Engine electrical MITSUBISHI LANCER 2005 Manual PDF

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 430 of 788

COMBINATION METER ASSEMBLY

CHASSIS ELECTRICAL54A-42

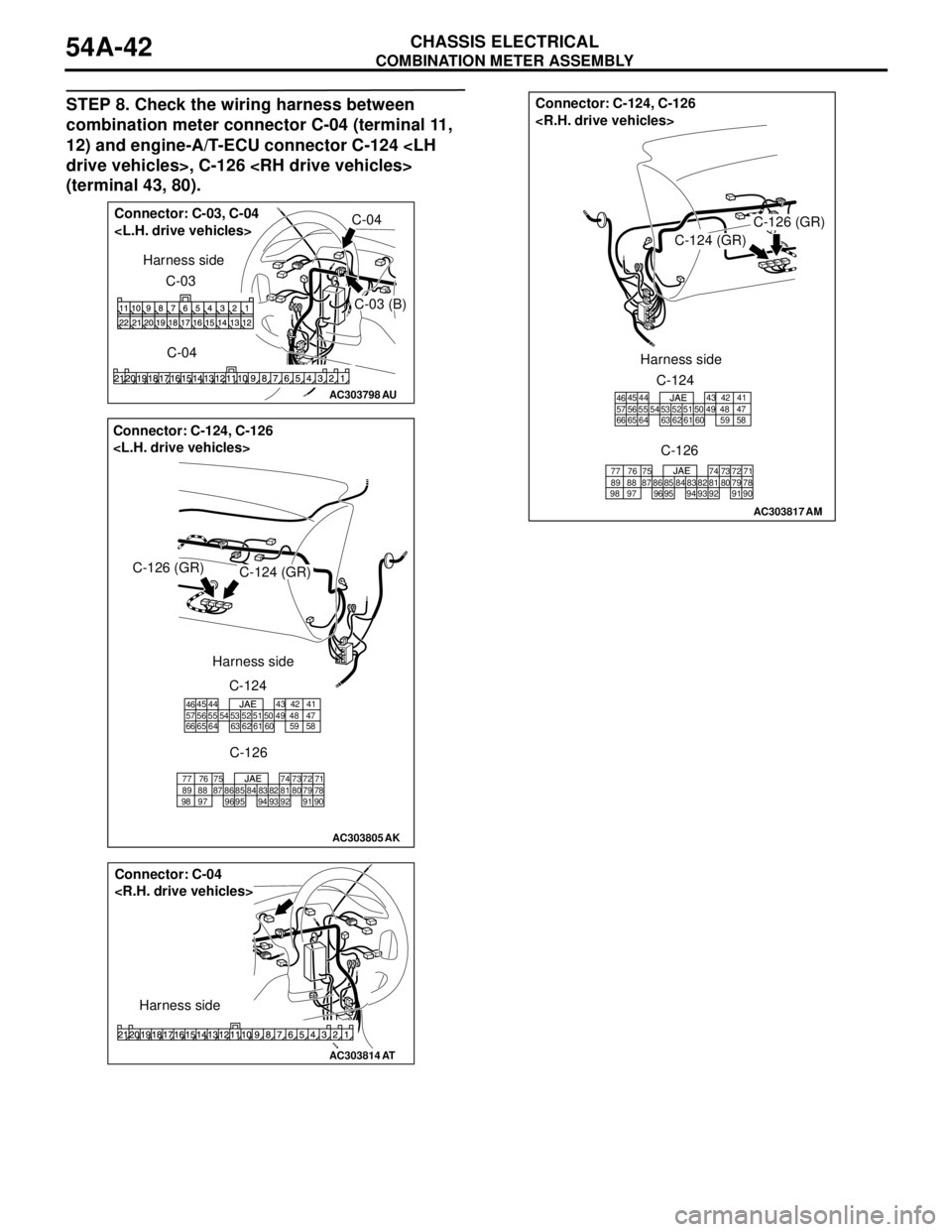

STEP 8. Check the wiring harness between

combination meter connector C-04 (terminal 11,

12) and engine-A/T-ECU connector C-124

(terminal 43, 80).

AC303798AU

Connector: C-03, C-04

C-03 (B)

C-04 C-03 Harness side

AC303805

Connector: C-124, C-126

C-124 (GR)C-126 (GR)

C-124

C-126 Harness side

41 42 43 44 45

57 56 55 54 53 52 51 50 49 48 47

58 59 60 61 62 63 64 65 6646

71 72 73 74 75 76 77

89 88 87 86 85 84 83 82 81 80 79 78

90 91 92 93 94 95 96 97 98

AK

AC303814

Connector: C-04

Harness side

AT

AC303817

Connector: C-124, C-126

C-124

C-126

C-126 (GR)

C-124 (GR)

