oil level MITSUBISHI LANCER 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 10 of 788

ON-VEHICLE SERVICE

ENGINE LUBRICATION12-4

ON-VEHICLE SERVICE

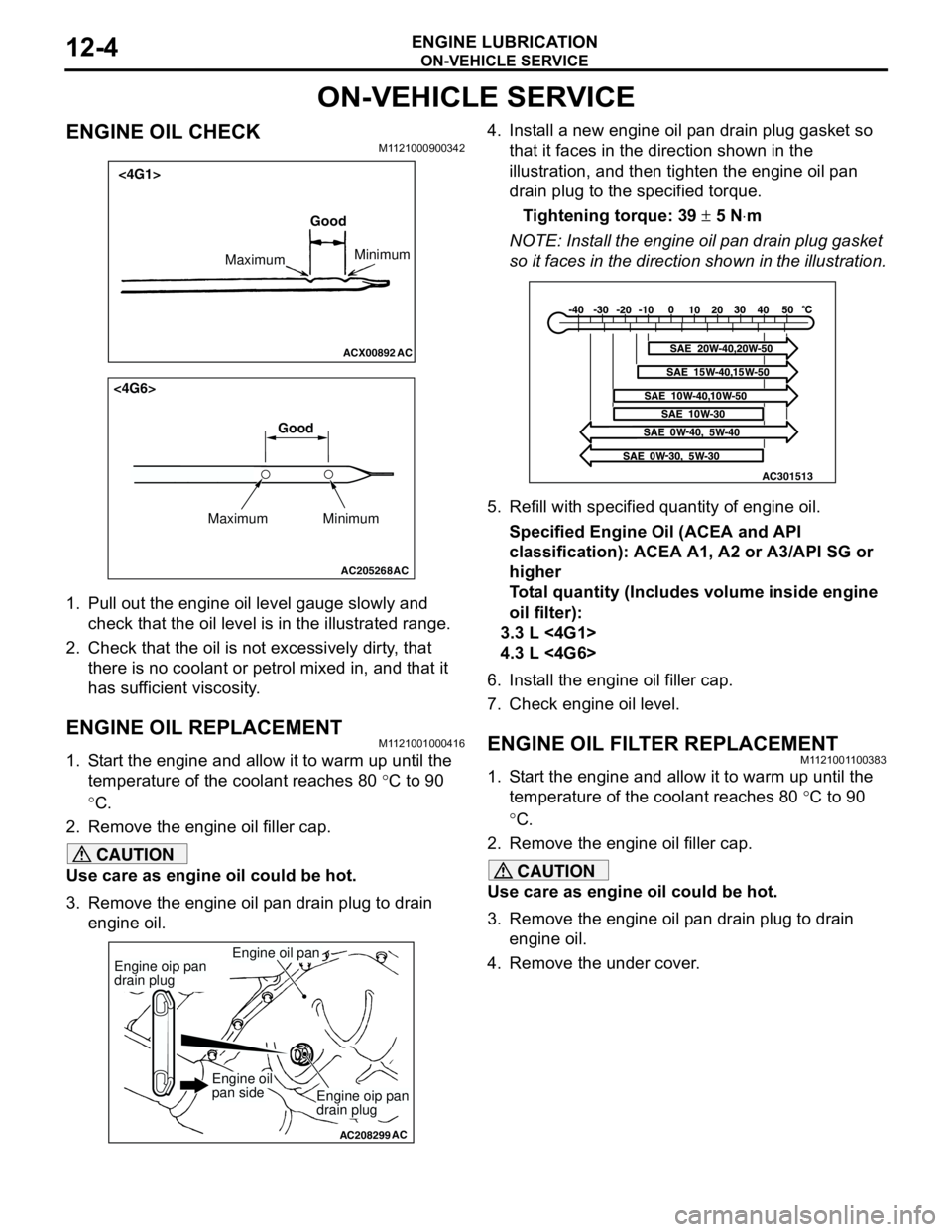

ENGINE OIL CHECKM1121000900342

1. Pull out the engine oil level gauge slowly and

check that the oil level is in the illustrated range.

2. Check that the oil is not excessively dirty, that

there is no coolant or petrol mixed in, and that it

has sufficient viscosity.

ENGINE OIL REPLACEMENTM1121001000416

1. Start the engine and allow it to warm up until the

temperature of the coolant reaches 80 °C to 90

°C.

2. Remove the engine oil filler cap.

CAUTION

Use care as engine oil could be hot.

3. Remove the engine oil pan drain plug to drain

engine oil.4. Install a new engine oil pan drain plug gasket so

that it faces in the direction shown in the

illustration, and then tighten the engine oil pan

drain plug to the specified torque.

Tightening torque: 39 ± 5 N⋅m

NOTE: Install the engine oil pan drain plug gasket

so it faces in the direction shown in the illustration.

5. Refill with specified quantity of engine oil.

Specified Engine Oil (ACEA and API

classification): ACEA A1, A2 or A3/API SG or

higher

Total quantity (Includes volume inside engine

oil filter):

3.3 L <4G1>

4.3 L <4G6>

6. Install the engine oil filler cap.

7. Check engine oil level.

ENGINE OIL FILTER REPLACEMENTM1121001100383

1. Start the engine and allow it to warm up until the

temperature of the coolant reaches 80 °C to 90

°C.

2. Remove the engine oil filler cap.

CAUTION

Use care as engine oil could be hot.

3. Remove the engine oil pan drain plug to drain

engine oil.

