service MITSUBISHI LANCER 2005 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 139 of 788

ON-VEHICLE SERVICE

FRONT AXLE26-7

ON-VEHICLE SERVICE

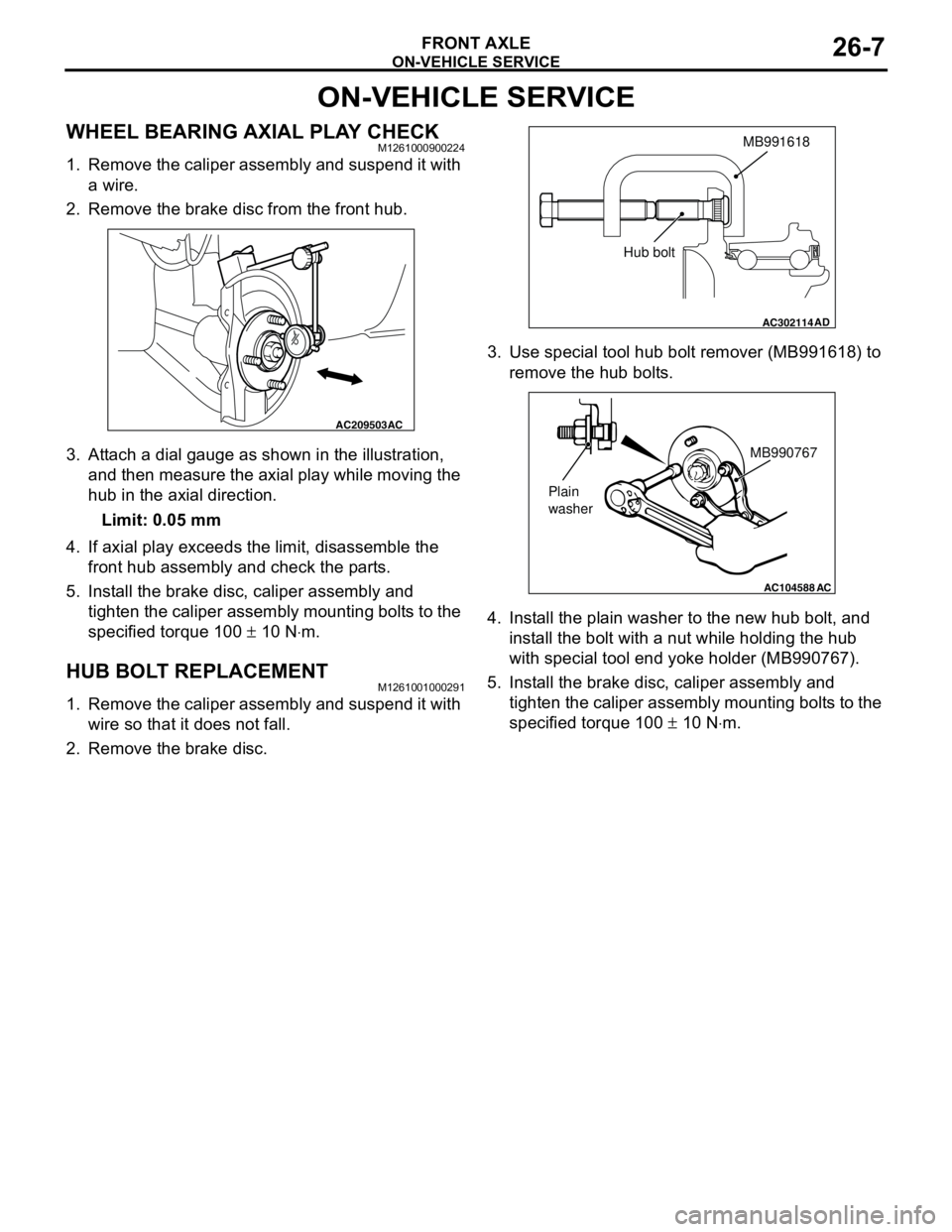

WHEEL BEARING AXIAL PLAY CHECKM1261000900224

1. Remove the caliper assembly and suspend it with

a wire.

2. Remove the brake disc from the front hub.

3. Attach a dial gauge as shown in the illustration,

and then measure the axial play while moving the

hub in the axial direction.

Limit: 0.05 mm

4. If axial play exceeds the limit, disassemble the

front hub assembly and check the parts.

5. Install the brake disc, caliper assembly and

tighten the caliper assembly mounting bolts to the

specified torque 100 ± 10 N⋅m.

