Engine electrical MITSUBISHI LANCER 2005 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 104 of 788

IGNITION SYSTEM

ENGINE ELECTRICAL16-40

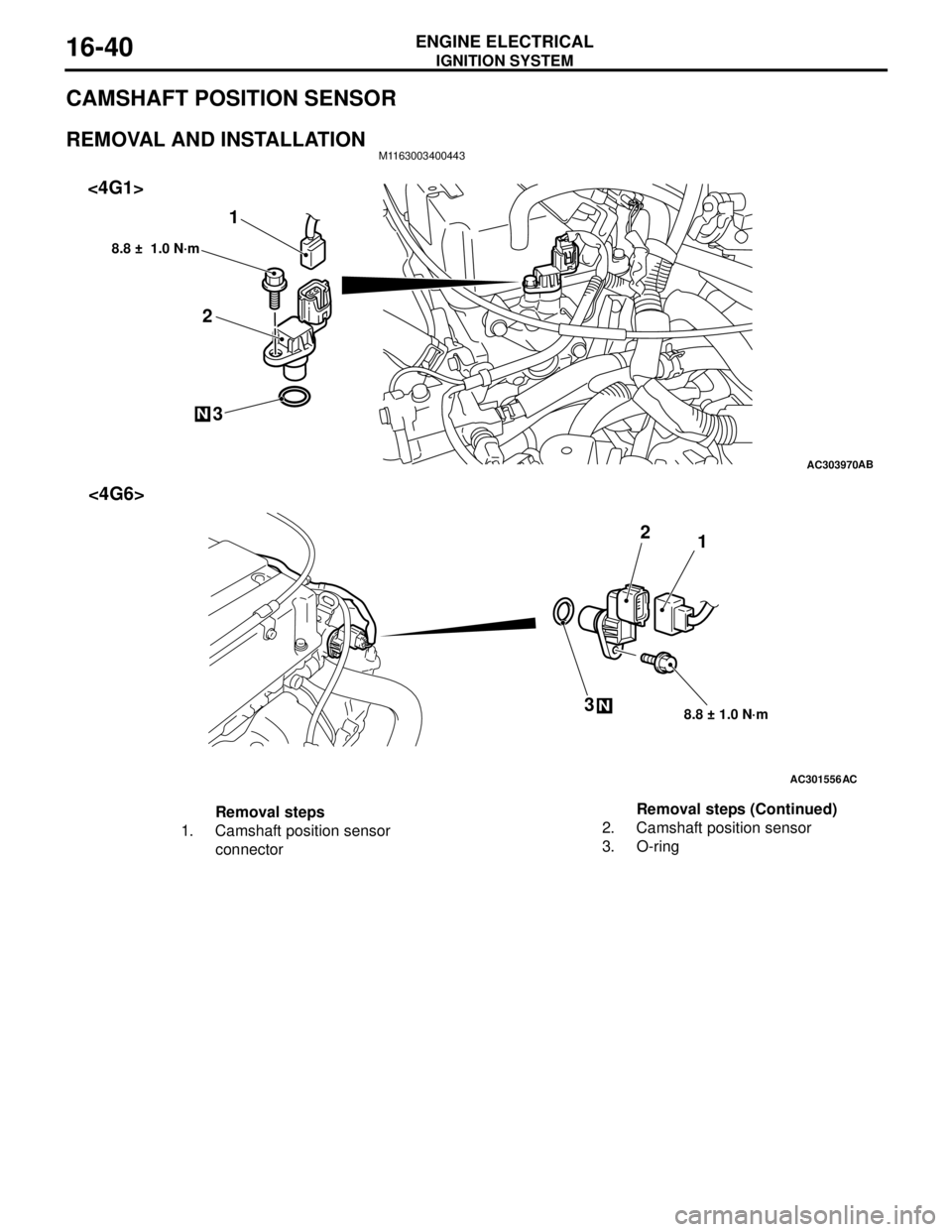

CAMSHAFT POSITION SENSOR

REMOVAL AND INSTALLATIONM1163003400443

AC303970AB

2

3

8.8 ± 1.0 N·m

N

1 <4G1>

AC301556

N

1 2

3

8.8 ± 1.0 N·m

AC

<4G6>

Removal steps

1. Camshaft position sensor

connector2. Camshaft position sensor

3. O-ringRemoval steps (Continued)

Page 105 of 788

IGNITION SYSTEM

ENGINE ELECTRICAL16-41

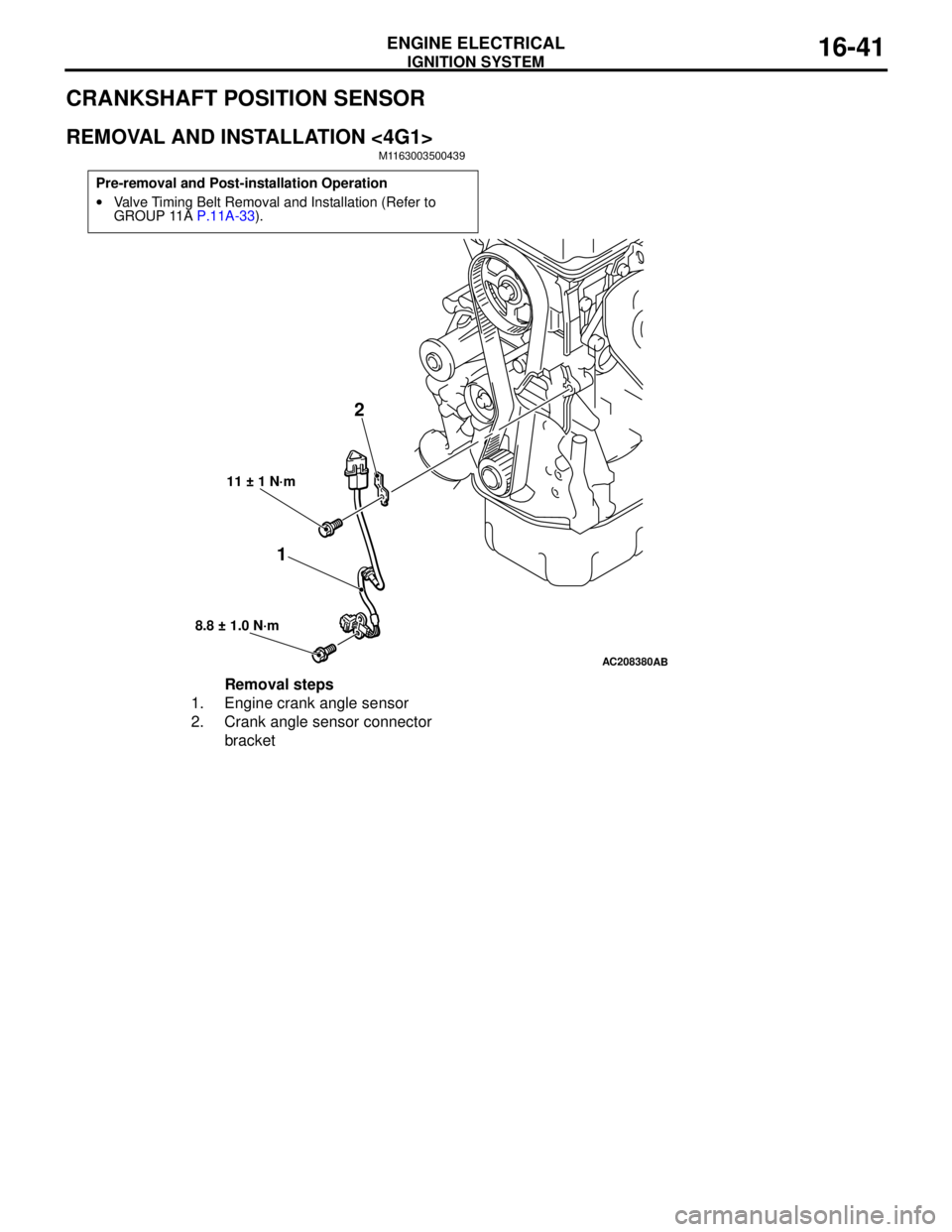

CRANKSHAFT POSITION SENSOR

