throttle body MITSUBISHI LANCER 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 45 of 788

WATER HOSE AND WATER PIPE

ENGINE COOLING14-31

WATER HOSE AND WATER PIPE

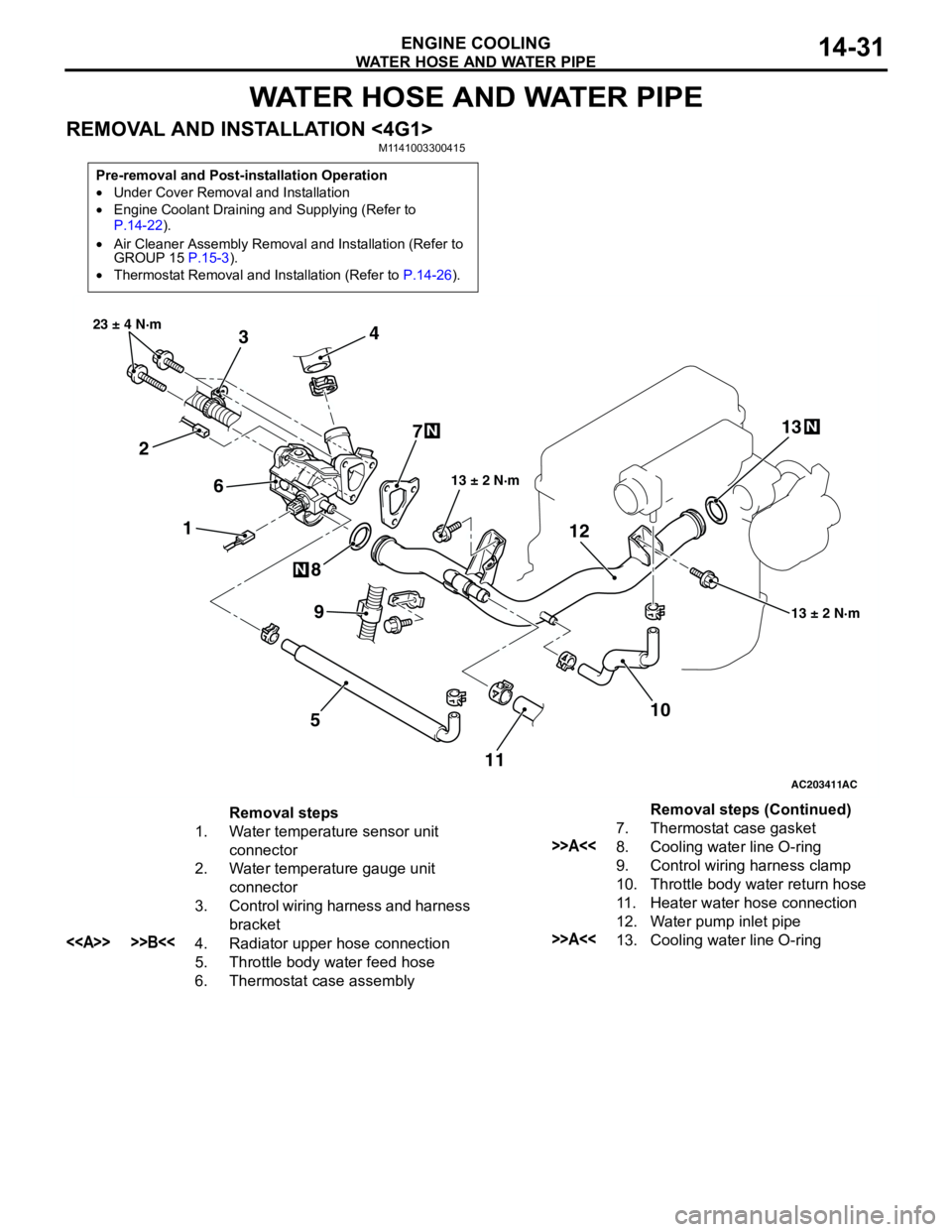

REMOVAL AND INSTALLATION <4G1>M1141003300415

Pre-removal and Post-installation Operation

•Under Cover Removal and Installation

•Engine Coolant Draining and Supplying (Refer to

P.14-22).

•Air Cleaner Assembly Removal and Installation (Refer to

GROUP 15 P.15-3).

•Thermostat Removal and Installation (Refer to P.14-26).

AC203411

1 234

5 67

8

10 9

13 ± 2 N·m 23 ± 4 N·m

13 ± 2 N·m

N

N

AC

111213

N

Removal steps

1. Water temperature sensor unit

connector

2. Water temperature gauge unit

connector

3. Control wiring harness and harness

bracket

<> >>B<<4. Radiator upper hose connection

5. Throttle body water feed hose

6. Thermostat case assembly7. Thermostat case gasket

>>A<<8. Cooling water line O-ring

9. Control wiring harness clamp

10. Throttle body water return hose

11. Heater water hose connection

12. Water pump inlet pipe

>>A<<13. Cooling water line O-ringRemoval steps (Continued)

