oil type MITSUBISHI LANCER 2005 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 243 of 788

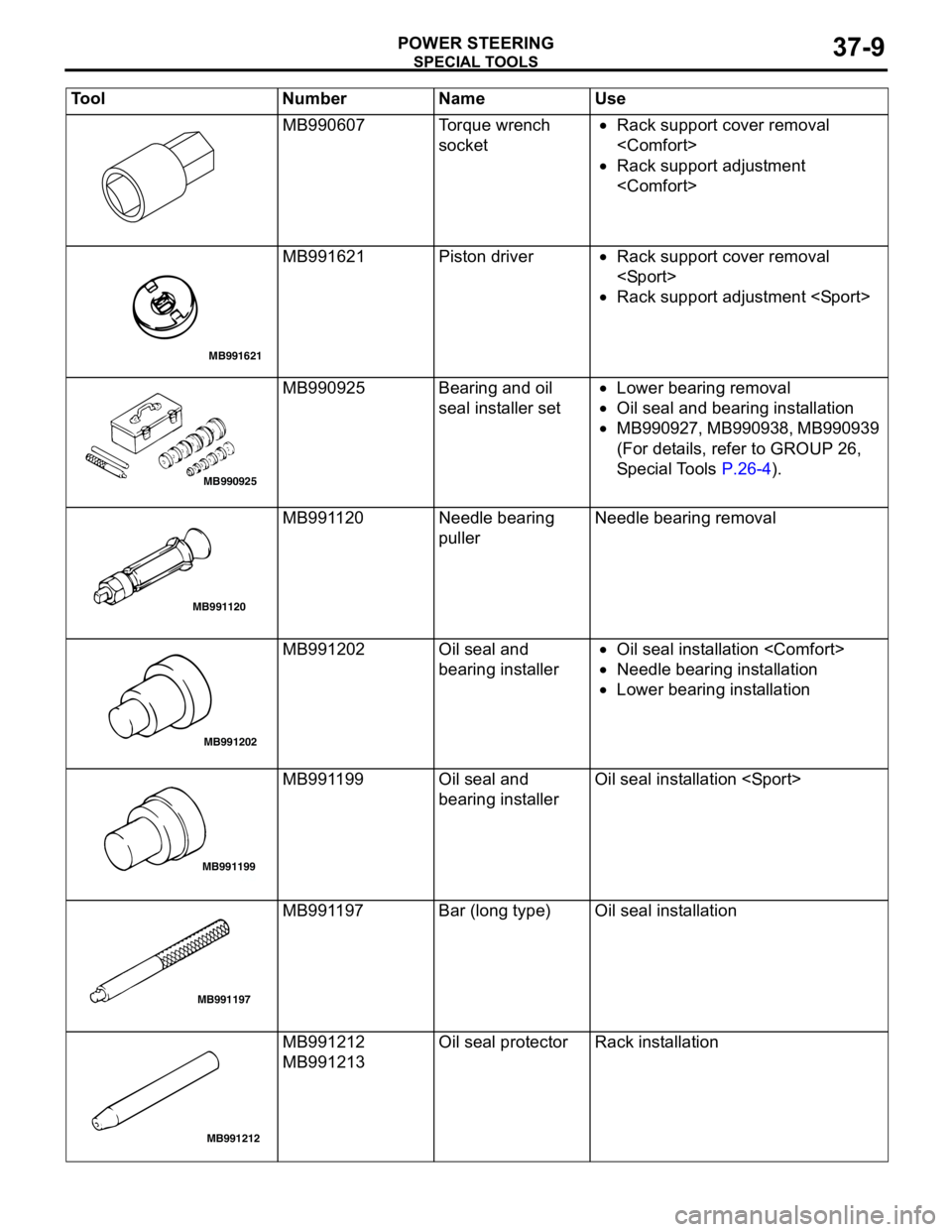

SPECIAL TOOLS

POWER STEERING37-9

MB990607 Torque wrench

socket•Rack support cover removal

•Rack support adjustment

MB991621 Piston driver•Rack support cover removal

•Rack support adjustment

MB990925 Bearing and oil

seal installer set•Lower bearing removal

•Oil seal and bearing installation

•MB990927, MB990938, MB990939

(For details, refer to GROUP 26,

Special Tools P.26-4).

