Rake MITSUBISHI LANCER 2005 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 160 of 788

ON-VEHICLE SERVICE

REAR AXLE27-4

ON-VEHICLE SERVICE

WHEEL BEARING AXIAL PLAY CHECKM1271000900452

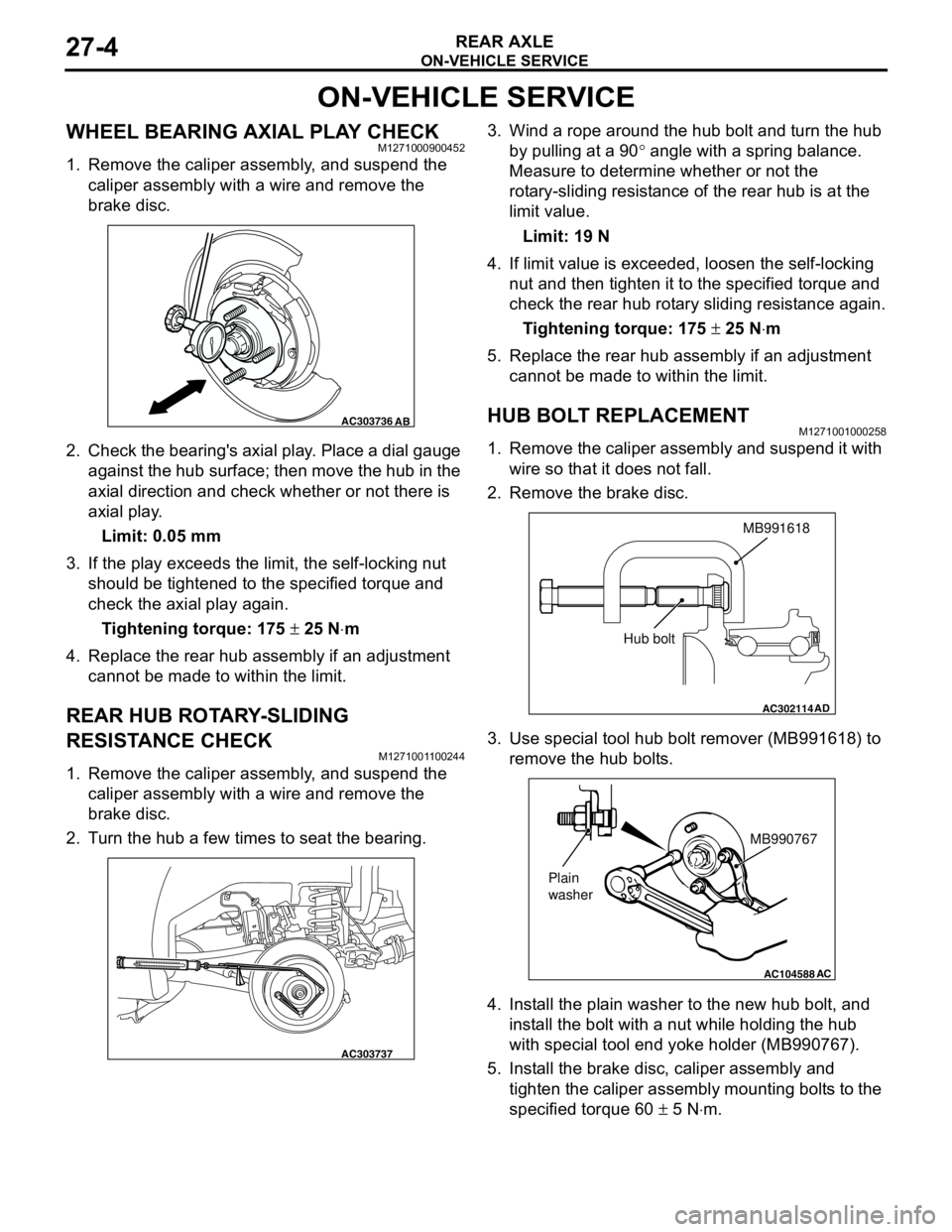

1. Remove the caliper assembly, and suspend the

caliper assembly with a wire and remove the

brake disc.

2. Check the bearing's axial play. Place a dial gauge

against the hub surface; then move the hub in the

axial direction and check whether or not there is

axial play.

Limit: 0.05 mm

3. If the play exceeds the limit, the self-locking nut

should be tightened to the specified torque and

check the axial play again.

Tightening torque: 175 ± 25 N⋅m

4. Replace the rear hub assembly if an adjustment

cannot be made to within the limit.

REAR HUB ROTARY-SLIDING

RESISTANCE CHECK

M1271001100244

1. Remove the caliper assembly, and suspend the

caliper assembly with a wire and remove the

brake disc.

2. Turn the hub a few times to seat the bearing.3. Wind a rope around the hub bolt and turn the hub

by pulling at a 90° angle with a spring balance.

Measure to determine whether or not the

rotary-sliding resistance of the rear hub is at the

limit value.

Limit: 19 N

4. If limit value is exceeded, loosen the self-locking

nut and then tighten it to the specified torque and

check the rear hub rotary sliding resistance again.

Tightening torque: 175 ± 25 N⋅m

5. Replace the rear hub assembly if an adjustment

cannot be made to within the limit.

