check engine MITSUBISHI LANCER 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 7 of 788

12-1

GROUP 12

ENGINE

LUBRICATION

CONTENTS

GENERAL INFORMATION . . . . . . . .12-2

SERVICE SPECIFICATION . . . . . . . .12-2

LUBRICANT . . . . . . . . . . . . . . . . . . . .12-2

SEALANT . . . . . . . . . . . . . . . . . . . . . .12-3SPECIAL TOOLS . . . . . . . . . . . . . . . .12-3

ON-VEHICLE SERVICE . . . . . . . . . . .12-4

ENGINE OIL CHECK . . . . . . . . . . . . . . . . . 12-4

ENGINE OIL REPLACEMENT . . . . . . . . . . 12-4

ENGINE OIL FILTER REPLACEMENT . . . . 12-4

OIL PRESSURE CHECK . . . . . . . . . . . . . . 12-5

Page 10 of 788

ON-VEHICLE SERVICE

ENGINE LUBRICATION12-4

ON-VEHICLE SERVICE

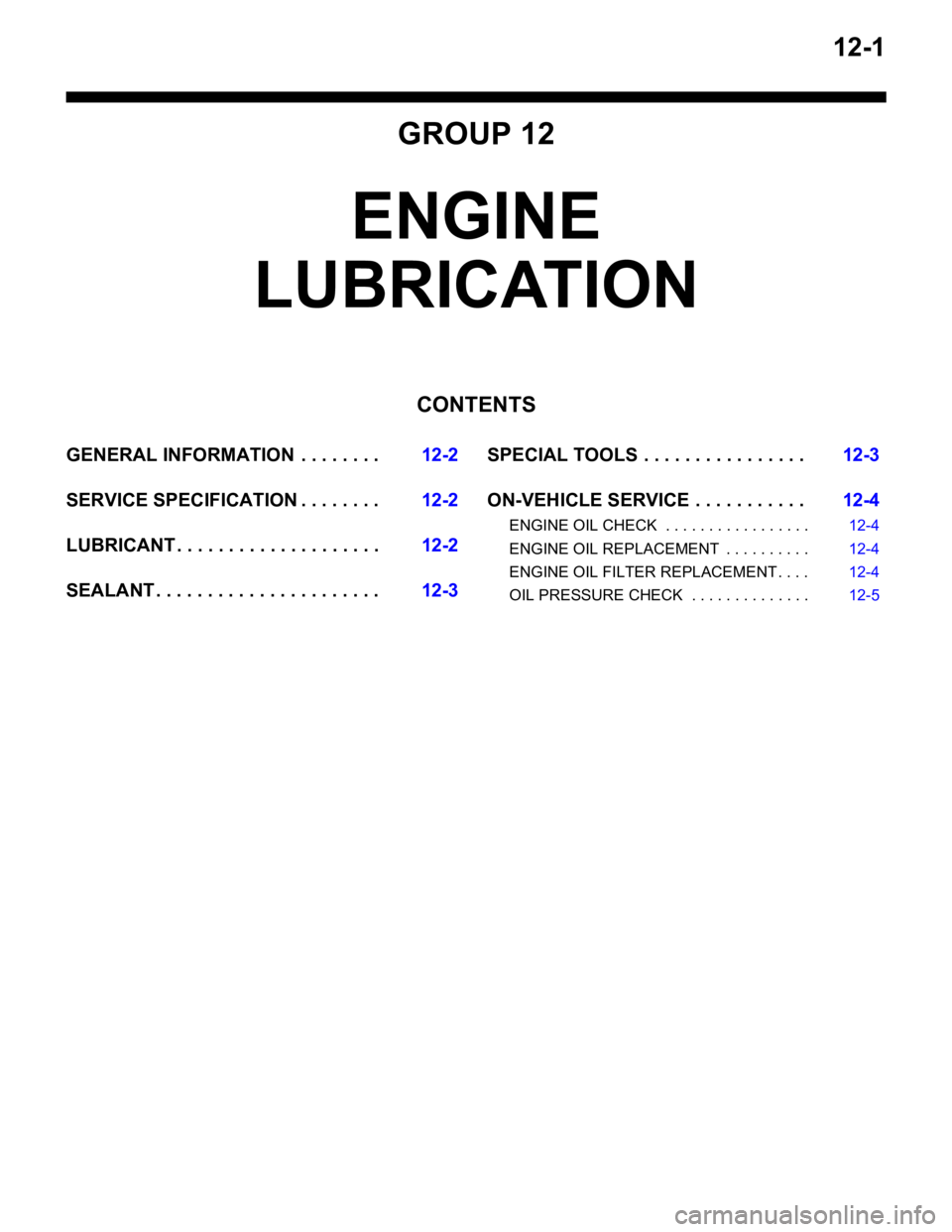

ENGINE OIL CHECKM1121000900342

1. Pull out the engine oil level gauge slowly and

check that the oil level is in the illustrated range.

2. Check that the oil is not excessively dirty, that

there is no coolant or petrol mixed in, and that it

has sufficient viscosity.

ENGINE OIL REPLACEMENTM1121001000416

1. Start the engine and allow it to warm up until the

temperature of the coolant reaches 80 °C to 90

°C.

2. Remove the engine oil filler cap.

CAUTION

Use care as engine oil could be hot.