Page 47 of 788

WATER HOSE AND WATER PIPE

ENGINE COOLING14-33

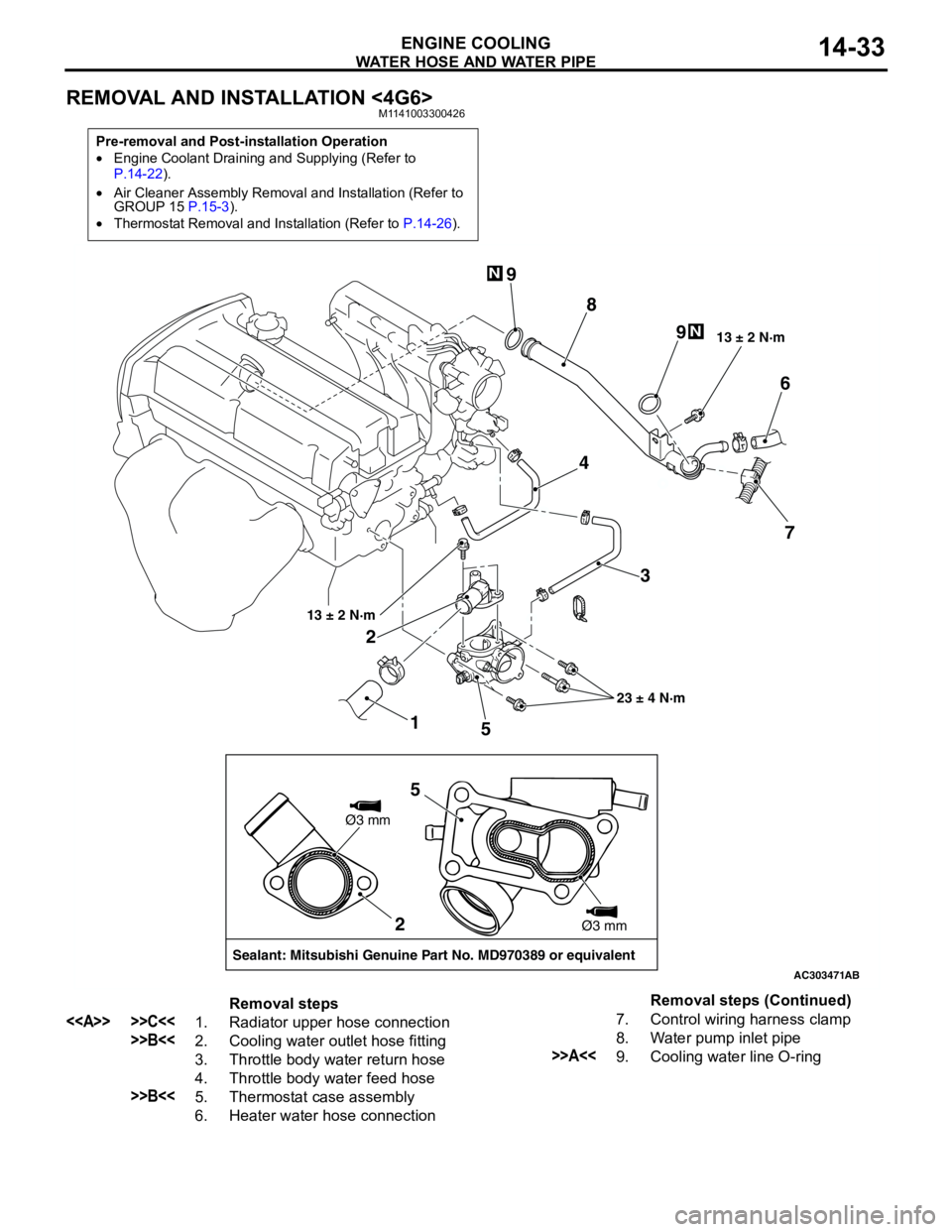

REMOVAL AND INSTALLATION <4G6>M1141003300426

Pre-removal and Post-installation Operation

•Engine Coolant Draining and Supplying (Refer to

P.14-22).

•Air Cleaner Assembly Removal and Installation (Refer to

GROUP 15 P.15-3).

•Thermostat Removal and Installation (Refer to P.14-26).

AC303471

1 23 4

56

7 8 9

9

13 ± 2 N·m

23 ± 4 N·m 13 ± 2 N·m

N

N

AB

2

Sealant: Mitsubishi Genuine Part No. MD970389 or equivalentØ3 mm

Ø3 mm

5

Removal steps

<> >>C<<1. Radiator upper hose connection

>>B<<2. Cooling water outlet hose fitting

3. Throttle body water return hose

4. Throttle body water feed hose

>>B<<5. Thermostat case assembly

6. Heater water hose connection7. Control wiring harness clamp

8. Water pump inlet pipe

>>A<<9. Cooling water line O-ringRemoval steps (Continued)

