service MITSUBISHI LANCER 2005 Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 70 of 788

CHARGING SYSTEM

ENGINE ELECTRICAL16-6

7. Connect a tachometer or the MUT-II/III (Refer to

GROUP 11A − On-vehicle Service − Idle speed

check <4G1> P.11A-11 or GROUP 11C −

On-vehicle Service − Idle speed check <4G6>

P.11C-11).

8. Leave the hood open.

9. Check that the reading on the voltmeter is equal

to the battery voltage.

NOTE: If the voltage is 0 V, the cause is probably

an open circuit in the wire or fusible link between

the alternator "B" terminal and the battery (+)

terminal.

10.Turn the light switch on to turn on headlamps and

then start the engine.

11.Immediately after setting the headlamps to high

beam and turning the heater blower switch to the

high revolution position, increase the engine

speed to 2,500 r/min and read the maximum

current output value displayed on the ammeter.

Limit: 70 % of normal current outputNOTE: .

•For the nominal current output, refer to the

Alternator Specifications.

•Because the current from the battery will soon

drop after the engine is started, the above step

should be carried out as quickly as possible in

order to obtain the maximum current output

value.

•The current output value will depend on the

electrical load and the temperature of the

alternator body.

•If the electrical load is small while testing, the

specified level of current may not be output

even though the alternator is normal. In such

cases, increase the electrical load by leaving

the headlamps turned on for some time to

discharge the battery or by using the lighting

system in another vehicle, and then test again.

•The specified level of current also may not be

output if the temperature of the alternator body

or the ambient temperature is too high. In such

cases, cool the alternator and then test again.

12.The reading on the ammeter should be above the

limit value. If the reading is below the limit value

and the alternator output wire is normal, remove

the alternator from the engine and check the

alternator.

13.Run the engine at idle after the test.

14.Turn the ignition switch to the "LOCK" (OFF)

position.

15.Remove the tachometer or the MUT-II/III.

16.Disconnect the negative battery cable.

17.Disconnect the ammeter and voltmeter.

18.Connect the negative battery cable.

Page 71 of 788

CHARGING SYSTEM

ENGINE ELECTRICAL16-7

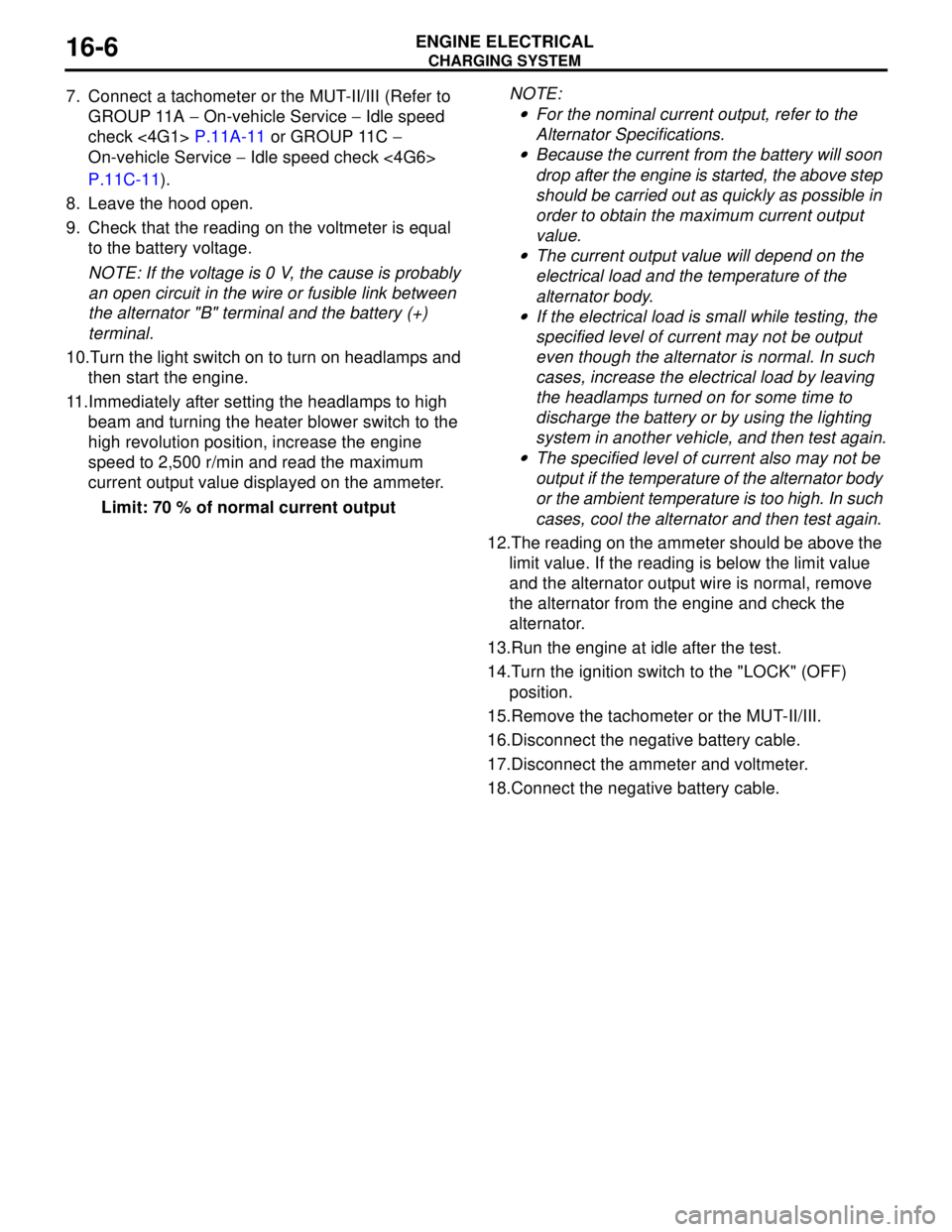

REGULATED VOLTAGE TESTM1161001100354

This test determines whether the voltage regulator

correctly controlling the alternator output voltage.