4. Remove the under cover.

ACX00892 AC

Good

MaximumMinimum

<4G1>

AC205268

Maximum MinimumGood

AC

<4G6>

AC208299

Engine oil pan

AC

Engine oip pan

drain plug

Engine oip pan

drain plug

Engine oil

pan side

AC301513

Page 58 of 788

INLET MANIFOLD

INTAKE AND EXHAUST15-6

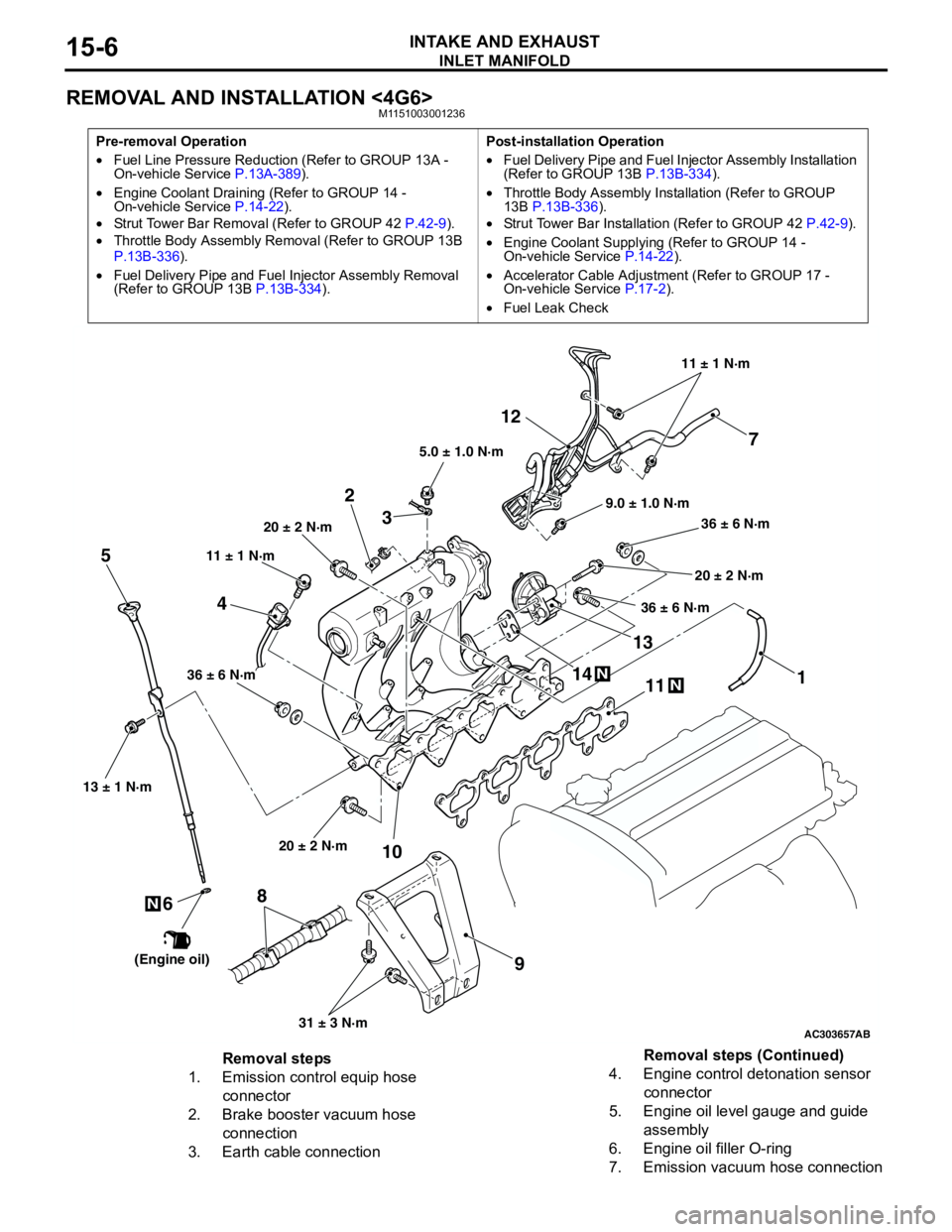

REMOVAL AND INSTALLATION <4G6>M1151003001236

Pre-removal Operation

•Fuel Line Pressure Reduction (Refer to GROUP 13A -

On-vehicle Service P.13A-389).

•Engine Coolant Draining (Refer to GROUP 14 -

On-vehicle Service P.14-22).

•Strut Tower Bar Removal (Refer to GROUP 42 P.42-9).

•Throttle Body Assembly Removal (Refer to GROUP 13B

P.13B-336).

•Fuel Delivery Pipe and Fuel Injector Assembly Removal

(Refer to GROUP 13B P.13B-334).Post-installation Operation

•Fuel Delivery Pipe and Fuel Injector Assembly Installation

(Refer to GROUP 13B P.13B-334).

•Throttle Body Assembly Installation (Refer to GROUP

13B P.13B-336).

•Strut Tower Bar Installation (Refer to GROUP 42 P.42-9).

•Engine Coolant Supplying (Refer to GROUP 14 -

On-vehicle Service P.14-22).

•Accelerator Cable Adjustment (Refer to GROUP 17 -

On-vehicle Service P.17-2).

•Fuel Leak Check

AC303657

9.0 ± 1.0 N·m11 ± 1 N·m

20 ± 2 N·m

31 ± 3 N·m 36 ± 6 N·m

20 ± 2 N·m

20 ± 2 N·m

36 ± 6 N·m

36 ± 6 N·m

11

9 10 212

N1413N

AB

5.0 ± 1.0 N·m

3

1

11 ± 1 N·m

4

N

13 ± 1 N·m

5

6

(Engine oil)

7

8

Removal steps

1. Emission control equip hose

connector

2. Brake booster vacuum hose

connection

3. Earth cable connection4. Engine control detonation sensor

connector

5. Engine oil level gauge and guide

assembly

6. Engine oil filler O-ring

7. Emission vacuum hose connectionRemoval steps (Continued)

Page 60 of 788

EXHAUST MANIFOLD

INTAKE AND EXHAUST15-8

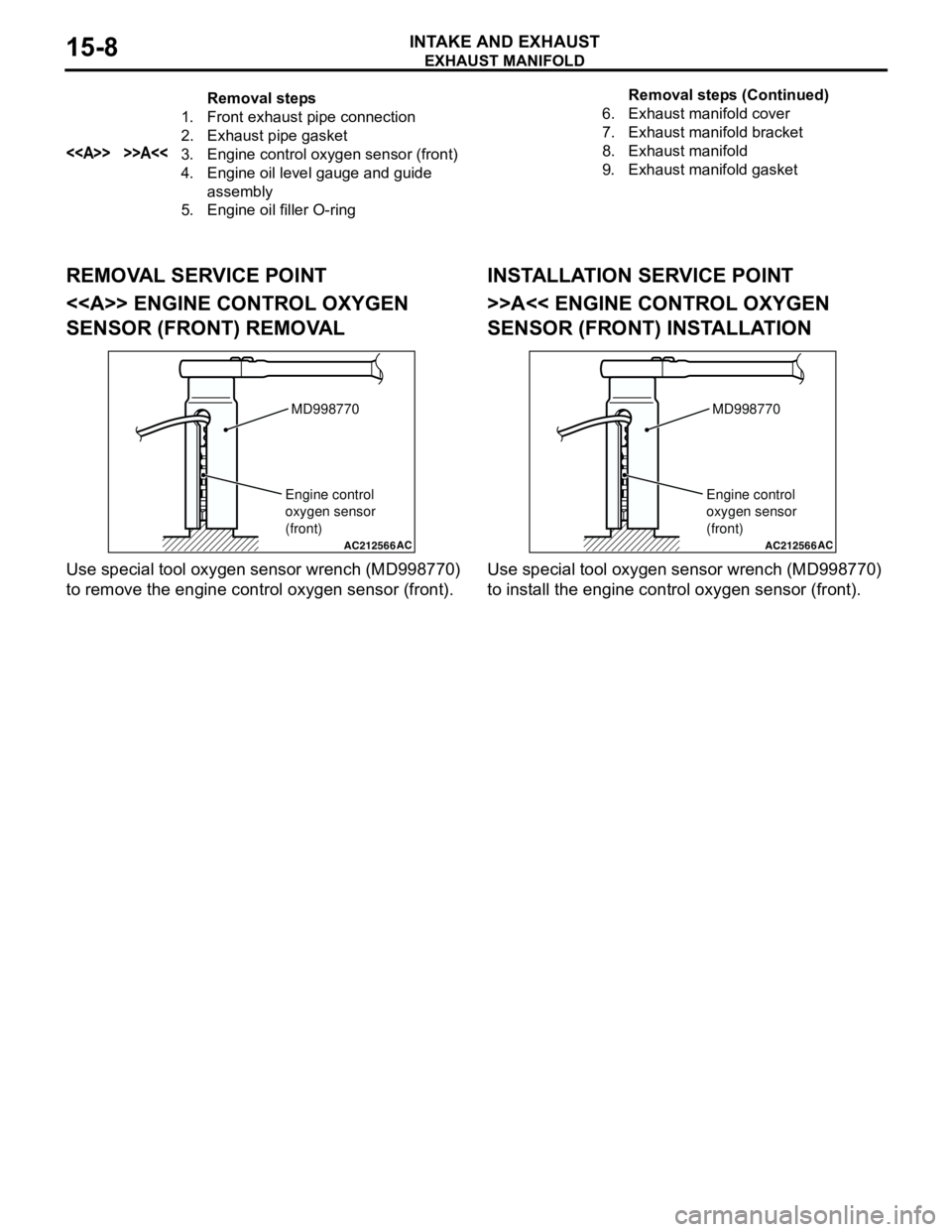

REMOVAL SERVICE POINT

<> ENGINE CONTROL OXYGEN

SENSOR (FRONT) REMOVAL

Use special tool oxygen sensor wrench (MD998770)

to remove the engine control oxygen sensor (front).

