rear MITSUBISHI LANCER 2005 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 179 of 788

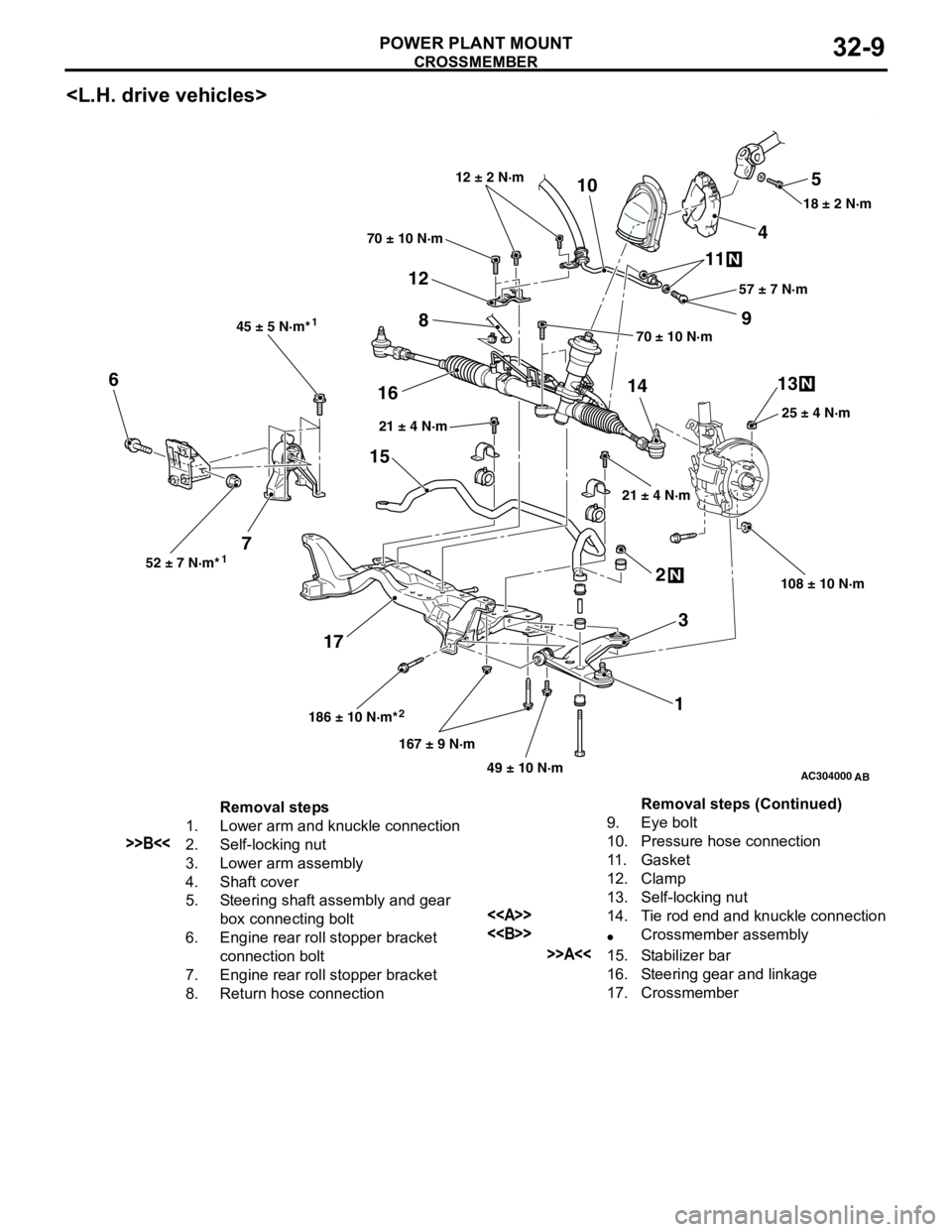

CROSSMEMBER

POWER PLANT MOUNT32-9

AC304000

108 ± 10 N·m 25 ± 4 N·m 18 ± 2 N·m

70 ± 10 N·m

21 ± 4 N·m 21 ± 4 N·m

186 ± 10 N·m*

167 ± 9 N·m

49 ± 10 N·m 52 ± 7 N·m*45 ± 5 N·m*

70 ± 10 N·m57 ± 7 N·m 12 ± 2 N·m

5

4 10

9 11

8

12

1413 6

716

15

172

3

1

N

N

N

2 11

AB

Removal steps

1. Lower arm and knuckle connection

>>B<<2. Self-locking nut

3. Lower arm assembly

4. Shaft cover

5. Steering shaft assembly and gear

box connecting bolt

6. Engine rear roll stopper bracket

connection bolt

7. Engine rear roll stopper bracket

8. Return hose connection9. Eye bolt

10. Pressure hose connection

11. Gasket

12. Clamp

13. Self-locking nut

<>14. Tie rod end and knuckle connection

<>•Crossmember assembly

>>A<<15. Stabilizer bar

16. Steering gear and linkage

17. CrossmemberRemoval steps (Continued)

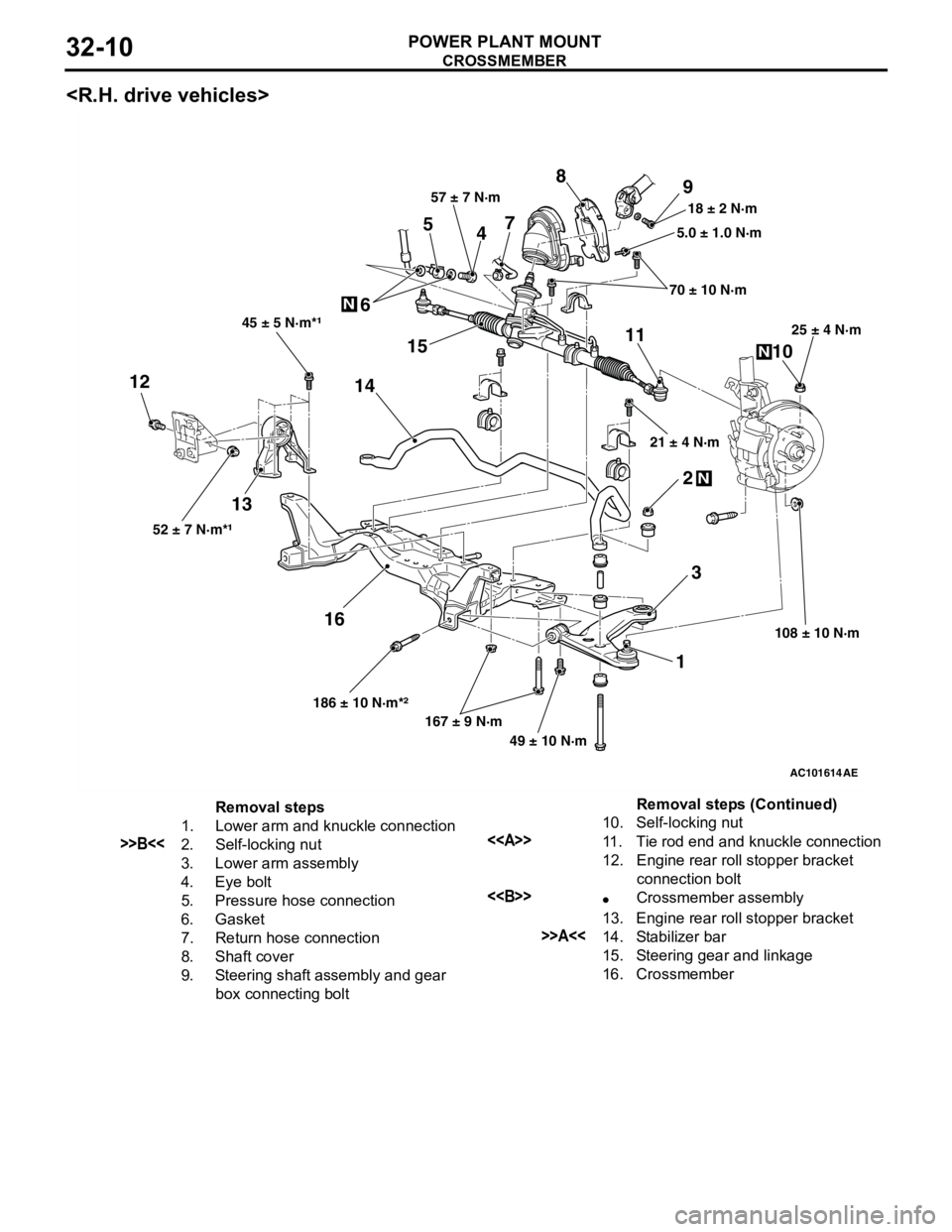