3. Remove the engine oil pan drain plug to drain

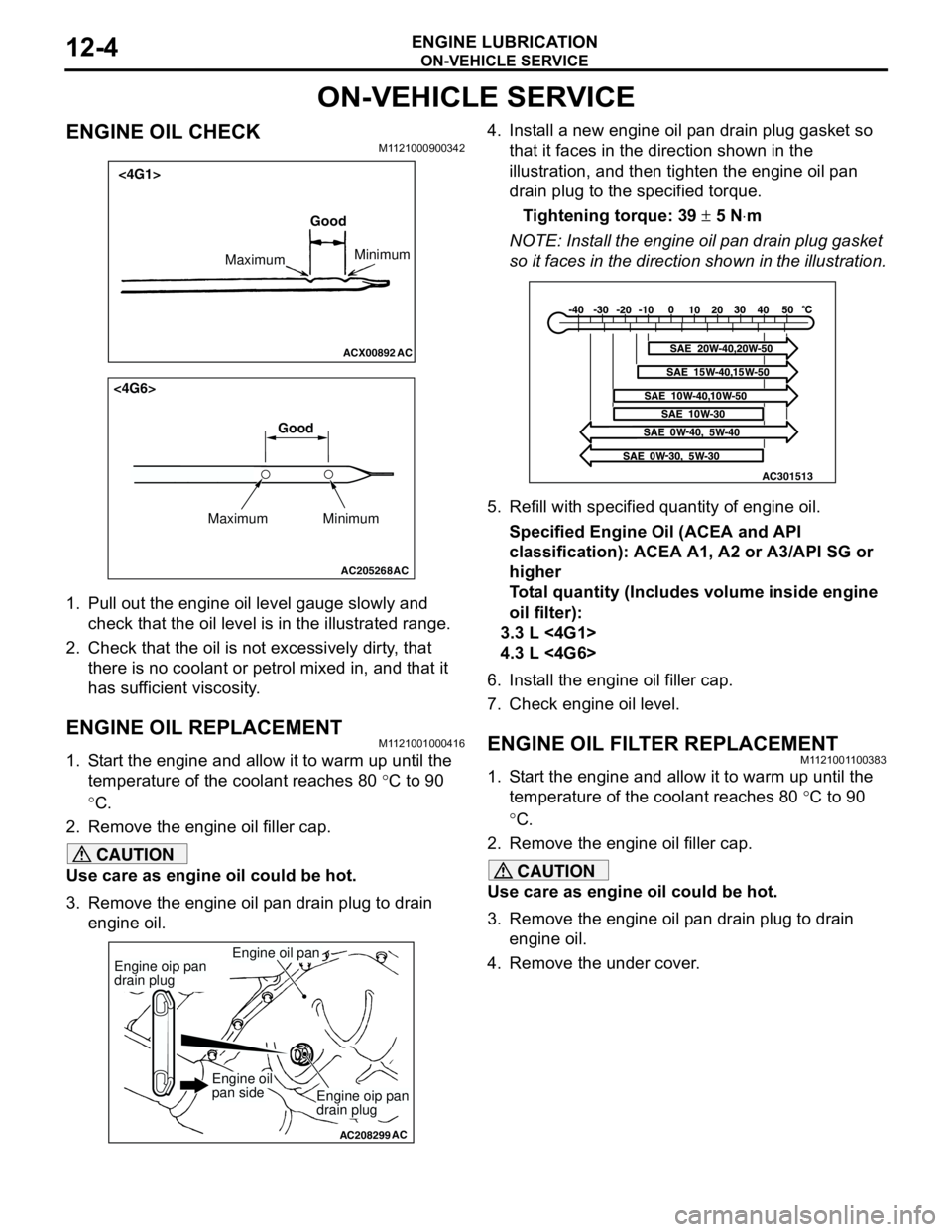

engine oil.4. Install a new engine oil pan drain plug gasket so

that it faces in the direction shown in the

illustration, and then tighten the engine oil pan

drain plug to the specified torque.

Tightening torque: 39 ± 5 N⋅m

NOTE: Install the engine oil pan drain plug gasket

so it faces in the direction shown in the illustration.

5. Refill with specified quantity of engine oil.

Specified Engine Oil (ACEA and API

classification): ACEA A1, A2 or A3/API SG or

higher

Total quantity (Includes volume inside engine

oil filter):

3.3 L <4G1>

4.3 L <4G6>

6. Install the engine oil filler cap.

7. Check engine oil level.

ENGINE OIL FILTER REPLACEMENTM1121001100383

1. Start the engine and allow it to warm up until the

temperature of the coolant reaches 80 °C to 90

°C.

2. Remove the engine oil filler cap.

CAUTION

Use care as engine oil could be hot.

3. Remove the engine oil pan drain plug to drain

engine oil.

4. Remove the under cover.

ACX00892 AC

Good

MaximumMinimum

<4G1>

AC205268

Maximum MinimumGood

AC

<4G6>

AC208299

Engine oil pan

AC

Engine oip pan

drain plug

Engine oip pan

drain plug

Engine oil

pan side

AC301513

Page 11 of 788

ON-VEHICLE SERVICE

ENGINE LUBRICATION12-5

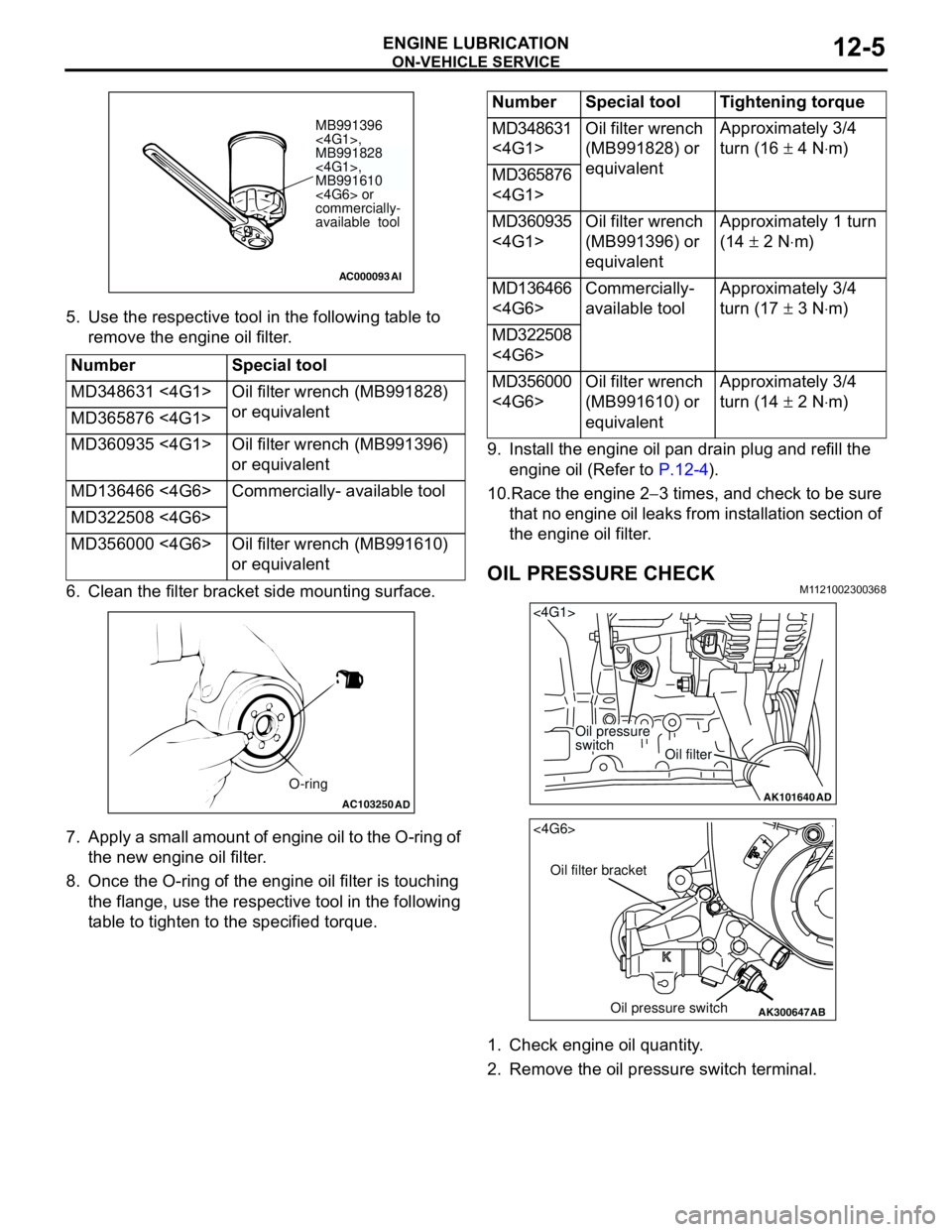

5. Use the respective tool in the following table to

remove the engine oil filter.

