rear MITSUBISHI LANCER 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 1 of 788

GROUP INDEX

00General . . . . . . . . . . . . . . . . . . . . . . . .

11Engine. . . . . . . . . . . . . . . . . . . . . . . . .

12Engine Lubrication . . . . . . . . . . . . . .

13Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . .

14Engine Cooling . . . . . . . . . . . . . . . . .

15Intake and Exhaust . . . . . . . . . . . . . .

16Engine Electrical . . . . . . . . . . . . . . . .

17Engine and Emission Control . . . . .

21Clutch . . . . . . . . . . . . . . . . . . . . . . . . .

22Manual Transmission . . . . . . . . . . . .

23Automatic Transmission. . . . . . . . . .

26Front Axle . . . . . . . . . . . . . . . . . . . . . .

27Rear Axle . . . . . . . . . . . . . . . . . . . . . .

31Wheel and Tyre . . . . . . . . . . . . . . . . .

32Power Plant Mount . . . . . . . . . . . . . .

33Front Suspension . . . . . . . . . . . . . . .

34Rear Suspension . . . . . . . . . . . . . . . .

35Service Brakes . . . . . . . . . . . . . . . . . .

36Parking Brakes . . . . . . . . . . . . . . . . .

37Power Steering . . . . . . . . . . . . . . . . .

42Body . . . . . . . . . . . . . . . . . . . . . . . . . .

51Exterior . . . . . . . . . . . . . . . . . . . . . . . .

52 . . . . . . . . . .

54Chassis Electrical . . . . . . . . . . . . . . .

55 . . . . . . .

70Component Locations. . . . . . . . . . . .

80Configration Diagrams . . . . . . . . . . .

90Circuit Diagrams . . . . . . . . . . . . . . . .

LANCER /

LANCER WAGON

WORKSHOP MANUAL

FOREWORD

This Workshop manual contains procedures for

service mechanics, including removal, disassembly,

inspection, adjustment, reassembly and installation.

Use the following manuals in combination with this

manual as required.

TECHNICAL INFORMATION MANUAL

PYME0302

PYME0302-A

WORKSHOP MANUAL

CHASSIS GROUP PWME0302

BODY REPAIR MANUAL

PBME0302

PBME0302-A

PARTS CATALOGUE

B606K005A_

All information, illustrations and product descriptions

contained in this manual are current as at the time of

publication. We, however, reserve the right to make

changes at any time without prior notice or obligation.

Mitsubishi Motors Corporation May 2004

Heater, Air Conditioner and

Ventilation Interior and Supplemental

Restraint System (SRS)