Harness side

41 42 43 44 45

57 56 55 54 53 52 51 50 49 48 47

58 59 60 61 62 63 64 65 6646

71 72 73 74 75 76 77

89 88 87 86 85 84 83 82 81 80 79 78

90 91 92 93 94 95 96 97 98

AM

Page 431 of 788

COMBINATION METER ASSEMBLY

CHASSIS ELECTRICAL54A-43

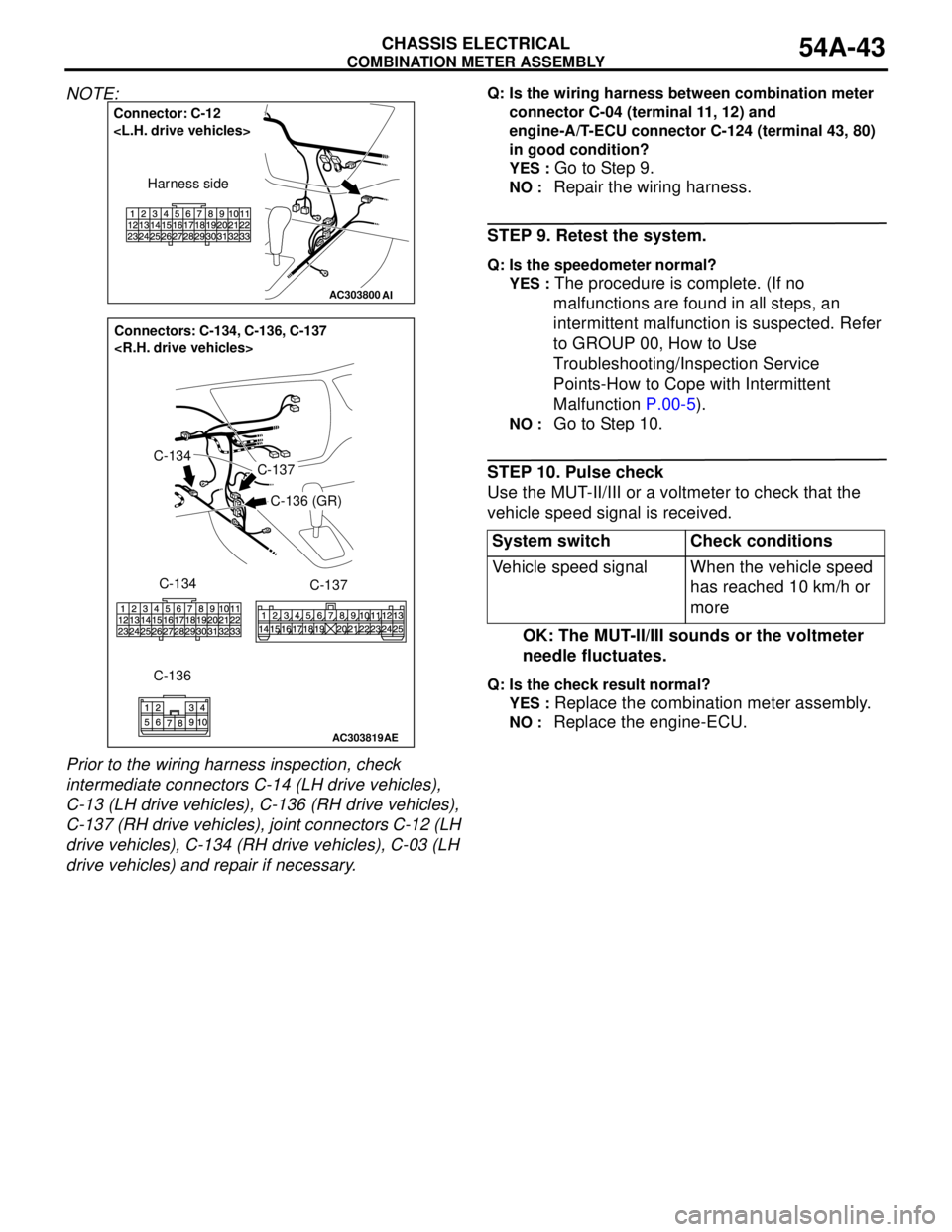

NOTE:

Prior to the wiring harness inspection, check

intermediate connectors C-14 (LH drive vehicles),

C-13 (LH drive vehicles), C-136 (RH drive vehicles),

C-137 (RH drive vehicles), joint connectors C-12 (LH

drive vehicles), C-134 (RH drive vehicles), C-03 (LH

drive vehicles) and repair if necessary.Q: Is the wiring harness between combination meter

connector C-04 (terminal 11, 12) and

engine-A/T-ECU connector C-124 (terminal 43, 80)

in good condition?

YES :

Go to Step 9.

NO : Repair the wiring harness.

STEP 9. Retest the system.

Q: Is the speedometer normal?

YES :

The procedure is complete. (If no

malfunctions are found in all steps, an

intermittent malfunction is suspected. Refer

to GROUP 00, How to Use

Troubleshooting/Inspection Service

Points-How to Cope with Intermittent

Malfunction P.00-5).

NO : Go to Step 10.

STEP 10. Pulse check

Use the MUT-II/III or a voltmeter to check that the

vehicle speed signal is received.

OK: The MUT-II/III sounds or the voltmeter

needle fluctuates.

Q: Is the check result normal?

YES :

Replace the combination meter assembly.

NO : Replace the engine-ECU.

AC303800

Connector: C-12

Harness side

AI

AC303819

Connectors: C-134, C-136, C-137

C-134

AE

C-134

C-136C-137

C-136 (GR)

