Clutch MITSUBISHI LANCER 2005 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 496 of 788

TROUBLESHOOTING

HEATER, AIR CONDITIONER AND VENTILATION55-12

COMMENTS ON TROUBLE SYMPTOM

If cool air is not distributed when the A/C switch is on,

the air thermo sensor or the A/C compressor relay

system may be defective.

TROUBLESHOOTING HINTS

•Improper amount of refrigerant

•Malfunction of the air thermo sensor

•Malfunction of the dual pressure switch

•Malfunction of the A/C compressor relay

•Malfunction of the A/C refrigerant temperature

switch

•Malfunction of the magnetic clutch

•Malfunction of the manual air conditioner control

panel (A/C-ECU)

•Damaged the wiring harness or connectors

•Malfunction of the engine-ECU

engine-A/T-ECU

DIAGNOSIS

STEP 1. Check the defogger and outside/inside

air selection damper control motor operation.

Q: Do the defogger and outside/inside air selection

damper control motor work normally?

YES :

Go to Step 2.

NO : Refer to Inspection procedure 9

"Malfunction of the A/C-ECU power supply

system

STEP 2. Check the blower motor operation.

Q: Does the blower motor work normally?

YES :

Go to Step 3.

NO : Refer to Inspection procedure 5 "Blower fan

and motor do not turn P.55-29."

STEP 3. Check the A/C compressor.

Check the A/C compressor for compressor oil leaks.

Q: Is the check result satisfactory?

YES :

Go to Step 4.

NO : Replace the A/C compressor or the

expansion valve.

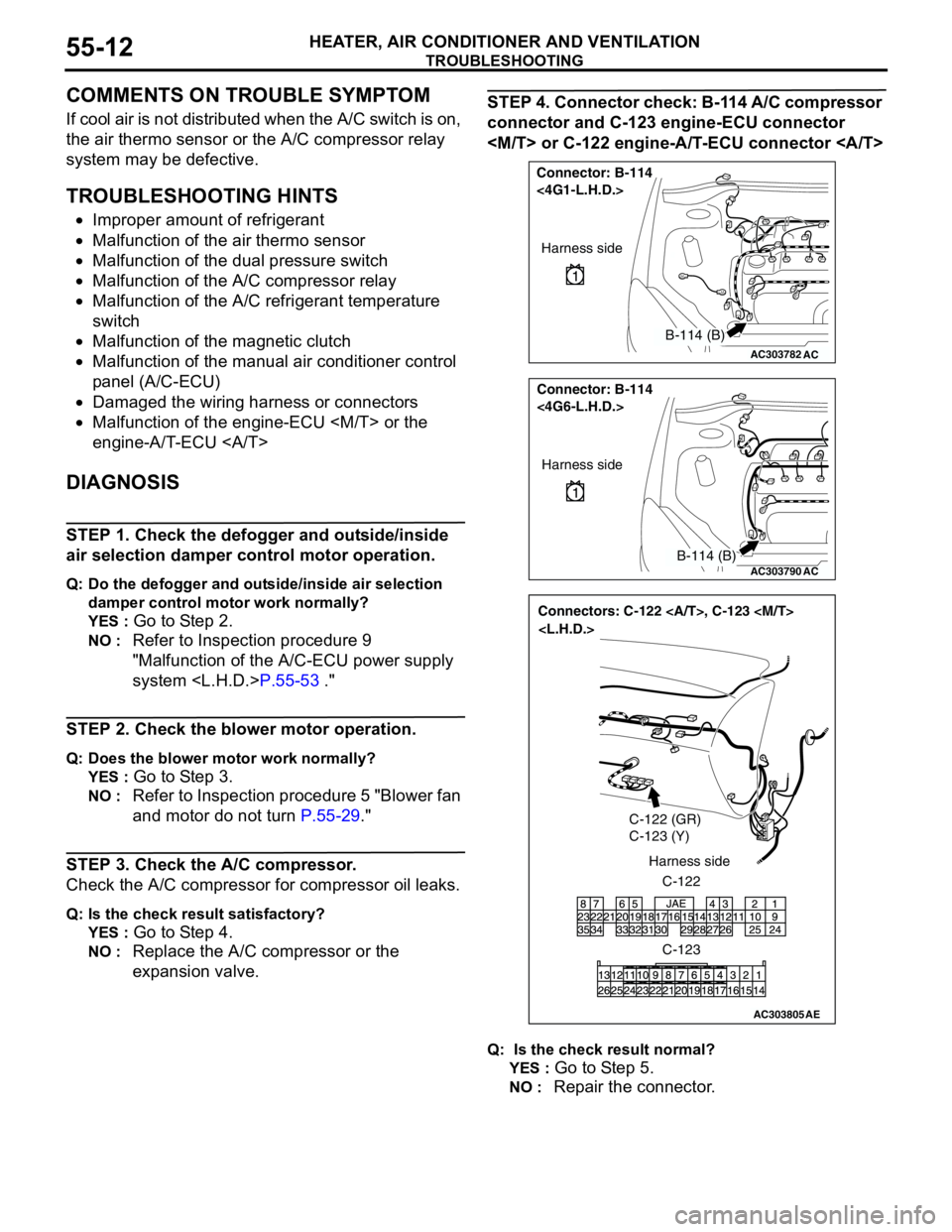

STEP 4. Connector check: B-114 A/C compressor

connector and C-123 engine-ECU connector

Q: Is the check result normal?

YES :

Go to Step 5.

NO : Repair the connector.