MB991120 Needle bearing

pullerNeedle bearing removal

MB991202 Oil seal and

bearing installer•Oil seal installation

•Needle bearing installation

•Lower bearing installation

MB991199 Oil seal and

bearing installerOil seal installation

MB991197 Bar (long type) Oil seal installation

MB991212

MB991213Oil seal protector Rack installation Tool Number Name Use

MB991621

MB990925

MB991120

MB991202

MB991199

AB

MB991197

MB991212

Page 266 of 788

POWER STEERING GEAR BOX AND LINKAGE

POWER STEERING37-32

REASSEMBLY SERVICE POINTS

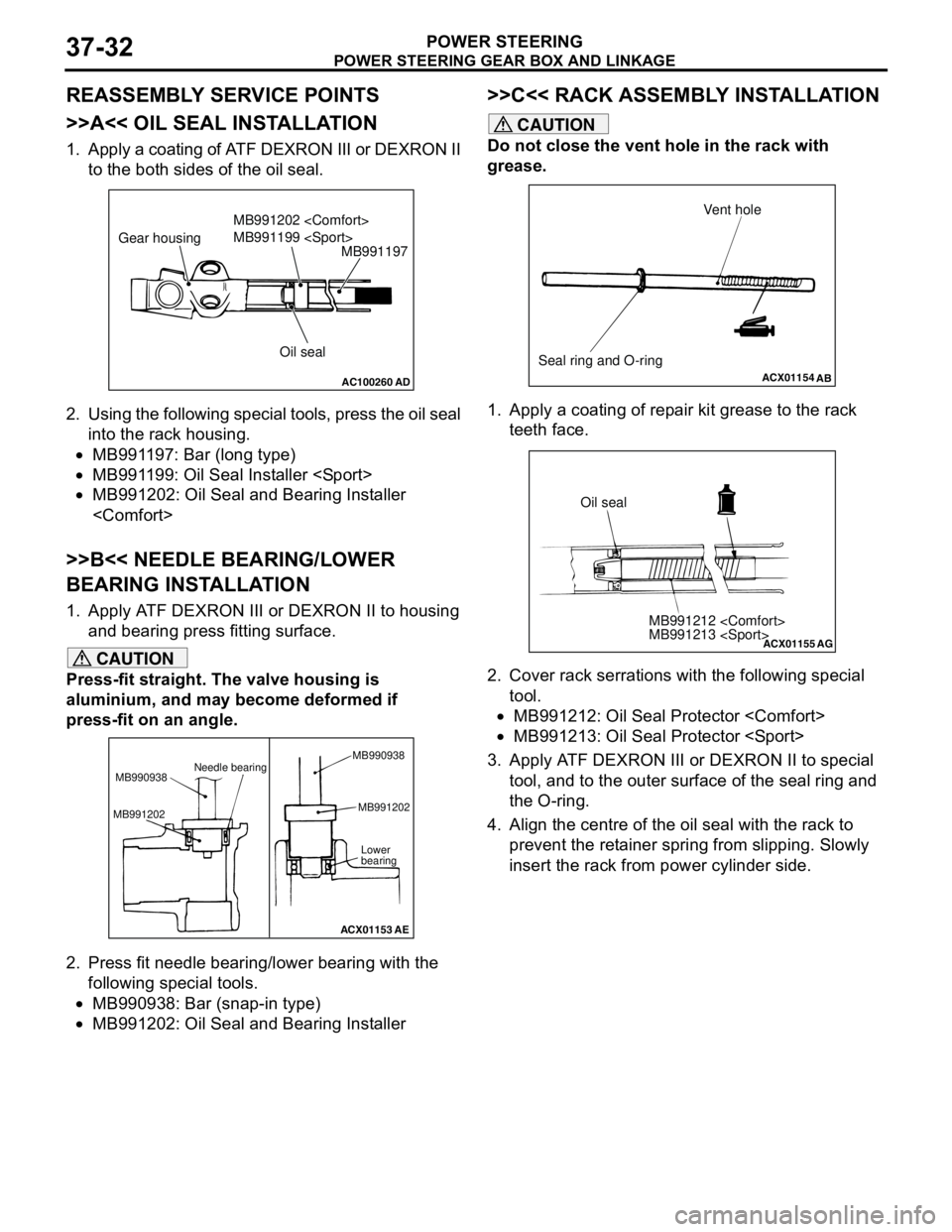

>>A<< OIL SEAL INSTALLATION

1. Apply a coating of ATF DEXRON III or DEXRON II

to the both sides of the oil seal.

