DIN cable MITSUBISHI LANCER 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 8 of 788

GENERAL INFORMATION

ENGINE LUBRICATION12-2

GENERAL INFORMATION

M1121000100357

The lubrication method is a fully force-fed, full-flow

filtration type. The engine oil pump is a trochoid type

which is driven by the crankshaft <4G1>.The engine

oil pump is a gear type which is driven by the

crankshaft via the balancer timing belt <4G6>.

ENGINE OILS

Health Warning

Prolonged and repeated contact with mineral oil will

result in the removal of natural fats from the skin,

leading to dryness, irritation and dermatitis. In

addition, used engine oil contains potentially harmful

contaminants which may cause skin cancer.

Adequate means of skin protection and washing

facilities must be provided.

Recommended Precautions

The most effective precaution is to adapt working

practices which prevent, as far as practicable, the

risk of skin contact with mineral oils, for example by

using enclosed systems for handling used engine oil

and by degreasing components, where practicable,

before handling them. Other precautions:

•Avoid prolonged and repeated contact with oils,

particularly used engine oils.

•Wear protective clothing, including impervious

gloves where practicable.•Avoid contaminating clothes, particularly

underpants, with oil.

•Do not put oily rags in pockets, the use of overalls

without pockets will avoid this.

•Do not wear heavily soiled clothing and

oil-impregnated foot-wear. Overalls must be

cleaned regularly and kept separate from

personal clothing.

•Where there is a risk of eye contact, eye

protection should be worn, for example, chemical

goggles or face shields; in addition an eye wash

facility should be provided.

•Obtain first aid treatment immediately for open

cuts and wounds.

•Wash regularly with soap and water to ensure all

oil is removed, especially before meals (skin

cleansers and nail brushes will help). After

cleaning, the application of preparations

containing lanolin to replace the natural skin oils

is advised.

•Do not use petrol, kerosine, diesel fuel, gas oil,

thinners or solvents for cleaning skin.

•Use barrier creams, applying them before each

work period, to help the removal of oil from the

skin after work.

•If skin disorders develop, obtain medical advice

without delay.

SERVICE SPECIFICATION

M1121000300232

LUBRICANT

M1121000400433

Item Standard value

Oil pressure kPa at idle 29 or more

at 3,500 r/min 294 − 686

Item Specification

Engine oil ACEA classification A1, A2 or A3

Engine oil API classification SG or higher

Engine oil quantity L 4G1 Oil filter 0.3

To t a l 3 . 3

4G6 Oil filter 0.3

To t a l 4 . 3

Page 68 of 788

CHARGING SYSTEM

ENGINE ELECTRICAL16-4

2. Turn the ignition switch to the "LOCK" (OFF)

position.

3. Disconnect the negative battery cable.

4. Connect a clamp-type DC test ammeter with a

range of 0 − 120 A to the alternator "B" terminal

output wire.

NOTE: The way of disconnecting the alternator

output wire and of connecting the ammeter is

possibly not found the problem that the output

current is dropping due to the insufficient

connection between terminal "B" and the output

wire.

5. Connect a digital-type voltmeter between the

alternator "B" terminal and the battery (+)

terminal. [Connect the (+) lead of the voltmeter to

the "B" terminal and the connect the (-) lead of the

voltmeter to the battery (+) cable].

6. Reconnect the negative battery cable.

7. Connect a tachometer or the MUT-II/III (Refer to

GROUP 11A − On-vehicle Service − Idle speed

check <4G1> P.11A-11 or GROUP 11C −

On-vehicle Service − Idle speed check <4G6>

P.11C-11).

8. Leave the hood open.

9. Start the engine.

10.With the engine running at 2,500 r/min, turn the

headlamps and other lamps on and off to adjust

the alternator load so that the value displayed on

the ammeter is slightly above 30 A.Adjust the engine speed by gradually decreasing

it until the value displayed on the ammeter is 30

A. Take a reading of the value displayed on the

voltmeter at this time.

Limit: maximum 0.3 V

NOTE: When the alternator output is high and the

value displayed on the ammeter does not

decrease until 30 A, set the value to 40 A. Read

the value displayed on the voltmeter at this time.

When the value range is 40 A, the limit is

maximum 0.4 V.

11.If the value displayed on the voltmeter is above

the limit value, there is probably a malfunction in

the alternator output wire, so check the wiring

between the alternator "B" terminal and the

battery (+) terminal (including fusible link).

If a terminal is not sufficiently tight or if the

harness has become discolored due to

overheating, repair and then test again.

12.After the test, run the engine at idle.

13.Turn off all lamps and the ignition switch.

14.Remove the tachometer or the MUT-II/III.

15.Disconnect the negative battery cable.

16.Disconnect the ammeter and voltmeter.

17.Connect the negative battery cable.

Page 70 of 788

CHARGING SYSTEM

ENGINE ELECTRICAL16-6

7. Connect a tachometer or the MUT-II/III (Refer to

GROUP 11A − On-vehicle Service − Idle speed

check <4G1> P.11A-11 or GROUP 11C −

On-vehicle Service − Idle speed check <4G6>

P.11C-11).