C-137

System switch Check conditions

Vehicle speed signal When the vehicle speed

has reached 10 km/h or

more

Page 432 of 788

COMBINATION METER ASSEMBLY

CHASSIS ELECTRICAL54A-44

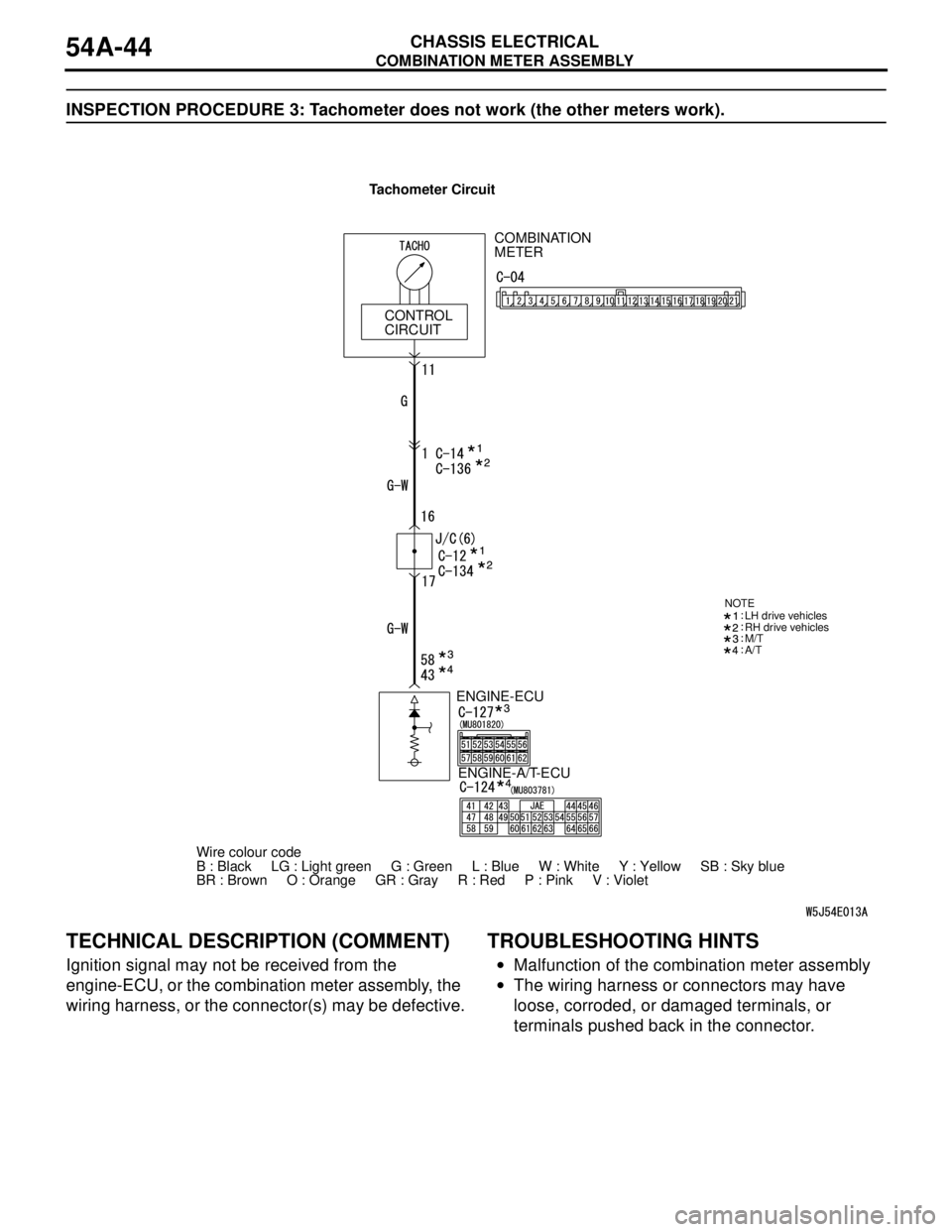

INSPECTION PROCEDURE 3: Tachometer does not work (the other meters work).

TECHNICAL DESCRIPTION (COMMENT)

Ignition signal may not be received from the

engine-ECU, or the combination meter assembly, the

wiring harness, or the connector(s) may be defective.

TROUBLESHOOTING HINTS

•Malfunction of the combination meter assembly

•The wiring harness or connectors may have

loose, corroded, or damaged terminals, or

terminals pushed back in the connector.

ENGINE-ECU

Wire colour code

B : Black LG : Light green G : Green L : Blue W : White Y : Yellow SB : Sky blue

BR : Brown O : Orange GR : Gray R : Red P : Pink V : Violet ENGINE-A/T-ECU

M/T

A/T

NOTELH drive vehicles

RH drive vehicles

COMBINATION

METER

CONTROL

CIRCUIT

Tachometer Circuit

Page 433 of 788

COMBINATION METER ASSEMBLY

CHASSIS ELECTRICAL54A-45

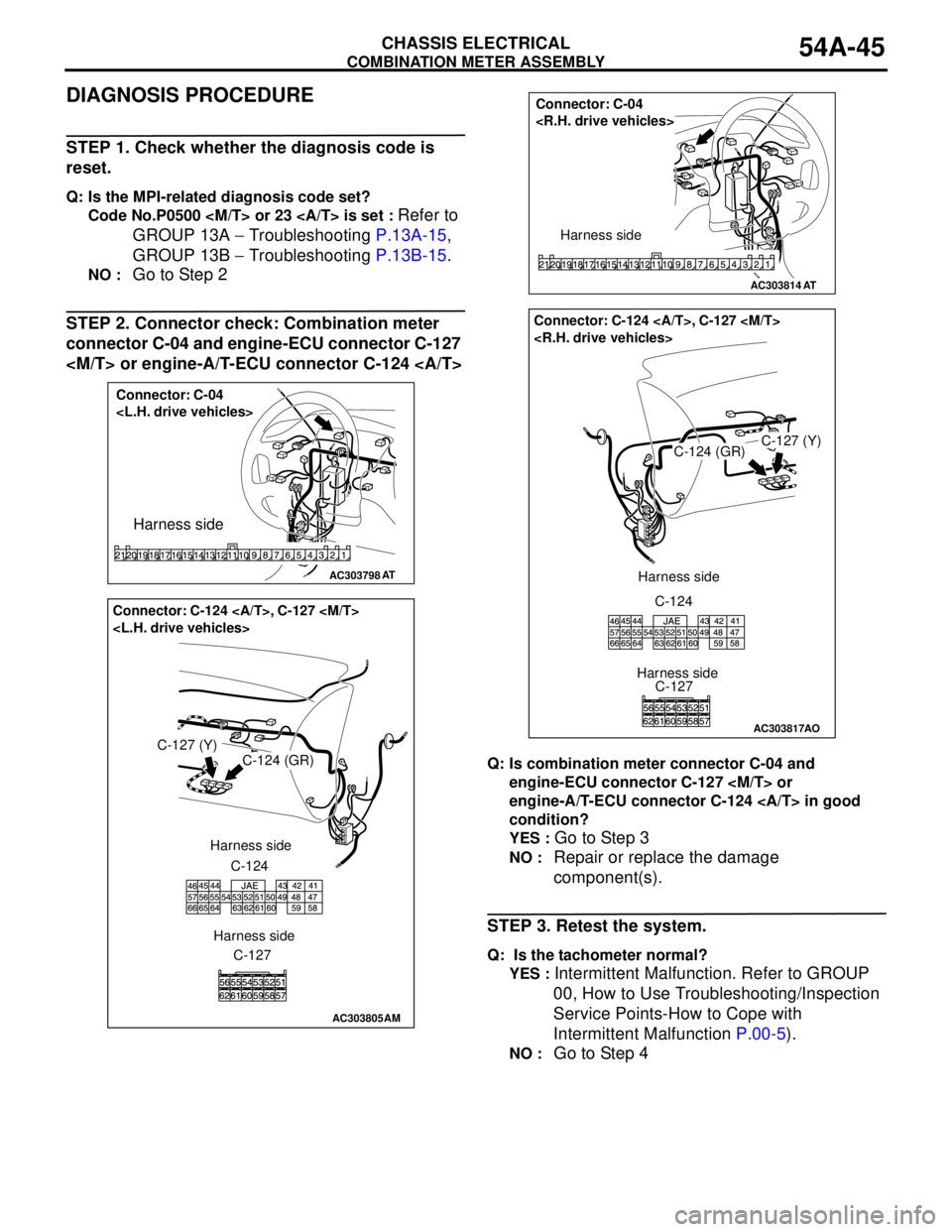

DIAGNOSIS PROCEDURE

STEP 1. Check whether the diagnosis code is

reset.

