oil type MITSUBISHI LANCER 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 8 of 788

GENERAL INFORMATION

ENGINE LUBRICATION12-2

GENERAL INFORMATION

M1121000100357

The lubrication method is a fully force-fed, full-flow

filtration type. The engine oil pump is a trochoid type

which is driven by the crankshaft <4G1>.The engine

oil pump is a gear type which is driven by the

crankshaft via the balancer timing belt <4G6>.

ENGINE OILS

Health Warning

Prolonged and repeated contact with mineral oil will

result in the removal of natural fats from the skin,

leading to dryness, irritation and dermatitis. In

addition, used engine oil contains potentially harmful

contaminants which may cause skin cancer.

Adequate means of skin protection and washing

facilities must be provided.

Recommended Precautions

The most effective precaution is to adapt working

practices which prevent, as far as practicable, the

risk of skin contact with mineral oils, for example by

using enclosed systems for handling used engine oil

and by degreasing components, where practicable,

before handling them. Other precautions:

•Avoid prolonged and repeated contact with oils,

particularly used engine oils.

•Wear protective clothing, including impervious

gloves where practicable.•Avoid contaminating clothes, particularly

underpants, with oil.

•Do not put oily rags in pockets, the use of overalls

without pockets will avoid this.

•Do not wear heavily soiled clothing and

oil-impregnated foot-wear. Overalls must be

cleaned regularly and kept separate from

personal clothing.

•Where there is a risk of eye contact, eye

protection should be worn, for example, chemical

goggles or face shields; in addition an eye wash

facility should be provided.

•Obtain first aid treatment immediately for open

cuts and wounds.

•Wash regularly with soap and water to ensure all

oil is removed, especially before meals (skin

cleansers and nail brushes will help). After

cleaning, the application of preparations

containing lanolin to replace the natural skin oils

is advised.

•Do not use petrol, kerosine, diesel fuel, gas oil,

thinners or solvents for cleaning skin.

•Use barrier creams, applying them before each

work period, to help the removal of oil from the

skin after work.

•If skin disorders develop, obtain medical advice

without delay.

SERVICE SPECIFICATION

M1121000300232

LUBRICANT

M1121000400433

Item Standard value

Oil pressure kPa at idle 29 or more

at 3,500 r/min 294 − 686

Item Specification

Engine oil ACEA classification A1, A2 or A3

Engine oil API classification SG or higher

Engine oil quantity L 4G1 Oil filter 0.3

To t a l 3 . 3

4G6 Oil filter 0.3

To t a l 4 . 3

Page 16 of 788

GENERAL INFORMATION

ENGINE COOLING14-2

GENERAL INFORMATION

M1141000100371The cooling system is designed to keep every part of

the engine at appropriate temperature in whatever

condition the engine may be operated. The cooling

method is of the water-cooled, pressure forced

circulation type in which the water pump pressurizes

coolant and circulates it throughout the engine. If the

coolant temperature exceeds the prescribed temperature, the thermostat opens to circulate the

coolant through the radiator as well so that the heat

absorbed by the coolant may be radiated into the air.

The water pump is of the centrifugal type and is

driven by the alternator drive belt from the

crankshaft. The radiator is the corrugated fin, down

flow type.

SERVICE SPECIFICATIONS

M1141000300416

LUBRICANT

M1141000400338

ItemSpecification

Radiator Performance kJ/h 4G13 Standard vehicles 137,720

Vehicles with capacity up radiator

(option)161,288

4G18 Standard vehicles 161,288

Vehicles with capacity up radiator

(option)181,800

4G63 181,800

A/T oil cooler Performance kJ/h 5,651

Item Standard value Limit

High-pressure valve opening pressure of radiator cap kPa 93 − 123 Minimum 83

Range of coolant antifreeze concentration of radiator % 30 − 60 -

Thermostat Valve opening temperature of

thermostat °C4G1 88 ± 1.5 -

4G6 82 ± 1.5 -

Full-opening temperature of

thermostat °C4G1 100 -

4G6 95 -

Valve lift mm 8.5 or more -

Item Specified coolant Quantity L

Engine coolant (including

condense tank)DIAQUEEN SUPER LONG LIFE COOLANT

or an equivalent4G1 5.0

4G6 7.0

Page 66 of 788

CHARGING SYSTEM

ENGINE ELECTRICAL16-2

CHARGING SYSTEM

GENERAL INFORMATIONM1161000100522

The charging system uses the alternator output to

keep the battery charged at a constant level under

various electrical loads.