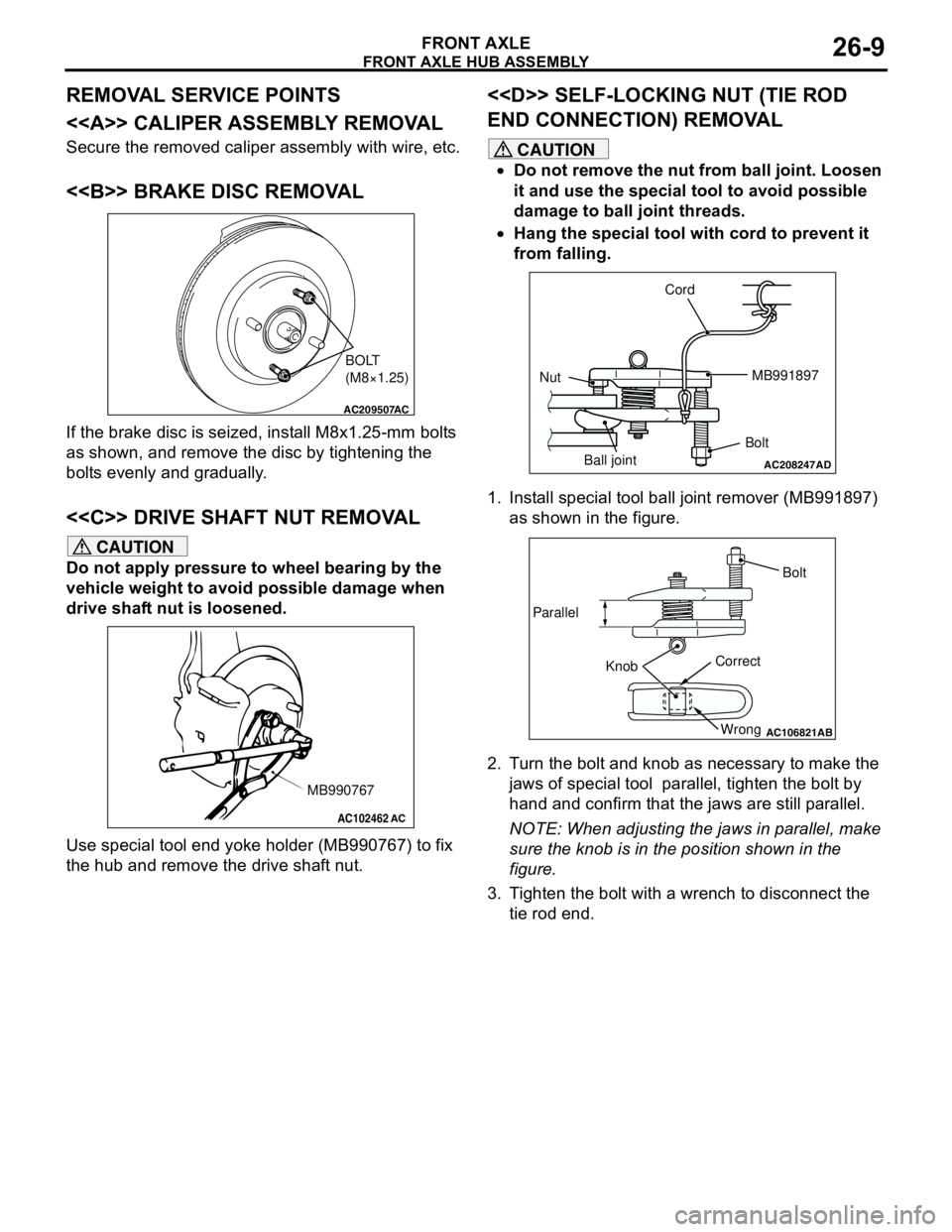

HUB BOLT REPLACEMENTM1261001000291

1. Remove the caliper assembly and suspend it with

wire so that it does not fall.

2. Remove the brake disc.3. Use special tool hub bolt remover (MB991618) to

remove the hub bolts.

4. Install the plain washer to the new hub bolt, and

install the bolt with a nut while holding the hub

with special tool end yoke holder (MB990767).

5. Install the brake disc, caliper assembly and

tighten the caliper assembly mounting bolts to the

specified torque 100 ± 10 N⋅m.

AC209503AC

AC302114

MB991618

AD

Hub bolt

AC104588

MB990767

Plain

washer

AC

Page 141 of 788

Page 142 of 788

FRONT AXLE HUB ASSEMBLY

FRONT AXLE26-10

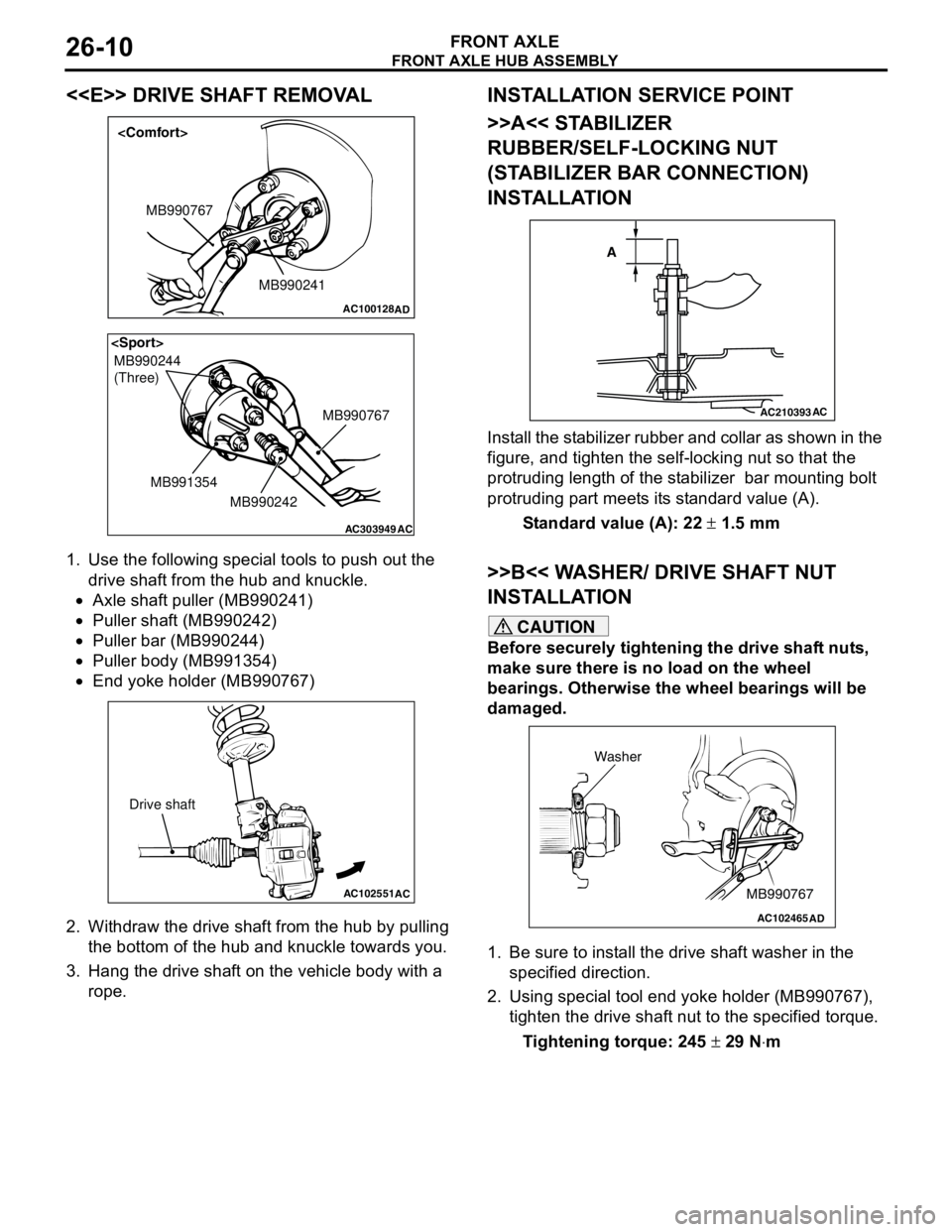

<

1. Use the following special tools to push out the

drive shaft from the hub and knuckle.