INSTALLATION SERVICE POINT

>>A<< ENGINE CONTROL OXYGEN

SENSOR (FRONT) INSTALLATION

Use special tool oxygen sensor wrench (MD998770)

to install the engine control oxygen sensor (front).

Removal steps

1. Front exhaust pipe connection

2. Exhaust pipe gasket

<> >>A<<3. Engine control oxygen sensor (front)

4. Engine oil level gauge and guide

assembly

5. Engine oil filler O-ring6. Exhaust manifold cover

7. Exhaust manifold bracket

8. Exhaust manifold

9. Exhaust manifold gasketRemoval steps (Continued)

AC212566AC

MD998770

Engine control

oxygen sensor

(front)

AC212566AC

MD998770

Engine control

oxygen sensor

(front)

Page 66 of 788

CHARGING SYSTEM

ENGINE ELECTRICAL16-2

CHARGING SYSTEM

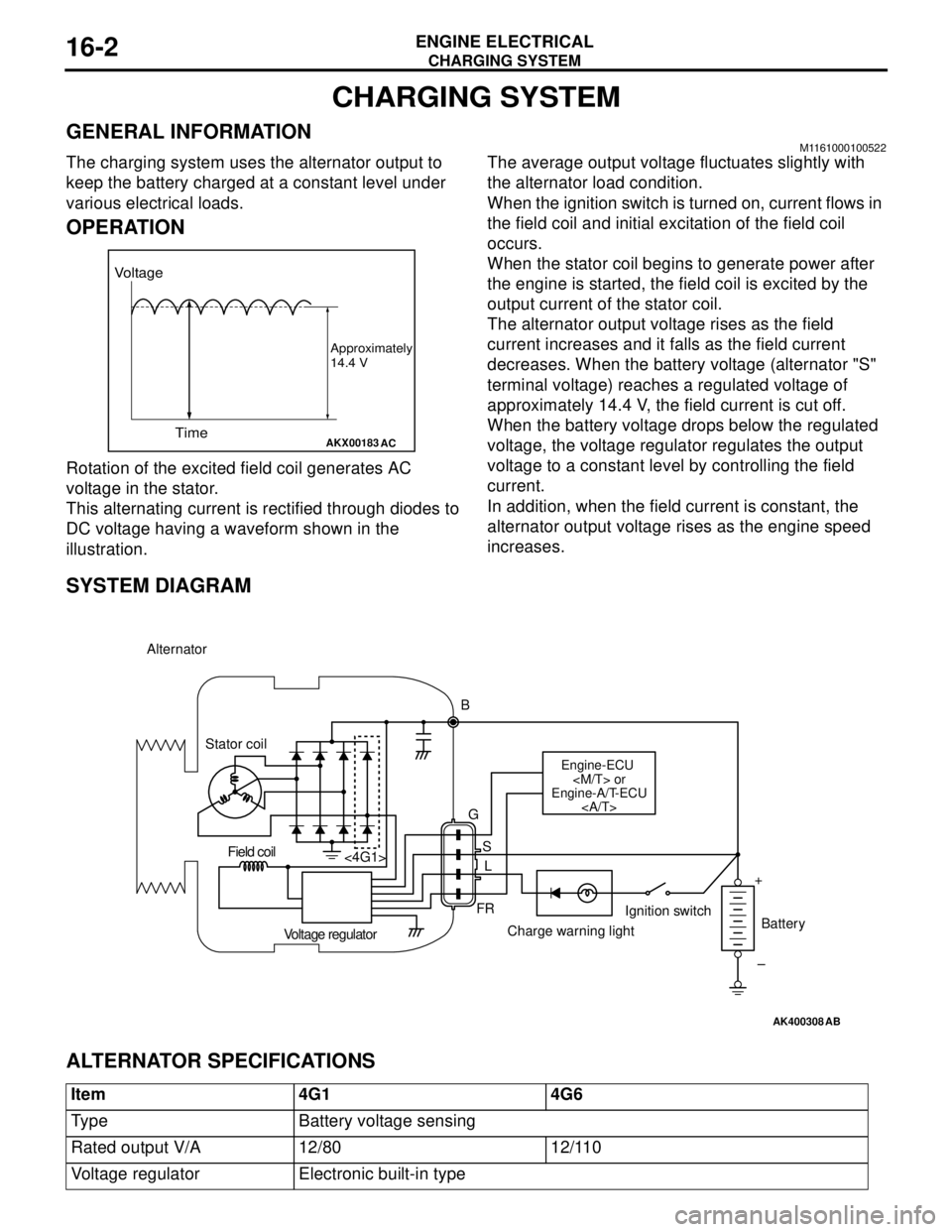

GENERAL INFORMATIONM1161000100522

The charging system uses the alternator output to

keep the battery charged at a constant level under

various electrical loads.

OPERATION

Rotation of the excited field coil generates AC

voltage in the stator.

This alternating current is rectified through diodes to

DC voltage having a waveform shown in the

illustration.The average output voltage fluctuates slightly with

the alternator load condition.

When the ignition switch is turned on, current flows in

the field coil and initial excitation of the field coil

occurs.

When the stator coil begins to generate power after

the engine is started, the field coil is excited by the

output current of the stator coil.

The alternator output voltage rises as the field

current increases and it falls as the field current

decreases. When the battery voltage (alternator "S"

terminal voltage) reaches a regulated voltage of

approximately 14.4 V, the field current is cut off.

When the battery voltage drops below the regulated

voltage, the voltage regulator regulates the output

voltage to a constant level by controlling the field

current.

In addition, when the field current is constant, the

alternator output voltage rises as the engine speed

increases.

SYSTEM DIAGRAM

ALTERNATOR SPECIFICATIONS

AKX00183

Voltage

Time

Approximately

14.4 V

AC

AK400308

Alternator

B

Stator coil

Engine-ECU

Engine-A/T-ECU

G

S

L

FR <4G1>

Voltage regulatorCharge warning lightIgnition switch

Battery Field coil

+

–

AB

Item 4G1 4G6

Type Battery voltage sensing

Rated output V/A 12/80 12/110

Voltage regulator Electronic built-in type

Page 205 of 788

ON-VEHICLE SERVICE

REAR SUSPENSION34-5

ON-VEHICLE SERVICE

REAR WHEEL ALIGNMENT CHECK AND

ADJUSTMENT

M1341011000372

Measure wheel alignment with an alignment

equipment on level earth.

