check engine light MITSUBISHI LANCER 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 68 of 788

CHARGING SYSTEM

ENGINE ELECTRICAL16-4

2. Turn the ignition switch to the "LOCK" (OFF)

position.

3. Disconnect the negative battery cable.

4. Connect a clamp-type DC test ammeter with a

range of 0 − 120 A to the alternator "B" terminal

output wire.

NOTE: The way of disconnecting the alternator

output wire and of connecting the ammeter is

possibly not found the problem that the output

current is dropping due to the insufficient

connection between terminal "B" and the output

wire.

5. Connect a digital-type voltmeter between the

alternator "B" terminal and the battery (+)

terminal. [Connect the (+) lead of the voltmeter to

the "B" terminal and the connect the (-) lead of the

voltmeter to the battery (+) cable].

6. Reconnect the negative battery cable.

7. Connect a tachometer or the MUT-II/III (Refer to

GROUP 11A − On-vehicle Service − Idle speed

check <4G1> P.11A-11 or GROUP 11C −

On-vehicle Service − Idle speed check <4G6>

P.11C-11).

8. Leave the hood open.

9. Start the engine.

10.With the engine running at 2,500 r/min, turn the

headlamps and other lamps on and off to adjust

the alternator load so that the value displayed on

the ammeter is slightly above 30 A.Adjust the engine speed by gradually decreasing

it until the value displayed on the ammeter is 30

A. Take a reading of the value displayed on the

voltmeter at this time.

Limit: maximum 0.3 V

NOTE: When the alternator output is high and the

value displayed on the ammeter does not

decrease until 30 A, set the value to 40 A. Read

the value displayed on the voltmeter at this time.

When the value range is 40 A, the limit is

maximum 0.4 V.

11.If the value displayed on the voltmeter is above

the limit value, there is probably a malfunction in

the alternator output wire, so check the wiring

between the alternator "B" terminal and the

battery (+) terminal (including fusible link).

If a terminal is not sufficiently tight or if the

harness has become discolored due to

overheating, repair and then test again.

12.After the test, run the engine at idle.

13.Turn off all lamps and the ignition switch.

14.Remove the tachometer or the MUT-II/III.

15.Disconnect the negative battery cable.

16.Disconnect the ammeter and voltmeter.

17.Connect the negative battery cable.

Page 69 of 788

CHARGING SYSTEM

ENGINE ELECTRICAL16-5

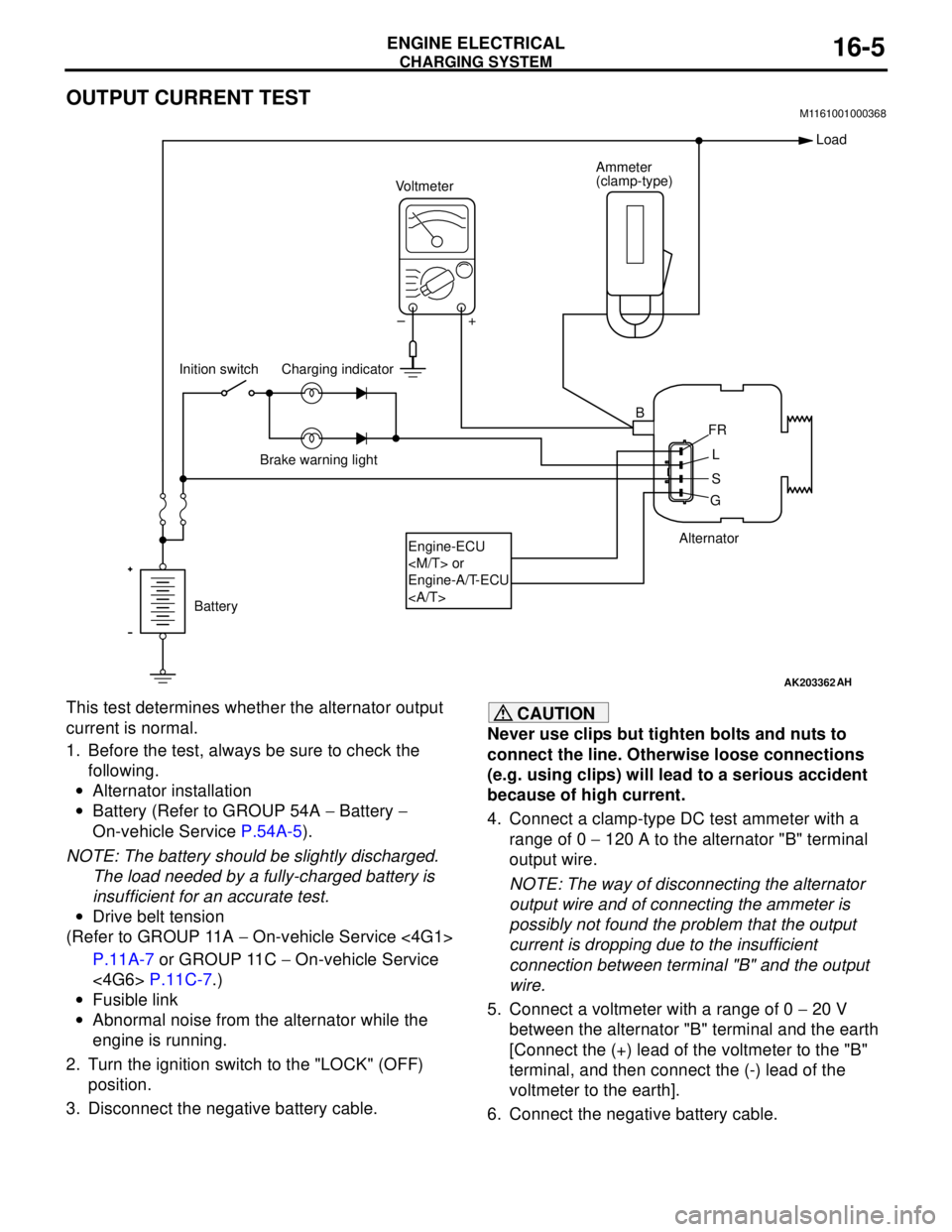

OUTPUT CURRENT TESTM1161001000368

This test determines whether the alternator output

current is normal.