AC303782

Connector: B-114

<4G1-L.H.D.>

AC

Harness side

B-114 (B)

AC303790

Connector: B-114

<4G6-L.H.D.>

AC

Harness side

B-114 (B)

AC303805

Connectors: C-122 , C-123

C-122 (GR)

C-123 (Y)

C-122 Harness side

C-123

AE

Page 503 of 788

TROUBLESHOOTING

HEATER, AIR CONDITIONER AND VENTILATION55-19

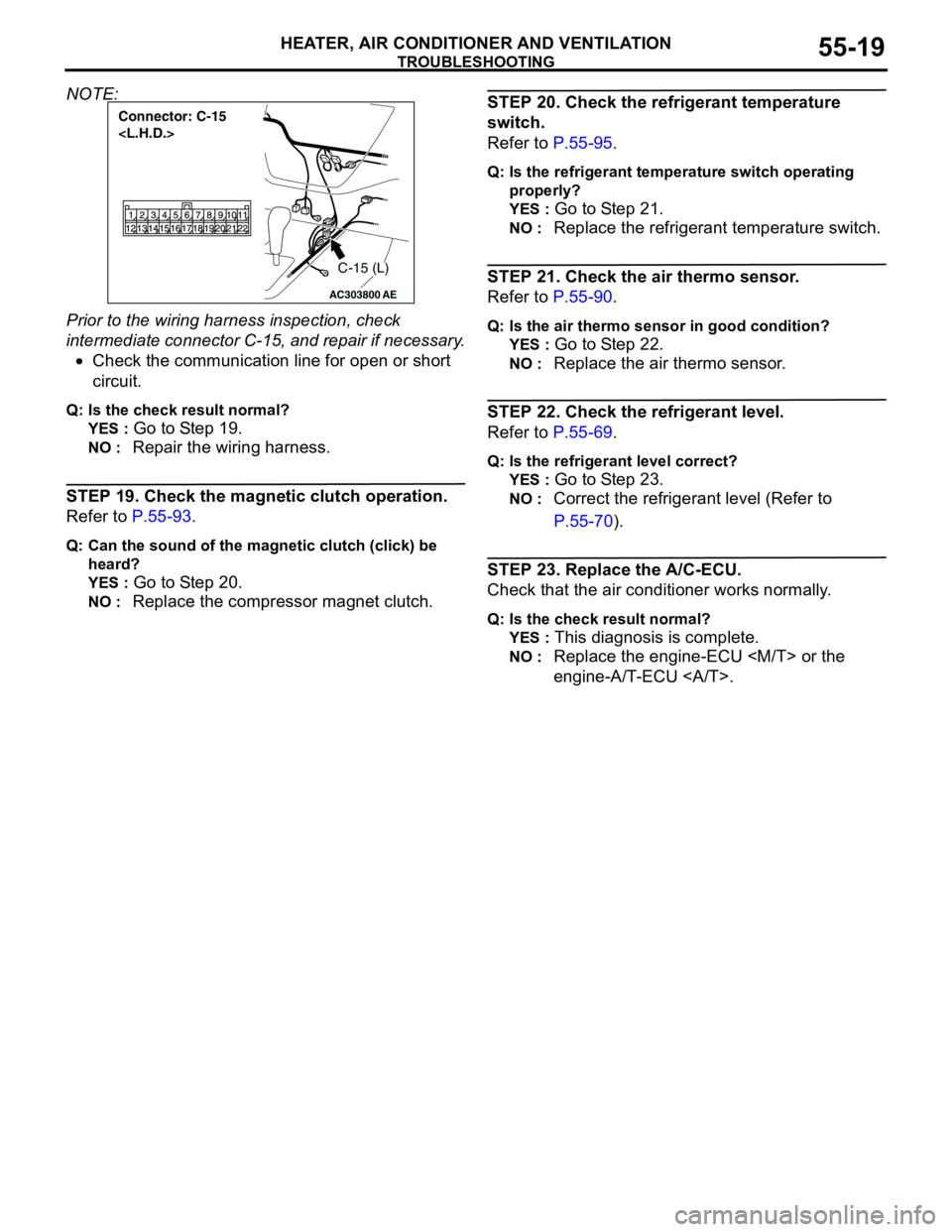

NOTE:

Prior to the wiring harness inspection, check

intermediate connector C-15, and repair if necessary.

•Check the communication line for open or short

circuit.

Q: Is the check result normal?

YES :

Go to Step 19.

NO : Repair the wiring harness.

STEP 19. Check the magnetic clutch operation.

Refer to P.55-93.

Q: Can the sound of the magnetic clutch (click) be

heard?

YES :

Go to Step 20.

NO : Replace the compressor magnet clutch.

STEP 20. Check the refrigerant temperature

switch.

Refer to P.55-95.

Q: Is the refrigerant temperature switch operating

properly?

YES :

Go to Step 21.

NO : Replace the refrigerant temperature switch.

STEP 21. Check the air thermo sensor.

Refer to P.55-90.

Q: Is the air thermo sensor in good condition?

YES :

Go to Step 22.

NO : Replace the air thermo sensor.

STEP 22. Check the refrigerant level.

Refer to P.55-69.

Q: Is the refrigerant level correct?

YES :

Go to Step 23.

NO : Correct the refrigerant level (Refer to

P.55-70).

STEP 23. Replace the A/C-ECU.

Check that the air conditioner works normally.

Q: Is the check result normal?

YES :

This diagnosis is complete.

NO : Replace the engine-ECU

engine-A/T-ECU .

AC303800

Connector: C-15

AE

C-15 (L)

Page 505 of 788

TROUBLESHOOTING

HEATER, AIR CONDITIONER AND VENTILATION55-21

COMMENTS ON TROUBLE SYMPTOM

If cool air is not distributed when the A/C switch is on,

the air thermo sensor or the A/C compressor relay

system may be defective.

