Head MITSUBISHI LANCER 2005 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 371 of 788

HEADLAMP WASHER

EXTERIOR51-33

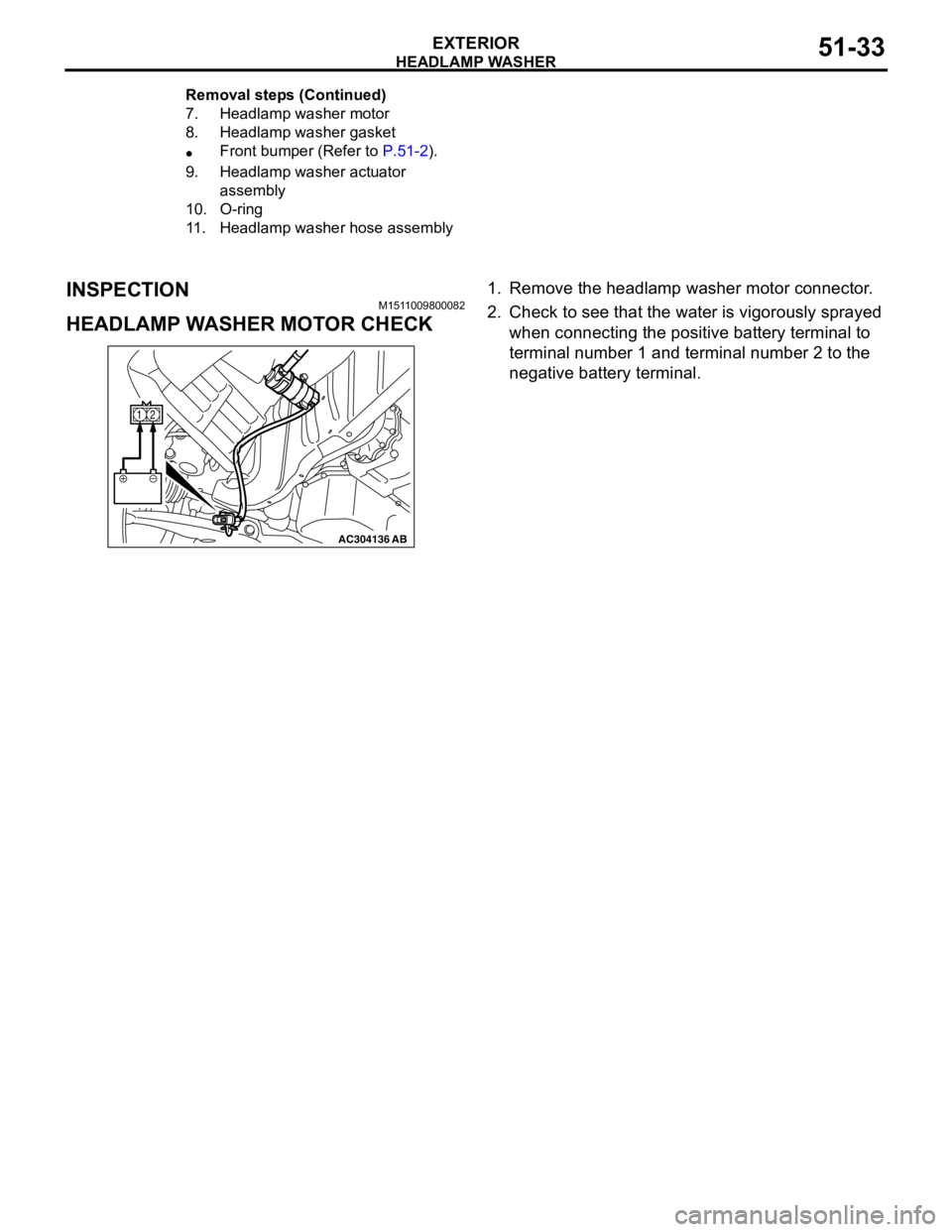

INSPECTIONM1511009800082

HEADLAMP WASHER MOTOR CHECK

1. Remove the headlamp washer motor connector.

2. Check to see that the water is vigorously sprayed

when connecting the positive battery terminal to

terminal number 1 and terminal number 2 to the

negative battery terminal.

7. Headlamp washer motor

8. Headlamp washer gasket

•Front bumper (Refer to P.51-2).

9. Headlamp washer actuator

assembly

10. O-ring

11. Headlamp washer hose assembly Removal steps (Continued)

AC304136AB

12

Page 390 of 788

54A-2

COMBINATION METER

ASSEMBLY . . . . . . . . . . . . . . . .

54A-29

SERVICE SPECIFICATIONS. . . . .

54A-29

SEALANT. . . . . . . . . . . . . . . . . . . .54A-29

SPECIAL TOOLS. . . . . . . . . . . . . .54A-29

TROUBLESHOOTING . . . . . . . . . .54A-31

SYMPTOM CHART . . . . . . . . . . . . . . . . 54A-31

SYMPTOM PROCEDURES . . . . . .54A-32

ON-VEHICLE SERVICE. . . . . . . . .54A-60

SPEEDOMETER CHECK . . . . . . . . . . . 54A-60

TACHOMETER CHECK . . . . . . . . . . . . 54A-60

FUEL TANK GAUGE UNIT CHECK . . . 54A-61

ENGINE COOLANT TEMPERATURE GAUGE

UNIT CHECK . . . . . . . . . . . . . . . . . . . . . 54A-61

COMBINATION METER ASSEMBLY54A-63

REMOVAL AND INSTALLATION . . . . . 54A-63

INSPECTION . . . . . . . . . . . . . . . . . . . . . 54A-64

DISASSEMBLY AND REASSEMBLY . . 54A-65

HEADLAMP . . . . . . . . . . . . . . . .54A-66

SERVICE SPECIFICATIONS. . . . .

