group 90 MITSUBISHI LANCER 2006 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER, Model: MITSUBISHI LANCER 2006Pages: 800, PDF Size: 45.03 MB

Page 33 of 800

TROUBLESHOOTING

ENGINE COOLING14-19

(8) Reconnect the connector with connector terminal

pin still installed.

Q: Does the cooling fan rotate? And when the

connector terminal pin is connected to the body

earth, does the cooling fan stop?

YES : Go to Step 7 .

NO : Replace the cooling fan motor drive control

unit (Refer to

P.14-33) <4G1> (Refer to

P.14-35) 4G6>. Then go to Step 8 .

STEP 7. M.U.T.-II/III self-diag code

Check if an MPI system self-diag code is set. (Refer

to GROUP 13A - Trouble shooting

P.13A-9) <4G1>

or (Refer to GROUP 13B - Trouble shooting

P.13B-9) <4G6>.

Q: Diagnosis code set?

YES : Inspection chart for diagnosis code (Refer

to GROUP 13A - Trouble shooting

P.13A-15) <4G1> or Inspection chart for

diagnosis code (Refer to GROUP 13B -

Trouble shooting

P.13B-15) <4G6>.

NO : Replace the engine-ECU

engine-A/T-ECU (Refer to GROUP

13A

P.13A-384). Then go to Step 8 .

STEP 8. Check the symptoms.

Q: Does the cooling fan motor (L.H.) and the cooling

fan motor (R.H.) <4G1 (Vehicles with A/C)> or A/C

condenser fan motor <4G6> operate correctly?

YES : This symptoms is complete.

NO : Return to Step 1 .

INSPECTION PROCEDURE 3: Cooling Fan (L.H.) does not Operate {When Cooling Fan (R.H.) <4G1> or

A/C Condenser Fan <4G6> Operate}

COOLING FAN (L.H.) AND COOLING FAN

(R.H.) OR A/C CONDENSER FAN DRIVE

CIRCUIT

Refer to P.14-6.

CIRCUIT OPERATION

Refer to P.14-6.

TECHNICAL DESCRIPTION

The cause could be a malfunction of the cooling fan

motor (L.H.) or cooling fan motor drive control unit.

TROUBLESHOOTING HINTS

•Malfunction of cooling fan motor (L.H.)

•Malfunction of cooling fan motor drive control unit

DIAGNOSIS

STEP 1. Check the cooling fan motor (L.H.).

Refer to P.14-24.

Q: Is the cooling fan motor (L.H.) in good condition?

YES : Go to Step 2 .

NO : Replace the cooling fan motor (L.H.) (Refer

to

P.14-33) <4G1> (Refer to P.14-35)

<4G6>. Then go to Step 3 .

STEP 2. Check the cooling fan motor drive

control unit.

Refer to P.14-22.

Q: Is the cooling fan motor drive control unit in good

condition?

YES : Go to Step 3 .

NO : Replace the cooling fan motor drive control

unit (Refer to

P.14-33) <4G1> (Refer to

P.14-35) <4G6>. Then go to Step 3 .

STEP 3. Check the symptoms.

Q: Do the cooling fan (L.H.) operate (when the cooling

fan (R.H.) <4G1> or A/C condenser fan <4G6>

operate)?

YES : This symptoms is complete.

NO : Return to Step 1 .

Page 34 of 800

TROUBLESHOOTING

ENGINE COOLING14-20

INSPECTION PROCEDURE 4: Cooling Fan (R.H.) <4G1> or A/C Condenser Fan <4G6> does not

Operate {When Cooling Fan (L.H.) Operate}

COOLING FAN (L.H.) AND COOLING FAN

(R.H.) OR A/C CONDENSER FAN DRIVE

CIRCUIT

Refer to P.14-6.

CIRCUIT OPERATION

Refer to P.14-6.

TECHNICAL DESCRIPTION

The cause could be a malfunction of the cooling fan

motor (R.H.) <4G1> or A/C condenser fan motor

<4G6> or cooling fan motor drive control unit.

TROUBLESHOOTING HINTS

•Malfunction of cooling fan motor (R.H.) <4G1> or

A/C condenser fan motor <4G6>

•Malfunction of cooling fan motor drive control unit

DIAGNOSIS

STEP 1. Check the cooling fan motor (R.H.)

<4G1> or A/C condenser fan motor <4G6>.

Cooling fan motor (R.H.) check. (Refer to P.14-24)

<4G1>.

A/C condenser fan motor check. (Refer to GROUP

55

P.55A-91) <4G6>.

Q: Is the cooling fan motor (R.H.) <4G1> or A/C

condenser fan motor <4G6> in good condition?

YES : Go to Step 2 .

NO : Replace the cooling fan motor (R.H.) (Refer

to

P.14-33) <4G1> or A/C condenser fan

motor (Refer to GROUP 55 P.55A-90)

<4G6>. Then go to Step 3 .

STEP 2. Check the cooling fan motor drive

control unit.

Refer to P.14-22.

Q: Is the cooling fan motor drive control unit in good

condition?

YES : Go to Step 3 .

NO : Replace the cooling fan motor drive control

unit (Refer to

P.14-33) <4G1> (Refer to

P.14-35) <4G6>. Then go to Step 3 .