1. Always be sure to check the following before the

test.

•Alternator installation

•Check that the battery installed in the vehicle is

fully charged.

(Refer to GROUP 54A − Battery − On-vehicle

Service − Charging P.54A-4).

•Drive belt tension

(Refer to GROUP 11A − On-vehicle Service <4G1>

P.11A-7 or GROUP 11C − On-vehicle Service

<4G6> P.11C-7.)

•Fusible link

•Abnormal noise from the alternator while the

engine is running

2. Turn the ignition switch to the "LOCK" (OFF)

position.

3. Disconnect the negative battery cable.

4. Use the special tool Alternator test harness

(MB991519) to connect a digital voltmeter

between the alternator "S" terminal and earth

[Connect the (+) lead of the voltmeter to the "S"

terminal, and then connect the (-) lead of the

voltmeter to a secure earth or to the battery (-)

terminal].

5. Connect a clamp-type DC test ammeter with a

range of 0 − 120 A to the alternator "B" terminal

output wire.NOTE: The way of disconnecting the alternator

output wire and of connecting the ammeter is

possibly not found the problem that the output

current is dropping due to the insufficient

connection between terminal "B" and the output

wire.

6. Reconnect the negative battery cable.

7. Connect a tachometer or the MUT-II/III (Refer to

GROUP 11A − On-vehicle Service − Idle speed

check <4G1> P.11A-11 or GROUP 11C −

On-vehicle Service − Idle speed check <4G6>

P.11C-11).

8. Turn the ignition switch to the "ON" position and

check that the reading on the voltmeter is equal to

the battery voltage.

NOTE: If the voltage is 0 V, the cause is probably

an open circuit in the wire or fusible link between

the alternator "S" terminal and the battery (+)

terminal.

9. Turn all lamps and accessories off.

10.Start the engine.

11.Increase the engine speed to 2,500 r/min.

12.Read the value displayed on the voltmeter when

the alternator output current alternator becomes

10 A or less.

13.If the voltage reading conforms to the value in the

voltage regulation, then the voltage regulator is

operating normally.