8. Leave the hood open.

9. Check that the reading on the voltmeter is equal

to the battery voltage.

NOTE: If the voltage is 0 V, the cause is probably

an open circuit in the wire or fusible link between

the alternator "B" terminal and the battery (+)

terminal.

10.Turn the light switch on to turn on headlamps and

then start the engine.

11.Immediately after setting the headlamps to high

beam and turning the heater blower switch to the

high revolution position, increase the engine

speed to 2,500 r/min and read the maximum

current output value displayed on the ammeter.

Limit: 70 % of normal current outputNOTE: .

•For the nominal current output, refer to the

Alternator Specifications.

•Because the current from the battery will soon

drop after the engine is started, the above step

should be carried out as quickly as possible in

order to obtain the maximum current output

value.

•The current output value will depend on the

electrical load and the temperature of the

alternator body.

•If the electrical load is small while testing, the

specified level of current may not be output

even though the alternator is normal. In such

cases, increase the electrical load by leaving

the headlamps turned on for some time to

discharge the battery or by using the lighting

system in another vehicle, and then test again.

•The specified level of current also may not be

output if the temperature of the alternator body

or the ambient temperature is too high. In such

cases, cool the alternator and then test again.

12.The reading on the ammeter should be above the

limit value. If the reading is below the limit value

and the alternator output wire is normal, remove

the alternator from the engine and check the

alternator.

13.Run the engine at idle after the test.

14.Turn the ignition switch to the "LOCK" (OFF)

position.

15.Remove the tachometer or the MUT-II/III.

16.Disconnect the negative battery cable.

17.Disconnect the ammeter and voltmeter.

18.Connect the negative battery cable.