TROUBLESHOOTING HINTS

•Improper amount of refrigerant

•Malfunction of the air thermo sensor

•Malfunction of the dual pressure switch

•Malfunction of the A/C compressor relay

•Malfunction of the A/C refrigerant temperature

switch

•Malfunction of the magnetic clutch

•Malfunction of the manual air conditioner control

panel (A/C-ECU)

•Damaged the wiring harness or connectors

•Malfunction of the engine-ECU

engine-A/T-ECU

DIAGNOSIS

STEP 1. Check the defogger and outside/inside

air selection damper control motor operation.

Q: Do the defogger and outside/inside air selection

damper control motor work normally?

YES :

Go to Step 2.

NO : Refer to Inspection procedure 10

"Malfunction of the A/C-ECU power supply

system

STEP 2. Check the blower motor operation.

Q: Does the blower motor work normally?

YES :

Go to Step 3.

NO : Refer to Inspection procedure 5 "Blower fan

and motor do not turn P.55-29."

STEP 3. Check the A/C compressor.

Check the A/C compressor for compressor oil leaks.

Q: Is the check result satisfactory?

YES :

Go to Step 4.

NO : Replace the A/C compressor or the

expansion valve.

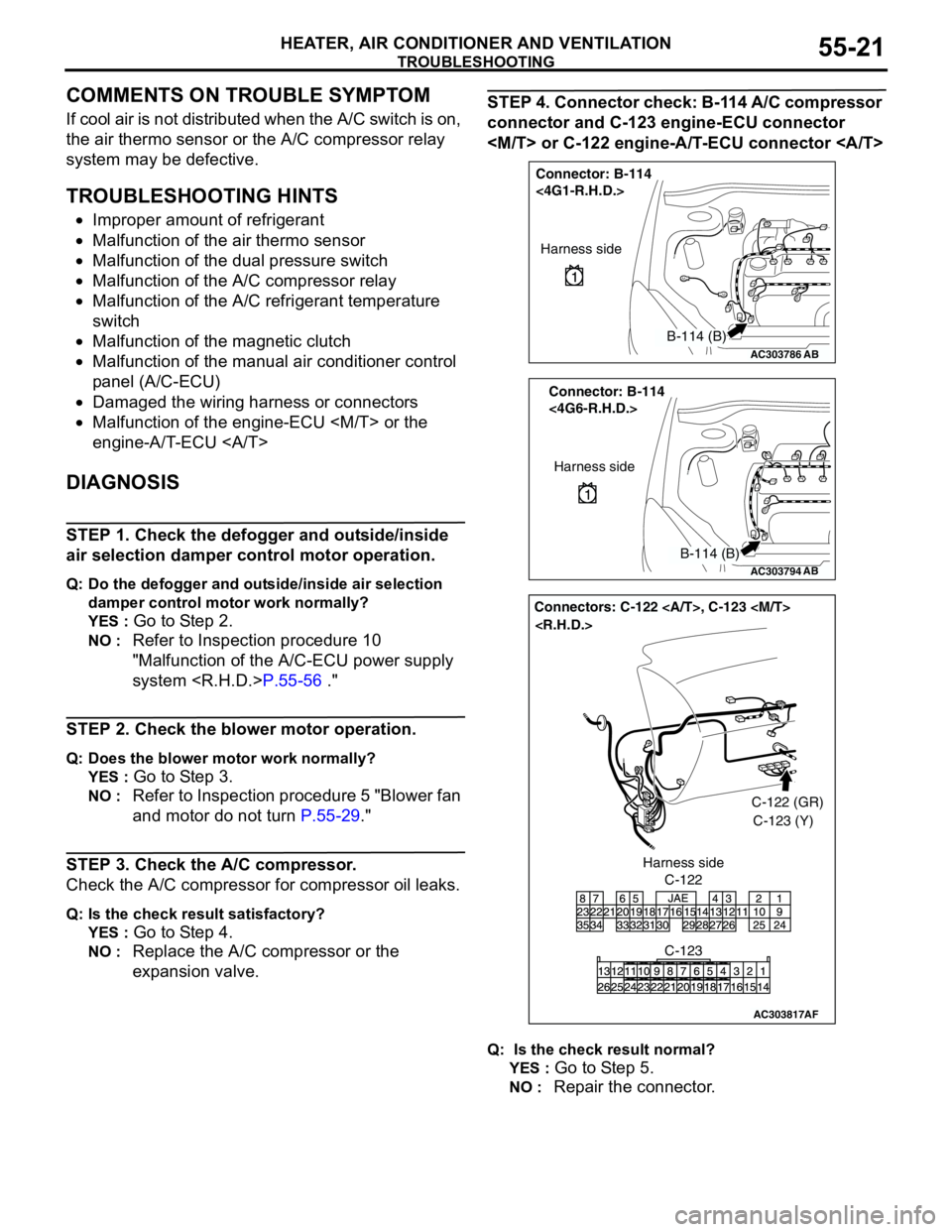

STEP 4. Connector check: B-114 A/C compressor

connector and C-123 engine-ECU connector

Q: Is the check result normal?

YES :

Go to Step 5.

NO : Repair the connector.

AC303786

Connector: B-114

<4G1-R.H.D.>

AB

Harness side

B-114 (B)

AC303794

Connector: B-114

<4G6-R.H.D.>

AB

Harness side

B-114 (B)

AC303817

Connectors: C-122 , C-123

AF

C-122C-122 (GR)

C-123 (Y)

C-123 Harness side

Page 512 of 788

TROUBLESHOOTING

HEATER, AIR CONDITIONER AND VENTILATION55-28

STEP 19. Check the magnetic clutch operation.