6. Clean the filter bracket side mounting surface.

7. Apply a small amount of engine oil to the O-ring of

the new engine oil filter.

8. Once the O-ring of the engine oil filter is touching

the flange, use the respective tool in the following

table to tighten to the specified torque.9. Install the engine oil pan drain plug and refill the

engine oil (Refer to P.12-4).

10.Race the engine 2−3 times, and check to be sure

that no engine oil leaks from installation section of

the engine oil filter.

OIL PRESSURE CHECKM1121002300368

1. Check engine oil quantity.

2. Remove the oil pressure switch terminal. Number Special tool

MD348631 <4G1> Oil filter wrench (MB991828)

or equivalent

MD365876 <4G1>

MD360935 <4G1> Oil filter wrench (MB991396)

or equivalent

MD136466 <4G6> Commercially- available tool

MD322508 <4G6>

MD356000 <4G6> Oil filter wrench (MB991610)

or equivalent

AC000093

MB991396

<4G1>,

MB991828

<4G1>,

MB991610

<4G6> or

commercially-

available tool

AI

AC103250AD

O-ring

Number Special tool Tightening torque

MD348631

<4G1>Oil filter wrench

(MB991828) or

equivalentApproximately 3/4

turn (16 ± 4 N⋅m)

MD365876

<4G1>

MD360935

<4G1>Oil filter wrench

(MB991396) or

equivalentApproximately 1 turn

(14 ± 2 N⋅m)

MD136466

<4G6>Commercially-

available toolApproximately 3/4

turn (17 ± 3 N⋅m)

MD322508

<4G6>

MD356000

<4G6>Oil filter wrench

(MB991610) or

equivalentApproximately 3/4

turn (14 ± 2 N⋅m)

AK101640

<4G1>

Oil pressure

switch

Oil filter

AD

AK300647

AB

<4G6>

Oil filter bracket

Oil pressure switch

Page 12 of 788

ON-VEHICLE SERVICE

ENGINE LUBRICATION12-6

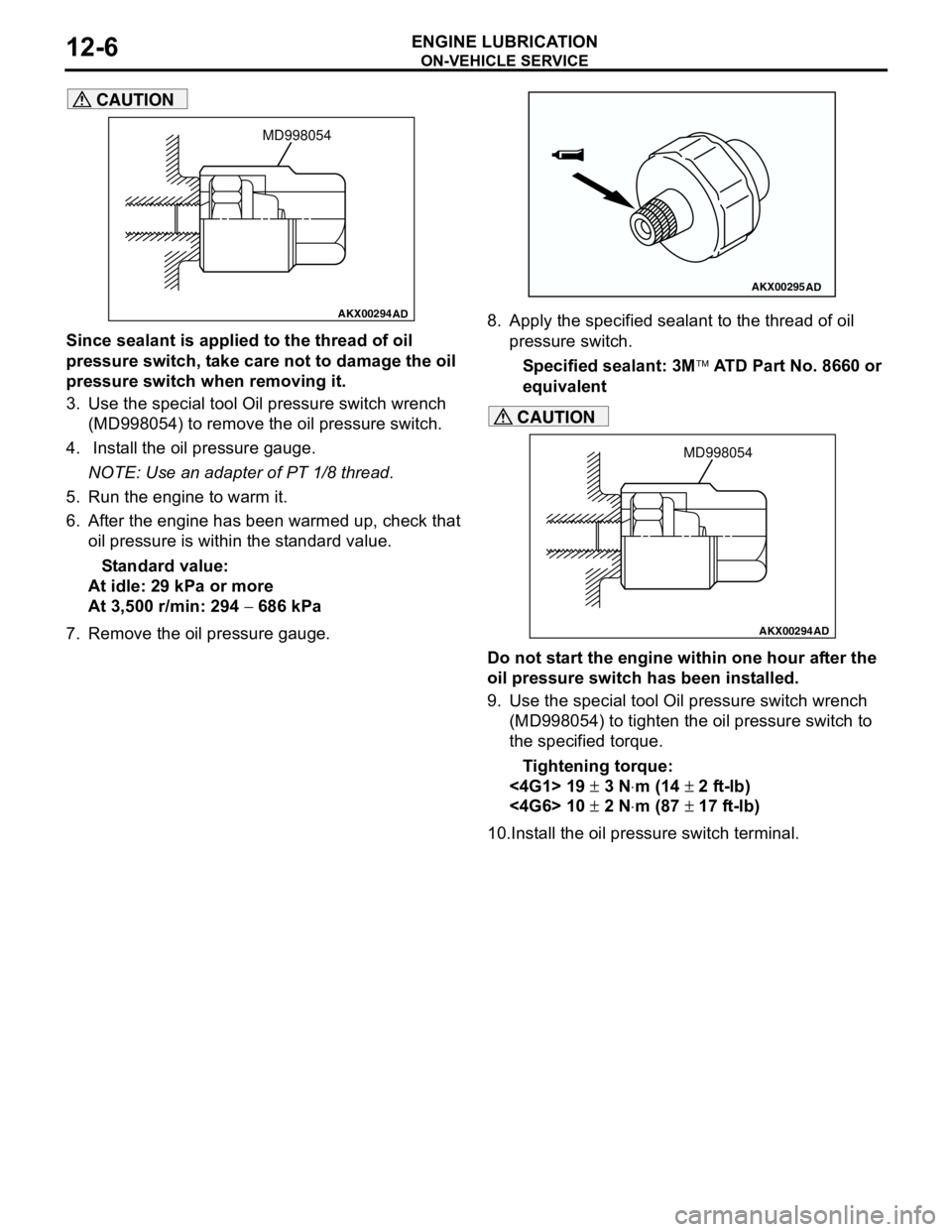

CAUTION

Since sealant is applied to the thread of oil

pressure switch, take care not to damage the oil

pressure switch when removing it.

3. Use the special tool Oil pressure switch wrench

(MD998054) to remove the oil pressure switch.