Page 71 of 788

CHARGING SYSTEM

ENGINE ELECTRICAL16-7

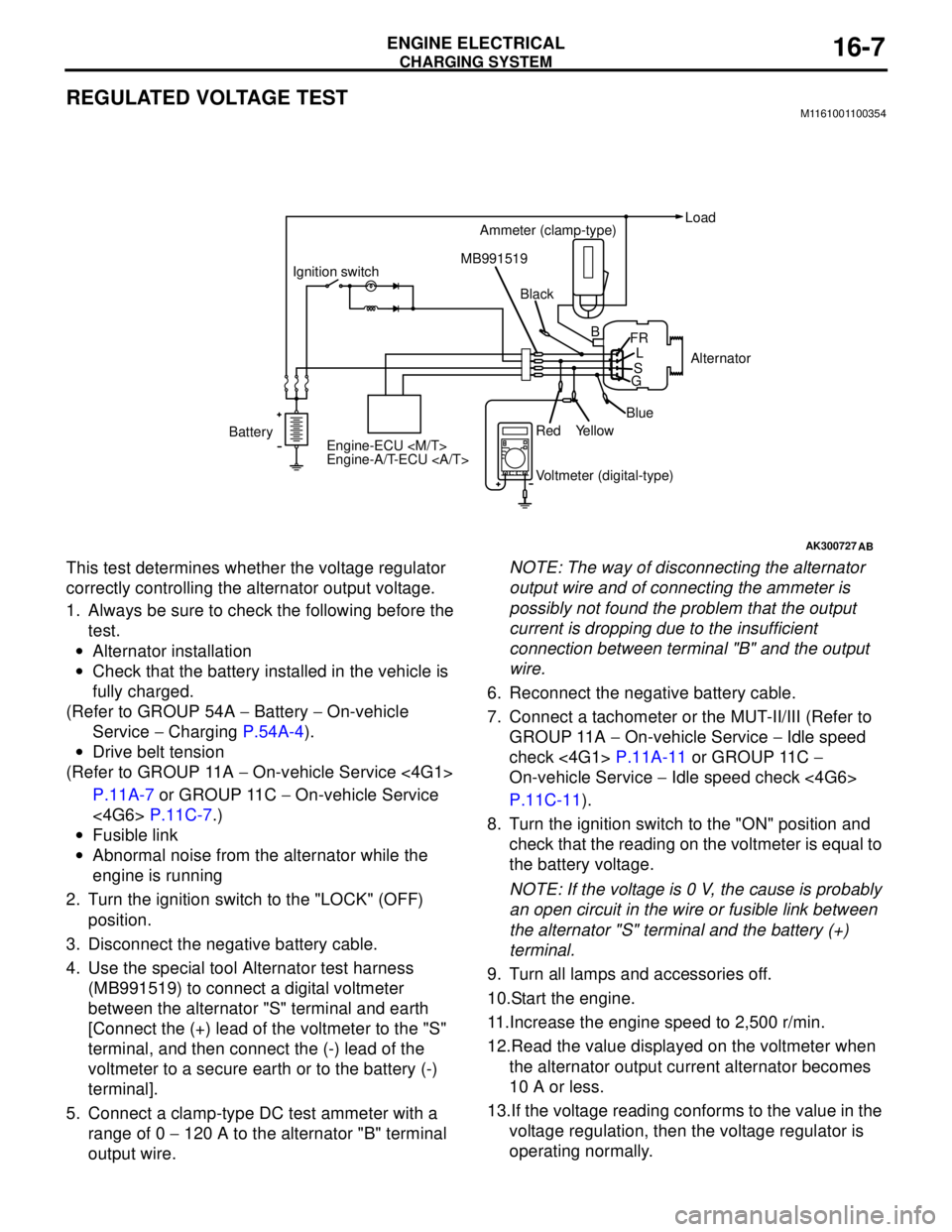

REGULATED VOLTAGE TESTM1161001100354

This test determines whether the voltage regulator

correctly controlling the alternator output voltage.

1. Always be sure to check the following before the

test.

•Alternator installation

•Check that the battery installed in the vehicle is

fully charged.

(Refer to GROUP 54A − Battery − On-vehicle

Service − Charging P.54A-4).

•Drive belt tension

(Refer to GROUP 11A − On-vehicle Service <4G1>

P.11A-7 or GROUP 11C − On-vehicle Service

<4G6> P.11C-7.)

•Fusible link

•Abnormal noise from the alternator while the

engine is running

2. Turn the ignition switch to the "LOCK" (OFF)

position.

3. Disconnect the negative battery cable.

4. Use the special tool Alternator test harness

(MB991519) to connect a digital voltmeter

between the alternator "S" terminal and earth

[Connect the (+) lead of the voltmeter to the "S"

terminal, and then connect the (-) lead of the

voltmeter to a secure earth or to the battery (-)

terminal].

5. Connect a clamp-type DC test ammeter with a

range of 0 − 120 A to the alternator "B" terminal

output wire.NOTE: The way of disconnecting the alternator

output wire and of connecting the ammeter is

possibly not found the problem that the output

current is dropping due to the insufficient

connection between terminal "B" and the output

wire.

6. Reconnect the negative battery cable.

7. Connect a tachometer or the MUT-II/III (Refer to

GROUP 11A − On-vehicle Service − Idle speed

check <4G1> P.11A-11 or GROUP 11C −

On-vehicle Service − Idle speed check <4G6>

P.11C-11).

8. Turn the ignition switch to the "ON" position and

check that the reading on the voltmeter is equal to

the battery voltage.

NOTE: If the voltage is 0 V, the cause is probably

an open circuit in the wire or fusible link between

the alternator "S" terminal and the battery (+)

terminal.

9. Turn all lamps and accessories off.

10.Start the engine.

11.Increase the engine speed to 2,500 r/min.

12.Read the value displayed on the voltmeter when

the alternator output current alternator becomes

10 A or less.

13.If the voltage reading conforms to the value in the

voltage regulation, then the voltage regulator is

operating normally.

AK300727AB

BatteryIgnition switch

Engine-ECU

Engine-A/T-ECU Ammeter (clamp-type)Load

Black MB991519

Voltmeter (digital-type) Red

YellowBlueAlternator B

FR

L

S

G

Page 96 of 788

IGNITION SYSTEM

ENGINE ELECTRICAL16-32

ON-VEHICLE SERVICE

IGNITION COIL (WITH BUILT-IN POWER

TRANSISTOR) CHECK

M1163001200324

Check by the following procedure, and replace if

there is a malfunction.