Refer to P.55-93.

Q: Can the sound of the magnetic clutch (click) be

heard?

YES :

Go to Step 20.

NO : Replace the compressor magnet clutch.

STEP 20. Check the refrigerant temperature

switch.

Refer to P.55-95.

Q: Is the refrigerant temperature switch operating

properly?

YES :

Go to Step 21.

NO : Replace the refrigerant temperature switch.

STEP 21. Check the air thermo sensor.

Refer to P.55-90.

Q: Is the air thermo sensor in good condition?

YES :

Go to Step 22.

NO : Replace the air thermo sensor.

STEP 22. Check the refrigerant level.

Refer to P.55-69.

Q: Is the refrigerant level correct?

YES :

Go to Step 23.

NO : Correct the refrigerant level (Refer to

On-vehicle Service P.55-70).

STEP 23. Replace the A/C-ECU.

Check that the air conditioner works normally.

Q: Is the check result normal?

YES :

This diagnosis is complete.

NO : Replace the engine-ECU

engine-A/T-ECU .

Page 543 of 788

TROUBLESHOOTING

HEATER, AIR CONDITIONER AND VENTILATION55-59

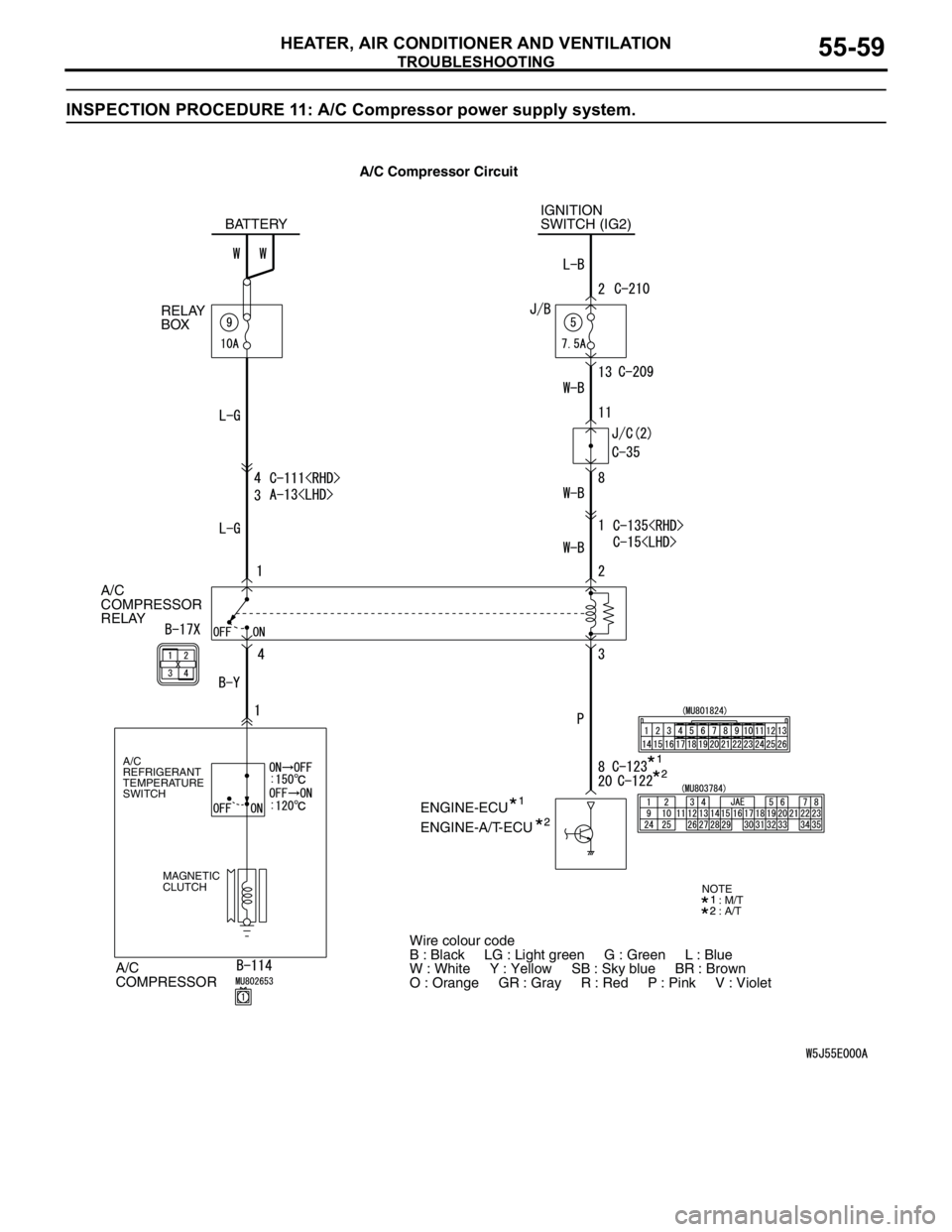

INSPECTION PROCEDURE 11: A/C Compressor power supply system.