AK300727AB

BatteryIgnition switch

Engine-ECU

Engine-A/T-ECU Ammeter (clamp-type)Load

Black MB991519

Voltmeter (digital-type) Red

YellowBlueAlternator B

FR

L

S

G

Page 76 of 788

CHARGING SYSTEM

ENGINE ELECTRICAL16-12

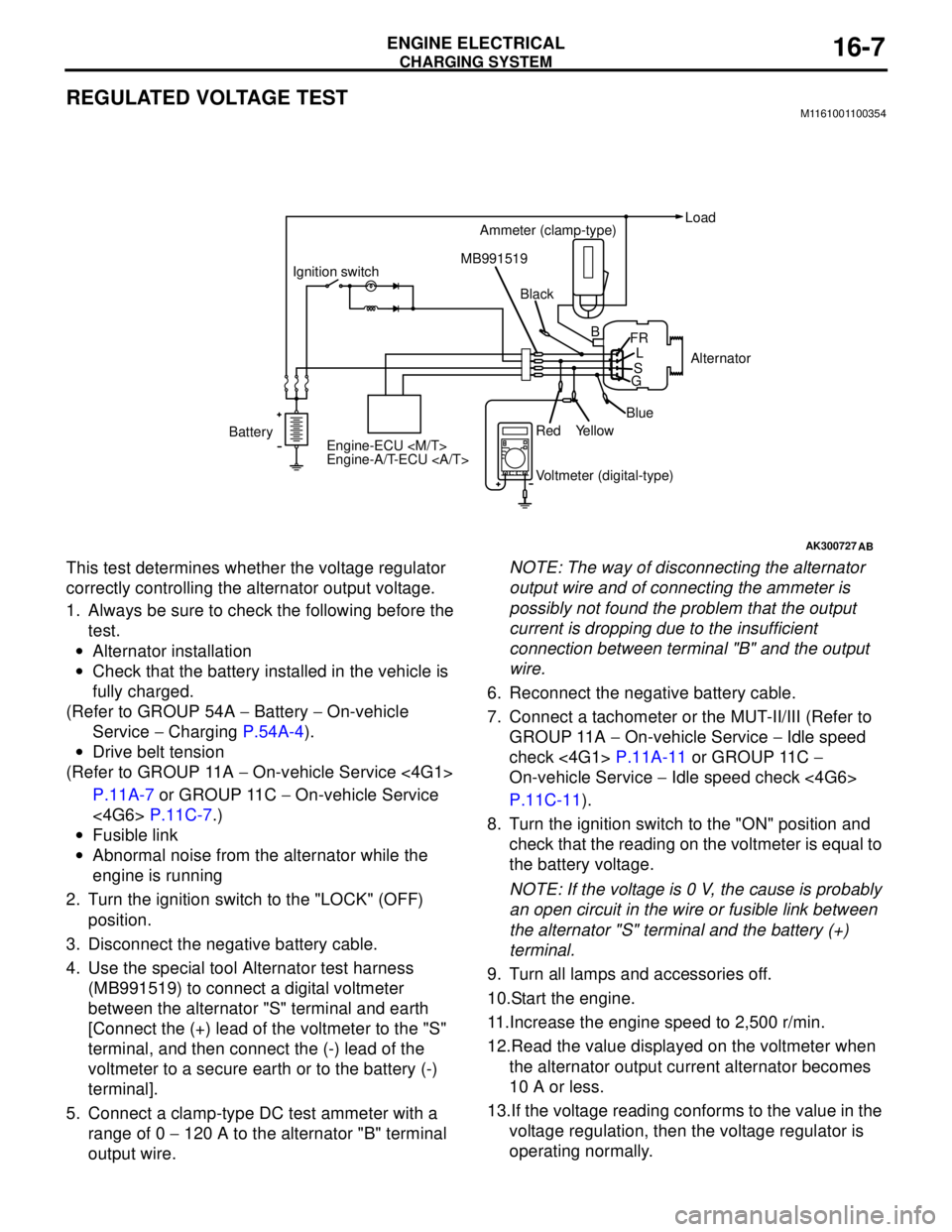

ALTERNATOR ASSEMBLY

REMOVAL AND INSTALLATION <4G1>M1161001400548

REMOVAL SERVICE POINT

<> ALTERNATOR ASSEMBLY

REMOVAL

Remove the alternator assembly from above the

vehicle.

Pre-removal Operation

•Under Cover Removal

•Drive Belt Removal (Refer to GROUP 11A - Crankshaft

Pulley P.11A-16).Post-installation Operation

•Drive Belt Installation (Refer to GROUP 11A - Crankshaft

Pulley P.11A-16).

•Drive Belt Tension Adjustment (Refer to GROUP 11A -

On-vehicle Service P.11A-7).

•Under Cover Installation

AC303729

1

2

4

3

44 ± 10 N·m

23 ± 2 N·m

24 ± 3 N·m12 ± 2 N·m

AB

Removal steps

1. Power steering pressure hose

clamp

2. Alternator connector and terminal3. Alternator adjusting brace

<>4. Alternator assemblyRemoval steps (Continued)

