oil temperature MITSUBISHI LANCER 2005 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 558 of 788

ON-VEHICLE SERVICE

HEATER, AIR CONDITIONER AND VENTILATION55-74

REFRIGERANT LEAK REPAIR

PROCEDURE

M1552001500277

LOST CHARGE

If the system has lost all charge due to a leak:

1. Evacuate the system (Refer to P.55-72).

2. Charge the system with approximately 480 − 520

g of refrigerant.

3. Check for leaks.

4. Discharge the system.

5. Repair leaks.

CAUTION

Replacement filter-drier units must be sealed

while in storage. The drier used in these units will

saturate water quickly upon exposure to the

atmosphere. When installing a drier, have all

tools and supplies ready for quick assembly to

avoid keeping the system open any longer than

necessary.

6. Replace receiver drier.

7. Evacuate and charge system.

LOW CHARGE

If the system has not lost all of its refrigerant charge;

locate and repair all leaks. If it is necessary to

increase the system pressure to find the leak

(because of an especially low charge) add

refrigerant. If it is possible to repair the leak without

discharging the refrigerant system, use the

procedure for correcting low refrigerant level.

HANDLING TUBING AND FITTINGS

Kinks in the refrigerant tubing or sharp bends in the

refrigerant hose lines will greatly reduce the capacity

of the entire system. High pressures are produced in

the system when it is operating. Extreme care must

be exercised to make sure that all connections are

pressure tight. Dirt and moisture can enter the

system when it is opened for repair or replacement of

lines or components. The following precautions must

be observed. The system must be completely

discharged before opening any fitting of connection

in the refrigeration system. Open fittings with caution

even after the system has been discharged. If any

pressure is noticed as a fitting is loosened, allow

trapped pressure to bleed off very slowly.

Never attempt to rebend formed lines to fit. Use the

correct line for the installation you are servicing. A

good rule for the flexible hose lines is keep the radius

of all bends at least 10 times the diameter of the

hose.Sharper bends will reduce the flow of refrigerant. The

flexible hose lines should be routed so that they are

at least 80 mm from the exhaust manifold. It is good

practice to inspect all flexible hose lines at least once

a year to make sure they are in good condition and

properly routed.

On standard plumbing fittings with O-rings, these

O-rings are not reusable.

COMPRESSOR NOISE CHECKM1552008700272

You must first know the conditions when the noise

occurs. These conditions are: weather, vehicle

speed, in gear or neutral, engine temperature or any

other special conditions.

Noises that develop during A/C operation can often

be misleading. For example: what sounds like a

failed front bearing or connecting rod, may be

caused by loose bolts, nuts, mounting brackets, or a

loose clutch assembly. Verify accessory drive belt

tension (power steering or alternator).

Improper accessory drive belt tension can cause a

misleading noise when the compressor is engaged

and little or no noise when the compressor is

disengaged.

Drive belts are speed-sensitive. That is, at different

engine speeds, and depending upon belt tension,

belts can develop unusual noises that are often

mistaken for mechanical problems within the

compressor.

ADJUSTMENT

1. Select a quiet area for testing. Duplicate

conditions as much as possible. Switch the

compressor on and off several times to clearly

identify compressor noise. To duplicate high

ambient conditions (high head pressure), restrict

air flow through the condenser. Install a manifold

gauge set to make sure discharge pressure

doesn't exceed 2,070 kPa.

2. Tighten all compressor mounting bolts, clutch

mounting bolt, and compressor drive belt. Check

to assure clutch coil is tight (no rotation or

wobble).

3. Check refrigerant hoses for rubbing or

interference that can cause unusual noises.

4. Check refrigerant charge (Refer to P.55-69).

5. Recheck compressor noise as in Step 1.

6. If noise still exists, loosen compressor mounting

bolts and retighten. Repeat Step 1.

7. If noise continues, replace compressor and repeat

Step 1.

