Group 80 MITSUBISHI LANCER 2005 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 178 of 788

CROSSMEMBER

POWER PLANT MOUNT32-8

INSTALLATION SERVICE POINTS

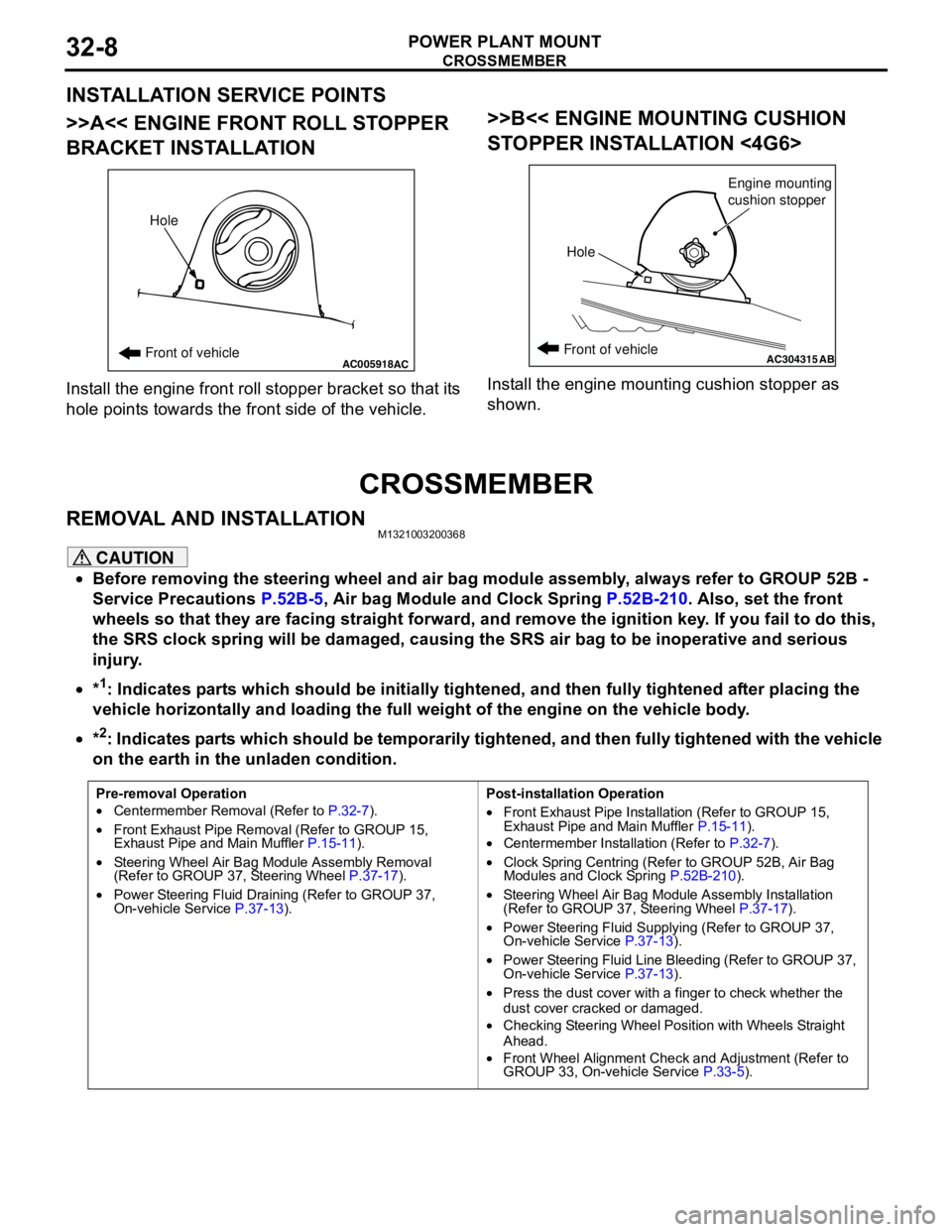

>>A<< ENGINE FRONT ROLL STOPPER

BRACKET INSTALLATION

Install the engine front roll stopper bracket so that its

hole points towards the front side of the vehicle.