REMOVAL AND INSTALLATION <4G1>

M1163003500439

Pre-removal and Post-installation Operation

•Valve Timing Belt Removal and Installation (Refer to

GROUP 11A P.11A-33).

AC208380AB

12

11 ± 1 N·m

8.8 ± 1.0 N·m

Removal steps

1. Engine crank angle sensor

2. Crank angle sensor connector

bracket

Page 106 of 788

IGNITION SYSTEM

ENGINE ELECTRICAL16-42

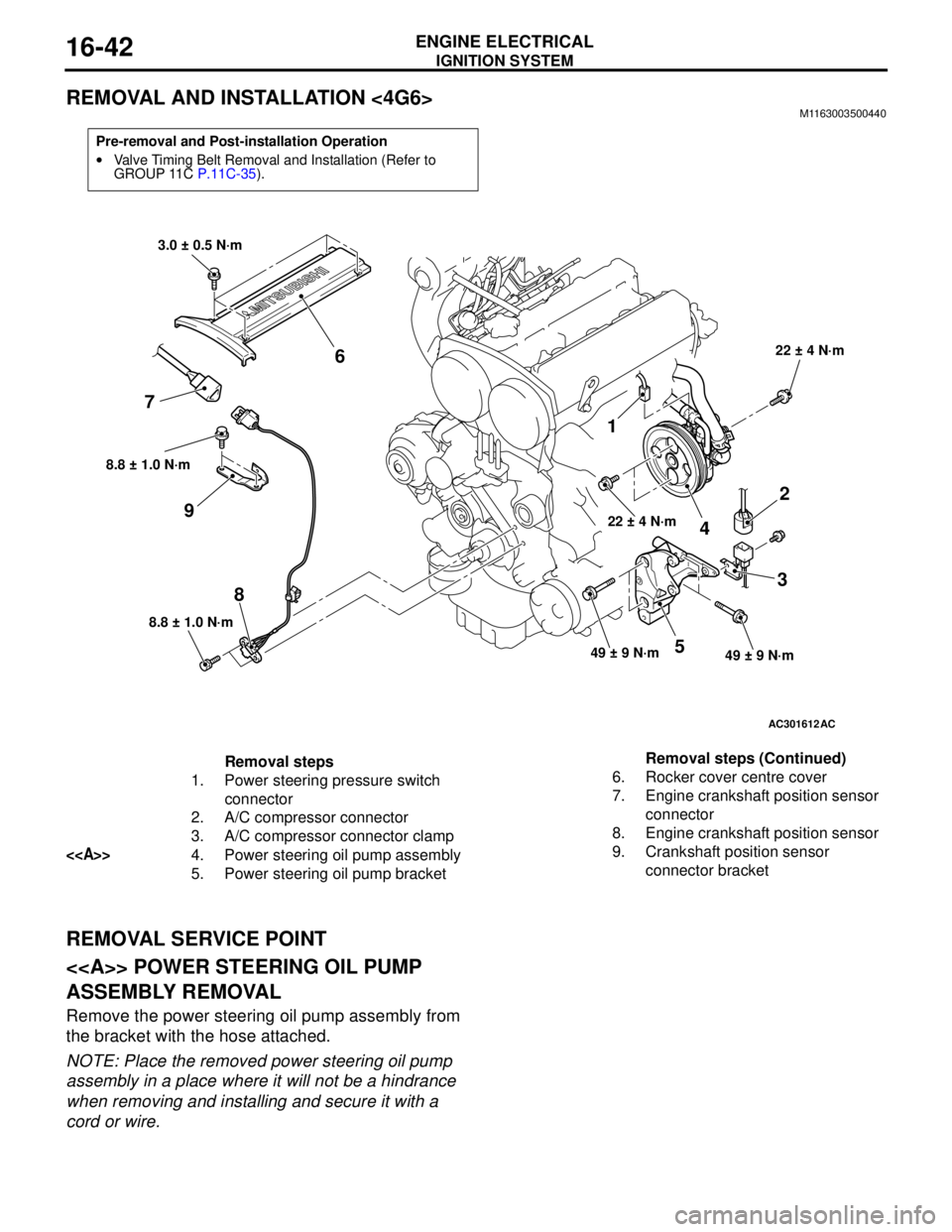

REMOVAL AND INSTALLATION <4G6>M1163003500440

REMOVAL SERVICE POINT

<> POWER STEERING OIL PUMP

ASSEMBLY REMOVAL

Remove the power steering oil pump assembly from

the bracket with the hose attached.