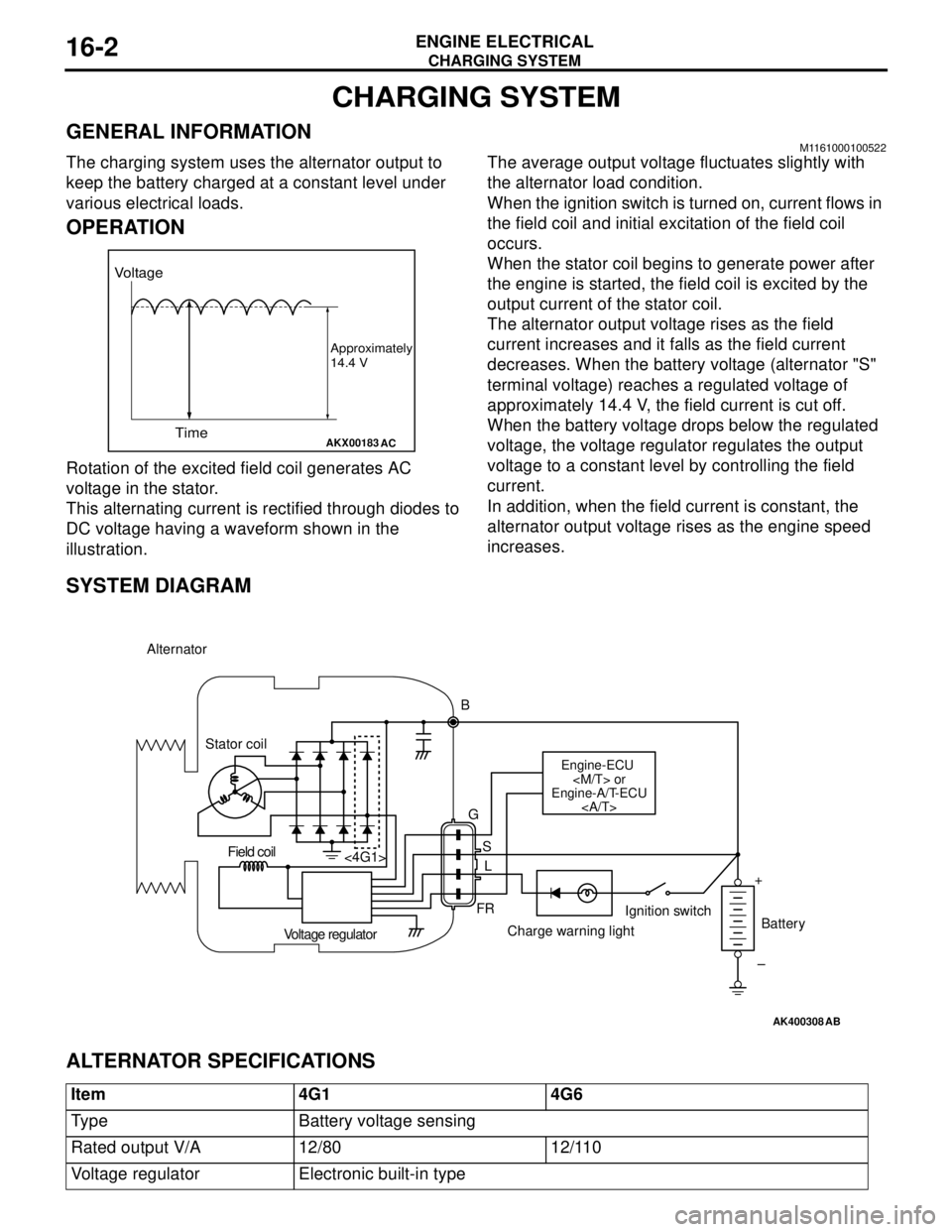

OPERATION

Rotation of the excited field coil generates AC

voltage in the stator.

This alternating current is rectified through diodes to

DC voltage having a waveform shown in the

illustration.The average output voltage fluctuates slightly with

the alternator load condition.

When the ignition switch is turned on, current flows in

the field coil and initial excitation of the field coil

occurs.

When the stator coil begins to generate power after

the engine is started, the field coil is excited by the

output current of the stator coil.

The alternator output voltage rises as the field

current increases and it falls as the field current

decreases. When the battery voltage (alternator "S"

terminal voltage) reaches a regulated voltage of

approximately 14.4 V, the field current is cut off.

When the battery voltage drops below the regulated

voltage, the voltage regulator regulates the output

voltage to a constant level by controlling the field

current.

In addition, when the field current is constant, the

alternator output voltage rises as the engine speed

increases.

