................ 196

ON-VEHICLE INSPECTION OF MFI

COMPONENTS

......251

Air Conditioning Switch and A/C Compressor Clutch Relay .....................................

285

Barometric Pressure Sensor .................... 266

Boost Meter

311Camshaft Position Sensor ........................

.

277Closed Throttle Position Switch

.....................

.

274

Component Location .............................

251Components Inspection Pocedure

................. 255

Crankshaft Position Sensor ..................... 280EGR

Solenord

...................

.

307EGR Temperature Sensor

.............

.

288Engrne Control Module Power Ground

................

.

257

Engine Coolant Temperature Sensor ..................

268Evaporative Emission Purge Solenoid .................

.

307

Fuel Pressure Solenoid

307Fuel Pressure Test...............................

.

312

Fuel Pump ...................................... 258

Heated Oxygen Sensor ............................ 290

Idle Air Control Motor (Stepper Motor) ................

238Ignition Coil and Ignition Power Transistor .............

.

302

Ignition Switch-ST .................................. 284

Ignition Switch-ST and Park/Neutral Position Switch .....284

Injectors .......................................

295Inspection of Engine Control Module Terminal

Voltage .......................................

.

315

Intake Air Temperature Sensor .......................263

Knock Sensor

Power Steering Pressure Switch ......................

284Power Supply and Ignition Switch ...................

.

255Resistor

..............................

.

298Terminal Voltage Check Chart

......................

.

315Throttle Position Sensor

..........................

.

270Turbocharger Waste Gate Solenoid

.........

.

309 Vehicle

Speed Sensor

............................... 284

Volume Air Flow Sensor ............................

261SERVICE ADJUSTMENT PROCEDURES ...............

.

245

Basic

idle Speed Adjustment .......................

.

245

Closed Throttle Position Switch (Fixed

SAS)Adjustment ......................................

.

250

Curb

Idle Speed Inspection

..........................245Throttle Body (Throttle Valve Area) Cleaning

...........

.

248Throttle Position Sensor Adjustment

..................

.

248

SPECIALTOOLS...................................

.

204

SPECIFICATIONS ...................................

201TROUBLESHOOTING ...............................

.

