ect MITSUBISHI LANCER 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 355 of 788

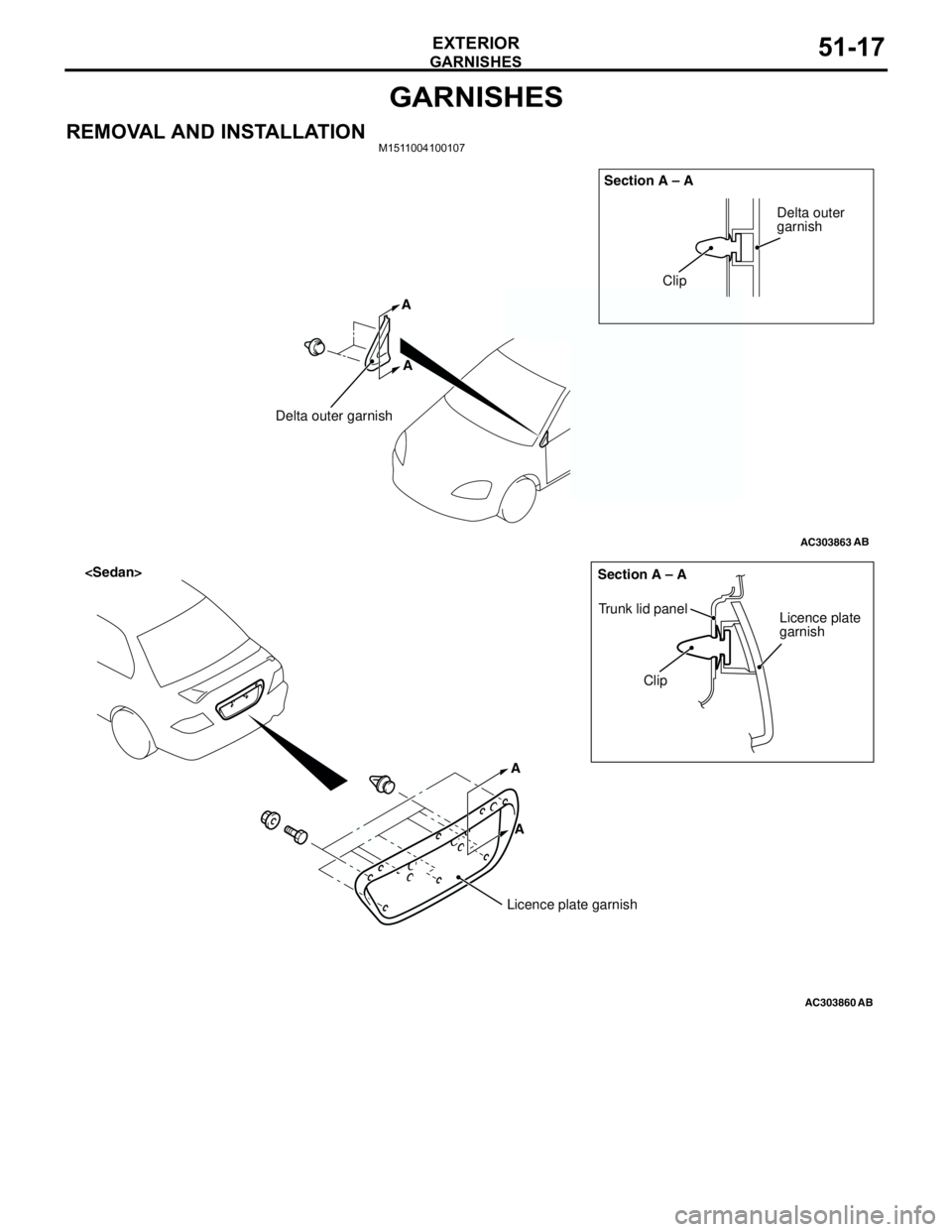

GARNISHES

EXTERIOR51-17

GARNISHES

REMOVAL AND INSTALLATIONM1511004100107

AC303863

Clip

Delta outer garnishSection A – A

AB

Delta outer

garnish

A A

AC303860

A A

Clip Trunk lid panel

Licence plate

garnish Section A – A

AB

Licence plate garnish

Page 356 of 788

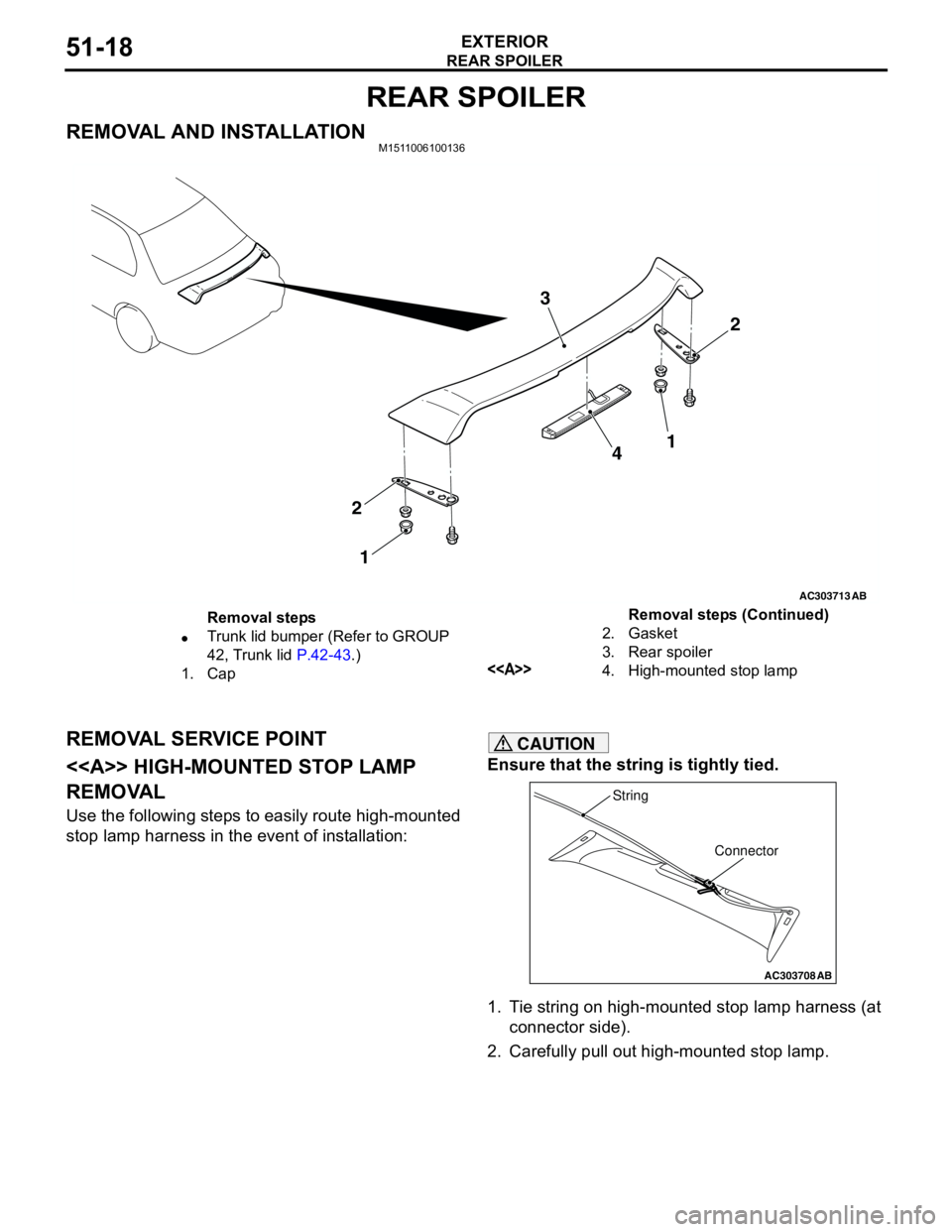

REAR SPOILER

EXTERIOR51-18

REAR SPOILER

REMOVAL AND INSTALLATIONM1511006100136

REMOVAL SERVICE POINT

<> HIGH-MOUNTED STOP LAMP

REMOVAL

Use the following steps to easily route high-mounted

stop lamp harness in the event of installation:

CAUTION

Ensure that the string is tightly tied.

1. Tie string on high-mounted stop lamp harness (at

connector side).

2. Carefully pull out high-mounted stop lamp.

AC303713

2 3

4

2

1

AB

1

Removal steps

•Trunk lid bumper (Refer to GROUP

42, Trunk lid P.42-43.)

1. Cap2. Gasket

3. Rear spoiler

<>4. High-mounted stop lampRemoval steps (Continued)