54A-66

TROUBLESHOOTING . . . . . . . . . .54A-66

ON-VEHICLE SERVICE. . . . . . . . .54A-66

HEADLAMP AIMING . . . . . . . . . . . . . . . 54A-66

LUMINOUS INTENSITY

MEASUREMENT . . . . . . . . . . . . . . . . . . 54A-67

BULB REPLACEMENT . . . . . . . . . . . . . 54A-68

HEADLAMP . . . . . . . . . . . . . . . . . .54A-69

REMOVAL AND INSTALLATION . . . . . 54A-69

HEADLAMP LEVELING SWITCH .54A-70

REMOVAL AND INSTALLATION . . . . . 54A-70

INSPECTION . . . . . . . . . . . . . . . . . . . . . 54A-70

FOG LAMP . . . . . . . . . . . . . . . . 54A-71

SERVICE SPECIFICATION . . . . . .

54A-71

SPECIAL TOOL . . . . . . . . . . . . . . .54A-71

TROUBLESHOOTING . . . . . . . . . .54A-71

ON-VEHICLE SERVICE . . . . . . . . .54A-71

FRONT FOG LAMP AIMING CHECK . . 54A-71

FOG LAMP . . . . . . . . . . . . . . . . . . .54A-73

REMOVAL AND INSTALLATION . . . . . . 54A-73

FOG LAMP SWITCH . . . . . . . . . . .54A-74

REMOVAL AND INSTALLATION . . . . . . 54A-74

INSPECTION . . . . . . . . . . . . . . . . . . . . . 54A-74

REAR FOG LAMP . . . . . . . . . . 54A-75

TROUBLESHOOTING . . . . . . . . . .

54A-75

SPECIAL TOOL . . . . . . . . . . . . . . .54A-75

REAR FOG LAMP . . . . . . . . . . . . .54A-76

REMOVAL AND INSTALLATION . . . . . . 54A-76

REAR FOG LAMP SWITCH . . . . . .54A-76

REMOVAL AND INSTALATION . . . . . . . 54A-76

INSPECTION . . . . . . . . . . . . . . . . . . . . . 54A-76

SIDE TURN-SIGNAL LAMP. . . 54A-77

SPECIAL TOOL . . . . . . . . . . . . . . .

54A-77

SIDE TURN-SIGNAL LAMP . . . . . .54A-77

REMOVAL AND INSTALLATION . . . . . . 54A-77

ROOM LAMP . . . . . . . . . . . . . . 54A-78

TROUBLESHOOTING . . . . . . . . . . . . . . 54A-78

Continued on next page

Page 393 of 788

BATTERY

CHASSIS ELECTRICAL54A-5

BATTERY TESTM1541001200506

BATTERY TESTING PROCEDURE

STEP 1. Check the battery cables.

Remove the negative cable, then the positive cable.

Check for dirty or corroded connections.

Q: Are the battery cables dirty or have corroded

connections?

YES :

Clean the battery cables. Then go to Step 2.

NO : Go to Step 2.

STEP 2. Check the battery post.

Check for loose battery post.

Q: Are the battery post faulty?

YES :

Replace the battery. Then go to Step 4.

NO : Go to Step 3.

STEP 3. Check the battery case and cover.

(1) Remove the hold-downs and shields.

(2) Check for broken/cracked case or cover.

Q: Is the battery case or cover faulty?

YES :

Replace the battery. Then go to Step 4.

NO : Go to Step 4.

STEP 4. Check the open circuit voltage.

(1) Turn headlamps on for 15 seconds.

(2) Turn headlamps off for two minutes to allow

battery positive voltage to stabilize.

(3) Disconnect the battery cables.

(4) Read open circuit voltage.

Q: Is open circuit voltage 12.4 volts or more?

YES :

Go to Step 6.

NO : Go to Step 5.

STEP 5. Charge battery.

Q: Charging the battery?

YES :

Go to Step 6.

NO : Charge the battery at 5 amps for 15 hours.

Then re-test, go to Step 4.

STEP 6. Check the load test.

(1) Connect a load tester to the battery.

(2) Load the battery at the recommended discharge

rate (See LOAD TEST RATE CHART) for 15

seconds.

(3) Read voltage after 15 seconds, then remove

load.

(4) Compare the measured value with the minimum

voltage. (See LOAD TEST CHART.)

Q: Is the voltage higher than minimum voltage?

NO :

Replace the battery. Then go to Step 4.

YES : The battery is normal.