205

Check Engine/Malfunction Indicator Lamp ..............205

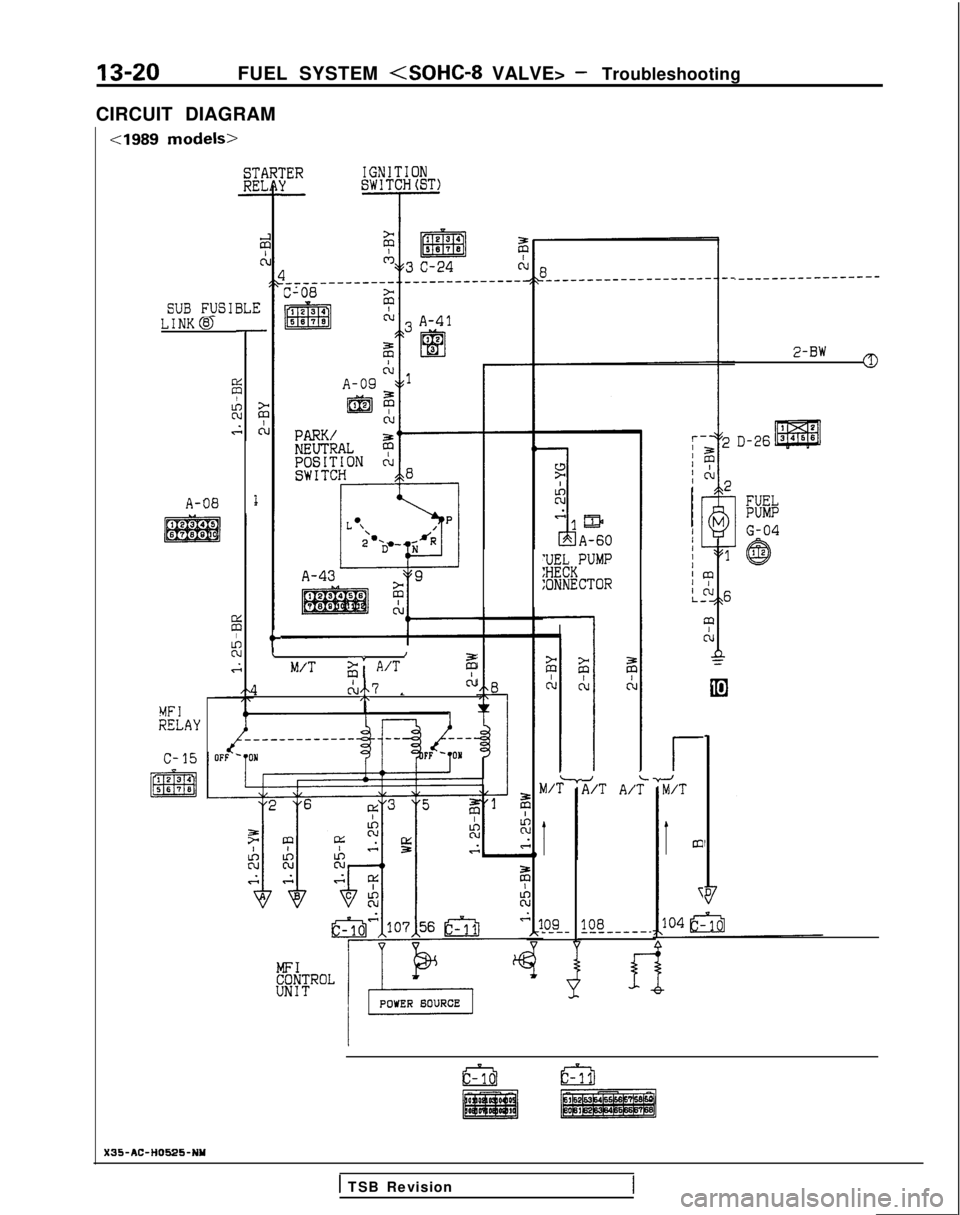

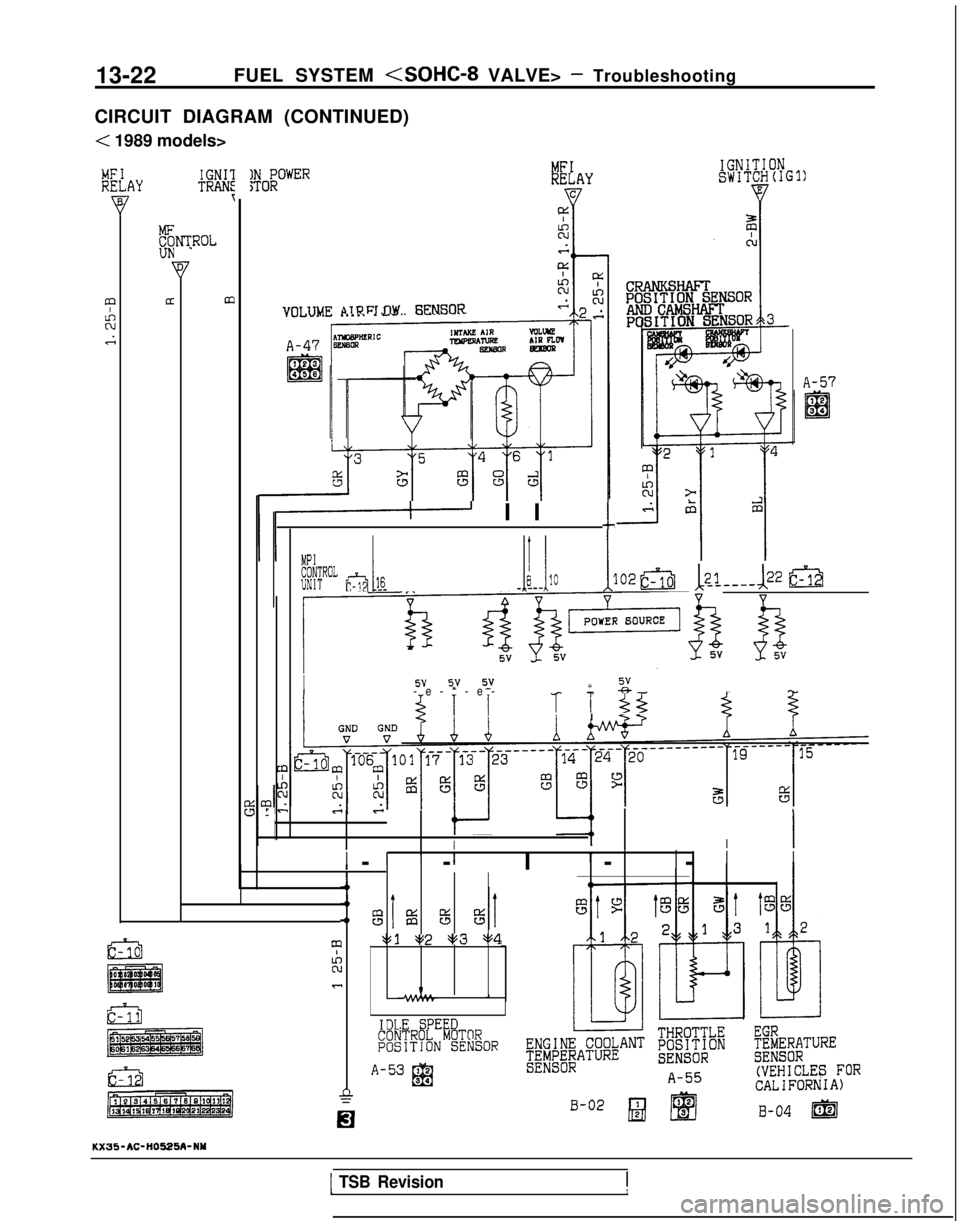

Circuit Diagram .................................... 214

Clear Memory of Diagnostic Trouble Code .............

211Explanation and Precaution Related to Harness

Checking ......................................

.

205Explanation of Troubleshooting Procedures

............

.

205Failsafe/Back-up Functions List

.....................

.

211Fuel tank and Fuel Line

............................

.

244

Read Out Diagnostic Trouble Code ...................

211Troubleshooting Table

.............................

.

208(CONTINUED ON NEXT PAGE)

Page 144 of 1273

13-2

FUEL SYSTEM

..........

FUEL FILTER ....................................

FUEL LINE AND VAPOR LINE .....................FUELTANK....................................

.

GENERAL INFORMATION ........................

ON-VEHICLE INSPECTION OF MFI

COMPONENTS . .

Air

Conditionrng Switch and A/C CompressorClutch Relay ......

.

.............

Barometric Pressure Sensor .........

Camshaft Position Sensor ...........

Closed Throttle Position Switch ...........

Component Location .............

Components

Inspectron Procedure .......

.

Crankshaft Positron Sensor ............

EGR Solenoid

. . .3. .

115..,.113

. 109

. . 3

. . . 38

83

536961384173101EGR Temperature Sensor

.

85

Enqine Control Module Power Ground ......

.

....

45

Engine Coolant Temperature Sensor ...............