AC303708

Connector String

AB

Page 357 of 788

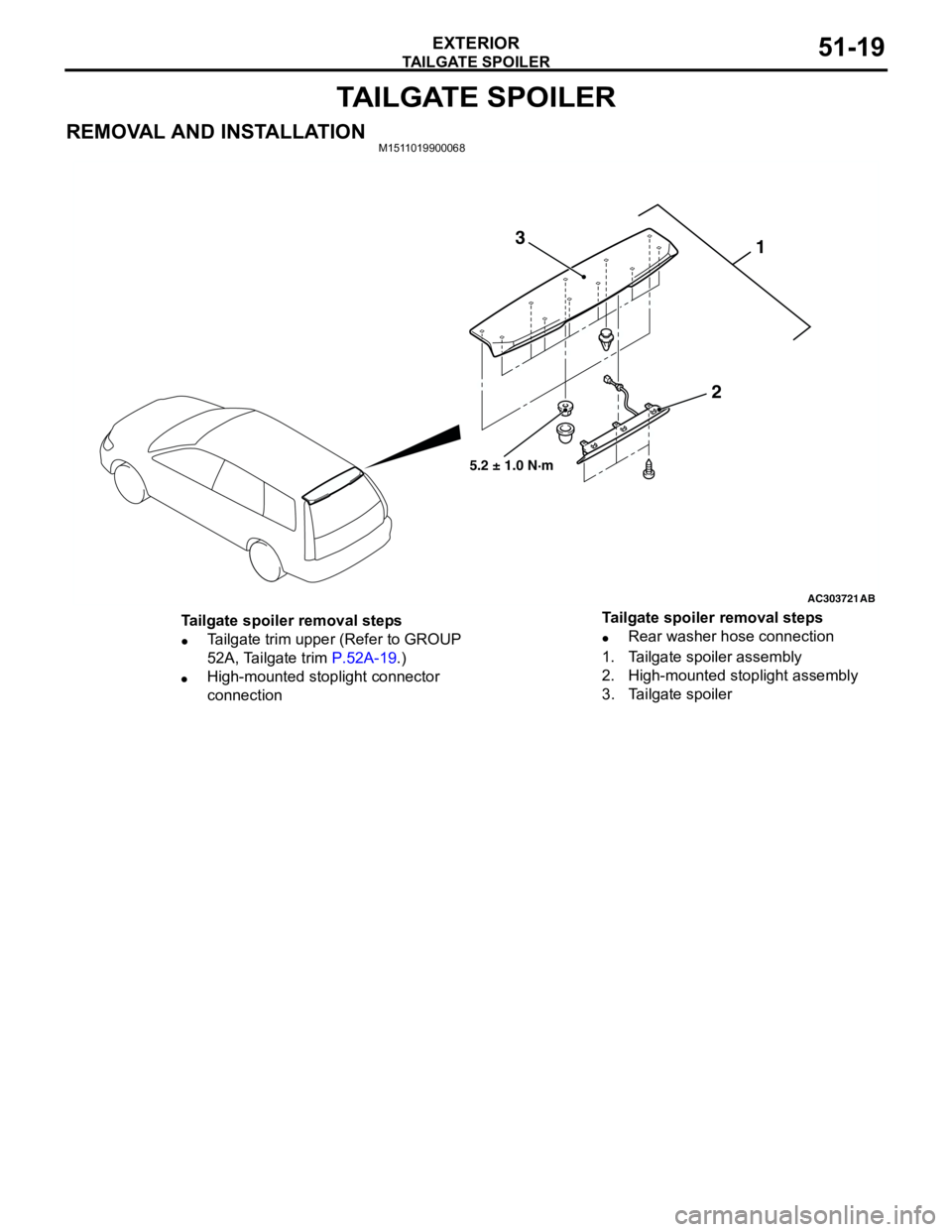

TAILGATE SPOILER

EXTERIOR51-19

TAILGATE SPOILER

REMOVAL AND INSTALLATIONM1511019900068

AC303721

1

2 3

AB

5.2 ± 1.0 N·m

Tailgate spoiler removal steps

•Tailgate trim upper (Refer to GROUP

52A, Tailgate trim P.52A-19.)