4. Install the oil pressure gauge.

NOTE: Use an adapter of PT 1/8 thread.

5. Run the engine to warm it.

6. After the engine has been warmed up, check that

oil pressure is within the standard value.

Standard value:

At idle: 29 kPa or more

At 3,500 r/min: 294 − 686 kPa

7. Remove the oil pressure gauge.8. Apply the specified sealant to the thread of oil

pressure switch.

Specified sealant: 3M ATD Part No. 8660 or

equivalent

CAUTION

Do not start the engine within one hour after the

oil pressure switch has been installed.

9. Use the special tool Oil pressure switch wrench

(MD998054) to tighten the oil pressure switch to

the specified torque.

Tightening torque:

<4G1> 19 ± 3 N⋅m (14 ± 2 ft-lb)

<4G6> 10 ± 2 N⋅m (87 ± 17 ft-lb)

10.Install the oil pressure switch terminal.

AKX00294

MD998054

AD

AKX00295AD

AKX00294

MD998054

AD

Page 15 of 788

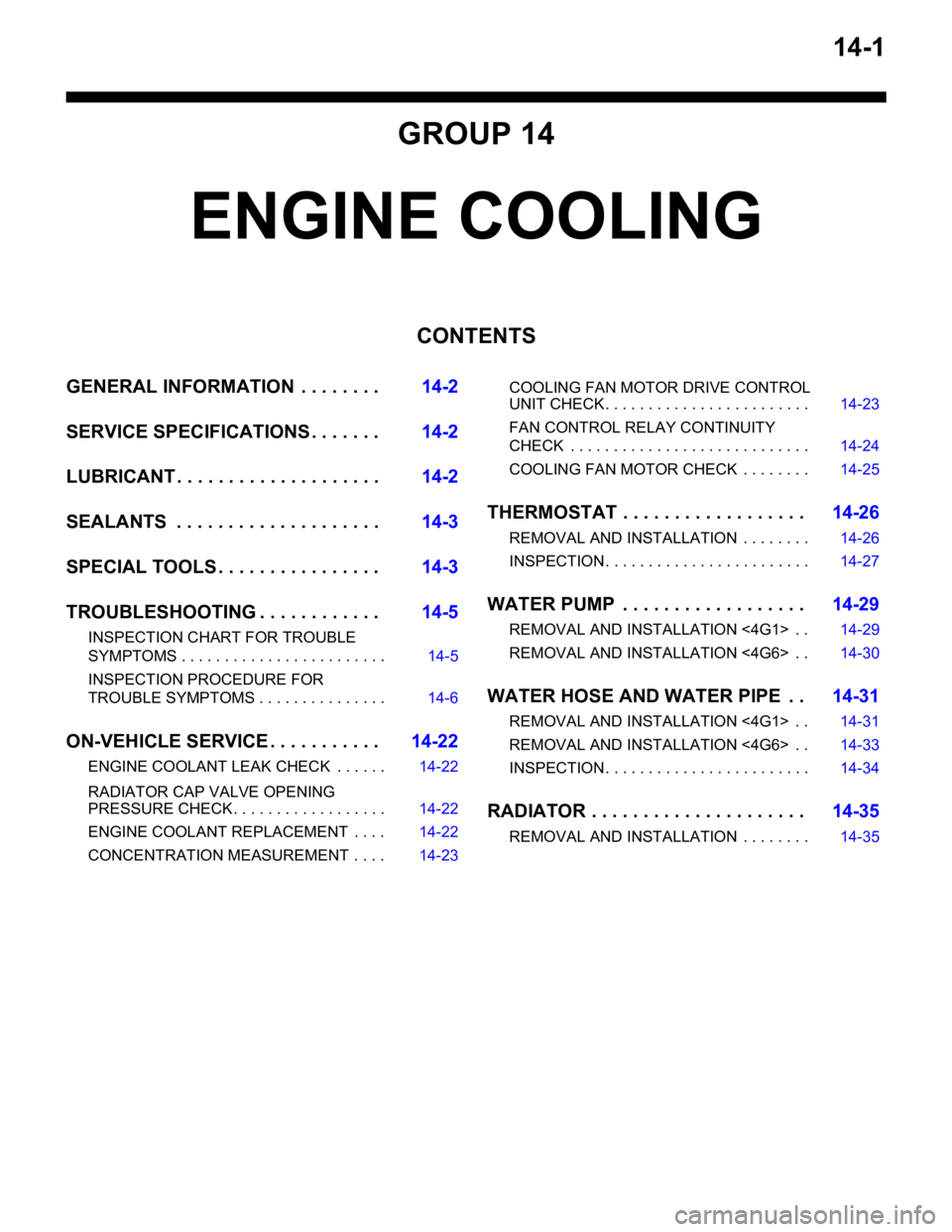

14-1

GROUP 14

ENGINE COOLING

CONTENTS

GENERAL INFORMATION . . . . . . . .14-2

SERVICE SPECIFICATIONS . . . . . . .14-2

LUBRICANT . . . . . . . . . . . . . . . . . . . .14-2

SEALANTS . . . . . . . . . . . . . . . . . . . .14-3

SPECIAL TOOLS . . . . . . . . . . . . . . . .14-3

TROUBLESHOOTING . . . . . . . . . . . .14-5

INSPECTION CHART FOR TROUBLE

SYMPTOMS . . . . . . . . . . . . . . . . . . . . . . . . 14-5

INSPECTION PROCEDURE FOR

TROUBLE SYMPTOMS . . . . . . . . . . . . . . . 14-6

ON-VEHICLE SERVICE . . . . . . . . . . .14-22