2. Using the following special tools, press the oil seal

into the rack housing.

•MB991197: Bar (long type)

•MB991199: Oil Seal Installer

•MB991202: Oil Seal and Bearing Installer

>>B<< NEEDLE BEARING/LOWER

BEARING INSTALLATION

1. Apply ATF DEXRON III or DEXRON II to housing

and bearing press fitting surface.

CAUTION

Press-fit straight. The valve housing is

aluminium, and may become deformed if

press-fit on an angle.

2. Press fit needle bearing/lower bearing with the

following special tools.

•MB990938: Bar (snap-in type)

•MB991202: Oil Seal and Bearing Installer

>>C<< RACK ASSEMBLY INSTALLATION

CAUTION

Do not close the vent hole in the rack with

grease.

1. Apply a coating of repair kit grease to the rack

teeth face.

2. Cover rack serrations with the following special

tool.

•MB991212: Oil Seal Protector

•MB991213: Oil Seal Protector

3. Apply ATF DEXRON III or DEXRON II to special

tool, and to the outer surface of the seal ring and

the O-ring.

4. Align the centre of the oil seal with the rack to

prevent the retainer spring from slipping. Slowly

insert the rack from power cylinder side.

AC100260AD

MB991197

Oil seal MB991202

MB991199

Gear housing

ACX01153

Needle bearing

MB990938

MB991202MB991202

Lower

bearing

AE MB990938

ACX01154

AB

Seal ring and O-ringVent hole

ACX01155

MB991212