STEP 3. Check the symptoms.

Q: Do the cooling fan (R.H.) <4G1> or A/C condenser

fan <4G6> operate (when the cooling fan (L.H.)

operate)?

YES : This symptoms is complete.

NO : Return to Step 1 .

Page 38 of 800

THERMOSTAT

ENGINE COOLING14-24

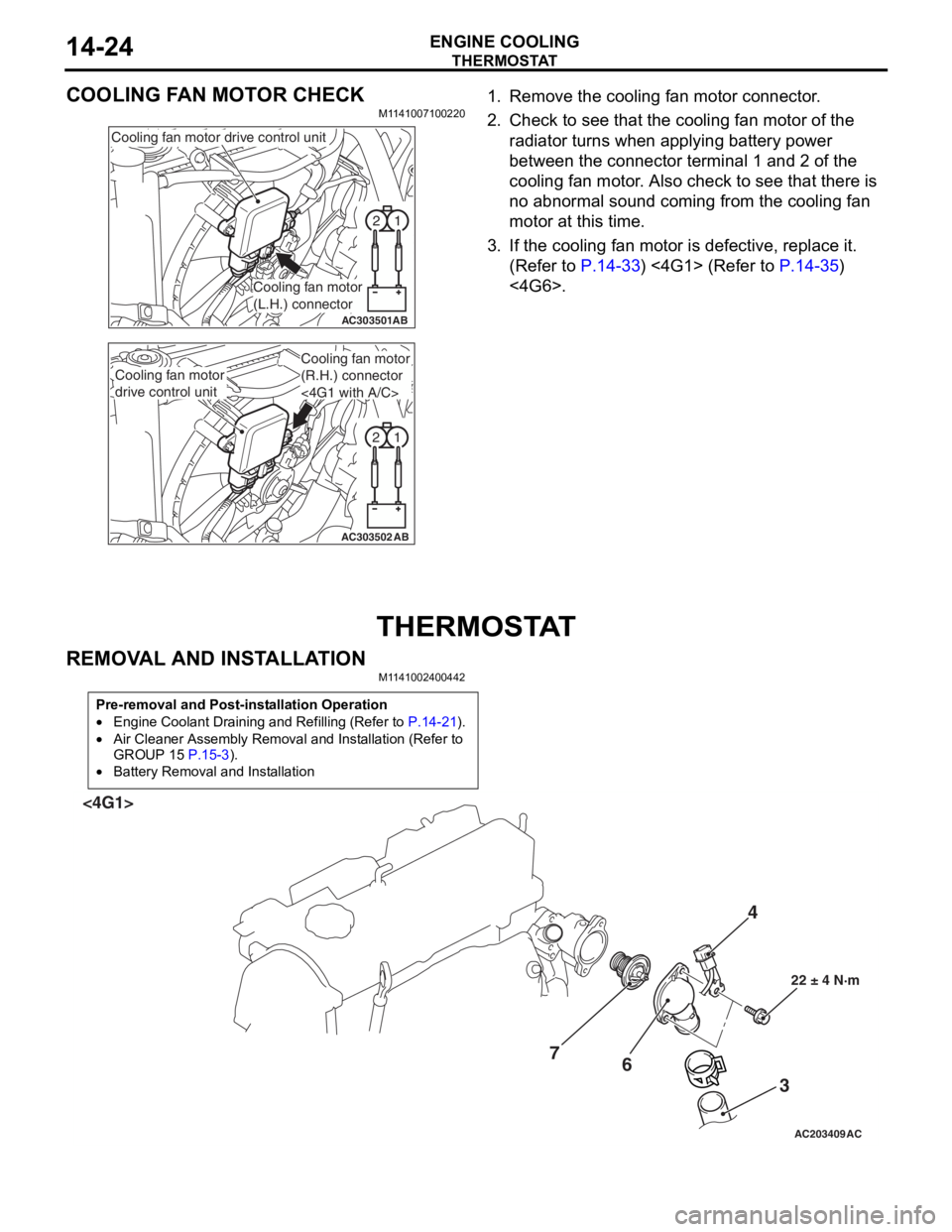

COOLING FAN MOTOR CHECK

M1141007100220

1

2

AC303501AB

Cooling fan motor drive control unit

Cooling fan motor

(L.H.) connector

1

2

AC303502AB

Cooling fan motor

drive control unit

Cooling fan motor

(R.H.) connector

<4G1 with A/C>

1. Remove the cooling fa n mot o r co nnector .

2.Check t o see that t he co oling fan motor of the

ra diato r turns wh en ap plying b a ttery power

b e tween th e con nect o r terminal 1 and 2 of t he

cooling fa n mo tor . Also ch eck to see tha t there is

n o abno rmal soun d co min g from the cooling fa n

motor a t this time.

3.If the cooling fan moto r is defective, replace it.

(Refe r to

P.14-33) <4G1> (Refer to P.14-35)

<4G6>.

THERMOSTA T

REMOVA L AND INST ALLA TION

M1141 0024 0044 2

Pre-removal and Post-installation Operation

•Engine Coolant Draining and Refilling (Refer to P.14-21).

•Air Cleaner Assembly Removal and Installation (Refer to

GROUP 15

P.15-3).