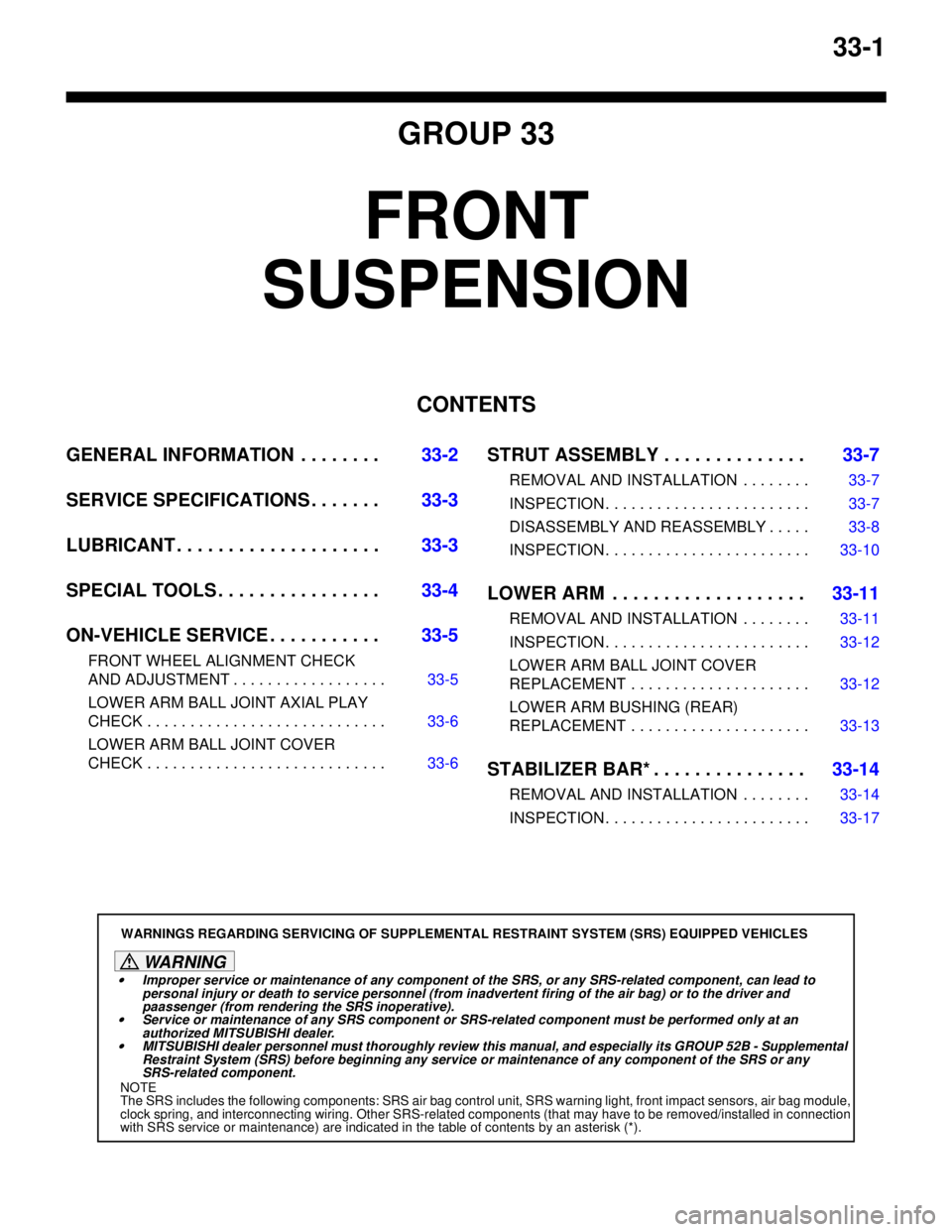

>>B<< ENGINE MOUNTING CUSHION

STOPPER INSTALLATION <4G6>

Install the engine mounting cushion stopper as

shown.

CROSSMEMBER

REMOVAL AND INSTALLATIONM1321003200368

CAUTION

•Before removing the steering wheel and air bag module assembly, always refer to GROUP 52B -

Service Precautions P.52B-5, Air bag Module and Clock Spring P.52B-210. Also, set the front

wheels so that they are facing straight forward, and remove the ignition key. If you fail to do this,

the SRS clock spring will be damaged, causing the SRS air bag to be inoperative and serious

injury.

•*

1: Indicates parts which should be initially tightened, and then fully tightened after placing the

vehicle horizontally and loading the full weight of the engine on the vehicle body.

•*

2: Indicates parts which should be temporarily tightened, and then fully tightened with the vehicle

on the earth in the unladen condition.

AC005918Front of vehicleHoleACAC304315ABFront of vehicle

HoleEngine mounting

cushion stopper

Pre-removal Operation

•Centermember Removal (Refer to P.32-7).

•Front Exhaust Pipe Removal (Refer to GROUP 15,

Exhaust Pipe and Main Muffler P.15-11).

•Steering Wheel Air Bag Module Assembly Removal

(Refer to GROUP 37, Steering Wheel P.37-17).

•Power Steering Fluid Draining (Refer to GROUP 37,

On-vehicle Service P.37-13).Post-installation Operation

•Front Exhaust Pipe Installation (Refer to GROUP 15,

Exhaust Pipe and Main Muffler P.15-11).

•Centermember Installation (Refer to P.32-7).

•Clock Spring Centring (Refer to GROUP 52B, Air Bag

Modules and Clock Spring P.52B-210).

•Steering Wheel Air Bag Module Assembly Installation

(Refer to GROUP 37, Steering Wheel P.37-17).