Q: Is the MPI-related diagnosis code set?

Code No.P0500

Refer to

GROUP 13A − Troubleshooting P.13A-15,

GROUP 13B − Troubleshooting P.13B-15.

NO : Go to Step 2

STEP 2. Connector check: Combination meter

connector C-04 and engine-ECU connector C-127

Q: Is combination meter connector C-04 and

engine-ECU connector C-127

engine-A/T-ECU connector C-124 in good

condition?

YES :

Go to Step 3

NO : Repair or replace the damage

component(s).

STEP 3. Retest the system.

Q: Is the tachometer normal?

YES :

Intermittent Malfunction. Refer to GROUP

00, How to Use Troubleshooting/Inspection

Service Points-How to Cope with

Intermittent Malfunction P.00-5).

NO : Go to Step 4

AC303798

Connector: C-04

Harness side

AT

AC303805

Connector: C-124 , C-127

C-124 (GR)

Harness side

C-124

C-127

AM

C-127 (Y)

Harness side

AC303814

Connector: C-04

Harness side

AT

AC303817

Connector: C-124 , C-127

C-127 (Y)C-124 (GR)

C-124

C-127 Harness side

AO

Harness side

Page 434 of 788

COMBINATION METER ASSEMBLY

CHASSIS ELECTRICAL54A-46

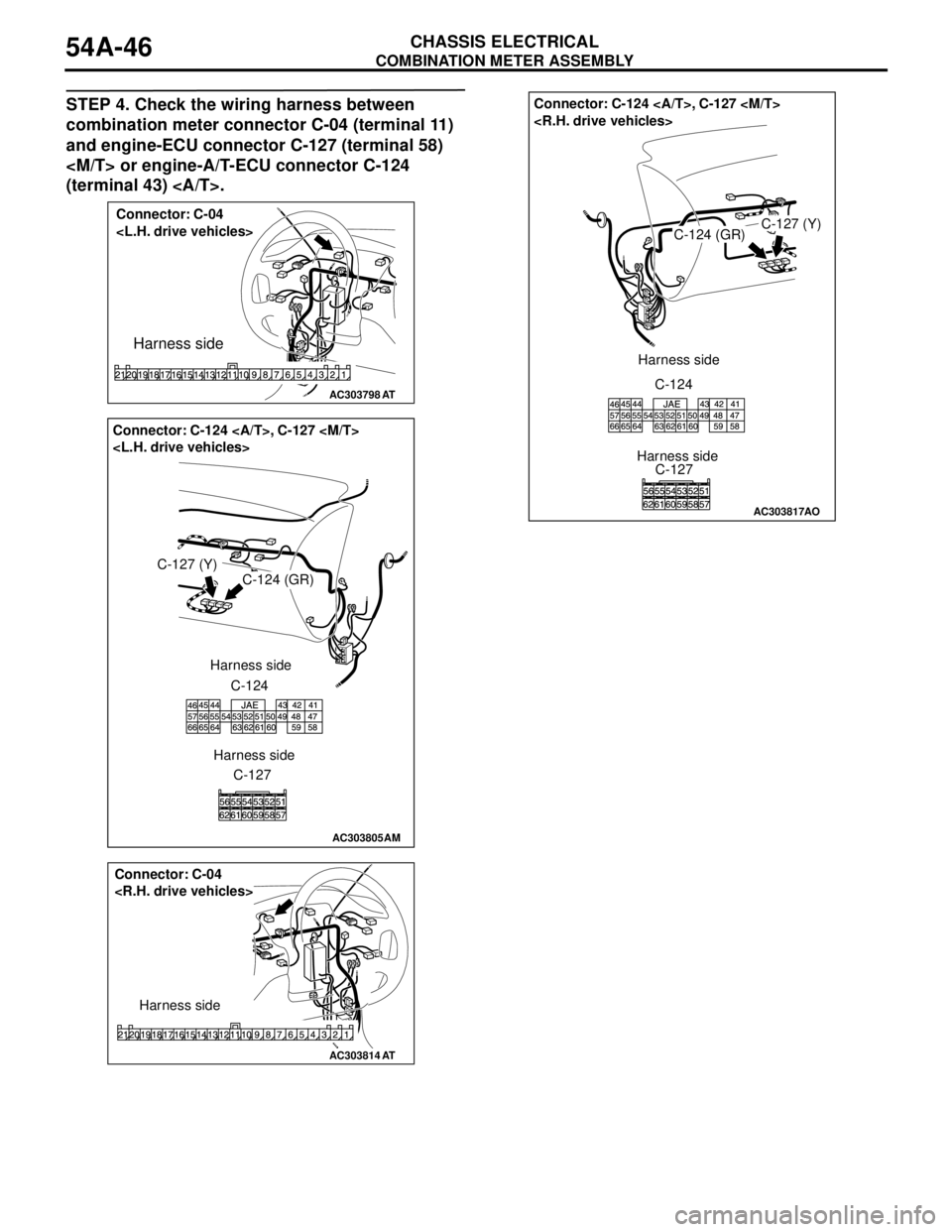

STEP 4. Check the wiring harness between

combination meter connector C-04 (terminal 11)

and engine-ECU connector C-127 (terminal 58)

(terminal 43) .