1. Before the test, always be sure to check the

following.

•Alternator installation

•Battery (Refer to GROUP 54A − Battery −

On-vehicle Service P.54A-5).

NOTE: The battery should be slightly discharged.

The load needed by a fully-charged battery is

insufficient for an accurate test.

•Drive belt tension

(Refer to GROUP 11A − On-vehicle Service <4G1>

P.11A-7 or GROUP 11C − On-vehicle Service

<4G6> P.11C-7.)

•Fusible link

•Abnormal noise from the alternator while the

engine is running.

2. Turn the ignition switch to the "LOCK" (OFF)

position.

3. Disconnect the negative battery cable.CAUTION

Never use clips but tighten bolts and nuts to

connect the line. Otherwise loose connections

(e.g. using clips) will lead to a serious accident

because of high current.

4. Connect a clamp-type DC test ammeter with a

range of 0 − 120 A to the alternator "B" terminal

output wire.

NOTE: The way of disconnecting the alternator

output wire and of connecting the ammeter is

possibly not found the problem that the output

current is dropping due to the insufficient

connection between terminal "B" and the output

wire.

5. Connect a voltmeter with a range of 0 − 20 V

between the alternator "B" terminal and the earth

[Connect the (+) lead of the voltmeter to the "B"

terminal, and then connect the (-) lead of the

voltmeter to the earth].

6. Connect the negative battery cable.

AK203362

Alternator Ammeter

(clamp-type)

Voltmeter

Battery Inition switch

Engine-ECU

Engine-A/T-ECU

Load

B

FR

L

S

G +

AH

–

Charging indicator

Brake warning light

Page 70 of 788

CHARGING SYSTEM

ENGINE ELECTRICAL16-6

7. Connect a tachometer or the MUT-II/III (Refer to

GROUP 11A − On-vehicle Service − Idle speed

check <4G1> P.11A-11 or GROUP 11C −

On-vehicle Service − Idle speed check <4G6>

P.11C-11).

8. Leave the hood open.

9. Check that the reading on the voltmeter is equal

to the battery voltage.

NOTE: If the voltage is 0 V, the cause is probably

an open circuit in the wire or fusible link between

the alternator "B" terminal and the battery (+)

terminal.

10.Turn the light switch on to turn on headlamps and

then start the engine.

11.Immediately after setting the headlamps to high

beam and turning the heater blower switch to the

high revolution position, increase the engine

speed to 2,500 r/min and read the maximum

current output value displayed on the ammeter.

Limit: 70 % of normal current outputNOTE: .

•For the nominal current output, refer to the

Alternator Specifications.

•Because the current from the battery will soon

drop after the engine is started, the above step

should be carried out as quickly as possible in

order to obtain the maximum current output

value.

•The current output value will depend on the

electrical load and the temperature of the

alternator body.

•If the electrical load is small while testing, the

specified level of current may not be output

even though the alternator is normal. In such

cases, increase the electrical load by leaving

the headlamps turned on for some time to

discharge the battery or by using the lighting

system in another vehicle, and then test again.

•The specified level of current also may not be

output if the temperature of the alternator body

or the ambient temperature is too high. In such

cases, cool the alternator and then test again.

12.The reading on the ammeter should be above the

limit value. If the reading is below the limit value

and the alternator output wire is normal, remove

the alternator from the engine and check the

alternator.

13.Run the engine at idle after the test.

14.Turn the ignition switch to the "LOCK" (OFF)

position.

15.Remove the tachometer or the MUT-II/III.

16.Disconnect the negative battery cable.

17.Disconnect the ammeter and voltmeter.

18.Connect the negative battery cable.

