ESP MITSUBISHI LANCER 2005 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 466 of 788

ROOM LAMP

CHASSIS ELECTRICAL54A-78

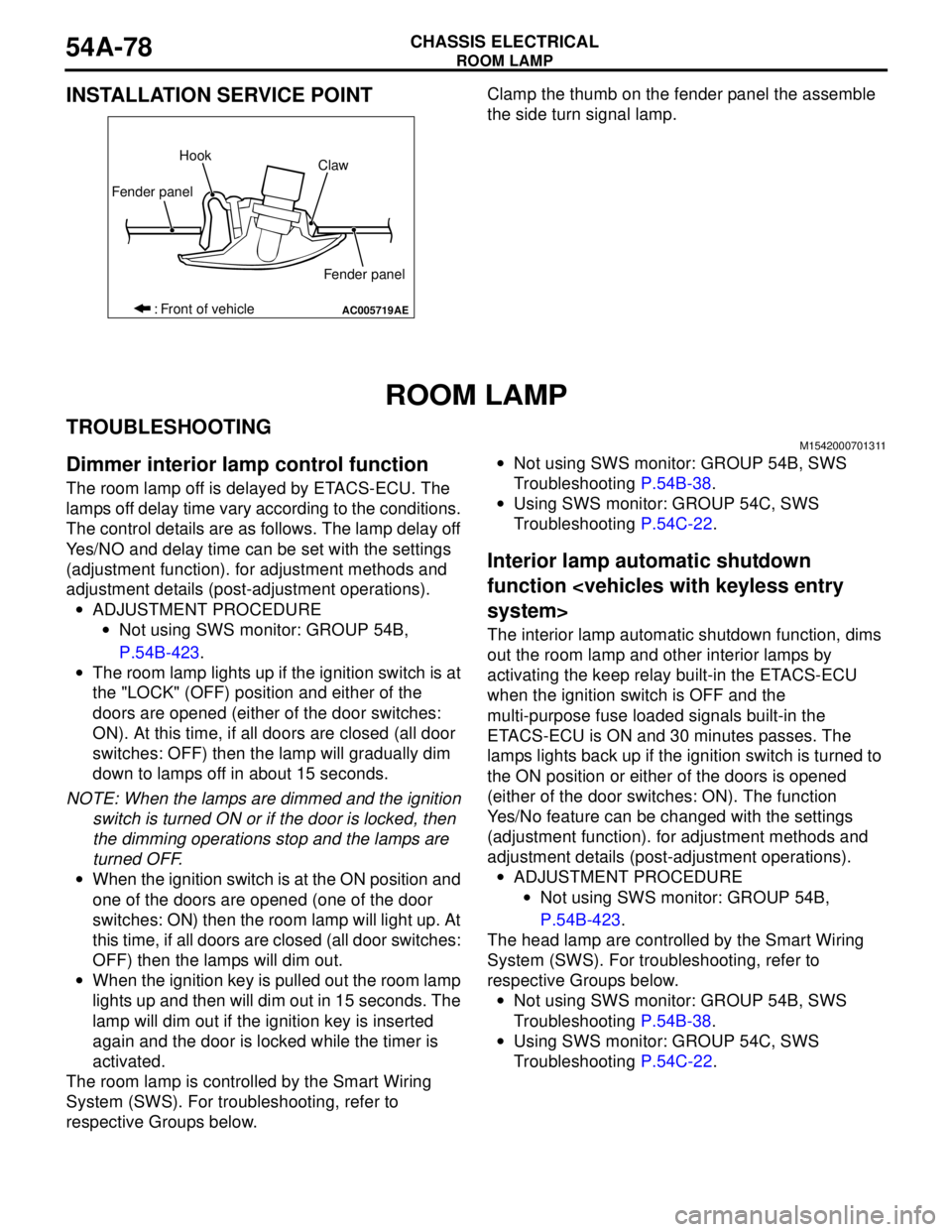

INSTALLATION SERVICE POINTClamp the thumb on the fender panel the assemble

the side turn signal lamp.

ROOM LAMP

TROUBLESHOOTINGM1542000701311

Dimmer interior lamp control function

The room lamp off is delayed by ETACS-ECU. The

lamps off delay time vary according to the conditions.

The control details are as follows. The lamp delay off

Yes/NO and delay time can be set with the settings

(adjustment function). for adjustment methods and

adjustment details (post-adjustment operations).

•ADJUSTMENT PROCEDURE

•Not using SWS monitor: GROUP 54B,

P.54B-423.

•The room lamp lights up if the ignition switch is at

the "LOCK" (OFF) position and either of the

doors are opened (either of the door switches:

ON). At this time, if all doors are closed (all door

switches: OFF) then the lamp will gradually dim

down to lamps off in about 15 seconds.

NOTE: When the lamps are dimmed and the ignition

switch is turned ON or if the door is locked, then

the dimming operations stop and the lamps are

turned OFF.

•When the ignition switch is at the ON position and

one of the doors are opened (one of the door

switches: ON) then the room lamp will light up. At

this time, if all doors are closed (all door switches:

OFF) then the lamps will dim out.

•When the ignition key is pulled out the room lamp

lights up and then will dim out in 15 seconds. The

lamp will dim out if the ignition key is inserted

again and the door is locked while the timer is

activated.

The room lamp is controlled by the Smart Wiring

System (SWS). For troubleshooting, refer to

respective Groups below.•Not using SWS monitor: GROUP 54B, SWS

Troubleshooting P.54B-38.

•Using SWS monitor: GROUP 54C, SWS

Troubleshooting P.54C-22.