Page 180 of 788

CROSSMEMBER

POWER PLANT MOUNT32-10

AC101614

12

3 4 5

678

9

10 11

12

131415

16

45 ± 5 N·m*¹

52 ± 7 N·m*¹

186 ± 10 N·m*²

167 ± 9 N·m

49 ± 10 N·m108 ± 10 N·m 25 ± 4 N·m

21 ± 4 N·m 70 ± 10 N·m 5.0 ± 1.0 N·m 18 ± 2 N·m 57 ± 7 N·m

N

N

N

AE

Removal steps

1. Lower arm and knuckle connection

>>B<<2. Self-locking nut

3. Lower arm assembly

4. Eye bolt

5. Pressure hose connection

6. Gasket

7. Return hose connection

8. Shaft cover

9. Steering shaft assembly and gear

box connecting bolt10. Self-locking nut<>11. Tie rod end and knuckle connection

12. Engine rear roll stopper bracket

connection bolt

<>•Crossmember assembly

13. Engine rear roll stopper bracket

>>A<<14. Stabilizer bar

15. Steering gear and linkage

16. CrossmemberRemoval steps (Continued)

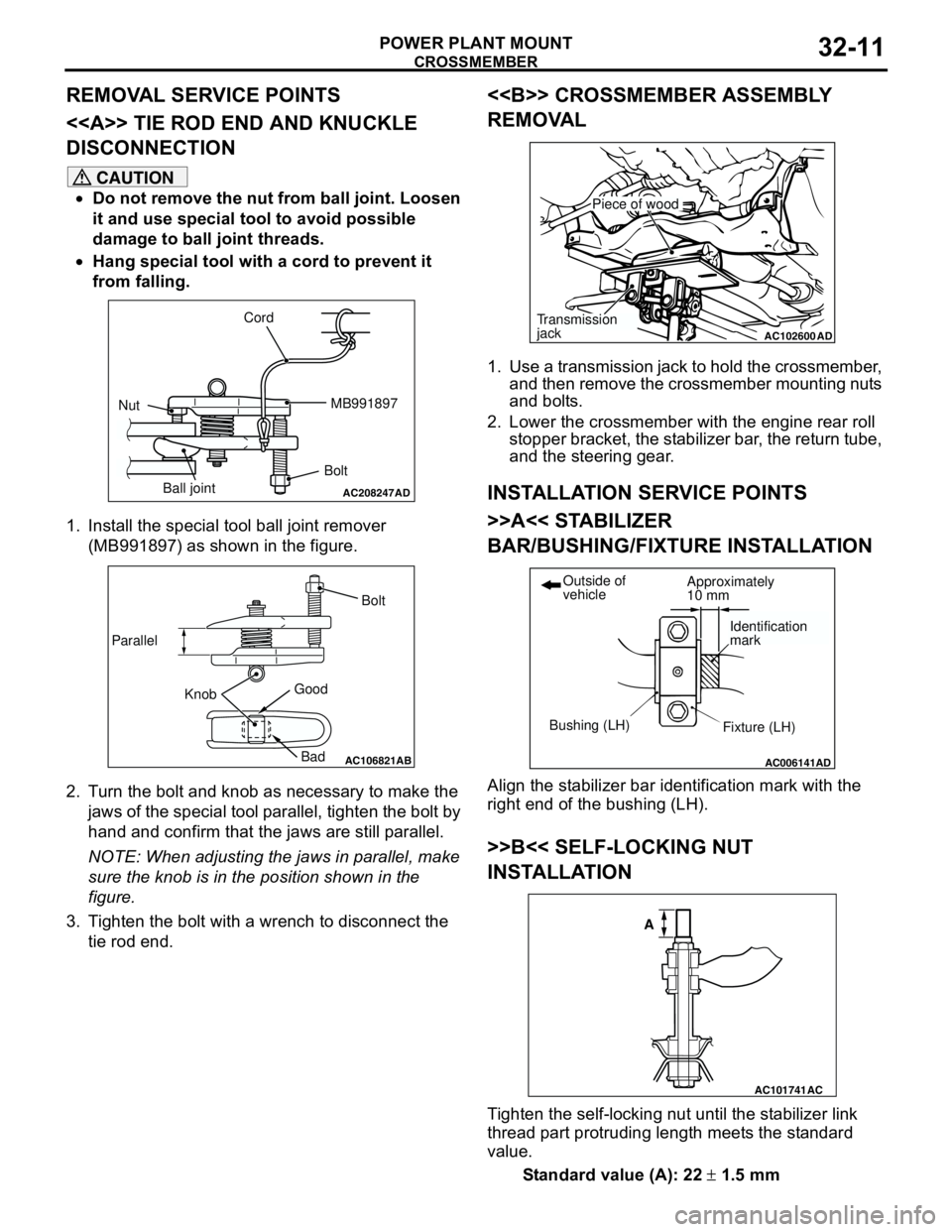

Page 181 of 788

Page 183 of 788

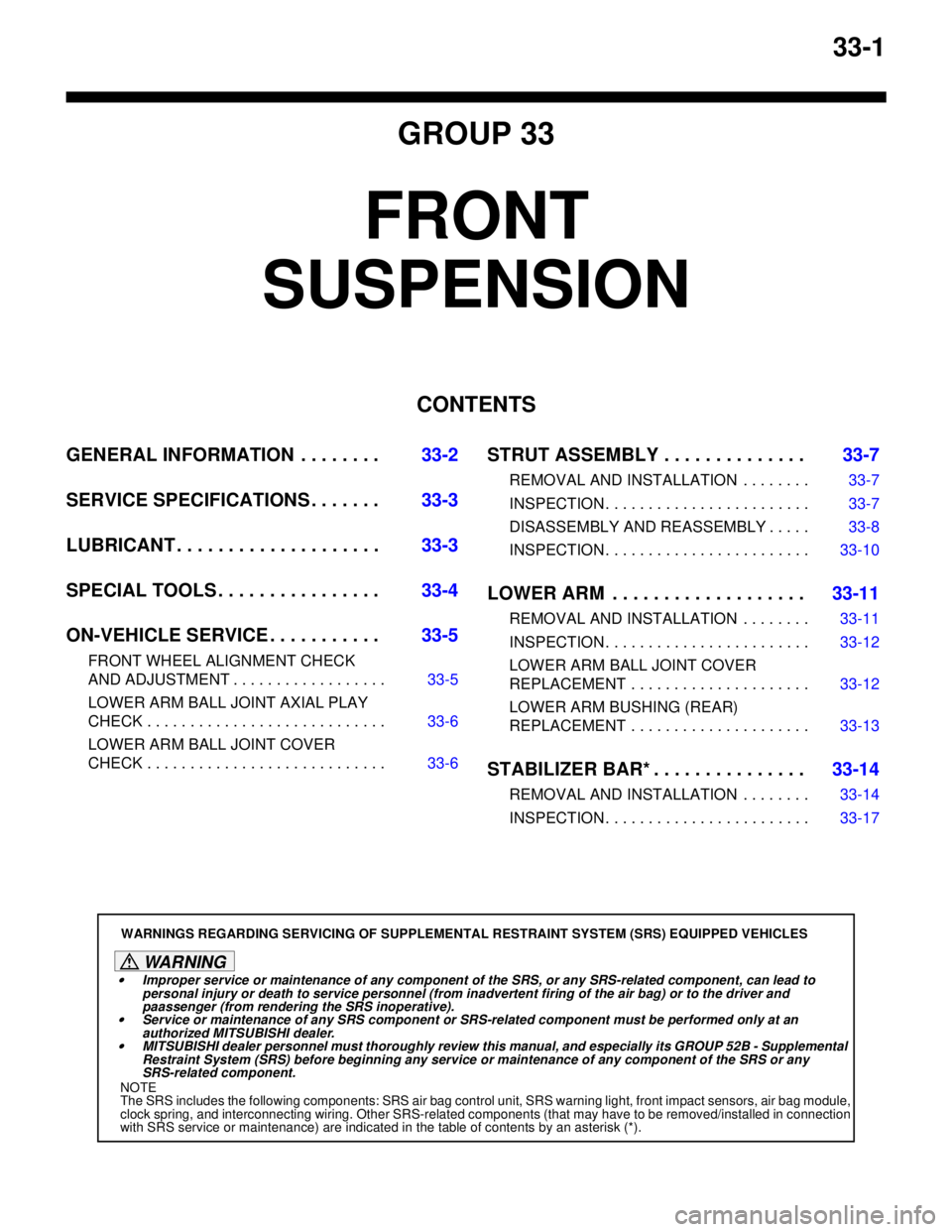

33-1

GROUP 33

FRONT

SUSPENSION

CONTENTS

GENERAL INFORMATION . . . . . . . .33-2

SERVICE SPECIFICATIONS . . . . . . .33-3

LUBRICANT . . . . . . . . . . . . . . . . . . . .33-3

SPECIAL TOOLS . . . . . . . . . . . . . . . .33-4

ON-VEHICLE SERVICE . . . . . . . . . . .33-5

FRONT WHEEL ALIGNMENT CHECK

AND ADJUSTMENT . . . . . . . . . . . . . . . . . . 33-5

LOWER ARM BALL JOINT AXIAL PLAY

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33-6

LOWER ARM BALL JOINT COVER

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33-6

STRUT ASSEMBLY . . . . . . . . . . . . . .33-7

REMOVAL AND INSTALLATION . . . . . . . . 33-7

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 33-7

DISASSEMBLY AND REASSEMBLY . . . . . 33-8

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 33-10

LOWER ARM . . . . . . . . . . . . . . . . . . .33-11

REMOVAL AND INSTALLATION . . . . . . . . 33-11

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 33-12

LOWER ARM BALL JOINT COVER

REPLACEMENT . . . . . . . . . . . . . . . . . . . . . 33-12

LOWER ARM BUSHING (REAR)