•Axle shaft puller (MB990241)

•Puller shaft (MB990242)

•Puller bar (MB990244)

•Puller body (MB991354)

•End yoke holder (MB990767)

2. Withdraw the drive shaft from the hub by pulling

the bottom of the hub and knuckle towards you.

3. Hang the drive shaft on the vehicle body with a

rope.

INSTALLATION SERVICE POINT

>>A<< STABILIZER

RUBBER/SELF-LOCKING NUT

(STABILIZER BAR CONNECTION)

INSTALLATION

Install the stabilizer rubber and collar as shown in the

figure, and tighten the self-locking nut so that the

protruding length of the stabilizer bar mounting bolt

protruding part meets its standard value (A).

Standard value (A): 22 ± 1.5 mm

>>B<< WASHER/ DRIVE SHAFT NUT

INSTALLATION

CAUTION

Before securely tightening the drive shaft nuts,

make sure there is no load on the wheel

bearings. Otherwise the wheel bearings will be

damaged.

1. Be sure to install the drive shaft washer in the

specified direction.

2. Using special tool end yoke holder (MB990767),

tighten the drive shaft nut to the specified torque.

Tightening torque: 245 ± 29 N⋅m

AC100128

MB990241 MB990767

AD

AC303949

MB990244

(Three)

MB990767

MB990242 MB991354

AC

AC102551

AC

Drive shaft

AC210393AC

A

AC102465AD

MB990767 Washer

Page 144 of 788

Page 145 of 788

FRONT AXLE HUB ASSEMBLY

FRONT AXLE26-13

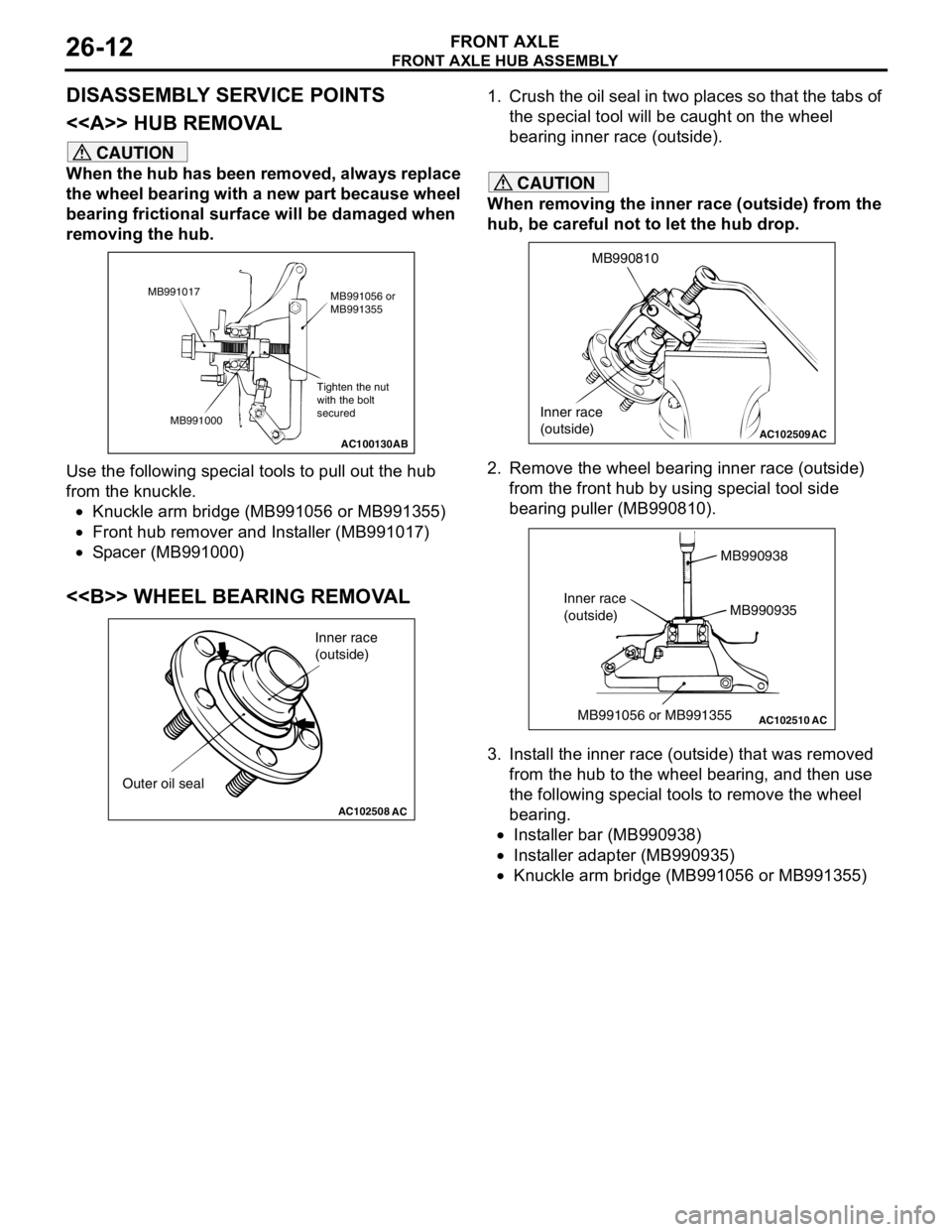

REASSEMBLY SERVICE POINTS

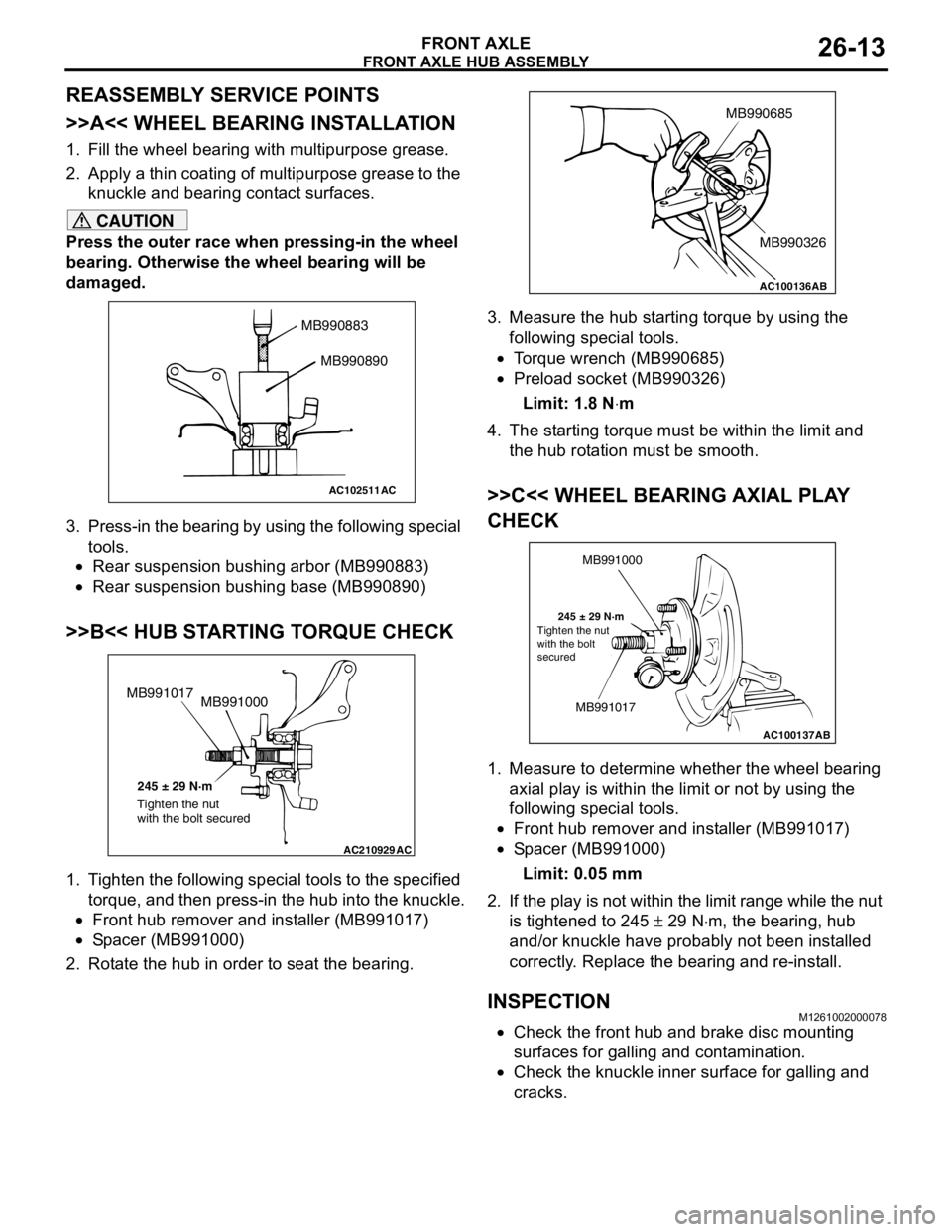

>>A<< WHEEL BEARING INSTALLATION

1. Fill the wheel bearing with multipurpose grease.

2. Apply a thin coating of multipurpose grease to the

knuckle and bearing contact surfaces.

CAUTION

Press the outer race when pressing-in the wheel

bearing. Otherwise the wheel bearing will be

damaged.

3. Press-in the bearing by using the following special

tools.

•Rear suspension bushing arbor (MB990883)

•Rear suspension bushing base (MB990890)