MB991213

AG

Oil seal

Page 267 of 788

POWER STEERING GEAR BOX AND LINKAGE

POWER STEERING37-33

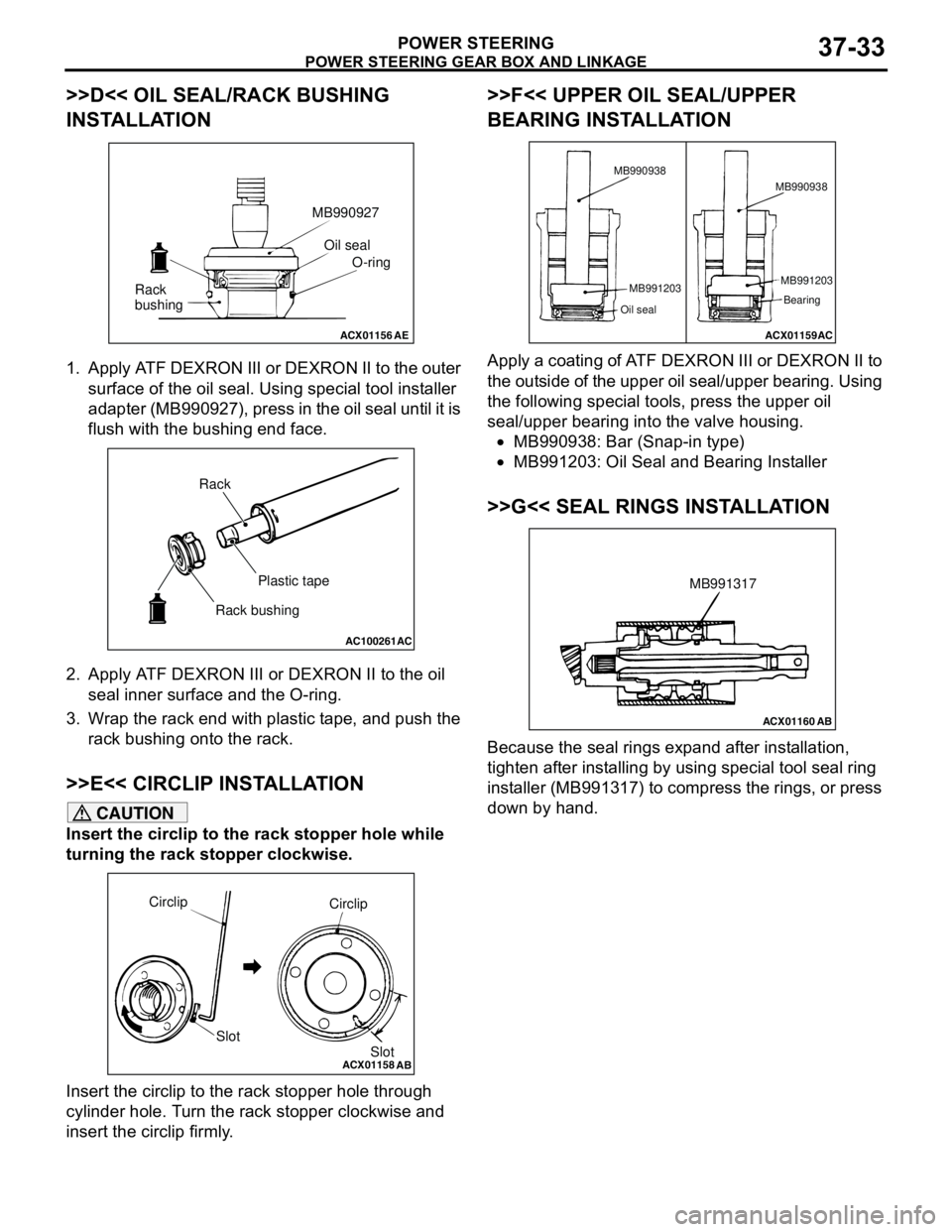

>>D<< OIL SEAL/RACK BUSHING

INSTALLATION

1. Apply ATF DEXRON III or DEXRON II to the outer

surface of the oil seal. Using special tool installer

adapter (MB990927), press in the oil seal until it is

flush with the bushing end face.

2. Apply ATF DEXRON III or DEXRON II to the oil

seal inner surface and the O-ring.

3. Wrap the rack end with plastic tape, and push the

rack bushing onto the rack.

>>E<< CIRCLIP INSTALLATION

CAUTION

Insert the circlip to the rack stopper hole while

turning the rack stopper clockwise.

Insert the circlip to the rack stopper hole through

cylinder hole. Turn the rack stopper clockwise and

insert the circlip firmly.

>>F<< UPPER OIL SEAL/UPPER

BEARING INSTALLATION

Apply a coating of ATF DEXRON III or DEXRON II to

the outside of the upper oil seal/upper bearing. Using

the following special tools, press the upper oil

seal/upper bearing into the valve housing.

•MB990938: Bar (Snap-in type)

•MB991203: Oil Seal and Bearing Installer

>>G<< SEAL RINGS INSTALLATION

Because the seal rings expand after installation,

tighten after installing by using special tool seal ring

installer (MB991317) to compress the rings, or press

down by hand.