•Power Steering Fluid Supplying (Refer to GROUP 37,

On-vehicle Service P.37-13).

•Power Steering Fluid Line Bleeding (Refer to GROUP 37,

On-vehicle Service P.37-13).

•Press the dust cover with a finger to check whether the

dust cover cracked or damaged.

•Checking Steering Wheel Position with Wheels Straight

Ahead.

•Front Wheel Alignment Check and Adjustment (Refer to

GROUP 33, On-vehicle Service P.33-5).

Page 183 of 788

33-1

GROUP 33

FRONT

SUSPENSION

CONTENTS

GENERAL INFORMATION . . . . . . . .33-2

SERVICE SPECIFICATIONS . . . . . . .33-3

LUBRICANT . . . . . . . . . . . . . . . . . . . .33-3

SPECIAL TOOLS . . . . . . . . . . . . . . . .33-4

ON-VEHICLE SERVICE . . . . . . . . . . .33-5

FRONT WHEEL ALIGNMENT CHECK

AND ADJUSTMENT . . . . . . . . . . . . . . . . . . 33-5

LOWER ARM BALL JOINT AXIAL PLAY

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33-6

LOWER ARM BALL JOINT COVER

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33-6

STRUT ASSEMBLY . . . . . . . . . . . . . .33-7

REMOVAL AND INSTALLATION . . . . . . . . 33-7

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 33-7

DISASSEMBLY AND REASSEMBLY . . . . . 33-8

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 33-10

LOWER ARM . . . . . . . . . . . . . . . . . . .33-11

REMOVAL AND INSTALLATION . . . . . . . . 33-11

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 33-12

LOWER ARM BALL JOINT COVER

REPLACEMENT . . . . . . . . . . . . . . . . . . . . . 33-12

LOWER ARM BUSHING (REAR)

REPLACEMENT . . . . . . . . . . . . . . . . . . . . . 33-13

STABILIZER BAR* . . . . . . . . . . . . . . .33-14

REMOVAL AND INSTALLATION . . . . . . . . 33-14

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 33-17

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES

WARNING

•Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to

personal injury or death to service personnel (from inadvertent firing of the air bag) or to the driver and

paassenger (from rendering the SRS inoperative).

•Service or maintenance of any SRS component or SRS-related component must be performed only at an

authorized MITSUBISHI dealer.

•MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B - Supplemental

Restraint System (SRS) before beginning any service or maintenance of any component of the SRS or any

SRS-related component.

NOTE

The SRS includes the following components: SRS air bag control unit, SRS warning light, front impact sensors, air bag module,

clock spring, and interconnecting wiring. Other SRS-related components (that may have to be removed/installed in connection

with SRS service or maintenance) are indicated in the table of contents by an asterisk (*).

Page 196 of 788

STABILIZER BAR

FRONT SUSPENSION33-14

STABILIZER BAR

REMOVAL AND INSTALLATIONM1332004000468

CAUTION

•Before removing the steering wheel and air bag module assembly, refer to GROUP 52B, Service

Precautions P.52B-5 and Air Bag Module and Clock Spring P.52B-210. Also, put the front wheels in

straight-ahead position. Failure to do so may damage the SRS clock spring and render the SRS air

bag inoperative, which results serious driver injury.

•

*: Indicates parts which should be initially tightened, and then fully tightened after placing the

vehicle horizontally and loading the full weight of the engine on the vehicle body.

Pre-removal Operation

•Steering Wheel and Air Bag Module Assembly Removal

(Comfort: refer to GROUP 37, Steering Wheel

P.37-17/Sport: refer to GROUP 37, Steering Wheel

P.37-19).

•Clock Spring Removal (Refer to GROUP 52B, Air Bag

Modules and Clock Spring P.52B-210).

•Centermember Removal (Refer to GROUP 32, Engine

Roll Stopper, Centermember P.32-7).

•Front Exhaust Pipe Removal (Refer to GROUP 15,

Exhaust Pipe and Main Muffler P.15-11).Post-installation Operation

•Front Exhaust Pipe Installation (Refer to GROUP 15,

Exhaust Pipe and Main Muffler P.15-11).

•Centermember Installation (Refer to GROUP 32, Engine

Roll Stopper, Centermember P.32-7).

•Clock Spring Installation (Refer to GROUP 52B, Air Bag

Modules and Clock Spring P.52B-210).

•Steering Wheel and Air Bag Module Assembly Installation

(Comfort: refer to GROUP 37, Steering Wheel

P.37-17/Sport: refer to GROUP 37, Steering Wheel

P.37-19).

•Check the dust covers for cracks or damage by pushing it

with your finger.

•Checking Steering Wheel Position with Wheels Straight

Ahead

•Front Wheel Alignment Check and Adjustment (Refer to

P.33-5).