The rear suspension, wheels, and tyres should be

serviced to the normal condition prior to wheel

alignment measurement.

CAMBER

Standard value: -0° 40' ± 30' (Left/right

deviation within 30')

CAUTION

Never subject the wheel bearings to the vehicle

load when the rear wheel hub nuts (self-locking

nuts) or special tool wheel alignment gauge

attachment (MB991014) are loosened.

NOTE:

For vehicles with aluminium wheels, attach the

camber/caster/kingpin gauge to the trailing arm

spindle by using special tool wheel alignment gauge

attachment (MB991014). Tighten the special tool to

the same torque 175

± 25 N⋅m as the rear wheel hub

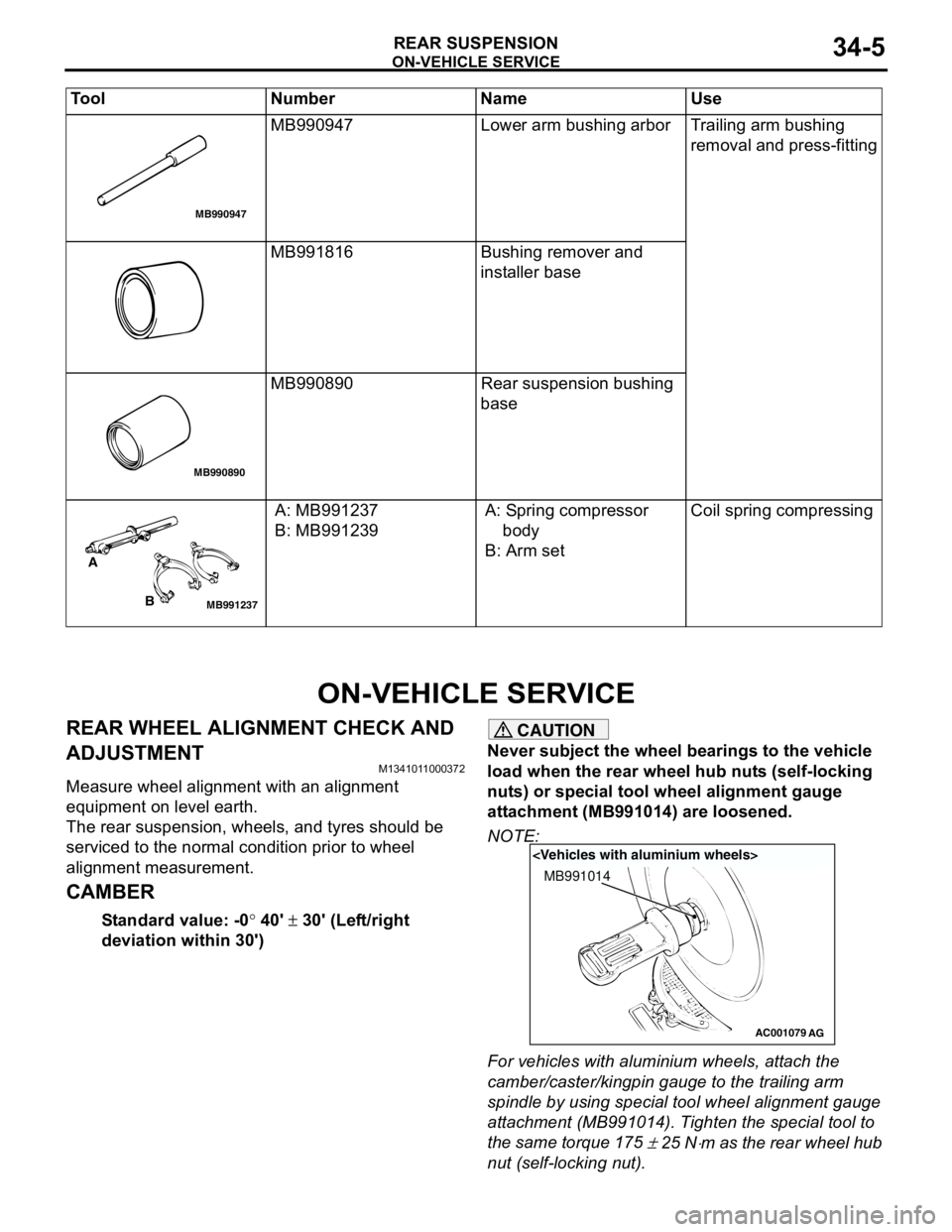

nut (self-locking nut). MB990947 Lower arm bushing arbor Trailing arm bushing

removal and press-fitting

MB991816 Bushing remover and

installer base

MB990890 Rear suspension bushing

base

A: MB991237

B: MB991239A: Spring compressor

body

B: Arm setCoil spring compressing Tool Number Name Use

MB990947

MB990890

MB991237

A

B

AC001079

MB991014

AG

Page 235 of 788

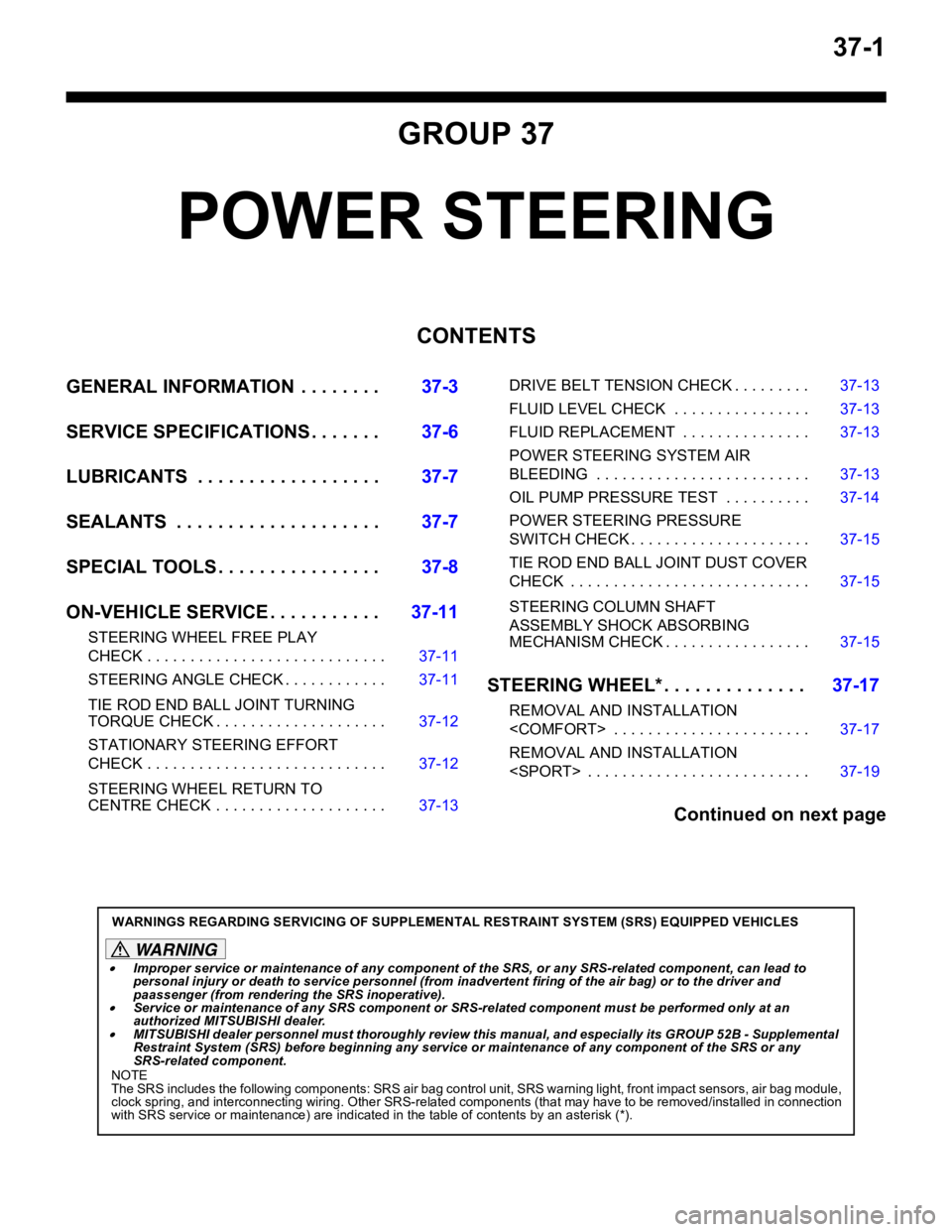

37-1

GROUP 37

POWER STEERING

CONTENTS

GENERAL INFORMATION . . . . . . . .37-3

SERVICE SPECIFICATIONS . . . . . . .37-6

LUBRICANTS . . . . . . . . . . . . . . . . . .37-7

SEALANTS . . . . . . . . . . . . . . . . . . . .37-7

SPECIAL TOOLS . . . . . . . . . . . . . . . .37-8

ON-VEHICLE SERVICE . . . . . . . . . . .37-11

STEERING WHEEL FREE PLAY

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37-11

STEERING ANGLE CHECK . . . . . . . . . . . . 37-11

TIE ROD END BALL JOINT TURNING

TORQUE CHECK . . . . . . . . . . . . . . . . . . . . 37-12

STATIONARY STEERING EFFORT

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37-12

STEERING WHEEL RETURN TO

CENTRE CHECK . . . . . . . . . . . . . . . . . . . . 37-13DRIVE BELT TENSION CHECK . . . . . . . . . 37-13