•High-mounted stoplight connector

connection•Rear washer hose connection

1. Tailgate spoiler assembly

2. High-mounted stoplight assembly

3. Tailgate spoiler Tailgate spoiler removal steps

Page 358 of 788

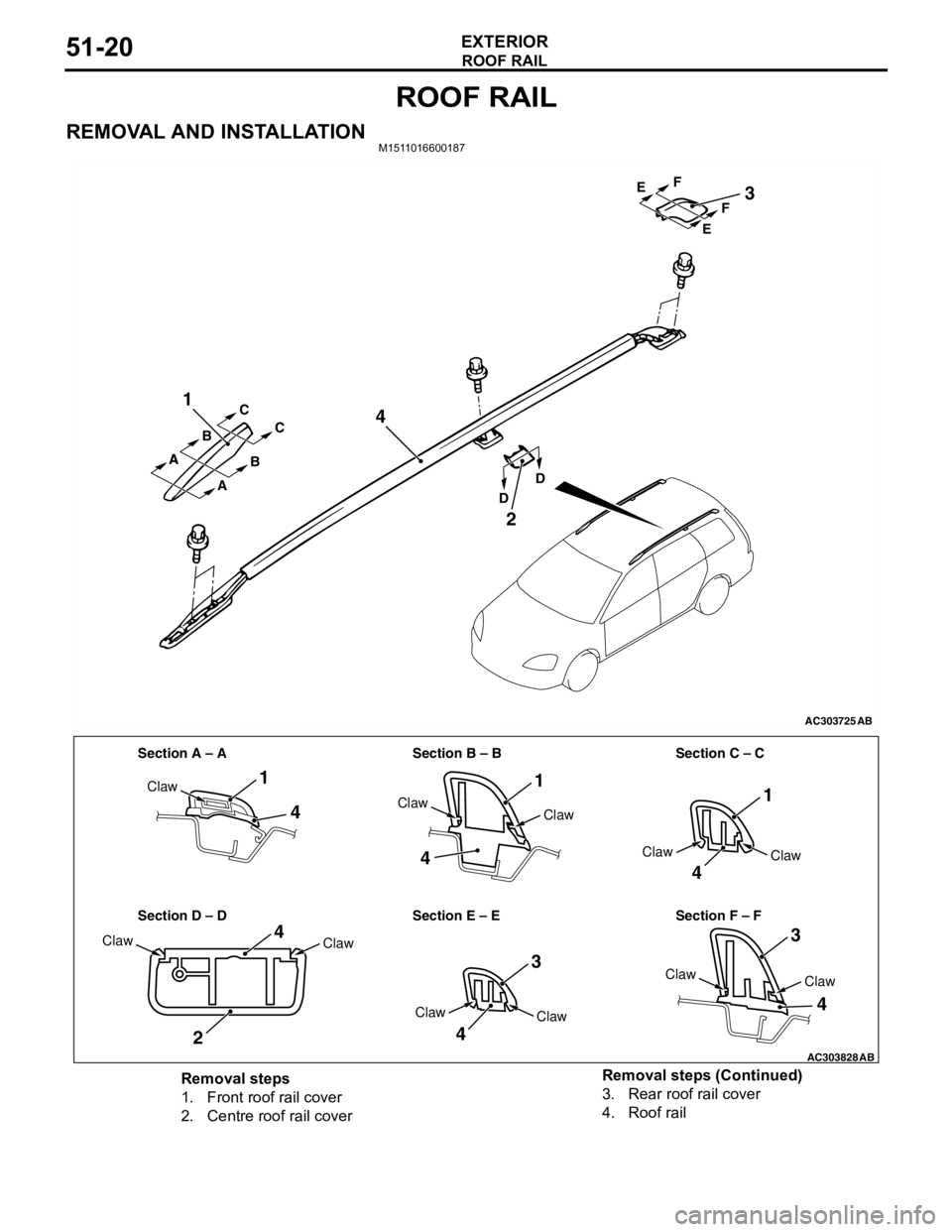

ROOF RAIL

EXTERIOR51-20

ROOF RAIL

REMOVAL AND INSTALLATIONM1511016600187

AC303725

1

4

2

3

AB

A A

A BC

C

B

DDEF EF

AC303828

Section A – A Section B – B Section C – C

Section D – D Section E – E Section F – F

1

4

4

11

4

3

3

4

4

2

4

Claw

Claw

Claw

Claw

Claw

Claw

ClawClaw

Claw

Claw

Claw

AB

Removal steps

1. Front roof rail cover

2. Centre roof rail cover3. Rear roof rail cover

4. Roof rail Removal steps (Continued)

Page 360 of 788

WINDSHIELD WIPER AND WASHER

EXTERIOR51-22

SERVICE SPECIFICATIONM1511000300325

TROUBLESHOOTINGM1511000700323

The windshield wiper and washer are controlled by

the Smart Wiring System (SWS). For

troubleshooting, refer to GROUP 54B,

Troubleshooting P.54B-17 or GROUP 54C,

Troubleshooting P.54C-4.

NOTE: Even when the ETACS-ECU has failed, the

windshield wiper can work at low speed as fail-safe

mode. (Normally, the windshield wiper operates

when the ignition switch is at the "ACC" position. But,

if it enters the fail-safe mode, the wiper can operate

only when the ignition switch is at the "ON" position.)

ON-VEHICLE SERVICEM1511000800461

WINDSHIELD INTERMITTENT WIPER

INSPECTION

1. If the windshield intermittent wiper interval

adjusting knob is operated, the wiper interval

should change.

2. Holding the windshield intermittent wiper interval

adjusting knob, input the simulated vehicle speed

with MUT-II MB991502 and check that the wiper

interval changes as the vehicle speed changes.