Page 201 of 788

34-1

GROUP 34

REAR SUSPENSION

CONTENTS

GENERAL INFORMATION . . . . . . . .34-2

SERVICE SPECIFICATIONS . . . . . . .34-3

LUBRICANT . . . . . . . . . . . . . . . . . . . .34-3

SPECIAL TOOLS . . . . . . . . . . . . . . . .34-4

ON-VEHICLE SERVICE . . . . . . . . . . .34-5

REAR WHEEL ALIGNMENT CHECK

AND ADJUSTMENT . . . . . . . . . . . . . . . . . . 34-5

CONTROL LINK PILLOW BALL BUSHING

AXIAL PLAY CHECK

UPPER ARM PILLOW BALL BUSHING

AXIAL PLAY CHECK

LOWER ARM PILLOW BALL BUSHING

AXIAL PLAY CHECK . . . . . . . . . . . . . . . . . 34-7

STABILIZER LINK BALL JOINT

DUST COVER INSPECTION . . . . . . . . . . . 34-7

CONTROL LINK, UPPER ARM AND

LOWER ARM . . . . . . . . . . . . . . . . . . .34-8

REMOVAL AND INSTALLATION . . . . . . . . 34-8

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 34-9

LOWER ARM BUSHING AND LOWER

ARM PILLOW BALL BUSHING

REPLACEMENT . . . . . . . . . . . . . . . . . . . . . 34-10

TRAILING ARM ASSEMBLY . . . . . . .34-12

REMOVAL AND INSTALLATION . . . . . . . . 34-12

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 34-13

TRAILING ARM BUSHING

REPLACEMENT . . . . . . . . . . . . . . . . . . . . . 34-13

SHOCK ABSORBER ASSEMBLY . . .34-15

REMOVAL AND INSTALLATION . . . . . . . . 34-15

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 34-16

DISASSEMBLY AND REASSEMBLY . . . . . 34-17

STABILIZER BAR. . . . . . . . . . . . . . . .34-20

REMOVAL AND INSTALLATION . . . . . . . . 34-20

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 34-21