Interior lamp automatic shutdown

function

The interior lamp automatic shutdown function, dims

out the room lamp and other interior lamps by

activating the keep relay built-in the ETACS-ECU

when the ignition switch is OFF and the

multi-purpose fuse loaded signals built-in the

ETACS-ECU is ON and 30 minutes passes. The

lamps lights back up if the ignition switch is turned to

the ON position or either of the doors is opened

(either of the door switches: ON). The function

Yes/No feature can be changed with the settings

(adjustment function). for adjustment methods and

adjustment details (post-adjustment operations).

•ADJUSTMENT PROCEDURE

•Not using SWS monitor: GROUP 54B,

P.54B-423.

The head lamp are controlled by the Smart Wiring

System (SWS). For troubleshooting, refer to

respective Groups below.

•Not using SWS monitor: GROUP 54B, SWS

Troubleshooting P.54B-38.

•Using SWS monitor: GROUP 54C, SWS

Troubleshooting P.54C-22.

AC005719

Fender panelHook

Claw

Fender panel

: Front of vehicle

AE

Page 467 of 788

REAR COMBINATION LAMP

CHASSIS ELECTRICAL54A-79

REAR COMBINATION LAMP

TROUBLESHOOTINGM1542000701322

The lamps setup on the rear combination lamp is

controlled in the same manner as the lamps of the

headlamp assembly. For details go to the reference.

For troubleshooting, refer to respective Groups

below.•Not using SWS monitor: GROUP 54B, SWS

Troubleshooting P.54B-38.

•Using SWS monitor: GROUP 54C, SWS

Troubleshooting P.54C-22.

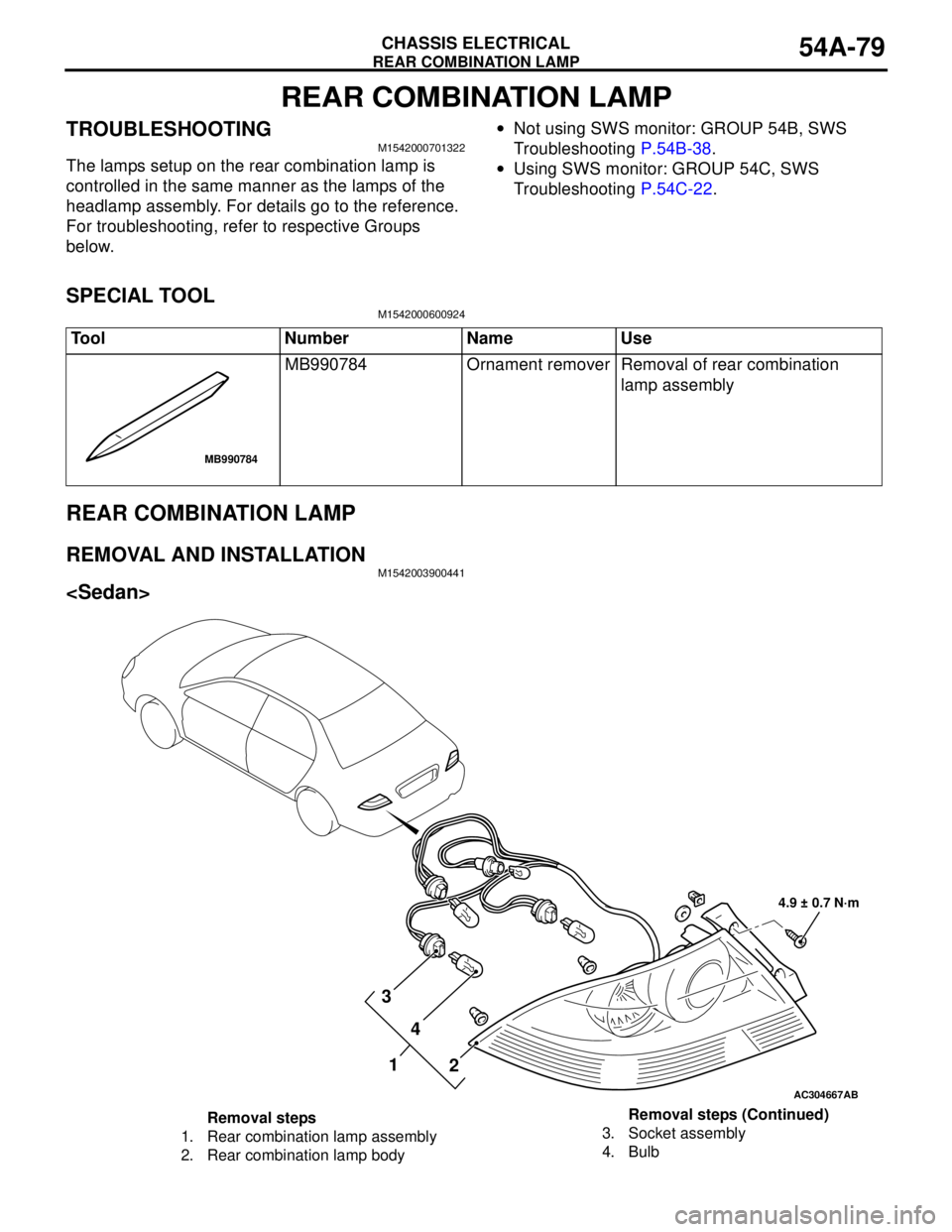

SPECIAL TOOLM1542000600924

REAR COMBINATION LAMP

REMOVAL AND INSTALLATIONM1542003900441

Tool Number Name Use

MB990784 Ornament remover Removal of rear combination

lamp assembly

MB990784

AC304667

4.9 ± 0.7 N·m

AB

3

4

2

1

Removal steps

1. Rear combination lamp assembly

2. Rear combination lamp body3. Socket assembly

4. BulbRemoval steps (Continued)

Page 473 of 788

HAZARD WARNING LAMP SWITCH

CHASSIS ELECTRICAL54A-85

HAZARD WARNING LAMP SWITCH

TROUBLESHOOTING

M1542000701333

FLASHER TIMER FUNCTION

The hazard warning lamps (flasher timer function)

are controlled by the Smart Wiring System (SWS).