•Battery Removal and Installation

AC203409AC

4

3

6

7

22 ± 4 N·m

<4G1>

Page 41 of 800

WATE R P U M P

ENGINE COOLING14-27

WAT E R P U M P

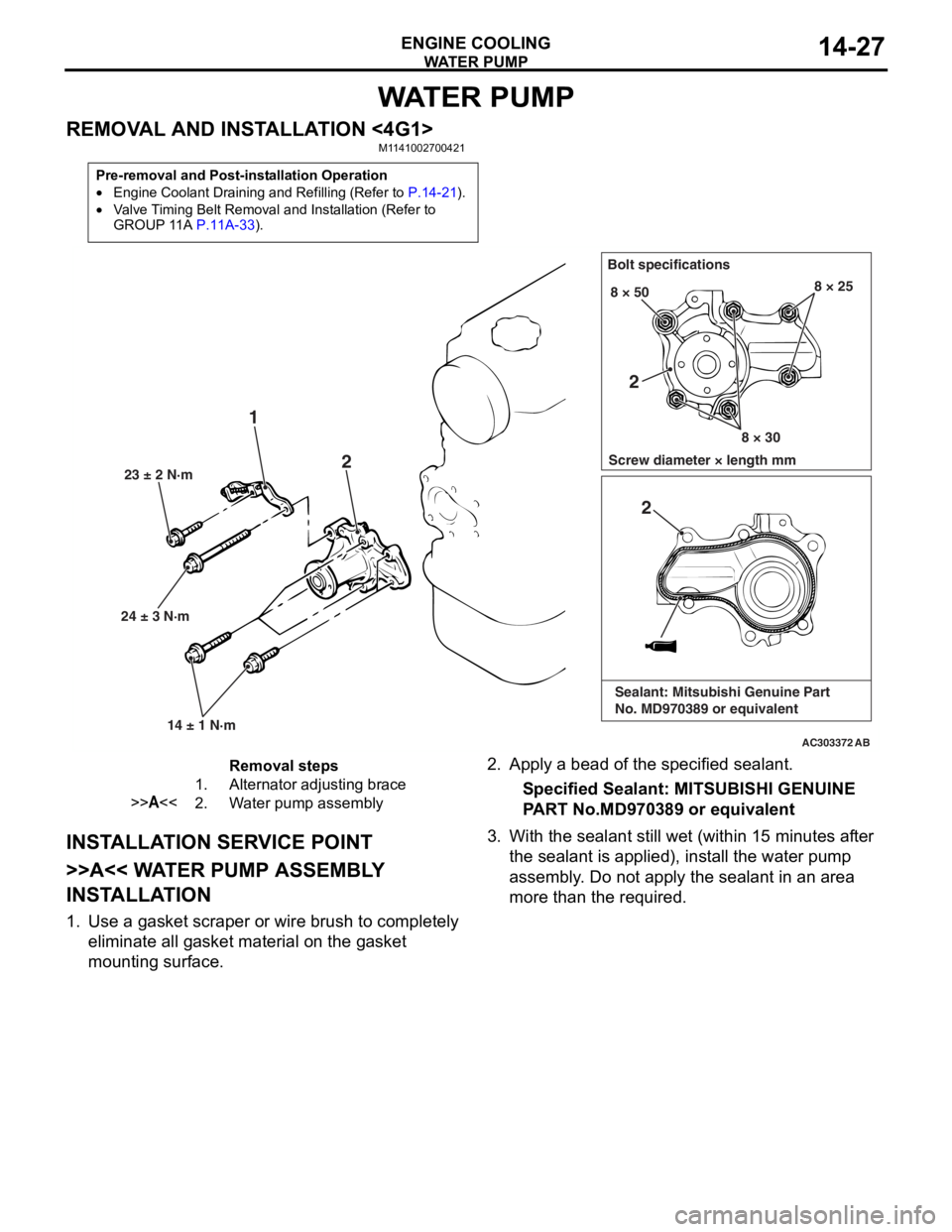

REMOVAL AND INSTALLATION <4G1>M1141002700421

Pre-removal and Post-installation Operation

•Engine Coolant Draining and Refilling (Refer to P.14-21).

•Valve Timing Belt Removal and Installation (Refer to

GROUP 11A P.11A-33).

AC303372

24 ± 3 N·m23 ± 2 N·m

14 ± 1 N·m

1 2

Bolt specifications

Screw diameter × length mm 8 × 50

8 × 308 × 25

AB

2

2

Sealant: Mitsubishi Genuine Part

No. MD970389 or equivalent

Removal steps

1.Alternator adjusting brace

>>A<<2.Water pump assembly

INST ALLA T ION SER VICE POINT

>>A<< WA TER PUMP ASSEMBL Y

INST

ALLA TION

1.Use a gaske t scraper o r wire brush to complet e ly

eliminate all gasket material o n the g a sket

mounting surface.

2. App l y a bead of the specified sealan t.

Specified Sealant: MITSUBISHI GENUINE

P

ART No.MD970 389 or eq uivalen t

3.With the sea l ant still wet (within 1 5 minutes af ter

th e se alant is applied), inst all the wa ter pump

a sse mbly . Do not a pply the sealant in an are a

more th an the required.