SYSTEM DIAGRAM

ALTERNATOR SPECIFICATIONS

AKX00183

Voltage

Time

Approximately

14.4 V

AC

AK400308

Alternator

B

Stator coil

Engine-ECU

Engine-A/T-ECU

G

S

L

FR <4G1>

Voltage regulatorCharge warning lightIgnition switch

Battery Field coil

+

–

AB

Item 4G1 4G6

Type Battery voltage sensing

Rated output V/A 12/80 12/110

Voltage regulator Electronic built-in type

Page 95 of 788

IGNITION SYSTEM

ENGINE ELECTRICAL16-31

IGNITION COIL SPECIFICATION

SPARK PLUG SPECIFICATIONS

SERVICE SPECIFICATIONS

M1163000300180

IGNITION COIL

SPARK PLUG

RESISTIVE CORD

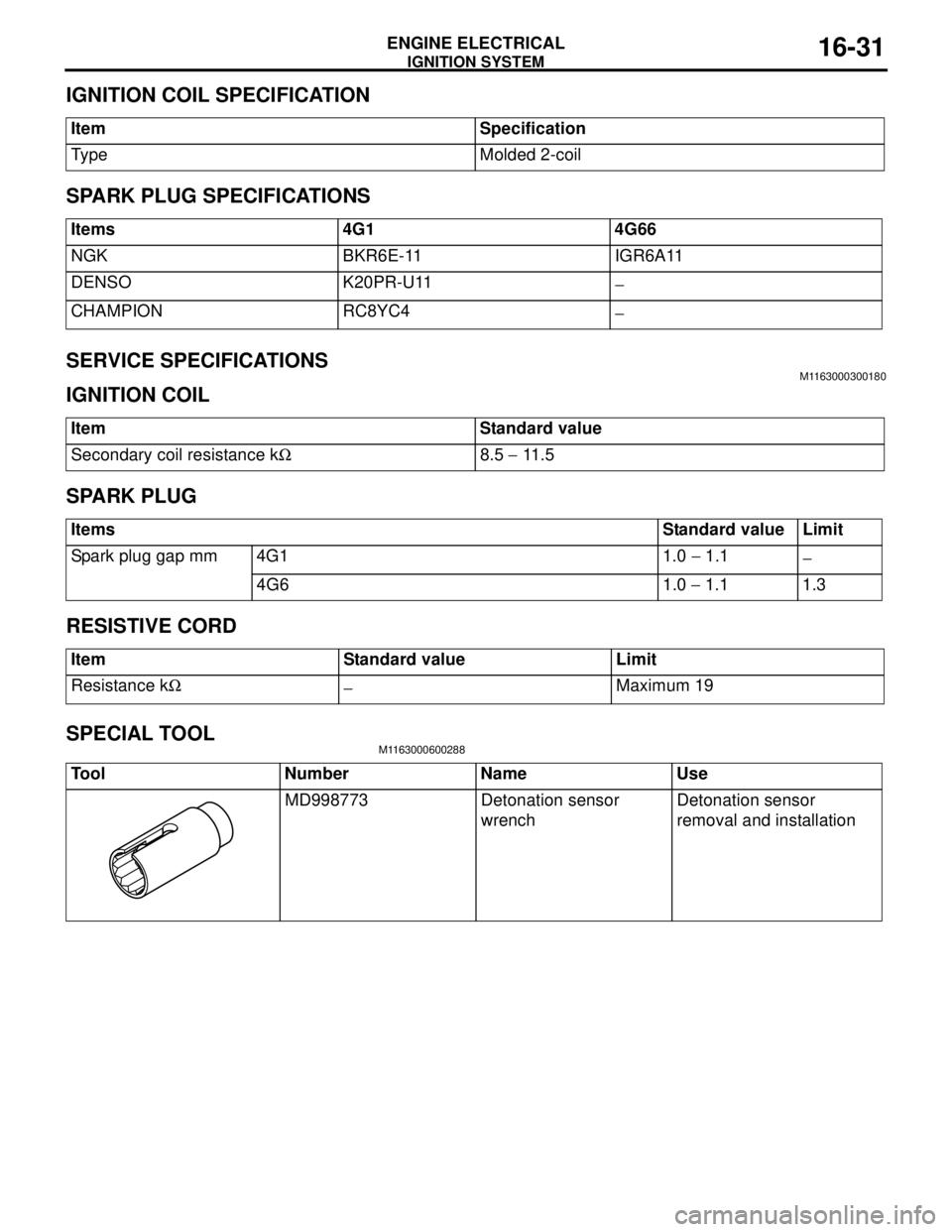

SPECIAL TOOL

M1163000600288

Item Specification

Type Molded 2-coil

Items 4G1 4G66

NGK BKR6E-11 IGR6A11

DENSO K20PR-U11

−

CHAMPION RC8YC4

−

Item Standard value

Secondary coil resistance kΩ8.5 − 11 . 5

ItemsStandard value Limit

Spark plug gap mm 4G1 1.0 − 1.1

−

4G6 1.0 − 1.1 1.3

Item Standard value Limit

Resistance kΩ

−Maximum 19

Tool Number Name Use

MD998773 Detonation sensor

wrenchDetonation sensor

removal and installation

Page 96 of 788

IGNITION SYSTEM

ENGINE ELECTRICAL16-32

ON-VEHICLE SERVICE

IGNITION COIL (WITH BUILT-IN POWER

TRANSISTOR) CHECK

M1163001200324

Check by the following procedure, and replace if

there is a malfunction.