AC303798

Connector: C-04

Harness side

AT

AC303805

Connector: C-124 , C-127

C-124 (GR)

Harness side

C-124

C-127

AM

C-127 (Y)

Harness side

AC303814

Connector: C-04

Harness side

AT

AC303817

Connector: C-124 , C-127

C-127 (Y)C-124 (GR)

C-124

C-127 Harness side

AO

Harness side

Page 435 of 788

COMBINATION METER ASSEMBLY

CHASSIS ELECTRICAL54A-47

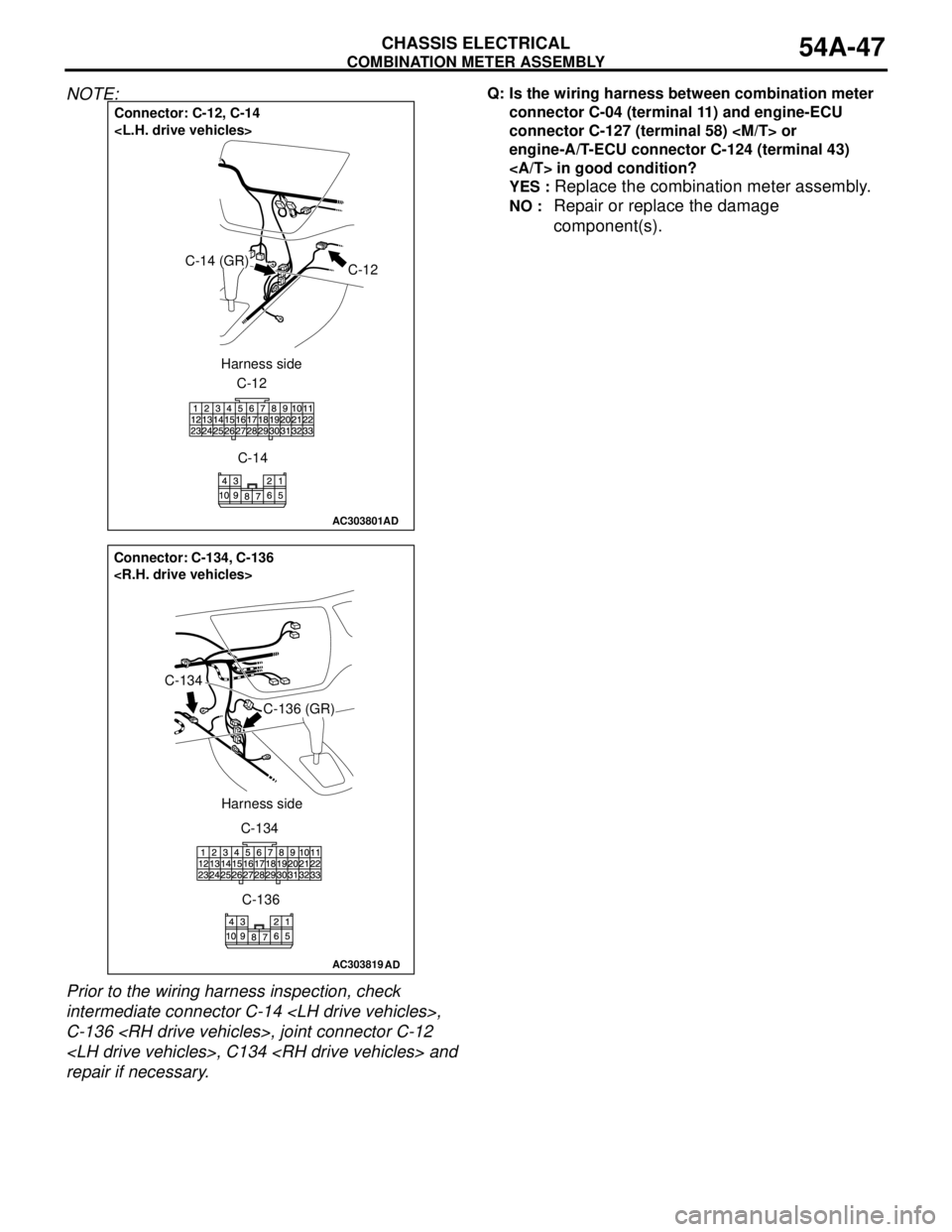

NOTE:

Prior to the wiring harness inspection, check

intermediate connector C-14

C-136

repair if necessary.Q: Is the wiring harness between combination meter

connector C-04 (terminal 11) and engine-ECU

connector C-127 (terminal 58)

engine-A/T-ECU connector C-124 (terminal 43)

in good condition?

YES :

Replace the combination meter assembly.

NO : Repair or replace the damage

component(s).

AC303801

Connector: C-12, C-14

C-12C-14 (GR)

C-12

C-14 Harness side

AD

AC303819

Connector: C-134, C-136

C-136 (GR)