Page 42 of 800

WATE R P U M P

ENGINE COOLING14-28

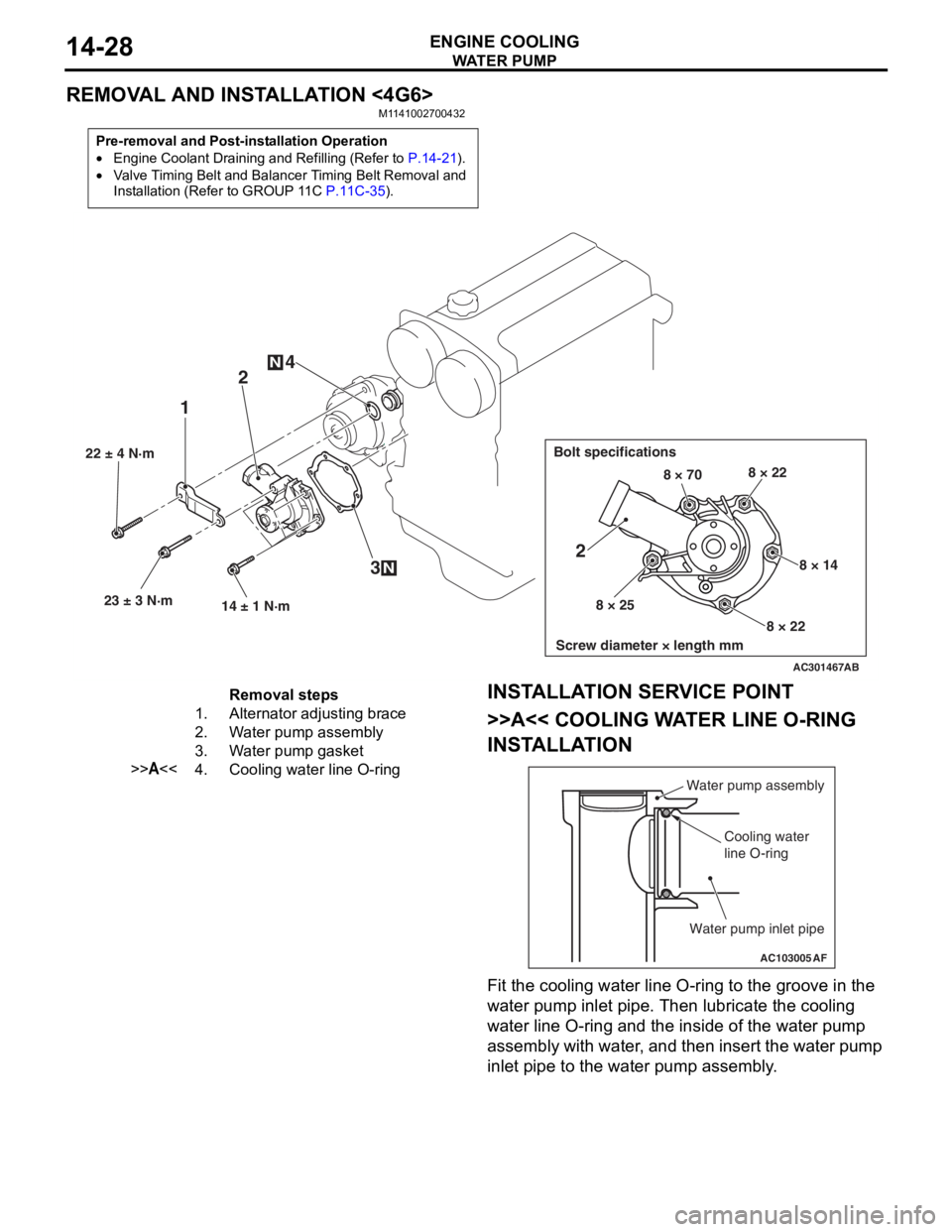

REMOVAL AND INSTALLATION <4G6>

M1141002700432

Pre-removal and Post-installation Operation

•Engine Coolant Draining and Refilling (Refer to P.14-21).

•Valve Timing Belt and Balancer Timing Belt Removal and

Installation (Refer to GROUP 11C

P.11C-35).

AC301467

22 ± 4 N·m23 ± 3 N·m 14 ± 1 N·m

12

3

4

N

N

Bolt specifications

Screw diameter × length mm

8 × 70 8 × 22

8 × 14

8 × 22

8 × 25

2

AB

Removal steps

1.Alternator adjusting brace

2.Water pump assembly

3.Water pump gasket

>>A<<4.Cooling water line O-ring

INST

ALLA T ION SER VICE POINT

>>A<< COOLING WA TER LINE O-RING

INST

ALLA TION

AC103005

Water pump assembly

Cooling water

line O-ring

Water pump inlet pipe

AF

Fit the coo ling water line O-ring to the groove in the

wa

ter pump in let p i pe. T hen lubricate th e co olin g

wa

ter line O-ring and the inside of the wat e r pump

assembly with wa

ter , and then insert the wa ter pu mp

inle

t pip e to the water pu mp asse mbly .