NOTE: Place the removed power steering oil pump

assembly in a place where it will not be a hindrance

when removing and installing and secure it with a

cord or wire.

Pre-removal and Post-installation Operation

•Valve Timing Belt Removal and Installation (Refer to

GROUP 11C P.11C-35).

AC301612

8.8 ± 1.0 N·m

8

8.8 ± 1.0 N·m

9

1

22 ± 4 N·m

4

2

3

49 ± 9 N·m49 ± 9 N·m5

22 ± 4 N·m

3.0 ± 0.5 N·m

6

7

AC

Removal steps

1. Power steering pressure switch

connector

2. A/C compressor connector

3. A/C compressor connector clamp

<>4. Power steering oil pump assembly

5. Power steering oil pump bracket6. Rocker cover centre cover

7. Engine crankshaft position sensor

connector

8. Engine crankshaft position sensor

9. Crankshaft position sensor

connector bracket Removal steps (Continued)

Page 107 of 788

IGNITION SYSTEM

ENGINE ELECTRICAL16-43

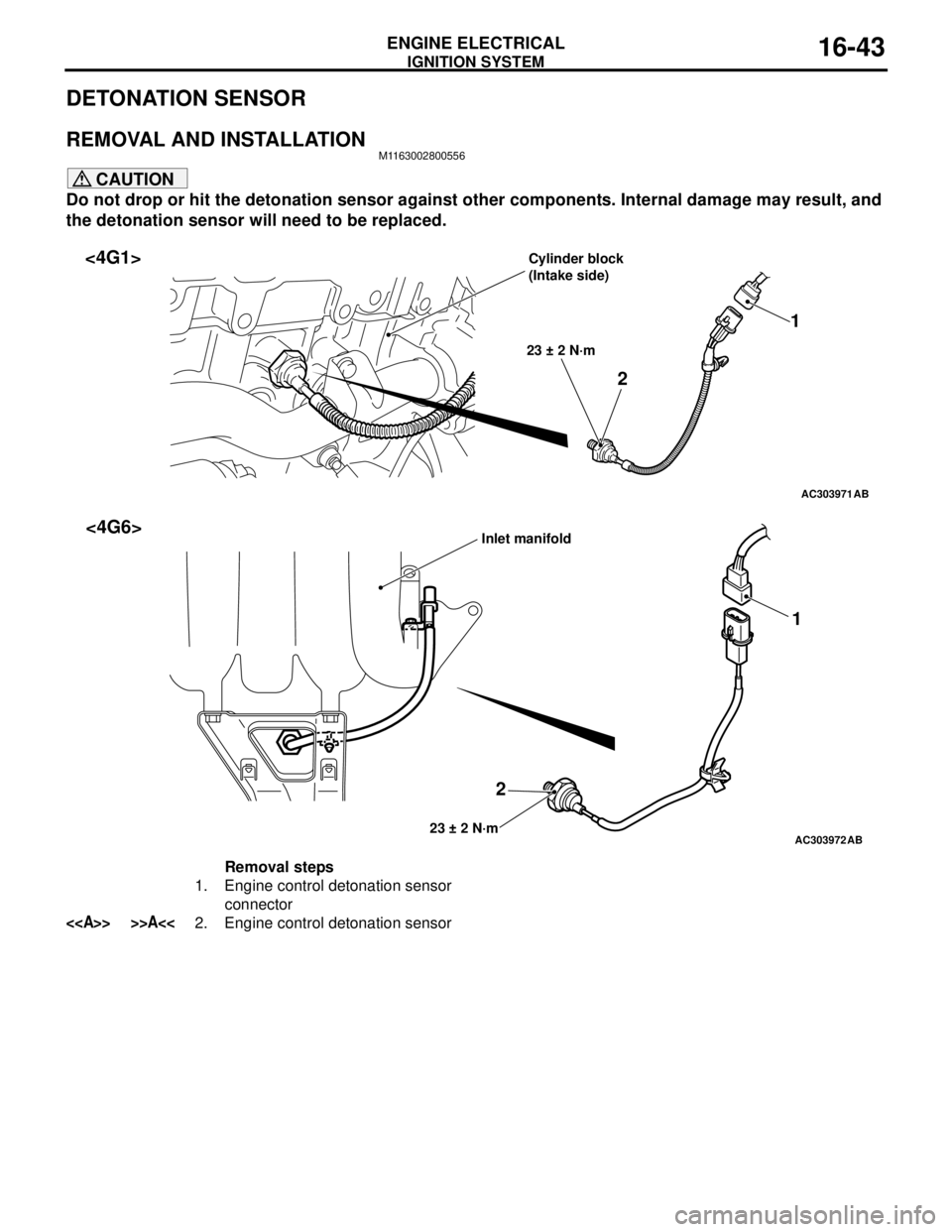

DETONATION SENSOR

REMOVAL AND INSTALLATIONM1163002800556

CAUTION

Do not drop or hit the detonation sensor against other components. Internal damage may result, and

the detonation sensor will need to be replaced.

AC303971

21

23 ± 2 N·m

AB

<4G1>Cylinder block

(Intake side)

