group 90 MITSUBISHI LANCER 2006 Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER, Model: MITSUBISHI LANCER 2006Pages: 800, PDF Size: 45.03 MB

Page 84 of 800

STARTING SYSTEM

ENGINE ELECTRICAL16-22

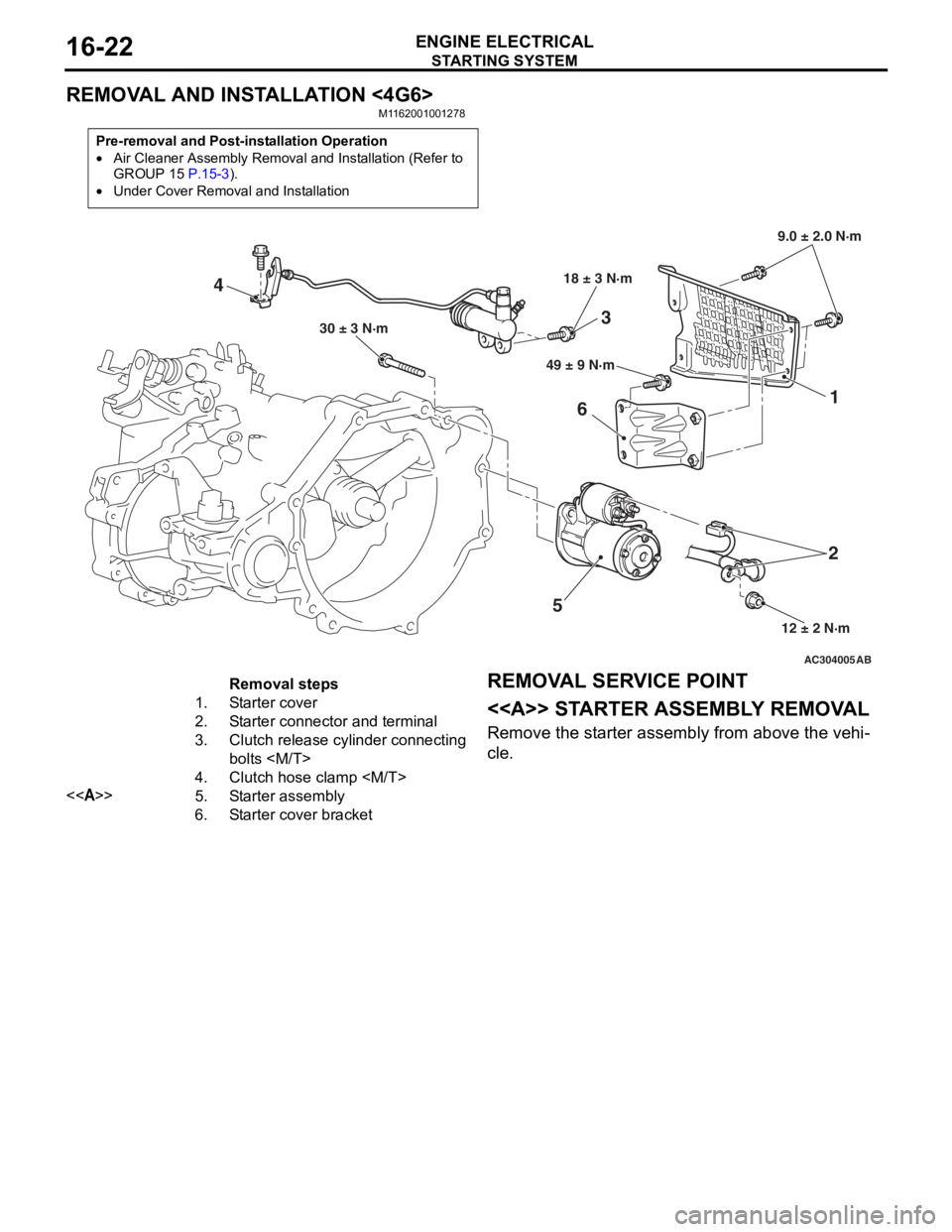

REMOVAL AND INSTALLATION <4G6>

M1162001001278

Pre-removal and Post-installation Operation

•Air Cleaner Assembly Removal and Installation (Refer to

GROUP 15 P.15-3).