For troubleshooting, refer to respective Groups

below.•Not using SWS monitor: GROUP 54B, SWS

Troubleshooting P.54B-38.

•Using SWS monitor: GROUP 54C, SWS

Troubleshooting P.54C-22.

SPECIAL TOOL

M1542000600935

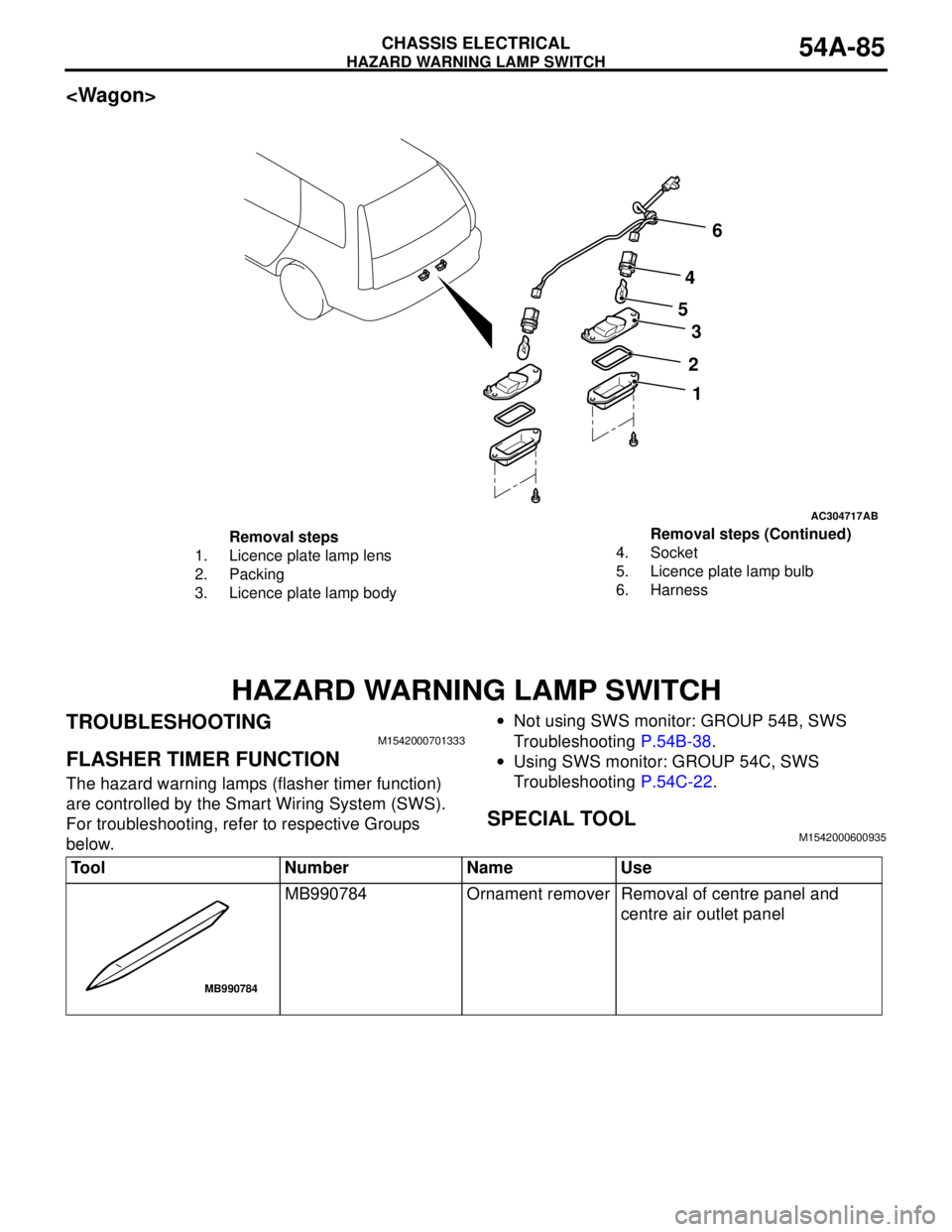

AC304717AB

2

1 3 4

56

Removal steps

1. Licence plate lamp lens

2. Packing

3. Licence plate lamp body4. Socket

5. Licence plate lamp bulb

6. HarnessRemoval steps (Continued)

Tool Number Name Use

MB990784 Ornament remover Removal of centre panel and

centre air outlet panel

MB990784

Page 476 of 788

COLUMN SWITCH

CHASSIS ELECTRICAL54A-88

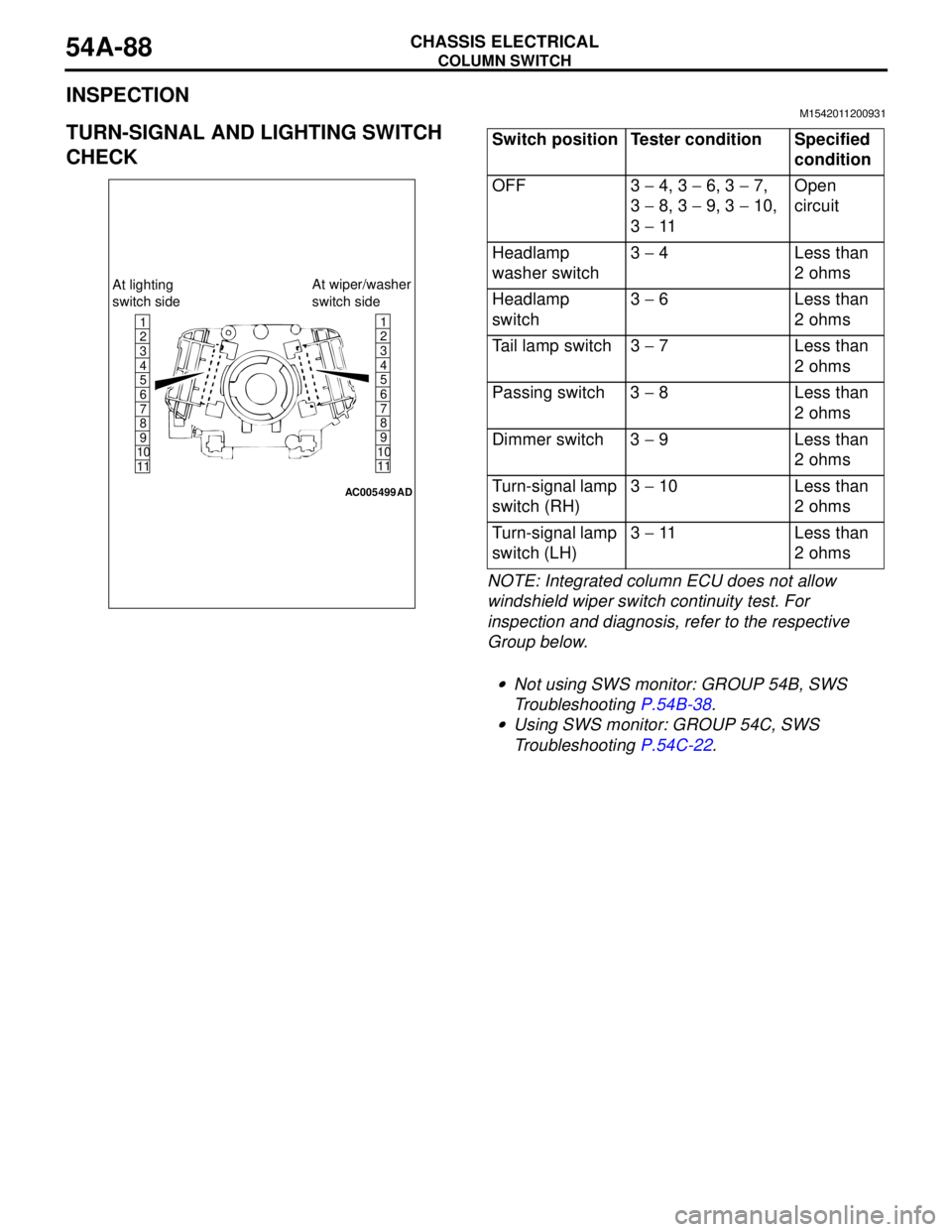

INSPECTIONM1542011200931

TURN-SIGNAL AND LIGHTING SWITCH

CHECK

NOTE: Integrated column ECU does not allow

windshield wiper switch continuity test. For

inspection and diagnosis, refer to the respective

Group below.

.

•Not using SWS monitor: GROUP 54B, SWS

Troubleshooting P.54B-38.

•Using SWS monitor: GROUP 54C, SWS

Troubleshooting P.54C-22.

1

6

8

11 109 7 5 4 3 21

6

8

11 109 7 5 4

3

2

AC005499

At lighting

switch sideAt wiper/washer

switch side

AD

Switch position Tester condition Specified

condition

OFF 3 − 4, 3 − 6, 3 − 7,

3 − 8, 3 − 9, 3 − 10,

3 − 11Open

circuit