HUB BOLT REPLACEMENTM1271001000258

1. Remove the caliper assembly and suspend it with

wire so that it does not fall.

2. Remove the brake disc.

3. Use special tool hub bolt remover (MB991618) to

remove the hub bolts.

4. Install the plain washer to the new hub bolt, and

install the bolt with a nut while holding the hub

with special tool end yoke holder (MB990767).

5. Install the brake disc, caliper assembly and

tighten the caliper assembly mounting bolts to the

specified torque 60 ± 5 N⋅m.

AC303736AB

AC303737

AC302114

MB991618

AD

Hub bolt

AC104588

MB990767

Plain

washer

AC

Page 161 of 788

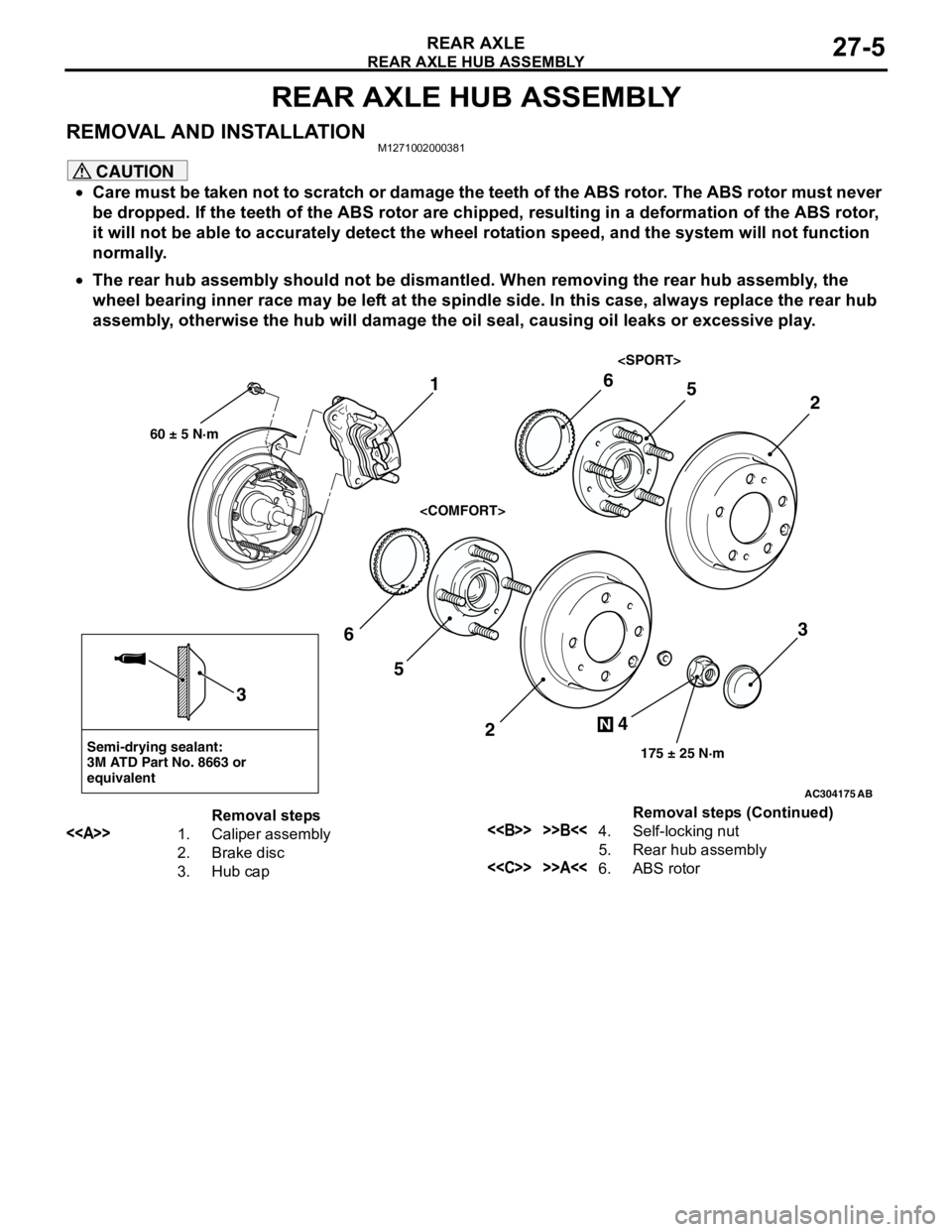

REAR AXLE HUB ASSEMBLY

REAR AXLE27-5

REAR AXLE HUB ASSEMBLY

REMOVAL AND INSTALLATIONM1271002000381

CAUTION

•Care must be taken not to scratch or damage the teeth of the ABS rotor. The ABS rotor must never

be dropped. If the teeth of the ABS rotor are chipped, resulting in a deformation of the ABS rotor,

it will not be able to accurately detect the wheel rotation speed, and the system will not function

normally.

•The rear hub assembly should not be dismantled. When removing the rear hub assembly, the

wheel bearing inner race may be left at the spindle side. In this case, always replace the rear hub

assembly, otherwise the hub will damage the oil seal, causing oil leaks or excessive play.