3. If not, carry out the troubleshooting (Refer to

GROUP 54B, Troubleshooting P.54B-17 or

GROUP 54C, Troubleshooting P.54C-4). ItemStandard value

Windshield wiper blade park position mm 34 ± 5

Page 361 of 788

WINDSHIELD WIPER AND WASHER

EXTERIOR51-23

WINDSHIELD WIPER AND WASHER

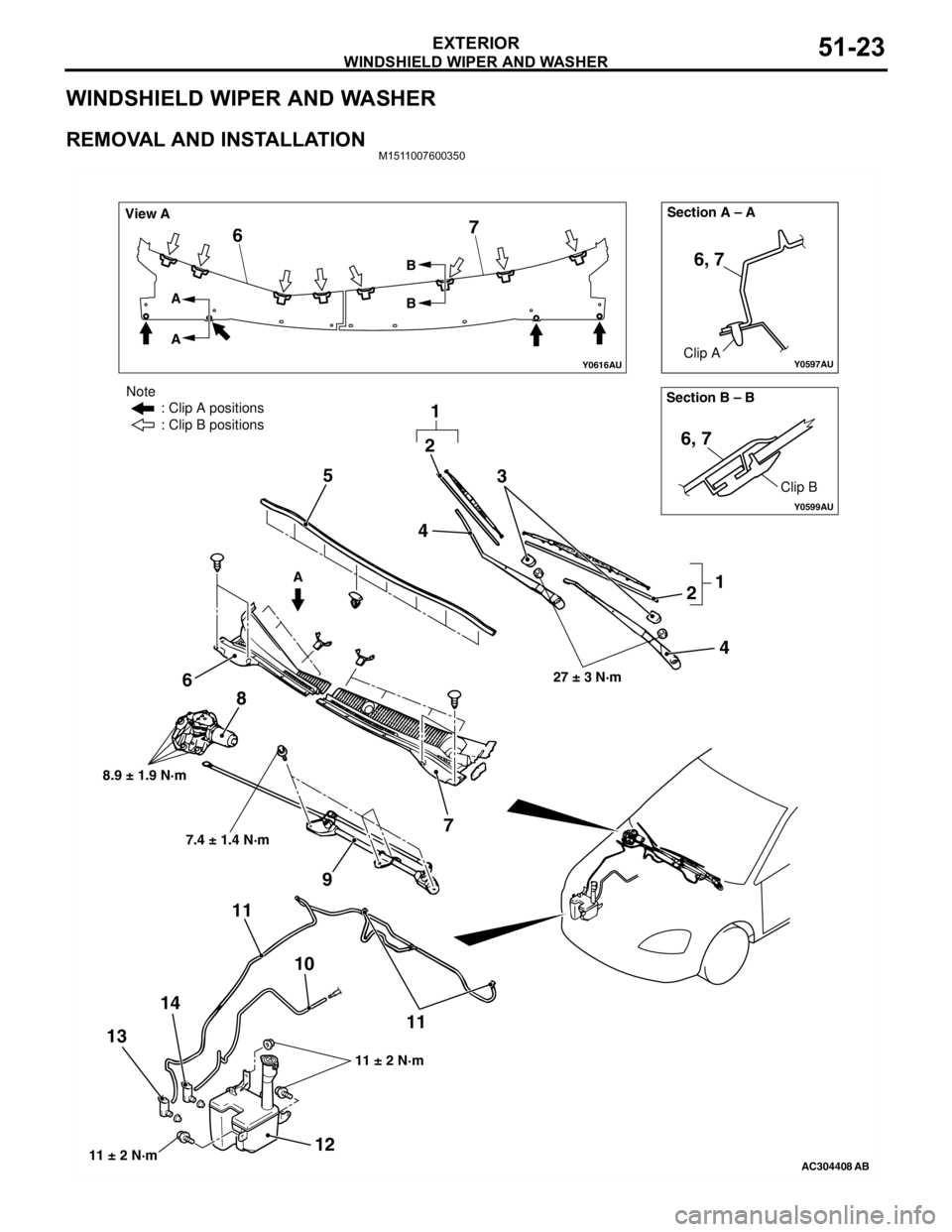

REMOVAL AND INSTALLATIONM1511007600350

Y0597AU

Y0616AU

Y0599AU

AC304408AB

Section B – B Section A – A

View A

A A

AB

B

Clip A

Clip B

6, 7

6, 7

67

3

2 5

6