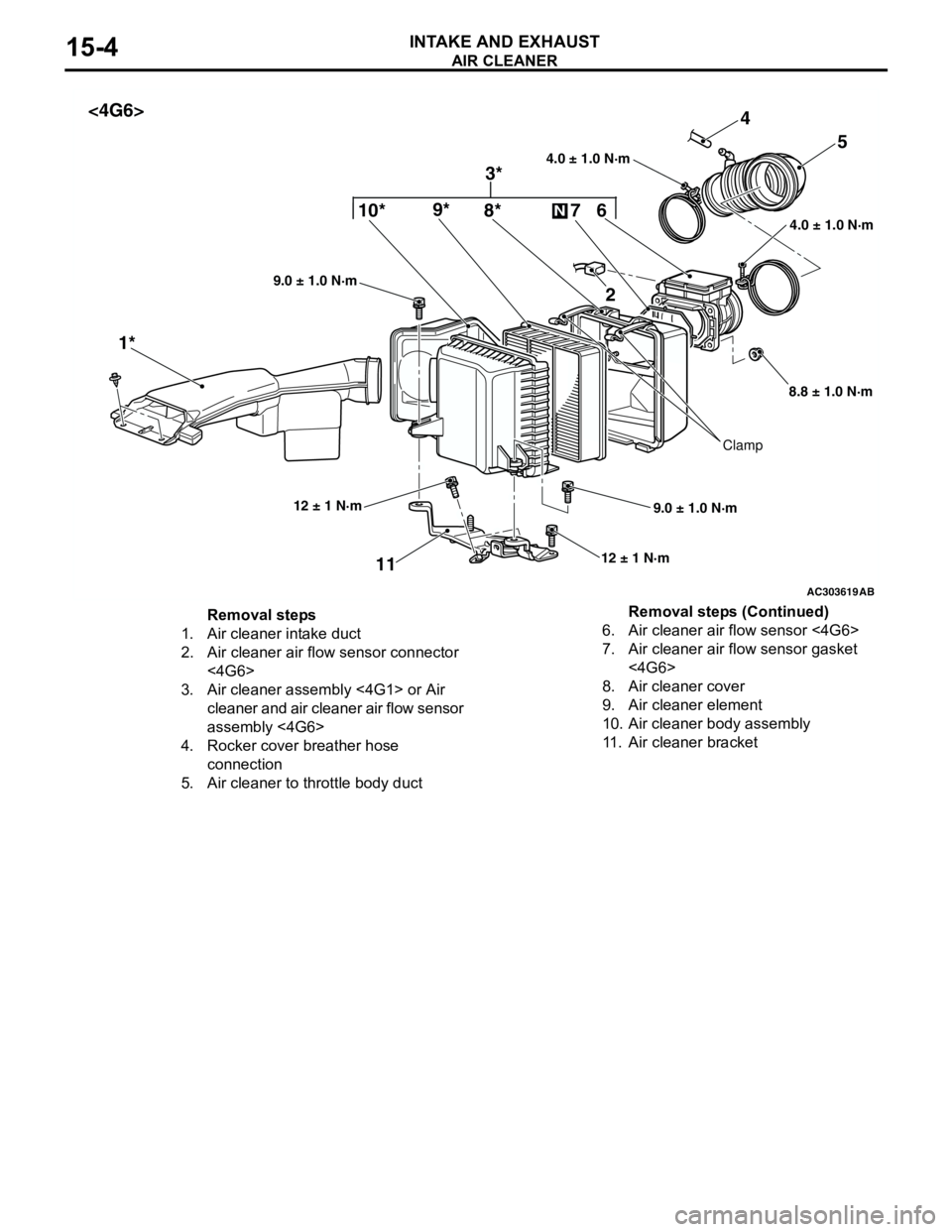

Page 48 of 788

Page 56 of 788

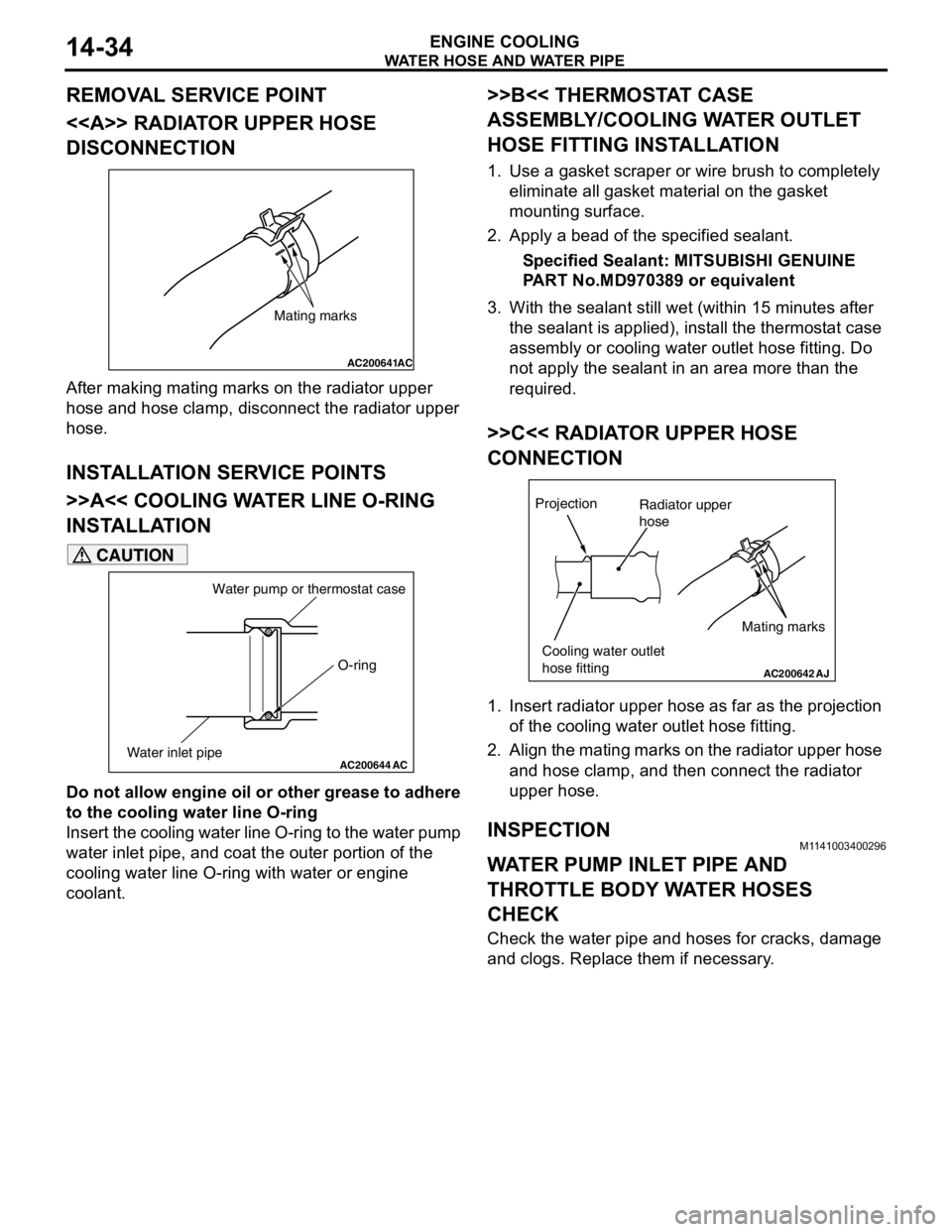

AIR CLEANER

INTAKE AND EXHAUST15-4

AC303619

4.0 ± 1.0 N·m 4.0 ± 1.0 N·m10*9*4

1*5

11

12 ± 1 N·m

9.0 ± 1.0 N·m 9.0 ± 1.0 N·m

AB

12 ± 1 N·m

Clamp

8*

3* <4G6>

6 7

N

2

8.8 ± 1.0 N·m

Removal steps

1. Air cleaner intake duct

2. Air cleaner air flow sensor connector

<4G6>

3. Air cleaner assembly <4G1> or Air

cleaner and air cleaner air flow sensor

assembly <4G6>

4. Rocker cover breather hose

connection

5. Air cleaner to throttle body duct6. Air cleaner air flow sensor <4G6>

7. Air cleaner air flow sensor gasket

<4G6>

8. Air cleaner cover

9. Air cleaner element

10. Air cleaner body assembly

11. Air cleaner bracketRemoval steps (Continued)

Page 57 of 788

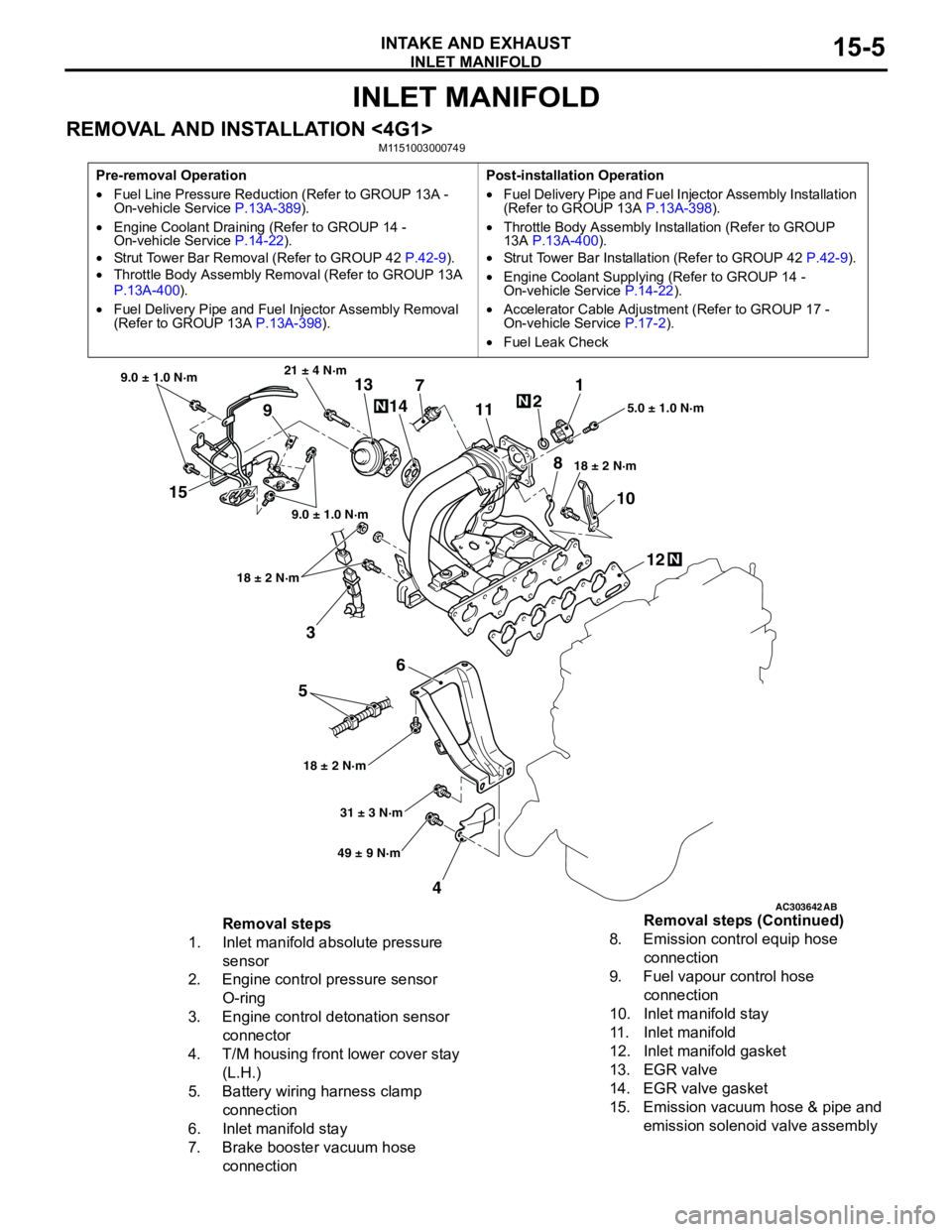

INLET MANIFOLD

INTAKE AND EXHAUST15-5

INLET MANIFOLD

REMOVAL AND INSTALLATION <4G1>M1151003000749

Pre-removal Operation

•Fuel Line Pressure Reduction (Refer to GROUP 13A -

On-vehicle Service P.13A-389).