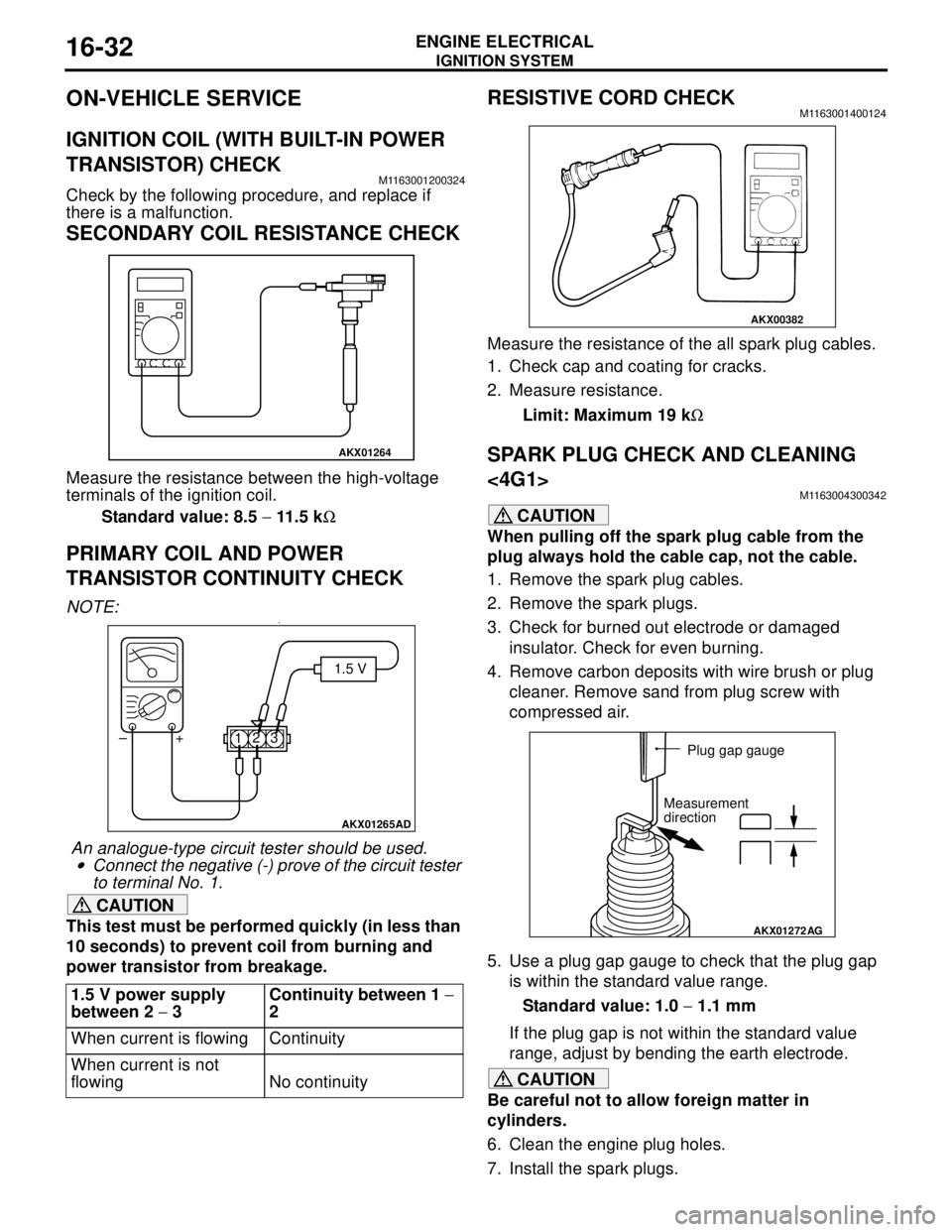

SECONDARY COIL RESISTANCE CHECK

Measure the resistance between the high-voltage

terminals of the ignition coil.

Standard value: 8.5 − 11.5 kΩ

PRIMARY COIL AND POWER

TRANSISTOR CONTINUITY CHECK

NOTE: .•

An analogue-type circuit tester should be used.

•Connect the negative (-) prove of the circuit tester

to terminal No. 1.

CAUTION

This test must be performed quickly (in less than

10 seconds) to prevent coil from burning and

power transistor from breakage.

RESISTIVE CORD CHECKM1163001400124

Measure the resistance of the all spark plug cables.

1. Check cap and coating for cracks.

2. Measure resistance.

Limit: Maximum 19 kΩ

SPARK PLUG CHECK AND CLEANING

<4G1>

M1163004300342

CAUTION

When pulling off the spark plug cable from the

plug always hold the cable cap, not the cable.

1. Remove the spark plug cables.

2. Remove the spark plugs.

3. Check for burned out electrode or damaged

insulator. Check for even burning.

4. Remove carbon deposits with wire brush or plug

cleaner. Remove sand from plug screw with

compressed air.

5. Use a plug gap gauge to check that the plug gap

is within the standard value range.

Standard value: 1.0 − 1.1 mm

If the plug gap is not within the standard value

range, adjust by bending the earth electrode.

CAUTION

Be careful not to allow foreign matter in

cylinders.