Page 110 of 788

ENGINE CONTROL

ENGINE AND EMISSION CONTROL17-2

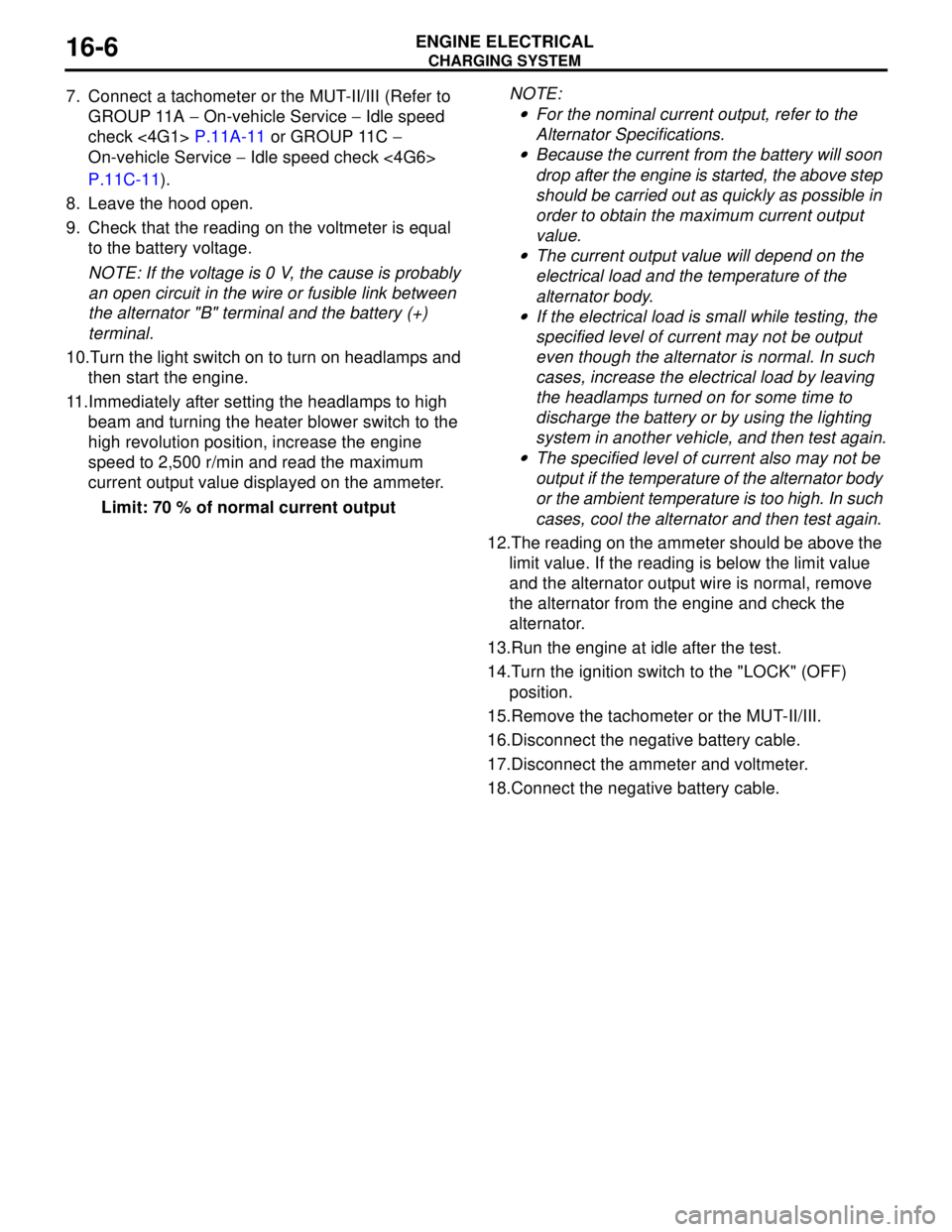

ENGINE CONTROL

GENERAL INFORMATIONM1171000100277

A cable-type accelerator mechanical

suspended-type pedal has been adopted.

SERVICE SPECIFICATIONSM1171000300088

ON-VEHICLE SERVICE

ACCEL CABLE CHECK AND

ADJUSTMENT

M1171000900314

1. Turn A/C and lights OFF. Inspect and adjust at no

load.

2. Warm engine until stabilized at idle.

3. Confirm idle speed is at standard value.

Standard value:

750 ± 50 r/min <4G1>

750 ± 100 r/min <4G6>

4. Stop engine. [ignition switch: LOCK (OFF)

position].

5. Confirm there are no sharp bends in the

accelerator cable.

6. Check the inner cable for correct slack.

Standard value: 1.0 − 2.0 mm

7. If there is too much slack or no slack, adjust play

by the following procedures.

(1) Loosen the adjusting bolts to release the

cable.

(2) Move the plate until the inner cable play is at

the standard value, and then tighten the

adjusting bolts.