REPLACEMENT . . . . . . . . . . . . . . . . . . . . . 33-13

STABILIZER BAR* . . . . . . . . . . . . . . .33-14

REMOVAL AND INSTALLATION . . . . . . . . 33-14

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 33-17

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES

WARNING

•Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to

personal injury or death to service personnel (from inadvertent firing of the air bag) or to the driver and

paassenger (from rendering the SRS inoperative).

•Service or maintenance of any SRS component or SRS-related component must be performed only at an

authorized MITSUBISHI dealer.

•MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B - Supplemental

Restraint System (SRS) before beginning any service or maintenance of any component of the SRS or any

SRS-related component.

NOTE

The SRS includes the following components: SRS air bag control unit, SRS warning light, front impact sensors, air bag module,

clock spring, and interconnecting wiring. Other SRS-related components (that may have to be removed/installed in connection

with SRS service or maintenance) are indicated in the table of contents by an asterisk (*).

Page 187 of 788

ON-VEHICLE SERVICE

FRONT SUSPENSION33-5

ON-VEHICLE SERVICE

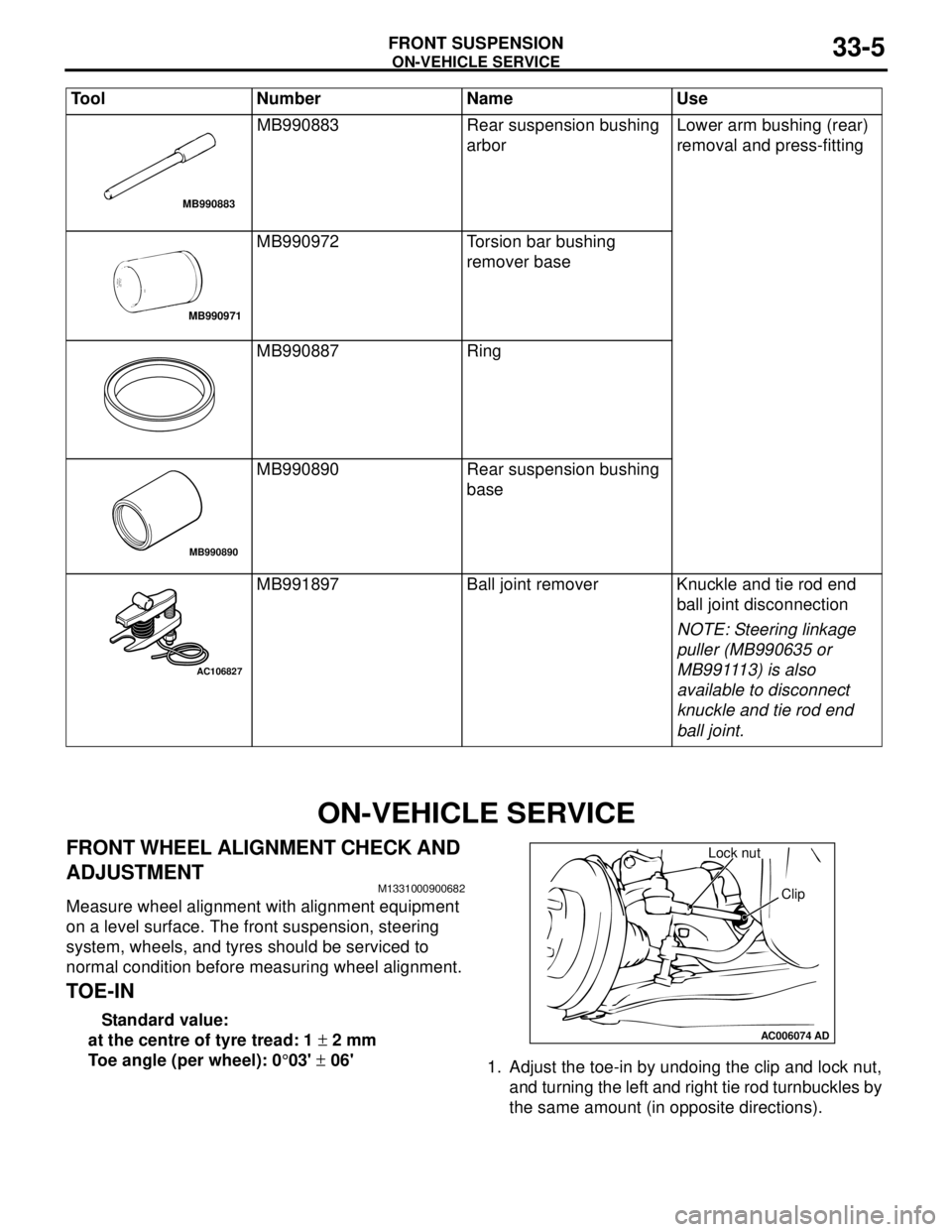

FRONT WHEEL ALIGNMENT CHECK AND

ADJUSTMENT

M1331000900682

Measure wheel alignment with alignment equipment

on a level surface. The front suspension, steering

system, wheels, and tyres should be serviced to

normal condition before measuring wheel alignment.