AC303972

21

23 ± 2 N·mAB

<4G6>Inlet manifold

Removal steps

1. Engine control detonation sensor

connector

<> >>A<<2. Engine control detonation sensor

Page 108 of 788

IGNITION SYSTEM

ENGINE ELECTRICAL16-44

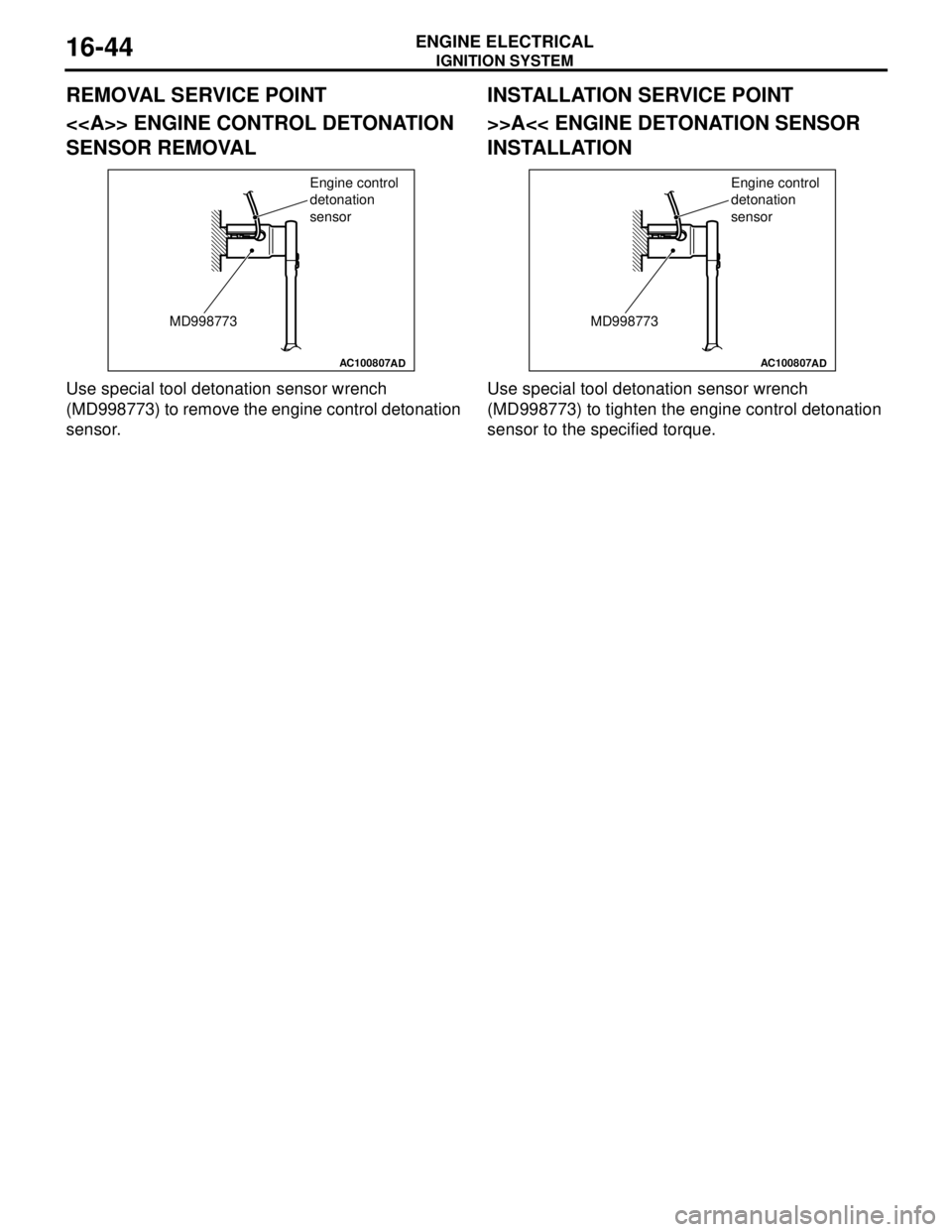

REMOVAL SERVICE POINT

<> ENGINE CONTROL DETONATION

SENSOR REMOVAL

Use special tool detonation sensor wrench

(MD998773) to remove the engine control detonation

sensor.

INSTALLATION SERVICE POINT

>>A<< ENGINE DETONATION SENSOR

INSTALLATION

Use special tool detonation sensor wrench

(MD998773) to tighten the engine control detonation

sensor to the specified torque.

AC100807

MD998773Engine control

detonation

sensor

ADAC100807

MD998773Engine control

detonation

sensor

AD

Page 394 of 788

IGNITION SWITCH

CHASSIS ELECTRICAL54A-6

IGNITION SWITCH

GENERAL INFORMATIONM1543009901274

IGNITION KEY REMINDER BUZZER

The ignition key reminder buzzer will sound under

the following condition, and warn the driver to

remove the ignition key.

•The driver's door is opened when the ignition

switch is at "LOCK" (OFF) or "ACC" position

without removing the ignition key.

However, the lamp reminder buzzer will take

precedence over this function.

DOOR LOCK PREVENTION FUNCTION

If the key is left in the ignition switch while the driver’s

door opened or the assistant door opened, all door

are automatically unlock to prevent locking the

ignition key in the vehicle after door is locked.