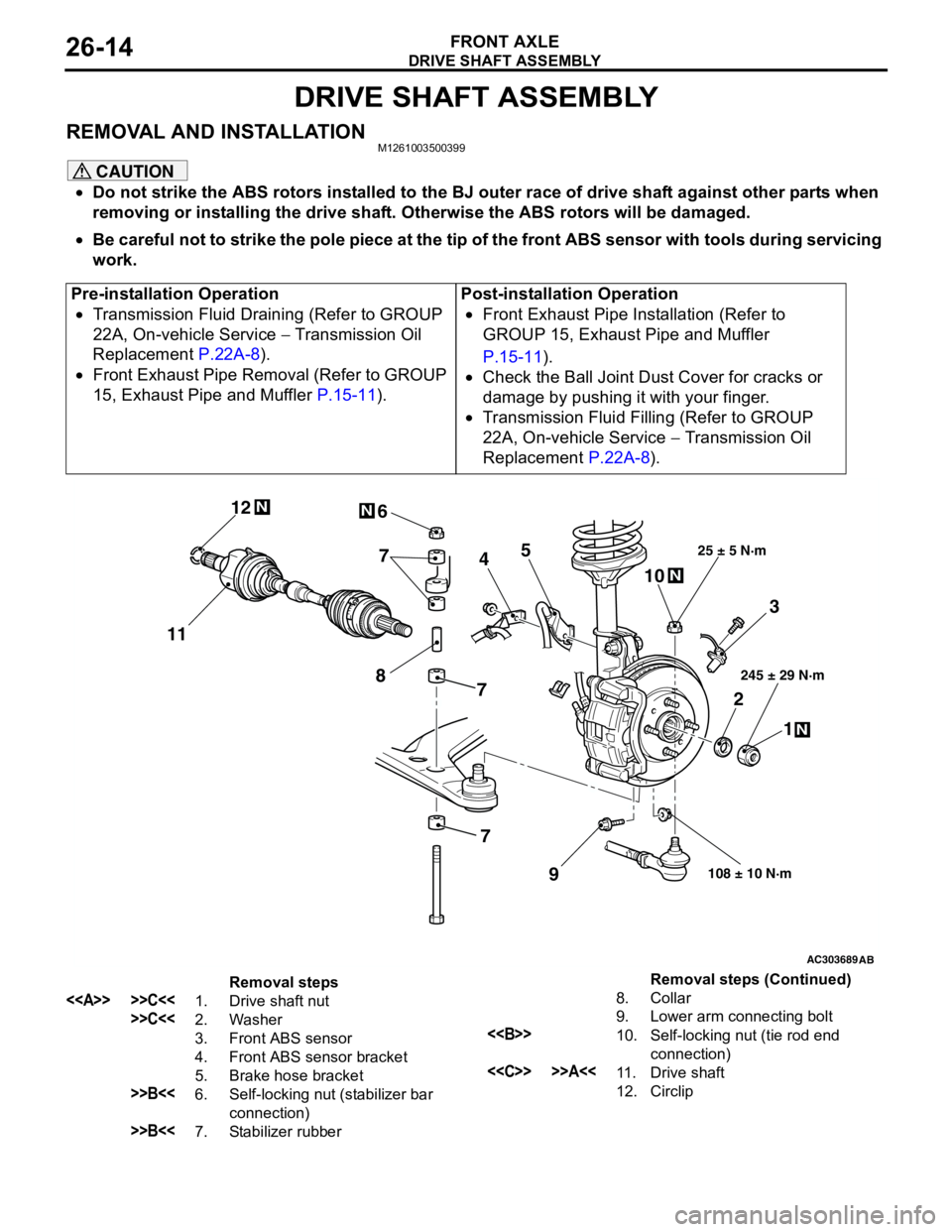

>>B<< HUB STARTING TORQUE CHECK

1. Tighten the following special tools to the specified

torque, and then press-in the hub into the knuckle.

•Front hub remover and installer (MB991017)

•Spacer (MB991000)

2. Rotate the hub in order to seat the bearing.3. Measure the hub starting torque by using the

following special tools.

•Torque wrench (MB990685)

•Preload socket (MB990326)

Limit: 1.8 N⋅m

4. The starting torque must be within the limit and

the hub rotation must be smooth.

>>C<< WHEEL BEARING AXIAL PLAY

CHECK

1. Measure to determine whether the wheel bearing

axial play is within the limit or not by using the

following special tools.

•Front hub remover and installer (MB991017)

•Spacer (MB991000)

Limit: 0.05 mm

2. If the play is not within the limit range while the nut

is tightened to 245 ± 29 N⋅m, the bearing, hub

and/or knuckle have probably not been installed

correctly. Replace the bearing and re-install.

INSPECTIONM1261002000078

•Check the front hub and brake disc mounting

surfaces for galling and contamination.

•Check the knuckle inner surface for galling and

cracks.