•Under Cover Removal and Installation

AC304005

521

6

49 ± 9 N·m 18 ± 3 N·m

9.0 ± 2.0 N·m

30 ± 3 N·m

AB

4 3

12 ± 2 N·m

Removal steps

1.Starter cover

2.Starter connector and terminal

3.Clutch release cylinder connecting

bolts

4.Clutch hose clamp

<>5.Sta rte r as se mb ly

6.Starter cover bracket

REMOVA L SER VICE POINT

<> STARTER ASSEMBL Y REMOV A L

Remove the st arter assembly from above the veh i-

cle.

Page 95 of 800

IGNITION SYSTEM

ENGINE ELECTRICAL16-33

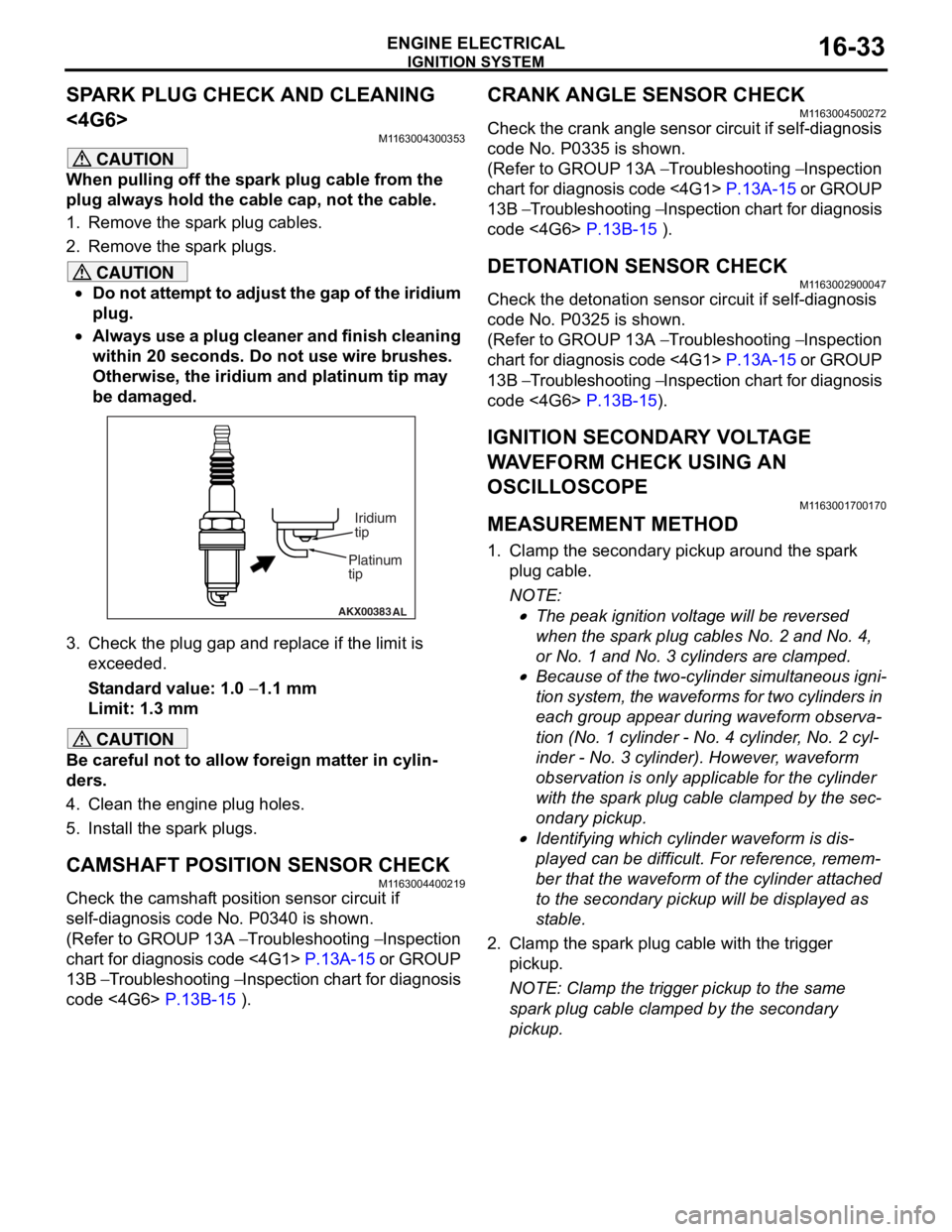

SPARK PLUG CHECK AND CLEANING

<4G6>

M1163004300353

CAUTION

When pulling off the spark plug cable from the

plug always hold the cable cap, not the cable.

1. Remove the spark plug cables.

2. Remove the spark plugs.

CAUTION

•Do not attempt to adjust the gap of the iridium

plug.

•

AKX00383 AL

Platinum

tipIridium

tip

Always use a plug cleaner and finish cleaning

within 20 seconds. Do not use wire brushes.

Otherwise, the iridium and platinum tip may

be damaged.

3. Check the plug gap and re

place if the limit is

exceeded.

Standard value: 1.0 − 1.1 mm

Limit: 1.3 mm

CAUTION

Be careful not to allow foreign matter in cylin-

ders.

4. Clean the engine plug holes.

5. Install the spark plugs.

CAMSHAFT POSITION SENSOR CHECK

M1163004400219

Check the camshaft position sensor circuit if

self-diagnosis code No. P0340 is shown.

(Refer to GROUP 13A − Troubleshooting − Inspection

chart for diagnosis code <4G1>

P.13A-15 or GROUP

13B − Troubleshooting − Inspection chart for diagnosis

code <4G6>

P.13B-15 ).

CRANK ANGLE SENSOR CHECK

M1163004500272