ENGINE COOLANT LEAK CHECK . . . . . . 14-22

RADIATOR CAP VALVE OPENING

PRESSURE CHECK . . . . . . . . . . . . . . . . . . 14-22

ENGINE COOLANT REPLACEMENT . . . . 14-22

CONCENTRATION MEASUREMENT . . . . 14-23COOLING FAN MOTOR DRIVE CONTROL

UNIT CHECK . . . . . . . . . . . . . . . . . . . . . . . . 14-23

FAN CONTROL RELAY CONTINUITY

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-24

COOLING FAN MOTOR CHECK . . . . . . . . 14-25

THERMOSTAT . . . . . . . . . . . . . . . . . .14-26

REMOVAL AND INSTALLATION . . . . . . . . 14-26

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 14-27

WATER PUMP . . . . . . . . . . . . . . . . . .14-29

REMOVAL AND INSTALLATION <4G1> . . 14-29

REMOVAL AND INSTALLATION <4G6> . . 14-30

WATER HOSE AND WATER PIPE . .14-31

REMOVAL AND INSTALLATION <4G1> . . 14-31

REMOVAL AND INSTALLATION <4G6> . . 14-33

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 14-34

RADIATOR . . . . . . . . . . . . . . . . . . . . .14-35

REMOVAL AND INSTALLATION . . . . . . . . 14-35

Page 18 of 788

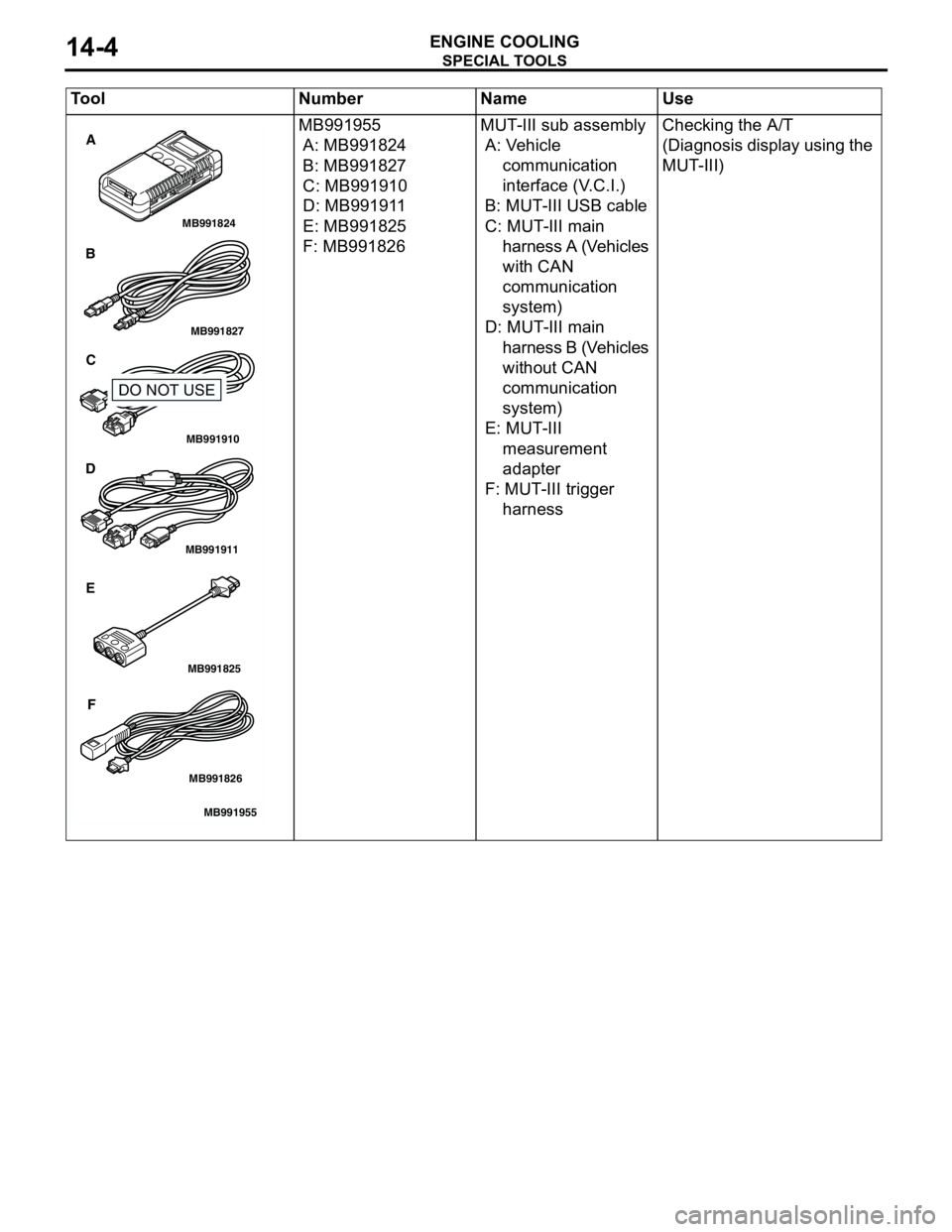

SPECIAL TOOLS

ENGINE COOLING14-4

MB991955

A: MB991824

B: MB991827

C: MB991910

D: MB991911

E: MB991825

F: MB991826MUT-III sub assembly

A: Vehicle

communication

interface (V.C.I.)

B: MUT-III USB cable

C: MUT-III main

harness A (Vehicles

with CAN

communication

system)

D: MUT-III main

harness B (Vehicles

without CAN

communication

system)