Page 574 of 788

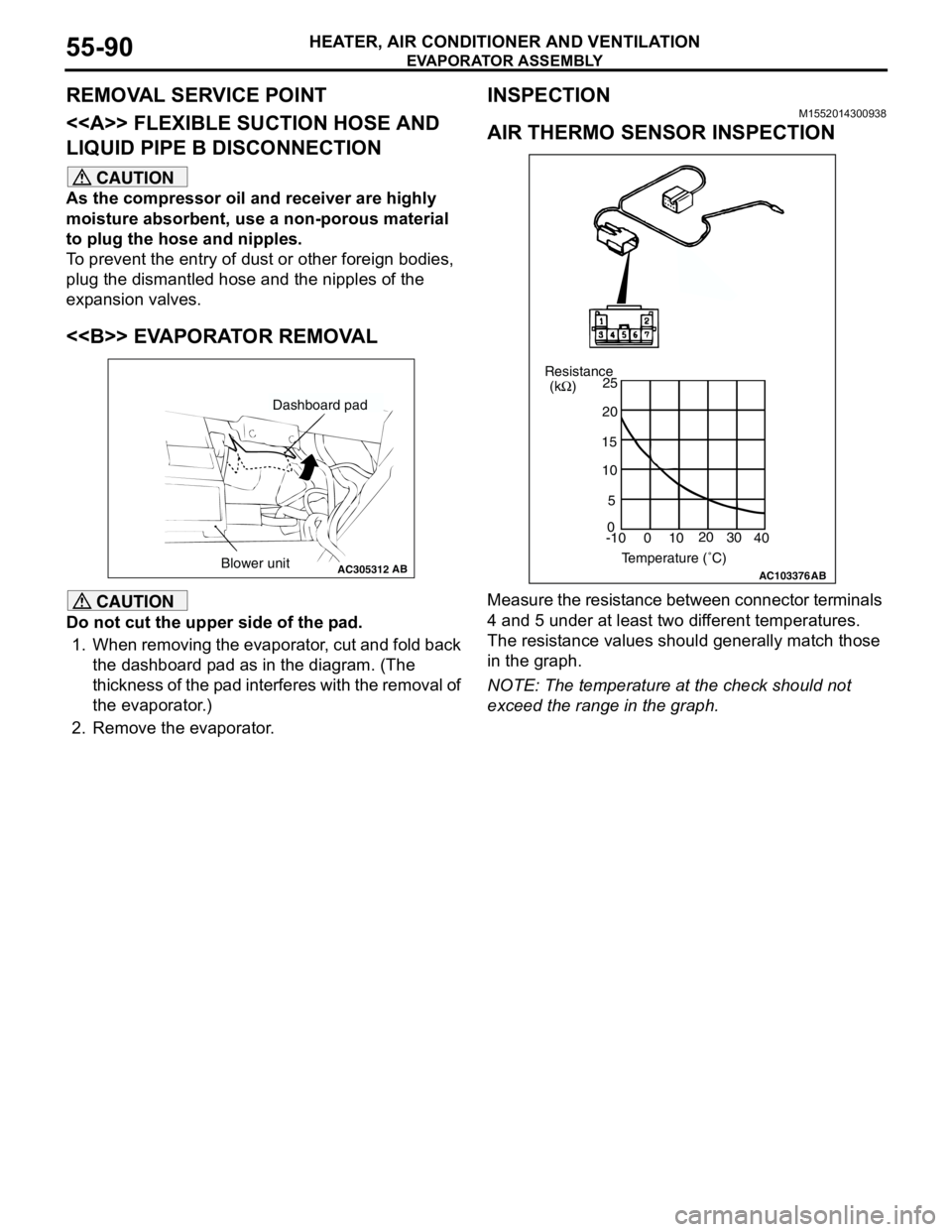

Page 579 of 788

COMPRESSOR ASSEMBLY AND TENSION PULLEY

HEATER, AIR CONDITIONER AND VENTILATION55-95

>>B<< SNAP RING INSTALLATION

Using snap ring pliers, fit the snap ring so that the

snap ring’s tapered part is on the outside.

>>C<< SELF-LOCKING NUT

INSTALLATION

Use the special tools to install the self-locking nut.

•Special spanner (MB991367)

•Pin (MB991386)

>>D<< AIR GAP ADJUSTMENT

Check that the clutch air gap is inside the standard

value. If outside the standard value, use a shim to

adjust the gap.

Standard value: 0.3 − 0.5 mm

INSPECTIONM1552014300950

REFRIGERANT TEMPERATURE SWITCH

CAUTION

Do not heat more than necessary.

1. Dip the metal part of the cooling temperature

switch into engine oil and increase the oil

temperature using a gas burner or similar.

2. When the oil temperature reaches the standard

value, check that voltage is supplied between the

terminals.

Standard value:

NOTE: When the oil temperature is 150

°C or

more and there is no continuity, the resistance will

not be 2

Ω or lower until the oil temperature

reduces to 120

°C or less.