Headlamp

washer switch3 − 4 Less than

2 ohms

Headlamp

switch3 − 6 Less than

2 ohms

Tail lamp switch 3 − 7 Less than

2 ohms

Passing switch 3 − 8 Less than

2 ohms

Dimmer switch 3 − 9 Less than

2 ohms

Turn-signal lamp

switch (RH)3 − 10 Less than

2 ohms

Turn-signal lamp

switch (LH)3 − 11 Less than

2 ohms

Page 485 of 788

55-1

GROUP 55

HEATER, AIR

CONDITIONER AND

VENTILATION

CONTENTS

SERVICE SPECIFICATIONS . . . . . . .55-3

LUBRICANTS . . . . . . . . . . . . . . . . . .55-3

SPECIAL TOOLS . . . . . . . . . . . . . . . .55-4

TROUBLESHOOTING . . . . . . . . . . . .55-5DIAGNOSIS TROUBLESHOOTING

FLOW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55-5

SYMPTOM CHART . . . . . . . . . . . . . . . . . . . 55-5

SYMPTOM PROCEDURES . . . . . . . . . . . . 55-5

CHECK AT ECU TERMINAL

CHECK AT ECU TERMINAL

Continued on next page

W ARNING S RE GA RDING S E RV ICIN G O F SUP P LE MEN TAL R ES TRAI NT S Y ST EM (SRS ) E Q UIP PE D VE HICL ES

I mp roper se rvi ce o r m ai nte na nce of a ny c omp onent of the SRS , or an y SRS -re la te d c om pone nt, ca n le a d to

personal injury or death to service personnel (from inadvertent firing of the air bag) or to the driver (from

re nd er ing the S RS inop er ati ve).