55Evaporative Emission Purge Solenord..............

.

99

Fuel Pressure ...............................

102Fuel Pump

...................................

.

46

Idle Speed Control Motor (DC Motor) ................

.

93

Idle Speed Control Motor Positron Sensor ............

.

64

lgnitron Co11 and Ignition Power Transistor .........

.

96

Ignition Switch-ST ..........................

77Ignition Switch-ST and Park/Neutral Position Switch

...78

Injectors..................................

.

90

Inspection of

Engrne Control Module Terminal

Voltage .........

.

..........................

105Intake Air Temperature Sensor ..................

.

51Oxygen Sensor

............................

.

87Power Steering Pressure Switch

..................

.

81Power Supply

.........................

.

42

Terminal Voltage Check Chart ......................

106Throttle Positron Sensor.....................

.

57Vehicle Speed Sensor

.........................

.

80

Volume Air Flow Sensor .........................

49

SERVICE ADJUSTMENT PROCEDURES .................

32

Basic

Idle Speed Adjustment ...................

.

33

Curb Idle Speed Inspection ..........................

32Throttle Body (Throttle Valve Area) Cleaning........

.

35

Throttle Positron Sensor Adjustment ................

35

SPECIAL TOOLS 7

.................

...................

SPECIFICATIONS ....................................

5

TROUBLESHOOTING .................................

8

Check Engine/Malfunction Indicator Lamp ..............

10Crrcuit Diagram.................................

.

20

Clear Memory of Diagnostic Trouble Code ............

17Explanation and Precaution Related to HarnessChecking......................................

.

9Explanation of Troubleshooting Procedures

...........

.

8

Failsafe/Back-up Functions List ....................

16Fuel Tank and Fuel Lrne.........................

.

32Read Out of Diagnostic Trouble Code

...............

.

16Troubleshooting Table

.........................

.

13

FUEL SYSTEM

116

FUEL FILTER .......................................

195

FUEL LINE AND VAPOR LINE ........................

195

FUEL TANK ........................................ 195

GENERAL INFORMATION ............................

116

ON-VEHICLE INSPECTION OF MFI

COMPONENTS

Air Conditioning Switch and A/C Compressor Clutch Relay .............................

Barometric Pressure Sensor .................

Camshaft Position Sensor ....................

Closed Throttle Position Switch ................

Component Location .......................

Components Inspectron Pocedure

..............

Crankshaft Position Sensor .................

EGR Solenoid

EGR Temperature Sensor

Engine Control Module Power Ground ..........

Engine Coolant Temperature Sensor .............

Evaporative Emission Purge Solenoid ............

Fuel Pressure Test ...........................

Fuel Pump ..................................

IAC Valve Positon Sensor

......................

Idle Air Control Motor (DC Motor) ..............

lgnrtion Coil and Ignition Power Transistor

.......

.

Ignition Switch-ST ...........................

Ignition Switch-ST and Park/Neutral Position Switch

Injectors ....................................

Inspection of Engine Control Module Terminal

Voltage .....................................

Intake Air Temperature Sensor .................

Oxygen Sensor .............................

Power Steering Pressure

Swatch..............

.

Power Supply ...............................

Terminal Voltage Check Chart ..................

Throttle Position Sensor .......................

Vehicle Speed Sensor ......................... . . . . 139

176

154

165

16013914216

7

..,_ 191177146

155

189192

147

162

184

186

171172181

192152

179

175

143

192

157

173

Volume Air Flow Sensor ...........................

.

150

SERVICE ADJUSTMENT PROCEDURES

...............

.

133

Basic Idle Speed Adjustment 133

Closed Throttle Position Switch and Throttle Position

Sensor Adjustment .................................

136Curb Idle Speed Inspection

.........................

.

133Fixed SAS Adjustment

.............................

.

138Throttle Body (Throttle Valve Area) Cleaning

...........

.

136

SPECIAL TOOLS

...................................

.

119

SPECIFICATIONS 118

.... ..............................

TROUBLESHOOTING ..................

.............

119

Check Engine/Malfunction Indicator Lamp ..............

120Circuit Diagram...................................

.

128Clear Memory of Diagnostic Trouble Code

............

.

126Explanation and Precaution Related to Harness

Checking ........................................

.

119Explanation of Troubleshooting Procedures

............

.

119Failsafe/Back-up

Fuctions List

........................

126

Fuel Tank and Fuel Line .............................

133Read Out of Diagnostic Trouble Code ................

.

126

Troubleshooting Table ..............................