(3) After adjusting, check that the throttle lever is

touching the stopper. Item Standard value

Accel cable play mm 1.0 − 2.0

Engine idle speed r/min 4G1 750 ± 50

4G6 750 ± 100

AC207966

Adjusting bolts

Plate

Accel cable

AC

<4G1>

AC301055

Adjusting bolts

Plate

Accel cable

AC

<4G6>

Page 245 of 788

ON-VEHICLE SERVICE

POWER STEERING37-11

ON-VEHICLE SERVICE

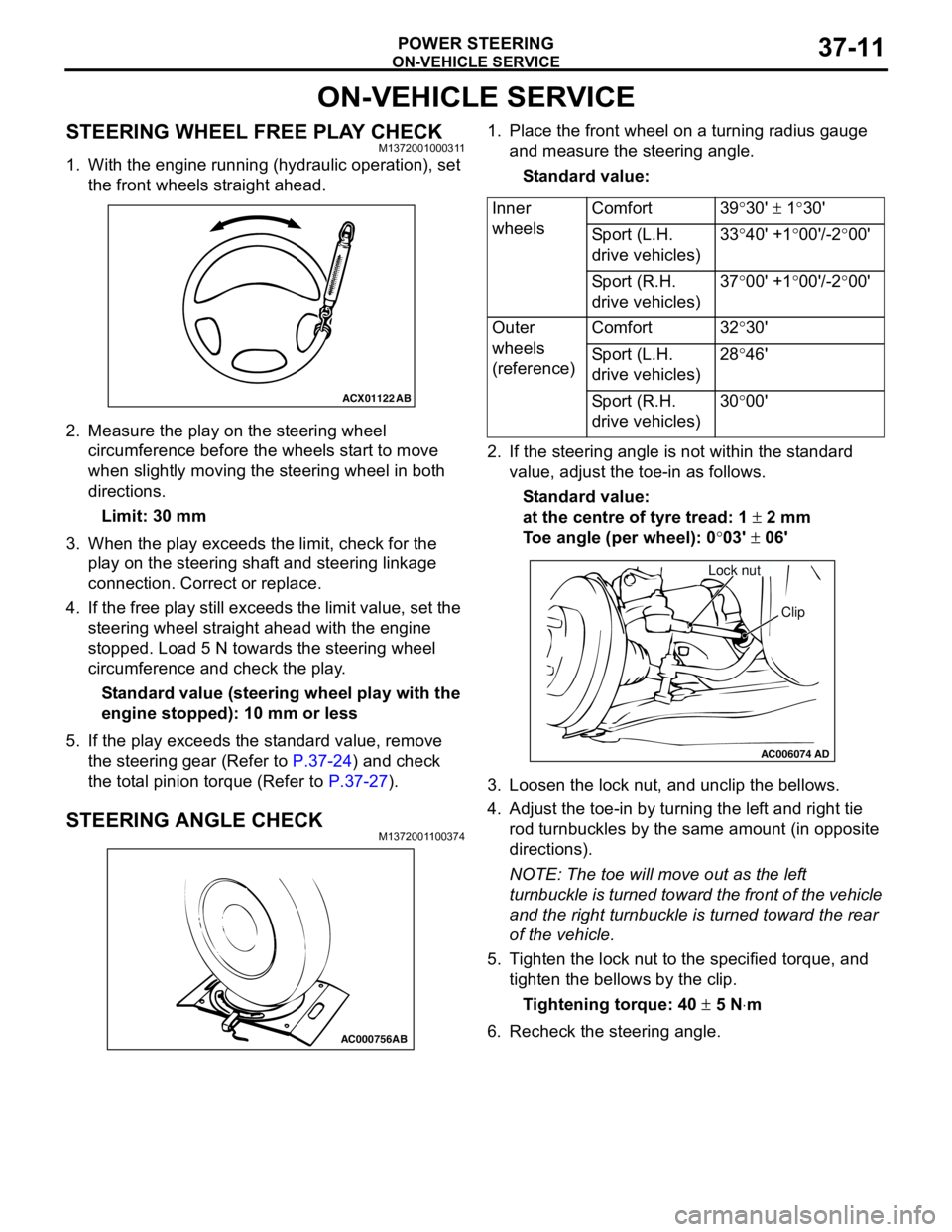

STEERING WHEEL FREE PLAY CHECKM1372001000311

1. With the engine running (hydraulic operation), set

the front wheels straight ahead.

2. Measure the play on the steering wheel

circumference before the wheels start to move

when slightly moving the steering wheel in both

directions.

Limit: 30 mm

3. When the play exceeds the limit, check for the

play on the steering shaft and steering linkage

connection. Correct or replace.

4. If the free play still exceeds the limit value, set the

steering wheel straight ahead with the engine

stopped. Load 5 N towards the steering wheel

circumference and check the play.

Standard value (steering wheel play with the

engine stopped): 10 mm or less

5. If the play exceeds the standard value, remove

the steering gear (Refer to P.37-24) and check

the total pinion torque (Refer to P.37-27).

STEERING ANGLE CHECKM1372001100374

1. Place the front wheel on a turning radius gauge

and measure the steering angle.

Standard value:

2. If the steering angle is not within the standard

value, adjust the toe-in as follows.

Standard value:

at the centre of tyre tread: 1 ± 2 mm

Toe angle (per wheel): 0°03' ± 06'

3. Loosen the lock nut, and unclip the bellows.

4. Adjust the toe-in by turning the left and right tie

rod turnbuckles by the same amount (in opposite

directions).

NOTE: The toe will move out as the left

turnbuckle is turned toward the front of the vehicle

and the right turnbuckle is turned toward the rear

of the vehicle.

5. Tighten the lock nut to the specified torque, and

tighten the bellows by the clip.

Tightening torque: 40 ± 5 N⋅m

6. Recheck the steering angle.

ACX01122

AB

AC000756AB

Inner

wheelsComfort 39°30' ± 1°30'

Sport (L.H.

drive vehicles)33°40' +1°00'/-2°00'

Sport (R.H.

drive vehicles)37°00' +1°00'/-2°00'

Outer

wheels

(reference)Comfort 32°30'

Sport (L.H.

drive vehicles)28°46'

Sport (R.H.

drive vehicles)30°00'

AC006074AD

Lock nut

Clip

Page 439 of 788

COMBINATION METER ASSEMBLY

CHASSIS ELECTRICAL54A-51

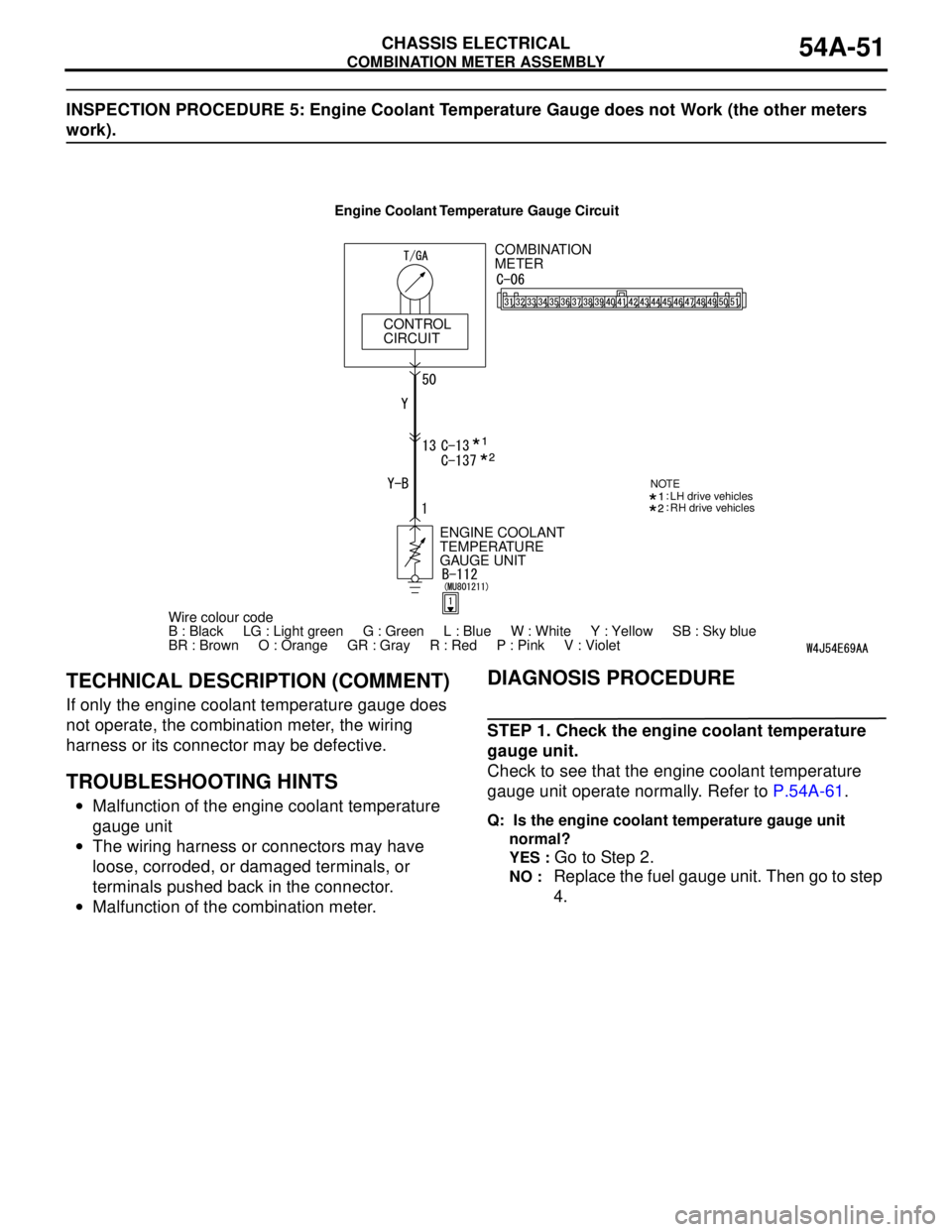

INSPECTION PROCEDURE 5: Engine Coolant Temperature Gauge does not Work (the other meters