AC001412

Snap ring

RotorClutch coil

Tapered part

AB

AC100633AB

MB991386

MB991367

AC100637AB

Thickness

gauge

Item Temperature

Less than 2

ohmsSlightly below 150°C

No continuity 150°C or more

AC100787

Thermometer

Engine oil

AB

AC100810

Continuity

No continuity

Oil temperature

AD

120˚C150˚C

Page 593 of 788

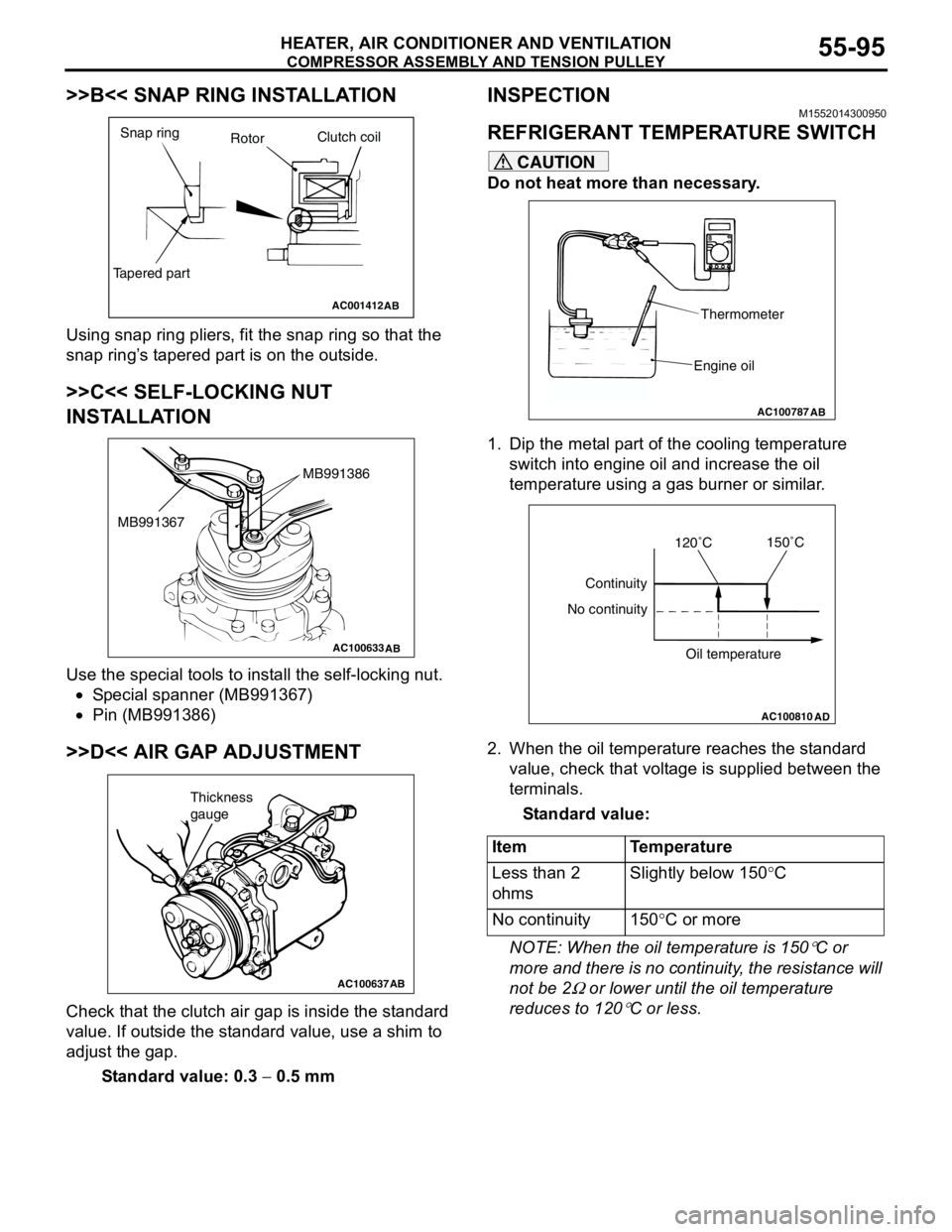

SENSOR

COMPONENT LOCATIONS70-7

AC208762

A

AD

Timing belt front

upper coverTiming belt front

lower coverEngine crank

angle sensor

<4G1>

Engine crank angle

sensor connector

AC302008

A<4G6>

ABHeat protector

Crankshaft

sprocket

Engine crank angle

sensor connectorEngine crank

angle sensor

AC301752

B

AB

Ignition coil 2

<4G1>

Engine control detonation

sensor connector

Engine control

detonation sensor

AC302009

B

AB

Hydraulic unit

<4G6>

Alternator

Engine control detonation

sensor connectorEngine control

detonation sensor

AC208541

C

AE

<4G1>

Throttle body

Throttle body

throttle sensor

Inlet manifold absolute pressure sensor

(incorporating intake air temperature sensor)