FLUID LEVEL CHECK . . . . . . . . . . . . . . . . 37-13

FLUID REPLACEMENT . . . . . . . . . . . . . . . 37-13

POWER STEERING SYSTEM AIR

BLEEDING . . . . . . . . . . . . . . . . . . . . . . . . . 37-13

OIL PUMP PRESSURE TEST . . . . . . . . . . 37-14

POWER STEERING PRESSURE

SWITCH CHECK . . . . . . . . . . . . . . . . . . . . . 37-15

TIE ROD END BALL JOINT DUST COVER

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37-15

STEERING COLUMN SHAFT

ASSEMBLY SHOCK ABSORBING

MECHANISM CHECK . . . . . . . . . . . . . . . . . 37-15

STEERING WHEEL* . . . . . . . . . . . . . .37-17

REMOVAL AND INSTALLATION

REMOVAL AND INSTALLATION

Continued on next page

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES

WARNING

•Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to

personal injury or death to service personnel (from inadvertent firing of the air bag) or to the driver and

paassenger (from rendering the SRS inoperative).

•Service or maintenance of any SRS component or SRS-related component must be performed only at an

authorized MITSUBISHI dealer.

•MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B - Supplemental

Restraint System (SRS) before beginning any service or maintenance of any component of the SRS or any

SRS-related component.

NOTE

The SRS includes the following components: SRS air bag control unit, SRS warning light, front impact sensors, air bag module,

clock spring, and interconnecting wiring. Other SRS-related components (that may have to be removed/installed in connection

with SRS service or maintenance) are indicated in the table of contents by an asterisk (*).

Page 237 of 788

GENERAL INFORMATION

POWER STEERING37-3

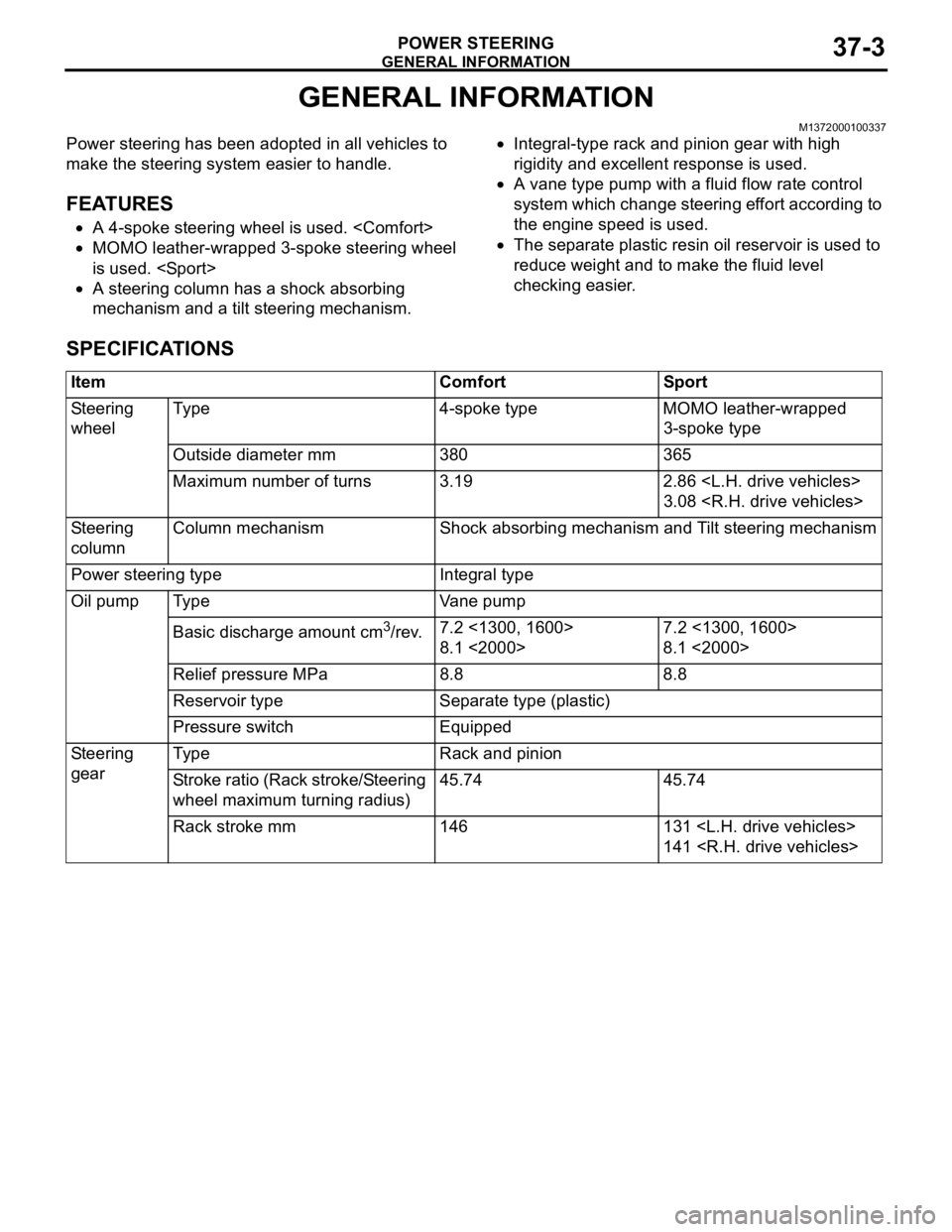

GENERAL INFORMATION

M1372000100337

Power steering has been adopted in all vehicles to

make the steering system easier to handle.