E: MUT-III

measurement

adapter

F: MUT-III trigger

harnessChecking the A/T

(Diagnosis display using the

MUT-III) Tool Number Name Use

MB991910

MB991826

MB991955

MB991911

MB991824

MB991827

MB991825

A

B

C

D

E

F

DO NOT USE

Page 21 of 788

TROUBLESHOOTING

ENGINE COOLING14-7

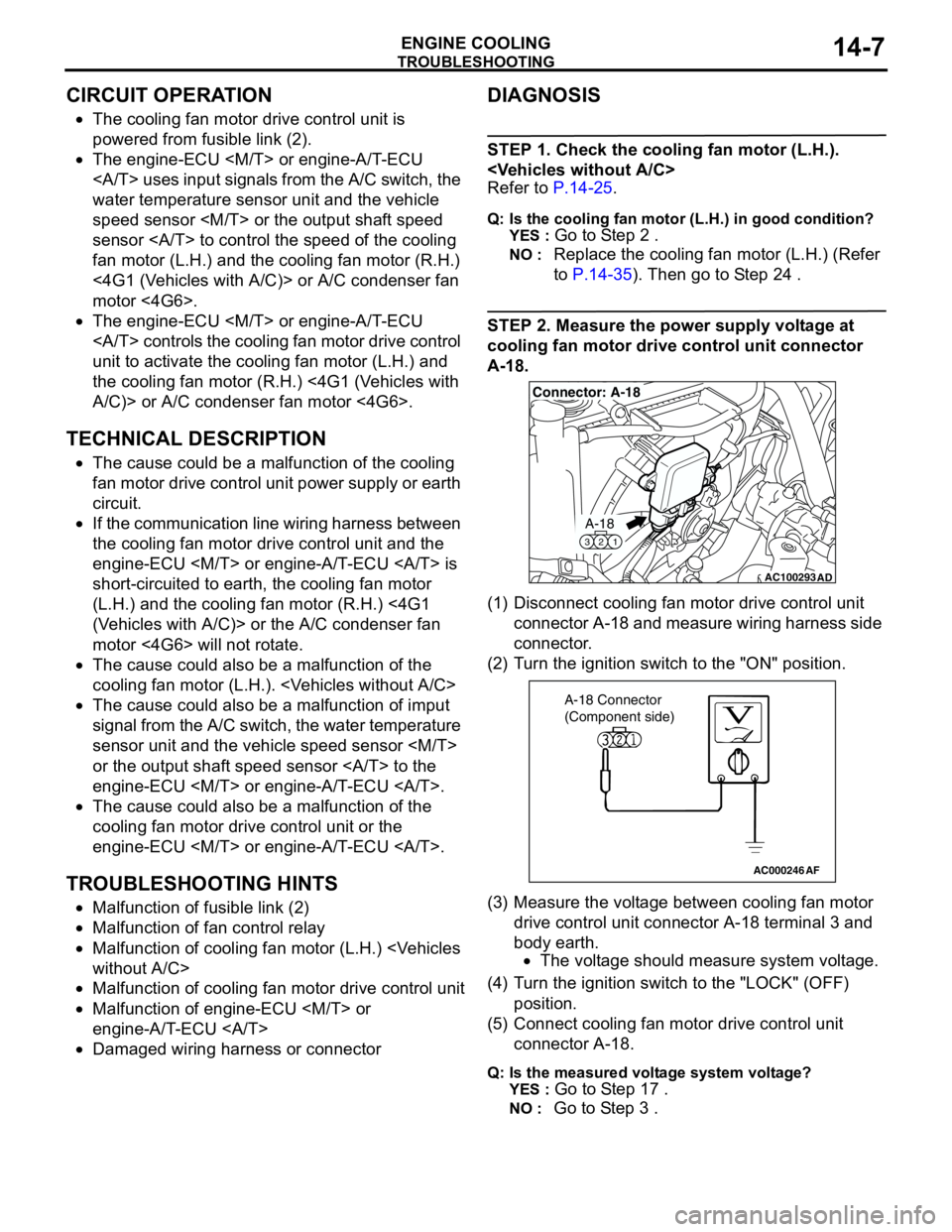

CIRCUIT OPERATION

•The cooling fan motor drive control unit is

powered from fusible link (2).

•The engine-ECU

uses input signals from the A/C switch, the

water temperature sensor unit and the vehicle

speed sensor

sensor to control the speed of the cooling

fan motor (L.H.) and the cooling fan motor (R.H.)

<4G1 (Vehicles with A/C)> or A/C condenser fan

motor <4G6>.

•The engine-ECU

controls the cooling fan motor drive control

unit to activate the cooling fan motor (L.H.) and

the cooling fan motor (R.H.) <4G1 (Vehicles with

A/C)> or A/C condenser fan motor <4G6>.

TECHNICAL DESCRIPTION

•The cause could be a malfunction of the cooling

fan motor drive control unit power supply or earth

circuit.

•If the communication line wiring harness between

the cooling fan motor drive control unit and the

engine-ECU

short-circuited to earth, the cooling fan motor

(L.H.) and the cooling fan motor (R.H.) <4G1

(Vehicles with A/C)> or the A/C condenser fan

motor <4G6> will not rotate.

•The cause could also be a malfunction of the

cooling fan motor (L.H.).

•The cause could also be a malfunction of imput

signal from the A/C switch, the water temperature

sensor unit and the vehicle speed sensor

or the output shaft speed sensor to the

engine-ECU

•The cause could also be a malfunction of the

cooling fan motor drive control unit or the

engine-ECU

TROUBLESHOOTING HINTS

•Malfunction of fusible link (2)

•Malfunction of fan control relay

•Malfunction of cooling fan motor (L.H.)

•Malfunction of cooling fan motor drive control unit

•Malfunction of engine-ECU

engine-A/T-ECU

•Damaged wiring harness or connector

DIAGNOSIS

STEP 1. Check the cooling fan motor (L.H.).

Refer to P.14-25.

Q: Is the cooling fan motor (L.H.) in good condition?

YES :

Go to Step 2 .

NO : Replace the cooling fan motor (L.H.) (Refer

to P.14-35). Then go to Step 24 .

STEP 2. Measure the power supply voltage at

cooling fan motor drive control unit connector

A-18.

(1) Disconnect cooling fan motor drive control unit

connector A-18 and measure wiring harness side

connector.

(2) Turn the ignition switch to the "ON" position.

(3) Measure the voltage between cooling fan motor

drive control unit connector A-18 terminal 3 and

body earth.

•The voltage should measure system voltage.

(4) Turn the ignition switch to the "LOCK" (OFF)

position.

(5) Connect cooling fan motor drive control unit

connector A-18.

Q: Is the measured voltage system voltage?

YES :

Go to Step 17 .

NO : Go to Step 3 .

AC100293

A-18

321

Connector: A-18

AD

AC000246AF

A-18 Connector

(Component side)