Page 77 of 788

CHARGING SYSTEM

ENGINE ELECTRICAL16-13

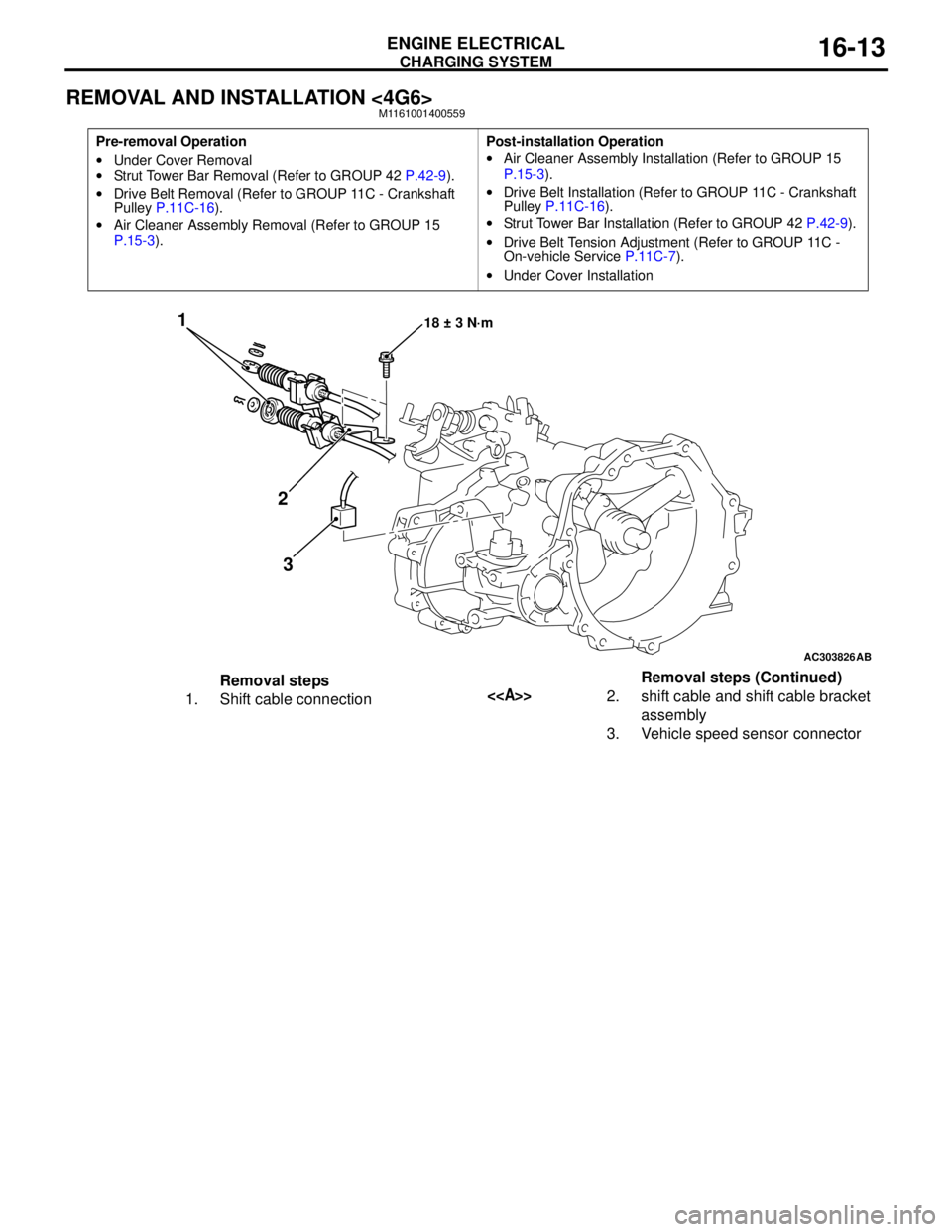

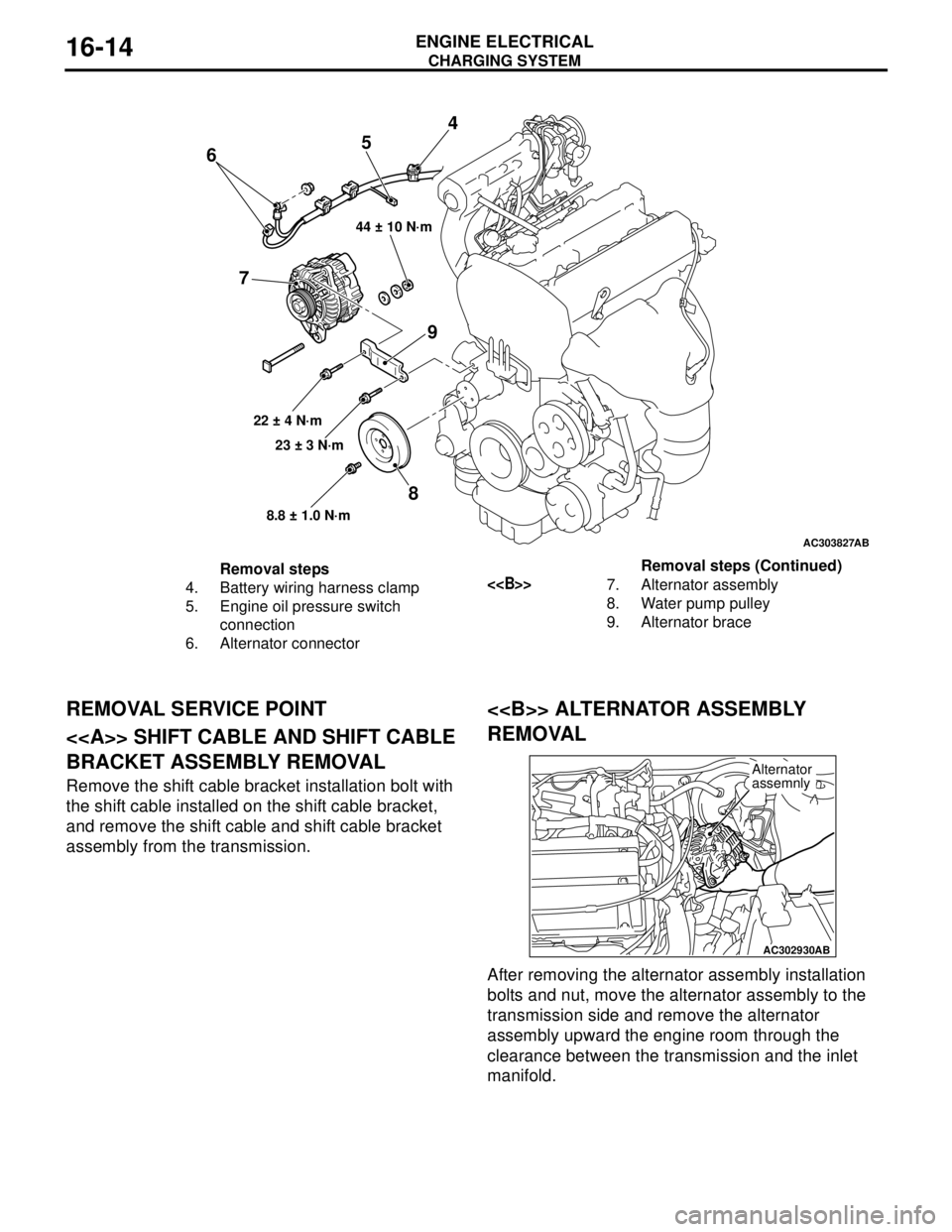

REMOVAL AND INSTALLATION <4G6>M1161001400559

Pre-removal Operation

•Under Cover Removal

•Strut Tower Bar Removal (Refer to GROUP 42 P.42-9).

•Drive Belt Removal (Refer to GROUP 11C - Crankshaft

Pulley P.11C-16).

•Air Cleaner Assembly Removal (Refer to GROUP 15

P.15-3).Post-installation Operation

•Air Cleaner Assembly Installation (Refer to GROUP 15

P.15-3).

•Drive Belt Installation (Refer to GROUP 11C - Crankshaft

Pulley P.11C-16).

•Strut Tower Bar Installation (Refer to GROUP 42 P.42-9).

•Drive Belt Tension Adjustment (Refer to GROUP 11C -

On-vehicle Service P.11C-7).