7 8

9

10 11

11

12 1314

27 ± 3 N·m

8.9 ± 1.9 N·m

11 ± 2 N·m

Note

: Clip A positions

: Clip B positions

11 ± 2 N·m

7.4 ± 1.4 N·m

2

1

1 4

4

Page 362 of 788

WINDSHIELD WIPER AND WASHER

EXTERIOR51-24

NOTE: For removal and installation of the wiper and

washer switch, refer to GROUP 54A, Column switch

P.54A-87.

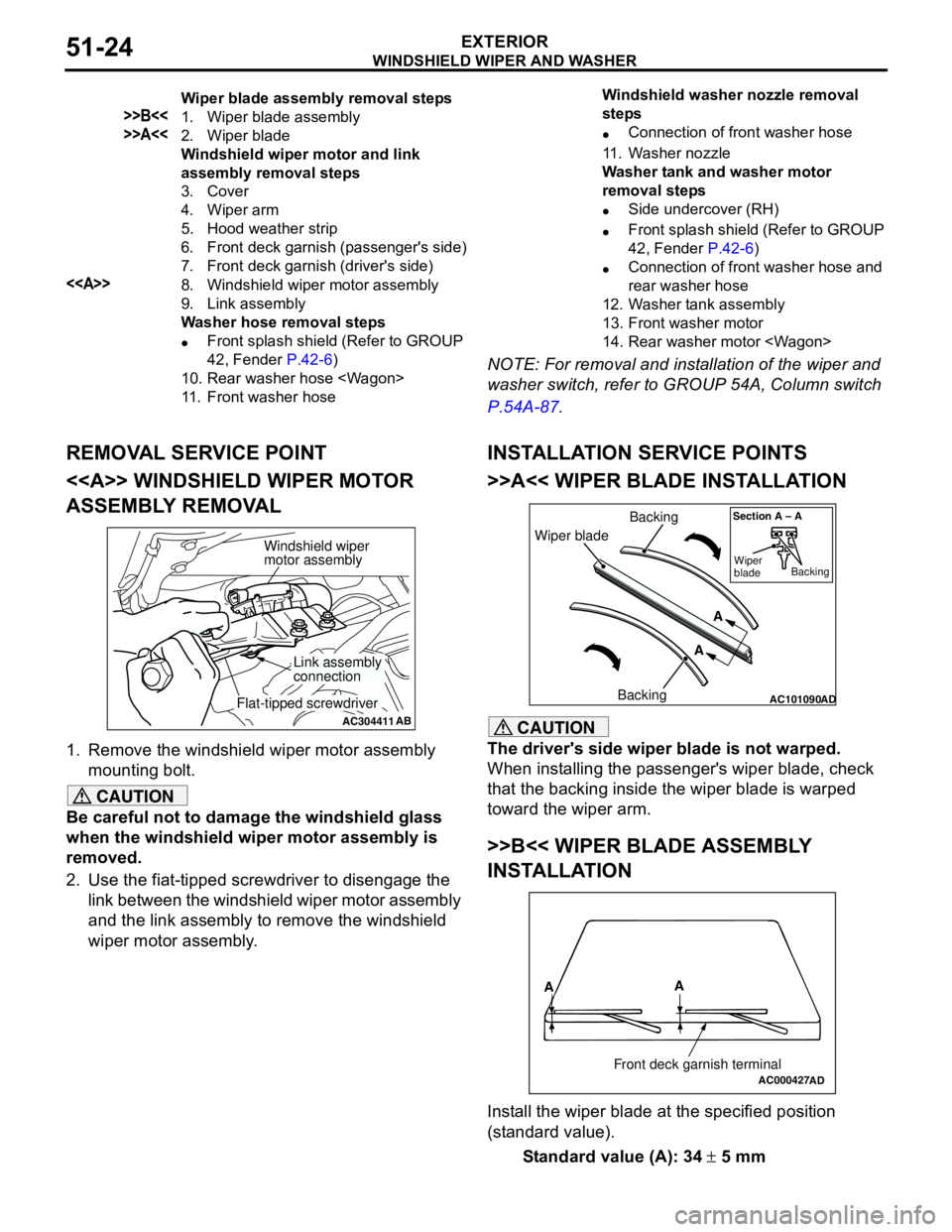

REMOVAL SERVICE POINT

<> WINDSHIELD WIPER MOTOR

ASSEMBLY REMOVAL

1. Remove the windshield wiper motor assembly

mounting bolt.