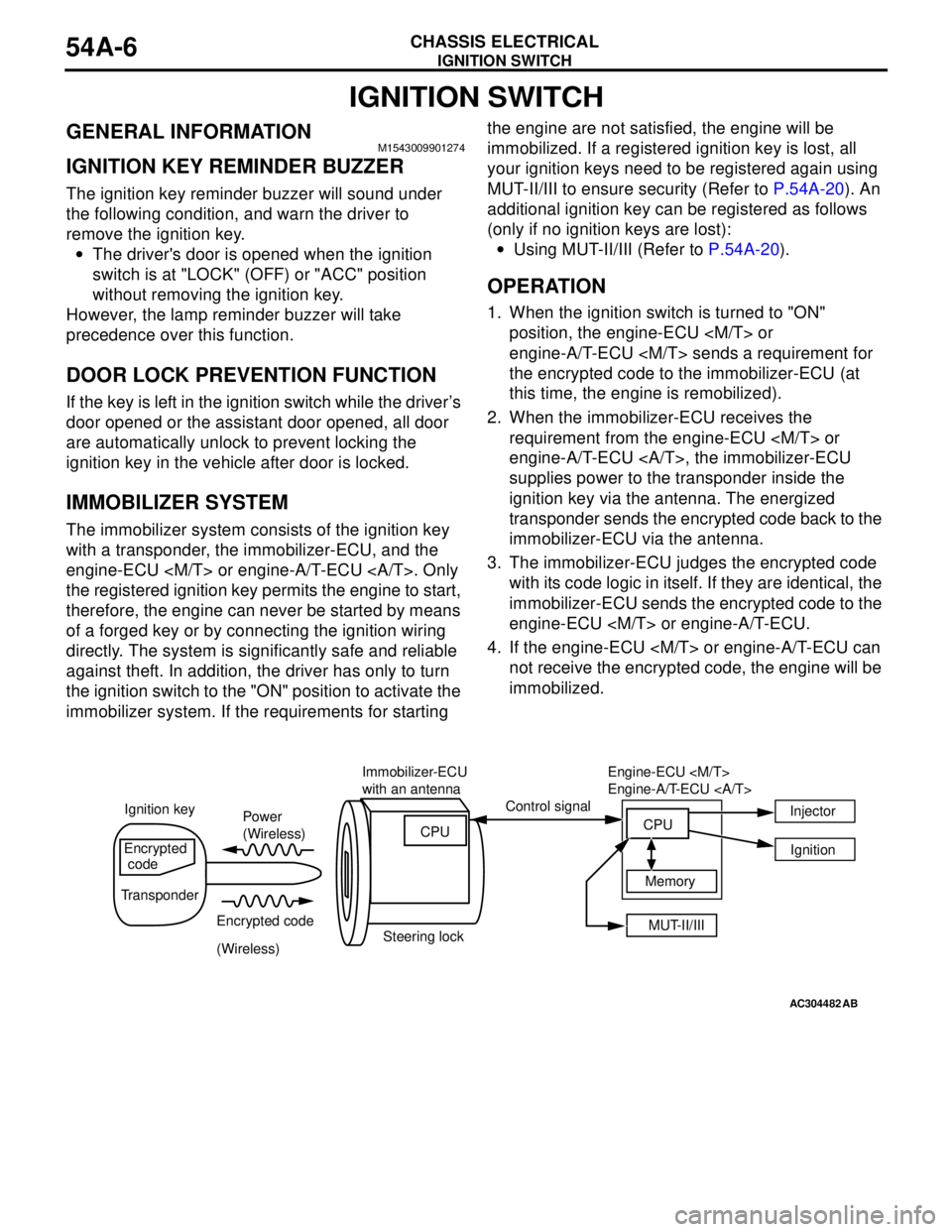

IMMOBILIZER SYSTEM

The immobilizer system consists of the ignition key

with a transponder, the immobilizer-ECU, and the

engine-ECU

the registered ignition key permits the engine to start,

therefore, the engine can never be started by means

of a forged key or by connecting the ignition wiring

directly. The system is significantly safe and reliable

against theft. In addition, the driver has only to turn

the ignition switch to the "ON" position to activate the

immobilizer system. If the requirements for starting the engine are not satisfied, the engine will be

immobilized. If a registered ignition key is lost, all

your ignition keys need to be registered again using

MUT-II/III to ensure security (Refer to P.54A-20). An

additional ignition key can be registered as follows

(only if no ignition keys are lost):

•Using MUT-II/III (Refer to P.54A-20).

OPERATION

1. When the ignition switch is turned to "ON"

position, the engine-ECU

engine-A/T-ECU

the encrypted code to the immobilizer-ECU (at

this time, the engine is remobilized).

2. When the immobilizer-ECU receives the

requirement from the engine-ECU

engine-A/T-ECU , the immobilizer-ECU

supplies power to the transponder inside the

ignition key via the antenna. The energized

transponder sends the encrypted code back to the

immobilizer-ECU via the antenna.

3. The immobilizer-ECU judges the encrypted code

with its code logic in itself. If they are identical, the

immobilizer-ECU sends the encrypted code to the

engine-ECU

4. If the engine-ECU

not receive the encrypted code, the engine will be

immobilized.

AC304482AB

Power

(Wireless)