123

Page 145 of 1273

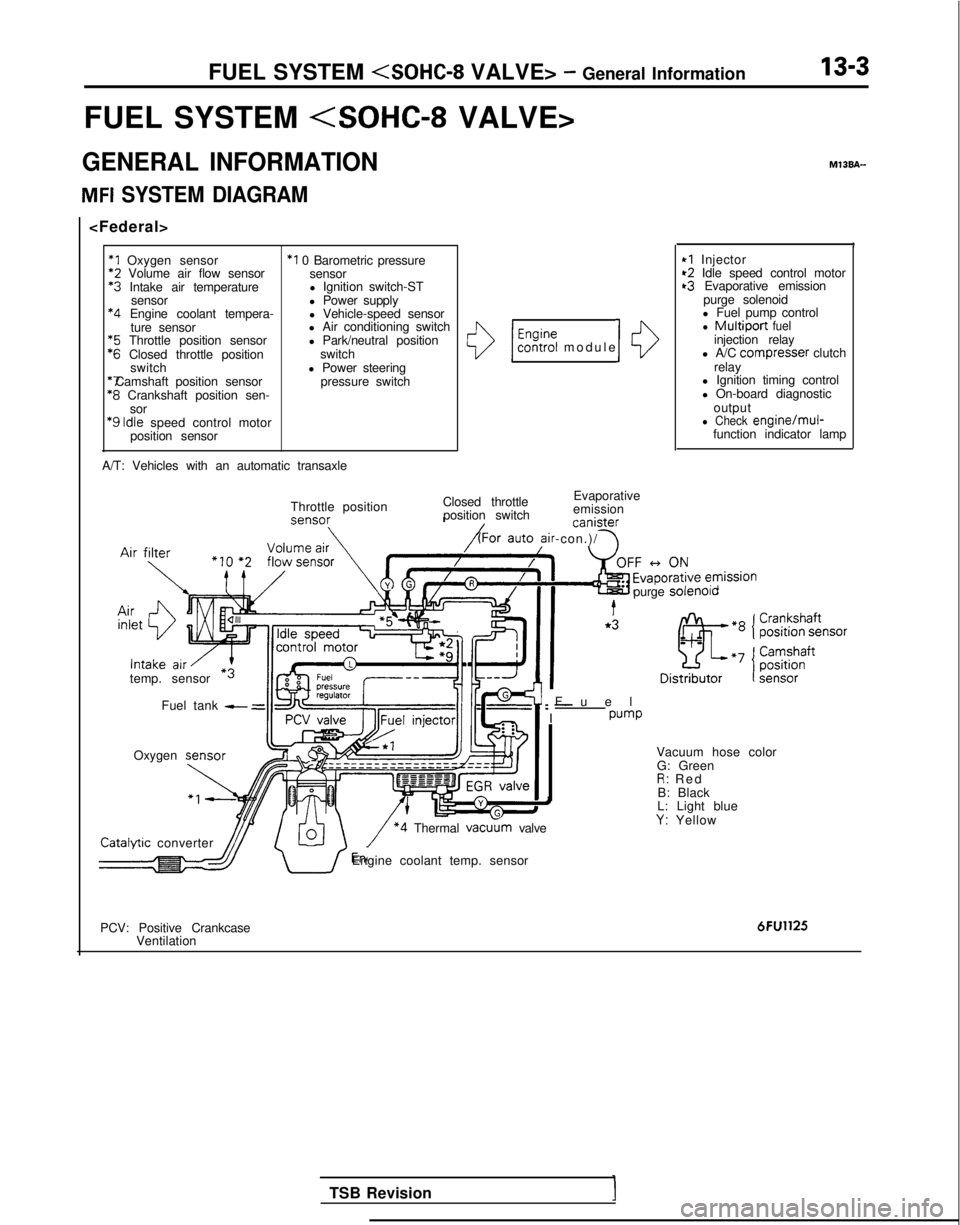

FUEL SYSTEM

FUEL SYSTEM

GENERAL INFORMATION

MFI SYSTEM DIAGRAM

*1 Oxygen sensor

*2

Volume air flow sensor *3

Intake air temperature

sensor *4

Engine coolant tempera-

ture sensor *5

Throttle position sensor *6

Closed throttle position

switch *7 Camshaft position sensor

*8

Crankshaft position sen-

sor

‘9 Idle

speed control motor

position sensor

*I 0 Barometric pressure sensor

l Ignition switch-ST

l Power supply

l Vehicle-speed sensor

l Air conditioning switch

l Park/neutral position

switch

l Power steering pressure switch

A/T: Vehicles with an automatic transaxle

()/ $%?i modul

e

Closed throttle Evaporative

position switch emission canister

ir-con.)/ \

10

Throttle position

temp. sensor Fuel tank

- =

Oxygen M13BA-

I

*I Injector~2 Idle speed control motort3 Evaporative emission

purge solenoid

l Fuel pump control

l Multiport fuelinjection relay

l A/C compresser clutch

relay

l Ignition timing control

l On-board diagnostic