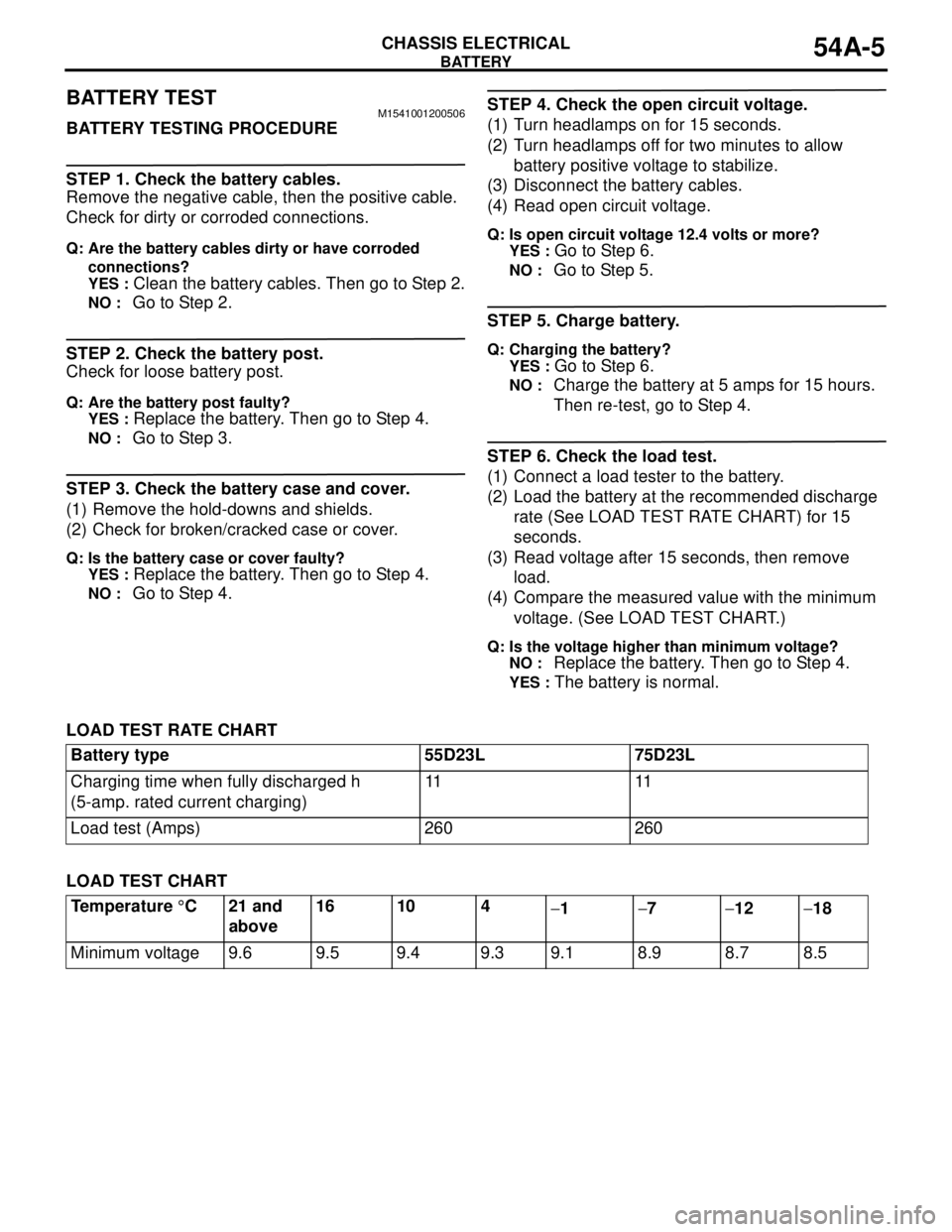

LOAD TEST RATE CHART

LOAD TEST CHARTBattery type 55D23L 75D23L

Charging time when fully discharged h

(5-amp. rated current charging)11 11

Load test (Amps) 260 260

Temperature °C 21 and

above16 10 4

−1−7−12−18

Minimum voltage 9.6 9.5 9.4 9.3 9.1 8.9 8.7 8.5

Page 416 of 788

Page 454 of 788

HEADLAMP

CHASSIS ELECTRICAL54A-66

HEADLAMP

SERVICE SPECIFICATIONSM1542000300332

TROUBLESHOOTING M1542000701281

Features the headlamp automatic shutdown function

to avoid battery drain when the headlamps are left

on. The main features are as follows:

•Extinguishes automatically in three minutes if the

ignition switch is turned off with the lighting switch

on.

•Extinguishes in one second if the driver's door is

opened within that 3-minute period.

•If the headlamps are turned on with the ignition

switch off, the headlamps and tail lamps will

extinguish in three minutes after the driver's door

is opened or closed.

The headlamps are controlled by the Smart Wiring

System (SWS). For troubleshooting, refer to

respective Groups below.

•Not using SWS monitor: GROUP 54B, SWS

Troubleshooting P.54B-38.

•Using SWS monitor: GROUP 54C, SWS

Troubleshooting P.54C-22.

ON-VEHICLE SERVICE

HEADLAMP AIMING

M1542000900538

PRE-AIMING INSTRUCTIONS

1. Inspect for badly rusted or faulty headlamp

assemblies.

2. These conditions must be corrected before a

satisfactory adjustment can be made.

3. Inspect tyre inflation, and adjust if it is necessary.

4. If the fuel tank is not full, place a weight in luggage

room of the vehicle to simulate weight of a full

tank (0.8 kg per litre).

5. There should be no other load in the vehicle other

than driver or substituted weight of approximately

75 kg placed in driver's position.