6. Clean the engine plug holes.

7. Install the spark plugs. 1.5 V power supply

between 2 − 3Continuity between 1 −

2

When current is flowing Continuity

When current is not

flowing No continuity

AKX01264

AKX01265AD

1.5 V

123 +

–

AKX00382

AKX01272

AG

Plug gap gauge

Measurement

direction

Page 212 of 788

TRAILING ARM ASSEMBLY

REAR SUSPENSION34-12

TRAILING ARM ASSEMBLY

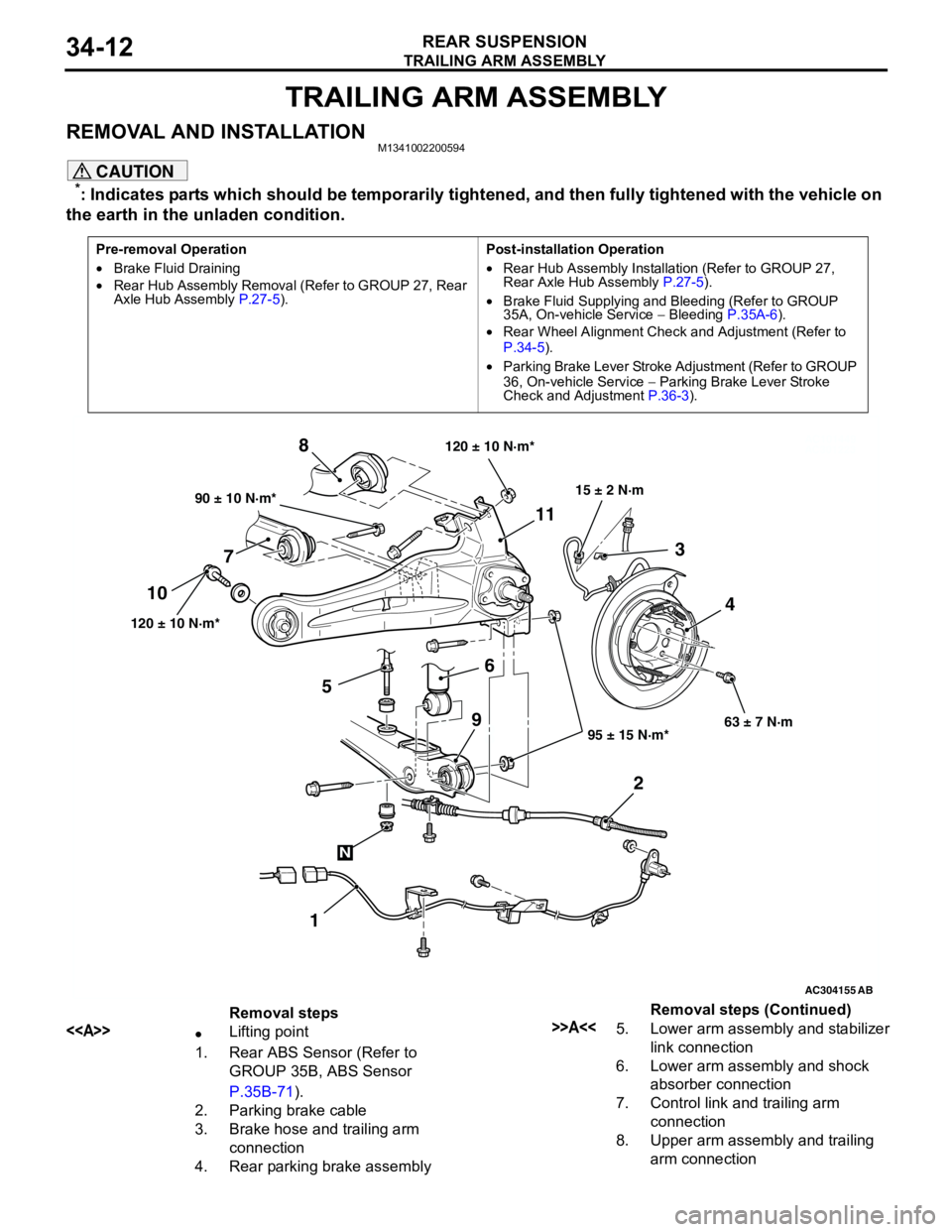

REMOVAL AND INSTALLATIONM1341002200594

CAUTION

*: Indicates parts which should be temporarily tightened, and then fully tightened with the vehicle on

the earth in the unladen condition.

Pre-removal Operation

•Brake Fluid Draining

•Rear Hub Assembly Removal (Refer to GROUP 27, Rear

Axle Hub Assembly P.27-5).Post-installation Operation

•Rear Hub Assembly Installation (Refer to GROUP 27,

Rear Axle Hub Assembly P.27-5).

•Brake Fluid Supplying and Bleeding (Refer to GROUP

35A, On-vehicle Service − Bleeding P.35A-6).

•Rear Wheel Alignment Check and Adjustment (Refer to

P.34-5).

•Parking Brake Lever Stroke Adjustment (Refer to GROUP

36, On-vehicle Service − Parking Brake Lever Stroke

Check and Adjustment P.36-3).

AC101449

AC301223

AC304155AB

90 ± 10 N·m*

120 ± 10 N·m*

95 ± 15 N·m*63 ± 7 N·m

6 78

1 1011

23

4

120 ± 10 N·m*

15 ± 2 N·m

N

9

5

Removal steps

<>•Lifting point

1. Rear ABS Sensor (Refer to

GROUP 35B, ABS Sensor

P.35B-71).

2. Parking brake cable

3. Brake hose and trailing arm

connection

4. Rear parking brake assembly>>A<<5. Lower arm assembly and stabilizer

link connection

6. Lower arm assembly and shock

absorber connection

7. Control link and trailing arm

connection

8. Upper arm assembly and trailing

arm connection Removal steps (Continued)