output

l Check engine/mul-function indicator lamp

Fue

l

: -

I

pump

purge

solenolo Catalvtic

converter

\/ *4 Thermal vacu

G: Green

R: Re

d

B: Black

L: Light blue

Y: Yellow

dJJ/ U’Engine coolant temp. sensor

PCV: Positive Crankcase Ventilation

6FU1125

TSB Revision

Page 146 of 1273

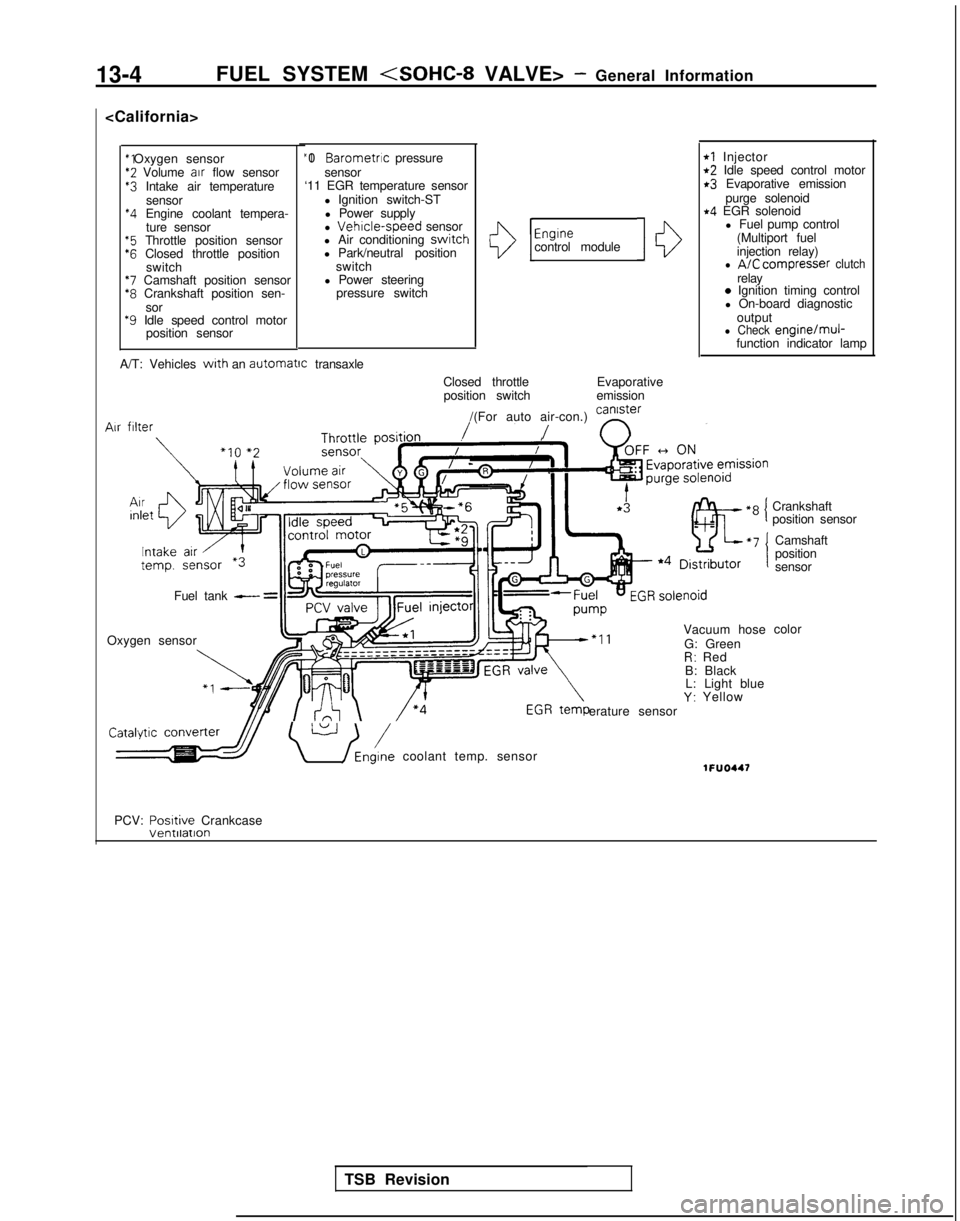

13-4FUEL SYSTEM

*2 Volume

air

flow sensor$3 Intake air temperature

sensor

*4 Engine coolant tempera-ture sensor

“5 Throttle position sensor‘6 Closed throttle position switch

*7 Camshaft position sensor*8 Crankshaft position sen-

sor

*9 Idle speed control motor position sensor “I 0

Barometric pressure

sensor

‘11 EGR temperature sensor

l Ignition switch-STl Power supply

l

Vehrcle-speed sensor

l Air conditioning switch

l Park/neutral position

switch

l Power steering pressure switchI13

Engrnecontrol module10

rl Injectort2 Idle speed control motorr3 Evaporative emission

purge solenoid

r4 EGR solenoidl Fuel pump control

(Multiport fuel

injection relay)