•Engine Coolant Draining (Refer to GROUP 14 -

On-vehicle Service P.14-22).

•Strut Tower Bar Removal (Refer to GROUP 42 P.42-9).

•Throttle Body Assembly Removal (Refer to GROUP 13A

P.13A-400).

•Fuel Delivery Pipe and Fuel Injector Assembly Removal

(Refer to GROUP 13A P.13A-398).Post-installation Operation

•Fuel Delivery Pipe and Fuel Injector Assembly Installation

(Refer to GROUP 13A P.13A-398).

•Throttle Body Assembly Installation (Refer to GROUP

13A P.13A-400).

•Strut Tower Bar Installation (Refer to GROUP 42 P.42-9).

•Engine Coolant Supplying (Refer to GROUP 14 -

On-vehicle Service P.14-22).

•Accelerator Cable Adjustment (Refer to GROUP 17 -

On-vehicle Service P.17-2).

•Fuel Leak Check

AC303642AB

15

3

6

5

412 10 71

2

11

913

14

21 ± 4 N·m

9.0 ± 1.0 N·m

9.0 ± 1.0 N·m

18 ± 2 N·m

18 ± 2 N·m18 ± 2 N·m5.0 ± 1.0 N·m

31 ± 3 N·m

49 ± 9 N·m

N

N

N

8

Removal steps

1. Inlet manifold absolute pressure

sensor

2. Engine control pressure sensor

O-ring

3. Engine control detonation sensor

connector

4. T/M housing front lower cover stay

(L.H.)