A/C

COMPRESSOR

RELAY

A/C

COMPRESSOR

A/C

REFRIGERANT

TEMPERATURE

SWITCH

MAGNETIC

CLUTCH

IGNITION

SWITCH (IG2)

ENGINE-ECU BATTERY

RELAY

BOX

ENGINE-A/T-ECU

Wire colour code

B : Black LG : Light green G : Green L : Blue

W : White Y : Yellow SB : Sky blue BR : Brown

O : Orange GR : Gray R : Red P : Pink V : Violet

: M/T

: A/TNOTE

A/C Compressor Circuit

Page 553 of 788

ON-VEHICLE SERVICE

HEATER, AIR CONDITIONER AND VENTILATION55-69

ON-VEHICLE SERVICE

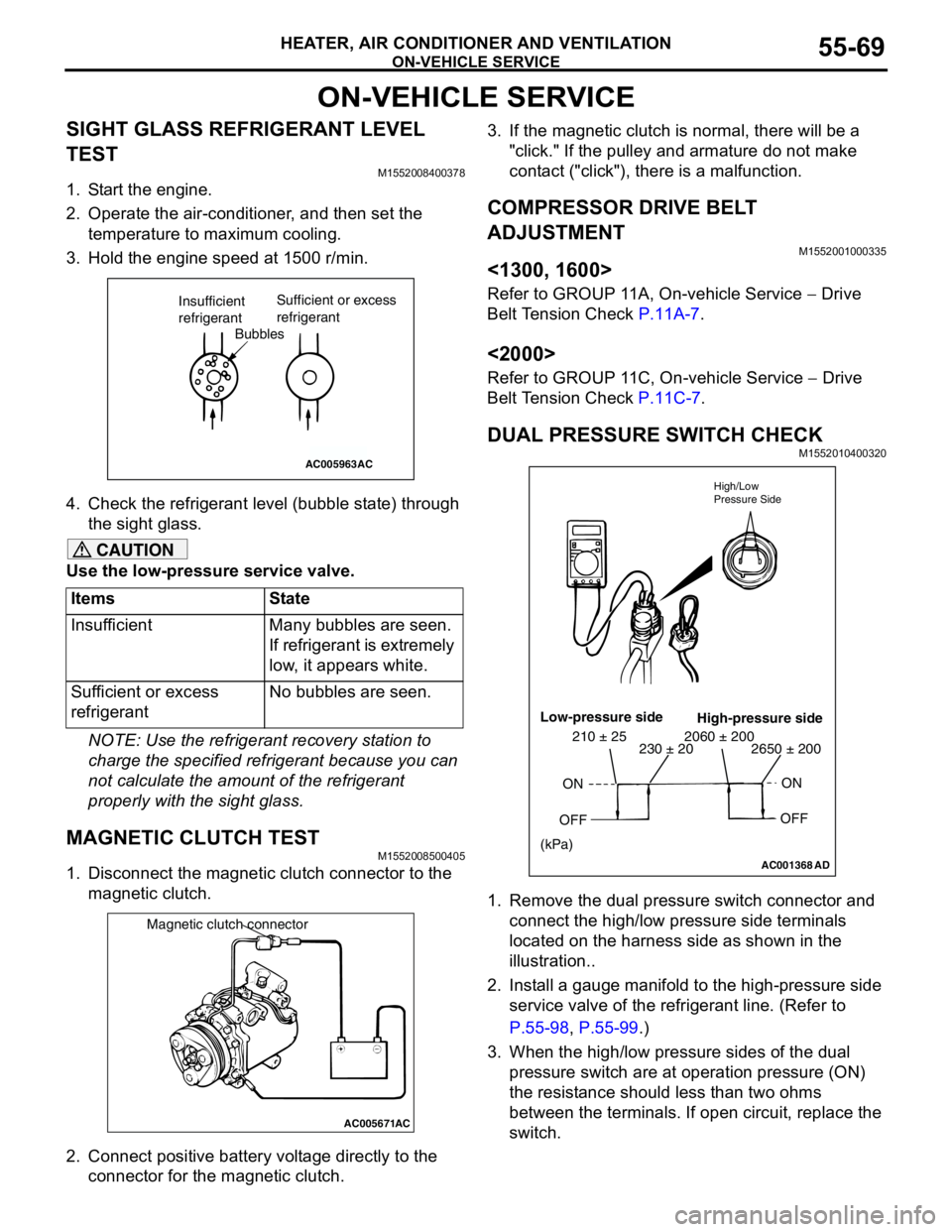

SIGHT GLASS REFRIGERANT LEVEL

TEST

M1552008400378

1. Start the engine.

2. Operate the air-conditioner, and then set the

temperature to maximum cooling.

3. Hold the engine speed at 1500 r/min.

4. Check the refrigerant level (bubble state) through

the sight glass.

CAUTION

Use the low-pressure service valve.

NOTE: Use the refrigerant recovery station to

charge the specified refrigerant because you can

not calculate the amount of the refrigerant

properly with the sight glass.

MAGNETIC CLUTCH TESTM1552008500405

1. Disconnect the magnetic clutch connector to the

magnetic clutch.

2. Connect positive battery voltage directly to the

connector for the magnetic clutch.3. If the magnetic clutch is normal, there will be a

"click." If the pulley and armature do not make

contact ("click"), there is a malfunction.

COMPRESSOR DRIVE BELT

ADJUSTMENT

M1552001000335

<1300, 1600>

Refer to GROUP 11A, On-vehicle Service − Drive

Belt Tension Check P.11A-7.

<2000>

Refer to GROUP 11C, On-vehicle Service − Drive

Belt Tension Check P.11C-7.

DUAL PRESSURE SWITCH CHECKM1552010400320

1. Remove the dual pressure switch connector and

connect the high/low pressure side terminals

located on the harness side as shown in the

illustration..

2. Install a gauge manifold to the high-pressure side

service valve of the refrigerant line. (Refer to

P.55-98, P.55-99.)

3. When the high/low pressure sides of the dual

pressure switch are at operation pressure (ON)

the resistance should less than two ohms

between the terminals. If open circuit, replace the

switch. Items State

Insufficient Many bubbles are seen.