Encrypted code

(Wireless) Ignition keyControl signal

Encrypted

code

TransponderImmobilizer-ECU

with an antenna

Steering lockCPU

MUT-II/III Memory Engine-ECU

Engine-A/T-ECU

CPUInjector

Ignition

Page 395 of 788

IGNITION SWITCH

CHASSIS ELECTRICAL54A-7

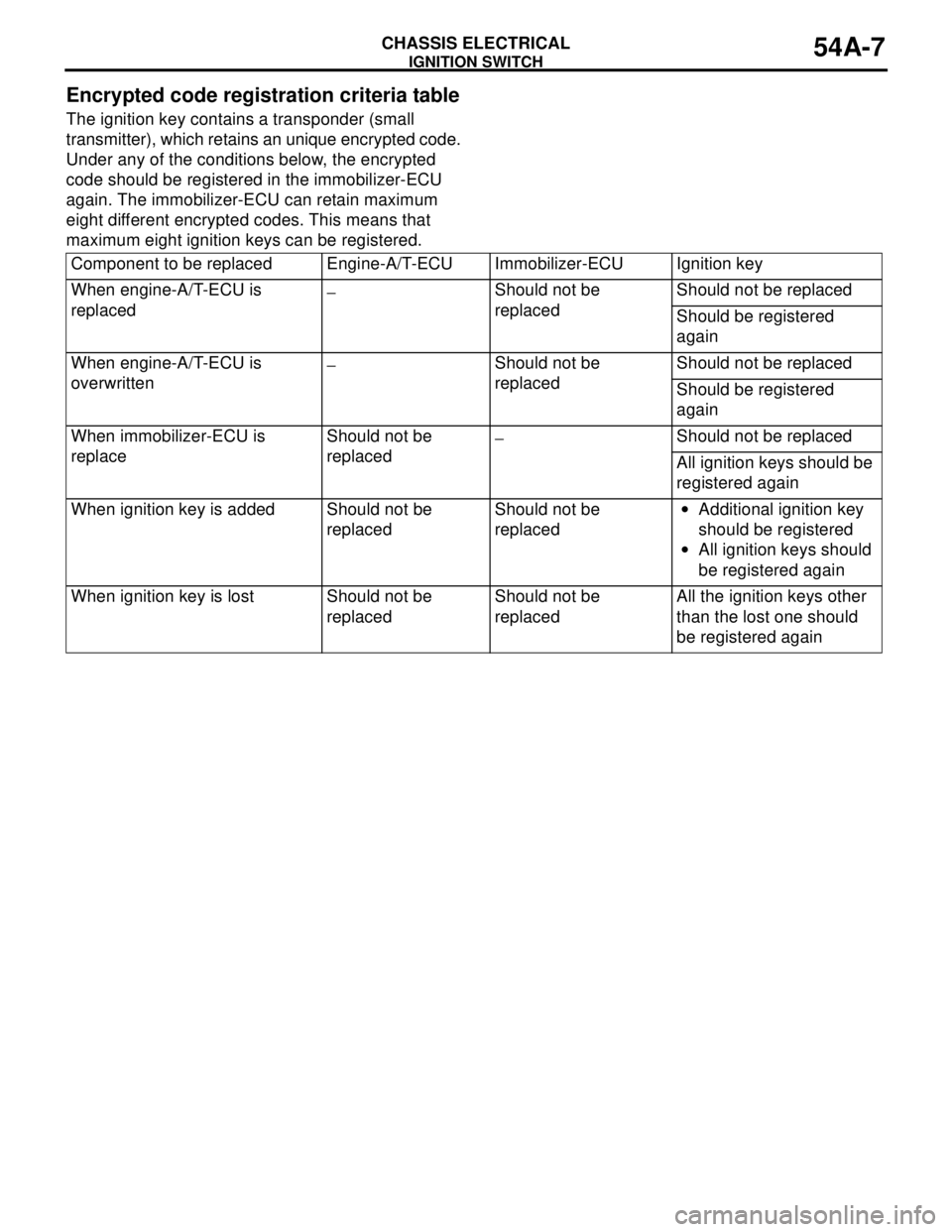

Encrypted code registration criteria table

The ignition key contains a transponder (small

transmitter), which retains an unique encrypted code.

Under any of the conditions below, the encrypted

code should be registered in the immobilizer-ECU

again. The immobilizer-ECU can retain maximum

eight different encrypted codes. This means that

maximum eight ignition keys can be registered.

Component to be replaced Engine-A/T-ECU Immobilizer-ECU Ignition key

When engine-A/T-ECU is

replaced−Should not be

replacedShould not be replaced

Should be registered

again

When engine-A/T-ECU is

overwritten−Should not be

replacedShould not be replaced

Should be registered

again

When immobilizer-ECU is

replaceShould not be

replaced−Should not be replaced

All ignition keys should be

registered again

When ignition key is added Should not be

replacedShould not be

replaced•Additional ignition key

should be registered

•All ignition keys should

be registered again

When ignition key is lost Should not be

replacedShould not be

replacedAll the ignition keys other

than the lost one should

be registered again

Page 399 of 788

IGNITION SWITCH

CHASSIS ELECTRICAL54A-11

DIAGNOSIS PROCEDURE

STEP 1. Check for presence of other key near the

key in the ignition.

Q: Is there any other key near the key in the ignition?

YES :

Move the other key well away from key

being used. Retest the system.

NO : Go to Step 2.

STEP 2. Check that the engine start using the

spare ignition key which encrypted code has

been registered.

Q: Does the engine start using the spare ignition key

for which the encrypted code has been registered?

YES :

Replace the ignition key that does not work.

Then register the password (secret code)

and encrypted code P.54A-20. Retest the

system.

NO : Go to Step 3.

STEP 3. Check whether the diagnosis code is

reset.

Q: Which diagnosis code is set, code No.11 or 12 the

encrypted code has been registered?

Code No.12 is set :

Refer toP.54A-11.

Code No.11 is set : Go to Step 4.

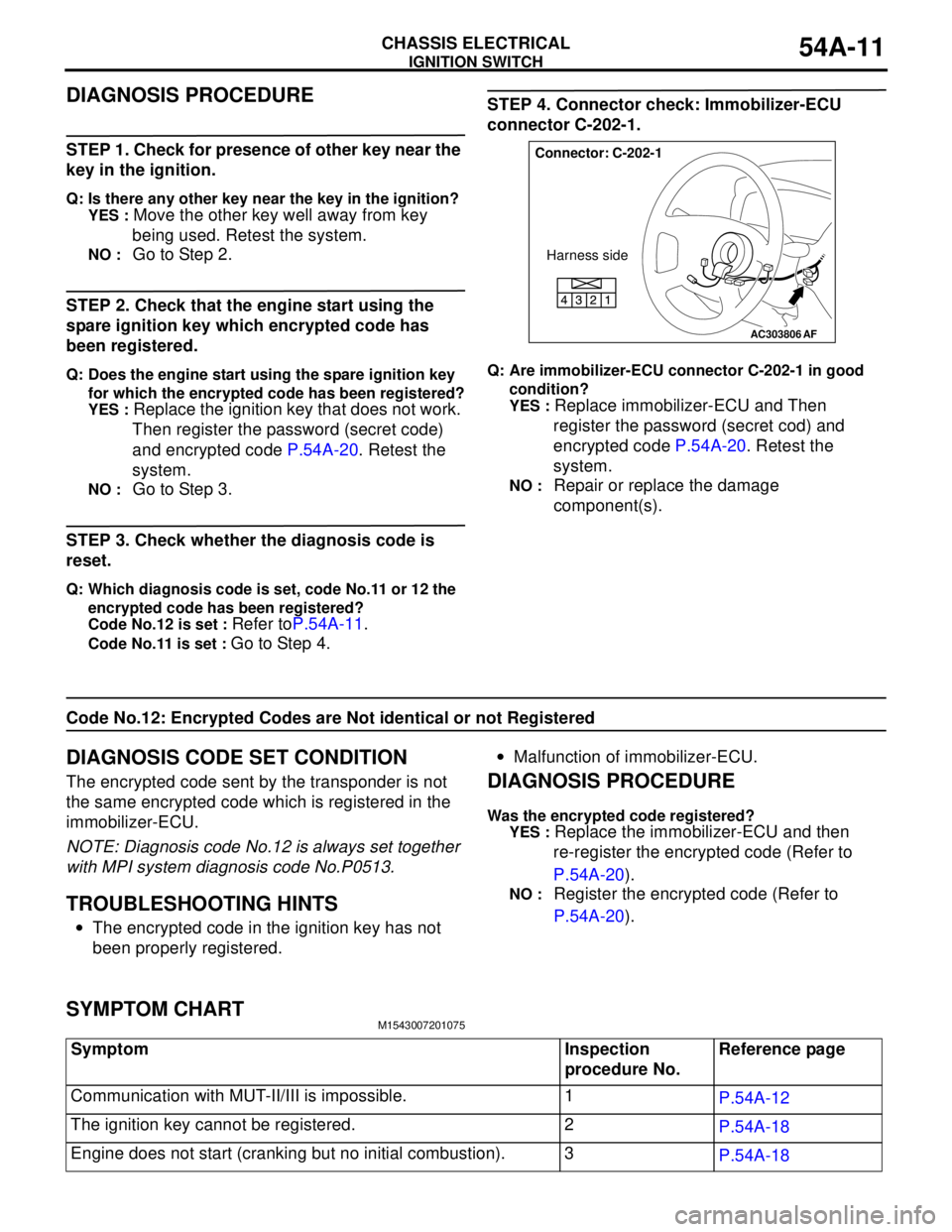

STEP 4. Connector check: Immobilizer-ECU

connector C-202-1.