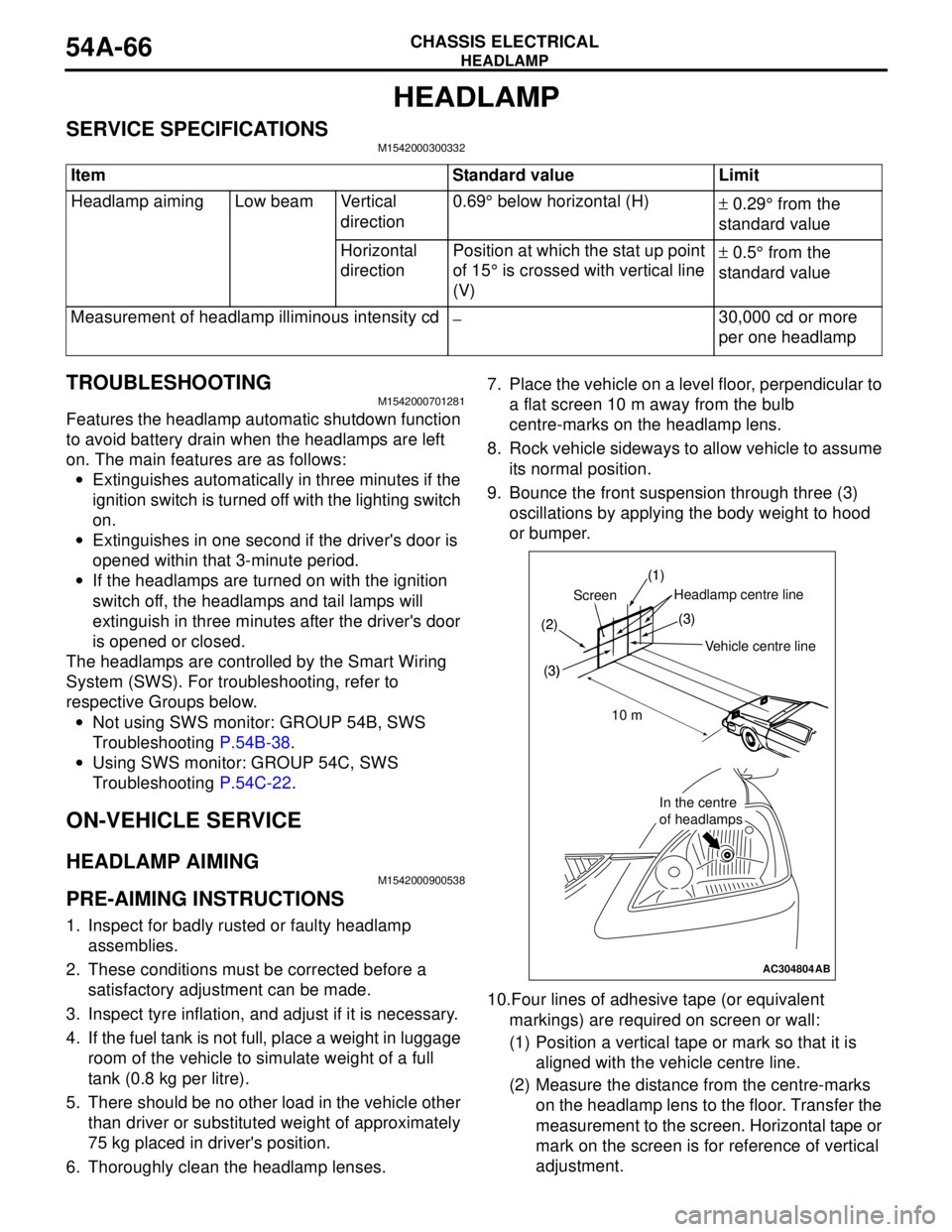

6. Thoroughly clean the headlamp lenses.7. Place the vehicle on a level floor, perpendicular to

a flat screen 10 m away from the bulb

centre-marks on the headlamp lens.

8. Rock vehicle sideways to allow vehicle to assume

its normal position.

9. Bounce the front suspension through three (3)

oscillations by applying the body weight to hood

or bumper.

10.Four lines of adhesive tape (or equivalent

markings) are required on screen or wall:

(1) Position a vertical tape or mark so that it is

aligned with the vehicle centre line.

(2) Measure the distance from the centre-marks

on the headlamp lens to the floor. Transfer the

measurement to the screen. Horizontal tape or

mark on the screen is for reference of vertical

adjustment. Item Standard value Limit

Headlamp aiming Low beam Vertical

direction0.69° below horizontal (H)

± 0.29° from the

standard value

Horizontal

directionPosition at which the stat up point

of 15° is crossed with vertical line

(V)± 0.5° from the

standard value

Measurement of headlamp illiminous intensity cd

−30,000 cd or more

per one headlamp

AC304804

(1)

(2)

(3)

Headlamp centre line

Vehicle crntre line Screen

(3)

10 m

In the centre

of headlamps

(1)

(2)

(3)(3)

In the centre

of headlamps

AB

Vehicle centre line

ScreenHeadlamp centre line

10 m

Page 455 of 788

HEADLAMP

CHASSIS ELECTRICAL54A-67

NOTE: Height from the floor to the centre of

the headlamps (Reference value): 840 mm

(3) Measure the distance from the centre line of

the vehicle to the centre of each headlamp.

Transfer the measurement to the screen.

Vertical tape or mark on the screen with

reference to the centre line of each headlamp

bulb.