AC102511

MB990883

MB990890

AC

AC210929AC

MB991000 MB991017

245 ± 29 N·m

Tighten the nut

with the bolt secured

AC100136

MB990685

MB990326

AB

AC100137

MB991000

MB991017

245 ± 29 N·m

AB Tighten the nut

with the bolt

secured

Page 146 of 788

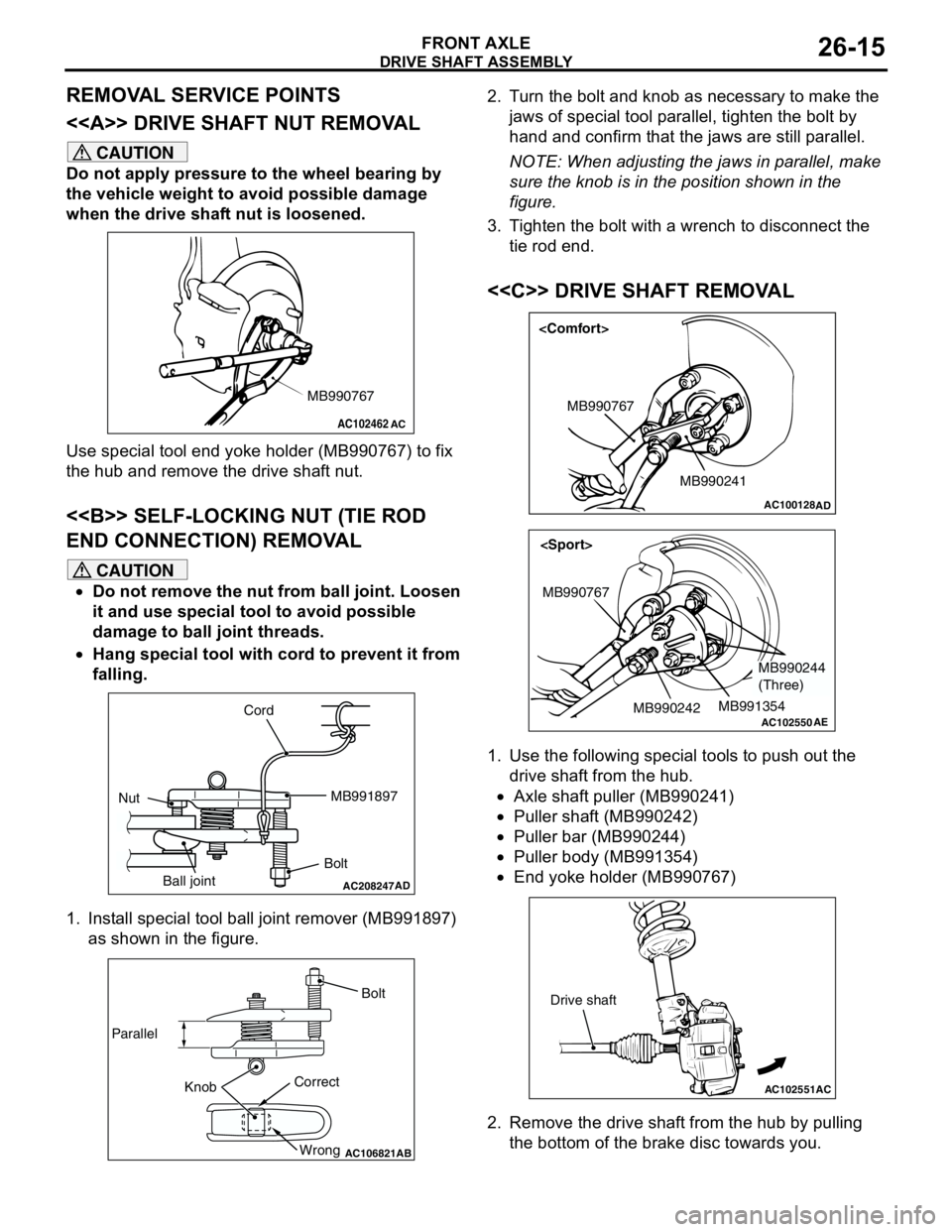

DRIVE SHAFT ASSEMBLY

FRONT AXLE26-14

DRIVE SHAFT ASSEMBLY

REMOVAL AND INSTALLATIONM1261003500399

CAUTION

•Do not strike the ABS rotors installed to the BJ outer race of drive shaft against other parts when

removing or installing the drive shaft. Otherwise the ABS rotors will be damaged.

•Be careful not to strike the pole piece at the tip of the front ABS sensor with tools during servicing

work.

Pre-installation Operation

•Transmission Fluid Draining (Refer to GROUP

22A, On-vehicle Service − Transmission Oil

Replacement P.22A-8).

•Front Exhaust Pipe Removal (Refer to GROUP

15, Exhaust Pipe and Muffler P.15-11).Post-installation Operation

•Front Exhaust Pipe Installation (Refer to

GROUP 15, Exhaust Pipe and Muffler

P.15-11).

•Check the Ball Joint Dust Cover for cracks or

damage by pushing it with your finger.

•Transmission Fluid Filling (Refer to GROUP

22A, On-vehicle Service − Transmission Oil

Replacement P.22A-8).

AC303689AB

9

N

N

NN

10 7

4

3

2

1

25 ± 5 N·m

245 ± 29 N·m

108 ± 10 N·m

8

5 6

1112

7

7

Removal steps

<> >>C<<1. Drive shaft nut

>>C<<2. Washer

3. Front ABS sensor

4. Front ABS sensor bracket

5. Brake hose bracket

>>B<<6. Self-locking nut (stabilizer bar

connection)

>>B<<7. Stabilizer rubber8. Collar

9. Lower arm connecting bolt

<>10. Self-locking nut (tie rod end

connection)

<

12. CirclipRemoval steps (Continued)

Page 147 of 788

Page 149 of 788

DRIVE SHAFT ASSEMBLY

FRONT AXLE26-17

INSTALLATION SERVICE POINTS

>>A<< DRIVE SHAFT INSTALLATION

CAUTION

When installing the drive shaft, be careful that

the spline part of the drive shaft does not

damage the oil seal.