Page 63 of 788

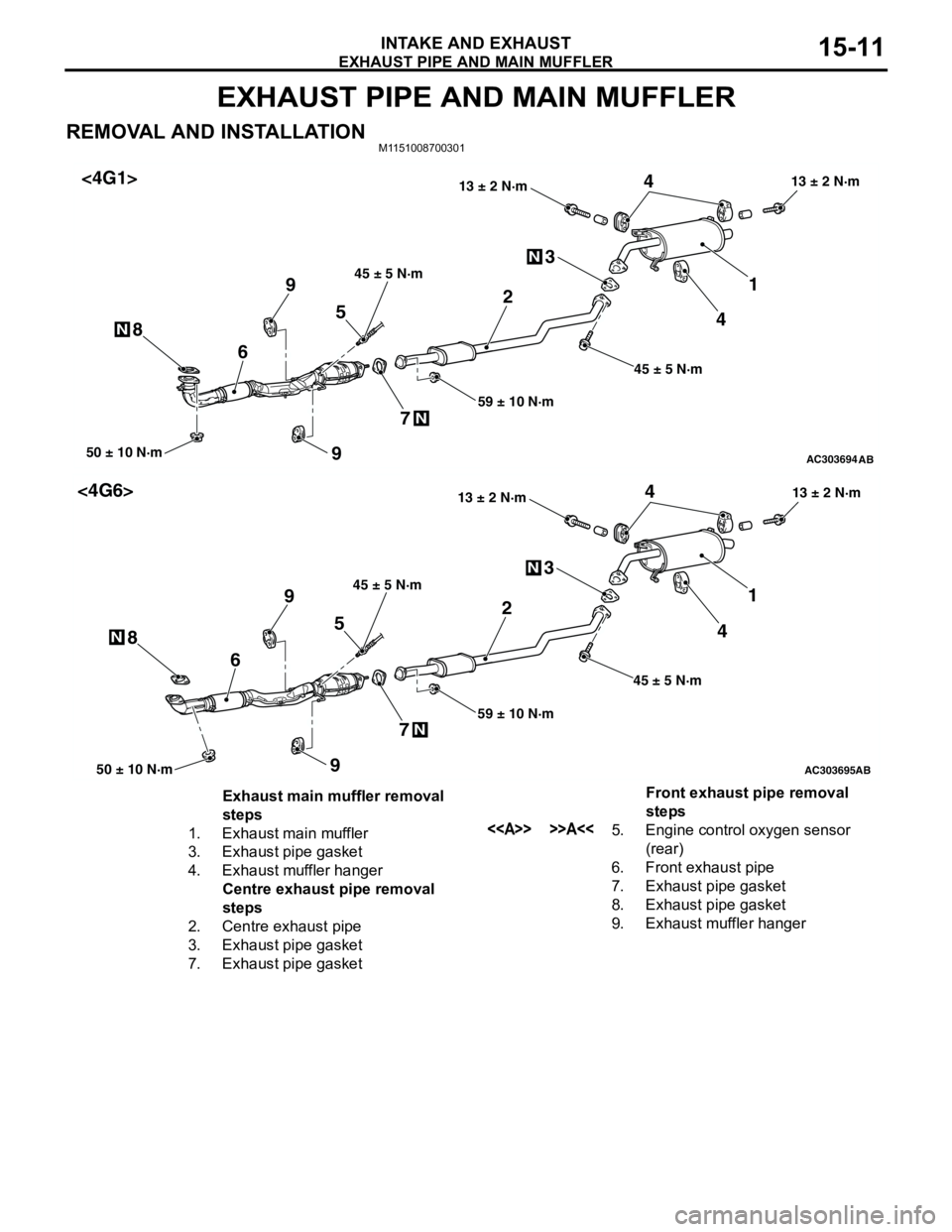

EXHAUST PIPE AND MAIN MUFFLER

INTAKE AND EXHAUST15-11

EXHAUST PIPE AND MAIN MUFFLER

REMOVAL AND INSTALLATIONM1151008700301

AC303694AB

1 3

50 ± 10 N·m

2

6

N

N

45

74

N89

59 ± 10 N·m 45 ± 5 N·m13 ± 2 N·m

45 ± 5 N·m

13 ± 2 N·m

9

<4G1>

AC303695AB

1 3

50 ± 10 N·m

2

6

N

N

45

74

N89

59 ± 10 N·m 45 ± 5 N·m13 ± 2 N·m

45 ± 5 N·m

13 ± 2 N·m

9

<4G6>

Exhaust main muffler removal

steps

1. Exhaust main muffler

3. Exhaust pipe gasket

4. Exhaust muffler hanger

Centre exhaust pipe removal

steps

2. Centre exhaust pipe

3. Exhaust pipe gasket

7. Exhaust pipe gasketFront exhaust pipe removal

steps

<> >>A<<5. Engine control oxygen sensor

(rear)