TOE-IN

Standard value:

at the centre of tyre tread: 1 ± 2 mm

Toe angle (per wheel): 0°03' ± 06'

1. Adjust the toe-in by undoing the clip and lock nut,

and turning the left and right tie rod turnbuckles by

the same amount (in opposite directions). MB990883 Rear suspension bushing

arborLower arm bushing (rear)

removal and press-fitting

MB990972 Torsion bar bushing

remover base

MB990887 Ring

MB990890 Rear suspension bushing

base

MB991897 Ball joint remover Knuckle and tie rod end

ball joint disconnection

NOTE: Steering linkage

puller (MB990635 or

MB991113) is also

available to disconnect

knuckle and tie rod end

ball joint. Tool Number Name Use

MB990883

MB990971

MB990890

AC106827

AC006074AD

Lock nut

Clip

Page 188 of 788

ON-VEHICLE SERVICE

FRONT SUSPENSION33-6

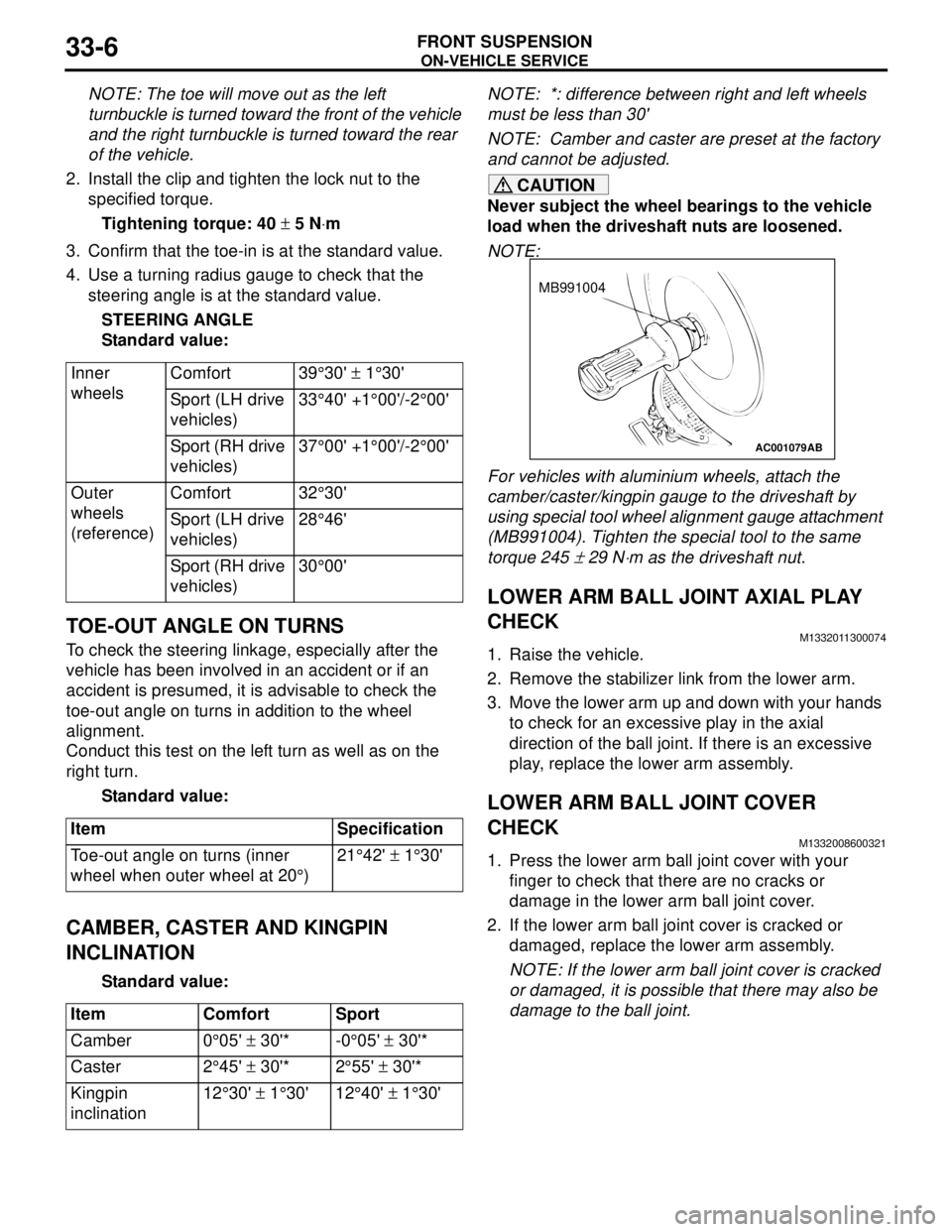

NOTE: The toe will move out as the left

turnbuckle is turned toward the front of the vehicle

and the right turnbuckle is turned toward the rear

of the vehicle.

2. Install the clip and tighten the lock nut to the

specified torque.

Tightening torque: 40 ± 5 N⋅m

3. Confirm that the toe-in is at the standard value.

4. Use a turning radius gauge to check that the

steering angle is at the standard value.

STEERING ANGLE

Standard value:

TOE-OUT ANGLE ON TURNS

To check the steering linkage, especially after the

vehicle has been involved in an accident or if an

accident is presumed, it is advisable to check the

toe-out angle on turns in addition to the wheel

alignment.

Conduct this test on the left turn as well as on the

right turn.

Standard value:

CAMBER, CASTER AND KINGPIN

INCLINATION

Standard value:NOTE: *: difference between right and left wheels

must be less than 30'

NOTE: Camber and caster are preset at the factory

and cannot be adjusted.

CAUTION

Never subject the wheel bearings to the vehicle

load when the driveshaft nuts are loosened.

NOTE:

For vehicles with aluminium wheels, attach the

camber/caster/kingpin gauge to the driveshaft by

using special tool wheel alignment gauge attachment

(MB991004). Tighten the special tool to the same

torque 245

± 29 N⋅m as the driveshaft nut.