AC302479

AB

C

Throttle body

<4G6>

Throttle body

throttle sensor

Page 615 of 788

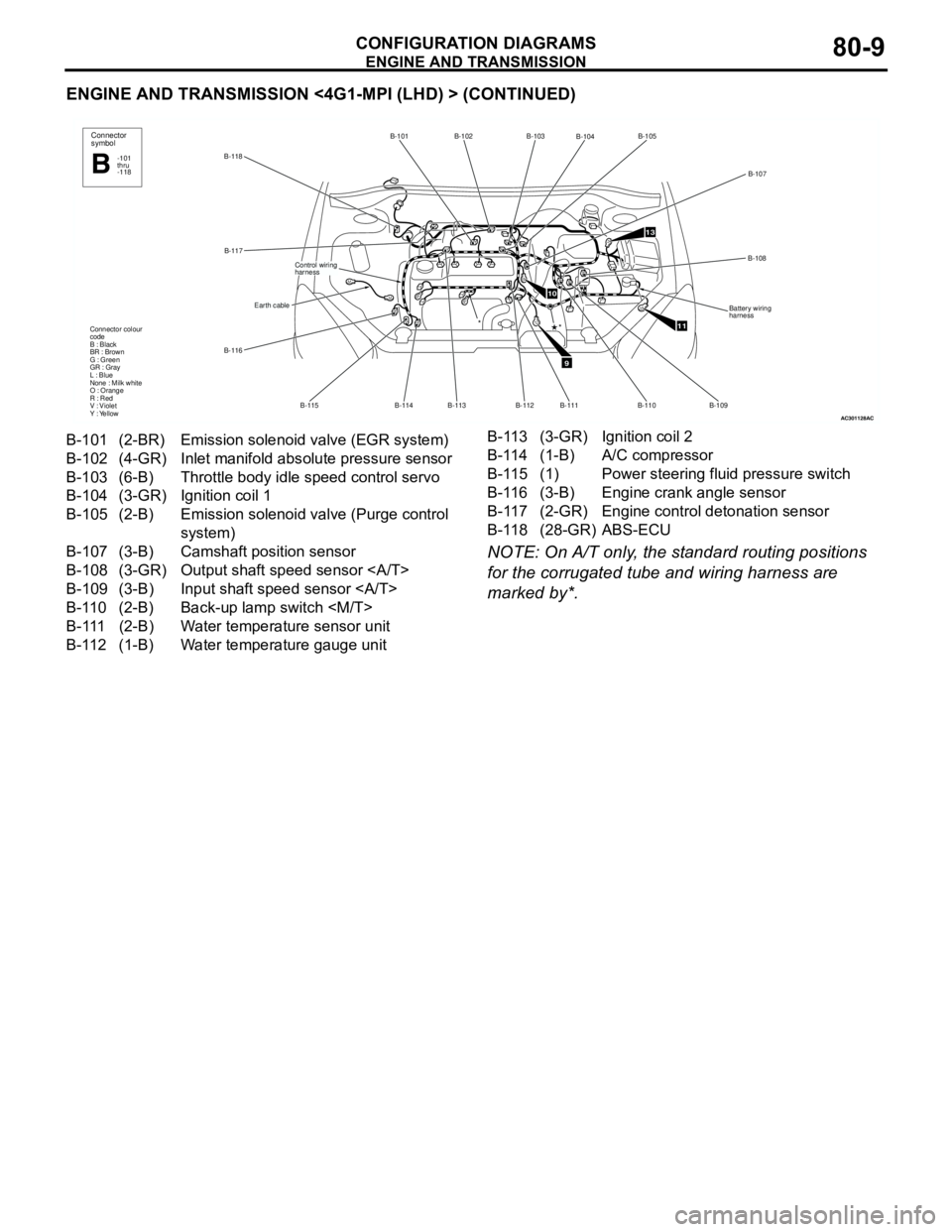

ENGINE AND TRANSMISSION

CONFIGURATION DIAGRAMS80-9

ENGINE AND TRANSMISSION <4G1-MPI (LHD) > (CONTINUED)

NOTE: On A/T only, the standard routing positions

for the corrugated tube and wiring harness are

marked by*.

AC301128

B-118B-101 B-102

B-113

B-114 B-115 B-116B-117

Earth cable

Control wiring

harness

Connector colour

code

B : Black

BR : Brown

G : Green

GR : Gray

L : Blue

None : Milk white

O : Orange

R : Red

V : Violet

Y : Yellow

Connector

symbol

-101

thru

-118B

*

AC

9

10

11

13

B-103

B-104B-105

B-107

B-108

Battery wiring

harness

B-109

B-110 B-111

*

B-112

B-101 (2-BR) Emission solenoid valve (EGR system)

B-102 (4-GR) Inlet manifold absolute pressure sensor

B-103 (6-B) Throttle body idle speed control servo

B-104 (3-GR) Ignition coil 1

B-105 (2-B) Emission solenoid valve (Purge control

system)

B-107 (3-B) Camshaft position sensor

B-108 (3-GR) Output shaft speed sensor

B-109 (3-B) Input shaft speed sensor

B-110 (2-B) Back-up lamp switch

B-111 (2-B) Water temperature sensor unit

B-112 (1-B) Water temperature gauge unitB-113 (3-GR) Ignition coil 2

B-114 (1-B) A/C compressor

B-115 (1) Power steering fluid pressure switch

B-116 (3-B) Engine crank angle sensor

B-117 (2-GR) Engine control detonation sensor

B-118 (28-GR) ABS-ECU

Page 617 of 788

ENGINE AND TRANSMISSION

CONFIGURATION DIAGRAMS80-11

ENGINE AND TRANSMISSION <4G1-MPI (RHD) > (CONTINUED)

NOTE: On A/T only, the standard routing positions

for the corrugated tube and wiring harness are

marked by*.

AC301131

B-117B-101 B-102

B-113 B-114 B-115 B-116

Earth cable

Control wiring

harness

Connector colour

code

B : Black

BR : Brown

G : Green

GR : Gray

L : Blue

None : Milk white

O : Orange

R : Red

V : Violet

Y : Yellow

Connector

symbol

-101

thru

-118B

*

AC

9

10

11

13

B-103

B-104B-105

B-107

B-108

Battery wiring

harness

B-109 B-110 B-111

*

B-112

B-118

B-101 (2-BR) Emission solenoid valve (EGR system)

B-102 (4-GR) Inlet manifold absolute pressure sensor

B-103 (6-B) Throttle body idle speed control servo

B-104 (3-GR) Ignition coil 1

B-105 (2-B) Emission solenoid valve (Purge control

system)