S e rvic e or m ai nten anc e of an y SRS com pon ent or SRS -re late d com pone nt m ust be pe rfor me d only a t an

authorized MITSUBISHI dealer.

M ITSUBISHI dealer p erso nnel must thoroughly review th is man ual, and esp ecially its GROU P 52B - Su pplemen tal

Restraint System (SR S) b efore beginn ing an y service o r maintenance of any comp onent of th e SRS or any SRS-

rel ated com ponent.

NOTE

The SRS includes the following components: front impact sens ors , SRS-ECU, SRS warning lamp, air bag module, c lock spring

and interconnecting wiring. Other SRS-related components (that may have to be remov ed/installed in connection with SRS

service or maintenance) are indicated in the table of c ontents by an asterisk (*).

Page 558 of 788

ON-VEHICLE SERVICE

HEATER, AIR CONDITIONER AND VENTILATION55-74

REFRIGERANT LEAK REPAIR

PROCEDURE

M1552001500277

LOST CHARGE

If the system has lost all charge due to a leak:

1. Evacuate the system (Refer to P.55-72).

2. Charge the system with approximately 480 − 520

g of refrigerant.

3. Check for leaks.

4. Discharge the system.

5. Repair leaks.

CAUTION

Replacement filter-drier units must be sealed

while in storage. The drier used in these units will

saturate water quickly upon exposure to the

atmosphere. When installing a drier, have all

tools and supplies ready for quick assembly to

avoid keeping the system open any longer than

necessary.

6. Replace receiver drier.

7. Evacuate and charge system.

LOW CHARGE

If the system has not lost all of its refrigerant charge;

locate and repair all leaks. If it is necessary to

increase the system pressure to find the leak

(because of an especially low charge) add

refrigerant. If it is possible to repair the leak without

discharging the refrigerant system, use the

procedure for correcting low refrigerant level.

HANDLING TUBING AND FITTINGS

Kinks in the refrigerant tubing or sharp bends in the

refrigerant hose lines will greatly reduce the capacity

of the entire system. High pressures are produced in

the system when it is operating. Extreme care must

be exercised to make sure that all connections are

pressure tight. Dirt and moisture can enter the

system when it is opened for repair or replacement of

lines or components. The following precautions must

be observed. The system must be completely

discharged before opening any fitting of connection

in the refrigeration system. Open fittings with caution

even after the system has been discharged. If any

pressure is noticed as a fitting is loosened, allow

trapped pressure to bleed off very slowly.

Never attempt to rebend formed lines to fit. Use the

correct line for the installation you are servicing. A

good rule for the flexible hose lines is keep the radius

of all bends at least 10 times the diameter of the

hose.Sharper bends will reduce the flow of refrigerant. The

flexible hose lines should be routed so that they are

at least 80 mm from the exhaust manifold. It is good

practice to inspect all flexible hose lines at least once

a year to make sure they are in good condition and

properly routed.

On standard plumbing fittings with O-rings, these

O-rings are not reusable.

COMPRESSOR NOISE CHECKM1552008700272

You must first know the conditions when the noise

occurs. These conditions are: weather, vehicle

speed, in gear or neutral, engine temperature or any

other special conditions.

Noises that develop during A/C operation can often

be misleading. For example: what sounds like a

failed front bearing or connecting rod, may be

caused by loose bolts, nuts, mounting brackets, or a

loose clutch assembly. Verify accessory drive belt

tension (power steering or alternator).

Improper accessory drive belt tension can cause a

misleading noise when the compressor is engaged

and little or no noise when the compressor is

disengaged.

Drive belts are speed-sensitive. That is, at different

engine speeds, and depending upon belt tension,

belts can develop unusual noises that are often

mistaken for mechanical problems within the

compressor.

ADJUSTMENT

1. Select a quiet area for testing. Duplicate

conditions as much as possible. Switch the

compressor on and off several times to clearly

identify compressor noise. To duplicate high

ambient conditions (high head pressure), restrict

air flow through the condenser. Install a manifold

gauge set to make sure discharge pressure

doesn't exceed 2,070 kPa.

2. Tighten all compressor mounting bolts, clutch

mounting bolt, and compressor drive belt. Check

to assure clutch coil is tight (no rotation or

wobble).

3. Check refrigerant hoses for rubbing or

interference that can cause unusual noises.

4. Check refrigerant charge (Refer to P.55-69).

5. Recheck compressor noise as in Step 1.

6. If noise still exists, loosen compressor mounting

bolts and retighten. Repeat Step 1.

7. If noise continues, replace compressor and repeat

Step 1.