LOWER ARM BALL JOINT AXIAL PLAY

CHECK

M1332011300074

1. Raise the vehicle.

2. Remove the stabilizer link from the lower arm.

3. Move the lower arm up and down with your hands

to check for an excessive play in the axial

direction of the ball joint. If there is an excessive

play, replace the lower arm assembly.

LOWER ARM BALL JOINT COVER

CHECK

M1332008600321

1. Press the lower arm ball joint cover with your

finger to check that there are no cracks or

damage in the lower arm ball joint cover.

2. If the lower arm ball joint cover is cracked or

damaged, replace the lower arm assembly.

NOTE: If the lower arm ball joint cover is cracked

or damaged, it is possible that there may also be

damage to the ball joint. Inner

wheelsComfort 39°30' ± 1°30'

Sport (LH drive

vehicles)33°40' +1°00'/-2°00'

Sport (RH drive

vehicles)37°00' +1°00'/-2°00'

Outer

wheels

(reference)Comfort 32°30'

Sport (LH drive

vehicles)28°46'

Sport (RH drive

vehicles)30°00'

Item Specification

Toe-out angle on turns (inner

wheel when outer wheel at 20°)21°42' ± 1°30'

Item Comfort Sport

Camber 0°05' ± 30'* -0°05' ± 30'*

Caster 2°45' ± 30'* 2°55' ± 30'*

Kingpin

inclination12°30' ± 1°30' 12°40' ± 1°30'

AC001079

MB991004

AB

Page 195 of 788

LOWER ARM

FRONT SUSPENSION33-13

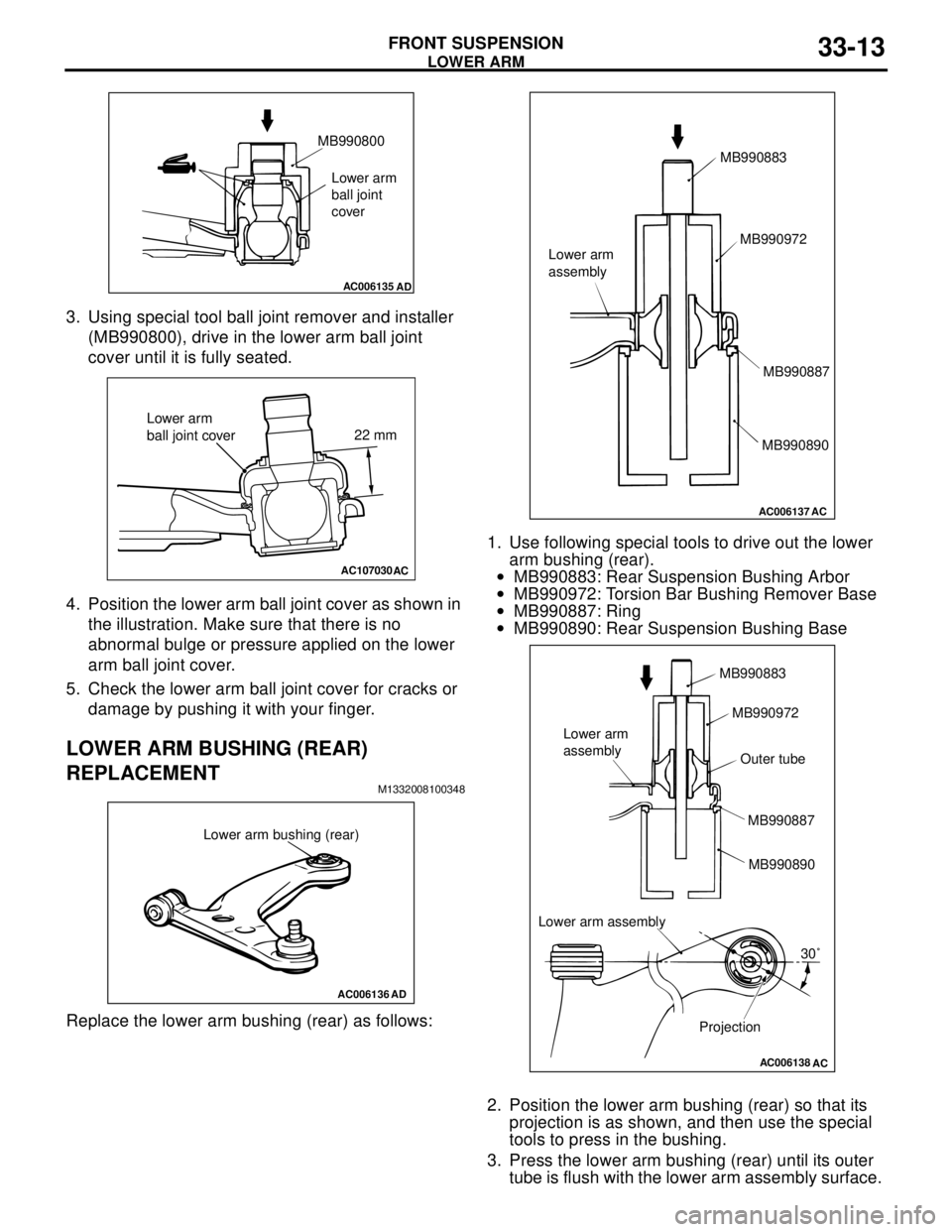

3. Using special tool ball joint remover and installer

(MB990800), drive in the lower arm ball joint

cover until it is fully seated.

4. Position the lower arm ball joint cover as shown in

the illustration. Make sure that there is no

abnormal bulge or pressure applied on the lower

arm ball joint cover.

5. Check the lower arm ball joint cover for cracks or

damage by pushing it with your finger.

LOWER ARM BUSHING (REAR)

REPLACEMENT

M1332008100348

Replace the lower arm bushing (rear) as follows:1. Use following special tools to drive out the lower

arm bushing (rear).

•MB990883: Rear Suspension Bushing Arbor

•MB990972: Torsion Bar Bushing Remover Base

•MB990887: Ring

•MB990890: Rear Suspension Bushing Base

2. Position the lower arm bushing (rear) so that its

projection is as shown, and then use the special

tools to press in the bushing.