•Under Cover Installation

AC303826

1

2

318 ± 3 N·m

AB

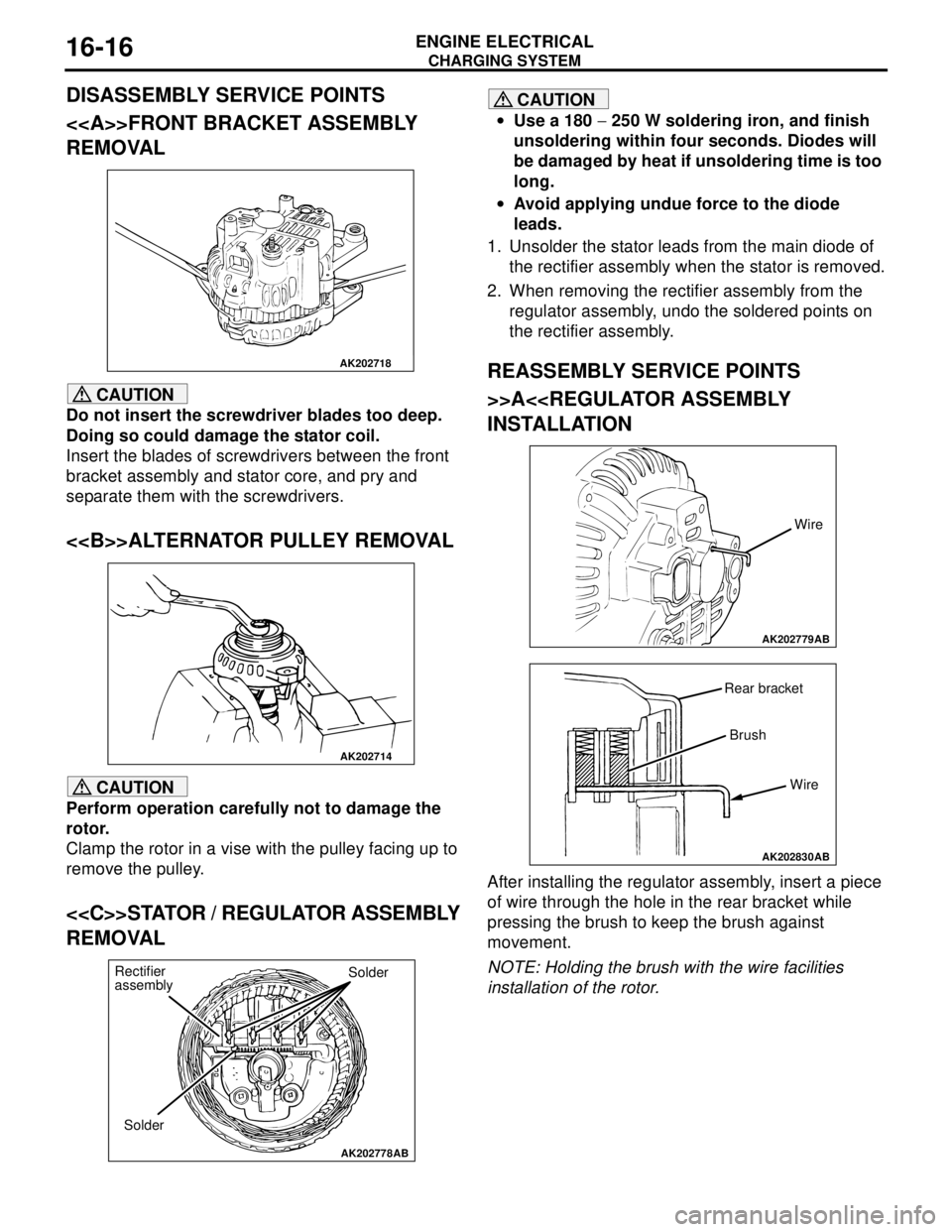

Removal steps

1. Shift cable connection<>2. shift cable and shift cable bracket

assembly

3. Vehicle speed sensor connectorRemoval steps (Continued)

Page 78 of 788

Page 80 of 788

Page 84 of 788

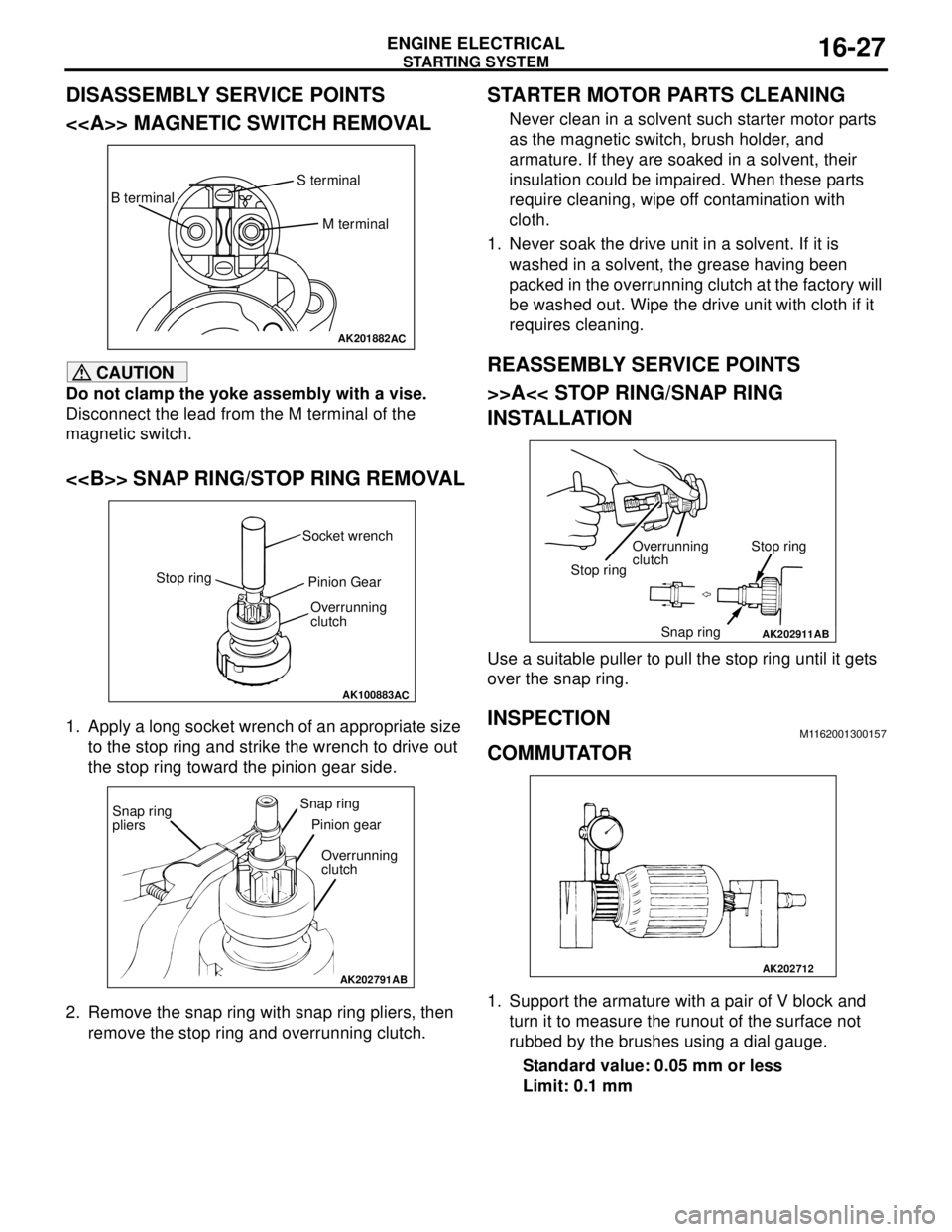

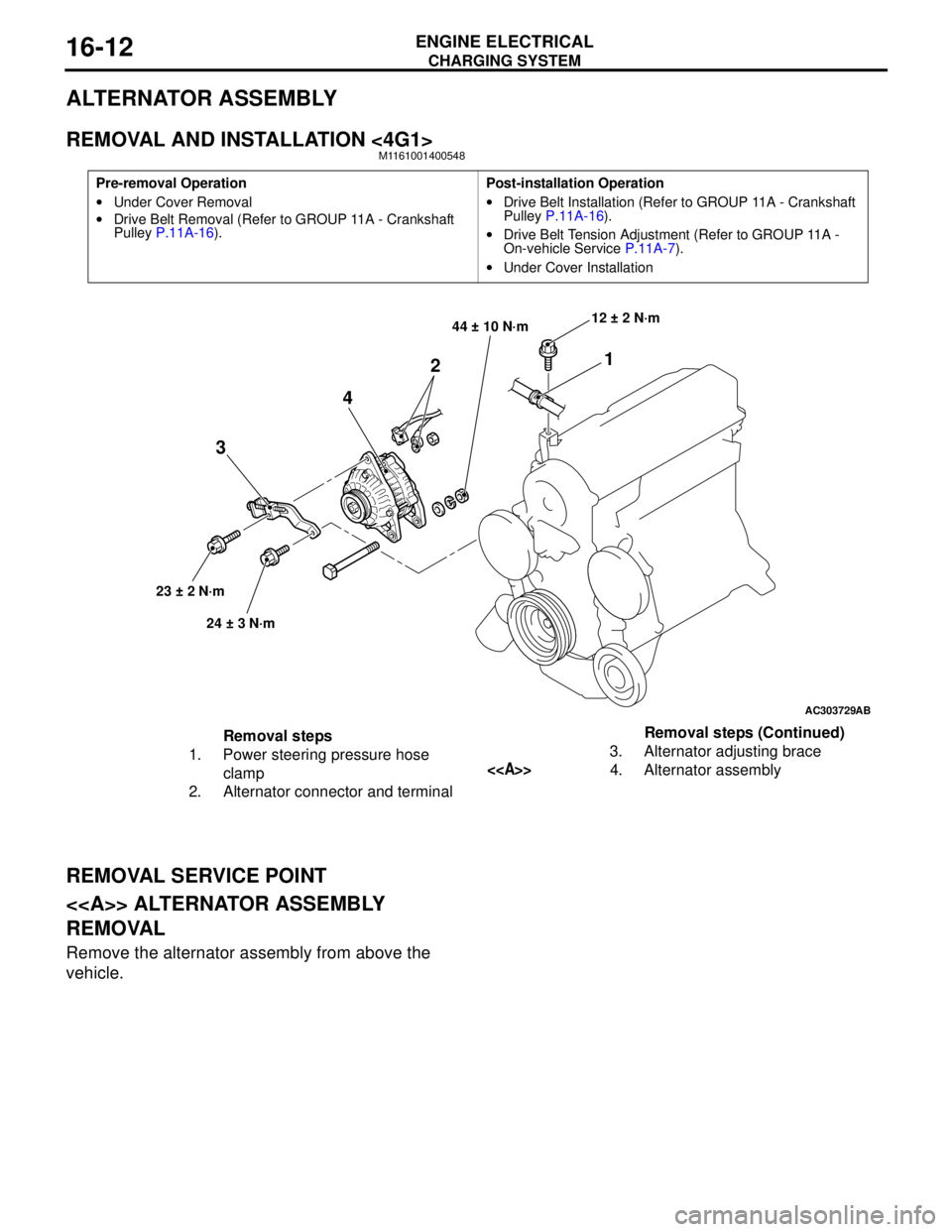

STARTING SYSTEM