CAUTION

Be careful not to damage the windshield glass

when the windshield wiper motor assembly is

removed.

2. Use the fiat-tipped screwdriver to disengage the

link between the windshield wiper motor assembly

and the link assembly to remove the windshield

wiper motor assembly.

INSTALLATION SERVICE POINTS

>>A<< WIPER BLADE INSTALLATION

CAUTION

The driver's side wiper blade is not warped.

When installing the passenger's wiper blade, check

that the backing inside the wiper blade is warped

toward the wiper arm.

>>B<< WIPER BLADE ASSEMBLY

INSTALLATION

Install the wiper blade at the specified position

(standard value).

Standard value (A): 34 ± 5 mm

Wiper blade assembly removal steps

>>B<<1. Wiper blade assembly

>>A<<2. Wiper blade

Windshield wiper motor and link

assembly removal steps

3. Cover

4. Wiper arm

5. Hood weather strip

6. Front deck garnish (passenger's side)

7. Front deck garnish (driver's side)

<>8. Windshield wiper motor assembly

9. Link assembly

Washer hose removal steps

•Front splash shield (Refer to GROUP

42, Fender P.42-6)

10. Rear washer hose

11. Front washer hoseWindshield washer nozzle removal

steps

•Connection of front washer hose

11. Washer nozzle

Washer tank and washer motor

removal steps

•Side undercover (RH)

•Front splash shield (Refer to GROUP

42, Fender P.42-6)

•Connection of front washer hose and

rear washer hose

12. Washer tank assembly

13. Front washer motor

14. Rear washer motor

AC304411AB

Windshield wiper

motor assembly

Link assembly

connection

Flat-tipped screwdriverAC101090AD

Wiper bladeBacking

BackingA

A

Section A – A

Wiper

bladeBacking

AC000427

A

A

Front deck garnish terminalAD

Page 363 of 788

WINDSHIELD WIPER AND WASHER

EXTERIOR51-25

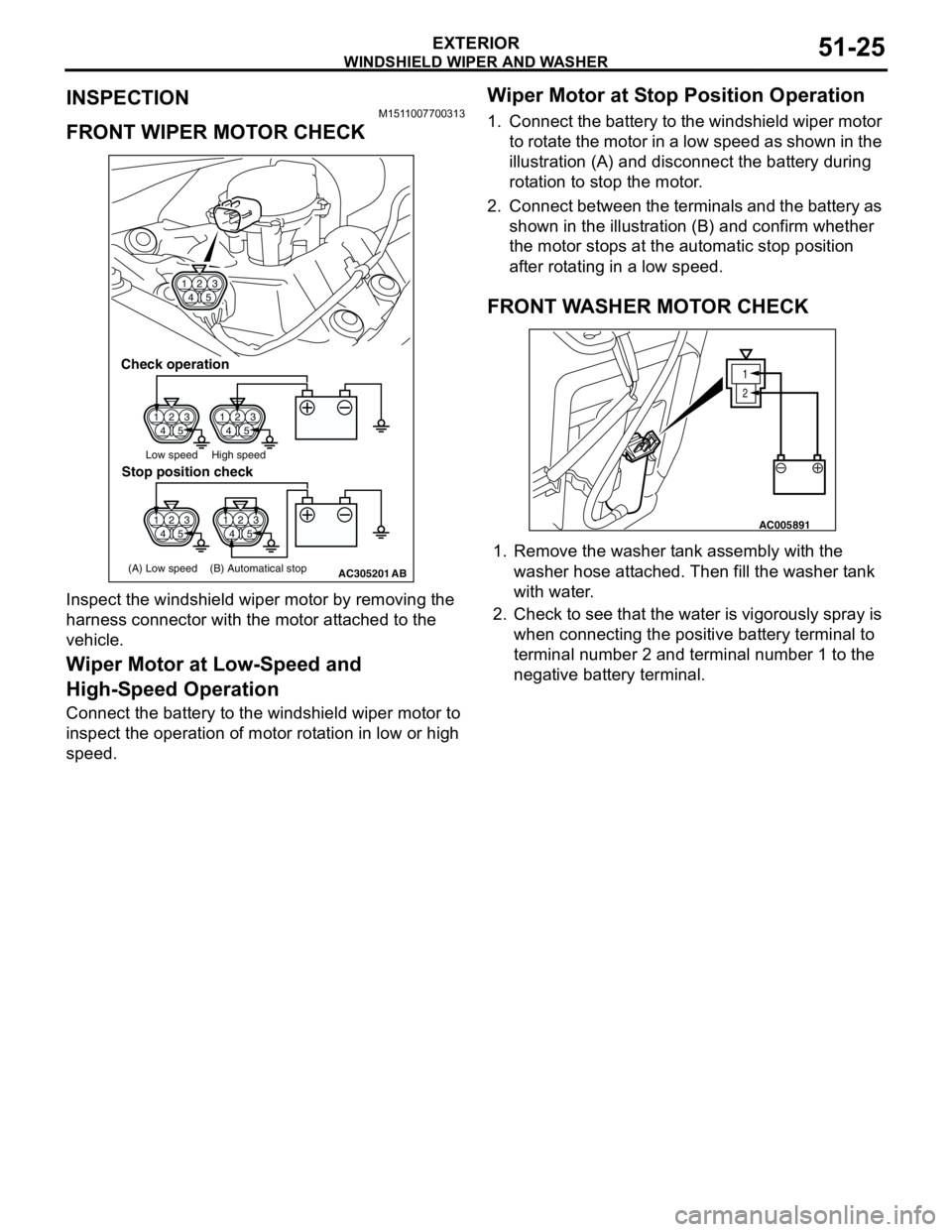

INSPECTIONM1511007700313

FRONT WIPER MOTOR CHECK

Inspect the windshield wiper motor by removing the

harness connector with the motor attached to the

vehicle.