5. Battery wiring harness clamp

connection

6. Inlet manifold stay

7. Brake booster vacuum hose

connection8. Emission control equip hose

connection

9. Fuel vapour control hose

connection

10. Inlet manifold stay

11. Inlet manifold

12. Inlet manifold gasket

13. EGR valve

14. EGR valve gasket

15. Emission vacuum hose & pipe and

emission solenoid valve assembly Removal steps (Continued)

Page 58 of 788

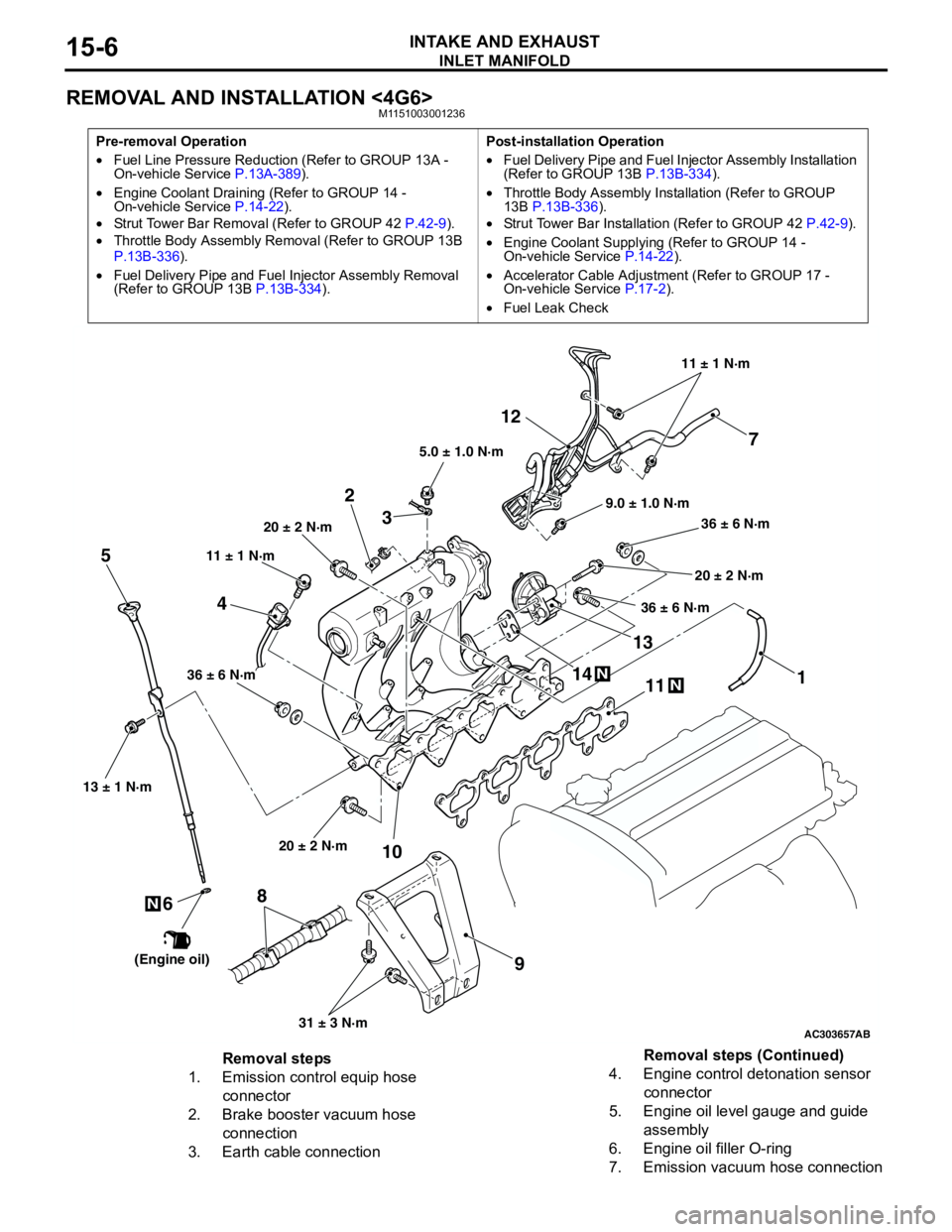

INLET MANIFOLD

INTAKE AND EXHAUST15-6

REMOVAL AND INSTALLATION <4G6>M1151003001236

Pre-removal Operation

•Fuel Line Pressure Reduction (Refer to GROUP 13A -

On-vehicle Service P.13A-389).

•Engine Coolant Draining (Refer to GROUP 14 -

On-vehicle Service P.14-22).

•Strut Tower Bar Removal (Refer to GROUP 42 P.42-9).

•Throttle Body Assembly Removal (Refer to GROUP 13B

P.13B-336).

•Fuel Delivery Pipe and Fuel Injector Assembly Removal

(Refer to GROUP 13B P.13B-334).Post-installation Operation

•Fuel Delivery Pipe and Fuel Injector Assembly Installation

(Refer to GROUP 13B P.13B-334).

•Throttle Body Assembly Installation (Refer to GROUP

13B P.13B-336).

•Strut Tower Bar Installation (Refer to GROUP 42 P.42-9).

•Engine Coolant Supplying (Refer to GROUP 14 -

On-vehicle Service P.14-22).

•Accelerator Cable Adjustment (Refer to GROUP 17 -

On-vehicle Service P.17-2).

•Fuel Leak Check

AC303657

9.0 ± 1.0 N·m11 ± 1 N·m

20 ± 2 N·m

31 ± 3 N·m 36 ± 6 N·m

20 ± 2 N·m

20 ± 2 N·m

36 ± 6 N·m

36 ± 6 N·m

11

9 10 212

N1413N

AB

5.0 ± 1.0 N·m

3

1

11 ± 1 N·m

4

N

13 ± 1 N·m

5

6

(Engine oil)