Q: Are immobilizer-ECU connector C-202-1 in good

condition?

YES :

Replace immobilizer-ECU and Then

register the password (secret cod) and

encrypted code P.54A-20. Retest the

system.

NO : Repair or replace the damage

component(s).

Code No.12: Encrypted Codes are Not identical or not Registered

DIAGNOSIS CODE SET CONDITION

The encrypted code sent by the transponder is not

the same encrypted code which is registered in the

immobilizer-ECU.

NOTE: Diagnosis code No.12 is always set together

with MPI system diagnosis code No.P0513.

TROUBLESHOOTING HINTS

•The encrypted code in the ignition key has not

been properly registered.•Malfunction of immobilizer-ECU.

DIAGNOSIS PROCEDURE

Was the encrypted code registered?

YES :

Replace the immobilizer-ECU and then

re-register the encrypted code (Refer to

P.54A-20).

NO : Register the encrypted code (Refer to

P.54A-20).

SYMPTOM CHARTM1543007201075

AC303806

Connector: C-202-1

Harness side

AF

Symptom Inspection

procedure No.Reference page

Communication with MUT-II/III is impossible. 1

P.54A-12

The ignition key cannot be registered. 2

P.54A-18

Engine does not start (cranking but no initial combustion). 3

P.54A-18

Page 400 of 788

IGNITION SWITCH

CHASSIS ELECTRICAL54A-12

SYMPTOM PROCEDURES

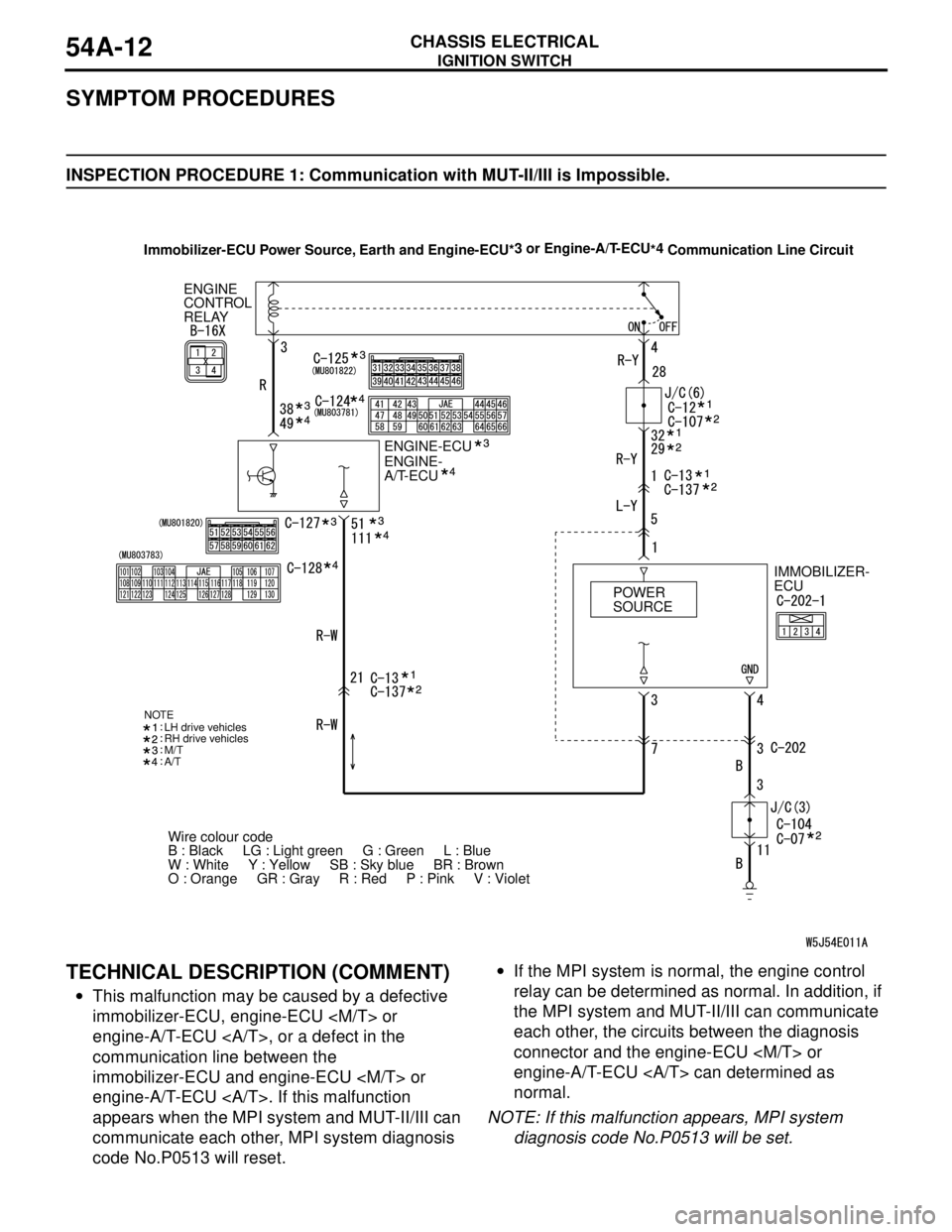

INSPECTION PROCEDURE 1: Communication with MUT-II/III is Impossible.

TECHNICAL DESCRIPTION (COMMENT)

•This malfunction may be caused by a defective

immobilizer-ECU, engine-ECU

engine-A/T-ECU , or a defect in the

communication line between the

immobilizer-ECU and engine-ECU

engine-A/T-ECU . If this malfunction

appears when the MPI system and MUT-II/III can

communicate each other, MPI system diagnosis

code No.P0513 will reset.•If the MPI system is normal, the engine control

relay can be determined as normal. In addition, if

the MPI system and MUT-II/III can communicate

each other, the circuits between the diagnosis

connector and the engine-ECU

engine-A/T-ECU can determined as

normal.