FEATURES

•A 4-spoke steering wheel is used.

•MOMO leather-wrapped 3-spoke steering wheel

is used.

•A steering column has a shock absorbing

mechanism and a tilt steering mechanism.•Integral-type rack and pinion gear with high

rigidity and excellent response is used.

•A vane type pump with a fluid flow rate control

system which change steering effort according to

the engine speed is used.

•The separate plastic resin oil reservoir is used to

reduce weight and to make the fluid level

checking easier.

SPECIFICATIONS

Item Comfort Sport

Steering

wheelType 4-spoke type MOMO leather-wrapped

3-spoke type

Outside diameter mm 380 365

Maximum number of turns 3.19 2.86

3.08

Steering

columnColumn mechanism Shock absorbing mechanism and Tilt steering mechanism

Power steering type Integral type

Oil pump Type Vane pump

Basic discharge amount cm

3/rev.7.2 <1300, 1600>

8.1 <2000>7.2 <1300, 1600>

8.1 <2000>

Relief pressure MPa 8.8 8.8

Reservoir type Separate type (plastic)

Pressure switch Equipped

Steering

gearType Rack and pinion

Stroke ratio (Rack stroke/Steering

wheel maximum turning radius)45.74 45.74

Rack stroke mm 146 131

141

Page 247 of 788

ON-VEHICLE SERVICE

POWER STEERING37-13

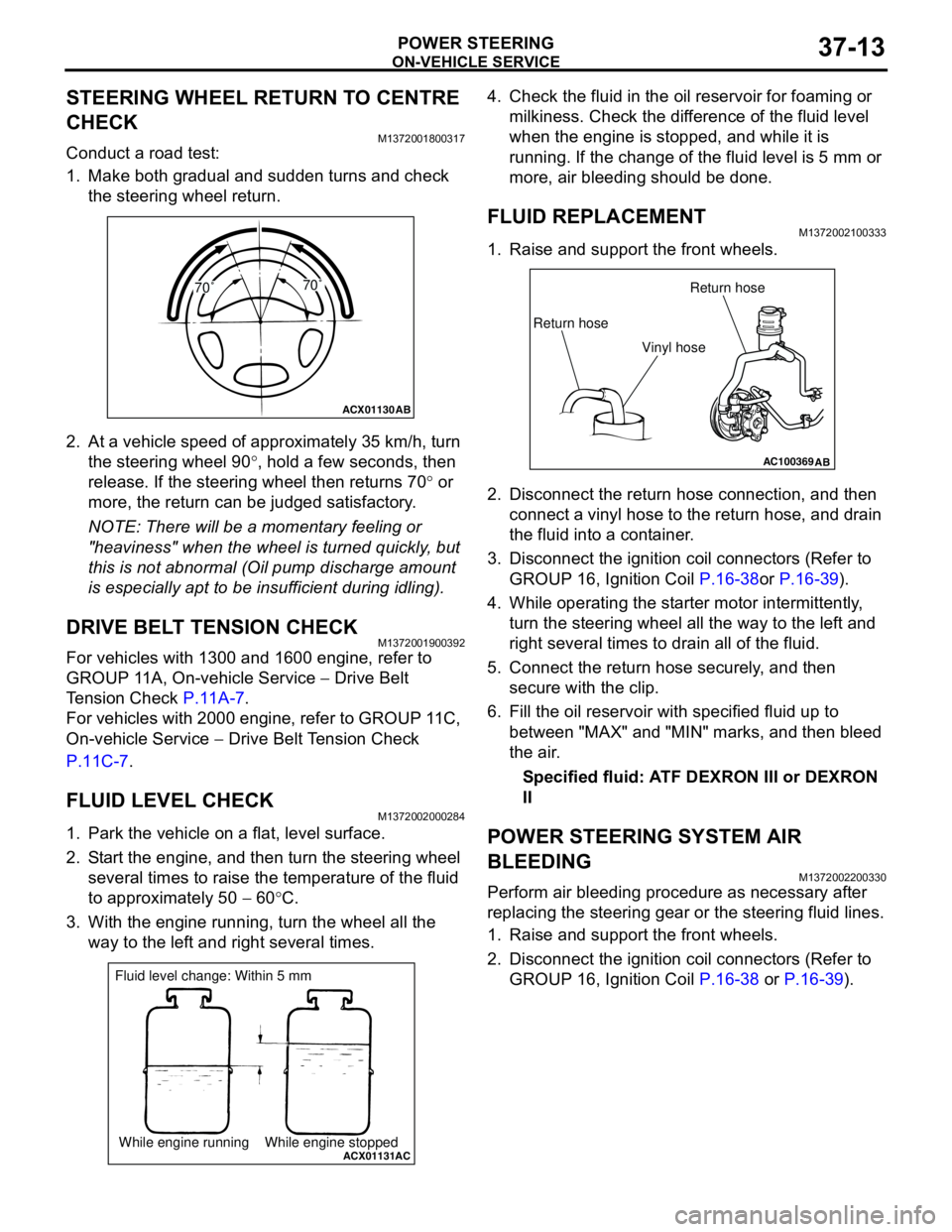

STEERING WHEEL RETURN TO CENTRE

CHECK

M1372001800317

Conduct a road test:

1. Make both gradual and sudden turns and check

the steering wheel return.

2. At a vehicle speed of approximately 35 km/h, turn

the steering wheel 90°, hold a few seconds, then

release. If the steering wheel then returns 70° or

more, the return can be judged satisfactory.

NOTE: There will be a momentary feeling or

"heaviness" when the wheel is turned quickly, but

this is not abnormal (Oil pump discharge amount

is especially apt to be insufficient during idling).

DRIVE BELT TENSION CHECKM1372001900392

For vehicles with 1300 and 1600 engine, refer to

GROUP 11A, On-vehicle Service − Drive Belt

Tension Check P.11A-7.

For vehicles with 2000 engine, refer to GROUP 11C,

On-vehicle Service − Drive Belt Tension Check

P.11C-7.

FLUID LEVEL CHECKM1372002000284

1. Park the vehicle on a flat, level surface.

2. Start the engine, and then turn the steering wheel

several times to raise the temperature of the fluid

to approximately 50 − 60°C.

3. With the engine running, turn the wheel all the

way to the left and right several times.4. Check the fluid in the oil reservoir for foaming or

milkiness. Check the difference of the fluid level

when the engine is stopped, and while it is

running. If the change of the fluid level is 5 mm or

more, air bleeding should be done.

FLUID REPLACEMENTM1372002100333

1. Raise and support the front wheels.

2. Disconnect the return hose connection, and then

connect a vinyl hose to the return hose, and drain

the fluid into a container.

3. Disconnect the ignition coil connectors (Refer to

GROUP 16, Ignition Coil P.16-38or P.16-39).