l A/C compresser clutchrelay0 Ignition timing control

l On-board diagnostic

output

l Check engine/muj-function indicator lamp

A/T: Vehicles

with an automatrc

transaxle

Closed throttleposition switch Evaporative

emission

/(For auto air-con.) can’ster

/ n

Vacuum hose

G: Green

R: Red

B: Black L: Light blue

Y: Yellow

erature sensor Air

filter

Fuel tank - =

Oxygen sensor

\ U /Eni coolant temp. sensor1FUO447

Crankshaft

position sensor

Camshaft

position

sensor

color

PCV: Posrtive

Crankcase

TSB Revision

Page 147 of 1273

FUEL SYSTEM

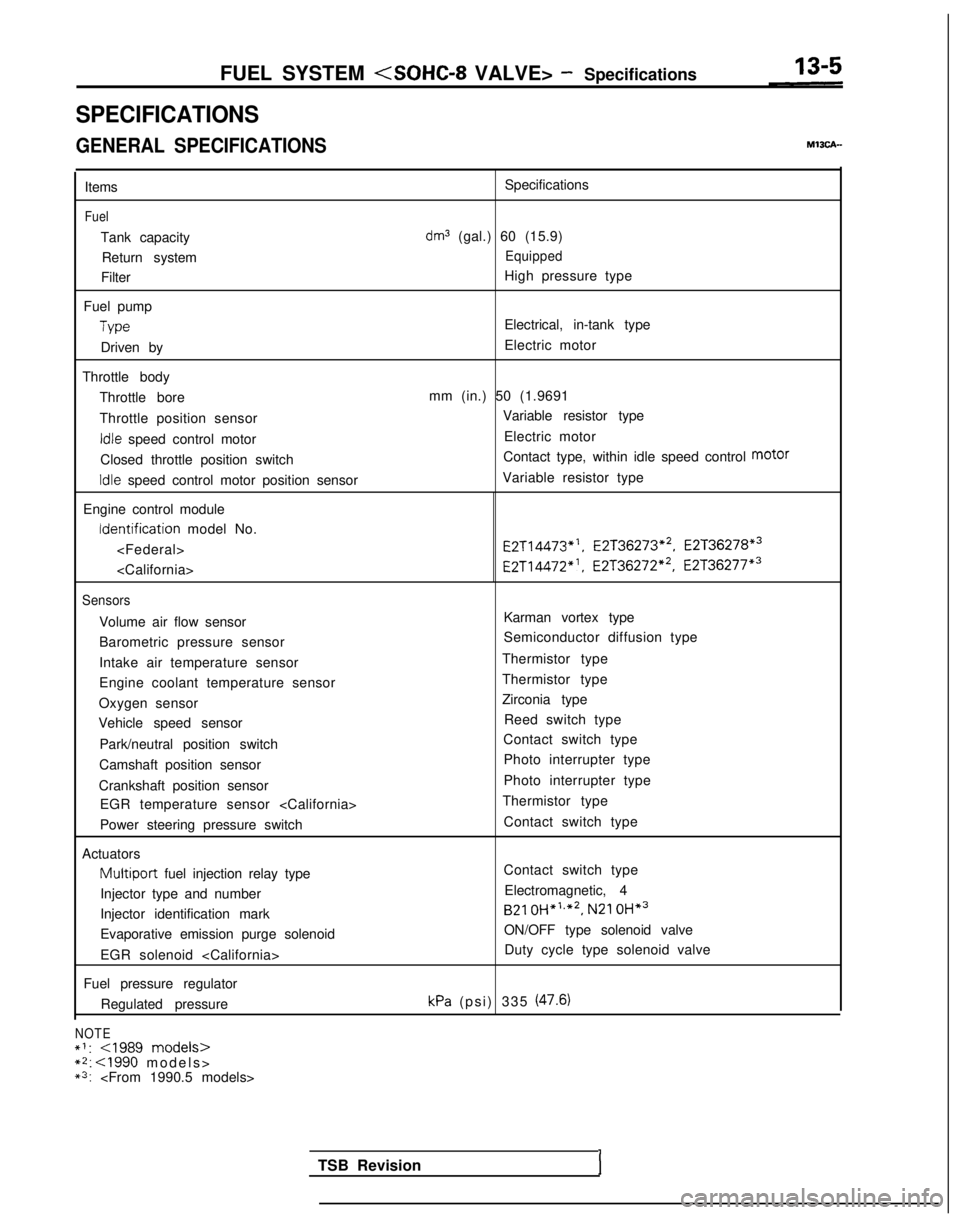

SPECIFICATIONS

GENERAL SPECIFICATIONS

Items

Fuel

Tank capacity

Return system

Filter

Fuel pump

Type

Driven by

Throttle body Throttle bore

Throttle position sensor

Idle speed control motor

Closed throttle position switch

Idle speed control motor position sensor

Engine control module Identification

model No.

Sensors

Volume air flow sensor

Barometric pressure sensor

Intake air temperature sensor

Engine coolant temperature sensor

Oxygen sensor

Vehicle speed sensor

Park/neutral position switch

Camshaft position sensor

Crankshaft position sensor EGR temperature sensor

Power steering pressure switch

Actuators

Multiport fuel injection relay type

Injector type and number

Injector identification mark

Evaporative emission purge solenoid

EGR solenoid

Fuel pressure regulator Regulated pressure

NOTE*I:

*3:

dm3 (gal.) 60 (15.9)

Equipped

High pressure type

Electrical, in-tank type

Electric motor

mm (in.) 50 (1.9691 Variable resistor type

Electric motor

Contact type, within idle speed control motor

Variable resistor type E2T14473*‘,

E2T36273*2, E2T36278*3

E2T14472”. E2T36272*2, E2T36277*3

Karman vortex type

Semiconductor diffusion type

Thermistor type

Thermistor type

Zirconia type Reed switch type

Contact switch type

Photo interrupter type

Photo interrupter type

Thermistor type

Contact switch type

Contact switch typeElectromagnetic, 4

B21 OH*‘,*2,

N21 OH*3

ON/OFF type solenoid valve

Duty cycle type solenoid valve

kPa (psi) 335 (47.6)