B-107 (3-B) Camshaft position sensor

B-108 (3-GR) Output shaft speed sensor

B-109 (3-B) Input shaft speed sensor

B-110 (2-B) Back-up lamp switch

B-111 (2-B) Water temperature sensor unit

B-112 (1-B) Water temperature gauge unitB-113 (3-GR) Ignition coil 2

B-114 (1-B) A/C compressor

B-115 (1) Power steering fluid pressure switch

B-116 (3-B) Engine crank angle sensor

B-117 (2-GR) Engine control detonation sensor

B-118 (28-GR) ABS-ECU

Page 619 of 788

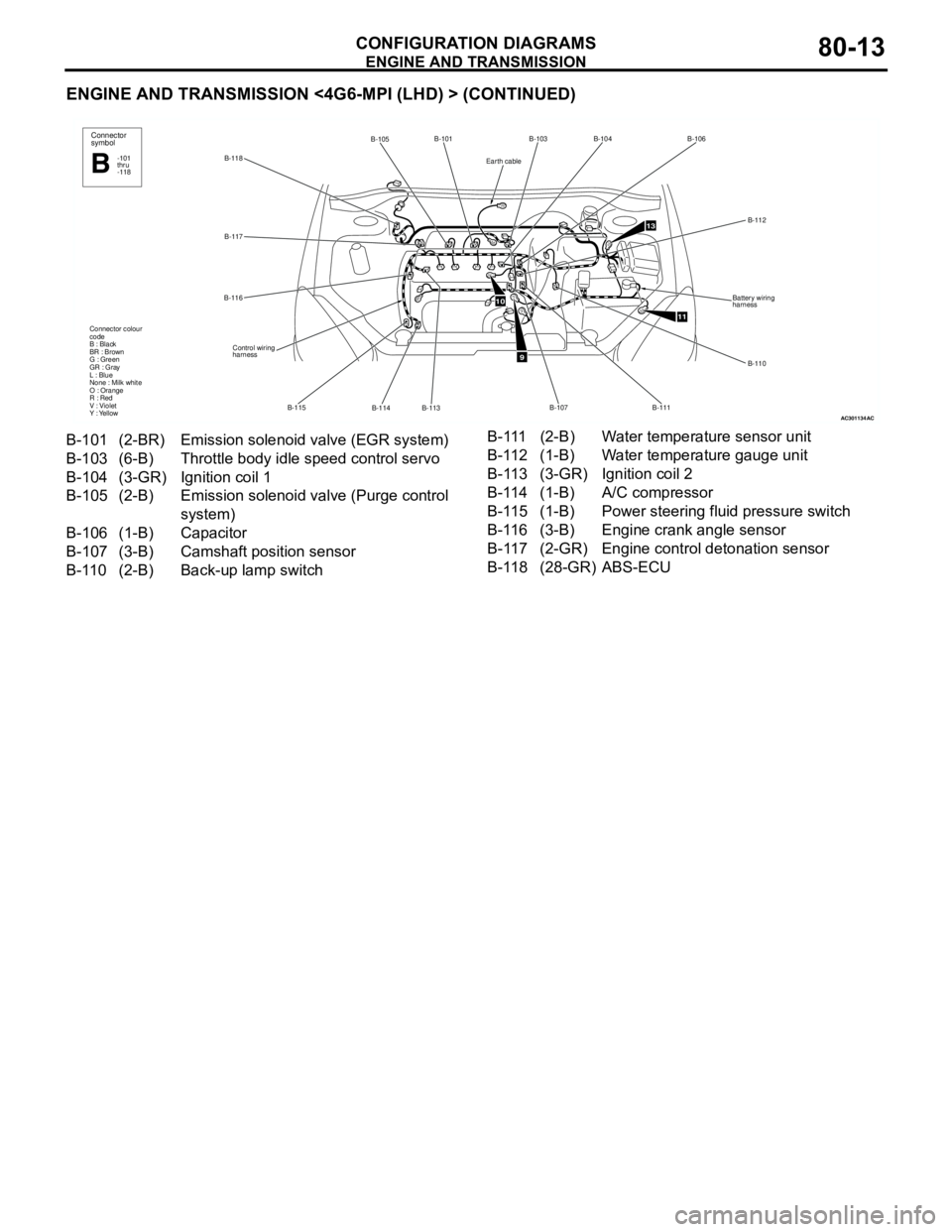

ENGINE AND TRANSMISSION

CONFIGURATION DIAGRAMS80-13

ENGINE AND TRANSMISSION <4G6-MPI (LHD) > (CONTINUED)

AC301134

B-118B-101

B-114 B-115 B-116B-117

Control wiring

harness Connector colour

code

B : Black

BR : Brown

G : Green

GR : Gray

L : Blue

None : Milk white

O : Orange

R : Red

V : Violet

Y : Yellow

B-113

B-105Connector

symbol

-101

thru

-118B

AC

9

10

11

13

B-103B-104B-106

B-112

B-110 Battery wiring

harness

B-111

B-107

Earth cable

B-101 (2-BR) Emission solenoid valve (EGR system)

B-103 (6-B) Throttle body idle speed control servo

B-104 (3-GR) Ignition coil 1

B-105 (2-B) Emission solenoid valve (Purge control

system)