work).

TECHNICAL DESCRIPTION (COMMENT)

If only the engine coolant temperature gauge does

not operate, the combination meter, the wiring

harness or its connector may be defective.

TROUBLESHOOTING HINTS

•Malfunction of the engine coolant temperature

gauge unit

•The wiring harness or connectors may have

loose, corroded, or damaged terminals, or

terminals pushed back in the connector.

•Malfunction of the combination meter.

DIAGNOSIS PROCEDURE

STEP 1. Check the engine coolant temperature

gauge unit.

Check to see that the engine coolant temperature

gauge unit operate normally. Refer to P.54A-61.

Q: Is the engine coolant temperature gauge unit

normal?

YES :

Go to Step 2.

NO : Replace the fuel gauge unit. Then go to step

4.

COMBINATION

METER

CONTROL

CIRCUIT

Wire colour code

B : Black LG : Light green G : Green L : Blue W : White Y : Yellow SB : Sky blue

BR : Brown O : Orange GR : Gray R : Red P : Pink V : Violet ENGINE COOLANT

TEMPERATURE

GAUGE UNIT

NOTELH drive vehicles

RH drive vehicles

Engine Coolant Temperature Gauge Circuit

Page 459 of 788

FOG LAMP

CHASSIS ELECTRICAL54A-71

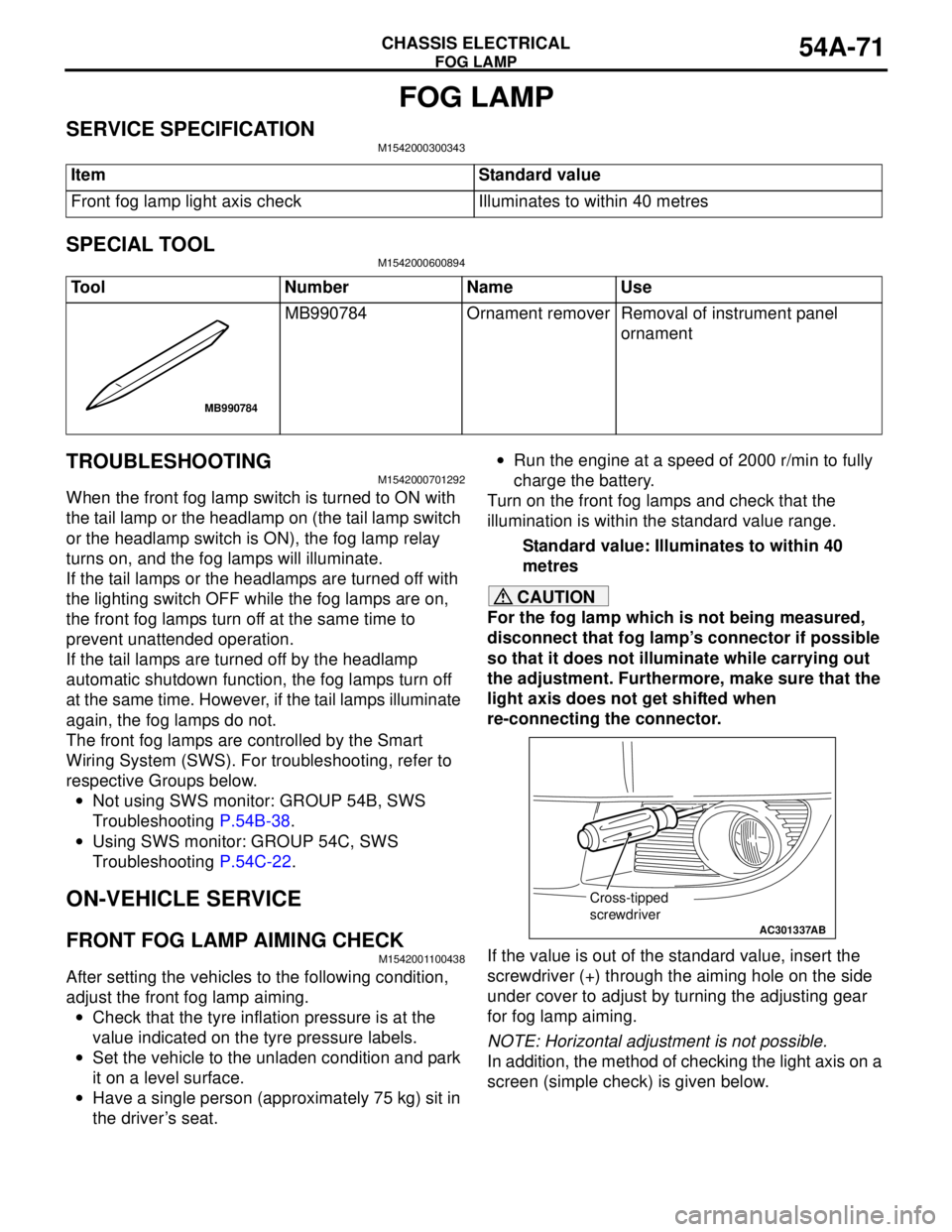

FOG LAMP

SERVICE SPECIFICATIONM1542000300343

SPECIAL TOOLM1542000600894

TROUBLESHOOTINGM1542000701292

When the front fog lamp switch is turned to ON with

the tail lamp or the headlamp on (the tail lamp switch

or the headlamp switch is ON), the fog lamp relay

turns on, and the fog lamps will illuminate.