Page 227 of 788

LUBRICANTS

PARKING BRAKES36-3

LUBRICANTS

M1361000400293

ON-VEHICLE SERVICE

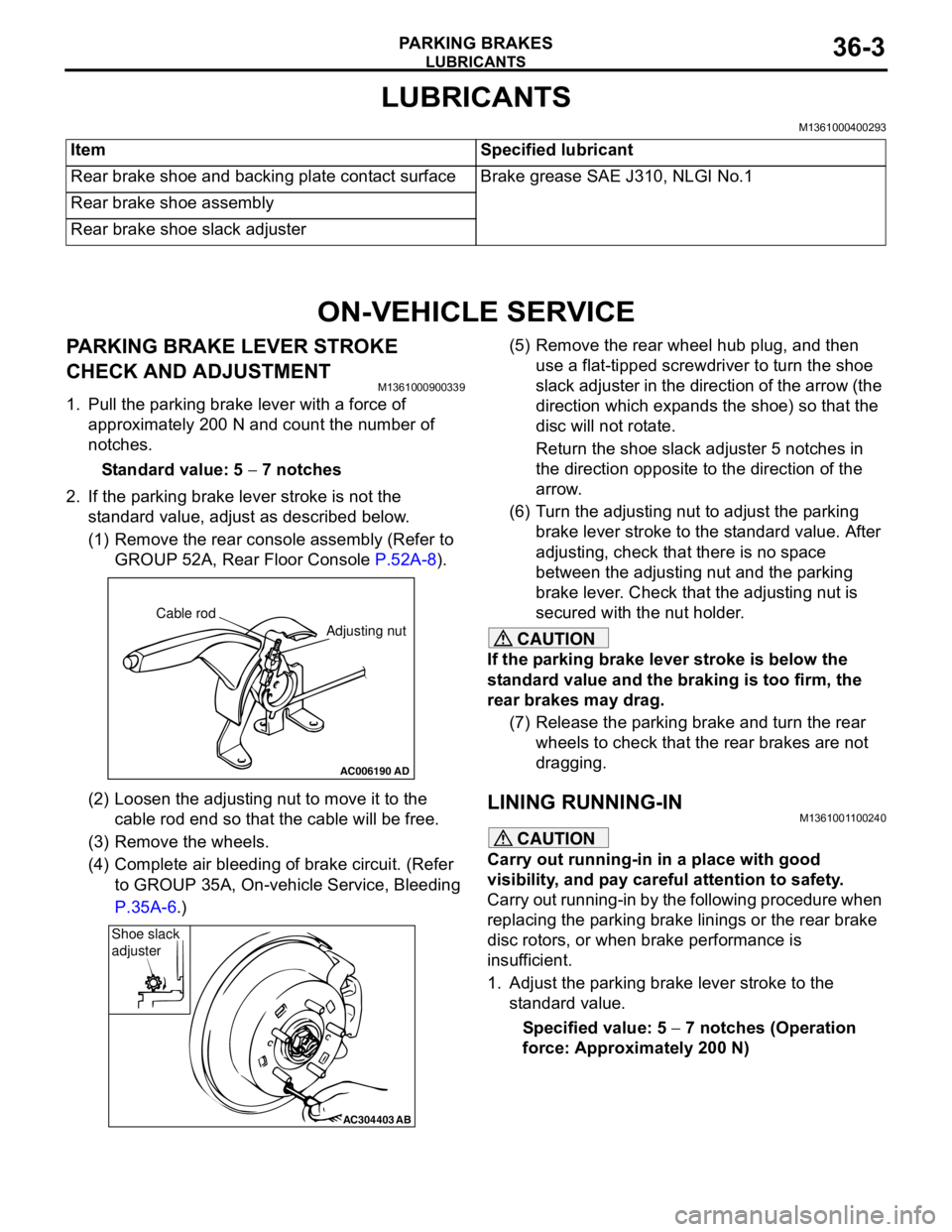

PARKING BRAKE LEVER STROKE

CHECK AND ADJUSTMENT

M1361000900339

1. Pull the parking brake lever with a force of

approximately 200 N and count the number of

notches.

Standard value: 5 − 7 notches

2. If the parking brake lever stroke is not the

standard value, adjust as described below.

(1) Remove the rear console assembly (Refer to

GROUP 52A, Rear Floor Console P.52A-8).

(2) Loosen the adjusting nut to move it to the

cable rod end so that the cable will be free.

(3) Remove the wheels.

(4) Complete air bleeding of brake circuit. (Refer

to GROUP 35A, On-vehicle Service, Bleeding

P.35A-6.)(5) Remove the rear wheel hub plug, and then

use a flat-tipped screwdriver to turn the shoe

slack adjuster in the direction of the arrow (the

direction which expands the shoe) so that the

disc will not rotate.

Return the shoe slack adjuster 5 notches in

the direction opposite to the direction of the

arrow.

(6) Turn the adjusting nut to adjust the parking

brake lever stroke to the standard value. After

adjusting, check that there is no space

between the adjusting nut and the parking

brake lever. Check that the adjusting nut is

secured with the nut holder.

CAUTION

If the parking brake lever stroke is below the

standard value and the braking is too firm, the

rear brakes may drag.

(7) Release the parking brake and turn the rear

wheels to check that the rear brakes are not

dragging.

LINING RUNNING-INM1361001100240

CAUTION

Carry out running-in in a place with good

visibility, and pay careful attention to safety.

Carry out running-in by the following procedure when

replacing the parking brake linings or the rear brake

disc rotors, or when brake performance is

insufficient.