AC304175

Semi-drying sealant:

3M ATD Part No. 8663 or

equivalent

2

3

5 6

4

N

175 ± 25 N·m

3

AB

1

60 ± 5 N·m

2

56

Removal steps

<>1. Caliper assembly

2. Brake disc

3. Hub cap<> >>B<<4. Self-locking nut

5. Rear hub assembly

<

Page 189 of 788

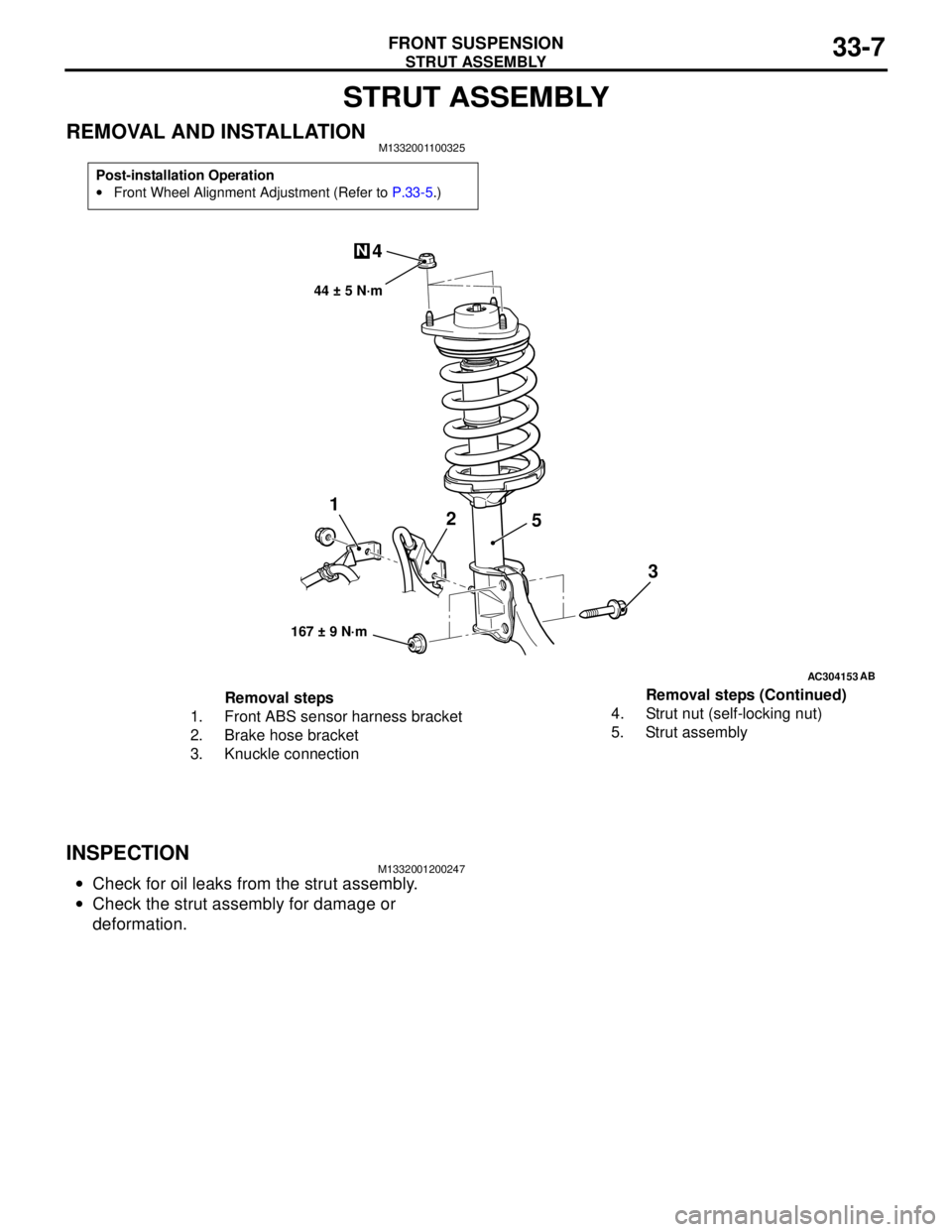

STRUT ASSEMBLY

FRONT SUSPENSION33-7

STRUT ASSEMBLY

REMOVAL AND INSTALLATIONM1332001100325

INSPECTIONM1332001200247

•Check for oil leaks from the strut assembly.

•Check the strut assembly for damage or

deformation.

Post-installation Operation

•Front Wheel Alignment Adjustment (Refer to P.33-5.)