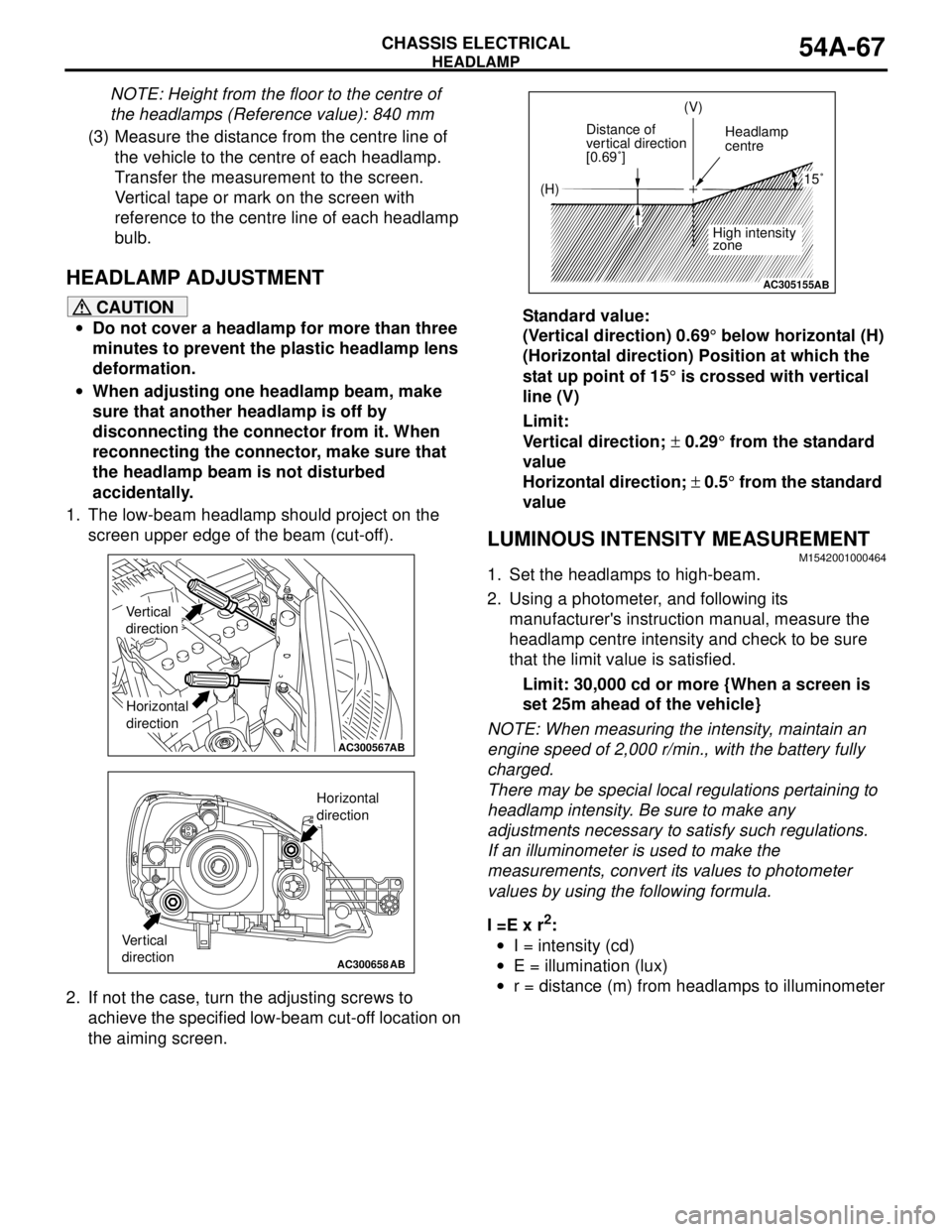

HEADLAMP ADJUSTMENT

CAUTION

•Do not cover a headlamp for more than three

minutes to prevent the plastic headlamp lens

deformation.

•When adjusting one headlamp beam, make

sure that another headlamp is off by

disconnecting the connector from it. When

reconnecting the connector, make sure that

the headlamp beam is not disturbed

accidentally.

1. The low-beam headlamp should project on the

screen upper edge of the beam (cut-off).

2. If not the case, turn the adjusting screws to

achieve the specified low-beam cut-off location on

the aiming screen.Standard value:

(Vertical direction) 0.69° below horizontal (H)

(Horizontal direction) Position at which the

stat up point of 15° is crossed with vertical

line (V)

Limit:

Vertical direction; ± 0.29° from the standard

value

Horizontal direction; ± 0.5° from the standard

value

LUMINOUS INTENSITY MEASUREMENTM1542001000464

1. Set the headlamps to high-beam.

2. Using a photometer, and following its

manufacturer's instruction manual, measure the

headlamp centre intensity and check to be sure

that the limit value is satisfied.

Limit: 30,000 cd or more {When a screen is

set 25m ahead of the vehicle}

NOTE: When measuring the intensity, maintain an

engine speed of 2,000 r/min., with the battery fully

charged.

There may be special local regulations pertaining to

headlamp intensity. Be sure to make any

adjustments necessary to satisfy such regulations.

If an illuminometer is used to make the

measurements, convert its values to photometer

values by using the following formula.

I =E x r

2:

•I = intensity (cd)

•E = illumination (lux)

•r = distance (m) from headlamps to illuminometer

AC300567AB

Vertical

direction

Horizontal

direction

AC300658AB

Vertical

direction

Horizontal

direction

AC305155

(H)(V)

Distance of

vertical direction

[0.69˚]Headlamp

centre

High intensity

zone

15˚

AB

Page 456 of 788

HEADLAMP

CHASSIS ELECTRICAL54A-68

BULB REPLACEMENTM1542001300658

Headlamp Bulb

CAUTION

Do not touch the surface of the bulb with hands

or dirty gloves as the bulb may pop after a short

time. If the surface does become dirty, clean it

with alcohol or thinner, and let it dry thoroughly

before installing.

1. Disconnect the battery.

2. Disconnect the connector.

3. Remove the socket cover.

4. Remove bulb mounting spring to pull out bulb.

5. After bulb is replaced, properly reconnect

connector.

Position Lamp Bulb

CAUTION

Do not touch the bulb surface bare-handed or

with dirty gloves. If dirt is attached on surface of

the bulb, immediately use alcohol or thinner to

remove dirt, and install the bulb after well dried.

1.

Disconnect the connector.

2. Screw out position lamp socket to pull out

position lamp bulb.

Front Turn-Signal Lamp Bulb

CAUTION

Do not touch the bulb surface bare-handed or

with dirty gloves. If dirt is attached on surface of

the bulb, immediately use alcohol or thinner to

remove dirt, and install the bulb after well dried.

1.

Disconnect the connector.

2. Screw out front turn-signal lamp socket to pull out

front turn-signal lamp bulb.