TSB RevisionI

Page 154 of 1273

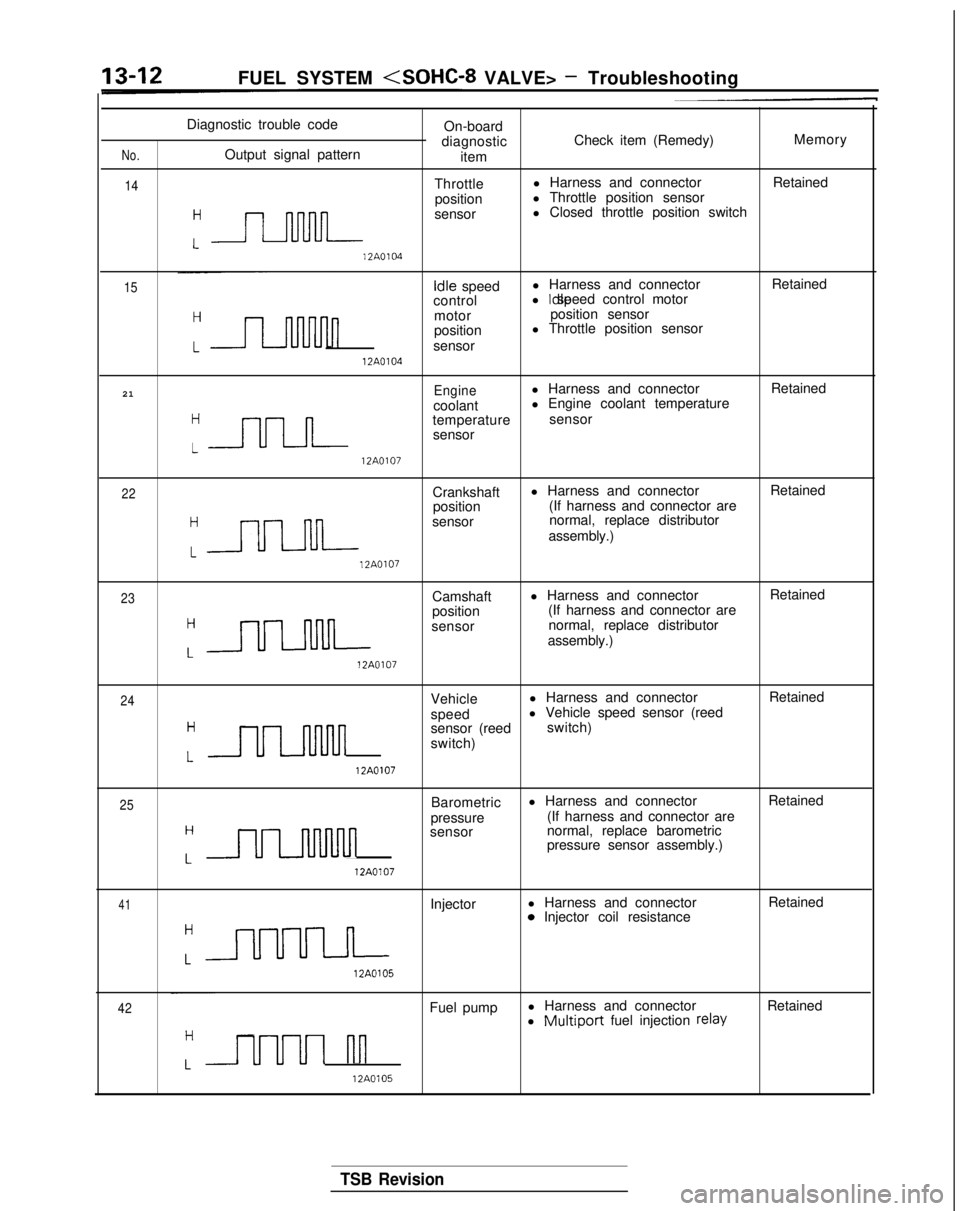

13-12

FUEL SYSTEM

No.

14

Diagnostic trouble code

On-board

diagnostic Check item (Remedy)

Memory

Output signal pattern item

Throttle l Harness and connector

Retained

position l Throttle position sensor

:-

sensor l Closed throttle position switch 12A0104

15

Idle

speed l Harness and connector

Retained

control l Idle speed control motor

n

motor

position sensor

position l Throttle position sensor

sensor 12A0104

21

Enginel Harness and connector Retained

coolant l Engine coolant temperature

“=

temperature

sensor

sensor 12A0107

22Crankshaft

l Harness and connector

Retained

position (If harness and connector are

:-

sensor normal, replace distributor

assembly.) 12A0107

23Camshaft

l Harness and connector

Retained

position (If harness and connector are

:=

sensor normal, replace distributor

assembly.) 12A0107

24Vehicle

l Harness and connector

Retained

speed l Vehicle speed sensor (reed

H

uulnnn

sensor (reed

switch)

switch)

L 12A0107

25Barometric

l Harness and connector

Retained

pressure (If harness and connector are

H

ULnMnn

sensor

normal, replace barometric

pressure sensor assembly.)