AC304153

44 ± 5 N·m

1

2

3 4

N

AB

167 ± 9 N·m

5

Removal steps

1. Front ABS sensor harness bracket

2. Brake hose bracket

3. Knuckle connection4. Strut nut (self-locking nut)

5. Strut assemblyRemoval steps (Continued)

Page 212 of 788

TRAILING ARM ASSEMBLY

REAR SUSPENSION34-12

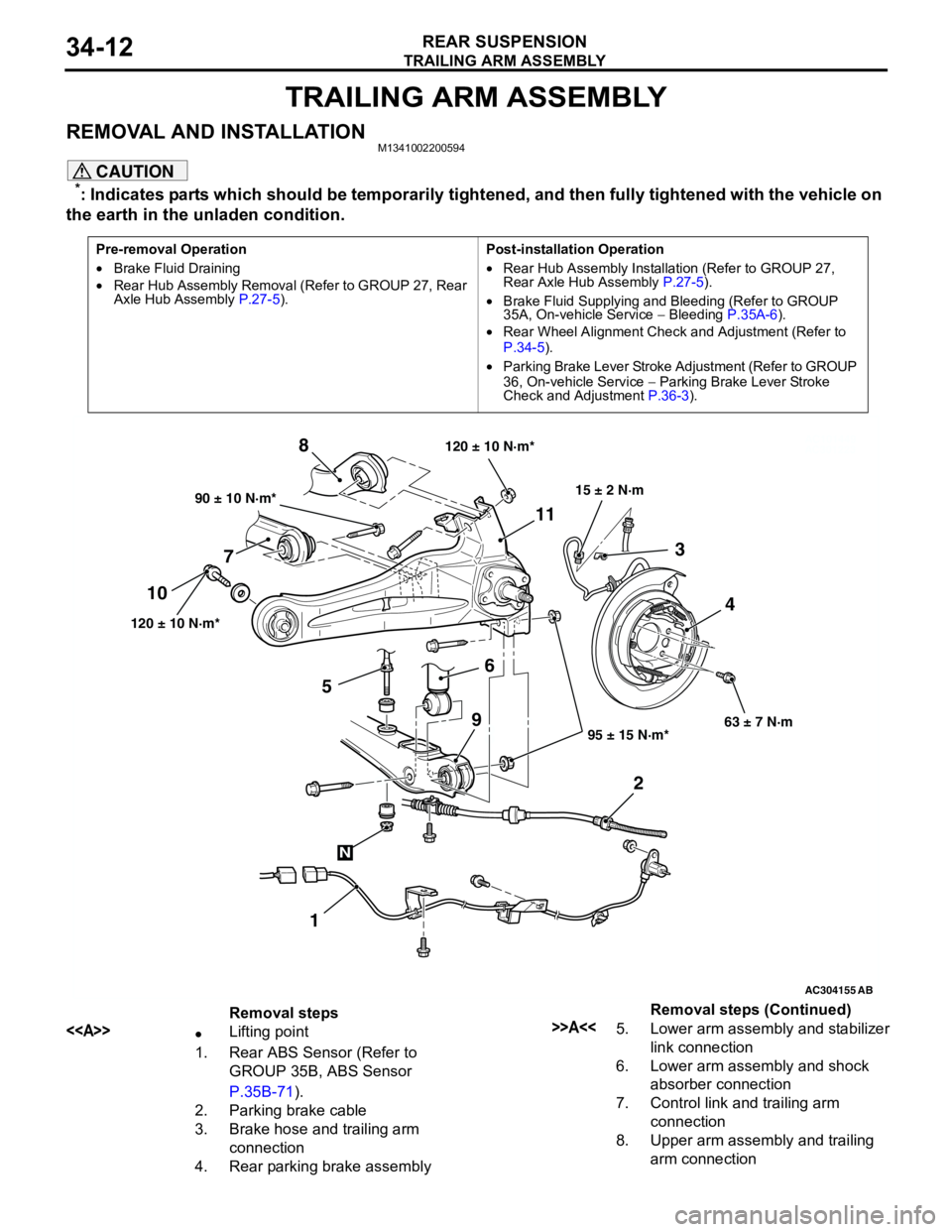

TRAILING ARM ASSEMBLY

REMOVAL AND INSTALLATIONM1341002200594

CAUTION

*: Indicates parts which should be temporarily tightened, and then fully tightened with the vehicle on

the earth in the unladen condition.

Pre-removal Operation

•Brake Fluid Draining

•Rear Hub Assembly Removal (Refer to GROUP 27, Rear

Axle Hub Assembly P.27-5).Post-installation Operation

•Rear Hub Assembly Installation (Refer to GROUP 27,

Rear Axle Hub Assembly P.27-5).

•Brake Fluid Supplying and Bleeding (Refer to GROUP

35A, On-vehicle Service − Bleeding P.35A-6).

•Rear Wheel Alignment Check and Adjustment (Refer to

P.34-5).

•Parking Brake Lever Stroke Adjustment (Refer to GROUP

36, On-vehicle Service − Parking Brake Lever Stroke

Check and Adjustment P.36-3).

AC101449

AC301223

AC304155AB

90 ± 10 N·m*

120 ± 10 N·m*

95 ± 15 N·m*63 ± 7 N·m

6 78

1 1011

23

4

120 ± 10 N·m*

15 ± 2 N·m

N

9

5

Removal steps

<>•Lifting point

1. Rear ABS Sensor (Refer to

GROUP 35B, ABS Sensor

P.35B-71).