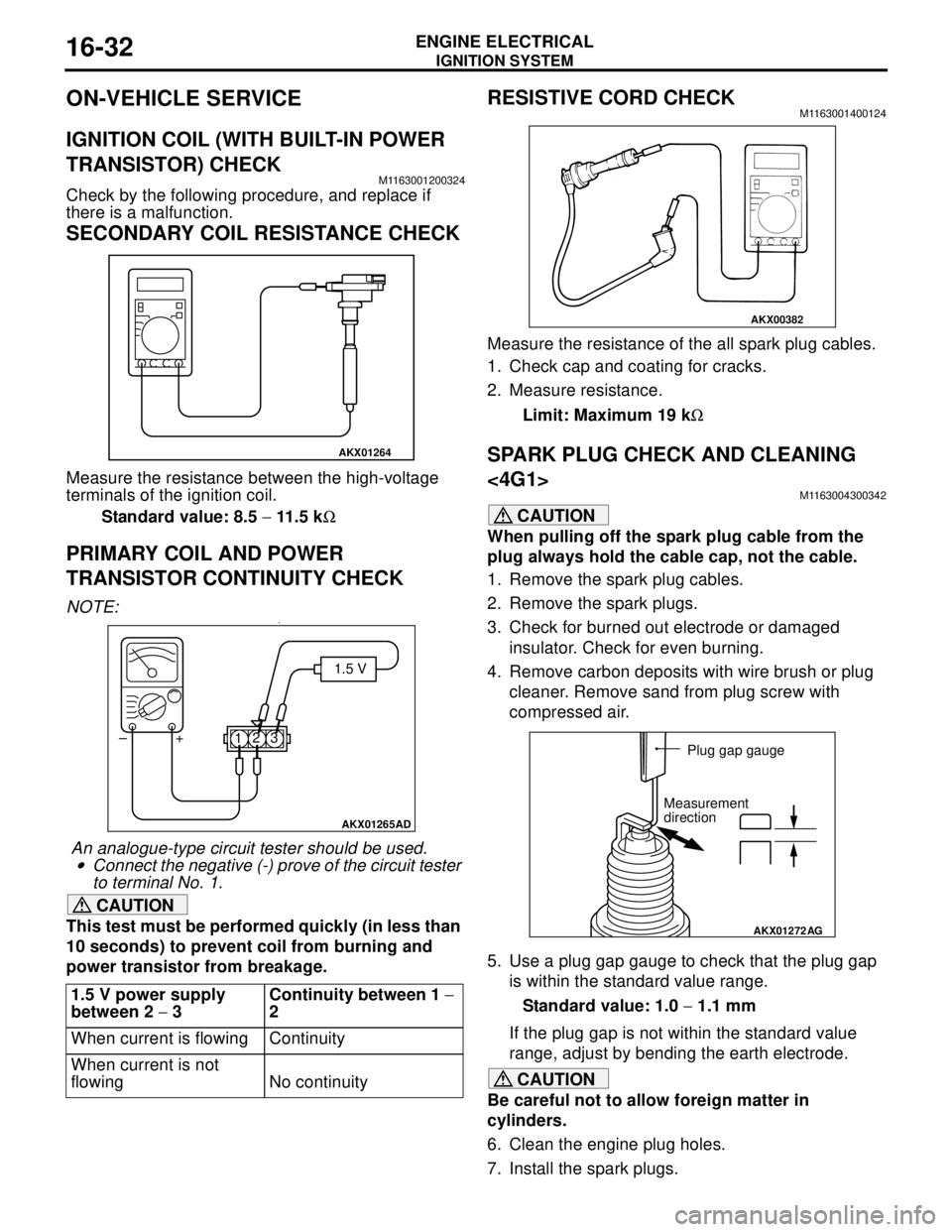

SECONDARY COIL RESISTANCE CHECK

Measure the resistance between the high-voltage

terminals of the ignition coil.

Standard value: 8.5 − 11.5 kΩ

PRIMARY COIL AND POWER

TRANSISTOR CONTINUITY CHECK

NOTE: .•

An analogue-type circuit tester should be used.

•Connect the negative (-) prove of the circuit tester

to terminal No. 1.

CAUTION

This test must be performed quickly (in less than

10 seconds) to prevent coil from burning and

power transistor from breakage.

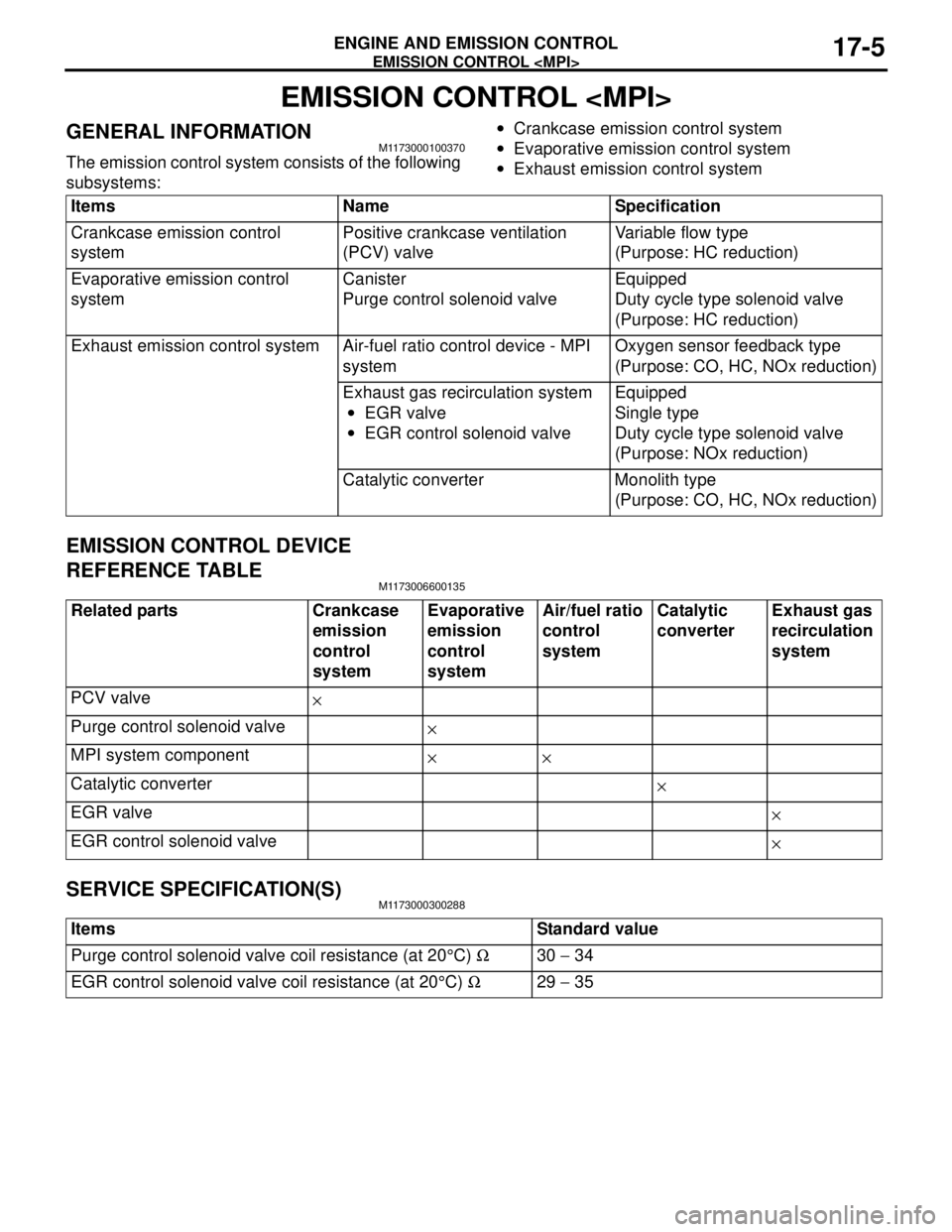

RESISTIVE CORD CHECKM1163001400124

Measure the resistance of the all spark plug cables.