B-106 (1-B) Capacitor

B-107 (3-B) Camshaft position sensor

B-110 (2-B) Back-up lamp switch B-111 (2-B) Water temperature sensor unit

B-112 (1-B) Water temperature gauge unit

B-113 (3-GR) Ignition coil 2

B-114 (1-B) A/C compressor

B-115 (1-B) Power steering fluid pressure switch

B-116 (3-B) Engine crank angle sensor

B-117 (2-GR) Engine control detonation sensor

B-118 (28-GR) ABS-ECU

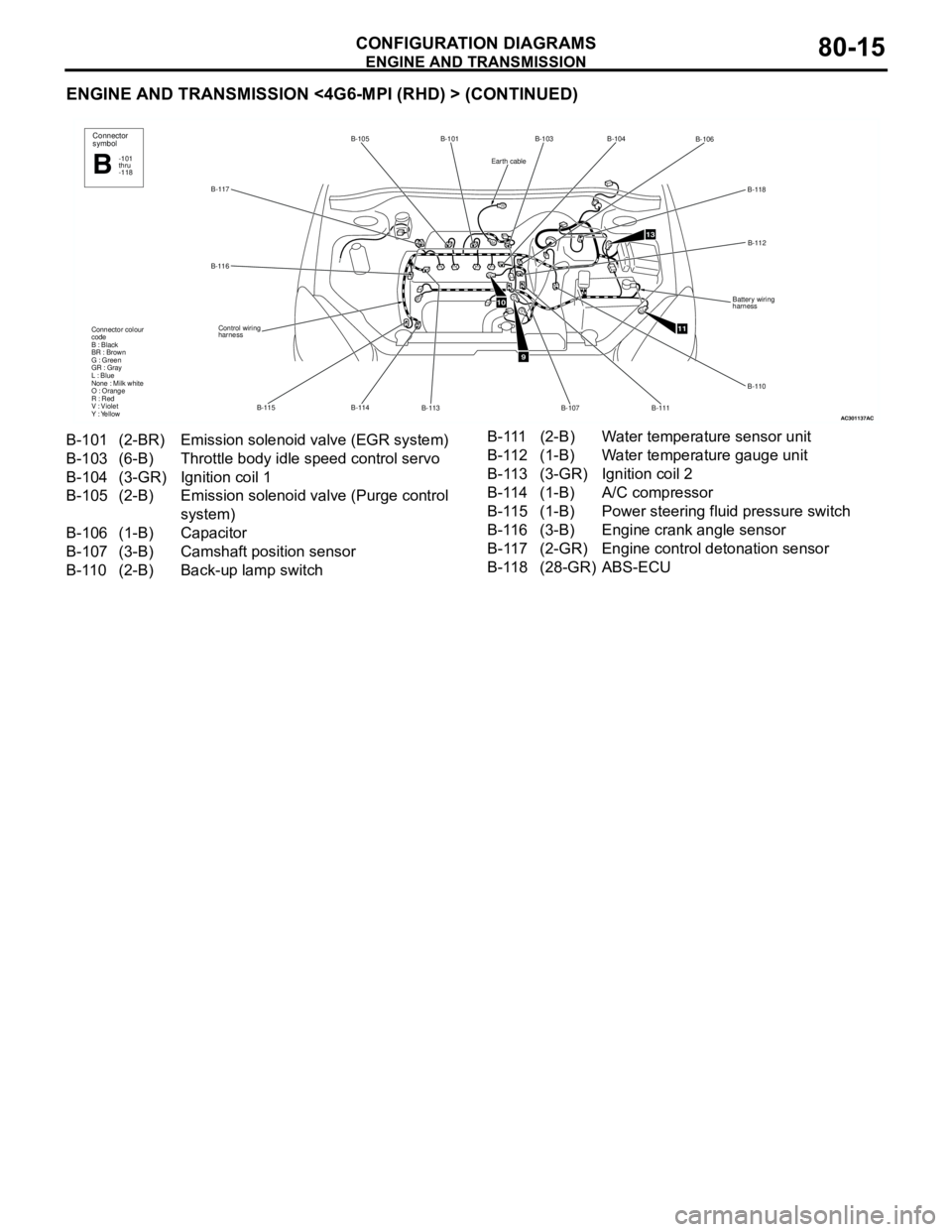

Page 621 of 788

ENGINE AND TRANSMISSION

CONFIGURATION DIAGRAMS80-15

ENGINE AND TRANSMISSION <4G6-MPI (RHD) > (CONTINUED)

AC301137

B-117B-105 B-101

B-113 B-114 B-115 B-116

Control wiring

harness Connector colour

code

B : Black

BR : Brown

G : Green

GR : Gray

L : Blue

None : Milk white

O : Orange

R : Red

V : Violet

Y : Yellow

Connector

symbol

-101

thru

-118B

AC

9

11

13

B-103

B-106

B-118

B-112

Battery wiring

harness

B-110

B-111

B-107

B-104

10

Earth cable

B-101 (2-BR) Emission solenoid valve (EGR system)

B-103 (6-B) Throttle body idle speed control servo

B-104 (3-GR) Ignition coil 1

B-105 (2-B) Emission solenoid valve (Purge control

system)