Wiper Motor at Low-Speed and

High-Speed Operation

Connect the battery to the windshield wiper motor to

inspect the operation of motor rotation in low or high

speed.

Wiper Motor at Stop Position Operation

1. Connect the battery to the windshield wiper motor

to rotate the motor in a low speed as shown in the

illustration (A) and disconnect the battery during

rotation to stop the motor.

2. Connect between the terminals and the battery as

shown in the illustration (B) and confirm whether

the motor stops at the automatic stop position

after rotating in a low speed.

FRONT WASHER MOTOR CHECK

1. Remove the washer tank assembly with the

washer hose attached. Then fill the washer tank

with water.

2. Check to see that the water is vigorously spray is

when connecting the positive battery terminal to

terminal number 2 and terminal number 1 to the

negative battery terminal.

1

423

5

1

423

51

423

5

1

423

5

AC305201

1

423

5

Check operation

Low speed High speed

(A) Low speed (B) Automatical stop

Stop position check

AB

1

2

AC005891

Page 364 of 788

WINDSHIELD WIPER AND WASHER

EXTERIOR51-26

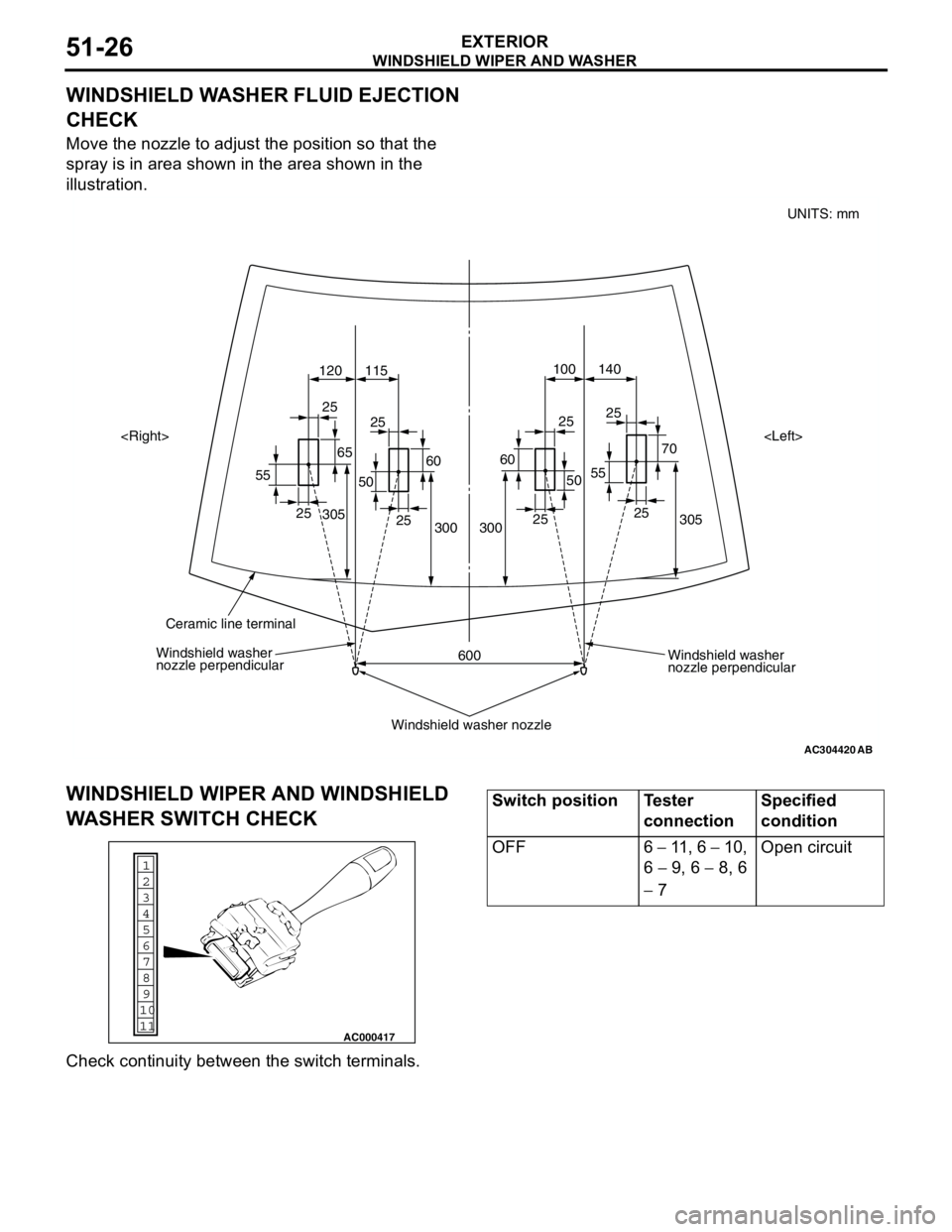

WINDSHIELD WASHER FLUID EJECTION

CHECK

Move the nozzle to adjust the position so that the

spray is in area shown in the area shown in the

illustration.