2. Parking brake cable

3. Brake hose and trailing arm

connection

4. Rear parking brake assembly>>A<<5. Lower arm assembly and stabilizer

link connection

6. Lower arm assembly and shock

absorber connection

7. Control link and trailing arm

connection

8. Upper arm assembly and trailing

arm connection Removal steps (Continued)

Page 223 of 788

35-1

GROUP 35

SERVICE BRAKES

CONTENTS

BASIC BRAKE SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35A

ANTI-SKID BRAKING SYSTEM (ABS) . . . . . . . . . . . . . . . . . . .35B

Page 225 of 788

36-1

GROUP 36

PARKING BRAKES

CONTENTS

GENERAL INFORMATION . . . . . . . .36-2

SERVICE SPECIFICATIONS . . . . . . .36-2

LUBRICANTS . . . . . . . . . . . . . . . . . .36-3

ON-VEHICLE SERVICE . . . . . . . . . . .36-3

PARKING BRAKE LEVER STROKE

CHECK AND ADJUSTMENT . . . . . . . . . . . 36-3

LINING RUNNING-IN . . . . . . . . . . . . . . . . . 36-3

PARKING BRAKE SWITCH CHECK . . . . . 36-4

PARKING BRAKE LEVER . . . . . . . . .36-5

REMOVAL AND INSTALLATION . . . . . . . . 36-5

PARKING BRAKE CABLE . . . . . . . . .36-6

REMOVAL AND INSTALLATION . . . . . . . . 36-6

PARKING BRAKE LINING AND

DRUM . . . . . . . . . . . . . . . . . . . . . . . . .36-7

REMOVAL AND INSTALLATION . . . . . . . . 36-7

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 36-9

Page 226 of 788

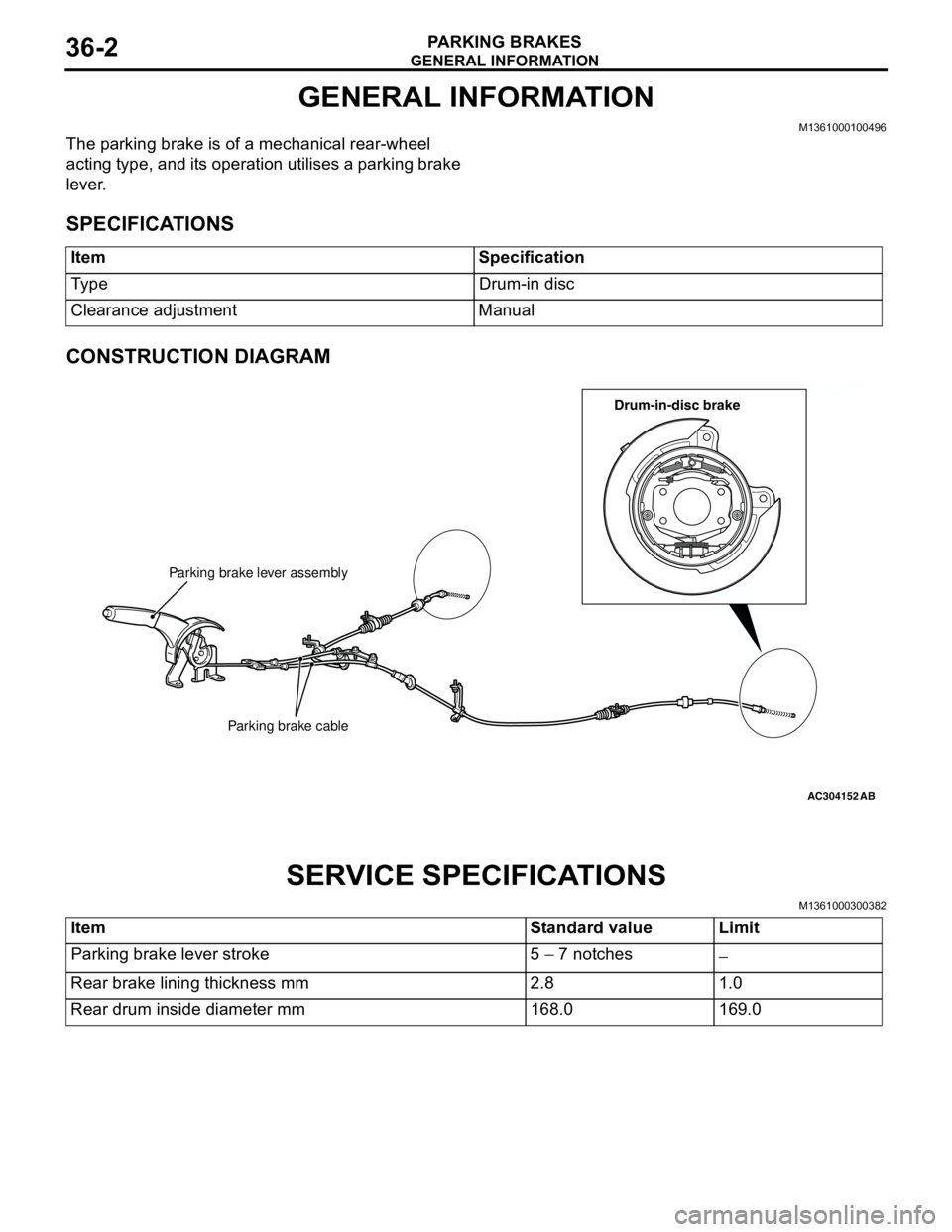

GENERAL INFORMATION

PARKING BRAKES36-2

GENERAL INFORMATION

M1361000100496

The parking brake is of a mechanical rear-wheel

acting type, and its operation utilises a parking brake

lever.