1. Check cap and coating for cracks.

2. Measure resistance.

Limit: Maximum 19 kΩ

SPARK PLUG CHECK AND CLEANING

<4G1>

M1163004300342

CAUTION

When pulling off the spark plug cable from the

plug always hold the cable cap, not the cable.

1. Remove the spark plug cables.

2. Remove the spark plugs.

3. Check for burned out electrode or damaged

insulator. Check for even burning.

4. Remove carbon deposits with wire brush or plug

cleaner. Remove sand from plug screw with

compressed air.

5. Use a plug gap gauge to check that the plug gap

is within the standard value range.

Standard value: 1.0 − 1.1 mm

If the plug gap is not within the standard value

range, adjust by bending the earth electrode.

CAUTION

Be careful not to allow foreign matter in

cylinders.

6. Clean the engine plug holes.

7. Install the spark plugs. 1.5 V power supply

between 2 − 3Continuity between 1 −

2

When current is flowing Continuity

When current is not

flowing No continuity

AKX01264

AKX01265AD

1.5 V

123 +

–

AKX00382

AKX01272

AG

Plug gap gauge

Measurement

direction

Page 113 of 788

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-5

EMISSION CONTROL

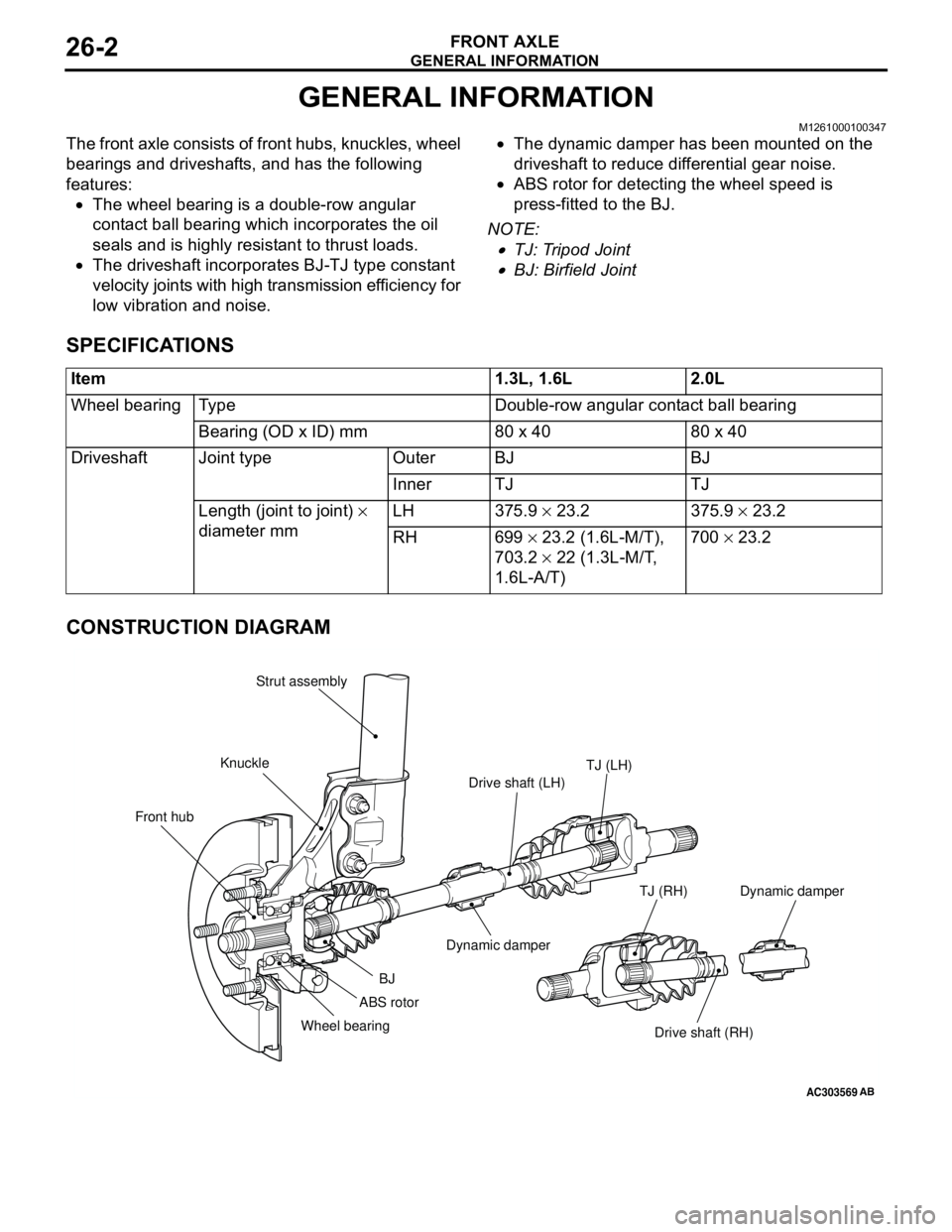

GENERAL INFORMATIONM1173000100370

The emission control system consists of the following

subsystems:•Crankcase emission control system

•Evaporative emission control system

•Exhaust emission control system

EMISSION CONTROL DEVICE

REFERENCE TABLE

M1173006600135

SERVICE SPECIFICATION(S)M1173000300288

Items Name Specification

Crankcase emission control

systemPositive crankcase ventilation

(PCV) valveVariable flow type

(Purpose: HC reduction)

Evaporative emission control

systemCanister

Purge control solenoid valveEquipped

Duty cycle type solenoid valve

(Purpose: HC reduction)