6. Front exhaust pipe

7. Exhaust pipe gasket

8. Exhaust pipe gasket

9. Exhaust muffler hanger

Page 64 of 788

EXHAUST PIPE AND MAIN MUFFLER

INTAKE AND EXHAUST15-12

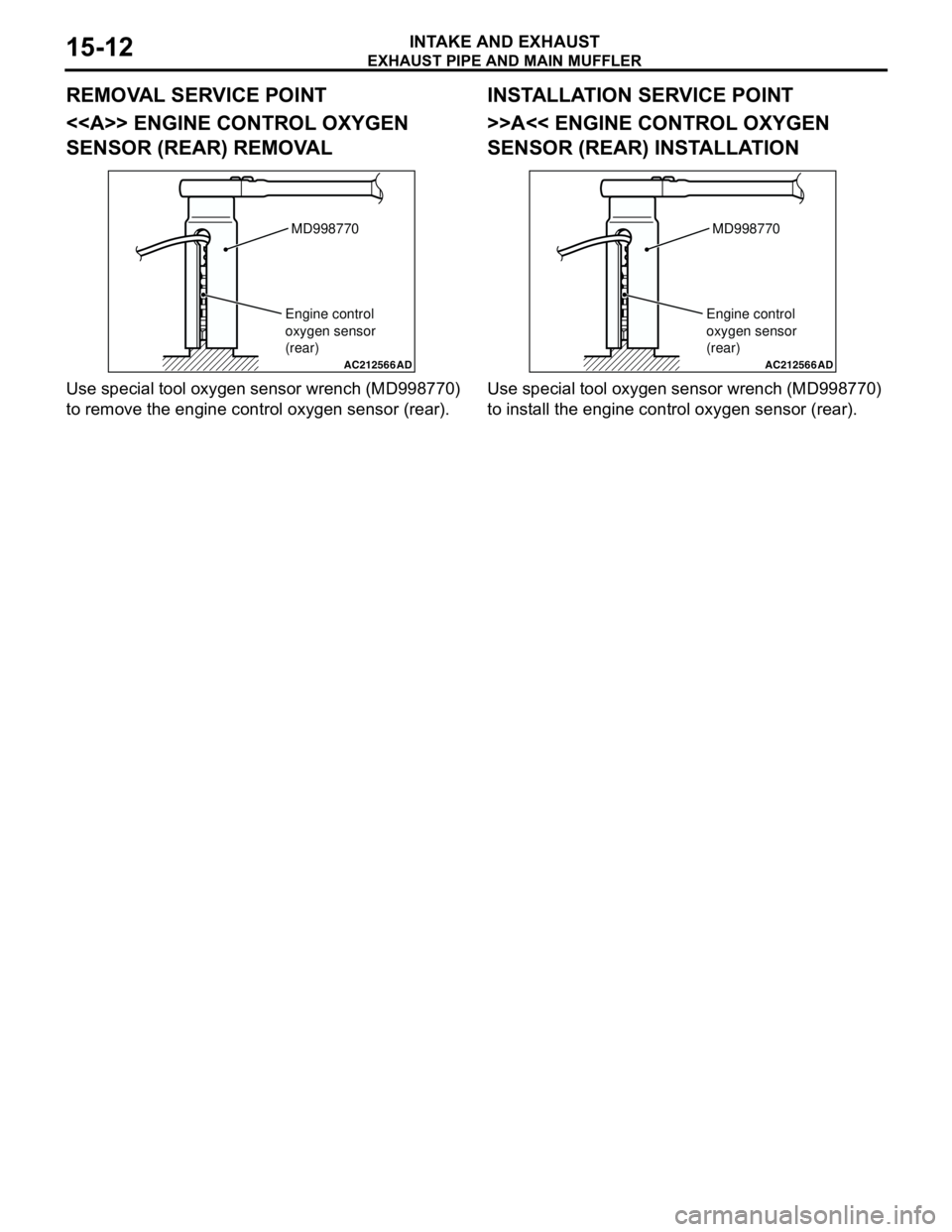

REMOVAL SERVICE POINT

<> ENGINE CONTROL OXYGEN

SENSOR (REAR) REMOVAL

Use special tool oxygen sensor wrench (MD998770)

to remove the engine control oxygen sensor (rear).

INSTALLATION SERVICE POINT

>>A<< ENGINE CONTROL OXYGEN

SENSOR (REAR) INSTALLATION

Use special tool oxygen sensor wrench (MD998770)

to install the engine control oxygen sensor (rear).

AC212566AD

MD998770

Engine control

oxygen sensor

(rear)

AC212566AD

MD998770

Engine control

oxygen sensor

(rear)