ENGINE ELECTRICAL16-20

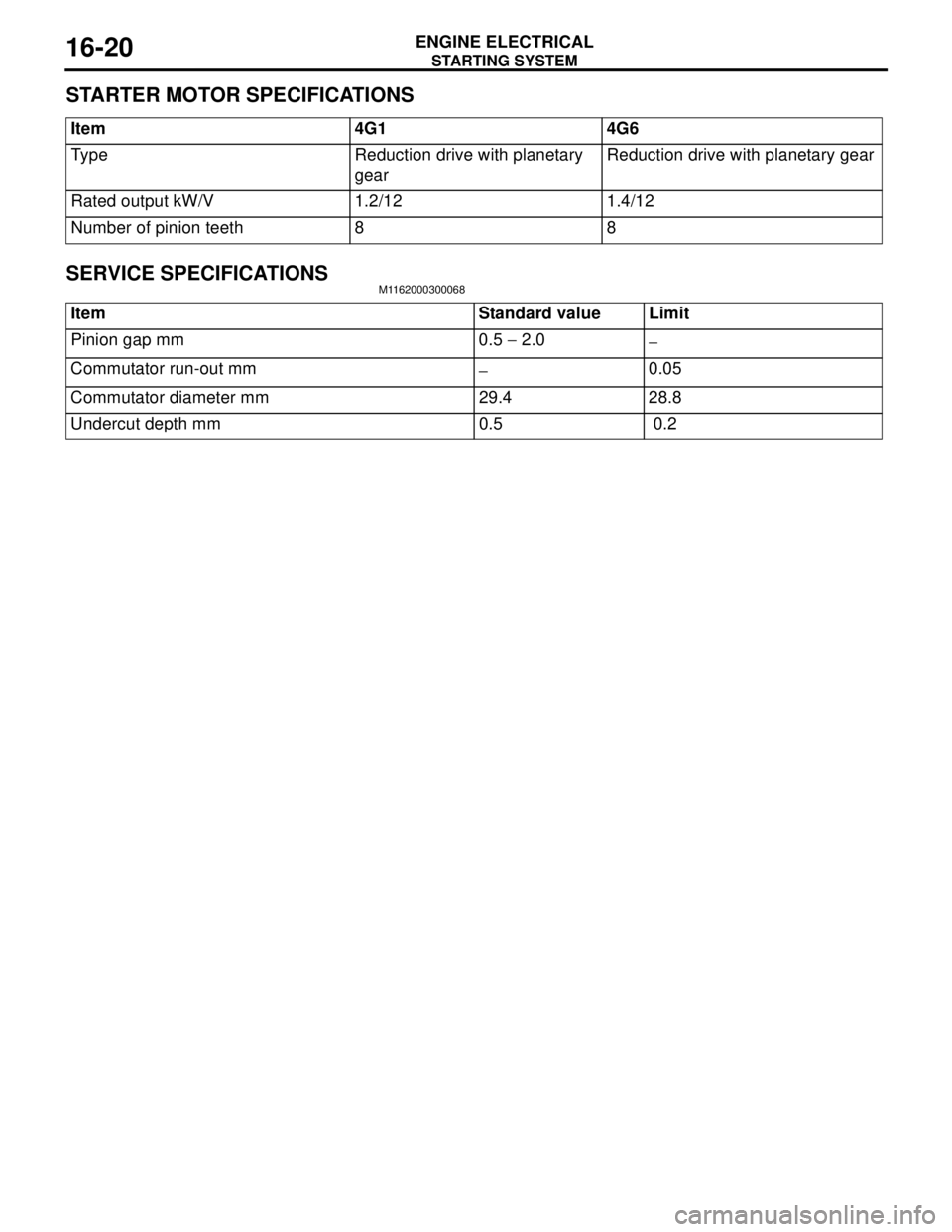

STARTER MOTOR SPECIFICATIONS

SERVICE SPECIFICATIONS

M1162000300068

Item 4G1 4G6

Type Reduction drive with planetary

gearReduction drive with planetary gear

Rated output kW/V 1.2/12 1.4/12

Number of pinion teeth 8 8

Item Standard value Limit

Pinion gap mm 0.5 − 2.0

−

Commutator run-out mm

−0.05

Commutator diameter mm 29.4 28.8

Undercut depth mm 0.5 0.2

Page 85 of 788

STARTING SYSTEM

ENGINE ELECTRICAL16-21

STARTER MOTOR ASSEMBLY

REMOVAL AND INSTALLATION <4G1>M1162001000628

REMOVAL SERVICE POINT

<> SHIFT CABLE AND SHIFT CABLE

BRACKET ASSEMBLY

Remove the shift cable bracket installation bolt with

the shift cable installed on the shift cable bracket,

and remove the shift cable and shift cable bracket

assembly from the transmission.