Exhaust emission control system Air-fuel ratio control device - MPI

systemOxygen sensor feedback type

(Purpose: CO, HC, NOx reduction)

Exhaust gas recirculation system

•EGR valve

•EGR control solenoid valveEquipped

Single type

Duty cycle type solenoid valve

(Purpose: NOx reduction)

Catalytic converter Monolith type

(Purpose: CO, HC, NOx reduction)

Related parts Crankcase

emission

control

systemEvaporative

emission

control

systemAir/fuel ratio

control

systemCatalytic

converterExhaust gas

recirculation

system

PCV valve

×

Purge control solenoid valve

×

MPI system component

××

Catalytic converter

×

EGR valve

×

EGR control solenoid valve

×

Items Standard value

Purge control solenoid valve coil resistance (at 20°C) Ω30 − 34

EGR control solenoid valve coil resistance (at 20°C) Ω29 − 35

Page 134 of 788

GENERAL INFORMATION

FRONT AXLE26-2

GENERAL INFORMATION

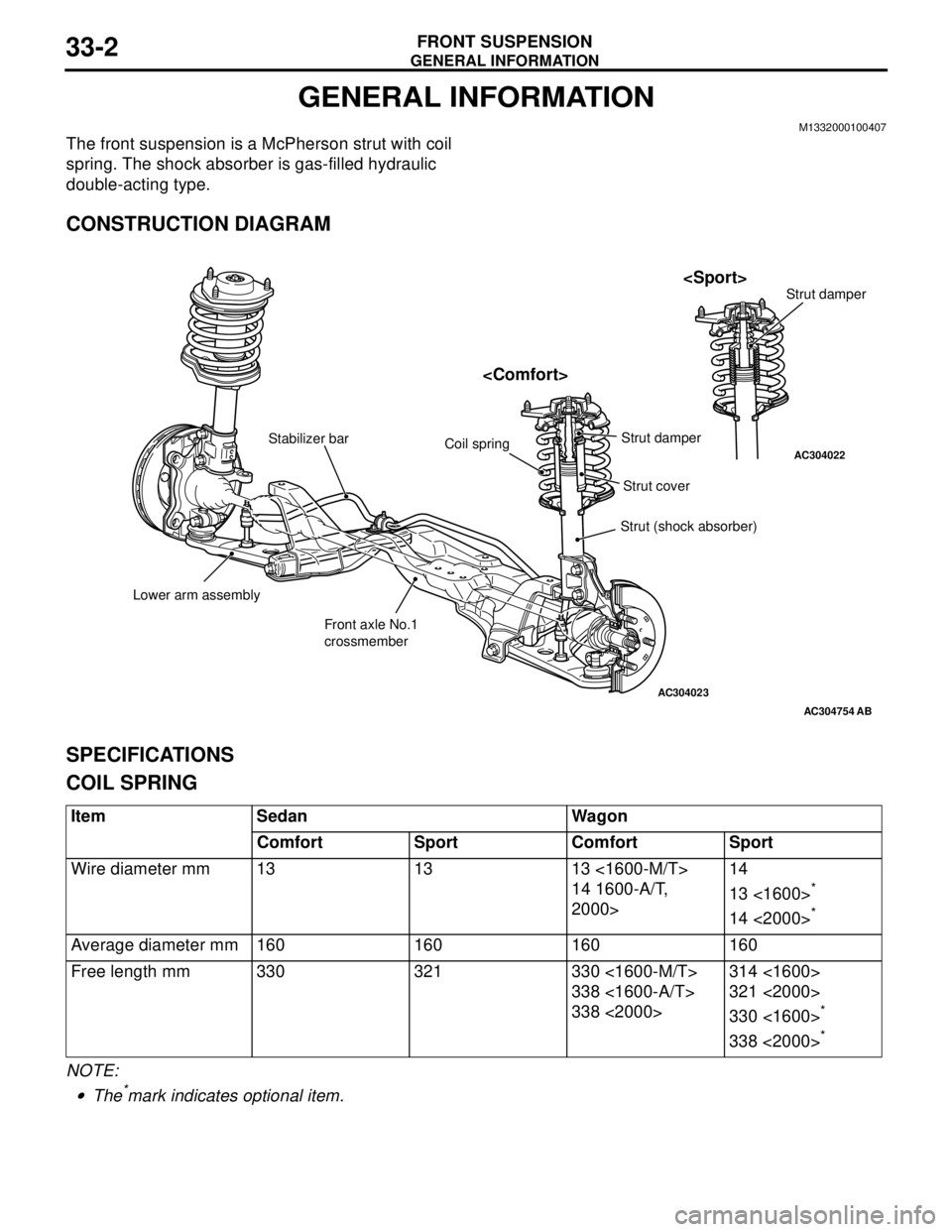

M1261000100347

The front axle consists of front hubs, knuckles, wheel

bearings and driveshafts, and has the following

features:

•The wheel bearing is a double-row angular

contact ball bearing which incorporates the oil

seals and is highly resistant to thrust loads.

•The driveshaft incorporates BJ-TJ type constant

velocity joints with high transmission efficiency for

low vibration and noise.•The dynamic damper has been mounted on the

driveshaft to reduce differential gear noise.

•ABS rotor for detecting the wheel speed is

press-fitted to the BJ.

NOTE: .