Page 79 of 788

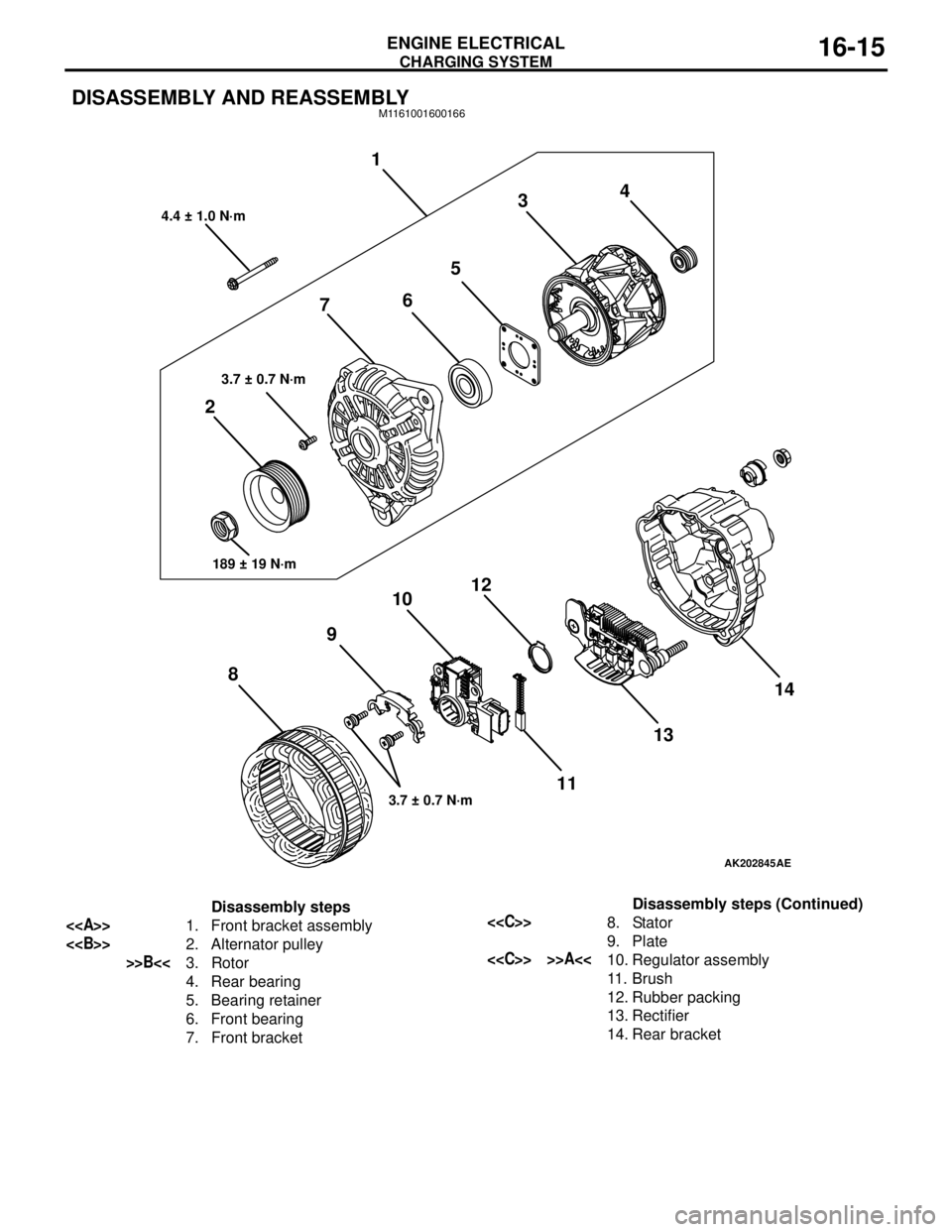

CHARGING SYSTEM

ENGINE ELECTRICAL16-15

DISASSEMBLY AND REASSEMBLYM1161001600166

AK202845

1

234

5

6

7

8910

11 12

1314

AE

4.4 ± 1.0 N·m

3.7 ± 0.7 N·m

189 ± 19 N·m

3.7 ± 0.7 N·m

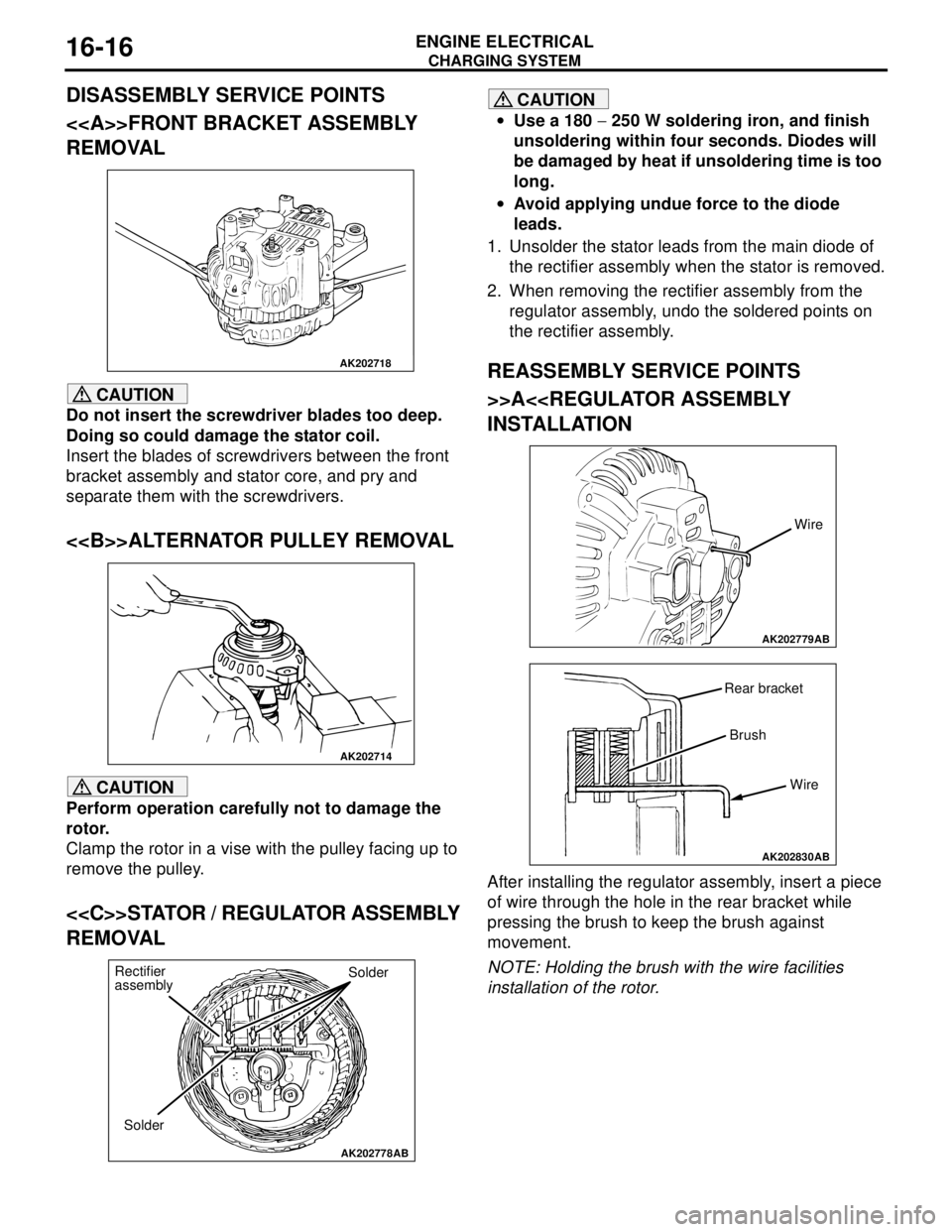

Disassembly steps

<>1. Front bracket assembly

<>2. Alternator pulley

>>B<<3. Rotor

4. Rear bearing

5. Bearing retainer

6. Front bearing

7. Front bracket

<

9. Plate

<

11 . B r u s h

12. Rubber packing

13. Rectifier

14. Rear bracketDisassembly steps (Continued)

Page 80 of 788

Page 90 of 788