7

8

Removal steps

1. Emission control equip hose

connector

2. Brake booster vacuum hose

connection

3. Earth cable connection4. Engine control detonation sensor

connector

5. Engine oil level gauge and guide

assembly

6. Engine oil filler O-ring

7. Emission vacuum hose connectionRemoval steps (Continued)

Page 111 of 788

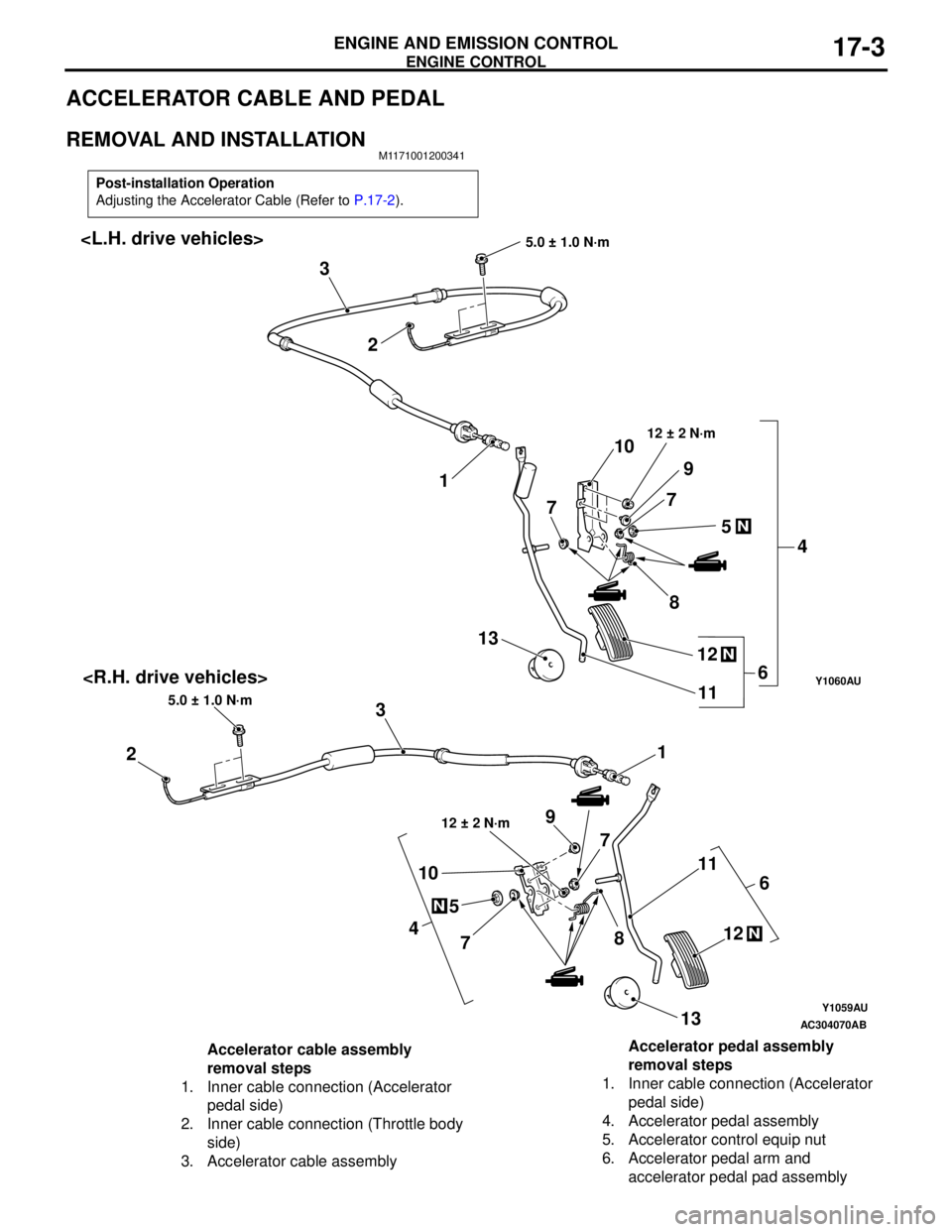

ENGINE CONTROL

ENGINE AND EMISSION CONTROL17-3

ACCELERATOR CABLE AND PEDAL

REMOVAL AND INSTALLATIONM1171001200341

Post-installation Operation

Adjusting the Accelerator Cable (Refer to P.17-2).

Y1059AU

Y1060AU

AC304070

N

4

5

78 1011

N12

13

AB

1

23

5.0 ± 1.0 N·m

6

12 ± 2 N·m9

7

1 2 3

5.0 ± 1.0 N·m

N

4 5 7

8 10

11

N12 13

6

12 ± 2 N·m

9

7

Accelerator cable assembly

removal steps

1. Inner cable connection (Accelerator

pedal side)

2. Inner cable connection (Throttle body

side)

3. Accelerator cable assemblyAccelerator pedal assembly

removal steps

1. Inner cable connection (Accelerator

pedal side)