SPECIFICATIONS

CONSTRUCTION DIAGRAM

SERVICE SPECIFICATIONS

M1361000300382

Item Specification

Type Drum-in disc

Clearance adjustment Manual

AC211553

AC104333

AC304152

Parking brake lever assembly

Parking brake cable

AB

Drum-in-disc brake

Item Standard value Limit

Parking brake lever stroke 5 − 7 notches

−

Rear brake lining thickness mm 2.8 1.0

Rear drum inside diameter mm 168.0 169.0

Page 227 of 788

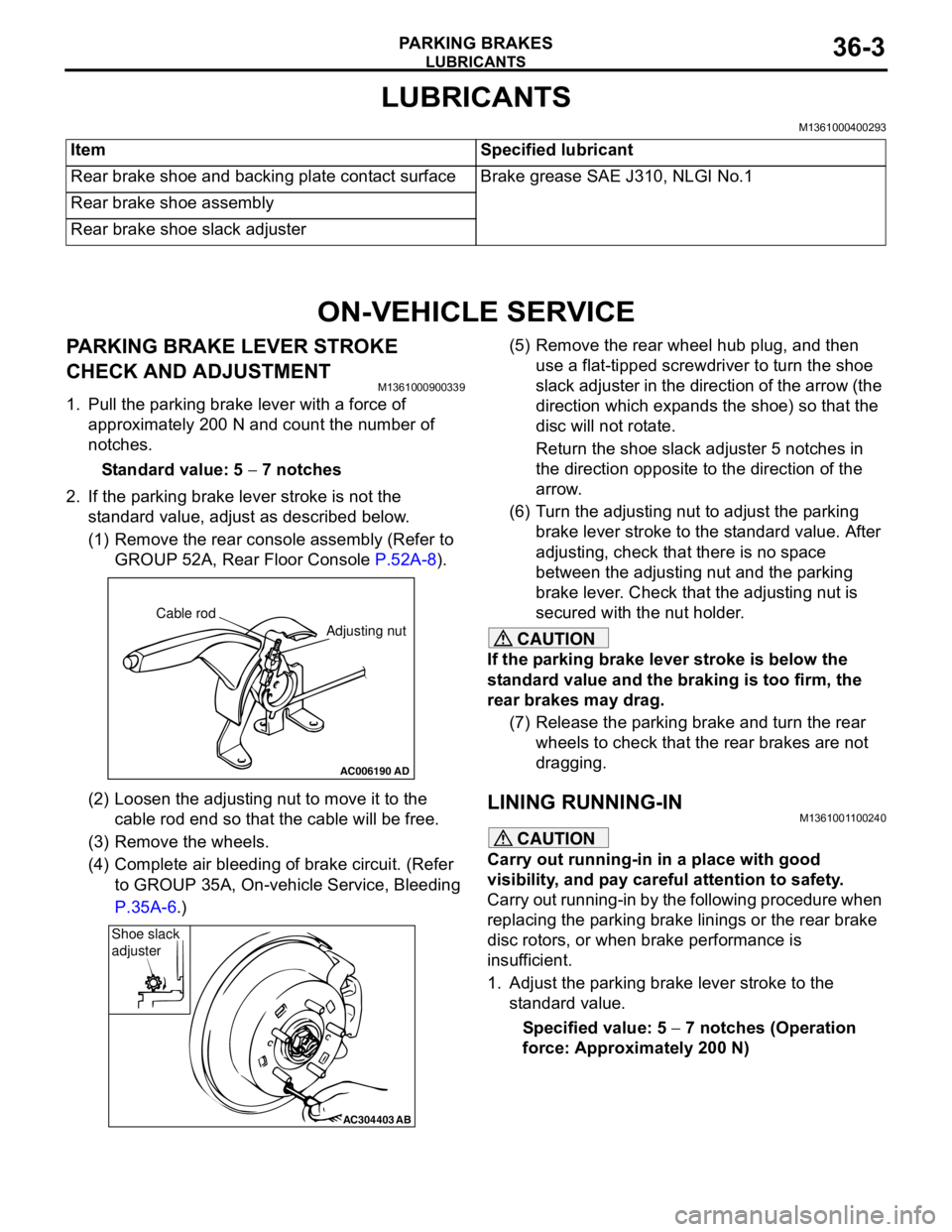

LUBRICANTS

PARKING BRAKES36-3

LUBRICANTS

M1361000400293

ON-VEHICLE SERVICE

PARKING BRAKE LEVER STROKE

CHECK AND ADJUSTMENT

M1361000900339

1. Pull the parking brake lever with a force of

approximately 200 N and count the number of

notches.

Standard value: 5 − 7 notches

2. If the parking brake lever stroke is not the

standard value, adjust as described below.

(1) Remove the rear console assembly (Refer to

GROUP 52A, Rear Floor Console P.52A-8).

(2) Loosen the adjusting nut to move it to the

cable rod end so that the cable will be free.

(3) Remove the wheels.

(4) Complete air bleeding of brake circuit. (Refer

to GROUP 35A, On-vehicle Service, Bleeding

P.35A-6.)(5) Remove the rear wheel hub plug, and then

use a flat-tipped screwdriver to turn the shoe

slack adjuster in the direction of the arrow (the

direction which expands the shoe) so that the

disc will not rotate.

Return the shoe slack adjuster 5 notches in

the direction opposite to the direction of the

arrow.