STARTING SYSTEM

ENGINE ELECTRICAL16-26

DISASSEMBLY AND REASSEMBLYM1162001200202

AK201881

14

1211

20

1

15161718191310 2

4

3

5

7

6

8

9

AG

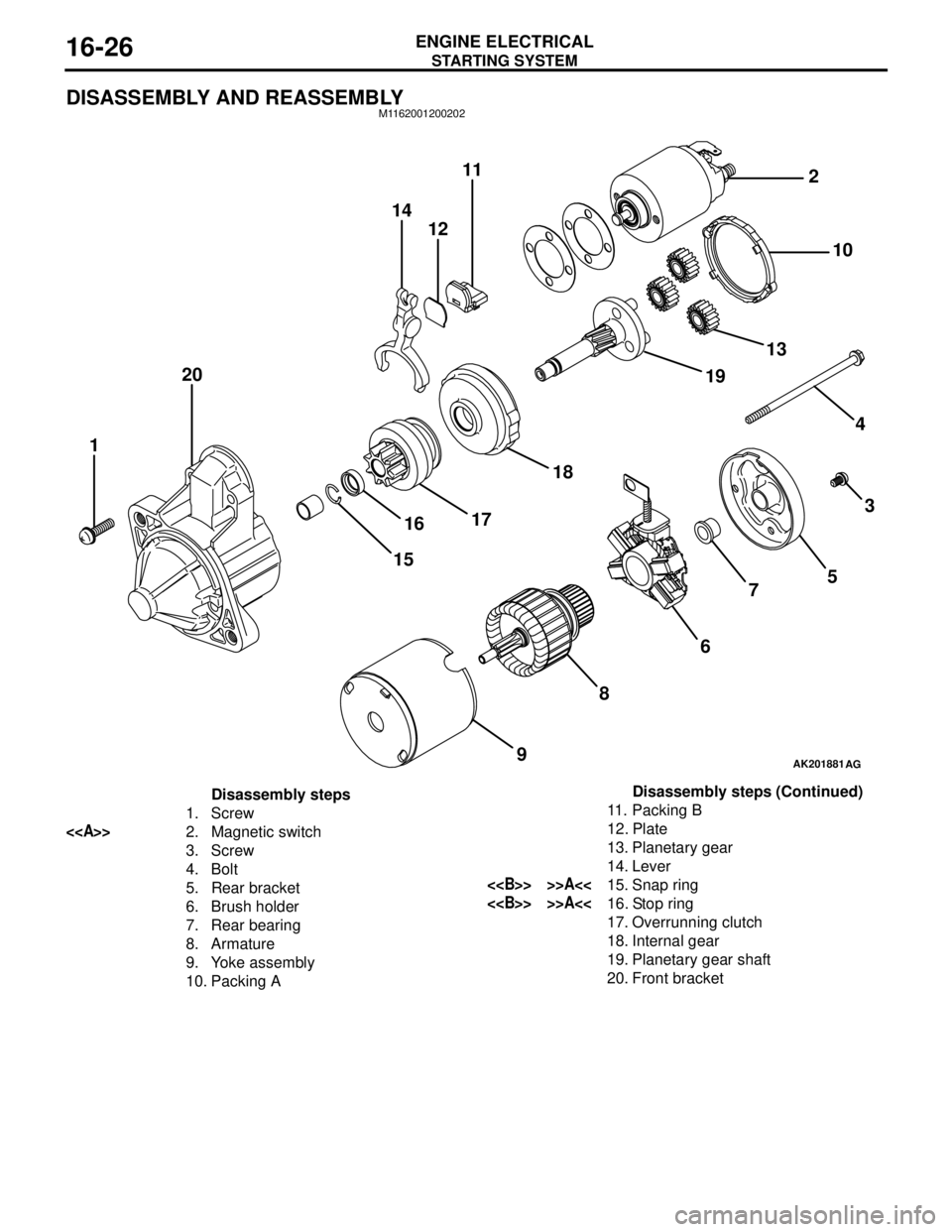

Disassembly steps

1. Screw

<>2. Magnetic switch

3. Screw

4. Bolt

5. Rear bracket

6. Brush holder

7. Rear bearing

8. Armature

9. Yoke assembly

10. Packing A11. Packing B

12. Plate

13. Planetary gear

14. Lever

<> >>A<<15. Snap ring

<> >>A<<16. Stop ring

17. Overrunning clutch

18. Internal gear

19. Planetary gear shaft

20. Front bracketDisassembly steps (Continued)

Page 114 of 788