AC300667AC300667

Headlamp bulb

AB

Spring

AC300668

Position lamp

AB

AC300669

Front turn signal lamp

AB

Page 457 of 788

HEADLAMP

CHASSIS ELECTRICAL54A-69

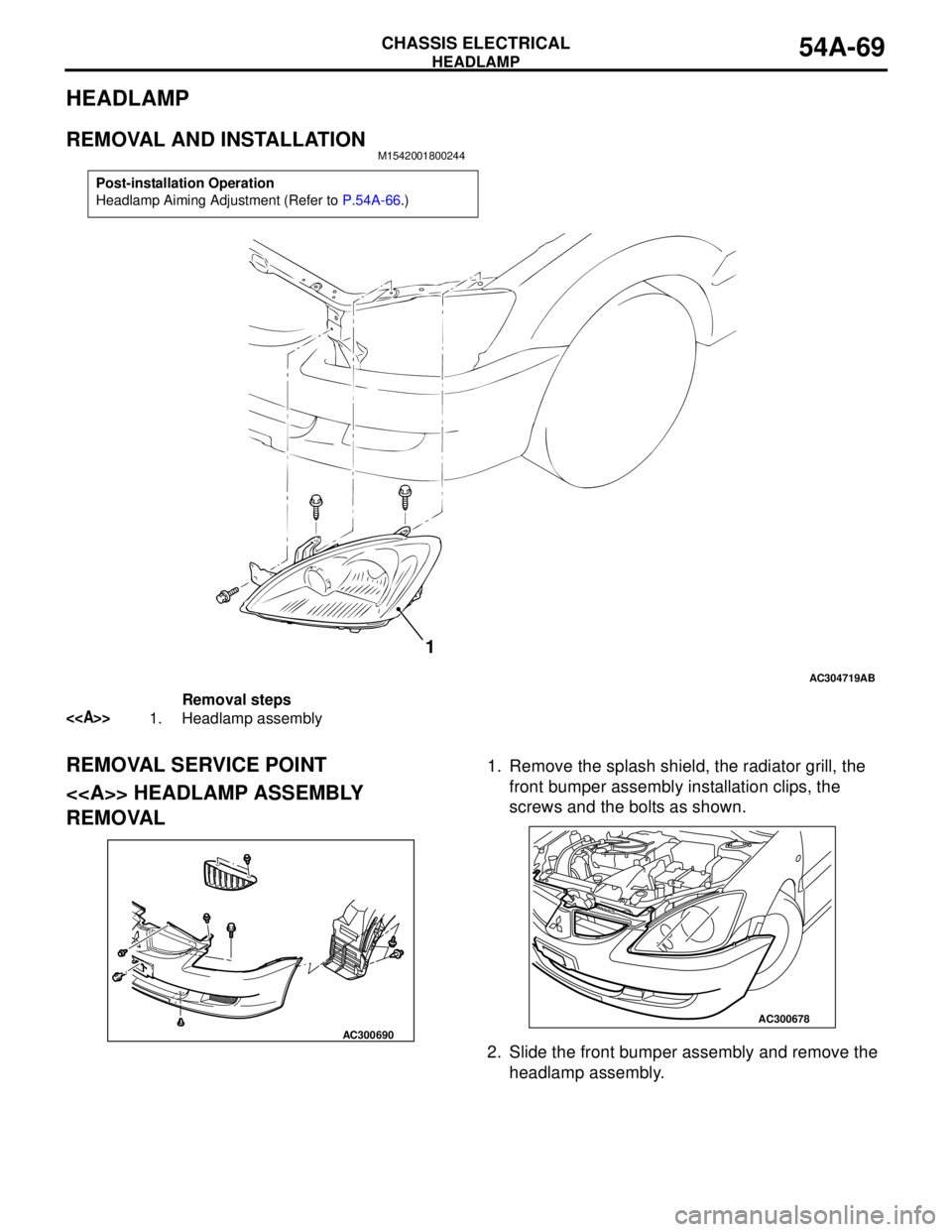

HEADLAMP

REMOVAL AND INSTALLATIONM1542001800244

REMOVAL SERVICE POINT

<> HEADLAMP ASSEMBLY

REMOVAL1. Remove the splash shield, the radiator grill, the

front bumper assembly installation clips, the

screws and the bolts as shown.

2. Slide the front bumper assembly and remove the

headlamp assembly.

Post-installation Operation

Headlamp Aiming Adjustment (Refer to P.54A-66.)