<> SHIFT CABLE CONNECTION

REMOVAL

Disengage the transmission, and remove the shift

cable assembly from the transmission.

<

Remove the starter assembly from above the

vehicle.

Pre-removal and Post-installation Operation

•Air Cleaner Assembly Removal and Installation (Refer to

GROUP 15 P.15-3).

•Battery and Battery Tray Removal and Installation

AC303962AB

1

1 2

3

56

7

4

30 ± 3 N·m18 ± 3 N·m

12 ± 2 N·m

Removal steps

1. Shift cable connection

<>2. shift cable and shift cable bracket

assembly

<>3. Shift cable connection 4. Starter connector and terminal

5. Harness bracket

6. Harness bracket <

Page 86 of 788

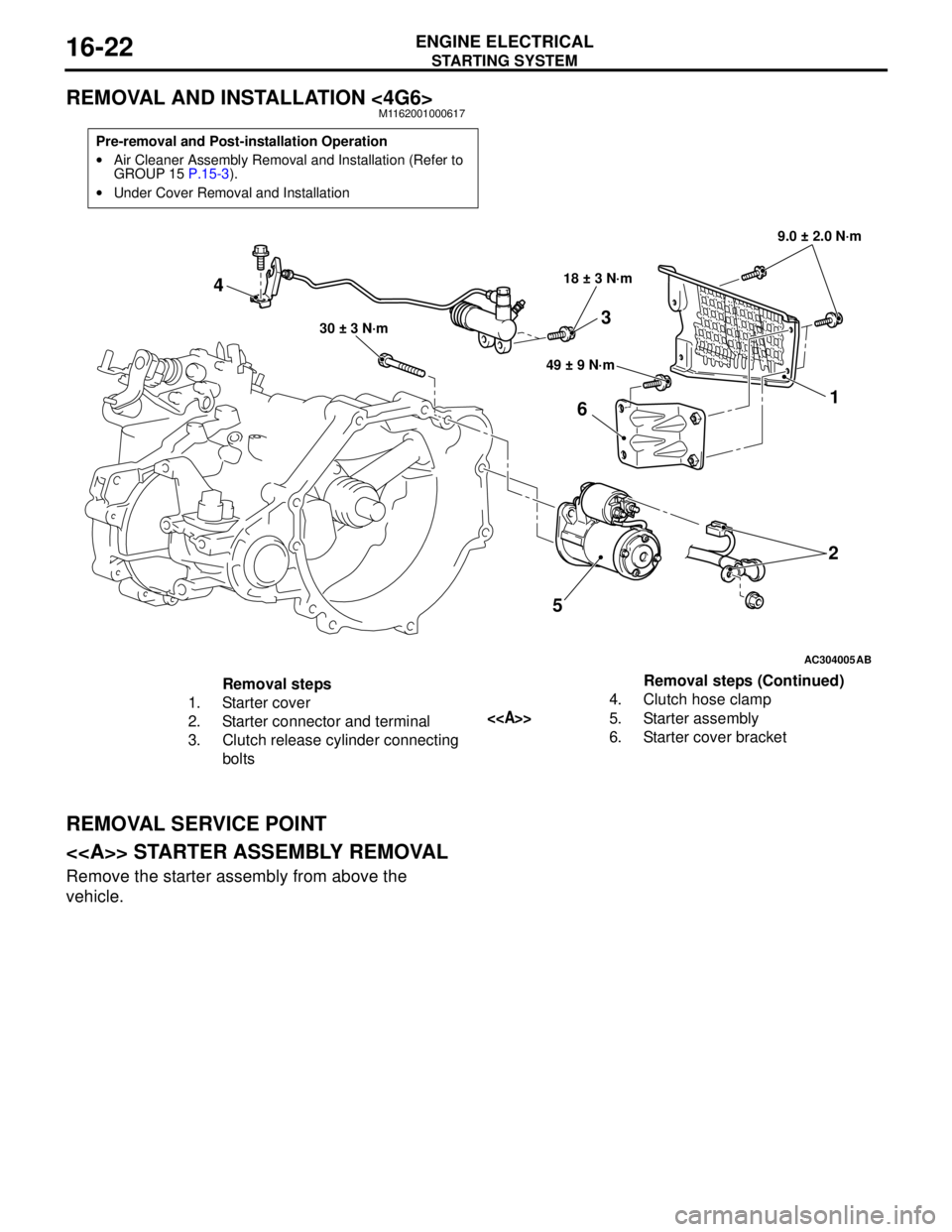

STARTING SYSTEM

ENGINE ELECTRICAL16-22

REMOVAL AND INSTALLATION <4G6>M1162001000617

REMOVAL SERVICE POINT

<> STARTER ASSEMBLY REMOVAL

Remove the starter assembly from above the

vehicle.

Pre-removal and Post-installation Operation

•Air Cleaner Assembly Removal and Installation (Refer to

GROUP 15 P.15-3).

•Under Cover Removal and Installation

AC304005

521

6

49 ± 9 N·m 18 ± 3 N·m9.0 ± 2.0 N·m

30 ± 3 N·m

AB

4

3

Removal steps

1. Starter cover

2. Starter connector and terminal

3. Clutch release cylinder connecting

bolts4. Clutch hose clamp

<>5. Starter assembly

6. Starter cover bracketRemoval steps (Continued)

Page 91 of 788