3. Press the lower arm bushing (rear) until its outer

tube is flush with the lower arm assembly surface.

AC006135

AD

MB990800

Lower arm

ball joint

cover

AC107030AC

22 mm

Lower arm

ball joint cover

AC006136

AD

Lower arm bushing (rear)

AC006137

AC

MB990883

MB990972

MB990887

MB990890 Lower arm

assembly

AC006138

AC

MB990883

MB990972

MB990887

MB990890 Lower arm

assembly

Projection30˚ Lower arm assemblyOuter tube

Page 197 of 788

STABILIZER BAR

FRONT SUSPENSION33-15

AC006139

AD

49 ± 10 N·m

108 ± 10 N·m

167 ± 9 N·m 167 ± 9 N·m 52 ± 7 N·m*25 ± 5 N·m 21 ± 4 N·m 18 ± 2 N·m

7 6

9

10

1

2

2 3

5

4 2 11

8

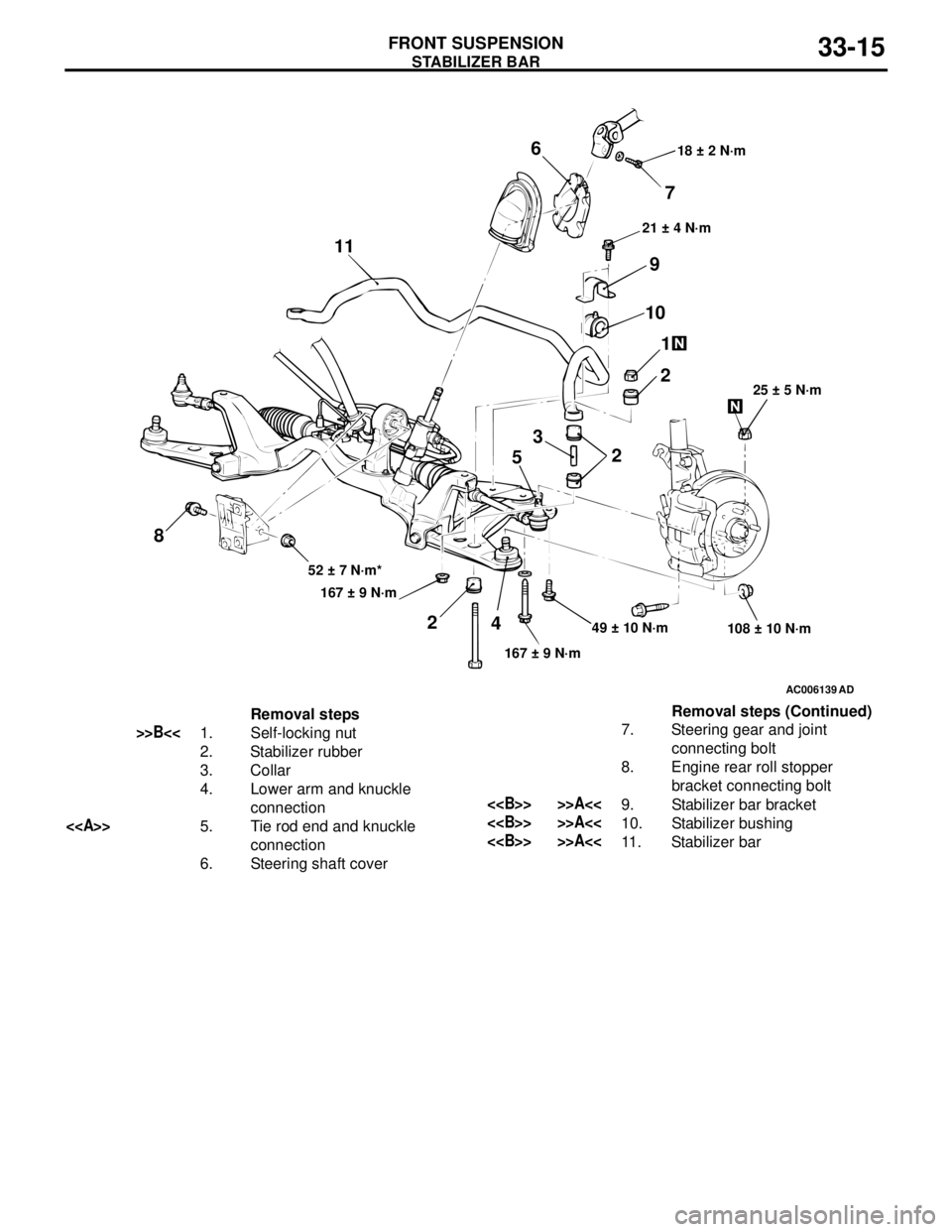

Removal steps

>>B<<1. Self-locking nut

2. Stabilizer rubber

3. Collar

4. Lower arm and knuckle

connection

<>5. Tie rod end and knuckle

connection

6. Steering shaft cover7. Steering gear and joint

connecting bolt

8. Engine rear roll stopper

bracket connecting bolt

<> >>A<<9. Stabilizer bar bracket

<> >>A<<10. Stabilizer bushing

<> >>A<<11. Stabilizer barRemoval steps (Continued)