Page 645 of 788

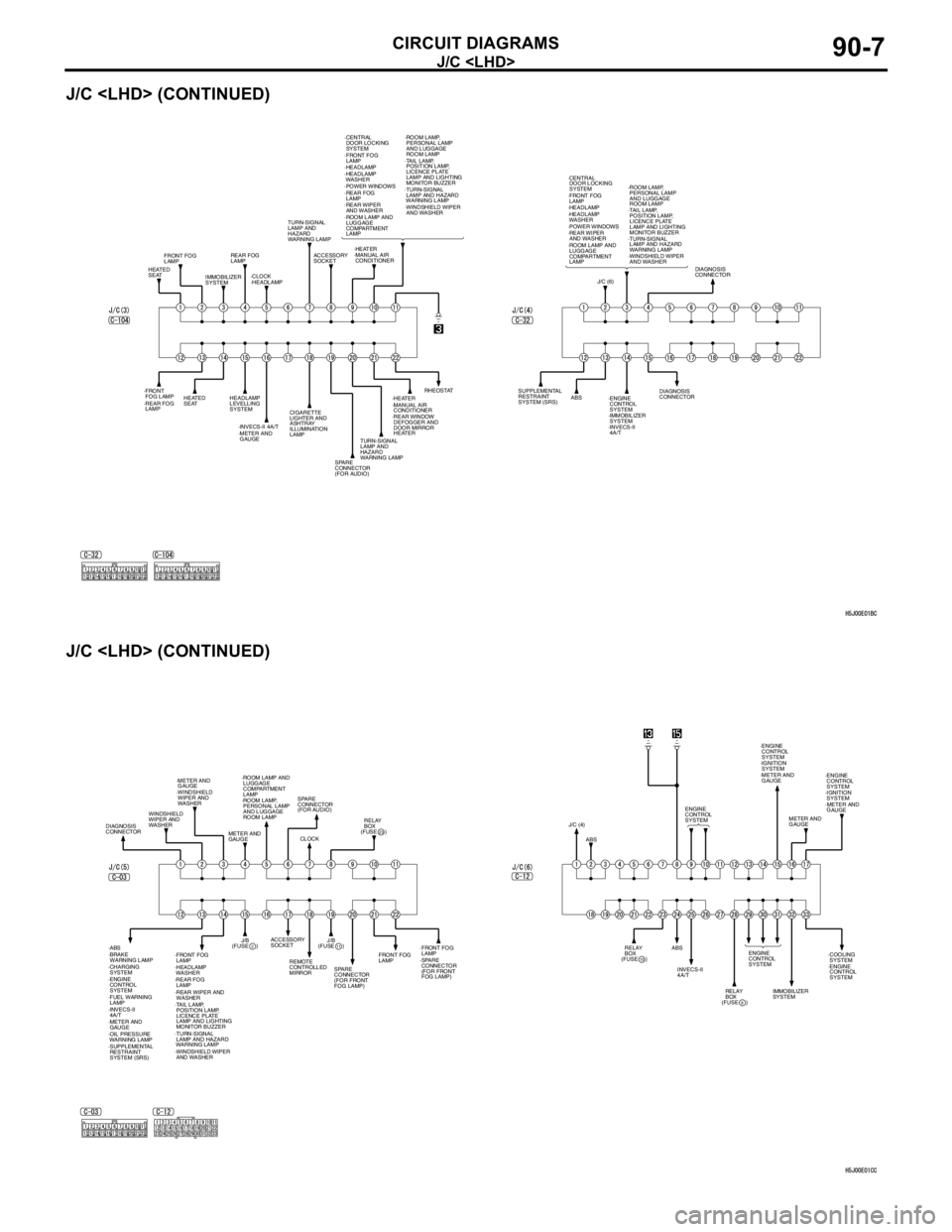

J/C

CIRCUIT DIAGRAMS90-7

J/C

J/C

FRONT FOG

LAMP

·FRONT

FOG LAMP·FRONT FOG

LAMP

REAR FOG

LAMP

·REAR FOG

LAMP·REAR FOG

LAMP

HEATED

SEAT

HEATED

SEATIMMOBILIZER

SYSTEM·CLOCK·HEATER TURN-SIGNAL

LAMP AND

HAZARD

WARNING LAMP·TURN-SIGNAL

LAMP AND HAZARD

WARNING LAMP

TURN-SIGNAL

LAMP AND

HAZARD

WARNING LAMP ·MANUAL AIR

CONDITIONER

·HEATER

·MANUAL AIR

CONDITIONER ·HEADLAMP·HEADLAMP

·HEADLAMP

WASHER

ACCESSORY

SOCKET·CENTRAL

DOOR LOCKING

SYSTEM

·POWER WINDOWS

·REAR WIPER

AND WASHER

·ROOM LAMP AND

LUGGAGE

COMPARTMENT

LAMP·ROOM LAMP,

PERSONAL LAMP

AND LUGGAGE

ROOM LAMP

·TAIL LAMP,

POSITION LAMP,

LICENCE PLATE

LAMP AND LIGHTING

MONITOR BUZZER

·WINDSHIELD WIPER

AND WASHER

HEADLAMP

LEVELLING

SYSTEM

·INVECS-II 4A/T

·METER AND

GAUGECIGARETTE

LIGHTER AND

ASHTRAY

ILLUMINATION

LAMP

SPARE

CONNECTOR

(FOR AUDIO)·REAR WINDOW

DEFOGGER AND

DOOR MIRROR

HEATERRHEOSTAT

·FRONT FOG

LAMP

·TURN-SIGNAL

LAMP AND HAZARD

WARNING LAMP ·HEADLAMP

·HEADLAMP

WASHER ·CENTRAL

DOOR LOCKING

SYSTEM

·POWER WINDOWS

·REAR WIPER

AND WASHER

·ROOM LAMP AND

LUGGAGE

COMPARTMENT

LAMP·ROOM LAMP,

PERSONAL LAMP

AND LUGGAGE

ROOM LAMP

·TAIL LAMP,

POSITION LAMP,

LICENCE PLATE

LAMP AND LIGHTING

MONITOR BUZZER

·WINDSHIELD WIPER

AND WASHER

J/C (6)DIAGNOSIS

CONNECTOR

DIAGNOSIS

CONNECTOR SUPPLEMENTAL

RESTRAINT

SYSTEM (SRS)ABS

·ENGINE

CONTROL

SYSTEM

·IMMOBILIZER

SYSTEM

·INVECS-II

4A/T

·FRONT FOG

LAMP·FRONT FOG

LAMP

FRONT FOG

LAMP

·TURN-SIGNAL

LAMP AND HAZARD

WARNING LAMP ·HEADLAMP

WASHER·ROOM LAMP AND

LUGGAGE

COMPARTMENT

LAMP

·ROOM LAMP,

PERSONAL LAMP

AND LUGGAGE

ROOM LAMP

·TAIL LAMP,

POSITION LAMP,

LICENCE PLATE

LAMP AND LIGHTING

MONITOR BUZZER

·WINDSHIELD WIPER

AND WASHER·WINDSHIELD

WIPER AND

WASHER

WINDSHIELD

WIPER AND

WASHER

DIAGNOSIS

CONNECTOR·METER AND

GAUGE

·METER AND

GAUGEMETER AND

GAUGESPARE

CONNECTOR

(FOR AUDIO)

SPARE

CONNECTOR

(FOR FRONT

FOG LAMP)·SPARE

CONNECTOR

(FOR FRONT

FOG LAMP) CLOCK(FUSE )

23

(FUSE )2

RELAY

BOX

·REAR FOG

LAMP

·REAR WIPER AND

WASHER ·ABS

·BRAKE

WARNING LAMP

·CHARGING

SYSTEM

·ENGINE

CONTROL

SYSTEM

·FUEL WARNING

LAMP

·INVECS-II

4A/T

·SUPPLEMENTAL

RESTRAINT

SYSTEM (SRS) ·OIL PRESSURE

WARNING LAMPJ/B

(FUSE )

11J/B ACCESSORY

SOCKET

REMOTE

CONTROLLED

MIRROR

J/C (4)

ABS

ABSENGINE

CONTROL

SYSTEM

ENGINE

CONTROL

SYSTEM·ENGINE

CONTROL

SYSTEM

·ENGINE

CONTROL

SYSTEMMETER AND

GAUGE

(FUSE )10RELAY

BOX

(FUSE )