If the tail lamps or the headlamps are turned off with

the lighting switch OFF while the fog lamps are on,

the front fog lamps turn off at the same time to

prevent unattended operation.

If the tail lamps are turned off by the headlamp

automatic shutdown function, the fog lamps turn off

at the same time. However, if the tail lamps illuminate

again, the fog lamps do not.

The front fog lamps are controlled by the Smart

Wiring System (SWS). For troubleshooting, refer to

respective Groups below.

•Not using SWS monitor: GROUP 54B, SWS

Troubleshooting P.54B-38.

•Using SWS monitor: GROUP 54C, SWS

Troubleshooting P.54C-22.

ON-VEHICLE SERVICE

FRONT FOG LAMP AIMING CHECKM1542001100438

After setting the vehicles to the following condition,

adjust the front fog lamp aiming.

•Check that the tyre inflation pressure is at the

value indicated on the tyre pressure labels.

•Set the vehicle to the unladen condition and park

it on a level surface.

•Have a single person (approximately 75 kg) sit in

the driver’s seat.•Run the engine at a speed of 2000 r/min to fully

charge the battery.

Turn on the front fog lamps and check that the

illumination is within the standard value range.

Standard value: Illuminates to within 40

metres

CAUTION

For the fog lamp which is not being measured,

disconnect that fog lamp’s connector if possible

so that it does not illuminate while carrying out

the adjustment. Furthermore, make sure that the

light axis does not get shifted when

re-connecting the connector.

If the value is out of the standard value, insert the

screwdriver (+) through the aiming hole on the side

under cover to adjust by turning the adjusting gear

for fog lamp aiming.

NOTE: Horizontal adjustment is not possible.