4. While operating the starter motor intermittently,

turn the steering wheel all the way to the left and

right several times to drain all of the fluid.

5. Connect the return hose securely, and then

secure with the clip.

6. Fill the oil reservoir with specified fluid up to

between "MAX" and "MIN" marks, and then bleed

the air.

Specified fluid: ATF DEXRON III or DEXRON

II

POWER STEERING SYSTEM AIR

BLEEDING

M1372002200330

Perform air bleeding procedure as necessary after

replacing the steering gear or the steering fluid lines.

1. Raise and support the front wheels.

2. Disconnect the ignition coil connectors (Refer to

GROUP 16, Ignition Coil P.16-38 or P.16-39).

ACX01130

AB

70˚70˚

ACX01131While engine running While engine stoppedAC

Fluid level change: Within 5 mm

AC100369AB

Return hoseReturn hose

Vinyl hose

Page 248 of 788

ON-VEHICLE SERVICE

POWER STEERING37-14

CAUTION

Perform air bleeding only while cranking the

engine. If air bleeding is performed while the

engine is running, air could enter the fluid.

During air bleeding, refill the steering fluid

supply so that the level never falls below the

"MIN" mark on the oil reservoir.

3. Turn the steering wheel all the way to the left and

right five or six times while using the starter motor

to crank the engine intermittently several times

(for 15 to 20 seconds).

4. Connect the ignition coil connectors (Refer to

GROUP 16, Ignition Coil P.16-38 or P.16-39).

5. Start the engine (idling).

6. Turn the steering wheel to the left and right until

there are no air bubbles in the oil reservoir.

7. Confirm that the fluid is not milky, and that the

level is between "MAX" and "MIN" marks.

8. Confirm that there is very little change in the fluid

level when the steering wheel is turned left and

right.

CAUTION

If the fluid level rises suddenly after the engine is

stopped, the air has not been completely bled. If

air bleeding is not complete, there will be

abnormal noises from the pump and the

flow-control valve, and this condition could

cause reduce the life of the power steering

components.

9. Confirm that the change in the fluid level is no

more than 5 mm when the engine is stopped and

when it is running.

10.If the change of the fluid level is 5 mm or more,

the air has not been completely bled from the

system. The air bleeding procedure must be

repeated.

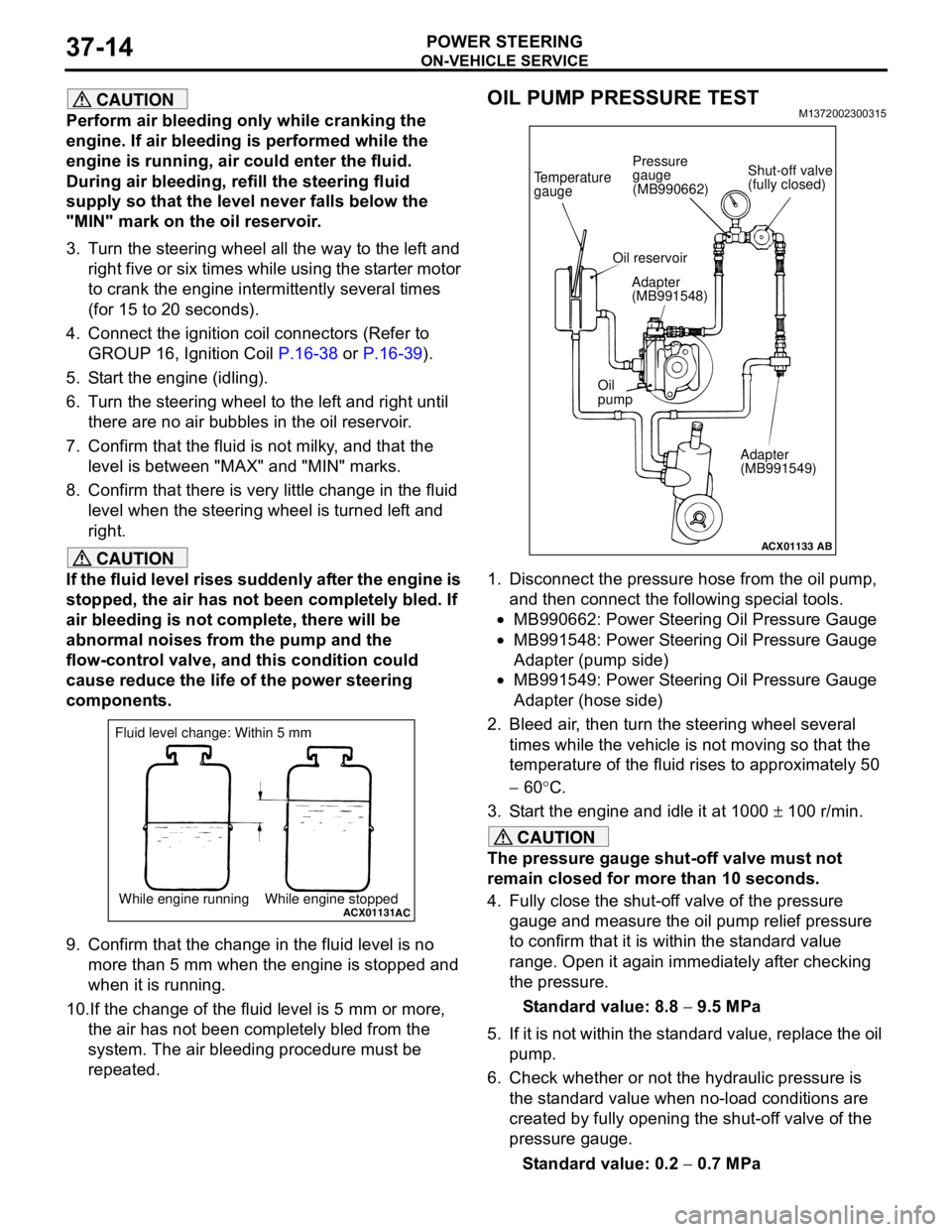

OIL PUMP PRESSURE TESTM1372002300315

1. Disconnect the pressure hose from the oil pump,

and then connect the following special tools.

•MB990662: Power Steering Oil Pressure Gauge

•MB991548: Power Steering Oil Pressure Gauge

Adapter (pump side)

•MB991549: Power Steering Oil Pressure Gauge

Adapter (hose side)

2. Bleed air, then turn the steering wheel several

times while the vehicle is not moving so that the

temperature of the fluid rises to approximately 50

− 60°C.

3. Start the engine and idle it at 1000 ± 100 r/min.

CAUTION

The pressure gauge shut-off valve must not

remain closed for more than 10 seconds.

4. Fully close the shut-off valve of the pressure

gauge and measure the oil pump relief pressure

to confirm that it is within the standard value

range. Open it again immediately after checking

the pressure.

Standard value: 8.8 − 9.5 MPa

5. If it is not within the standard value, replace the oil

pump.

6. Check whether or not the hydraulic pressure is

the standard value when no-load conditions are

created by fully opening the shut-off valve of the

pressure gauge.