Page 43 of 800

WATER HOSE AND WATER PIPE

ENGINE COOLING14-29

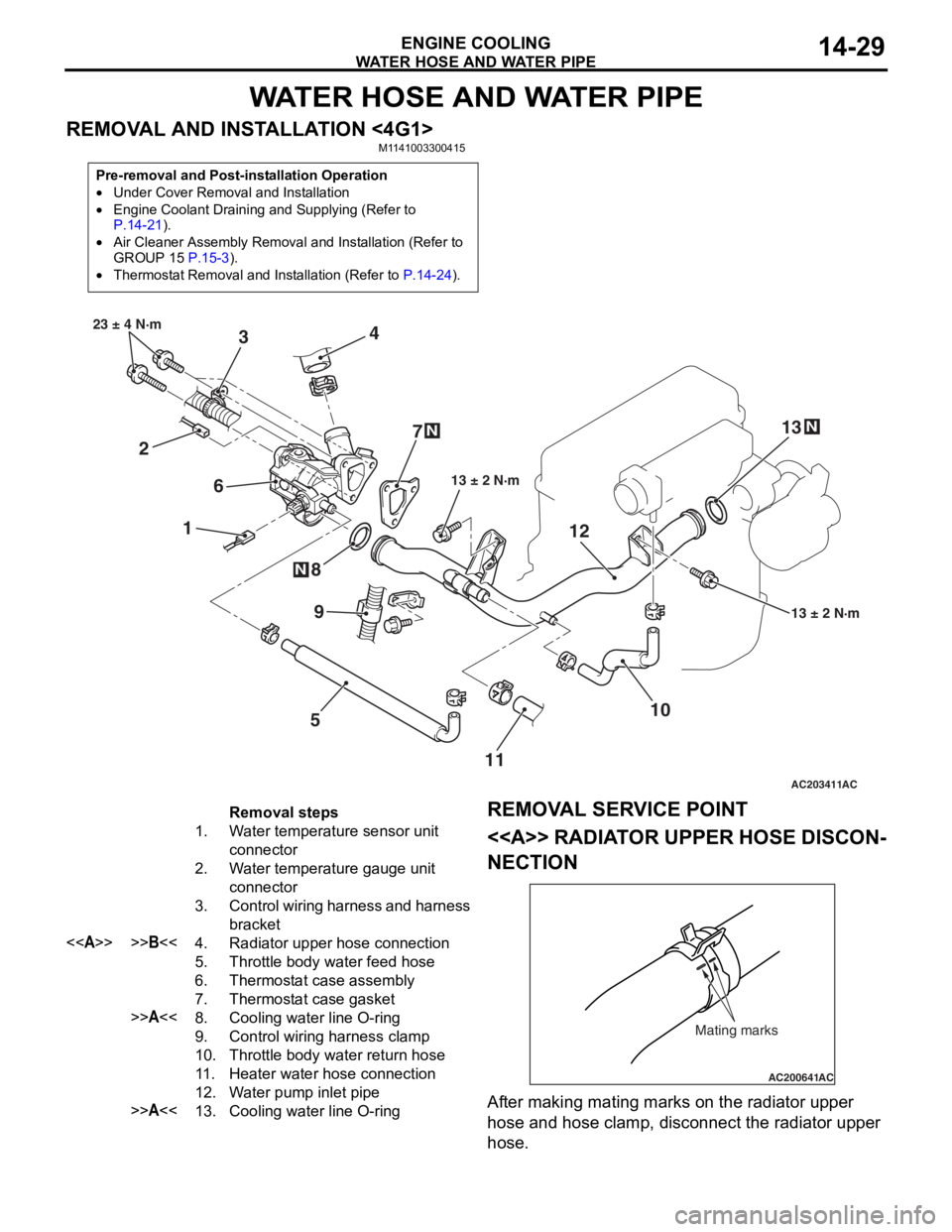

WATER HOSE AND WATER PIPE

REMOVAL AND INSTALLATION <4G1>M1141003300415

Pre-removal and Post-installation Operation

•Under Cover Removal and Installation

•Engine Coolant Draining and Supplying (Refer to P.14-21).

•Air Cleaner Assembly Removal and Installation (Refer to

GROUP 15 P.15-3).

•Thermostat Removal and Installation (Refer to P.14-24).

AC203411

1

2 3

4

5

6

7

8

10

9

13 ± 2 N·m

23 ± 4 N·m

13 ± 2 N·m

N

N

AC

1112

13

N

Removal steps

1.Water temperature sensor unit

connector

2.Water temperature gauge unit

connector

3.Control wiring harness and harness

bracket

<>>>B<<4.Radiator upper hose connection

5.Throttle body water feed hose

6.Thermostat case assembly

7.Thermostat case gasket

>>A<<8.Cooling water line O-ring

9.Control wiring harness clamp

10.Throttle body water return hose

11 .Heater water hose connection

12.Water pump inlet pipe

>>A<<13.Cooling water line O-ring

REMOV

A L SER VICE POINT

<> RADIAT OR UPPER HOSE DISCON-

NECTION

AC200641AC

Mating marks

After making matin g ma rks on the radia t or upp er

hose

and h o se clamp, disconnect the radia t or upp er

hose

.