C-134

C-134

C-136 Harness side

AD

Page 439 of 788

COMBINATION METER ASSEMBLY

CHASSIS ELECTRICAL54A-51

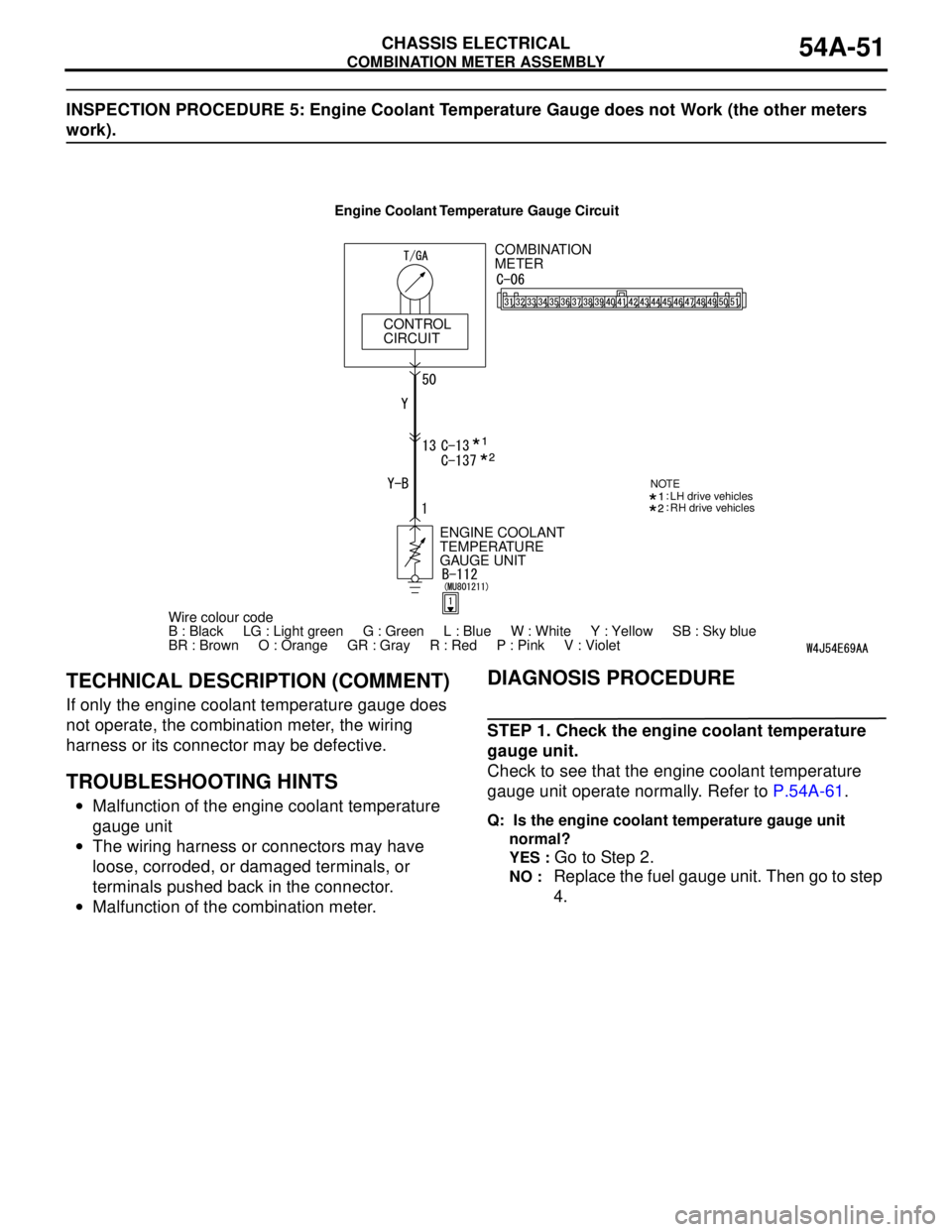

INSPECTION PROCEDURE 5: Engine Coolant Temperature Gauge does not Work (the other meters

work).

TECHNICAL DESCRIPTION (COMMENT)

If only the engine coolant temperature gauge does

not operate, the combination meter, the wiring

harness or its connector may be defective.

TROUBLESHOOTING HINTS

•Malfunction of the engine coolant temperature

gauge unit

•The wiring harness or connectors may have

loose, corroded, or damaged terminals, or

terminals pushed back in the connector.

•Malfunction of the combination meter.

DIAGNOSIS PROCEDURE

STEP 1. Check the engine coolant temperature

gauge unit.

Check to see that the engine coolant temperature

gauge unit operate normally. Refer to P.54A-61.

Q: Is the engine coolant temperature gauge unit

normal?

YES :

Go to Step 2.

NO : Replace the fuel gauge unit. Then go to step

4.