B-106 (1-B) Capacitor

B-107 (3-B) Camshaft position sensor

B-110 (2-B) Back-up lamp switch B-111 (2-B) Water temperature sensor unit

B-112 (1-B) Water temperature gauge unit

B-113 (3-GR) Ignition coil 2

B-114 (1-B) A/C compressor

B-115 (1-B) Power steering fluid pressure switch

B-116 (3-B) Engine crank angle sensor

B-117 (2-GR) Engine control detonation sensor

B-118 (28-GR) ABS-ECU

Page 659 of 788

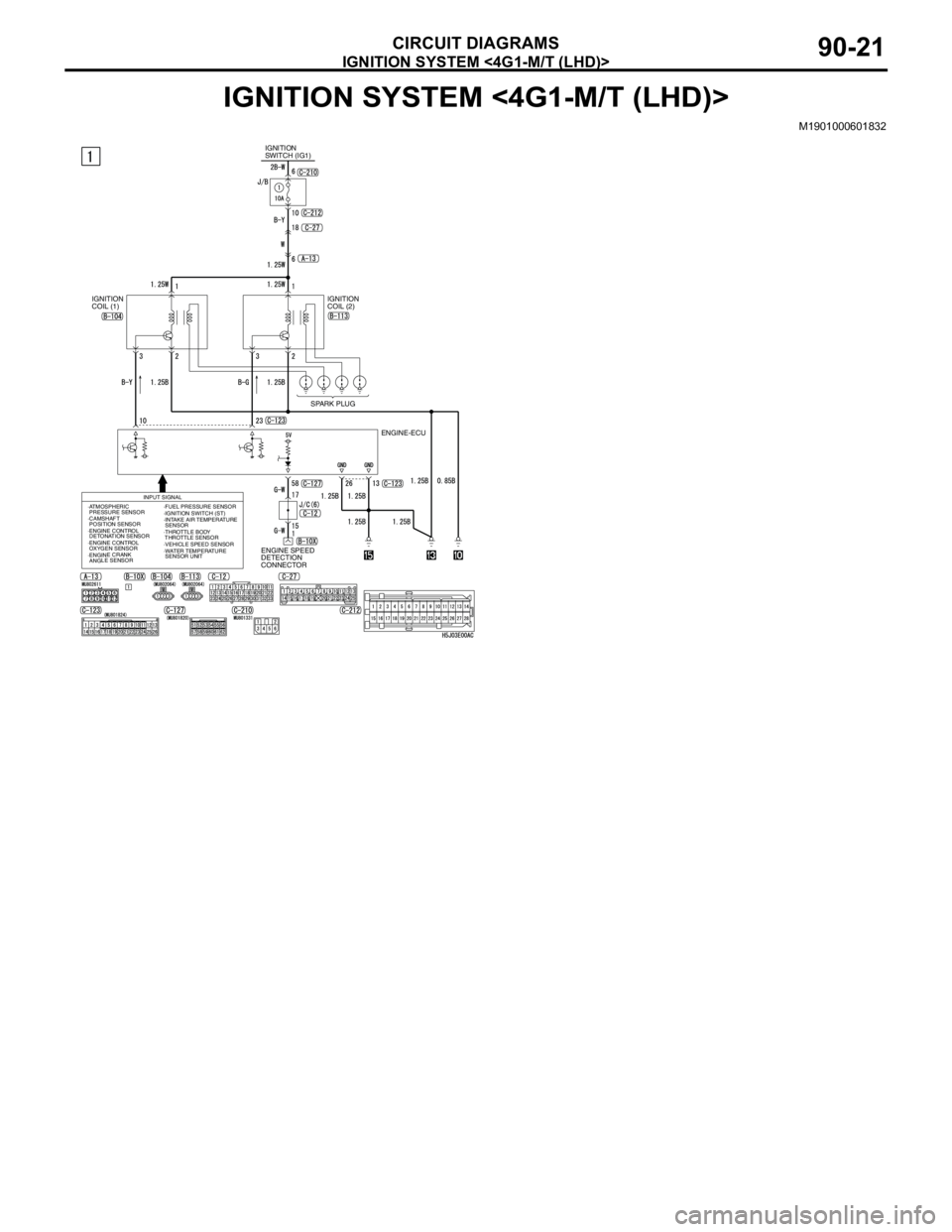

IGNITION SYSTEM <4G1-M/T (LHD)>

CIRCUIT DIAGRAMS90-21

IGNITION SYSTEM <4G1-M/T (LHD)>

M1901000601832

IGNITION

SWITCH (IG1)

IGNITION

COIL (1)IGNITION

COIL (2)

SPARK PLUG

ENGINE-ECU

ENGINE SPEED

DETECTION

CONNECTOR

INPUT SIGNAL

·ATMOSPHERIC

PRESSURE SENSOR

·CAMSHAFT

POSITION SENSOR

·ENGINE CRANK

ANGLE SENSOR·WATER TEMPERATURE

SENSOR UNIT ·ENGINE CONTROL

DETONATION SENSOR·FUEL PRESSURE SENSOR

·IGNITION SWITCH (ST)