In addition, the method of checking the light axis on a

screen (simple check) is given below. Item Standard value

Front fog lamp light axis check Illuminates to within 40 metres

Tool Number Name Use

MB990784 Ornament remover Removal of instrument panel

ornament

MB990784

AC301337

Cross-tipped

screwdriver

AB

Page 551 of 788

TROUBLESHOOTING

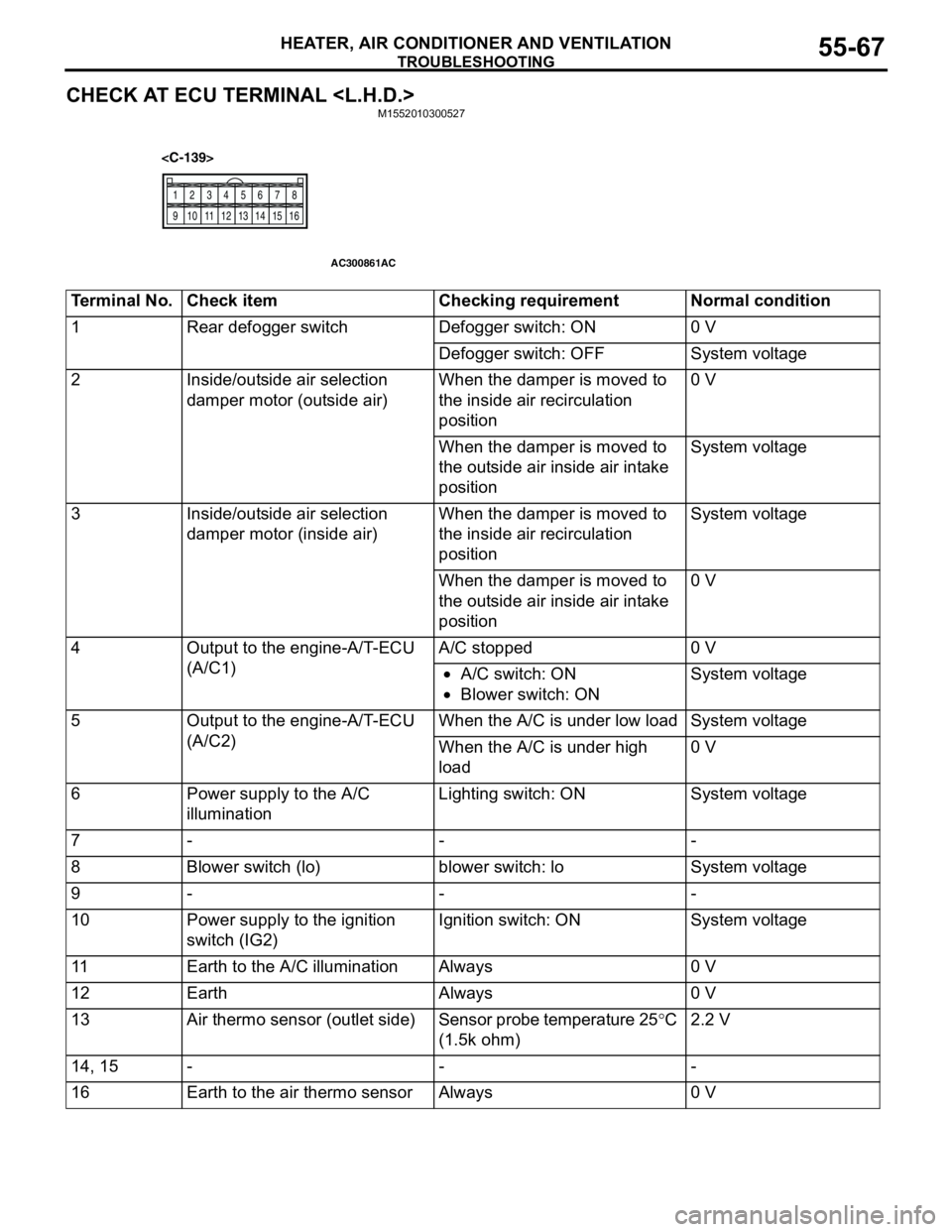

HEATER, AIR CONDITIONER AND VENTILATION55-67

CHECK AT ECU TERMINAL

12

345

678

9 10111213141516

AC300861AC

Terminal No. Check item Checking requirement Normal condition

1 Rear defogger switch Defogger switch: ON 0 V

Defogger switch: OFF System voltage

2 Inside/outside air selection

damper motor (outside air)When the damper is moved to

the inside air recirculation

position0 V

When the damper is moved to

the outside air inside air intake

positionSystem voltage

3 Inside/outside air selection

damper motor (inside air)When the damper is moved to

the inside air recirculation

positionSystem voltage

When the damper is moved to

the outside air inside air intake

position0 V

4 Output to the engine-A/T-ECU

(A/C1)A/C stopped 0 V

•A/C switch: ON

•Blower switch: ONSystem voltage

5 Output to the engine-A/T-ECU

(A/C2)When the A/C is under low load System voltage

When the A/C is under high

load0 V

6 Power supply to the A/C

illuminationLighting switch: ON System voltage

7---

8 Blower switch (lo) blower switch: lo System voltage

9---

10 Power supply to the ignition

switch (IG2)Ignition switch: ON System voltage

11 Earth to the A/C illumination Always 0 V

12 Earth Always 0 V

13 Air thermo sensor (outlet side) Sensor probe temperature 25°C

(1.5k ohm)2.2 V

14, 15 - - -

16 Earth to the air thermo sensor Always 0 V

Page 552 of 788

TROUBLESHOOTING

HEATER, AIR CONDITIONER AND VENTILATION55-68

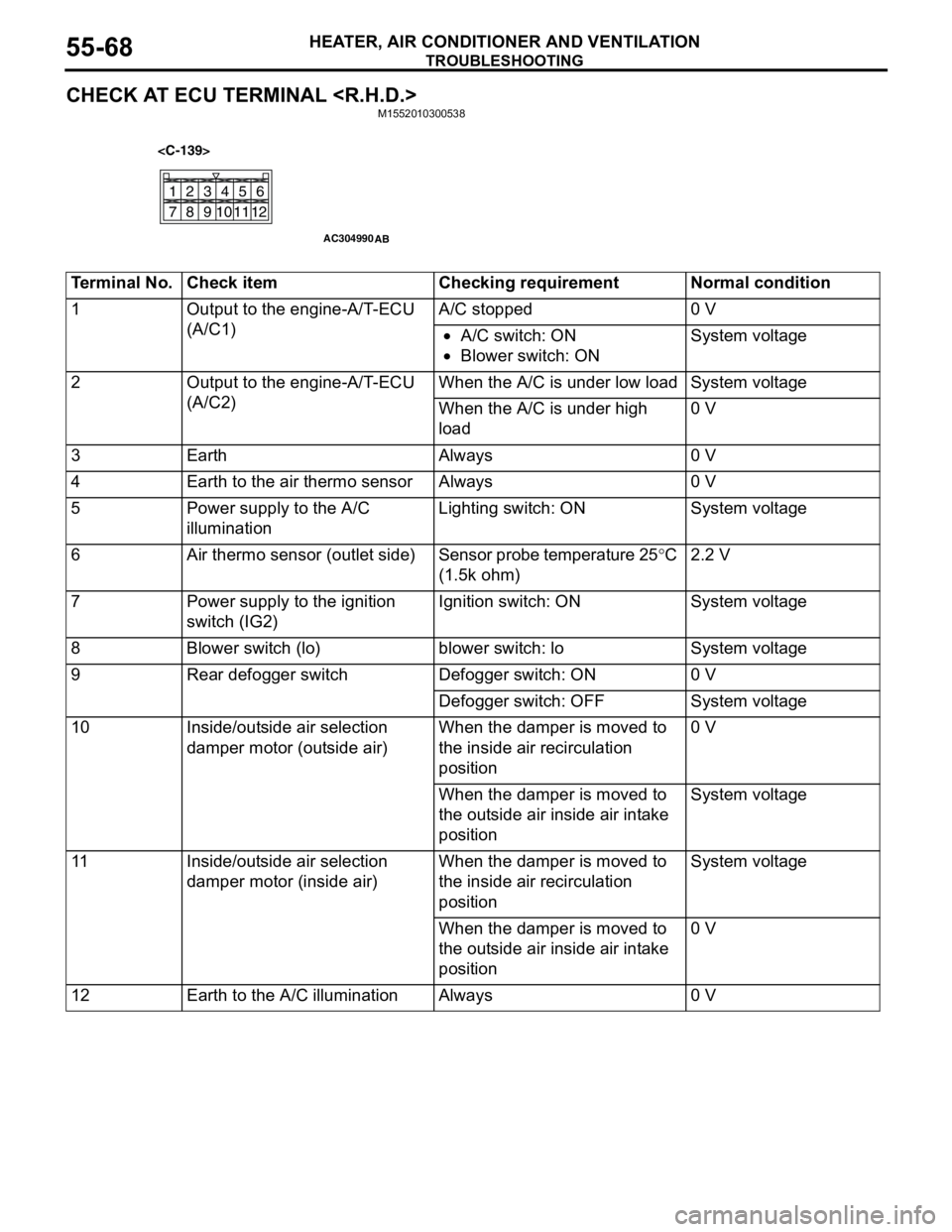

CHECK AT ECU TERMINAL

21

78

6 534

11

10912

AC304990

AB

Terminal No. Check item Checking requirement Normal condition

1 Output to the engine-A/T-ECU

(A/C1)A/C stopped 0 V

•A/C switch: ON

•Blower switch: ONSystem voltage

2 Output to the engine-A/T-ECU

(A/C2)When the A/C is under low load System voltage

When the A/C is under high

load0 V

3 Earth Always 0 V

4 Earth to the air thermo sensor Always 0 V