•TJ: Tripod Joint

•BJ: Birfield Joint

SPECIFICATIONS

CONSTRUCTION DIAGRAM

Item 1.3L, 1.6L 2.0L

Wheel bearing Type Double-row angular contact ball bearing

Bearing (OD x ID) mm 80 x 40 80 x 40

Driveshaft Joint type Outer BJ BJ

Inner TJ TJ

Length (joint to joint) ×

diameter mm LH 375.9 × 23.2 375.9 × 23.2

RH 699 × 23.2 (1.6L-M/T),

703.2 × 22 (1.3L-M/T,

1.6L-A/T)700 × 23.2

AC303569

Front hubKnuckleStrut assembly

TJ (LH)

Drive shaft (LH)

Dynamic damper

BJ

Wheel bearing

Drive shaft (RH) TJ (RH)

AB

ABS rotorDynamic damper

Page 184 of 788

GENERAL INFORMATION

FRONT SUSPENSION33-2

GENERAL INFORMATION

M1332000100407

The front suspension is a McPherson strut with coil

spring. The shock absorber is gas-filled hydraulic

double-acting type.

CONSTRUCTION DIAGRAM

SPECIFICATIONS

COIL SPRING

NOTE: .

•The*mark indicates optional item.

AC304023

AC304022

AC304754

Lower arm assembly

Front axle No.1

crossmember Stabilizer bar

Strut (shock absorber) Coil spring

AB

Strut cover Strut damper

Item Sedan Wagon

Comfort Sport Comfort Sport

Wire diameter mm 13 13 13 <1600-M/T>

14 1600-A/T,

2000>14

13 <1600>

*

14 <2000>*

Average diameter mm 160 160 160 160

Free length mm 330 321 330 <1600-M/T>

338 <1600-A/T>

338 <2000>314 <1600>

321 <2000>

330 <1600>

*

338 <2000>*

Page 202 of 788

GENERAL INFORMATION

REAR SUSPENSION34-2

GENERAL INFORMATION

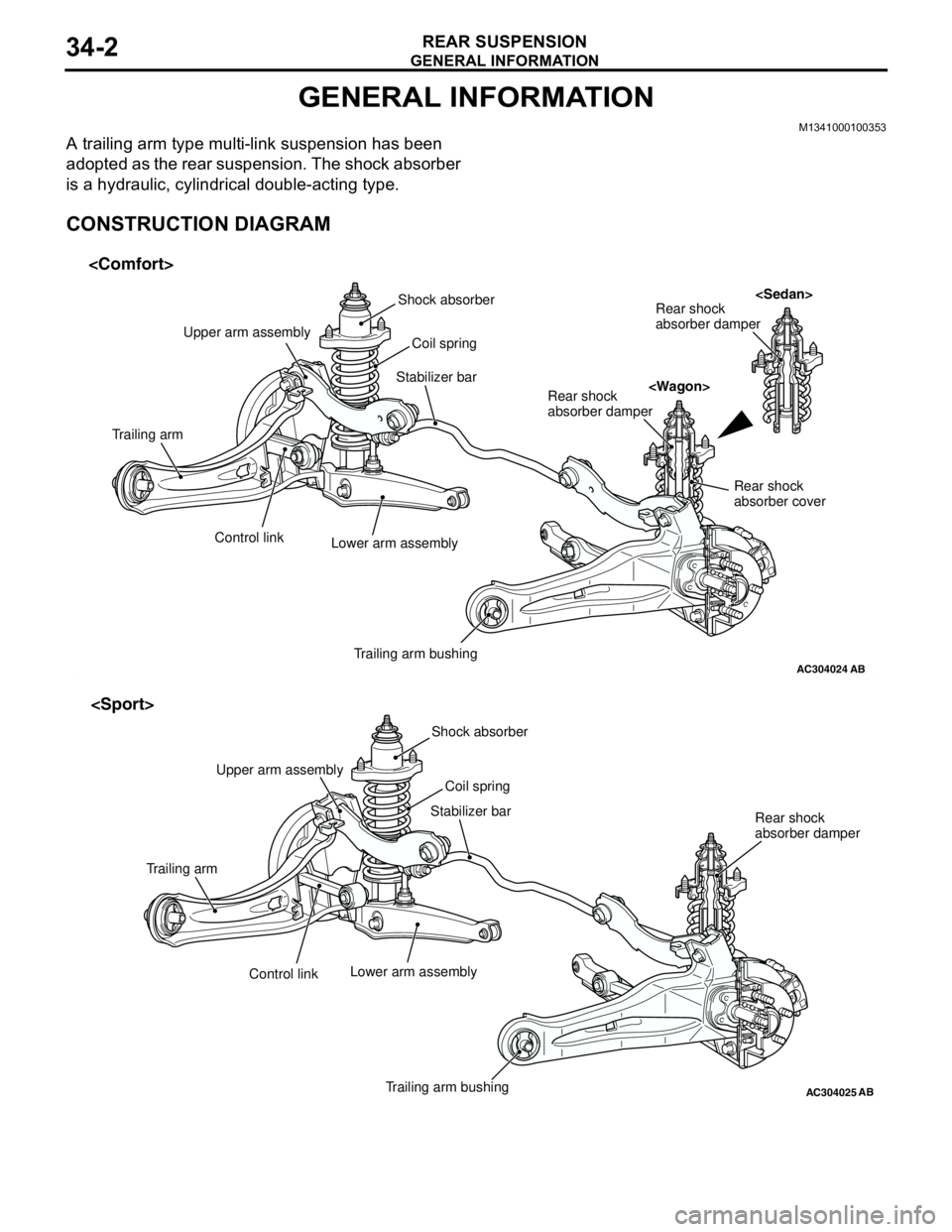

M1341000100353

A trailing arm type multi-link suspension has been

adopted as the rear suspension. The shock absorber

is a hydraulic, cylindrical double-acting type.