8RELAY

BOX INVECS-II

4A/T

IMMOBILIZER

SYSTEM·COOLING

SYSTEM

·METER AND

GAUGE·IGNITION

SYSTEM ·ENGINE

CONTROL

SYSTEM

·METER AND

GAUGE·IGNITION

SYSTEM

Page 647 of 788

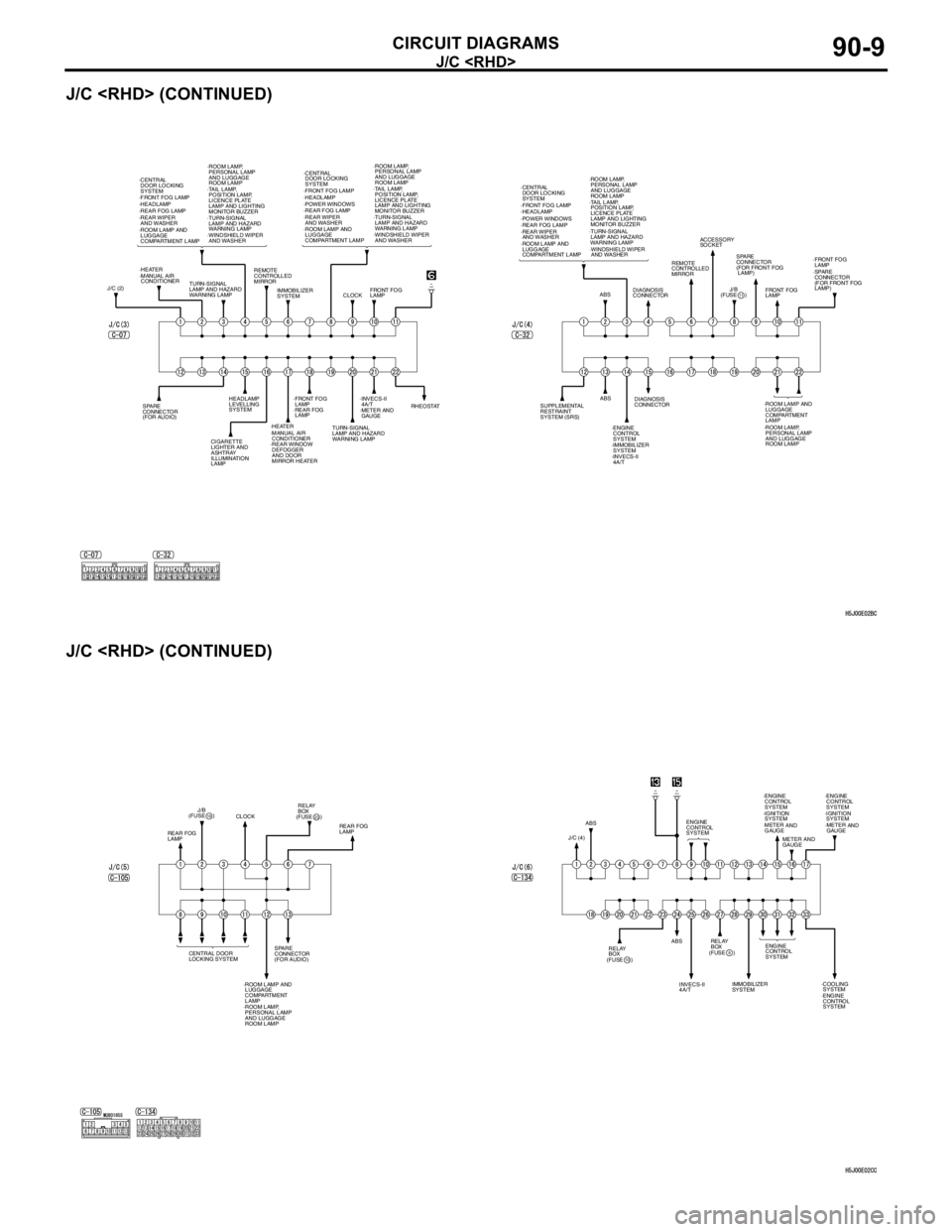

J/C

CIRCUIT DIAGRAMS90-9

J/C

J/C

·METER AND

GAUGESPARE

CONNECTOR

(FOR AUDIO)·REAR FOG

LAMP·INVECS-II

4A/T IMMOBILIZER

SYSTEMFRONT FOG

LAMP CLOCK REMOTE

CONTROLLED

MIRROR

TURN-SIGNAL

LAMP AND HAZARD

WARNING LAMP

TURN-SIGNAL

LAMP AND HAZARD

WARNING LAMP J/C (2)·FRONT FOG LAMP

·TURN-SIGNAL

LAMP AND HAZARD

WARNING LAMP ·HEADLAMP ·CENTRAL

DOOR LOCKING

SYSTEM

·POWER WINDOWS

·REAR WIPER

AND WASHER

·ROOM LAMP AND

LUGGAGE

COMPARTMENT LAMP·ROOM LAMP,

PERSONAL LAMP

AND LUGGAGE

ROOM LAMP

·TAIL LAMP,

POSITION LAMP,

LICENCE PLATE

LAMP AND LIGHTING

MONITOR BUZZER

·HEATER

·MANUAL AIR

CONDITIONER

·MANUAL AIR

CONDITIONER HEADLAMP

LEVELLING

SYSTEM

CIGARETTE

LIGHTER AND

ASHTRAY

ILLUMINATION

LAMP·REAR WINDOW

DEFOGGER

AND DOOR

MIRROR HEATERRHEOSTAT ·FRONT FOG LAMP

·REAR FOG LAMP

·TURN-SIGNAL

LAMP AND HAZARD

WARNING LAMP ·HEADLAMP ·CENTRAL

DOOR LOCKING

SYSTEM

·REAR WIPER

AND WASHER

·ROOM LAMP AND

LUGGAGE

COMPARTMENT LAMP·ROOM LAMP,

PERSONAL LAMP

AND LUGGAGE

ROOM LAMP

·TAIL LAMP,

POSITION LAMP,

LICENCE PLATE

LAMP AND LIGHTING

MONITOR BUZZER

·WINDSHIELD WIPER

AND WASHER·REAR FOG LAMP