COMBINATION

METER

CONTROL

CIRCUIT

Wire colour code

B : Black LG : Light green G : Green L : Blue W : White Y : Yellow SB : Sky blue

BR : Brown O : Orange GR : Gray R : Red P : Pink V : Violet ENGINE COOLANT

TEMPERATURE

GAUGE UNIT

NOTELH drive vehicles

RH drive vehicles

Engine Coolant Temperature Gauge Circuit

Page 440 of 788

COMBINATION METER ASSEMBLY

CHASSIS ELECTRICAL54A-52

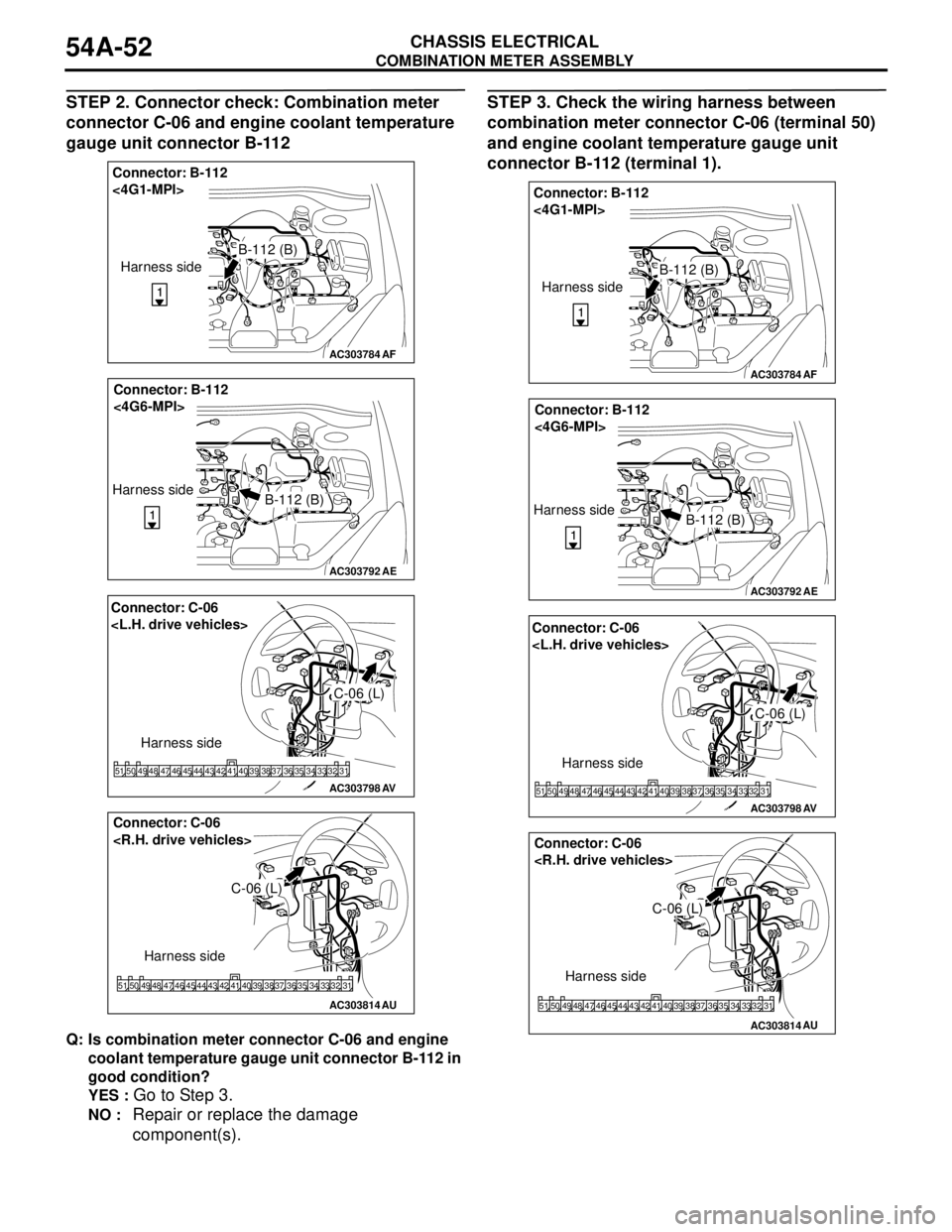

STEP 2. Connector check: Combination meter

connector C-06 and engine coolant temperature

gauge unit connector B-112

Q: Is combination meter connector C-06 and engine

coolant temperature gauge unit connector B-112 in

good condition?

YES :

Go to Step 3.

NO : Repair or replace the damage

component(s).

STEP 3. Check the wiring harness between

combination meter connector C-06 (terminal 50)

and engine coolant temperature gauge unit

connector B-112 (terminal 1).

AC303784

Connector: B-112

<4G1-MPI>

Harness side

B-112 (B)

AF

AC303792

AE

Connector: B-112

<4G6-MPI>

B-112 (B) Harness side

AC303798

Connector: C-06

Harness side

C-06 (L)

31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51

AV

AC303814AU

Connector: C-06

Harness side

31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51

C-06 (L)

AC303784

Connector: B-112

<4G1-MPI>

Harness side

B-112 (B)

AF

AC303792

AE

Connector: B-112

<4G6-MPI>

B-112 (B) Harness side

AC303798

Connector: C-06

Harness side

C-06 (L)

31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51

AV

AC303814AU

Connector: C-06

Harness side

31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51

C-06 (L)

Page 441 of 788

COMBINATION METER ASSEMBLY

CHASSIS ELECTRICAL54A-53

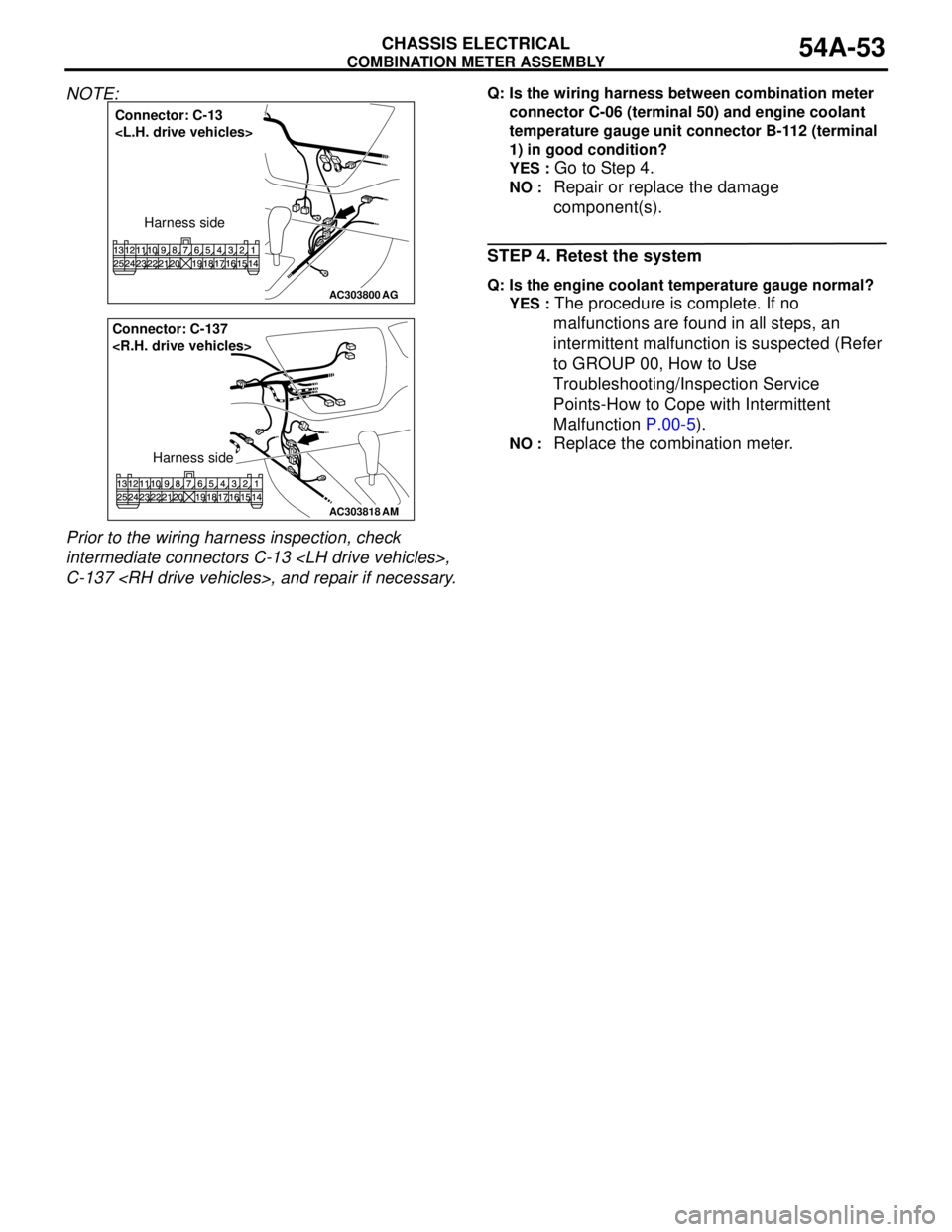

NOTE:

Prior to the wiring harness inspection, check

intermediate connectors C-13

C-137

connector C-06 (terminal 50) and engine coolant

temperature gauge unit connector B-112 (terminal

1) in good condition?

YES :

Go to Step 4.

NO : Repair or replace the damage

component(s).

STEP 4. Retest the system

Q: Is the engine coolant temperature gauge normal?