(6) Turn the adjusting nut to adjust the parking

brake lever stroke to the standard value. After

adjusting, check that there is no space

between the adjusting nut and the parking

brake lever. Check that the adjusting nut is

secured with the nut holder.

CAUTION

If the parking brake lever stroke is below the

standard value and the braking is too firm, the

rear brakes may drag.

(7) Release the parking brake and turn the rear

wheels to check that the rear brakes are not

dragging.

LINING RUNNING-INM1361001100240

CAUTION

Carry out running-in in a place with good

visibility, and pay careful attention to safety.

Carry out running-in by the following procedure when

replacing the parking brake linings or the rear brake

disc rotors, or when brake performance is

insufficient.

1. Adjust the parking brake lever stroke to the

standard value.

Specified value: 5 − 7 notches (Operation

force: Approximately 200 N) Item Specified lubricant

Rear brake shoe and backing plate contact surface Brake grease SAE J310, NLGI No.1

Rear brake shoe assembly

Rear brake shoe slack adjuster

AC006190

Cable rod

Adjusting nut

AD

AC304403AB

Shoe slack

adjuster

Page 228 of 788

ON-VEHICLE SERVICE

PARKING BRAKES36-4

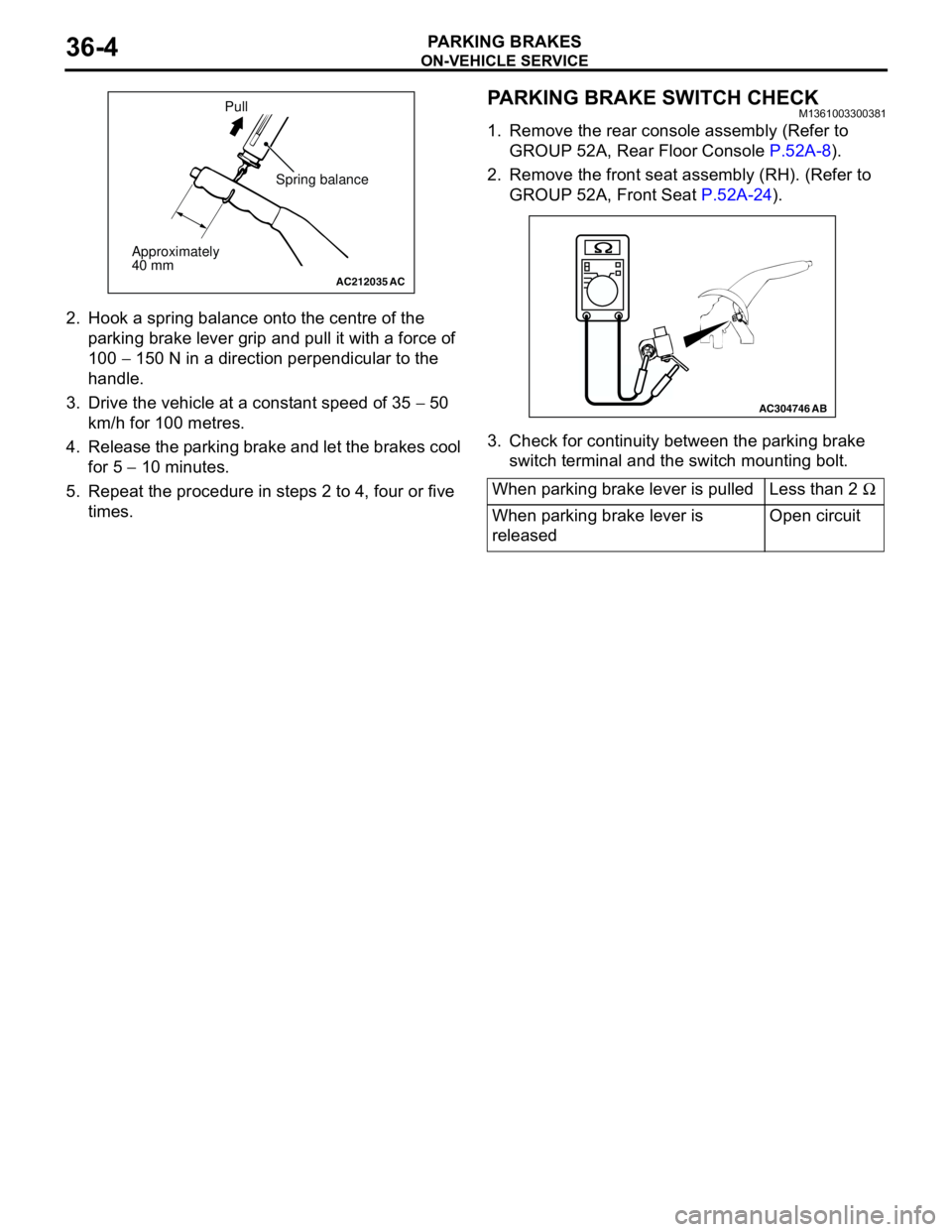

2. Hook a spring balance onto the centre of the

parking brake lever grip and pull it with a force of

100 − 150 N in a direction perpendicular to the

handle.

3. Drive the vehicle at a constant speed of 35 − 50

km/h for 100 metres.

4. Release the parking brake and let the brakes cool

for 5 − 10 minutes.