If refrigerant is extremely

low, it appears white.

Sufficient or excess

refrigerantNo bubbles are seen.

AC005963

Bubbles Insufficient

refrigerantSufficient or excess

refrigerant

AC

AC005671

Magnetic clutch connector

AC

AC001368AD High/Low

Pressure Side

Low-pressure side

High-pressure side

ON

OFFON

OFF

2650 ± 200 2060 ± 200230 ± 20 210 ± 25

(kPa)

Page 557 of 788

ON-VEHICLE SERVICE

HEATER, AIR CONDITIONER AND VENTILATION55-73

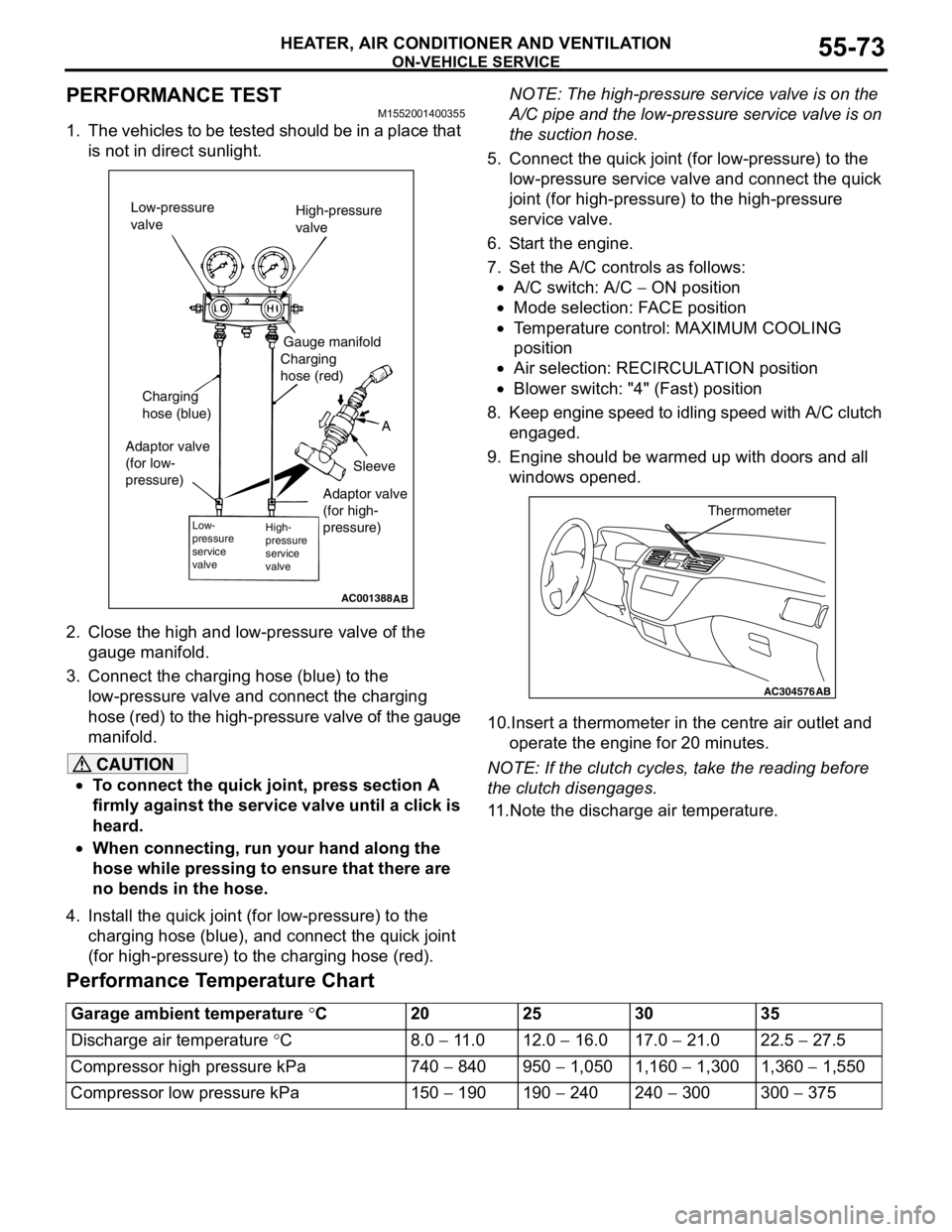

PERFORMANCE TEST M1552001400355

1. The vehicles to be tested should be in a place that

is not in direct sunlight.

2. Close the high and low-pressure valve of the

gauge manifold.

3. Connect the charging hose (blue) to the

low-pressure valve and connect the charging

hose (red) to the high-pressure valve of the gauge

manifold.

CAUTION

•To connect the quick joint, press section A

firmly against the service valve until a click is

heard.

•When connecting, run your hand along the

hose while pressing to ensure that there are

no bends in the hose.

4. Install the quick joint (for low-pressure) to the

charging hose (blue), and connect the quick joint

(for high-pressure) to the charging hose (red).NOTE: The high-pressure service valve is on the

A/C pipe and the low-pressure service valve is on

the suction hose.

5. Connect the quick joint (for low-pressure) to the

low-pressure service valve and connect the quick

joint (for high-pressure) to the high-pressure

service valve.

6. Start the engine.

7. Set the A/C controls as follows:

•A/C switch: A/C − ON position

•Mode selection: FACE position

•Temperature control: MAXIMUM COOLING

position

•Air selection: RECIRCULATION position

•Blower switch: "4" (Fast) position

8. Keep engine speed to idling speed with A/C clutch

engaged.