Page 22 of 788

TROUBLESHOOTING

ENGINE COOLING14-8

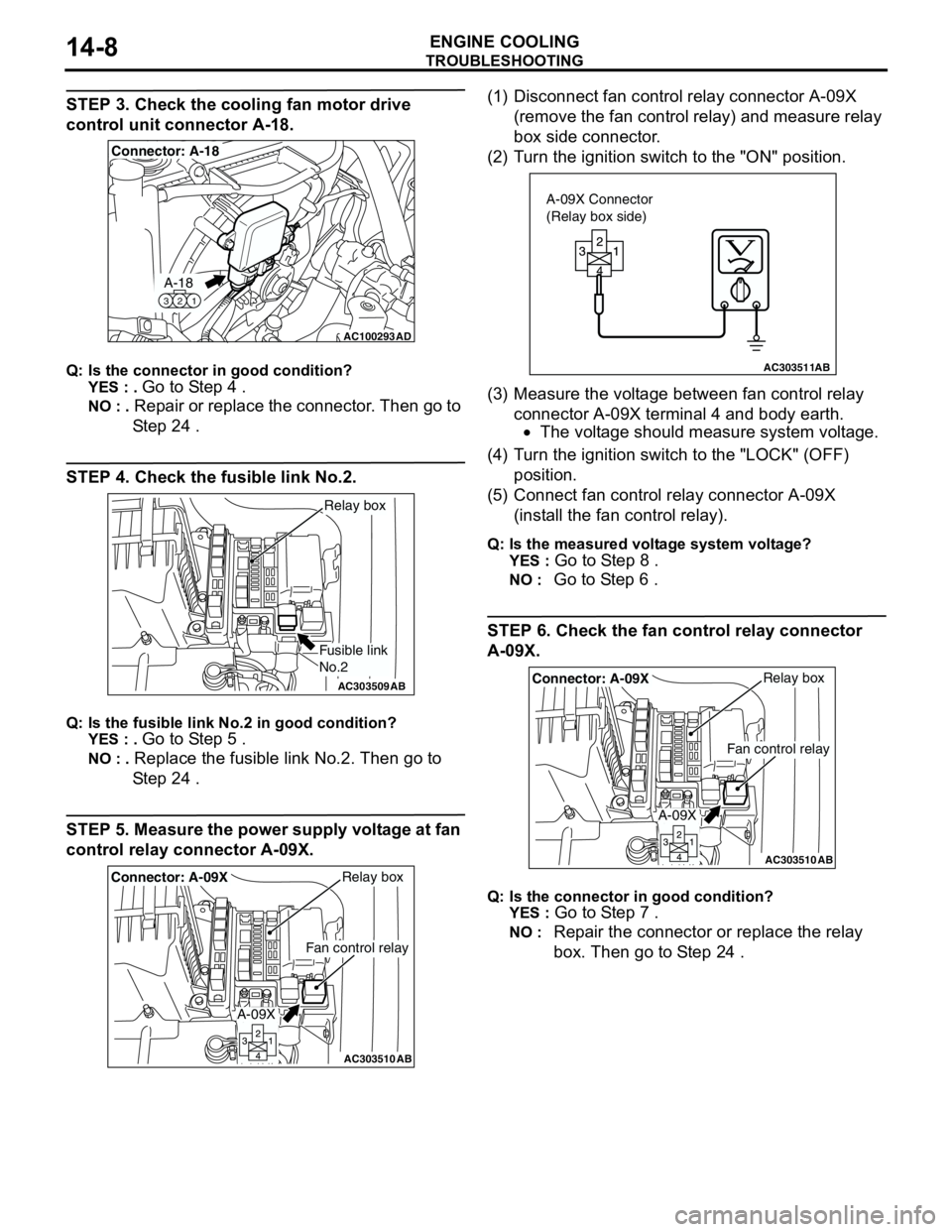

STEP 3. Check the cooling fan motor drive

control unit connector A-18.

Q: Is the connector in good condition?

YES : .

Go to Step 4 .

NO : . Repair or replace the connector. Then go to

Step 24 .

STEP 4. Check the fusible link No.2.

Q: Is the fusible link No.2 in good condition?

YES : .

Go to Step 5 .

NO : . Replace the fusible link No.2. Then go to

Step 24 .

STEP 5. Measure the power supply voltage at fan

control relay connector A-09X.(1) Disconnect fan control relay connector A-09X

(remove the fan control relay) and measure relay

box side connector.

(2) Turn the ignition switch to the "ON" position.

(3) Measure the voltage between fan control relay

connector A-09X terminal 4 and body earth.

•The voltage should measure system voltage.

(4) Turn the ignition switch to the "LOCK" (OFF)

position.

(5) Connect fan control relay connector A-09X

(install the fan control relay).

Q: Is the measured voltage system voltage?

YES :

Go to Step 8 .

NO : Go to Step 6 .

STEP 6. Check the fan control relay connector

A-09X.

Q: Is the connector in good condition?

YES :

Go to Step 7 .

NO : Repair the connector or replace the relay

box. Then go to Step 24 .

AC100293

A-18

321

Connector: A-18

AD

AC303509AB

Fusible link

No.2

Relay box

AC303510AB

Fan control relay

Relay boxConnector: A-09X

A-09X

AC303511AB

A-09X Connector

(Relay box side)

AC303510AB

Fan control relay

Relay boxConnector: A-09X

A-09X

Page 23 of 788

TROUBLESHOOTING

ENGINE COOLING14-9

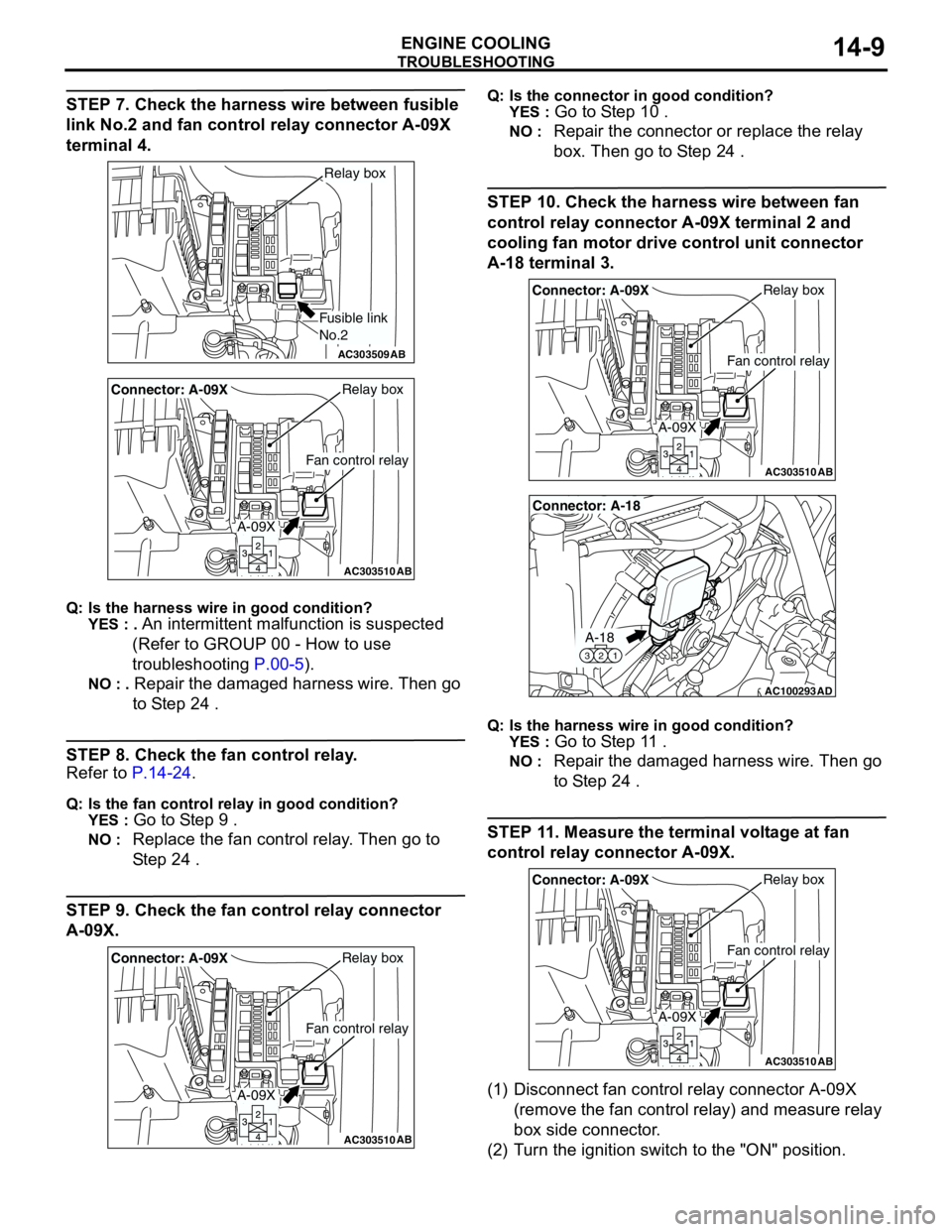

STEP 7. Check the harness wire between fusible

link No.2 and fan control relay connector A-09X

terminal 4.