5. Repeat the procedure in steps 2 to 4, four or five

times.

PARKING BRAKE SWITCH CHECKM1361003300381

1. Remove the rear console assembly (Refer to

GROUP 52A, Rear Floor Console P.52A-8).

2. Remove the front seat assembly (RH). (Refer to

GROUP 52A, Front Seat P.52A-24).

3. Check for continuity between the parking brake

switch terminal and the switch mounting bolt.

AC212035AC

Spring balance

Approximately

40 mmPull

When parking brake lever is pulled Less than 2 Ω

When parking brake lever is

releasedOpen circuit

AC304746AB

Page 229 of 788

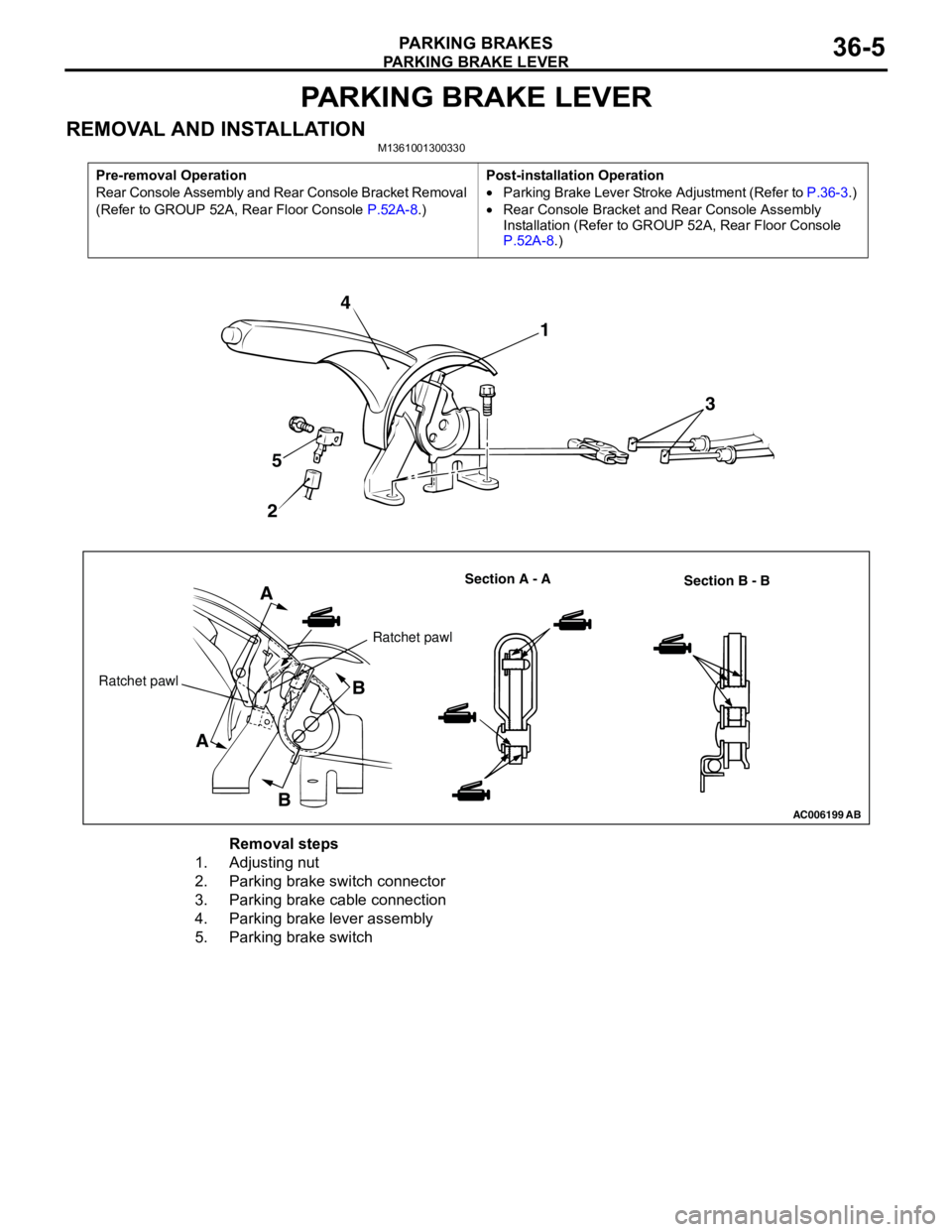

PARKING BRAKE LEVER

PARKING BRAKES36-5

PARKING BRAKE LEVER

REMOVAL AND INSTALLATIONM1361001300330

Pre-removal Operation

Rear Console Assembly and Rear Console Bracket Removal

(Refer to GROUP 52A, Rear Floor Console P.52A-8.)Post-installation Operation

•Parking Brake Lever Stroke Adjustment (Refer to P.36-3.)

•Rear Console Bracket and Rear Console Assembly

Installation (Refer to GROUP 52A, Rear Floor Console

P.52A-8.)

AC006199AB

4

5

21

3

A

AB

B

Ratchet pawlSection A - A

Section B - B

Ratchet pawl

Removal steps

1. Adjusting nut

2. Parking brake switch connector

3. Parking brake cable connection

4. Parking brake lever assembly

5. Parking brake switch