Page 45 of 800

WATER HOSE AND WATER PIPE

ENGINE COOLING14-31

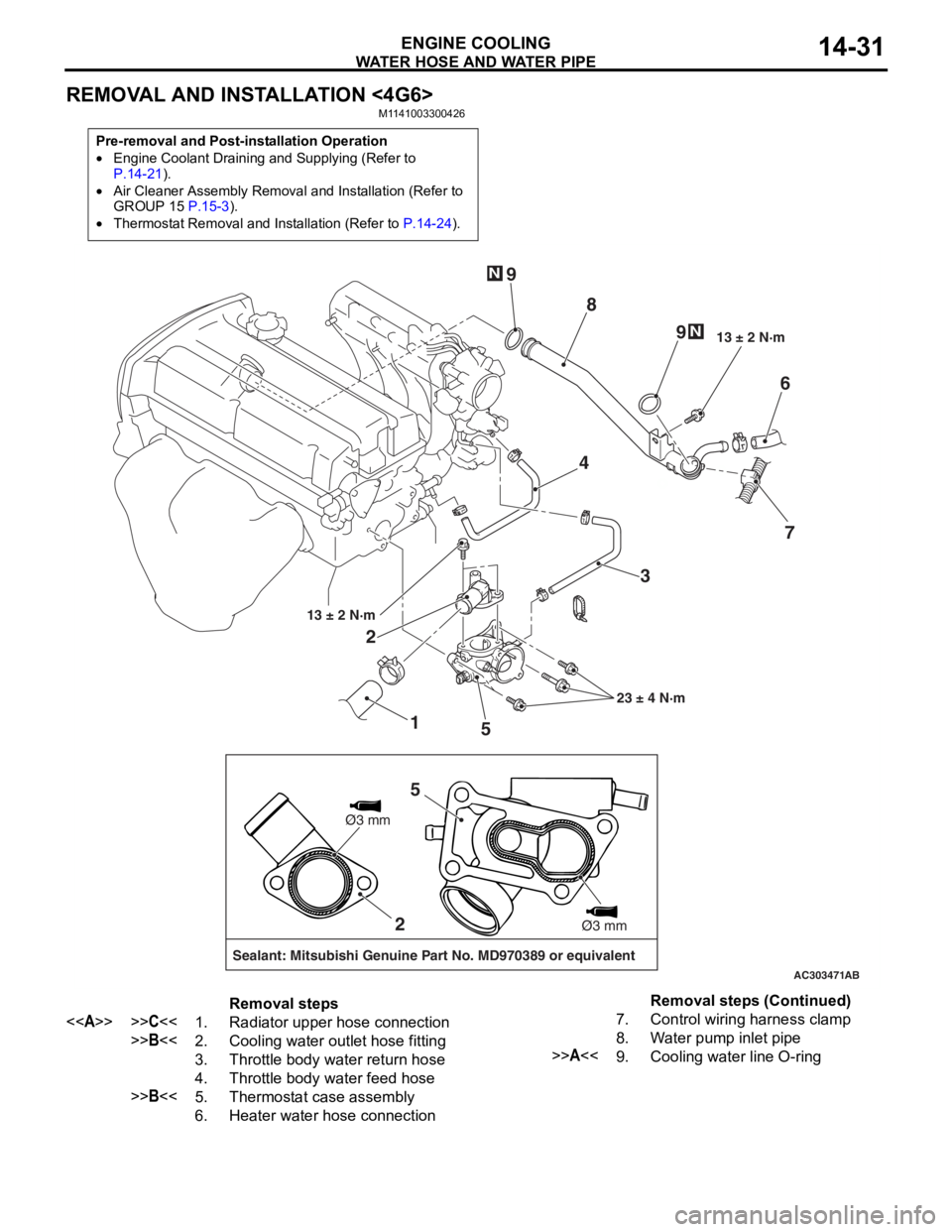

REMOVAL AND INSTALLATION <4G6>

M1141003300426

Pre-removal and Post-installation Operation

•Engine Coolant Draining and Supplying (Refer to P.14-21).

•Air Cleaner Assembly Removal and Installation (Refer to

GROUP 15 P.15-3).

•Thermostat Removal and Installation (Refer to P.14-24).

AC303471

1

2

3

4

5 6

7

8

9

9

13 ± 2 N·m

23 ± 4 N·m

13 ± 2 N·m

N

N

AB

2

Sealant: Mitsubishi Genuine Part No. MD970389 or equivalent

Ø3 mm

Ø3 mm

5

Removal steps

<>>>C<<1.Radiator upper hose connection

>>B<<2.Cooling water outlet hose fitting

3.Throttle body water return hose

4.Throttle body water feed hose

>>B<<5.Thermostat case assembly

6.Heater water hose connection

7.Control wiring harness clamp

8.Water pump inlet pipe

>>A<<9.Cooling water line O-ring

Removal steps (Continued)