Page 201 of 788

34-1

GROUP 34

REAR SUSPENSION

CONTENTS

GENERAL INFORMATION . . . . . . . .34-2

SERVICE SPECIFICATIONS . . . . . . .34-3

LUBRICANT . . . . . . . . . . . . . . . . . . . .34-3

SPECIAL TOOLS . . . . . . . . . . . . . . . .34-4

ON-VEHICLE SERVICE . . . . . . . . . . .34-5

REAR WHEEL ALIGNMENT CHECK

AND ADJUSTMENT . . . . . . . . . . . . . . . . . . 34-5

CONTROL LINK PILLOW BALL BUSHING

AXIAL PLAY CHECK

UPPER ARM PILLOW BALL BUSHING

AXIAL PLAY CHECK

LOWER ARM PILLOW BALL BUSHING

AXIAL PLAY CHECK . . . . . . . . . . . . . . . . . 34-7

STABILIZER LINK BALL JOINT

DUST COVER INSPECTION . . . . . . . . . . . 34-7

CONTROL LINK, UPPER ARM AND

LOWER ARM . . . . . . . . . . . . . . . . . . .34-8

REMOVAL AND INSTALLATION . . . . . . . . 34-8

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 34-9

LOWER ARM BUSHING AND LOWER

ARM PILLOW BALL BUSHING

REPLACEMENT . . . . . . . . . . . . . . . . . . . . . 34-10

TRAILING ARM ASSEMBLY . . . . . . .34-12

REMOVAL AND INSTALLATION . . . . . . . . 34-12

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 34-13

TRAILING ARM BUSHING

REPLACEMENT . . . . . . . . . . . . . . . . . . . . . 34-13

SHOCK ABSORBER ASSEMBLY . . .34-15

REMOVAL AND INSTALLATION . . . . . . . . 34-15

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 34-16

DISASSEMBLY AND REASSEMBLY . . . . . 34-17

STABILIZER BAR. . . . . . . . . . . . . . . .34-20

REMOVAL AND INSTALLATION . . . . . . . . 34-20

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 34-21

STABILIZER LINK BALL JOINT

DUST COVER REPLACEMENT . . . . . . . . . 34-21

Page 202 of 788

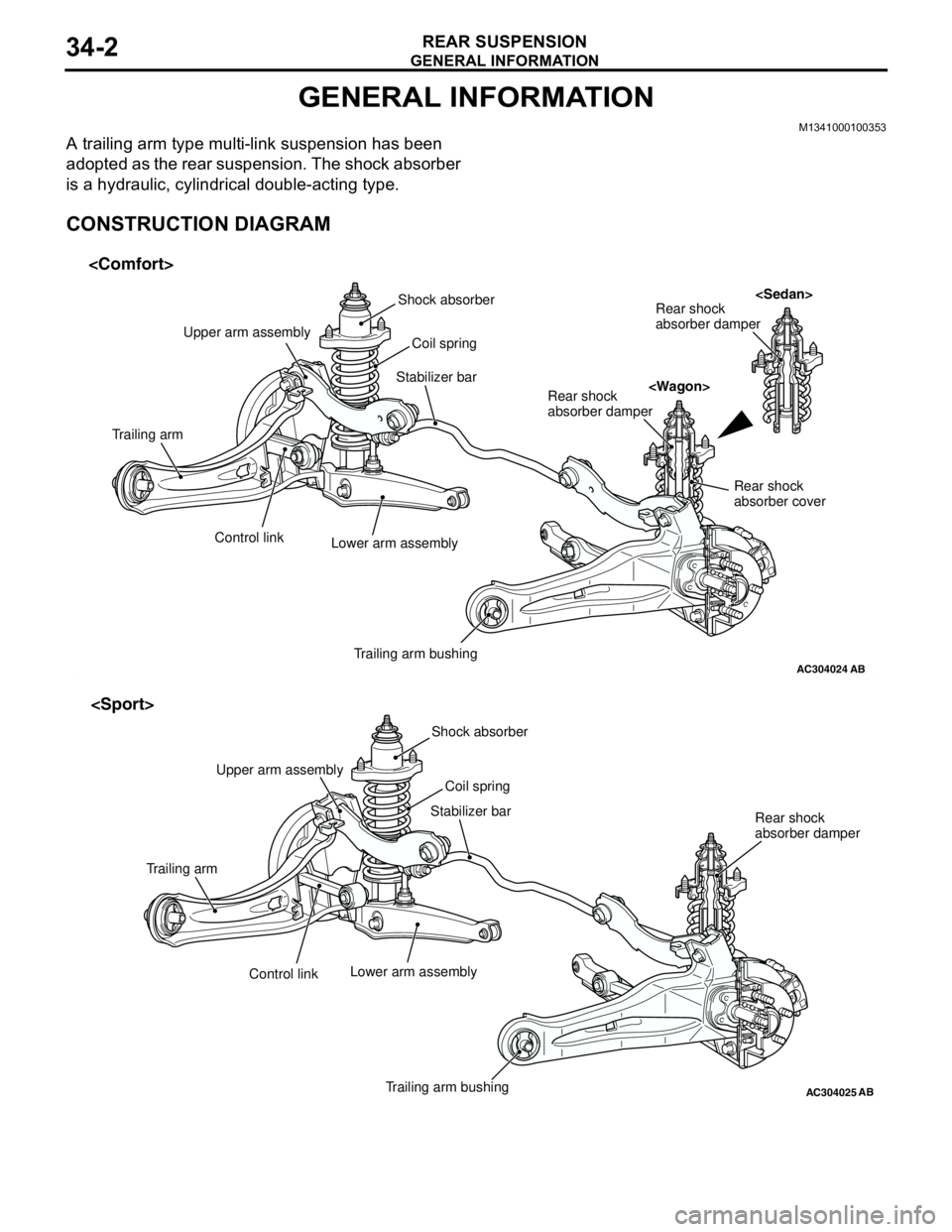

GENERAL INFORMATION

REAR SUSPENSION34-2

GENERAL INFORMATION

M1341000100353

A trailing arm type multi-link suspension has been

adopted as the rear suspension. The shock absorber

is a hydraulic, cylindrical double-acting type.

CONSTRUCTION DIAGRAM

AC304024AB

Shock absorber

Coil spring

Trailing arm bushing Lower arm assembly Control link Trailing armUpper arm assembly

Stabilizer barRear shock

absorber damper

Rear shock

absorber damper

Rear shock

absorber cover

AC304025AB

Shock absorber

Trailing arm bushing Control link Trailing armStabilizer bar

Coil spring

Lower arm assembly

Rear shock

absorber damper Upper arm assembly