Q: Is the harness wire in good condition?

YES : .

An intermittent malfunction is suspected

(Refer to GROUP 00 - How to use

troubleshooting P.00-5).

NO : . Repair the damaged harness wire. Then go

to Step 24 .

STEP 8. Check the fan control relay.

Refer to P.14-24.

Q: Is the fan control relay in good condition?

YES :

Go to Step 9 .

NO : Replace the fan control relay. Then go to

Step 24 .

STEP 9. Check the fan control relay connector

A-09X.

Q: Is the connector in good condition?

YES :

Go to Step 10 .

NO : Repair the connector or replace the relay

box. Then go to Step 24 .

STEP 10. Check the harness wire between fan

control relay connector A-09X terminal 2 and

cooling fan motor drive control unit connector

A-18 terminal 3.

Q: Is the harness wire in good condition?

YES :

Go to Step 11 .

NO : Repair the damaged harness wire. Then go

to Step 24 .

STEP 11. Measure the terminal voltage at fan

control relay connector A-09X.

(1) Disconnect fan control relay connector A-09X

(remove the fan control relay) and measure relay

box side connector.

(2) Turn the ignition switch to the "ON" position.

AC303509AB

Fusible link

No.2

Relay box

AC303510AB

Fan control relay

Relay boxConnector: A-09X

A-09X

AC303510AB

Fan control relay

Relay boxConnector: A-09X

A-09X

AC303510AB

Fan control relay

Relay boxConnector: A-09X

A-09X

AC100293

A-18

321

Connector: A-18

AD

AC303510AB

Fan control relay

Relay boxConnector: A-09X

A-09X

Page 24 of 788

TROUBLESHOOTING

ENGINE COOLING14-10

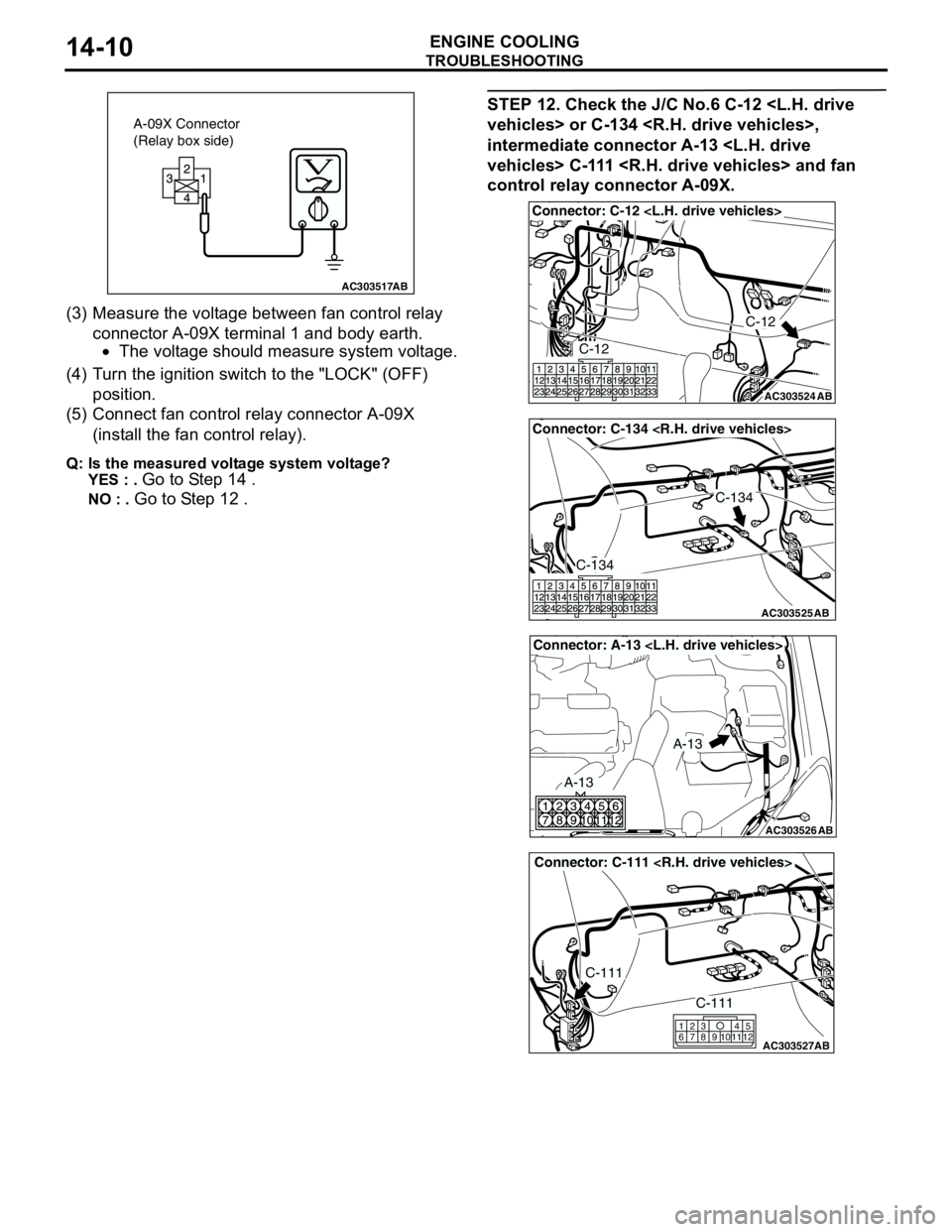

(3) Measure the voltage between fan control relay

connector A-09X terminal 1 and body earth.

•The voltage should measure system voltage.

(4) Turn the ignition switch to the "LOCK" (OFF)

position.

(5) Connect fan control relay connector A-09X

(install the fan control relay).

Q: Is the measured voltage system voltage?

YES : .

Go to Step 14 .

NO : . Go to Step 12 .

STEP 12. Check the J/C No.6 C-12

intermediate connector A-13

control relay connector A-09X.

AC303517AB

A-09X Connector

(Relay box side)

AC303524

Connector: C-12

AB

C-12

C-12

AC303525

Connector: C-134

AB

C-134

C-134

AC303526

Connector: A-13

AB

A-13

A-13

AC303527

Connector: C-111

AB

C-111

C-111

615

121179

810234