·INTAKE AIR TEMPERATURE

SENSOR

·ENGINE CONTROL

OXYGEN SENSOR·VEHICLE SPEED SENSOR ·THROTTLE BODY

THROTTLE SENSOR

Page 660 of 788

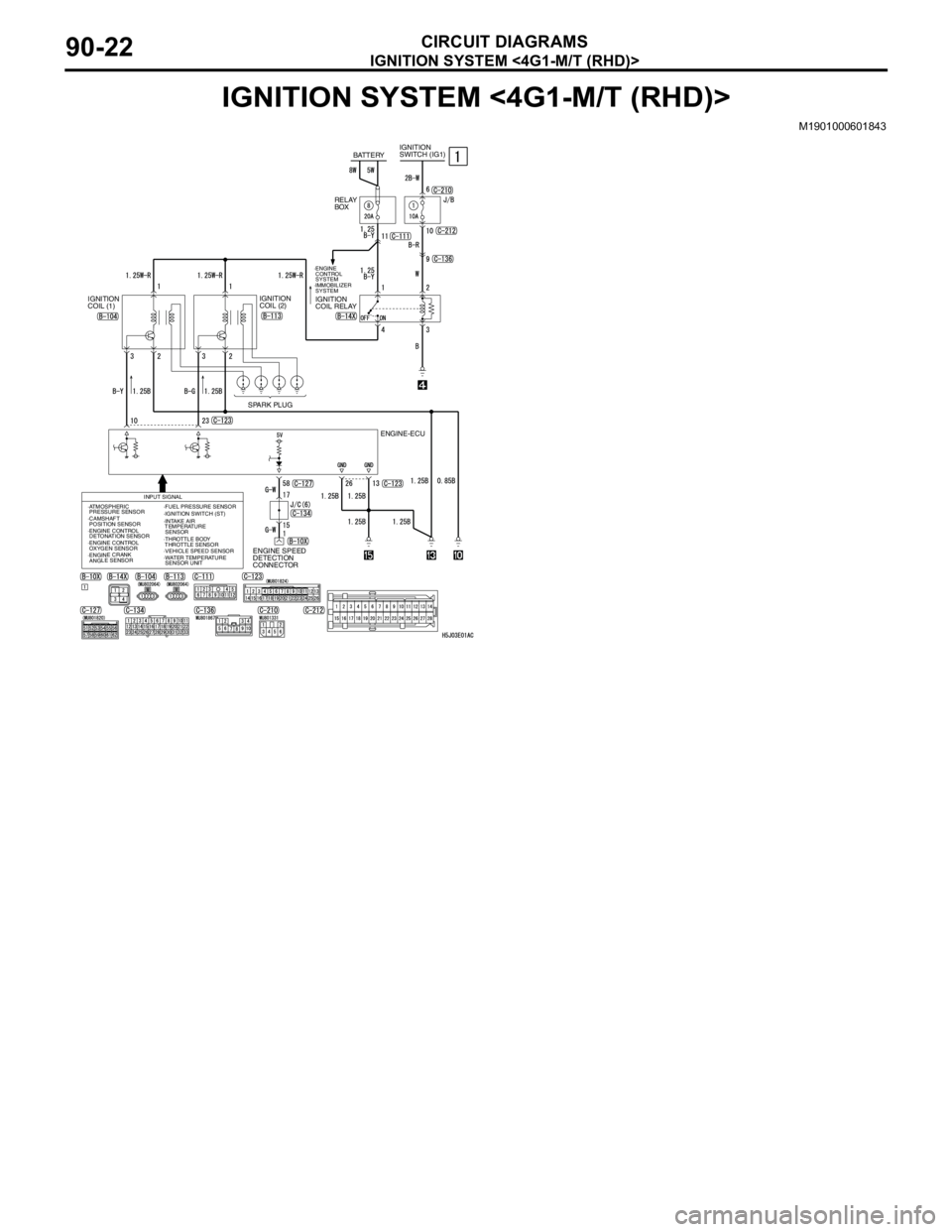

IGNITION SYSTEM <4G1-M/T (RHD)>

CIRCUIT DIAGRAMS90-22

IGNITION SYSTEM <4G1-M/T (RHD)>

M1901000601843

IGNITION

SWITCH (IG1)

IGNITION

COIL (1)IGNITION

COIL (2)

SPARK PLUG

ENGINE-ECU

ENGINE SPEED

DETECTION

CONNECTOR

INPUT SIGNAL

BATTERY

IGNITION

COIL RELAYRELAY

BOX

·ENGINE

CONTROL

SYSTEM

·IMMOBILIZER

SYSTEM

·ATMOSPHERIC

PRESSURE SENSOR

·CAMSHAFT

POSITION SENSOR

·ENGINE CRANK

ANGLE SENSOR·WATER TEMPERATURE

SENSOR UNIT ·ENGINE CONTROL

DETONATION SENSOR·FUEL PRESSURE SENSOR

·IGNITION SWITCH (ST)

·INTAKE AIR

TEMPERATURE

SENSOR

·ENGINE CONTROL

OXYGEN SENSOR

·VEHICLE SPEED SENSOR ·THROTTLE BODY

THROTTLE SENSOR