1. Adjust the parking brake lever stroke to the

standard value.

Specified value: 5 − 7 notches (Operation

force: Approximately 200 N) Item Specified lubricant

Rear brake shoe and backing plate contact surface Brake grease SAE J310, NLGI No.1

Rear brake shoe assembly

Rear brake shoe slack adjuster

AC006190

Cable rod

Adjusting nut

AD

AC304403AB

Shoe slack

adjuster

Page 350 of 788

MOULDINGS

EXTERIOR51-12

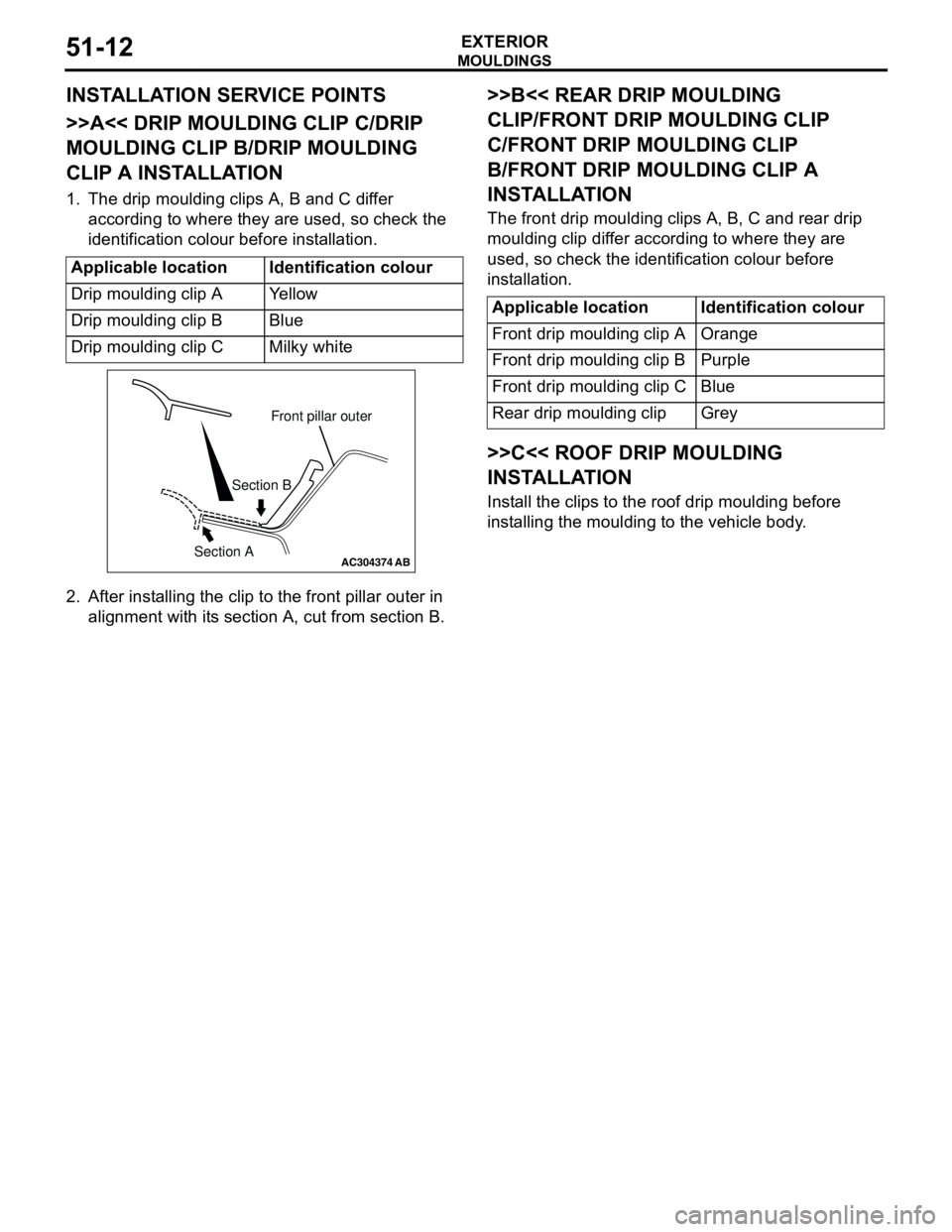

INSTALLATION SERVICE POINTS

>>A<< DRIP MOULDING CLIP C/DRIP

MOULDING CLIP B/DRIP MOULDING

CLIP A INSTALLATION

1. The drip moulding clips A, B and C differ

according to where they are used, so check the

identification colour before installation.

2. After installing the clip to the front pillar outer in

alignment with its section A, cut from section B.

>>B<< REAR DRIP MOULDING

CLIP/FRONT DRIP MOULDING CLIP

C/FRONT DRIP MOULDING CLIP

B/FRONT DRIP MOULDING CLIP A

INSTALLATION

The front drip moulding clips A, B, C and rear drip

moulding clip differ according to where they are

used, so check the identification colour before

installation.