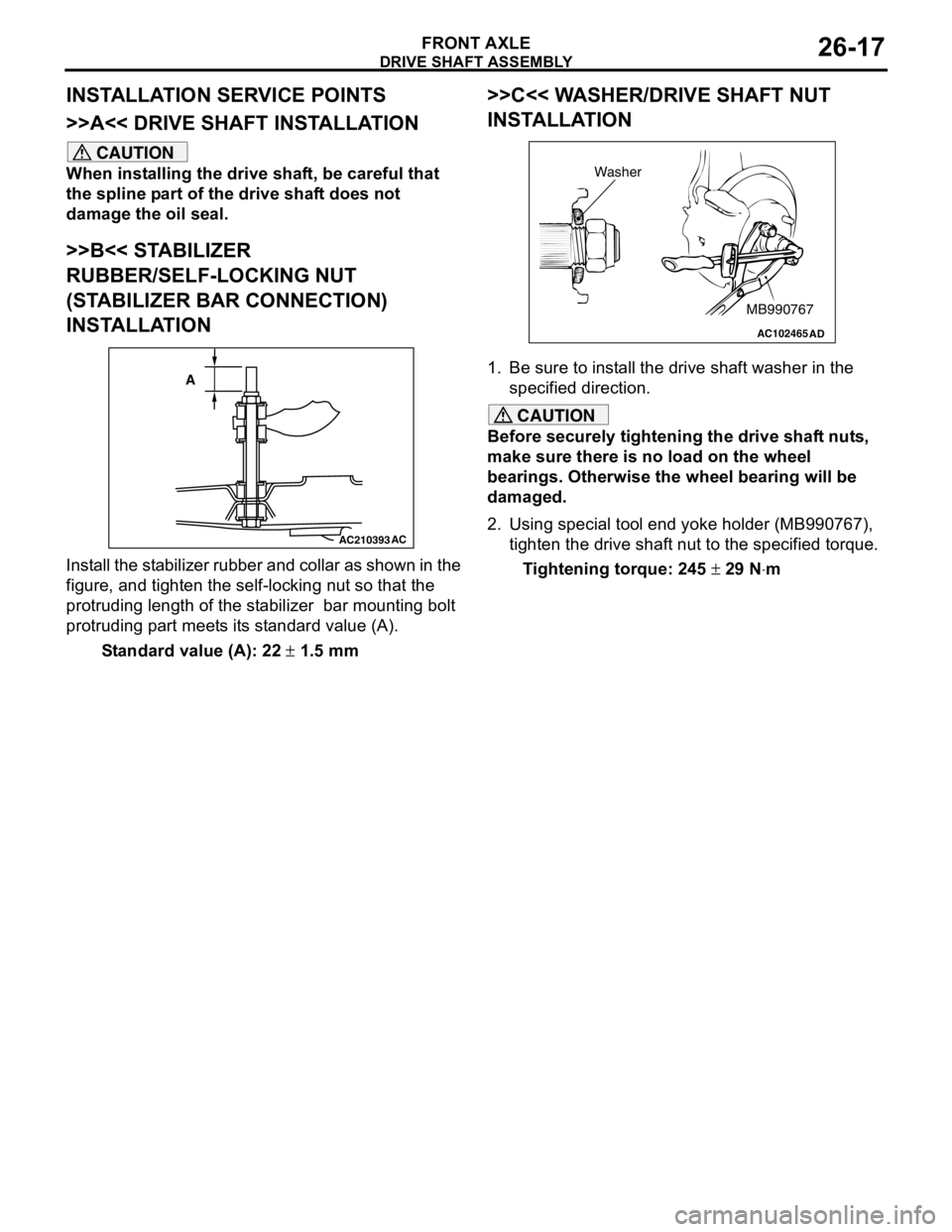

>>B<< STABILIZER

RUBBER/SELF-LOCKING NUT

(STABILIZER BAR CONNECTION)

INSTALLATION

Install the stabilizer rubber and collar as shown in the

figure, and tighten the self-locking nut so that the

protruding length of the stabilizer bar mounting bolt

protruding part meets its standard value (A).

Standard value (A): 22 ± 1.5 mm

>>C<< WASHER/DRIVE SHAFT NUT

INSTALLATION

1. Be sure to install the drive shaft washer in the

specified direction.

CAUTION

Before securely tightening the drive shaft nuts,

make sure there is no load on the wheel

bearings. Otherwise the wheel bearing will be

damaged.

2. Using special tool end yoke holder (MB990767),

tighten the drive shaft nut to the specified torque.