5 Power supply to the A/C

illuminationLighting switch: ON System voltage

6 Air thermo sensor (outlet side) Sensor probe temperature 25°C

(1.5k ohm)2.2 V

7 Power supply to the ignition

switch (IG2)Ignition switch: ON System voltage

8 Blower switch (lo) blower switch: lo System voltage

9 Rear defogger switch Defogger switch: ON 0 V

Defogger switch: OFF System voltage

10 Inside/outside air selection

damper motor (outside air)When the damper is moved to

the inside air recirculation

position0 V

When the damper is moved to

the outside air inside air intake

positionSystem voltage

11 Inside/outside air selection

damper motor (inside air)When the damper is moved to

the inside air recirculation

positionSystem voltage

When the damper is moved to

the outside air inside air intake

position0 V

12 Earth to the A/C illumination Always 0 V

Page 579 of 788

COMPRESSOR ASSEMBLY AND TENSION PULLEY

HEATER, AIR CONDITIONER AND VENTILATION55-95

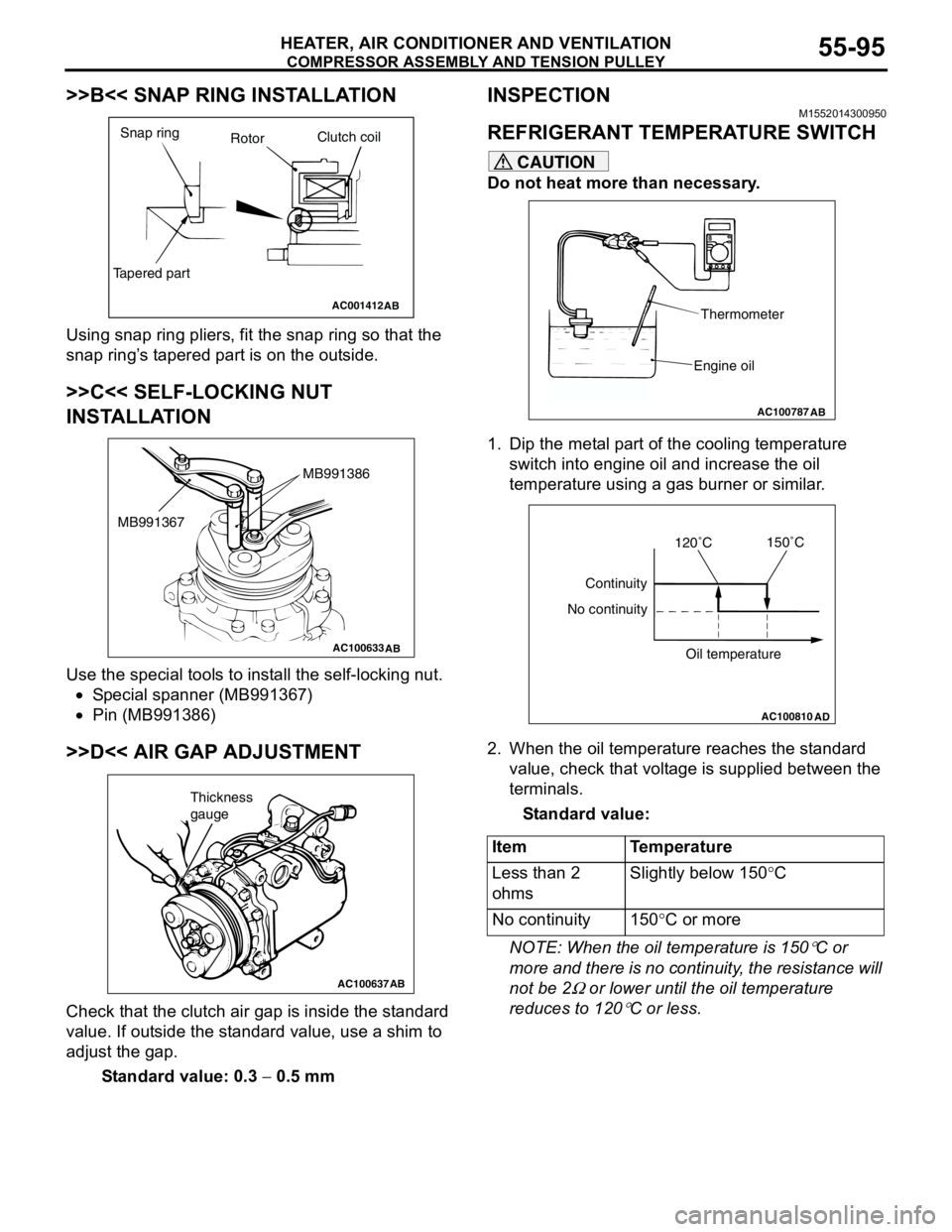

>>B<< SNAP RING INSTALLATION

Using snap ring pliers, fit the snap ring so that the

snap ring’s tapered part is on the outside.

>>C<< SELF-LOCKING NUT

INSTALLATION

Use the special tools to install the self-locking nut.

•Special spanner (MB991367)

•Pin (MB991386)

>>D<< AIR GAP ADJUSTMENT

Check that the clutch air gap is inside the standard

value. If outside the standard value, use a shim to

adjust the gap.

Standard value: 0.3 − 0.5 mm

INSPECTIONM1552014300950

REFRIGERANT TEMPERATURE SWITCH

CAUTION

Do not heat more than necessary.

1. Dip the metal part of the cooling temperature

switch into engine oil and increase the oil

temperature using a gas burner or similar.

2. When the oil temperature reaches the standard

value, check that voltage is supplied between the

terminals.

Standard value:

NOTE: When the oil temperature is 150

°C or

more and there is no continuity, the resistance will

not be 2

Ω or lower until the oil temperature

reduces to 120

°C or less.

AC001412

Snap ring

RotorClutch coil

Tapered part

AB

AC100633AB

MB991386

MB991367

AC100637AB

Thickness

gauge

Item Temperature

Less than 2

ohmsSlightly below 150°C

No continuity 150°C or more

AC100787

Thermometer

Engine oil

AB

AC100810

Continuity

No continuity

Oil temperature

AD

120ËšC150ËšC