Page 47 of 800

RADIATOR

ENGINE COOLING14-33

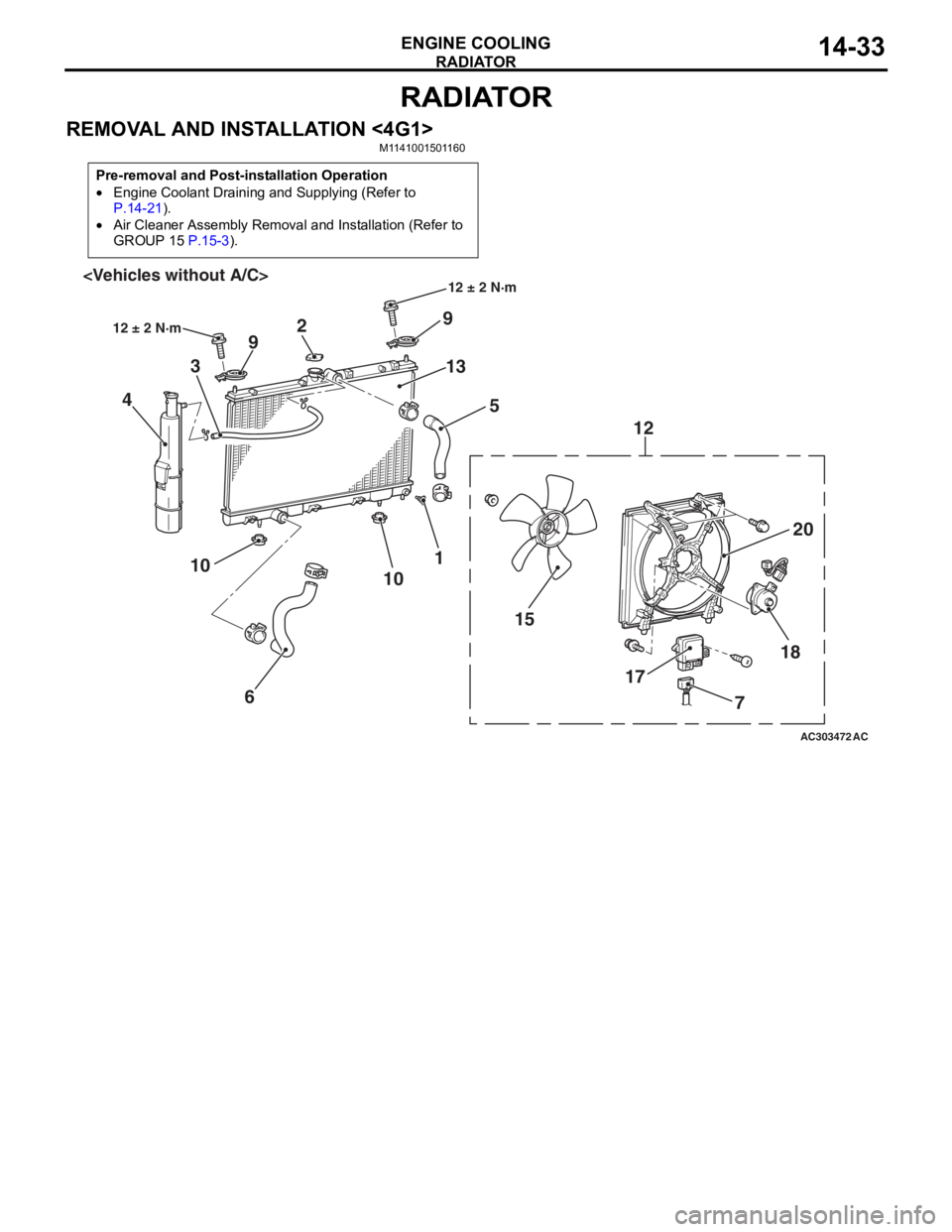

RADIATOR

REMOVAL AND INSTALLATION <4G1>M1141001501160

Pre-removal and Post-installation Operation

•Engine Coolant Draining and Supplying (Refer to

P.14-21).

•Air Cleaner Assembly Removal and Installation (Refer to

GROUP 15

P.15-3).