CONSTRUCTION DIAGRAM

AC304024AB

Shock absorber

Coil spring

Trailing arm bushing Lower arm assembly Control link Trailing armUpper arm assembly

Stabilizer barRear shock

absorber damper

Rear shock

absorber damper

Rear shock

absorber cover

AC304025AB

Shock absorber

Trailing arm bushing Control link Trailing armStabilizer bar

Coil spring

Lower arm assembly

Rear shock

absorber damper Upper arm assembly

Page 237 of 788

GENERAL INFORMATION

POWER STEERING37-3

GENERAL INFORMATION

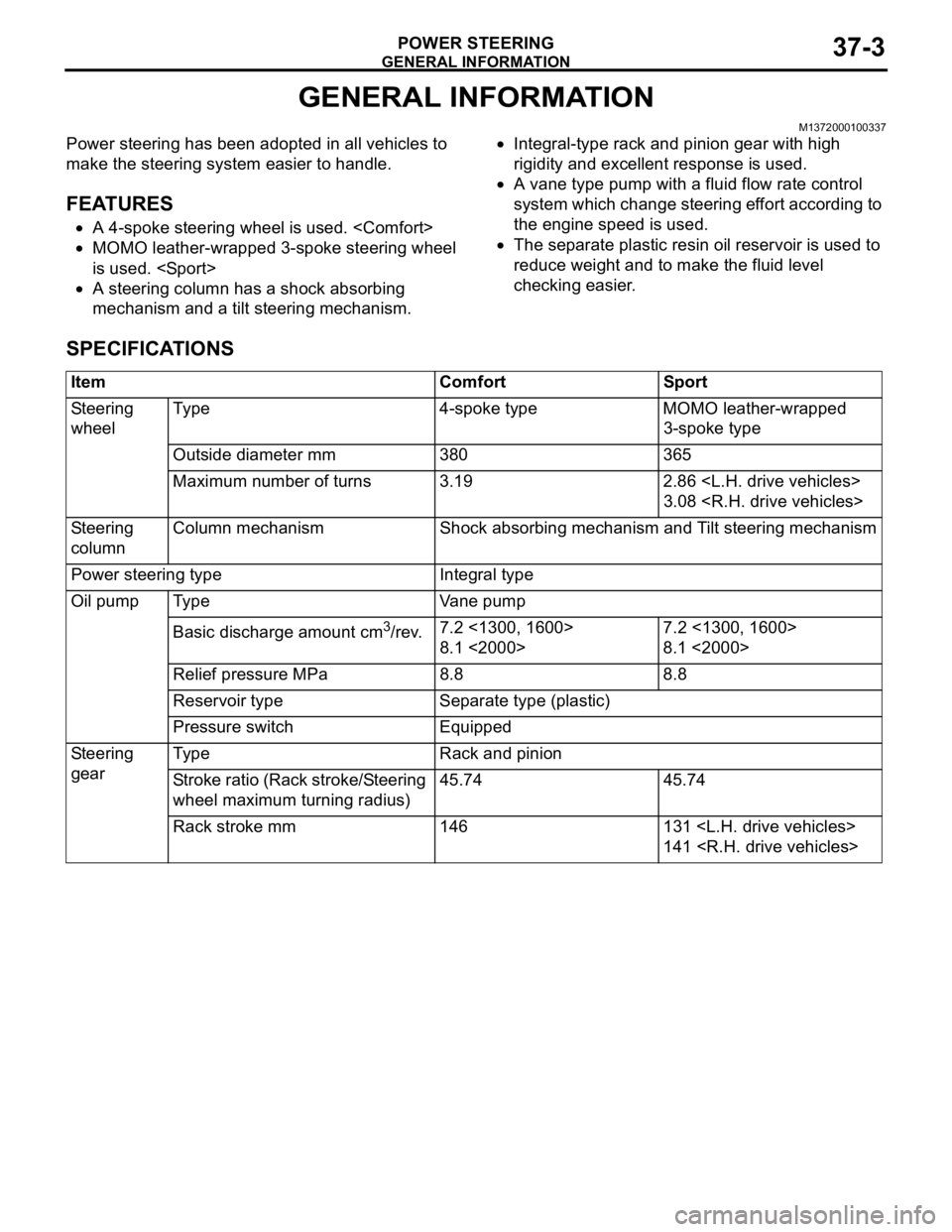

M1372000100337

Power steering has been adopted in all vehicles to

make the steering system easier to handle.

FEATURES

•A 4-spoke steering wheel is used.

•MOMO leather-wrapped 3-spoke steering wheel

is used.

•A steering column has a shock absorbing

mechanism and a tilt steering mechanism.•Integral-type rack and pinion gear with high

rigidity and excellent response is used.

•A vane type pump with a fluid flow rate control

system which change steering effort according to

the engine speed is used.

•The separate plastic resin oil reservoir is used to

reduce weight and to make the fluid level

checking easier.

SPECIFICATIONS

Item Comfort Sport

Steering

wheelType 4-spoke type MOMO leather-wrapped

3-spoke type

Outside diameter mm 380 365

Maximum number of turns 3.19 2.86

3.08

Steering

columnColumn mechanism Shock absorbing mechanism and Tilt steering mechanism

Power steering type Integral type

Oil pump Type Vane pump

Basic discharge amount cm

3/rev.7.2 <1300, 1600>

8.1 <2000>7.2 <1300, 1600>

8.1 <2000>

Relief pressure MPa 8.8 8.8

Reservoir type Separate type (plastic)

Pressure switch Equipped

Steering

gearType Rack and pinion

Stroke ratio (Rack stroke/Steering

wheel maximum turning radius)45.74 45.74

Rack stroke mm 146 131

141