compression ratio MITSUBISHI LANCER 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 94 of 788

IGNITION SYSTEM

ENGINE ELECTRICAL16-30

IGNITION SYSTEM

GENERAL INFORMATIONM1163000100294

This system is equipped with two ignition coils (A and

B) with built-in power transistors for the No. 1 and

No. 4 cylinders and the No. 2 and No. 3 cylinders

respectively.

Interruption of the primary current flowing in the

primary side of ignition coil A generates a high

voltage in the secondary side of ignition coil A. The

high voltage thus generated is applied to the spark

plugs of No. 1 and No. 4 cylinders to generate

sparks. At the time that the sparks are generated at

both spark plugs, if one cylinder is at the

compression stroke, the other cylinder is at the

exhaust stroke, so that ignition of the compressed

air/fuel mixture occurs only for the cylinder which is

at the compression stroke.

In the same way, when the primary current flowing in

ignition coil B is interrupted, the high voltage thus

generated is applied to the spark plugs of No. 2 and

No. 3 cylinders.The engine-ECU

turns the two power transistors inside the ignition

coils alternately on and off. This causes the primary

currents in the ignition coils to be alternately

interrupted and allowed to flow to fire the cylinders in

the order 1-3-4-2.

The engine-ECU

determines which ignition coil should be controlled

by means of the signals from the camshaft position

sensor which is incorporated in the camshaft and

from the crank angle sensor which is incorporated in

the crankshaft. It also detects the crankshaft position

in order to provide ignition at the most appropriate

timing in response to the engine operation

conditions. It also detects the crankshaft position in

order to provide ignition at the most appropriate

timing in response to the engine operation

conditions.

When the engine is cold or operated at high

altitudes, the ignition timing is slightly advanced to

provide optimum performance.

When the automatic transmission shifts gears, the

ignition timing is also retarded in order to reduce

output torque, thereby alleviating shifting shocks.

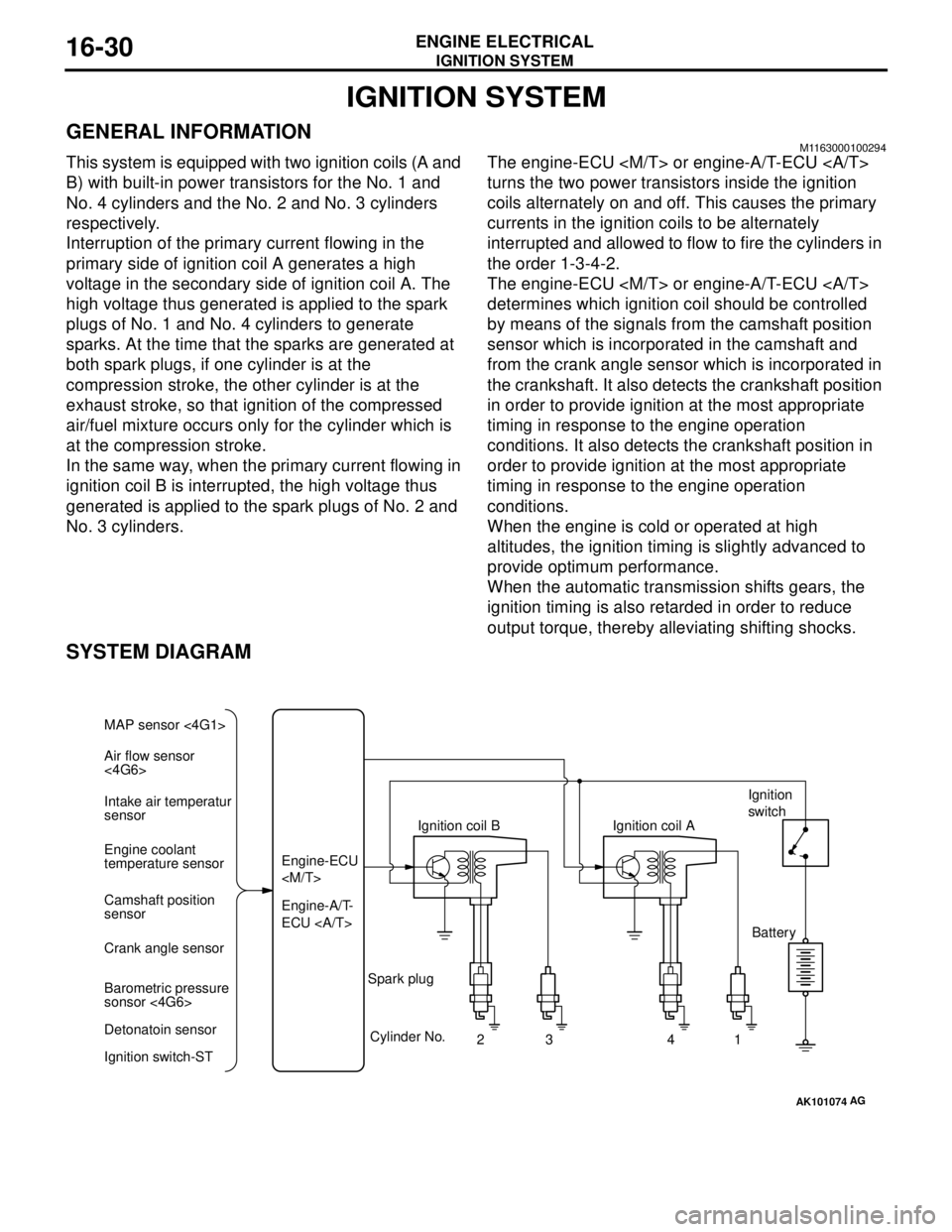

SYSTEM DIAGRAM

AK101074

Air flow sensor

<4G6> MAP sensor <4G1>

Intake air temperatur

sensor

Engine coolant

temperature sensor

Camshaft position

sensor

Crank angle sensor

Barometric pressure

sonsor <4G6>

Detonatoin sensor

Ignition switch-STEngine-A/T-

ECU Engine-ECU

Cylinder No.