Standard value: 0.2 − 0.7 MPa

ACX01131While engine running While engine stoppedAC

Fluid level change: Within 5 mm

ACX01133

Temperature

gauge

Oil reservoir

Adapter

(MB991548)

Oil

pump

Adapter

(MB991549)

AB

Shut-off valve

(fully closed) Pressure

gauge

(MB990662)

Page 486 of 788

55-2

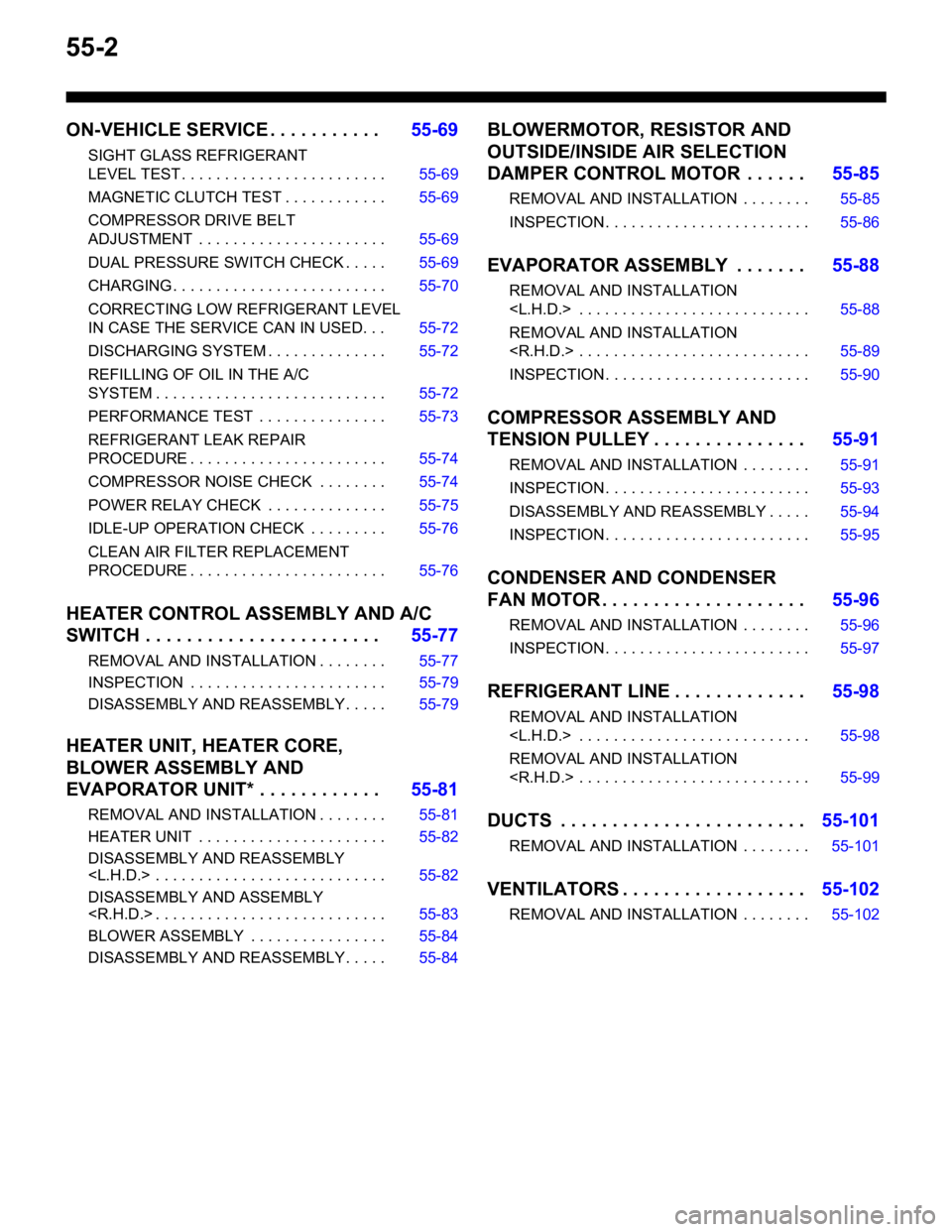

ON-VEHICLE SERVICE . . . . . . . . . . .55-69

SIGHT GLASS REFRIGERANT

LEVEL TEST . . . . . . . . . . . . . . . . . . . . . . . . 55-69

MAGNETIC CLUTCH TEST . . . . . . . . . . . . 55-69

COMPRESSOR DRIVE BELT

ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . 55-69

DUAL PRESSURE SWITCH CHECK . . . . . 55-69

CHARGING . . . . . . . . . . . . . . . . . . . . . . . . . 55-70

CORRECTING LOW REFRIGERANT LEVEL

IN CASE THE SERVICE CAN IN USED. . . 55-72

DISCHARGING SYSTEM . . . . . . . . . . . . . . 55-72

REFILLING OF OIL IN THE A/C

SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . 55-72

PERFORMANCE TEST . . . . . . . . . . . . . . . 55-73

REFRIGERANT LEAK REPAIR

PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . 55-74

COMPRESSOR NOISE CHECK . . . . . . . . 55-74

POWER RELAY CHECK . . . . . . . . . . . . . . 55-75

IDLE-UP OPERATION CHECK . . . . . . . . . 55-76

CLEAN AIR FILTER REPLACEMENT

PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . 55-76

HEATER CONTROL ASSEMBLY AND A/C

SWITCH . . . . . . . . . . . . . . . . . . . . . . .55-77

REMOVAL AND INSTALLATION . . . . . . . . 55-77

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . 55-79

DISASSEMBLY AND REASSEMBLY . . . . . 55-79

HEATER UNIT, HEATER CORE,

BLOWER ASSEMBLY AND

EVAPORATOR UNIT* . . . . . . . . . . . .55-81

REMOVAL AND INSTALLATION . . . . . . . . 55-81

HEATER UNIT . . . . . . . . . . . . . . . . . . . . . . 55-82

DISASSEMBLY AND REASSEMBLY

DISASSEMBLY AND ASSEMBLY

BLOWER ASSEMBLY . . . . . . . . . . . . . . . . 55-84

DISASSEMBLY AND REASSEMBLY . . . . . 55-84

BLOWERMOTOR, RESISTOR AND

OUTSIDE/INSIDE AIR SELECTION

DAMPER CONTROL MOTOR . . . . . .55-85

REMOVAL AND INSTALLATION . . . . . . . . 55-85

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 55-86

EVAPORATOR ASSEMBLY . . . . . . .55-88

REMOVAL AND INSTALLATION

REMOVAL AND INSTALLATION

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 55-90

COMPRESSOR ASSEMBLY AND

TENSION PULLEY . . . . . . . . . . . . . . .55-91

REMOVAL AND INSTALLATION . . . . . . . . 55-91

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 55-93

DISASSEMBLY AND REASSEMBLY . . . . . 55-94

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 55-95

CONDENSER AND CONDENSER

FAN MOTOR . . . . . . . . . . . . . . . . . . . .55-96

REMOVAL AND INSTALLATION . . . . . . . . 55-96

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 55-97

REFRIGERANT LINE . . . . . . . . . . . . .55-98

REMOVAL AND INSTALLATION

REMOVAL AND INSTALLATION

DUCTS . . . . . . . . . . . . . . . . . . . . . . . .55-101

REMOVAL AND INSTALLATION . . . . . . . . 55-101

VENTILATORS . . . . . . . . . . . . . . . . . .55-102

REMOVAL AND INSTALLATION . . . . . . . . 55-102