STABILIZER LINK BALL JOINT

DUST COVER REPLACEMENT . . . . . . . . . 34-21

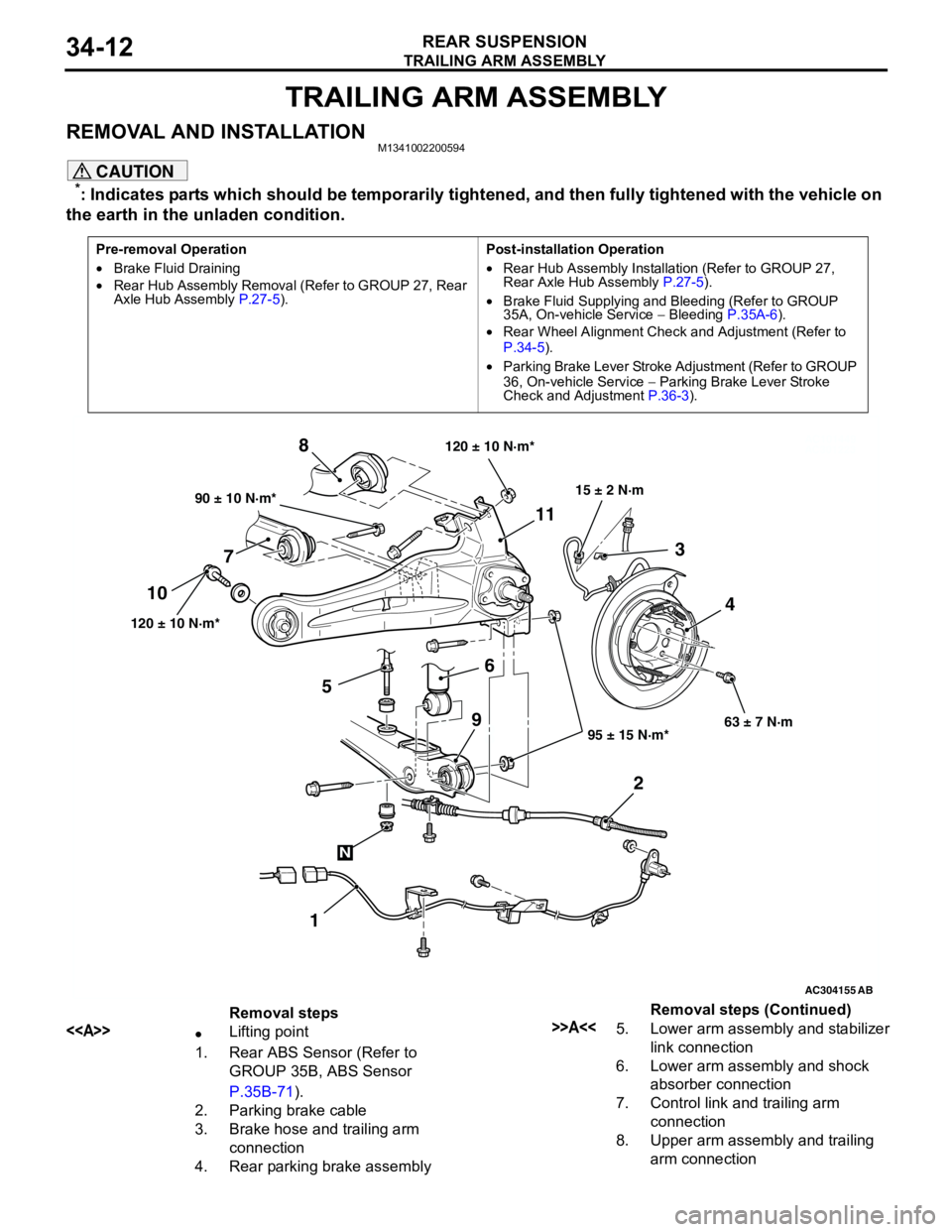

Page 212 of 788

TRAILING ARM ASSEMBLY

REAR SUSPENSION34-12

TRAILING ARM ASSEMBLY

REMOVAL AND INSTALLATIONM1341002200594

CAUTION

*: Indicates parts which should be temporarily tightened, and then fully tightened with the vehicle on

the earth in the unladen condition.

Pre-removal Operation

•Brake Fluid Draining

•Rear Hub Assembly Removal (Refer to GROUP 27, Rear

Axle Hub Assembly P.27-5).Post-installation Operation

•Rear Hub Assembly Installation (Refer to GROUP 27,

Rear Axle Hub Assembly P.27-5).

•Brake Fluid Supplying and Bleeding (Refer to GROUP

35A, On-vehicle Service − Bleeding P.35A-6).

•Rear Wheel Alignment Check and Adjustment (Refer to

P.34-5).

•Parking Brake Lever Stroke Adjustment (Refer to GROUP

36, On-vehicle Service − Parking Brake Lever Stroke

Check and Adjustment P.36-3).

AC101449

AC301223

AC304155AB

90 ± 10 N·m*

120 ± 10 N·m*

95 ± 15 N·m*63 ± 7 N·m

6 78

1 1011

23

4

120 ± 10 N·m*

15 ± 2 N·m

N

9

5

Removal steps

<>•Lifting point

1. Rear ABS Sensor (Refer to

GROUP 35B, ABS Sensor

P.35B-71).

2. Parking brake cable

3. Brake hose and trailing arm

connection

4. Rear parking brake assembly>>A<<5. Lower arm assembly and stabilizer

link connection

6. Lower arm assembly and shock

absorber connection

7. Control link and trailing arm

connection

8. Upper arm assembly and trailing

arm connection Removal steps (Continued)