AC304719

1

AB

Removal steps

<>1. Headlamp assembly

AC300690

AC300678

Page 458 of 788

HEADLAMP

CHASSIS ELECTRICAL54A-70

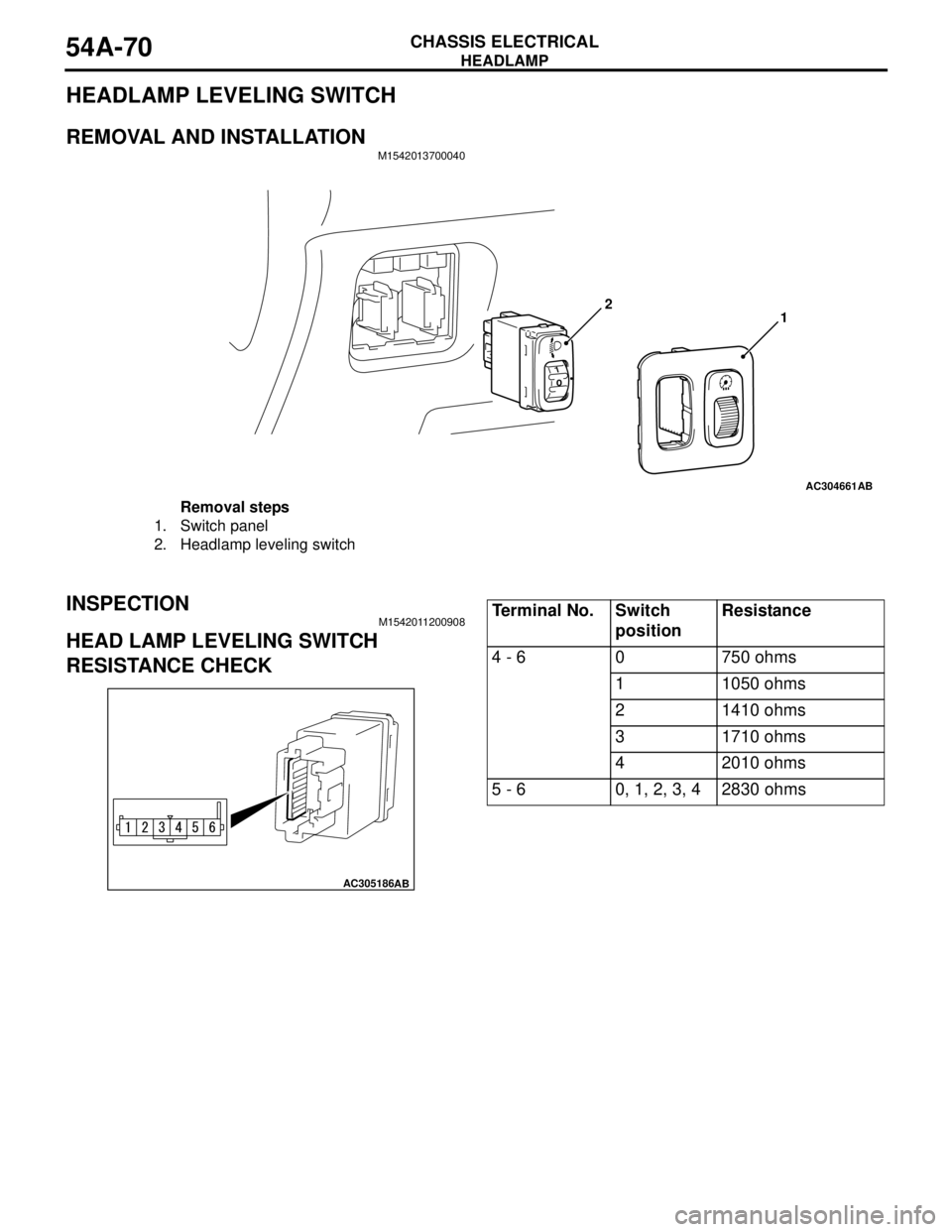

HEADLAMP LEVELING SWITCH

REMOVAL AND INSTALLATIONM1542013700040

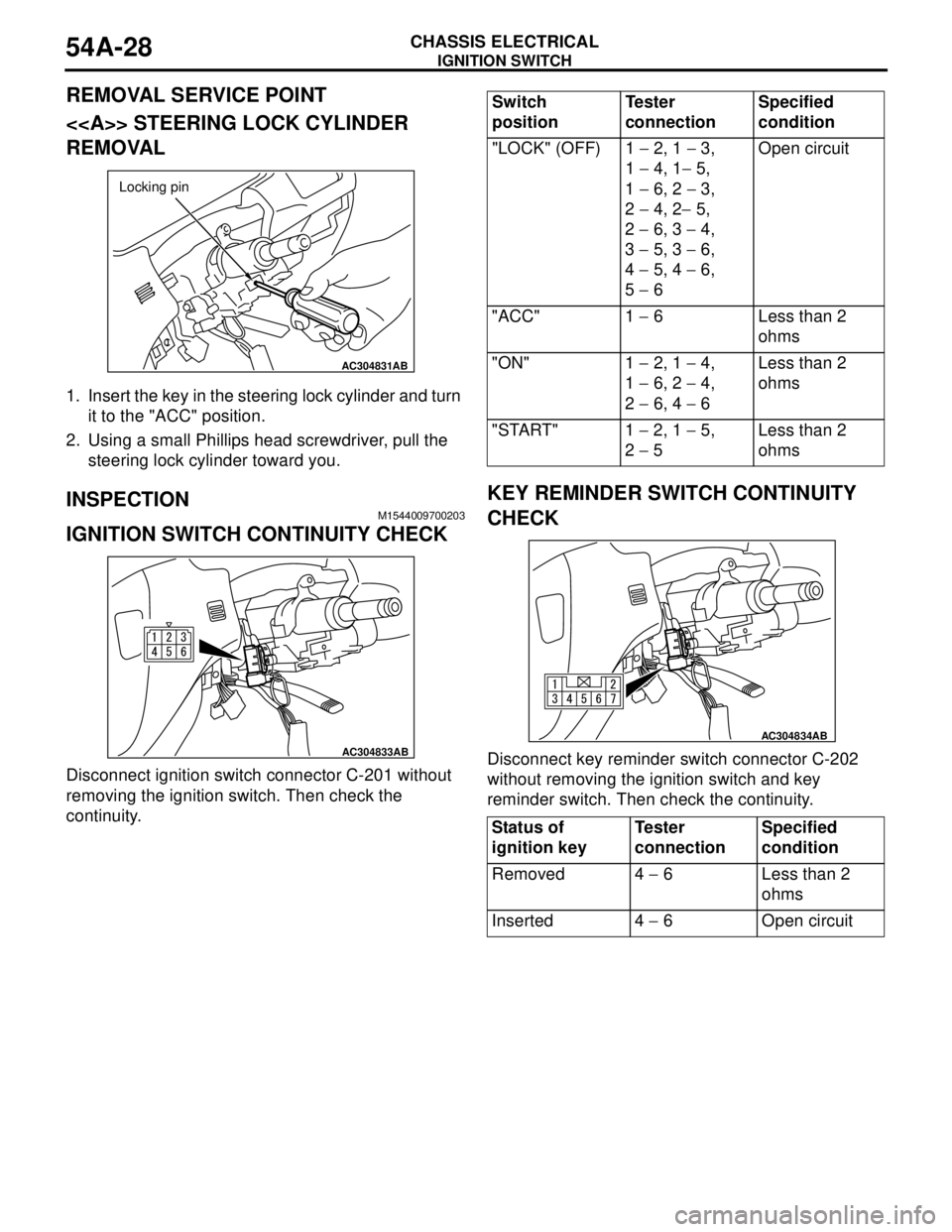

INSPECTIONM1542011200908

HEAD LAMP LEVELING SWITCH

RESISTANCE CHECK

AC304661AB

2

1

Removal steps

1. Switch panel

2. Headlamp leveling switch

AC305186AB

Te r m i n a l N o . S w i t c h

positionResistance

4 - 6 0 750 ohms

1 1050 ohms

2 1410 ohms

3 1710 ohms

4 2010 ohms

5 - 6 0, 1, 2, 3, 4 2830 ohms

Page 459 of 788

FOG LAMP

CHASSIS ELECTRICAL54A-71

FOG LAMP

SERVICE SPECIFICATIONM1542000300343

SPECIAL TOOLM1542000600894

TROUBLESHOOTINGM1542000701292

When the front fog lamp switch is turned to ON with

the tail lamp or the headlamp on (the tail lamp switch

or the headlamp switch is ON), the fog lamp relay

turns on, and the fog lamps will illuminate.