WINDSHIELD WIPER AND WINDSHIELD

WASHER SWITCH CHECK

Check continuity between the switch terminals.

AC304420

305 70 25

55140 100

120 115

305

300

600 300252525

25

25

25 25

55

6560

50

60

50

AB

Windshield washer

nozzle perpendicular Windshield washer

nozzle perpendicular

Windshield washer nozzle

Ceramic line terminal

UNITS: mm

1

6

8

11 109 7

5 4

3

2

AC000417

Switch position Tester

connectionSpecified

condition

OFF 6 − 11 , 6 − 10,

6 − 9, 6 − 8, 6

− 7Open circuit

Page 365 of 788

WINDSHIELD WIPER AND WASHER

EXTERIOR51-27

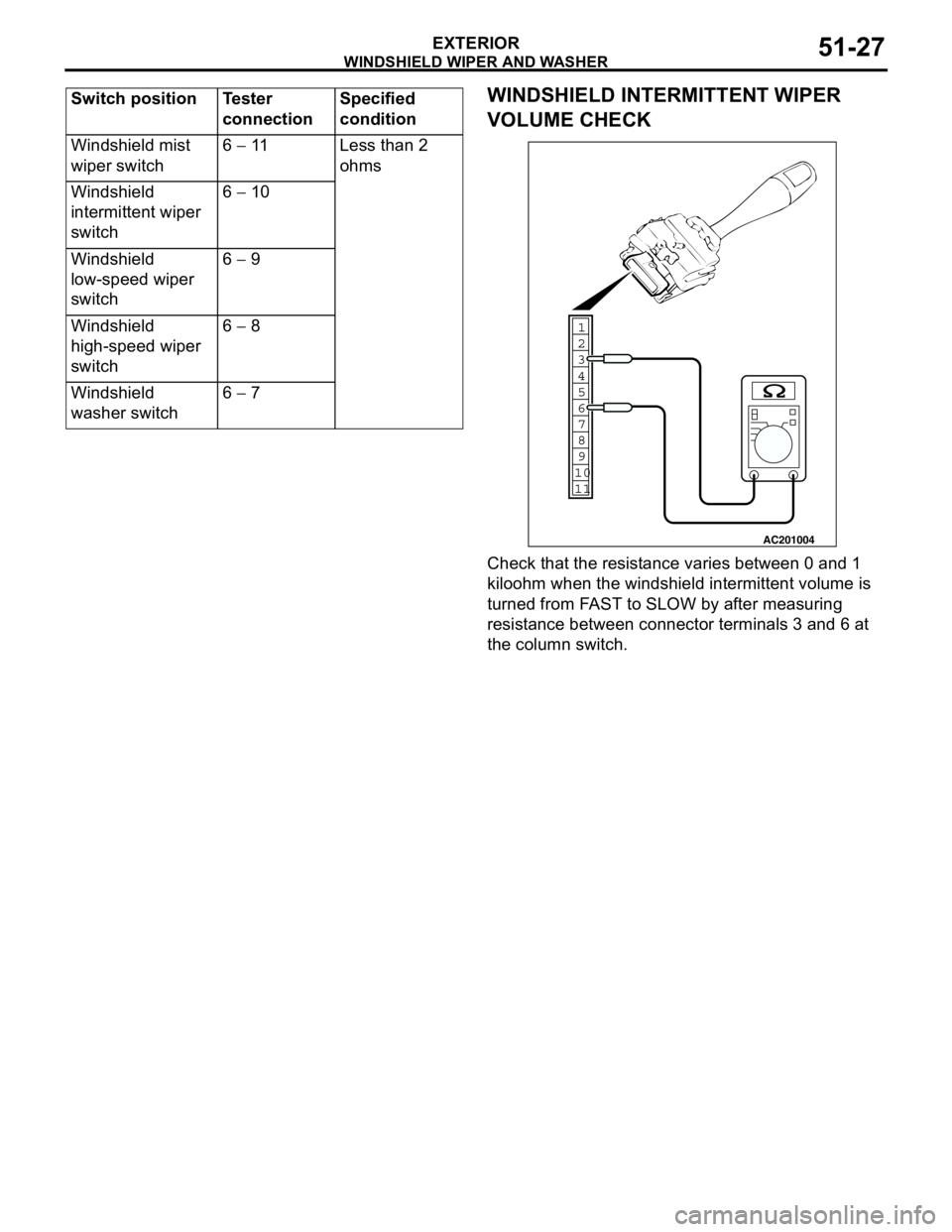

WINDSHIELD INTERMITTENT WIPER

VOLUME CHECK

Check that the resistance varies between 0 and 1

kiloohm when the windshield intermittent volume is

turned from FAST to SLOW by after measuring

resistance between connector terminals 3 and 6 at

the column switch. Windshield mist

wiper switch6 − 11 Less than 2

ohms

Windshield

intermittent wiper

switch6 − 10

Windshield

low-speed wiper

switch6 − 9

Windshield

high-speed wiper

switch6 − 8

Windshield

washer switch6 − 7 Switch position Tester

connectionSpecified

condition

1

6

8

11 109 7

5 4 3

2

AC201004