ACX01156AE

Oil seal

O-ring MB990927

Rack

bushing

AC100261

AC

Rack

Plastic tape

Rack bushing

ACX01158

Circlip

Slot

AB

Circlip

Slot

ACX01159AC MB990938

MB991203

Oil seal

MB991203

Bearing MB990938

ACX01160AB

MB991317

Page 275 of 788

POWER STEERING OIL PUMP ASSEMBLY

POWER STEERING37-41

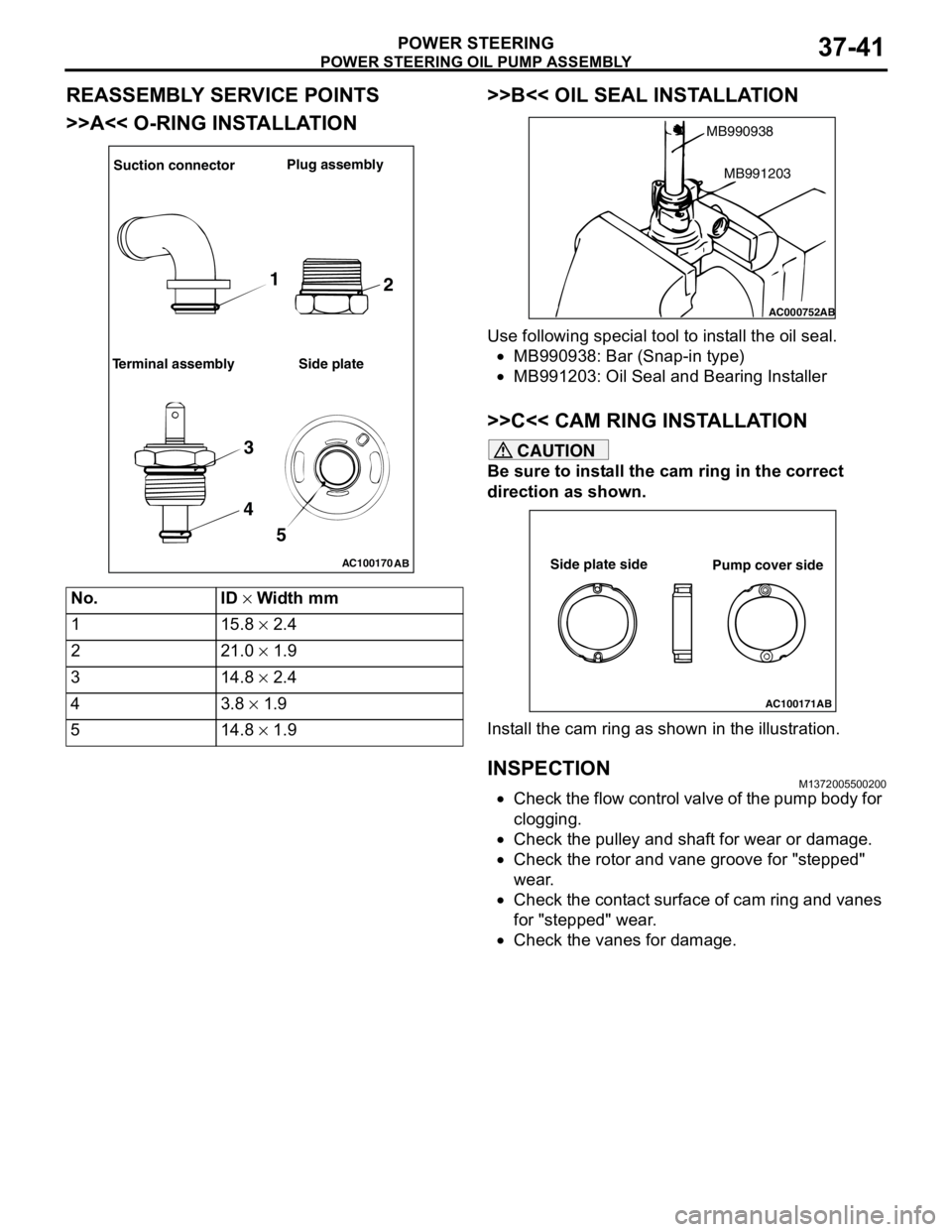

REASSEMBLY SERVICE POINTS

>>A<< O-RING INSTALLATION>>B<< OIL SEAL INSTALLATION

Use following special tool to install the oil seal.

•MB990938: Bar (Snap-in type)

•MB991203: Oil Seal and Bearing Installer

>>C<< CAM RING INSTALLATION

CAUTION

Be sure to install the cam ring in the correct

direction as shown.

Install the cam ring as shown in the illustration.

INSPECTIONM1372005500200

•Check the flow control valve of the pump body for

clogging.

•Check the pulley and shaft for wear or damage.

•Check the rotor and vane groove for "stepped"

wear.

•Check the contact surface of cam ring and vanes

for "stepped" wear.

•Check the vanes for damage. No. ID × Width mm

1 15.8 × 2.4

2 21.0 × 1.9

3 14.8 × 2.4

43.8 × 1.9

5 14.8 × 1.9

AC100170

AB

Suction connectorPlug assembly

Terminal assembly Side plate

1

2

3

4

5

AC000752

MB990938

AB

MB991203

AC100171AB

Side plate side

Pump cover side