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-6

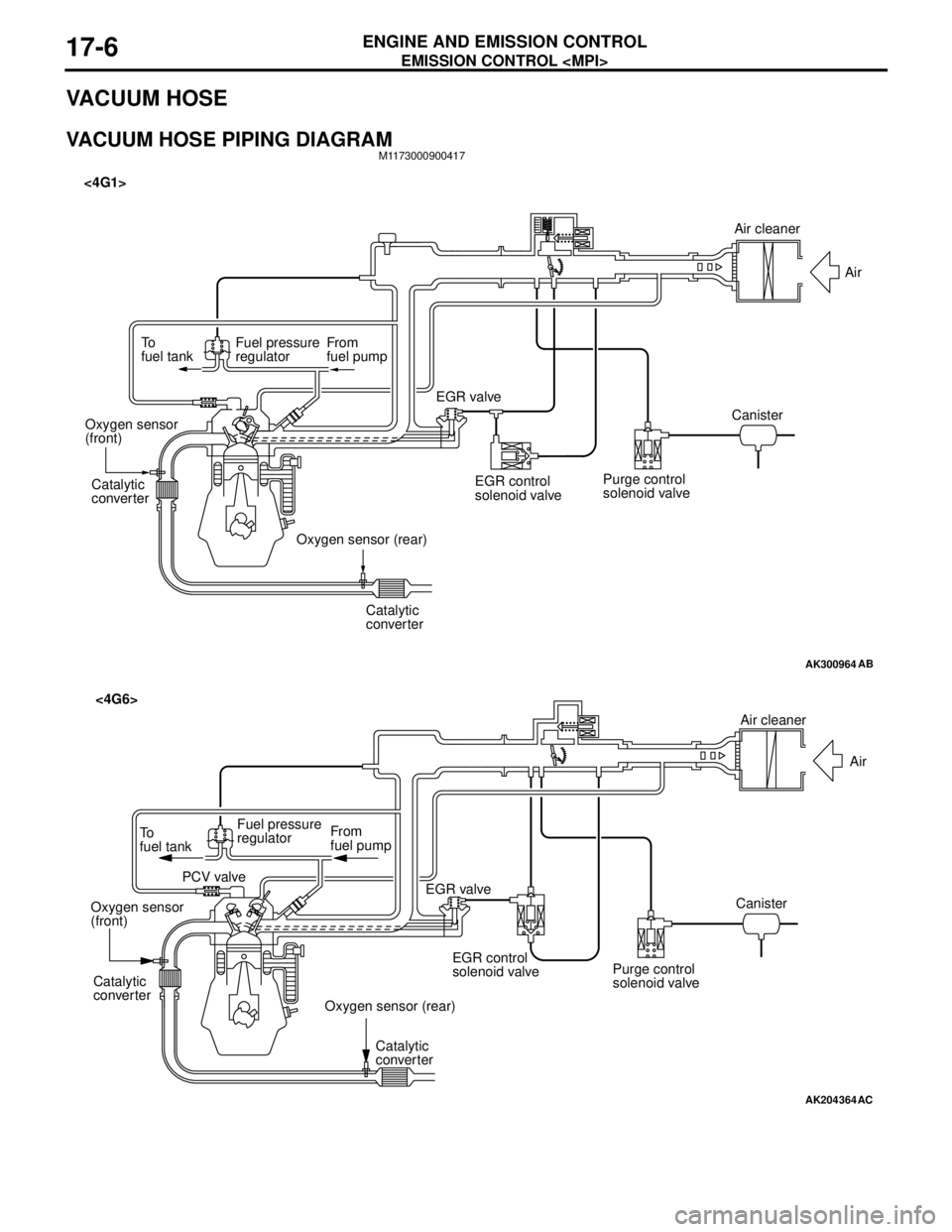

VACUUM HOSE

VACUUM HOSE PIPING DIAGRAMM1173000900417

AK300964

To

fuel tankFuel pressure

regulatorFrom

fuel pump

Catalytic

converter

Catalytic

converter Oxygen sensor

(front)

Oxygen sensor (rear)EGR valve <4G1>

EGR control

solenoid valvePurge control

solenoid valveCanisterAir

AB

Air cleaner

AK204364

AC

Air cleaner

Air

Canister

Purge control

solenoid valve EGR control

solenoid valve EGR valve From

fuel pump To

fuel tankFuel pressure

regulator

PCV valve

Oxygen sensor

(front)