Tightening torque: 245 ± 29 N⋅m

AC210393AC

A

AC102465AD

MB990767 Washer

Page 151 of 788

Page 152 of 788

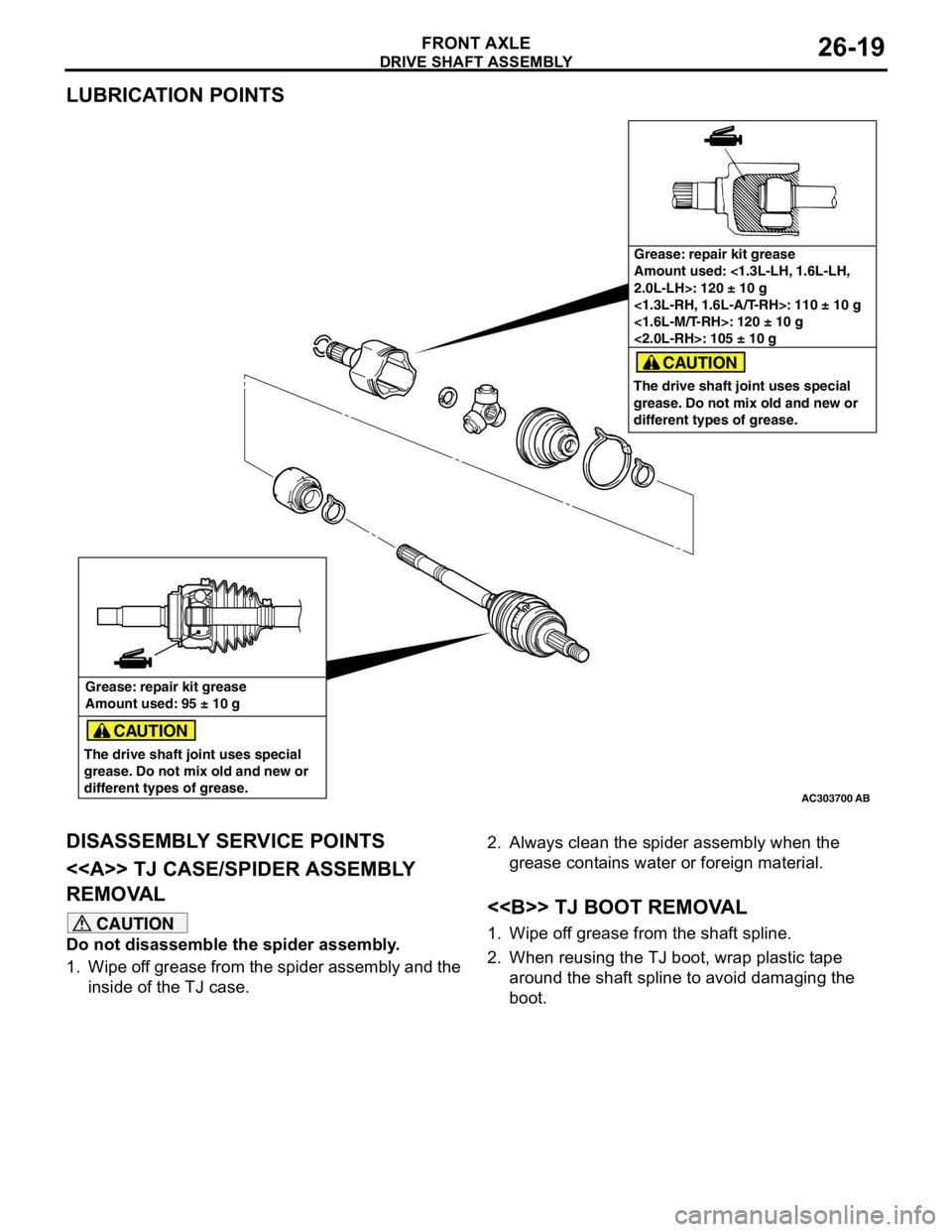

DRIVE SHAFT ASSEMBLY

FRONT AXLE26-20

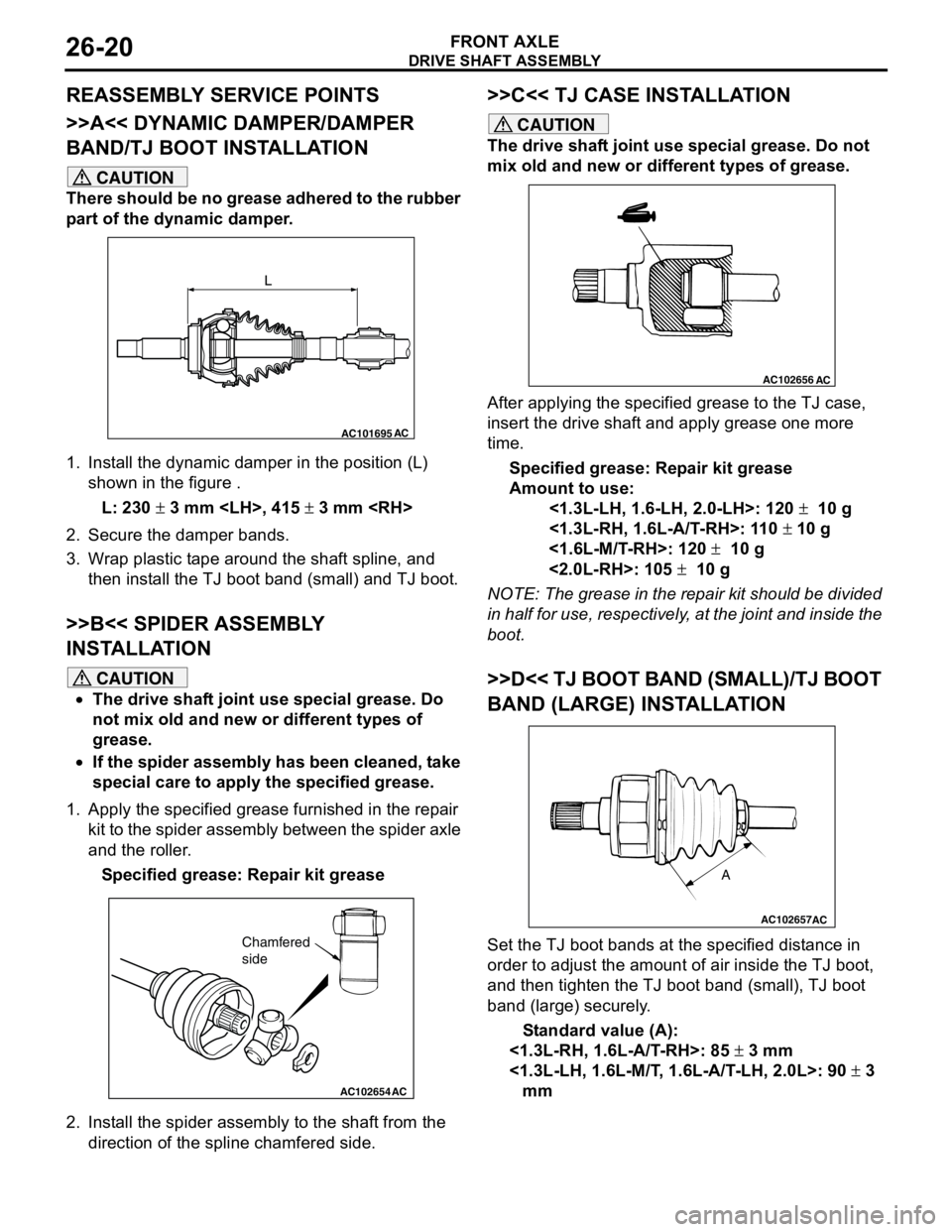

REASSEMBLY SERVICE POINTS

>>A<< DYNAMIC DAMPER/DAMPER

BAND/TJ BOOT INSTALLATION

CAUTION

There should be no grease adhered to the rubber

part of the dynamic damper.

1. Install the dynamic damper in the position (L)

shown in the figure .

L: 230 ± 3 mm

2. Secure the damper bands.

3. Wrap plastic tape around the shaft spline, and

then install the TJ boot band (small) and TJ boot.

>>B<< SPIDER ASSEMBLY

INSTALLATION

CAUTION

•The drive shaft joint use special grease. Do

not mix old and new or different types of

grease.

•If the spider assembly has been cleaned, take

special care to apply the specified grease.

1. Apply the specified grease furnished in the repair

kit to the spider assembly between the spider axle

and the roller.

Specified grease: Repair kit grease