9. Engine should be warmed up with doors and all

windows opened.

10.Insert a thermometer in the centre air outlet and

operate the engine for 20 minutes.

NOTE: If the clutch cycles, take the reading before

the clutch disengages.

11.Note the discharge air temperature.

Performance Temperature Chart

AC001388

Low-pressure

valveHigh-pressure

valve

Gauge manifold

Charging

hose (red)

A

Sleeve Charging

hose (blue)

Adaptor valve

(for low-

pressure)

Low-

pressure

service

valveHigh-

pressure

service

valve

AB

Adaptor valve

(for high-

pressure)

AC304576

Thermometer

AB

Garage ambient temperature °C20 25 30 35

Discharge air temperature °C8.0 − 11.0 12.0 − 16.0 17.0 − 21.0 22.5 − 27.5

Compressor high pressure kPa 740 − 840 950 − 1,050 1,160 − 1,300 1,360 − 1,550

Compressor low pressure kPa 150 − 190 190 − 240 240 − 300 300 − 375

Page 558 of 788

ON-VEHICLE SERVICE

HEATER, AIR CONDITIONER AND VENTILATION55-74

REFRIGERANT LEAK REPAIR

PROCEDURE

M1552001500277

LOST CHARGE

If the system has lost all charge due to a leak:

1. Evacuate the system (Refer to P.55-72).

2. Charge the system with approximately 480 − 520

g of refrigerant.

3. Check for leaks.

4. Discharge the system.

5. Repair leaks.

CAUTION

Replacement filter-drier units must be sealed

while in storage. The drier used in these units will

saturate water quickly upon exposure to the

atmosphere. When installing a drier, have all

tools and supplies ready for quick assembly to

avoid keeping the system open any longer than

necessary.

6. Replace receiver drier.

7. Evacuate and charge system.

LOW CHARGE

If the system has not lost all of its refrigerant charge;

locate and repair all leaks. If it is necessary to

increase the system pressure to find the leak

(because of an especially low charge) add

refrigerant. If it is possible to repair the leak without

discharging the refrigerant system, use the

procedure for correcting low refrigerant level.

HANDLING TUBING AND FITTINGS

Kinks in the refrigerant tubing or sharp bends in the

refrigerant hose lines will greatly reduce the capacity

of the entire system. High pressures are produced in

the system when it is operating. Extreme care must

be exercised to make sure that all connections are

pressure tight. Dirt and moisture can enter the

system when it is opened for repair or replacement of

lines or components. The following precautions must

be observed. The system must be completely

discharged before opening any fitting of connection

in the refrigeration system. Open fittings with caution

even after the system has been discharged. If any

pressure is noticed as a fitting is loosened, allow

trapped pressure to bleed off very slowly.

Never attempt to rebend formed lines to fit. Use the

correct line for the installation you are servicing. A

good rule for the flexible hose lines is keep the radius

of all bends at least 10 times the diameter of the

hose.Sharper bends will reduce the flow of refrigerant. The

flexible hose lines should be routed so that they are

at least 80 mm from the exhaust manifold. It is good

practice to inspect all flexible hose lines at least once

a year to make sure they are in good condition and

properly routed.

On standard plumbing fittings with O-rings, these

O-rings are not reusable.

COMPRESSOR NOISE CHECKM1552008700272

You must first know the conditions when the noise

occurs. These conditions are: weather, vehicle

speed, in gear or neutral, engine temperature or any

other special conditions.

Noises that develop during A/C operation can often

be misleading. For example: what sounds like a

failed front bearing or connecting rod, may be

caused by loose bolts, nuts, mounting brackets, or a

loose clutch assembly. Verify accessory drive belt

tension (power steering or alternator).

Improper accessory drive belt tension can cause a

misleading noise when the compressor is engaged

and little or no noise when the compressor is

disengaged.

Drive belts are speed-sensitive. That is, at different

engine speeds, and depending upon belt tension,

belts can develop unusual noises that are often

mistaken for mechanical problems within the

compressor.

ADJUSTMENT

1. Select a quiet area for testing. Duplicate

conditions as much as possible. Switch the

compressor on and off several times to clearly

identify compressor noise. To duplicate high

ambient conditions (high head pressure), restrict

air flow through the condenser. Install a manifold

gauge set to make sure discharge pressure

doesn't exceed 2,070 kPa.

2. Tighten all compressor mounting bolts, clutch

mounting bolt, and compressor drive belt. Check

to assure clutch coil is tight (no rotation or

wobble).

3. Check refrigerant hoses for rubbing or

interference that can cause unusual noises.

4. Check refrigerant charge (Refer to P.55-69).

5. Recheck compressor noise as in Step 1.

6. If noise still exists, loosen compressor mounting

bolts and retighten. Repeat Step 1.

7. If noise continues, replace compressor and repeat

Step 1.

Page 577 of 788

COMPRESSOR ASSEMBLY AND TENSION PULLEY

HEATER, AIR CONDITIONER AND VENTILATION55-93

INSTALLATION SERVICE POINT

>>A<< A/C COMPRESSOR

INSTALLATION

If a new compressor is installed, first adjust the

amount of oil according to the procedures described

below, and then install the compressor.

1. Measure the amount (X mL) of oil within the

removed compressor.

2. Drain (from the new compressor) the amount of

oil calculated according to the following formula,

and then install the new compressor.

New compressor oil amount = 140mL <1300,

1600>, 120 mL <2000>

140 mL−X mL = Y mL <1300, 1600>

120 mL−X mL = Y mL <2000>

NOTE: Y mL indicates the amount of oil in the

refrigerant line, the condenser, the evaporator, etc.