>>C<< ROOF DRIP MOULDING

INSTALLATION

Install the clips to the roof drip moulding before

installing the moulding to the vehicle body. Applicable location Identification colour

Drip moulding clip A Yellow

Drip moulding clip B Blue

Drip moulding clip C Milky white

AC304374

Front pillar outer

Section B

Section A

AB

Applicable location Identification colour

Front drip moulding clip A Orange

Front drip moulding clip B Purple

Front drip moulding clip C Blue

Rear drip moulding clip Grey

Page 418 of 788

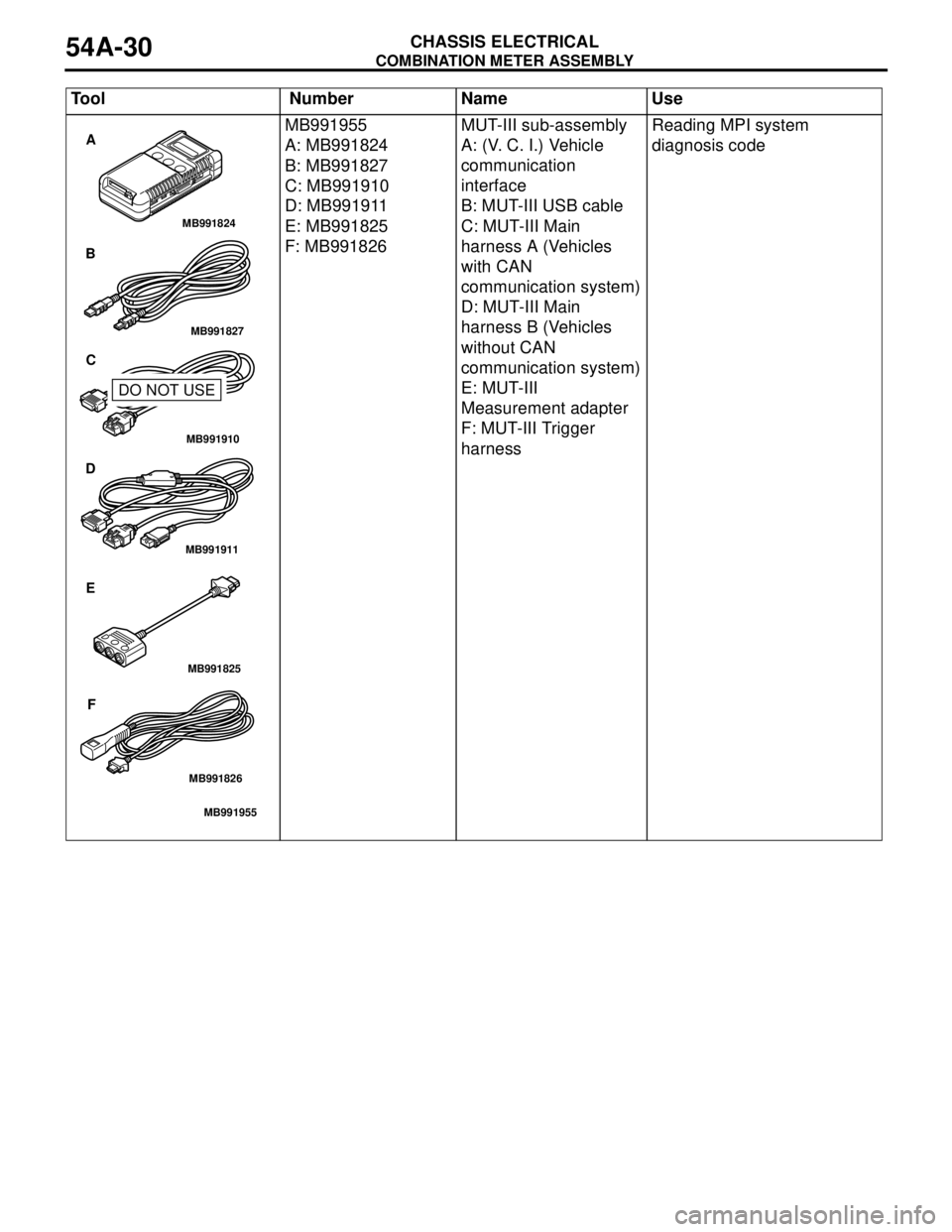

COMBINATION METER ASSEMBLY

CHASSIS ELECTRICAL54A-30

MB991955

A: MB991824

B: MB991827

C: MB991910

D: MB991911

E: MB991825

F: MB991826MUT-III sub-assembly

A: (V. C. I.) Vehicle

communication

interface

B: MUT-III USB cable

C: MUT-III Main

harness A (Vehicles

with CAN

communication system)

D: MUT-III Main

harness B (Vehicles

without CAN

communication system)

E: MUT-III

Measurement adapter

F: MUT-III Trigger

harnessReading MPI system

diagnosis code Tool Number Name Use

MB991910

MB991826

MB991955

MB991911

MB991824

MB991827

MB991825

A

B

C

D

E

F

DO NOT USE