Page 223 of 788

35-1

GROUP 35

SERVICE BRAKES

CONTENTS

BASIC BRAKE SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35A

ANTI-SKID BRAKING SYSTEM (ABS) . . . . . . . . . . . . . . . . . . .35B

Page 225 of 788

36-1

GROUP 36

PARKING BRAKES

CONTENTS

GENERAL INFORMATION . . . . . . . .36-2

SERVICE SPECIFICATIONS . . . . . . .36-2

LUBRICANTS . . . . . . . . . . . . . . . . . .36-3

ON-VEHICLE SERVICE . . . . . . . . . . .36-3

PARKING BRAKE LEVER STROKE

CHECK AND ADJUSTMENT . . . . . . . . . . . 36-3

LINING RUNNING-IN . . . . . . . . . . . . . . . . . 36-3

PARKING BRAKE SWITCH CHECK . . . . . 36-4

PARKING BRAKE LEVER . . . . . . . . .36-5

REMOVAL AND INSTALLATION . . . . . . . . 36-5

PARKING BRAKE CABLE . . . . . . . . .36-6

REMOVAL AND INSTALLATION . . . . . . . . 36-6

PARKING BRAKE LINING AND

DRUM . . . . . . . . . . . . . . . . . . . . . . . . .36-7

REMOVAL AND INSTALLATION . . . . . . . . 36-7

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 36-9

Page 227 of 788

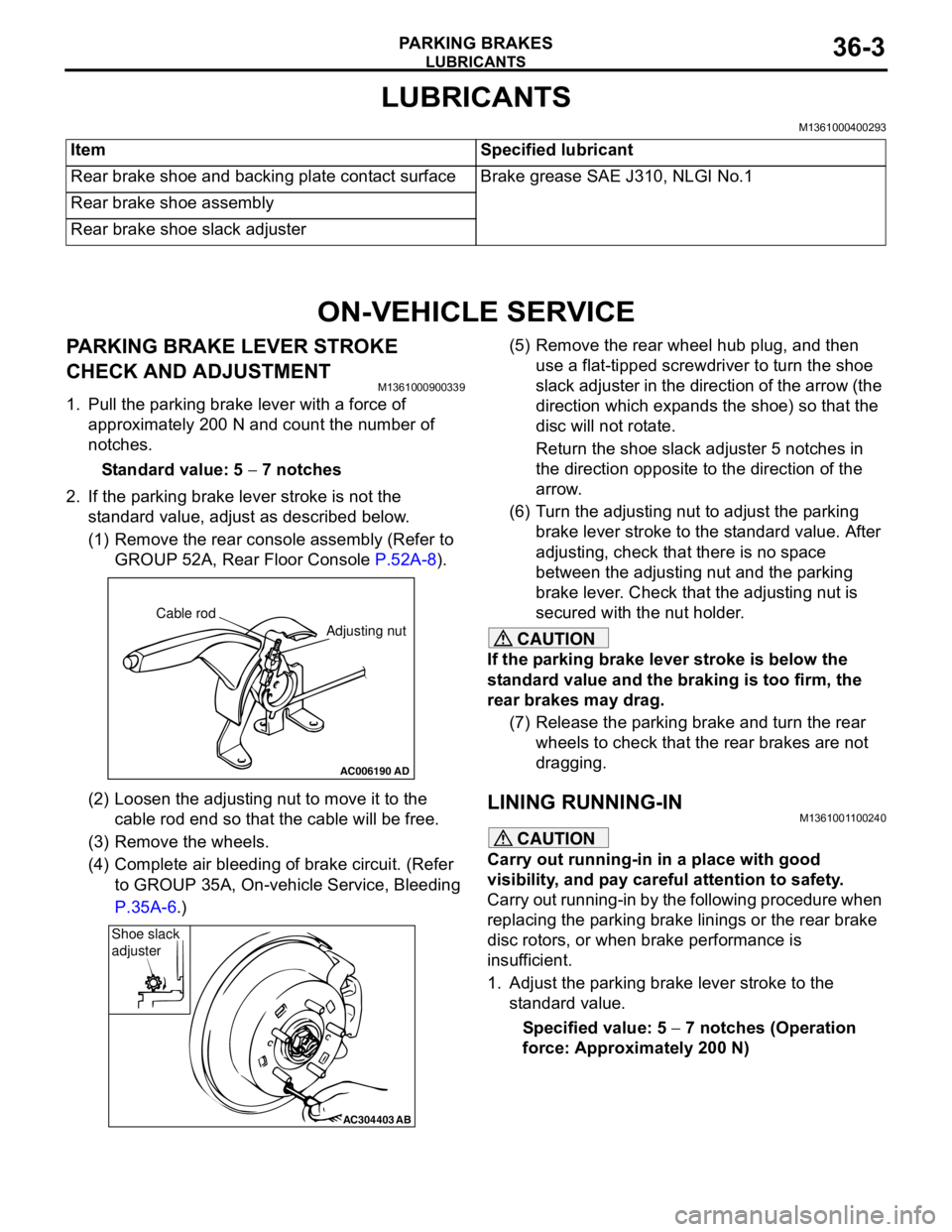

LUBRICANTS

PARKING BRAKES36-3

LUBRICANTS

M1361000400293

ON-VEHICLE SERVICE

PARKING BRAKE LEVER STROKE

CHECK AND ADJUSTMENT

M1361000900339

1. Pull the parking brake lever with a force of

approximately 200 N and count the number of

notches.

Standard value: 5 − 7 notches

2. If the parking brake lever stroke is not the

standard value, adjust as described below.

(1) Remove the rear console assembly (Refer to

GROUP 52A, Rear Floor Console P.52A-8).

(2) Loosen the adjusting nut to move it to the

cable rod end so that the cable will be free.

(3) Remove the wheels.

(4) Complete air bleeding of brake circuit. (Refer

to GROUP 35A, On-vehicle Service, Bleeding

P.35A-6.)(5) Remove the rear wheel hub plug, and then

use a flat-tipped screwdriver to turn the shoe

slack adjuster in the direction of the arrow (the

direction which expands the shoe) so that the

disc will not rotate.

Return the shoe slack adjuster 5 notches in

the direction opposite to the direction of the

arrow.

(6) Turn the adjusting nut to adjust the parking

brake lever stroke to the standard value. After

adjusting, check that there is no space

between the adjusting nut and the parking

brake lever. Check that the adjusting nut is

secured with the nut holder.

CAUTION

If the parking brake lever stroke is below the

standard value and the braking is too firm, the

rear brakes may drag.

(7) Release the parking brake and turn the rear

wheels to check that the rear brakes are not

dragging.

LINING RUNNING-INM1361001100240

CAUTION

Carry out running-in in a place with good

visibility, and pay careful attention to safety.

Carry out running-in by the following procedure when

replacing the parking brake linings or the rear brake

disc rotors, or when brake performance is

insufficient.

1. Adjust the parking brake lever stroke to the

standard value.