If the tail lamps or the headlamps are turned off with

the lighting switch OFF while the fog lamps are on,

the front fog lamps turn off at the same time to

prevent unattended operation.

If the tail lamps are turned off by the headlamp

automatic shutdown function, the fog lamps turn off

at the same time. However, if the tail lamps illuminate

again, the fog lamps do not.

The front fog lamps are controlled by the Smart

Wiring System (SWS). For troubleshooting, refer to

respective Groups below.

•Not using SWS monitor: GROUP 54B, SWS

Troubleshooting P.54B-38.

•Using SWS monitor: GROUP 54C, SWS

Troubleshooting P.54C-22.

ON-VEHICLE SERVICE

FRONT FOG LAMP AIMING CHECKM1542001100438

After setting the vehicles to the following condition,

adjust the front fog lamp aiming.

•Check that the tyre inflation pressure is at the

value indicated on the tyre pressure labels.

•Set the vehicle to the unladen condition and park

it on a level surface.

•Have a single person (approximately 75 kg) sit in

the driver’s seat.•Run the engine at a speed of 2000 r/min to fully

charge the battery.

Turn on the front fog lamps and check that the

illumination is within the standard value range.

Standard value: Illuminates to within 40

metres

CAUTION

For the fog lamp which is not being measured,

disconnect that fog lamp’s connector if possible

so that it does not illuminate while carrying out

the adjustment. Furthermore, make sure that the

light axis does not get shifted when

re-connecting the connector.

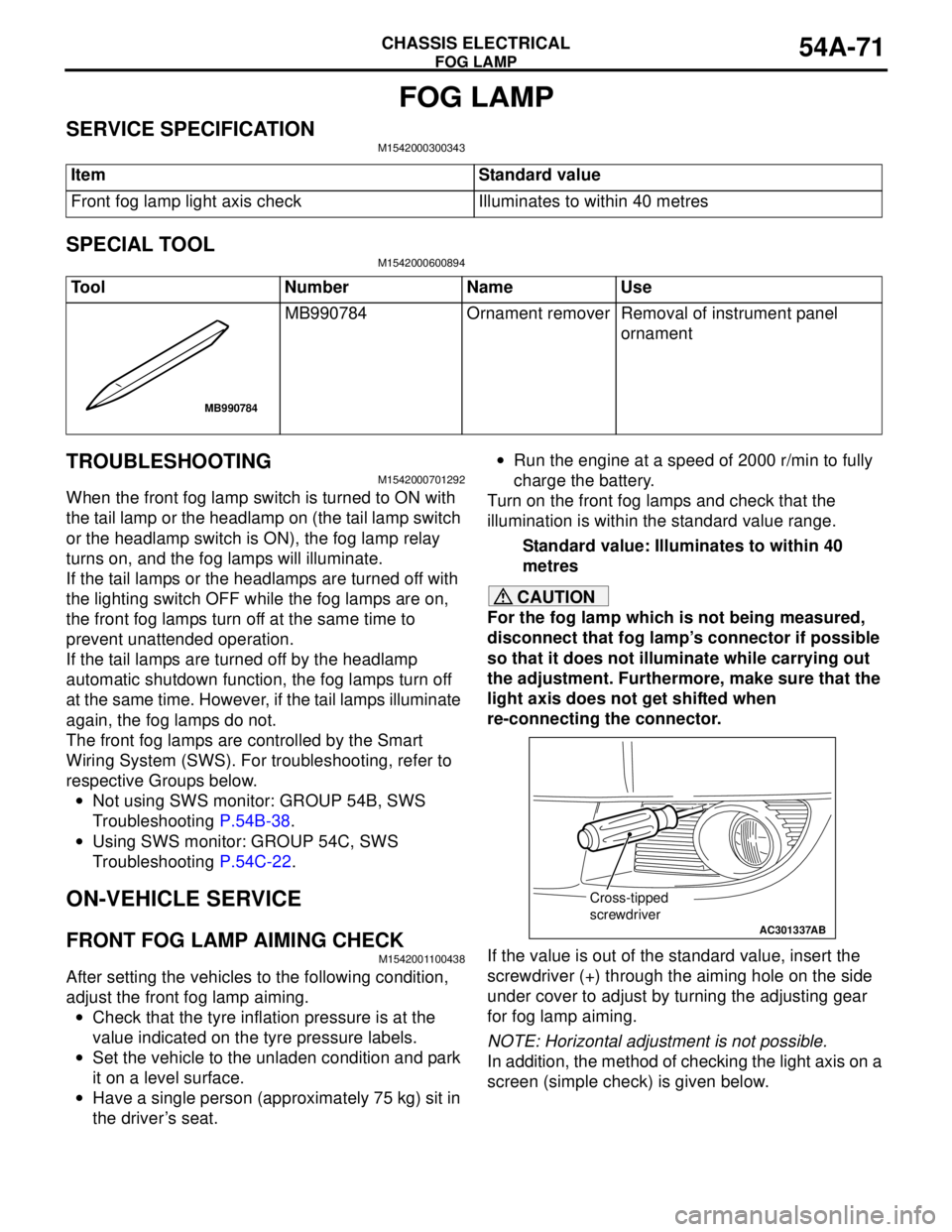

If the value is out of the standard value, insert the

screwdriver (+) through the aiming hole on the side

under cover to adjust by turning the adjusting gear

for fog lamp aiming.

NOTE: Horizontal adjustment is not possible.

In addition, the method of checking the light axis on a

screen (simple check) is given below. Item Standard value

Front fog lamp light axis check Illuminates to within 40 metres

Tool Number Name Use

MB990784 Ornament remover Removal of instrument panel

ornament

MB990784

AC301337

Cross-tipped

screwdriver

AB