4. Accelerator pedal assembly

5. Accelerator control equip nut

6. Accelerator pedal arm and

accelerator pedal pad assembly

Page 115 of 788

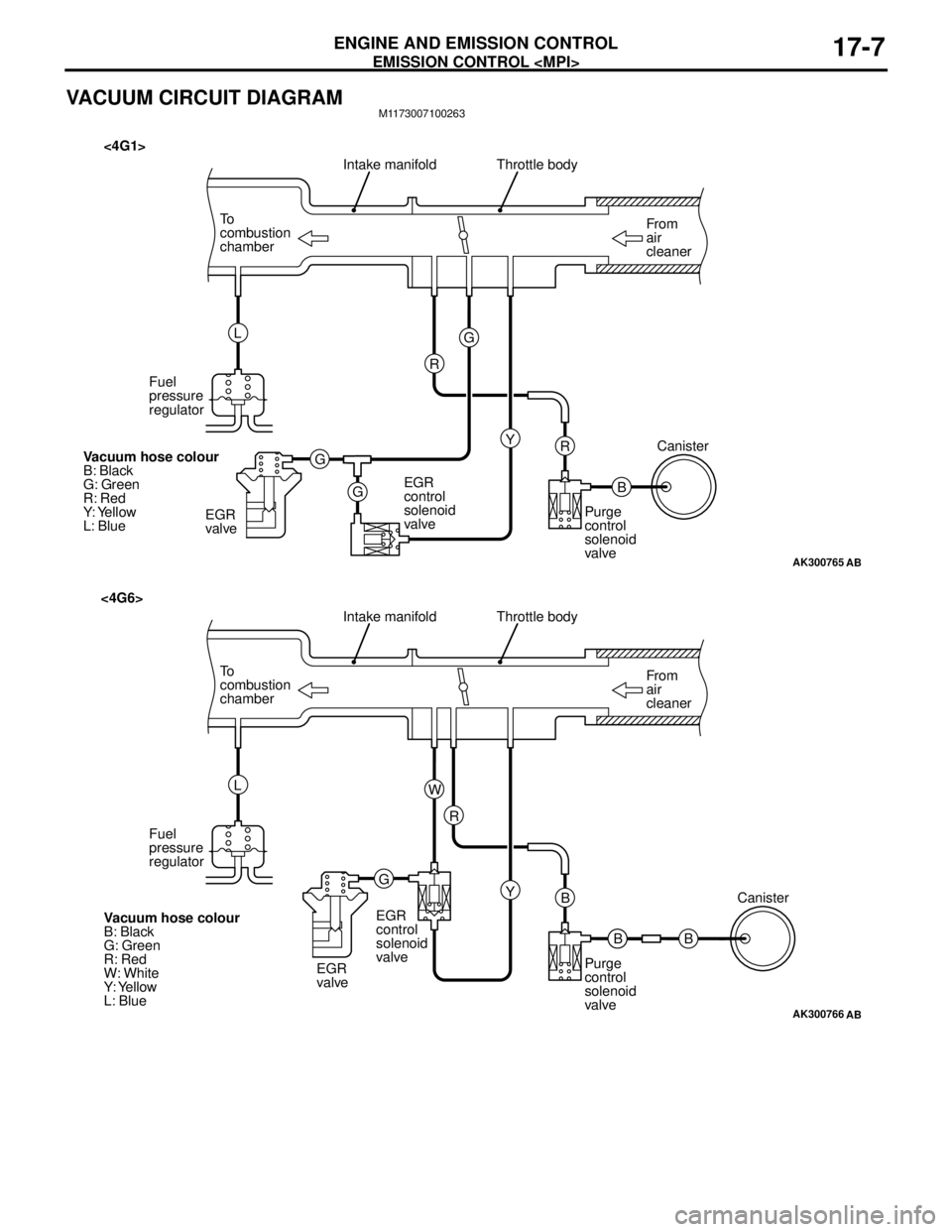

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-7

VACUUM CIRCUIT DIAGRAMM1173007100263

AK300765

From

air

cleaner To

combustion

chamberThrottle body

B R

AB

Intake manifold

Y G

G

GR L

Fuel

pressure

regulator

EGR

valveEGR

control

solenoid

valvePurge

control

solenoid

valveCanister

Vacuum hose colour

B: Black

G: Green

R: Red

Y: Yellow

L: Blue

<4G1>

AK300766

From

air

cleaner To

combustion

chamberThrottle body

B B

AB

Intake manifold

Y R

GW L

Fuel

pressure

regulator

EGR

valveEGR

control

solenoid

valve

Purge

control

solenoid

valveCanister

Vacuum hose colour

B: Black

G: Green

R: Red

W: White

Y: Yellow

L: Blue

<4G6>

B

Page 118 of 788

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-10

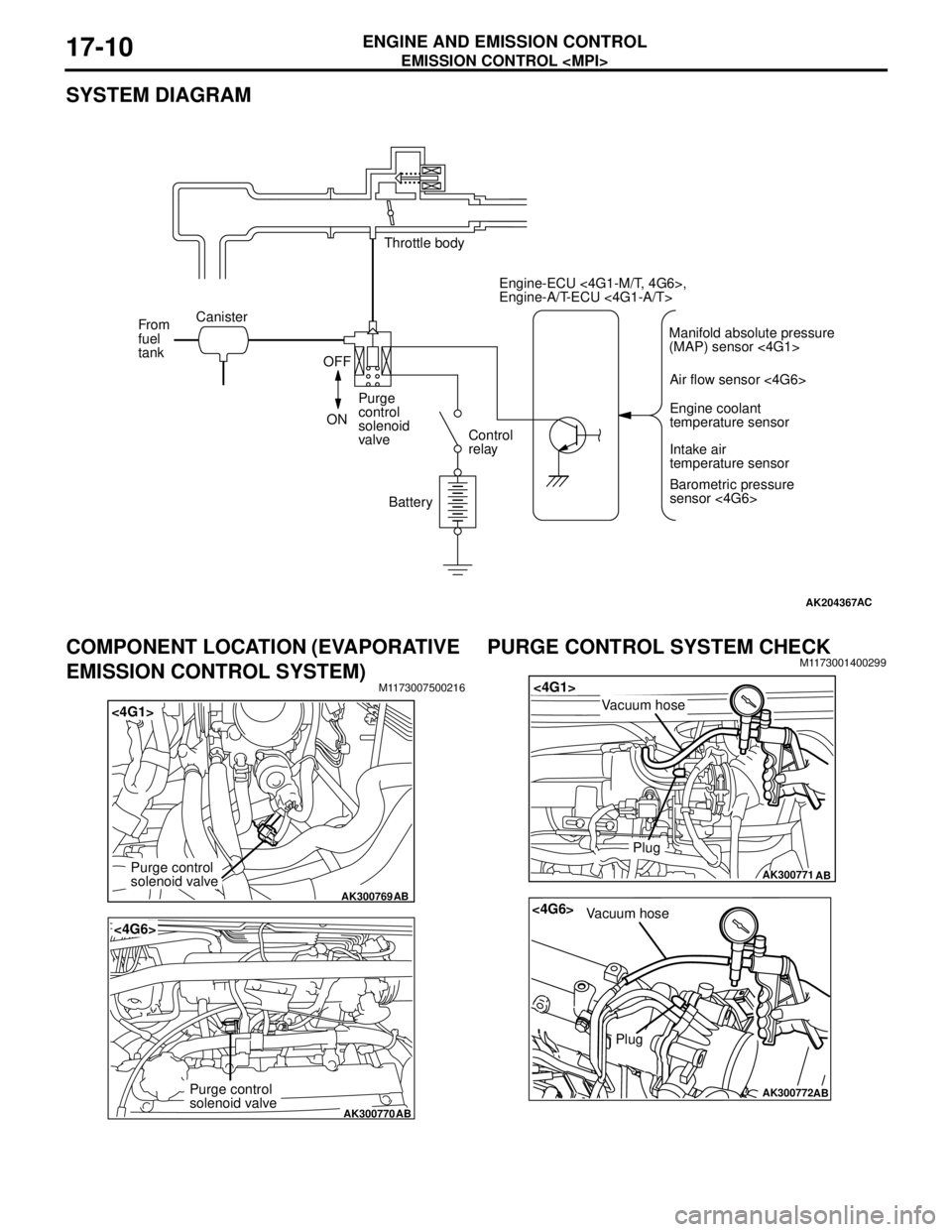

SYSTEM DIAGRAM

COMPONENT LOCATION (EVAPORATIVE

EMISSION CONTROL SYSTEM)