Specified value: 5 − 7 notches (Operation

force: Approximately 200 N) Item Specified lubricant

Rear brake shoe and backing plate contact surface Brake grease SAE J310, NLGI No.1

Rear brake shoe assembly

Rear brake shoe slack adjuster

AC006190

Cable rod

Adjusting nut

AD

AC304403AB

Shoe slack

adjuster

Page 228 of 788

ON-VEHICLE SERVICE

PARKING BRAKES36-4

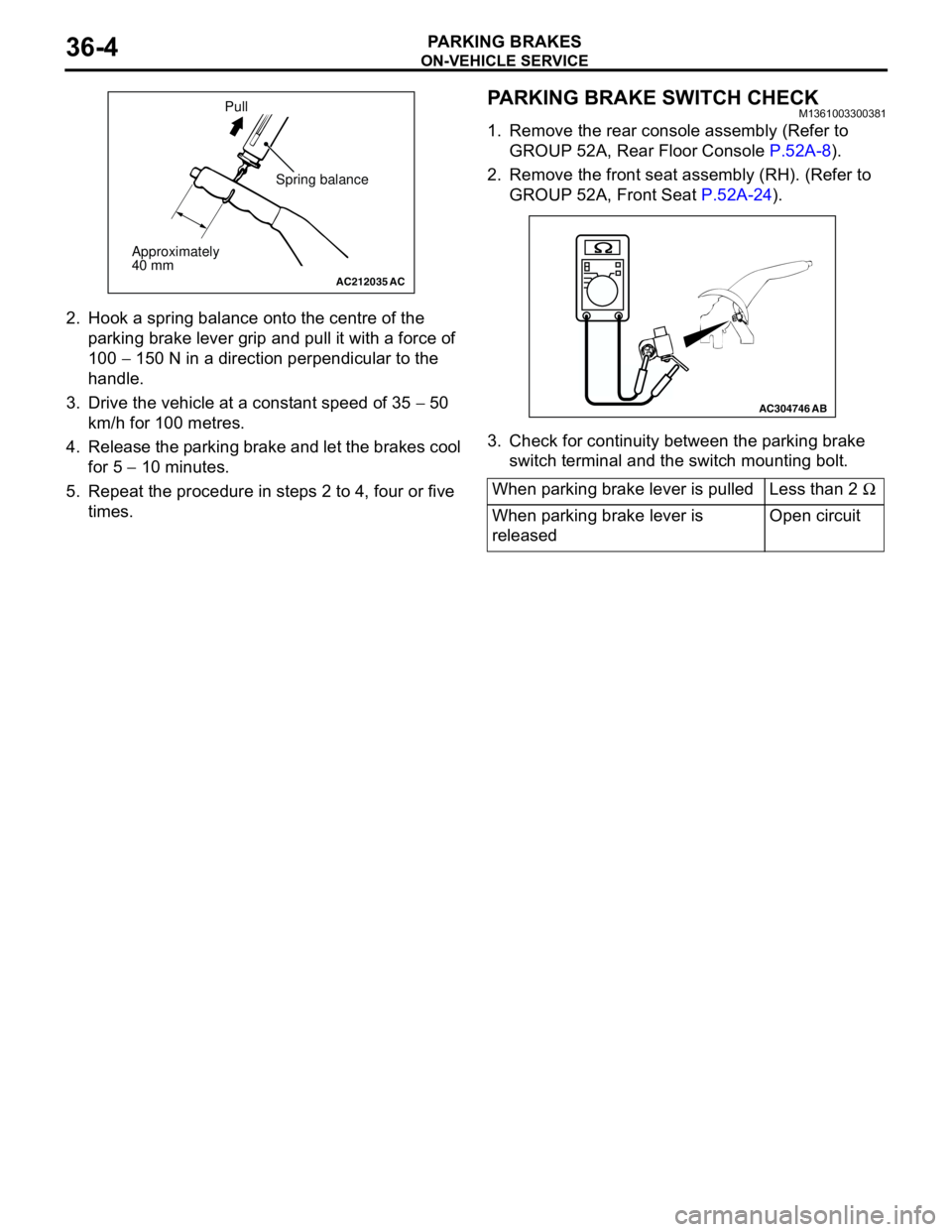

2. Hook a spring balance onto the centre of the

parking brake lever grip and pull it with a force of

100 − 150 N in a direction perpendicular to the

handle.

3. Drive the vehicle at a constant speed of 35 − 50

km/h for 100 metres.

4. Release the parking brake and let the brakes cool

for 5 − 10 minutes.

5. Repeat the procedure in steps 2 to 4, four or five

times.

PARKING BRAKE SWITCH CHECKM1361003300381

1. Remove the rear console assembly (Refer to

GROUP 52A, Rear Floor Console P.52A-8).

2. Remove the front seat assembly (RH). (Refer to

GROUP 52A, Front Seat P.52A-24).