AC303472

18

17

15 20

12

9

13 5

2

9

3

4

1

10

6

10

AC

12 ± 2 N·m

12 ± 2 N·m

7

Page 49 of 800

RADIATOR

ENGINE COOLING14-35

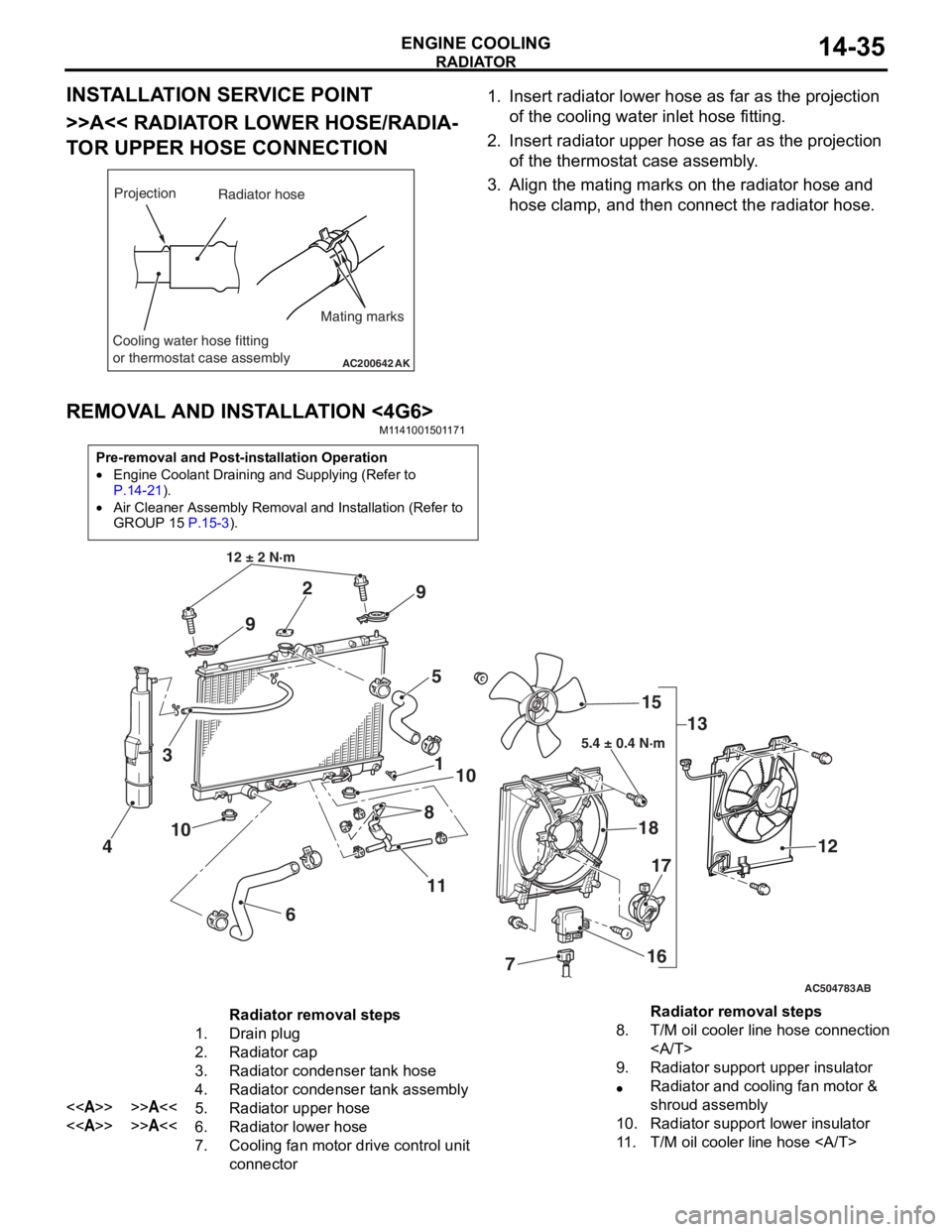

INSTALLATION SERVICE POINT

>>A<< RADIATOR LOWER HOSE/RADIA-

TOR UPPER HOSE CONNECTION

AC200642

Mating marks

Projection

Cooling water hose fitting

or thermostat case assembly

AK

Radiator hose

1.In sert ra diato r lower h o se as fa r as th e projection

o f the cooling wate r inlet hose fit t ing.

2.In sert radia t or up per h o se as far a s t he pro j ection

o f the th ermost at ca se asse mbly .

3.Align th e ma ting marks on the rad i ator hose and

h o se clamp, an d then conn ect the radiator h o se.

REMOVA L AND INST ALLA TION <4G6>

M11 4100 1501 17 1

Pre-removal and Post-installation Operation

•Engine Coolant Draining and Supplying (Refer to

P.14-21).

•Air Cleaner Assembly Removal and Installation (Refer to

GROUP 15

P.15-3).

AC504783

1

12 ± 2 N·m

10

2

3

4

5

6

7

8

9

9

10

11 13

15

18

16

17

12

AB

5.4 ± 0.4 N·m

Radiator removal steps

1.Drain plug

2.Radiator cap

3.Radiator condenser tank hose

4.Radiator condenser tank assembly

<>>>A<<5.Radiator upper hose

<>>>A<<6.Radiator lower hose

7.Cooling fan motor drive control unit

connector

8.T/M oil cooler line hose connection

9.Radiator support upper insulator

•Radiator and cooling fan motor &

shroud assembly

10.Radiator support lower insulator

11 .T/M oil cooler line hose

Radiator removal steps

Page 51 of 800

15-1

GROUP 15

INTAKE AND

EXHAUST

CONTENTS

GENERAL INFORMATIO N . . . . . . . .15-2

SERVICE SPECIFICATION . . . . . . . .15-2

SPECIAL TOOL . . . . . . . . . . . . . . . . .15-2

AIR CLEANER . . . . . . . . . . . . . . . . . .15-3

REMOVAL AND INSTALLATION . . . . . . . . 15-3

INLET MANIFOLD . . . . . . . . . . . . . . .15-5

REMOVAL AND INSTALLATION <4G1> . . 15-5

REMOVAL AND INSTALLATION <4G6> . . 15-6

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 15-7

EXHAUST MANIFOLD . . . . . . . . . . . .15-7

REMOVAL AND INSTALLATION <4G1> . . 15-7

REMOVAL AND INSTALLATION <4G6> . . 15-9

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 15-10

EXHAUST PIPE AND MAIN

MUFFLER . . . . . . . . . . . . . . . . . . . . . .15-10

REMOVAL AND INSTALLATION . . . . . . . . 15-10