M1173007500216

PURGE CONTROL SYSTEM CHECKM1173001400299

AK204367AC

Throttle body

Canister

From

fuel

tank

OFF

ONPurge

control

solenoid

valveControl

relay

BatteryEngine-ECU <4G1-M/T, 4G6>,

Engine-A/T-ECU <4G1-A/T>

Air flow sensor <4G6>

Engine coolant

temperature sensor

Intake air

temperature sensor

Barometric pressure

sensor <4G6> Manifold absolute pressure

(MAP) sensor <4G1>

AK300769

<4G1>

AB

Purge control

solenoid valve

AK300770

<4G6>

AB

Purge control

solenoid valve

AK300771

<4G1>

AB

Plug

Vacuum hose

AK300772

<4G6>

AB

Plug

Vacuum hose

Page 119 of 788

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-11

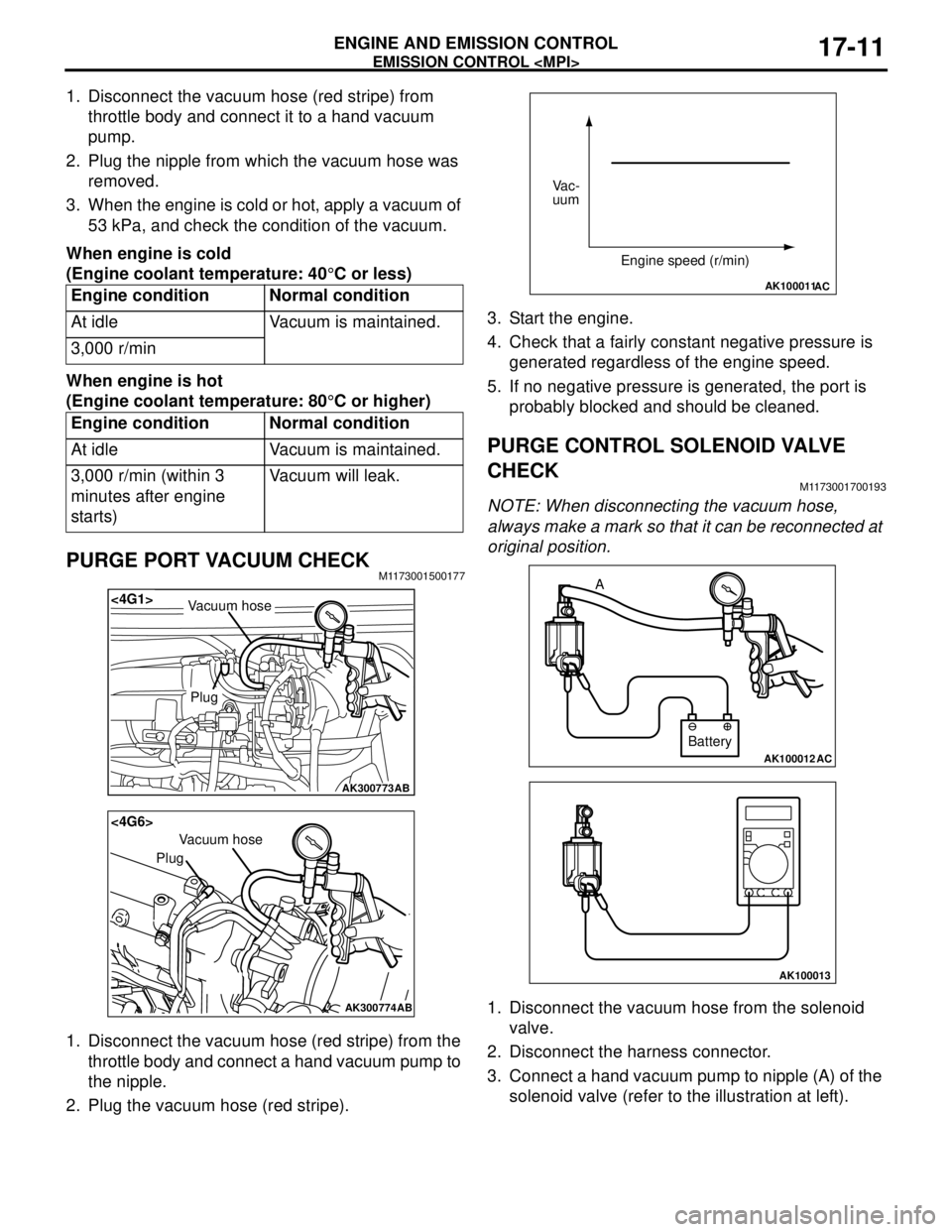

1. Disconnect the vacuum hose (red stripe) from

throttle body and connect it to a hand vacuum

pump.

2. Plug the nipple from which the vacuum hose was

removed.

3. When the engine is cold or hot, apply a vacuum of

53 kPa, and check the condition of the vacuum.

When engine is cold

(Engine coolant temperature: 40°C or less)

When engine is hot

(Engine coolant temperature: 80°C or higher)

PURGE PORT VACUUM CHECKM1173001500177

1. Disconnect the vacuum hose (red stripe) from the

throttle body and connect a hand vacuum pump to

the nipple.

2. Plug the vacuum hose (red stripe).3. Start the engine.

4. Check that a fairly constant negative pressure is

generated regardless of the engine speed.

5. If no negative pressure is generated, the port is

probably blocked and should be cleaned.

PURGE CONTROL SOLENOID VALVE

CHECK

M1173001700193

NOTE: When disconnecting the vacuum hose,

always make a mark so that it can be reconnected at

original position.

1. Disconnect the vacuum hose from the solenoid

valve.

2. Disconnect the harness connector.

3. Connect a hand vacuum pump to nipple (A) of the

solenoid valve (refer to the illustration at left). Engine condition Normal condition

At idle Vacuum is maintained.

3,000 r/min

Engine condition Normal condition

At idle Vacuum is maintained.

3,000 r/min (within 3

minutes after engine

starts)Vacuum will leak.

AK300773

<4G1>

AB

Plug

Vacuum hose

AK300774

<4G6>

AB

Plug

Vacuum hose

AK100011AC

Vac-

uum

Engine speed (r/min)

AK100012AC

Battery A

AK100013