NOTE: If this malfunction appears, MPI system

diagnosis code No.P0513 will be set.

ENGINE-ECU ENGINE

CONTROL

RELAY

ENGINE-

A/T-ECU

IMMOBILIZER-

ECU

Wire colour code

B : Black LG : Light green G : Green L : Blue

W : White Y : Yellow SB : Sky blue BR : Brown

O : Orange GR : Gray R : Red P : Pink V : Violet POWER

SOURCE

M/T

A/T NOTE

LH drive vehicles

RH drive vehicles

Immobilizer-ECU Power Source, Earth and Engine-ECU*3 or Engine-A/T-ECU

*4

Communication Line Circuit

Page 401 of 788

IGNITION SWITCH

CHASSIS ELECTRICAL54A-13

TROUBLESHOOTING HINTS

•Malfunction of the immobilizer-ECU.

•Malfunction of the engine-ECU

engine-A/T-ECU .

•The wiring harness or connectors may have

loose, corroded, or damaged terminals, or

terminals pushed back in the connector.

DIAGNOSIS PROCEDURE

STEP 1. Check if MUT-II/III can communicate with

the MPI system and if an MPI system diagnosis

code other than P0513 is set.

Q: Can MUT-II/III communicate with the MPI system?

Is an MPI system diagnosis code other than P0513

set?

YES :

Go to Step 2.

NO : Refer to GROUP 13A, MPI Diagnosis

P.13A-15, GROUP 13B, MPI Diagnosis

P.13B-15.

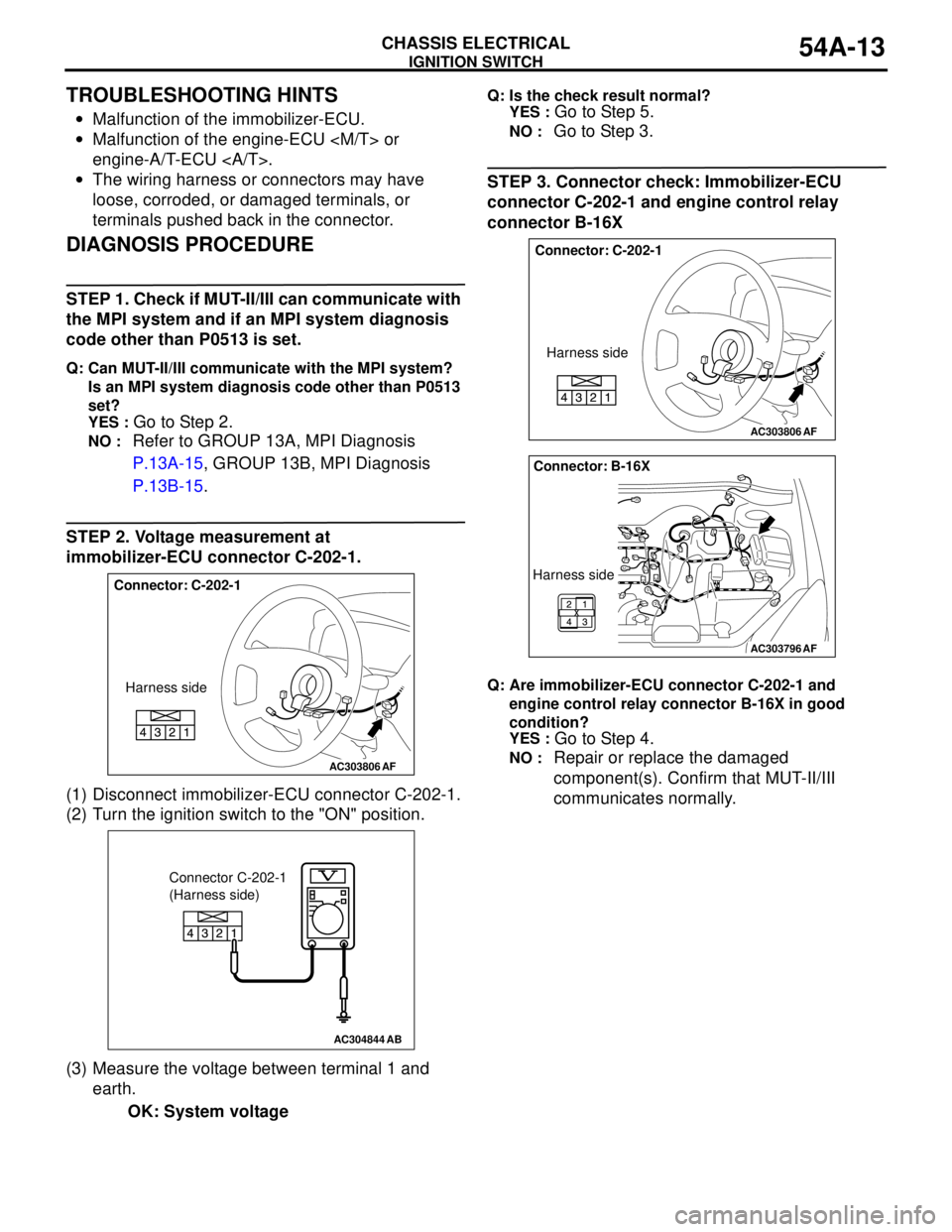

STEP 2. Voltage measurement at

immobilizer-ECU connector C-202-1.

(1) Disconnect immobilizer-ECU connector C-202-1.

(2) Turn the ignition switch to the "ON" position.

(3) Measure the voltage between terminal 1 and

earth.

OK: System voltage

Q: Is the check result normal?

YES :

Go to Step 5.

NO : Go to Step 3.

STEP 3. Connector check: Immobilizer-ECU

connector C-202-1 and engine control relay

connector B-16X

Q: Are immobilizer-ECU connector C-202-1 and

engine control relay connector B-16X in good

condition?

YES :

Go to Step 4.

NO : Repair or replace the damaged

component(s). Confirm that MUT-II/III

communicates normally.AC303806

Connector: C-202-1

Harness side

AF

AC304844AB

Connector C-202-1

(Harness side)

AC303806

Connector: C-202-1

Harness side

AF

AC303796

Connector: B-16X

Harness side

AF