·HEATER·WINDSHIELD WIPER

AND WASHERACCESSORY

SOCKET

·SPARE

CONNECTOR

(FOR FRONT FOG

LAMP)

(FUSE )

11J/B ·WINDSHIELD WIPER

AND WASHER

DIAGNOSIS

CONNECTOR

DIAGNOSIS

CONNECTOR

SUPPLEMENTAL

RESTRAINT

SYSTEM (SRS)ABS

·ENGINE

CONTROL

SYSTEM

·IMMOBILIZER

SYSTEM

·INVECS-II

4A/TFRONT FOG

LAMP REMOTE

CONTROLLED

MIRROR

·ROOM LAMP AND

LUGGAGE

COMPARTMENT

LAMP

·ROOM LAMP,

PERSONAL LAMP

AND LUGGAGE

ROOM LAMP·FRONT FOG

LAMP SPARE

CONNECTOR

(FOR FRONT FOG

LAMP)

ABS ·FRONT FOG LAMP

·TURN-SIGNAL

LAMP AND HAZARD

WARNING LAMP ·HEADLAMP ·CENTRAL

DOOR LOCKING

SYSTEM

·POWER WINDOWS

·REAR WIPER

AND WASHER

·ROOM LAMP AND

LUGGAGE

COMPARTMENT LAMP·ROOM LAMP,

PERSONAL LAMP

AND LUGGAGE

ROOM LAMP

·TAIL LAMP,

POSITION LAMP,

LICENCE PLATE

LAMP AND LIGHTING

MONITOR BUZZER

·REAR FOG LAMP

·FRONT FOG

LAMP

REAR FOG

LAMP

·ROOM LAMP AND

LUGGAGE

COMPARTMENT

LAMP

·ROOM LAMP,

PERSONAL LAMP

AND LUGGAGE

ROOM LAMPSPARE

CONNECTOR

(FOR AUDIO) CLOCK

(FUSE )23RELAY

BOX

(FUSE )16J/B

REAR FOG

LAMP

CENTRAL DOOR

LOCKING SYSTEM

J/C (4)ABS

ABSENGINE

CONTROL

SYSTEM

ENGINE

CONTROL

SYSTEM·ENGINE

CONTROL

SYSTEM

·ENGINE

CONTROL

SYSTEMMETER AND

GAUGE·METER AND

GAU GE

·IGNITION

SYSTEM

(FUSE )

10RELAY

BOX(FUSE )8RELAY

BOX

INVECS-II

4A/TIMMOBILIZER

SYSTEM·COOLING

SYSTEM

·ENGINE

CONTROL

SYSTEM

·METER AND

GAUGE·IGNITION

SYSTEM