3. Check for continuity between the parking brake

switch terminal and the switch mounting bolt.

AC212035AC

Spring balance

Approximately

40 mmPull

When parking brake lever is pulled Less than 2 Ω

When parking brake lever is

releasedOpen circuit

AC304746AB

Page 229 of 788

PARKING BRAKE LEVER

PARKING BRAKES36-5

PARKING BRAKE LEVER

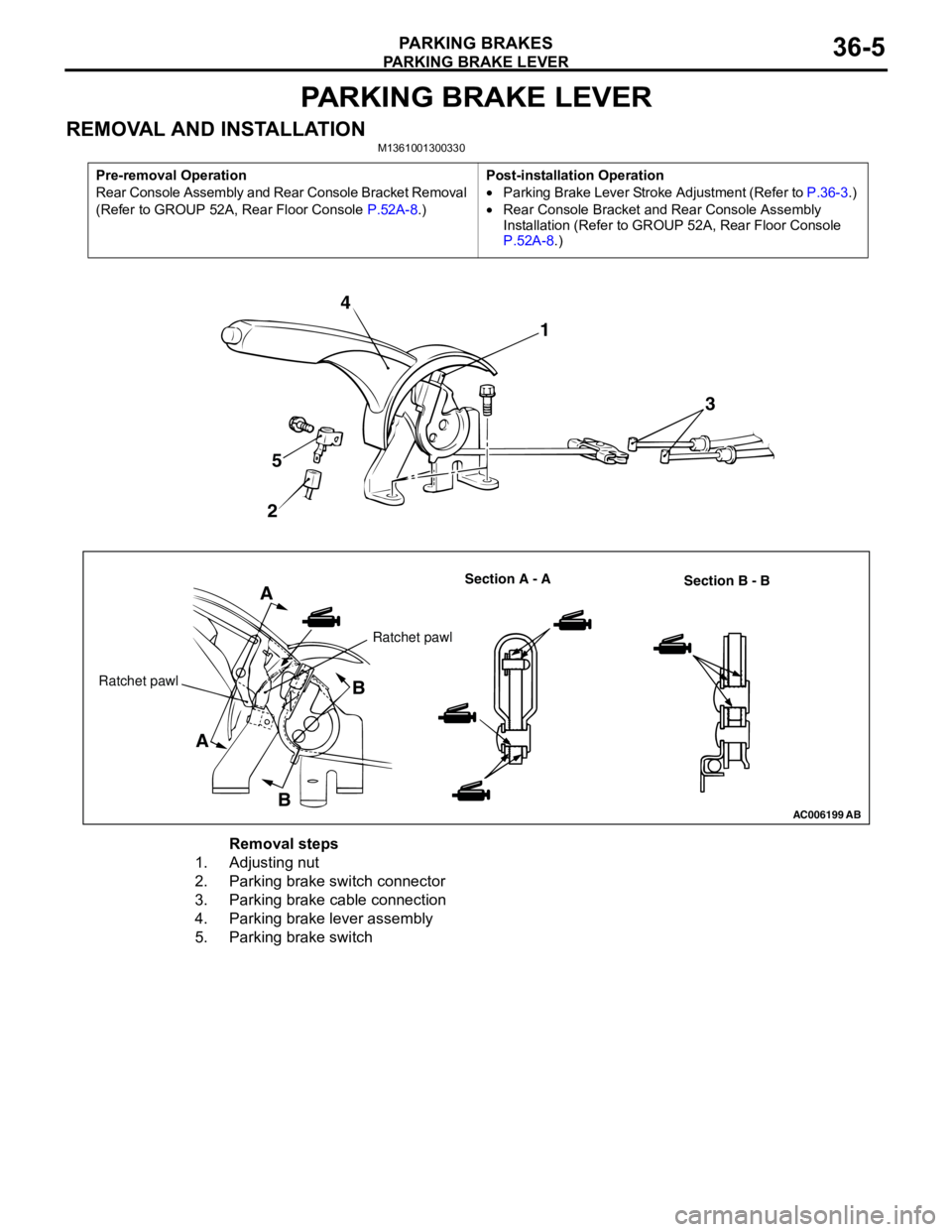

REMOVAL AND INSTALLATIONM1361001300330

Pre-removal Operation

Rear Console Assembly and Rear Console Bracket Removal

(Refer to GROUP 52A, Rear Floor Console P.52A-8.)Post-installation Operation

•Parking Brake Lever Stroke Adjustment (Refer to P.36-3.)

•Rear Console Bracket and Rear Console Assembly

Installation (Refer to GROUP 52A, Rear Floor Console

P.52A-8.)

AC006199AB

4

5

21

3

A

AB

B

Ratchet pawlSection A - A

Section B - B

Ratchet pawl

Removal steps

1. Adjusting nut

2. Parking brake switch connector

3. Parking brake cable connection

4. Parking brake lever assembly

5. Parking brake switch