NOTE: When replacing the following parts at the

same times as the compressor, subtract the rated oil

amount of the each part from Y mL and discharge

from the new compressor.

Quantity:

•Evaporator: 60 mL

•Condenser: 15 mL

•Suction hose: 10 mL

•Receiver: 10 mL

INSPECTIONM1552014300949

COMPRESSOR MAGNETIC CLUTCH

OPERATION CHECK

Connect the compressor connector terminal to the

battery positive (+) terminal and earth the battery’s

negative (−) terminal to the compressor unit. At that

time, the magnetic clutch should make a definite

operating sound.

AC005671

Magnetic clutch connector

AC

Page 578 of 788

COMPRESSOR ASSEMBLY AND TENSION PULLEY

HEATER, AIR CONDITIONER AND VENTILATION55-94

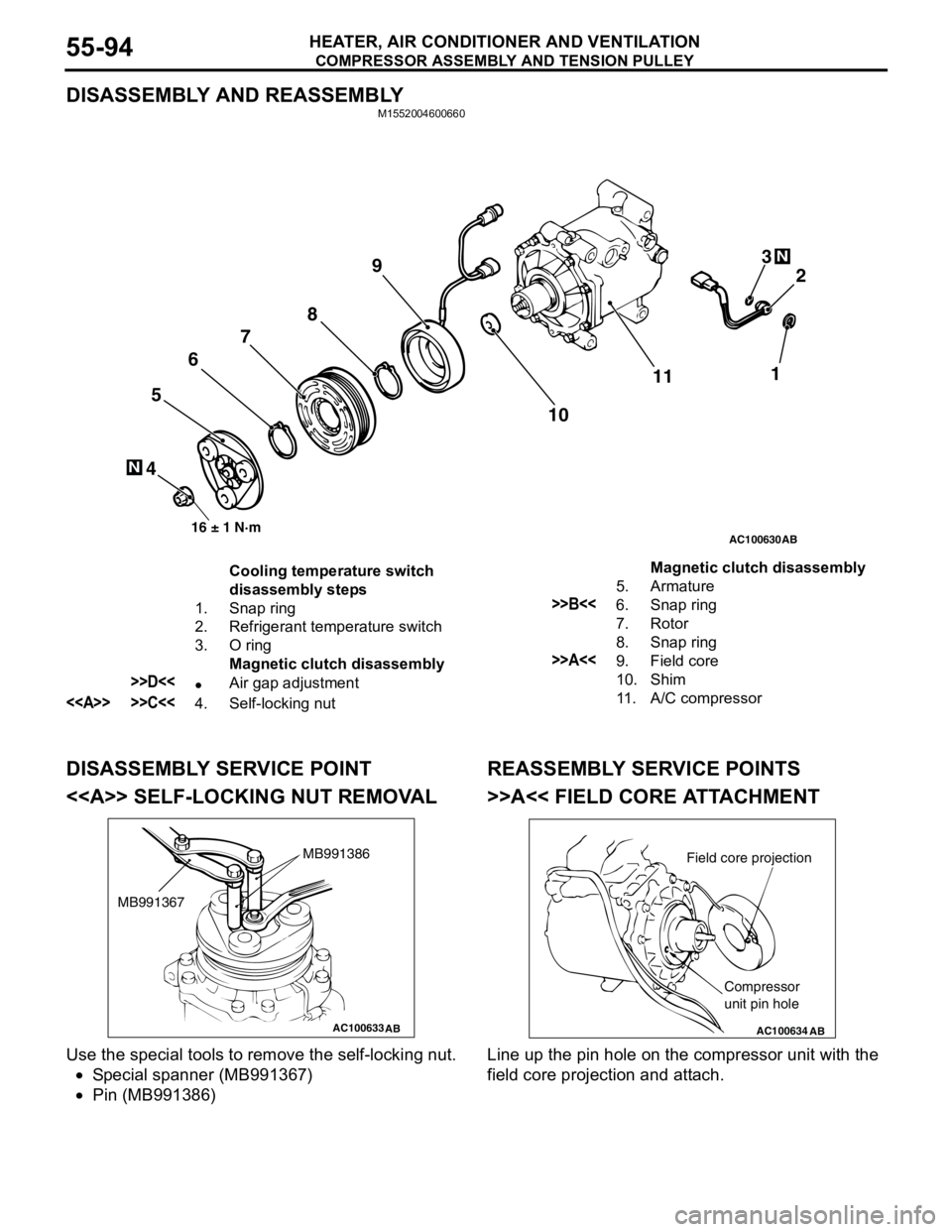

DISASSEMBLY AND REASSEMBLYM1552004600660

DISASSEMBLY SERVICE POINT

<> SELF-LOCKING NUT REMOVAL

Use the special tools to remove the self-locking nut.

•Special spanner (MB991367)

•Pin (MB991386)

REASSEMBLY SERVICE POINTS

>>A<< FIELD CORE ATTACHMENT

Line up the pin hole on the compressor unit with the

field core projection and attach.

AC100630

N

N

16 ± 1 N·m

10

46789

512

AB

3

11

Cooling temperature switch

disassembly steps

1. Snap ring

2. Refrigerant temperature switch

3. O ring

Magnetic clutch disassembly

>>D<<•Air gap adjustment

<> >>C<<4. Self-locking nut5. Armature

>>B<<6. Snap ring

7. Rotor

8. Snap ring

>>A<<9. Field core

10. Shim

11. A/C compressorMagnetic clutch disassembly

AC100633AB

MB991386

MB991367

AC100634AB

Field core projection

Compressor

unit pin hole