Oxygen sensor (rear) Catalytic

converter

Catalytic

converter

<4G6>

Page 137 of 788

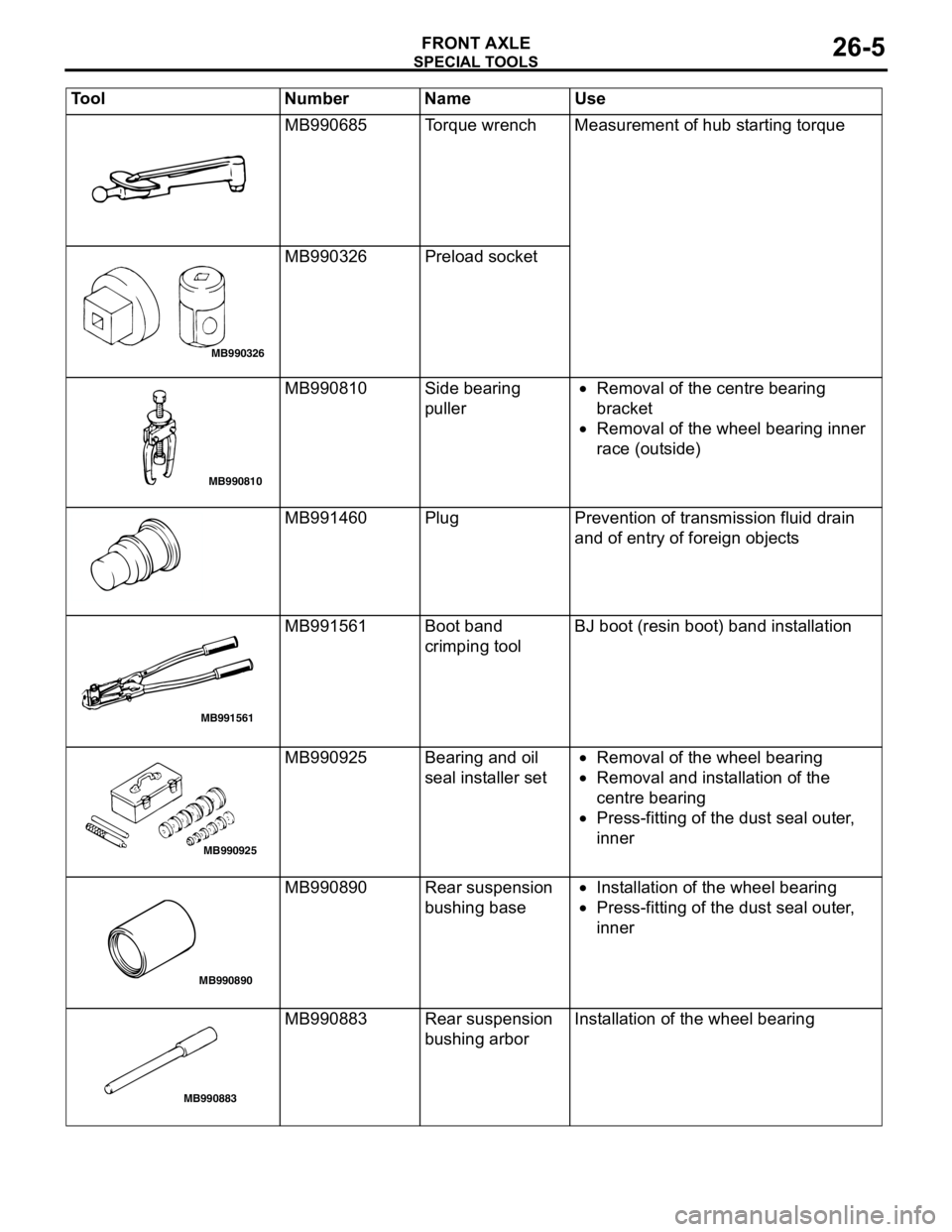

SPECIAL TOOLS

FRONT AXLE26-5

MB990685 Torque wrench Measurement of hub starting torque

MB990326 Preload socket

MB990810 Side bearing

puller•Removal of the centre bearing

bracket

•Removal of the wheel bearing inner

race (outside)