L 12A0107

41Injector

l Harness and connector

Retained0 Injector coil resistance

:a 12A0105

42Fuel pump

l Harness and connector

Retained

l Multiport fuel injection relay

Luuul nn

12A0105

TSB Revision

Page 157 of 1273

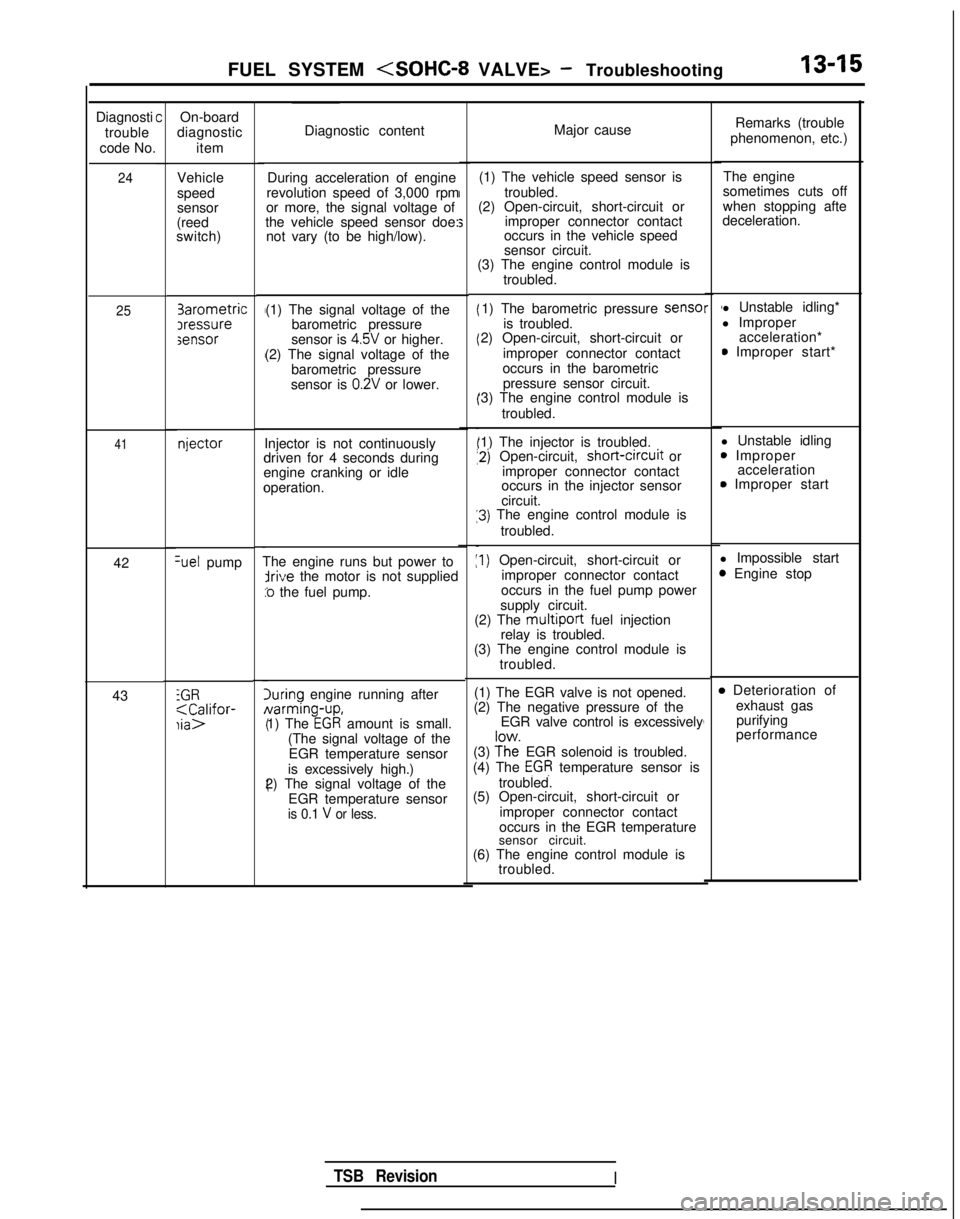

FUEL SYSTEM

Diagnosti

trouble

code No.

24

25

41

42Set pump

43

iGR;aC;lifor-

COn-board

diagnostic

item

Vehicle

speed

sensor

(reed

switch) 3arometric

Iressuresensor

njector

Diagnostic content

Major cause

During acceleration of engine

revolution speed of 3,000 rpm

or more, the signal voltage of

the vehicle speed sensor doe: not vary (to be high/low). (1) The vehicle speed sensor is

troubled.

(2) Open-circuit, short-circuit or

improper connector contact

occurs in the vehicle speed

sensor circuit.

(1) The signal voltage of the barometric pressure

sensor is 4.5V or higher.

(2) The signal voltage of the barometric pressure

sensor is

0.2V or lower.

Injector is not continuously

driven for 4 seconds during

engine cranking or idle

operation.

The engine runs but power to

irive the motor is not supplied

:o the fuel pump.

luring engine running after Narming-up,

1) The

EGR amount is small.

(The signal voltage of the EGR temperature sensor

is excessively high.)

2) The signal voltage of the

EGR temperature sensor

is 0.1 V or less.

(3) The engine control module is troubled.

1) The barometric pressure sense

is troubled.

2) Open-circuit, short-circuit or

improper connector contact

occurs in the barometric pressure sensor circuit.

‘3) The engine control module is

troubled.

‘1) The injector is troubled.

12) Open-circuit, short-crrcuit

or

improper connector contact

occurs in the injector sensor

circuit.

13) The engine control module is

troubled.

:I) Open-circuit, short-circuit or improper connector contact

occurs in the fuel pump power

supply circuit.

(2) The

multiport fuel injection

relay is troubled.

(3) The engine control module is

troubled.

(1) The EGR valve is not opened.

(2) The negative pressure of the EGR valve control is excessively

(3)

?h”e EGR solenoid is troubled.

(4) The EGR temperature sensor is

troubled.

(5) Open-circuit, short-circuit or

improper connector contact

occurs in the EGR temperature

sensor circuit.

(6) The engine control module is troubled.

r 1l Unstable idling*

l Improper acceleration*

0 Improper start*

l Unstable idling

0 Improper acceleration

0 Improper start

l Impossible start

3 Engine stop4

4

,

B Deterioration of exhaust gaspurifying

performance

Remarks (trouble

phenomenon, etc.)

The engine

sometimes cuts off

when stopping afte

deceleration.

TSB RevisionI

Page 162 of 1273

13-20FUEL SYSTEM

CIRCUIT DIAGRAM

cl989 models>

iERIGNITIONSWITCHbST)-

SUB F_USIBLE

.-__-____----w-w--

2-BW0

LINK@

A-08

;;IJkKPUMP

:ONNECTOR

t\I

M/Tg' A/Tz

1ch7 LCL/.MFIRELAY

r

TuT;T

Im

\

Zi/T A/r;

09108_------------

X35-AC-H0525-NY

1 TSB Revision

Page 164 of 1273

13-22

FUEL SYSTEM

CIRCUIT DIAGRAM (CONTINUED)

< 1989 models>

IGNITIONSWITCHlIGl)#OF?OWERMFIRELAYIGNIlTRANf

;ROLKUN1

am\lR Fl.tlW i=XNSOR

A-57

II Il-

EF g?JEi _______ JLllOI:02&j12_1---& im

Y-+-I

k$$

Yh

I5VI I 5Y

syv s_v-e-*-e

-

“,

*-r

-5. IIII 5.5

c

L

III I

III1II --I-

-

I

II,---

1’ 8Iis%%

Gi3mv1 a+2 pg3 $14I

?Ic

IDLE SPEEDCONTROL MOTORPOSITJON SENSOR

A-53 12El(VEHICLES FOR94CALIFORNIA)

B-02 B @

KX35-AC-HO525A-NY

B-04 m

1 TSB Revision1I