YES :

The procedure is complete. If no

malfunctions are found in all steps, an

intermittent malfunction is suspected (Refer

to GROUP 00, How to Use

Troubleshooting/Inspection Service

Points-How to Cope with Intermittent

Malfunction P.00-5).

NO : Replace the combination meter.

AC303800

Connector: C-13

Harness side

AG

AC303818

AM

Connector: C-137

Harness side

Page 448 of 788

COMBINATION METER ASSEMBLY

CHASSIS ELECTRICAL54A-60

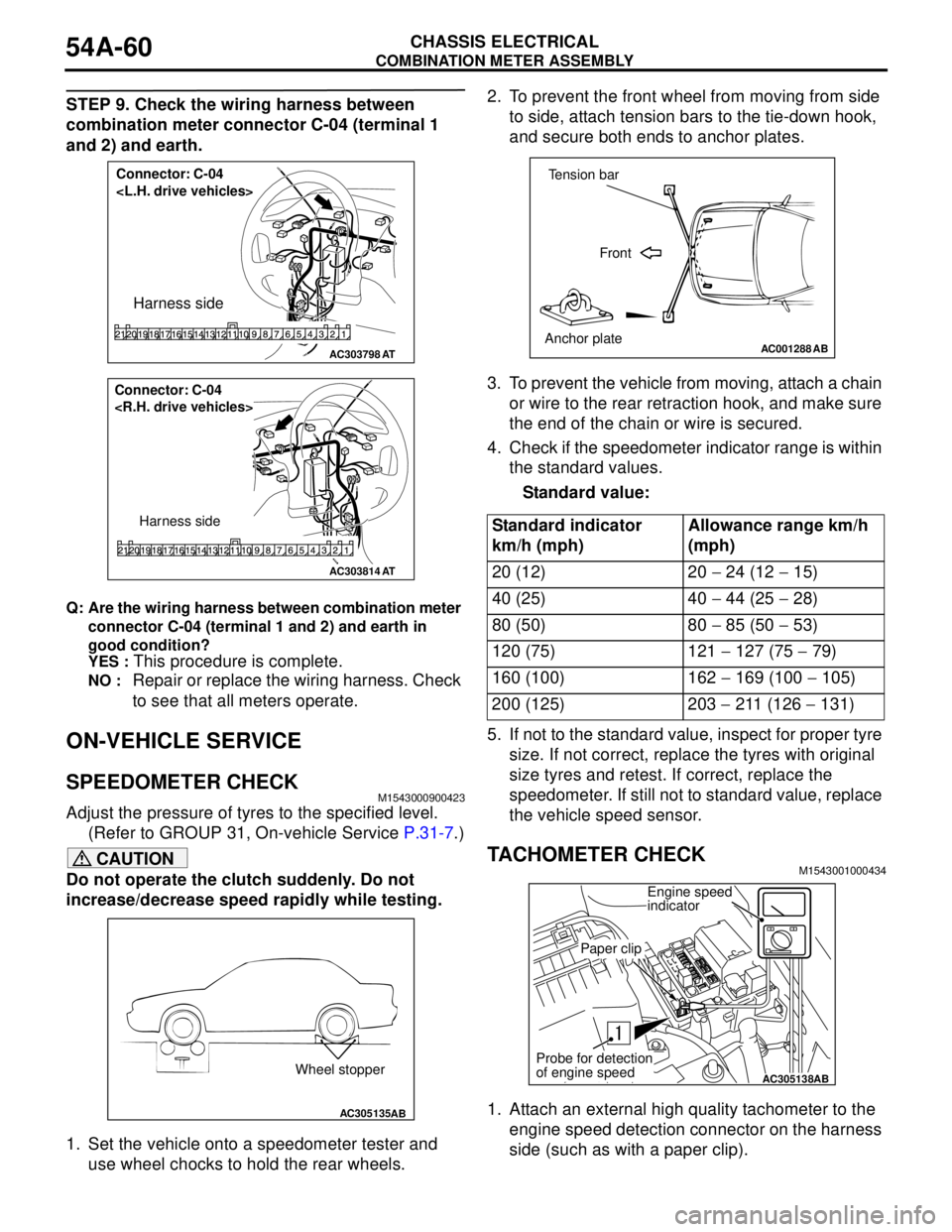

STEP 9. Check the wiring harness between

combination meter connector C-04 (terminal 1

and 2) and earth.

Q: Are the wiring harness between combination meter

connector C-04 (terminal 1 and 2) and earth in

good condition?

YES :

This procedure is complete.

NO : Repair or replace the wiring harness. Check

to see that all meters operate.

ON-VEHICLE SERVICE

SPEEDOMETER CHECKM1543000900423

Adjust the pressure of tyres to the specified level.

(Refer to GROUP 31, On-vehicle Service P.31-7.)

CAUTION

Do not operate the clutch suddenly. Do not

increase/decrease speed rapidly while testing.

1. Set the vehicle onto a speedometer tester and

use wheel chocks to hold the rear wheels.2. To prevent the front wheel from moving from side

to side, attach tension bars to the tie-down hook,

and secure both ends to anchor plates.

3. To prevent the vehicle from moving, attach a chain

or wire to the rear retraction hook, and make sure

the end of the chain or wire is secured.

4. Check if the speedometer indicator range is within

the standard values.

Standard value:

5. If not to the standard value, inspect for proper tyre

size. If not correct, replace the tyres with original

size tyres and retest. If correct, replace the

speedometer. If still not to standard value, replace

the vehicle speed sensor.

TACHOMETER CHECKM1543001000434

1. Attach an external high quality tachometer to the

engine speed detection connector on the harness

side (such as with a paper clip).

AC303798

Connector: C-04

Harness side

AT

AC303814

Connector: C-04

Harness side

AT

AC305135AB

Wheel stopper

Standard indicator

km/h (mph)Allowance range km/h

(mph)

20 (12) 20 − 24 (12 − 15)

40 (25) 40 − 44 (25 − 28)

80 (50) 80 − 85 (50 − 53)

120 (75) 121 − 127 (75 − 79)

160 (100) 162 − 169 (100 − 105)

200 (125) 203 − 211 (126 − 131)

AC001288

Tension bar

Front

Anchor plate

AB

AC305138AB

Engine speed

indicator

Paper clip

Probe for detection

of engine speed