MB991460 Plug Prevention of transmission fluid drain

and of entry of foreign objects

MB991561 Boot band

crimping toolBJ boot (resin boot) band installation

MB990925 Bearing and oil

seal installer set•Removal of the wheel bearing

•Removal and installation of the

centre bearing

•Press-fitting of the dust seal outer,

inner

MB990890 Rear suspension

bushing base•Installation of the wheel bearing

•Press-fitting of the dust seal outer,

inner

MB990883 Rear suspension

bushing arborInstallation of the wheel bearing Tool Number Name Use

MB990326

MB990810

MB991561

MB990925

MB990890

MB990883

Page 145 of 788

FRONT AXLE HUB ASSEMBLY

FRONT AXLE26-13

REASSEMBLY SERVICE POINTS

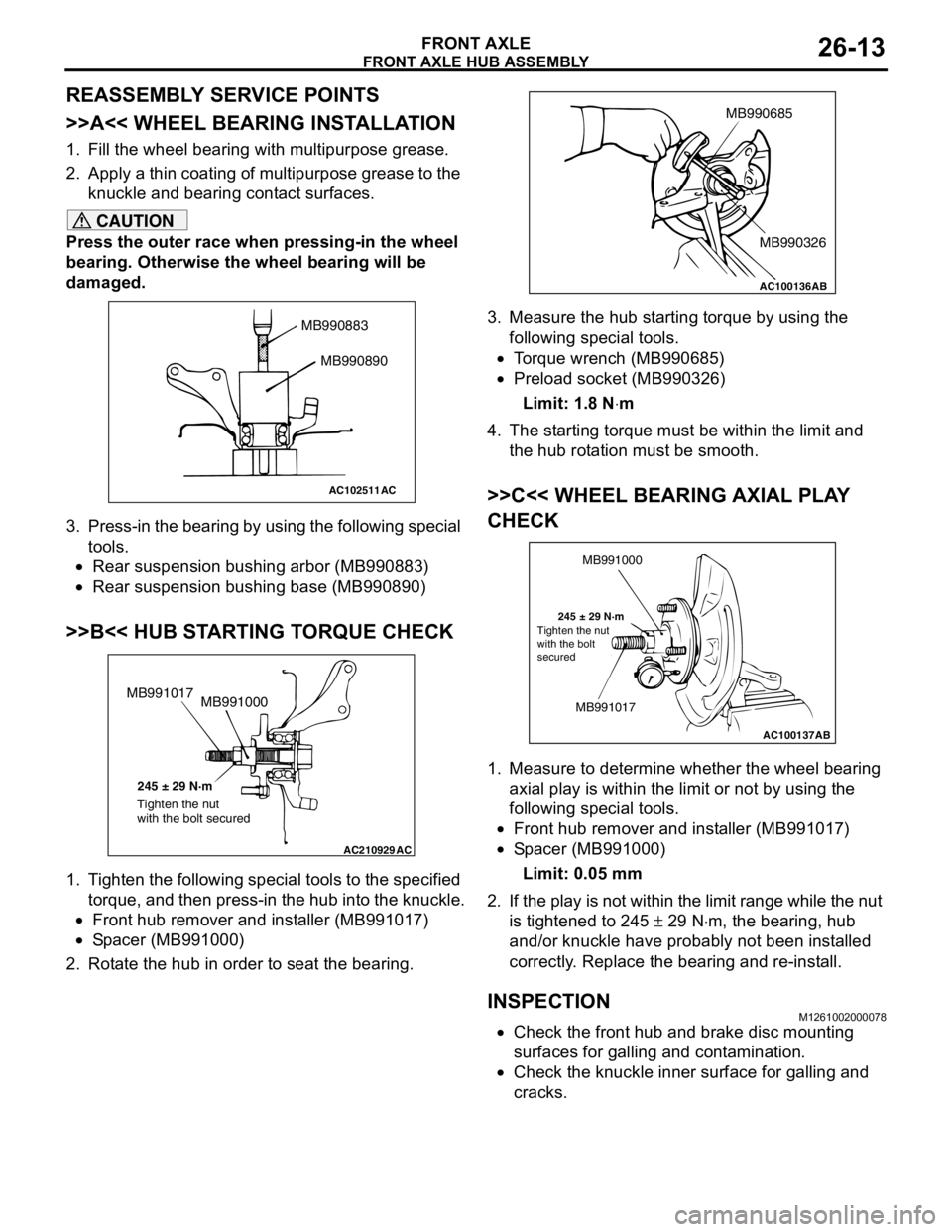

>>A<< WHEEL BEARING INSTALLATION

1. Fill the wheel bearing with multipurpose grease.

2. Apply a thin coating of multipurpose grease to the

knuckle and bearing contact surfaces.

CAUTION

Press the outer race when pressing-in the wheel

bearing. Otherwise the wheel bearing will be

damaged.

3. Press-in the bearing by using the following special

tools.

•Rear suspension bushing arbor (MB990883)

•Rear suspension bushing base (MB990890)

>>B<< HUB STARTING TORQUE CHECK

1. Tighten the following special tools to the specified

torque, and then press-in the hub into the knuckle.

•Front hub remover and installer (MB991017)

•Spacer (MB991000)

2. Rotate the hub in order to seat the bearing.3. Measure the hub starting torque by using the

following special tools.

•Torque wrench (MB990685)

•Preload socket (MB990326)

Limit: 1.8 N⋅m

4. The starting torque must be within the limit and

the hub rotation must be smooth.

>>C<< WHEEL BEARING AXIAL PLAY

CHECK

1. Measure to determine whether the wheel bearing

axial play is within the limit or not by using the

following special tools.

•Front hub remover and installer (MB991017)

•Spacer (MB991000)

Limit: 0.05 mm

2. If the play is not within the limit range while the nut

is tightened to 245 ± 29 N⋅m, the bearing, hub

and/or knuckle have probably not been installed

correctly. Replace the bearing and re-install.

INSPECTIONM1261002000078

•Check the front hub and brake disc mounting

surfaces for galling and contamination.

•Check the knuckle inner surface for galling and

cracks.

AC102511

MB990883

MB990890

AC

AC210929AC

MB991000 MB991017

245 ± 29 N·m

Tighten the nut

with the bolt secured

AC100136

MB990685

MB990326

AB

AC100137

MB991000

MB991017

245 ± 29 N·m

AB Tighten the nut

with the bolt

secured

Page 157 of 788

27-1

GROUP 27

REAR AXLE

CONTENTS

GENERAL INFORMATION . . . . . . . .27-2

SERVICE SPECIFICATIONS . . . . . . .27-2

SEALANT . . . . . . . . . . . . . . . . . . . . . .27-2

SPECIAL TOOLS . . . . . . . . . . . . . . . .27-3ON-VEHICLE SERVICE . . . . . . . . . . .27-4

WHEEL BEARING AXIAL PLAY CHECK . . 27-4

REAR HUB ROTARY-SLIDING

RESISTANCE CHECK . . . . . . . . . . . . . . . . 27-4

HUB BOLT REPLACEMENT . . . . . . . . . . . . 27-4

REAR AXLE HUB ASSEMBLY . . . . .27-5

REMOVAL AND INSTALLATION . . . . . . . . 27-5

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 27-6