2. Install the spider assembly to the shaft from the

direction of the spline chamfered side.

>>C<< TJ CASE INSTALLATION

CAUTION

The drive shaft joint use special grease. Do not

mix old and new or different types of grease.

After applying the specified grease to the TJ case,

insert the drive shaft and apply grease one more

time.

Specified grease: Repair kit grease

Amount to use:

<1.3L-LH, 1.6-LH, 2.0-LH>: 120 ± 10 g

<1.3L-RH, 1.6L-A/T-RH>: 110 ± 10 g

<1.6L-M/T-RH>: 120 ± 10 g

<2.0L-RH>: 105 ± 10 g

NOTE: The grease in the repair kit should be divided

in half for use, respectively, at the joint and inside the

boot.

>>D<< TJ BOOT BAND (SMALL)/TJ BOOT

BAND (LARGE) INSTALLATION

Set the TJ boot bands at the specified distance in

order to adjust the amount of air inside the TJ boot,

and then tighten the TJ boot band (small), TJ boot

band (large) securely.

Standard value (A):

<1.3L-RH, 1.6L-A/T-RH>: 85 ± 3 mm

<1.3L-LH, 1.6L-M/T, 1.6L-A/T-LH, 2.0L>: 90 ± 3

mm

AC101695AC

L

AC102654AC

Chamfered

side

AC102656AC

AC102657

A

AC