23 4

AG

1 Spark plugIgnition coil AIgnition

switch

Battery

Page 99 of 788

IGNITION SYSTEM

ENGINE ELECTRICAL16-35

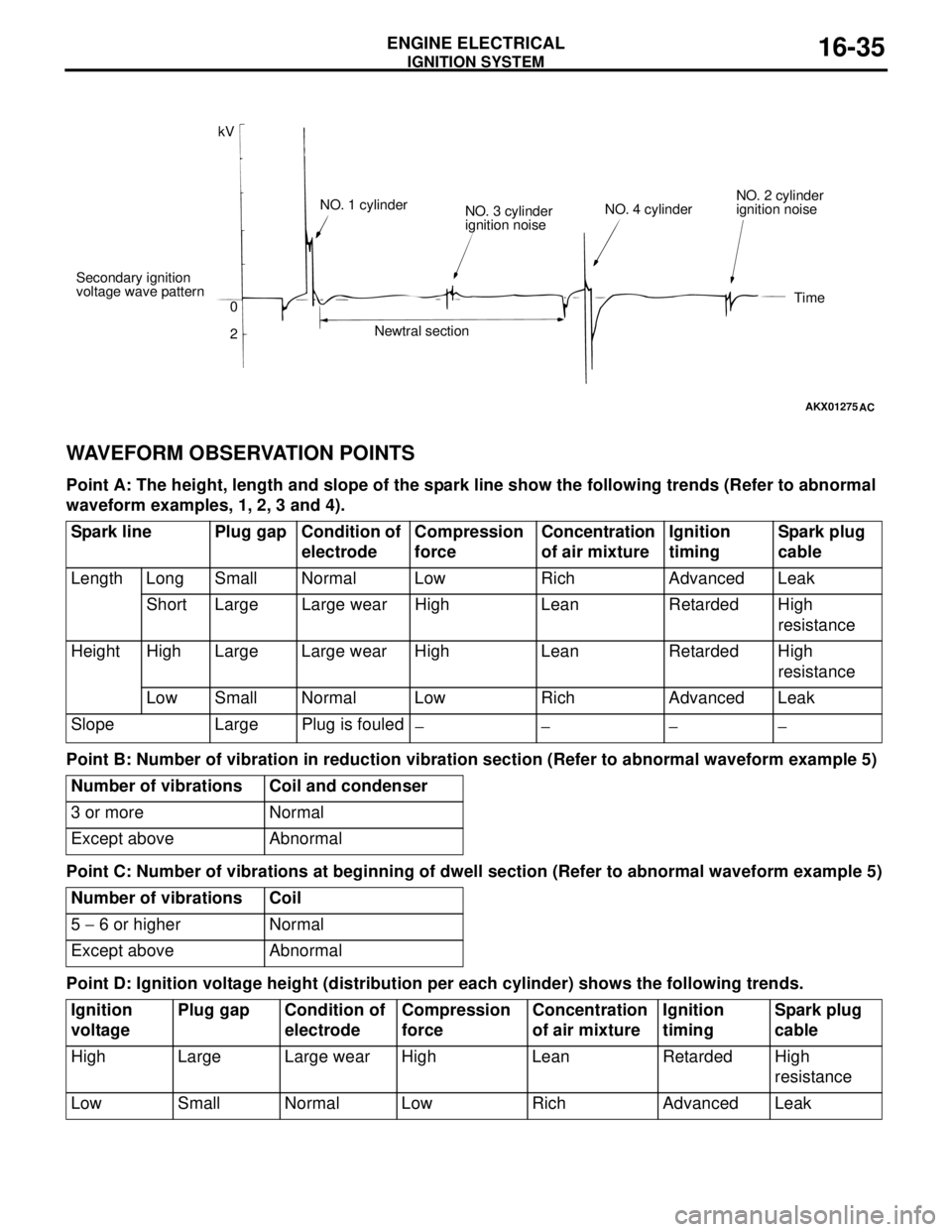

WAVEFORM OBSERVATION POINTS

Point A: The height, length and slope of the spark line show the following trends (Refer to abnormal

waveform examples, 1, 2, 3 and 4).

Point B: Number of vibration in reduction vibration section (Refer to abnormal waveform example 5)

Point C: Number of vibrations at beginning of dwell section (Refer to abnormal waveform example 5)

Point D: Ignition voltage height (distribution per each cylinder) shows the following trends.

AKX01275

kV

Secondary ignition

voltage wave pattern

0

2NO. 1 cylinder

NO. 3 cylinder

ignition noise

Newtral sectionNO. 4 cylinderNO. 2 cylinder

ignition noise

Time

AC

Spark line Plug gap Condition of

electrodeCompression

force Concentration

of air mixtureIgnition

timingSpark plug

cable

Length Long Small Normal Low Rich Advanced Leak

Short Large Large wear High Lean Retarded High

resistance

Height High Large Large wear High Lean Retarded High

resistance

Low Small Normal Low Rich Advanced Leak

Slope Large Plug is fouled

−− −−

Number of vibrations Coil and condenser

3 or more Normal

Except above Abnormal

Number of vibrations Coil

5 − 6 or higher Normal

Except above Abnormal

Ignition

voltagePlug gap Condition of

electrodeCompression

forceConcentration

of air mixtureIgnition

timingSpark plug

cable

High Large Large wear High Lean Retarded High

resistance

Low Small Normal Low Rich Advanced Leak