Check the crank angle sensor circuit if self-diagnosis

code No. P0335 is shown.

(Refer to GROUP 13A − Troubleshooting − Inspection

chart for diagnosis code <4G1>

P.13A-15 or GROUP

13B − Troubleshooting − Inspection chart for diagnosis

code <4G6>

P.13B-15 ).

DETONATION SENSOR CHECKM1163002900047

Check the detonation sensor circuit if self-diagnosis

code No. P0325 is shown.

(Refer to GROUP 13A − Troubleshooting − Inspection

chart for diagnosis code <4G1>

P.13A-15 or GROUP

13B − Troubleshooting − Inspection chart for diagnosis

code <4G6>

P.13B-15).

IGNITION SECONDARY VOLTAGE

WAVEFORM CHECK USING AN

OSCILLOSCOPE

M1163001700170

MEASUREMENT METHOD

1. Clamp the secondary pickup around the spark

plug cable.

NOTE: .

•The peak ignition voltage will be reversed

when the spark plug cables No. 2 and No. 4,

or No. 1 and No. 3 cylinders are clamped.

•Because of the two-cylinder simultaneous igni-

tion system, the waveforms for two cylinders in

each group appear during waveform observa

-

tion (No. 1 cylinder - No. 4 cylinder, No. 2 cyl-

inder - No. 3 cylinder). However, waveform

observation is only applicable for the cylinder

with the spark plug cable clamped by the sec

-

ondary pickup.

•Identifying which cylinder waveform is dis-

played can be difficult. For reference, remem-

ber that the waveform of the cylinder attached

to the secondary pickup will be displayed as

stable.

2. Clamp the spark plug cable with the trigger pickup.

NOTE: Clamp the trigger pickup to the same

spark plug cable clamped by the secondary

pickup.

Page 103 of 800

IGNITION SYSTEM

ENGINE ELECTRICAL16-41

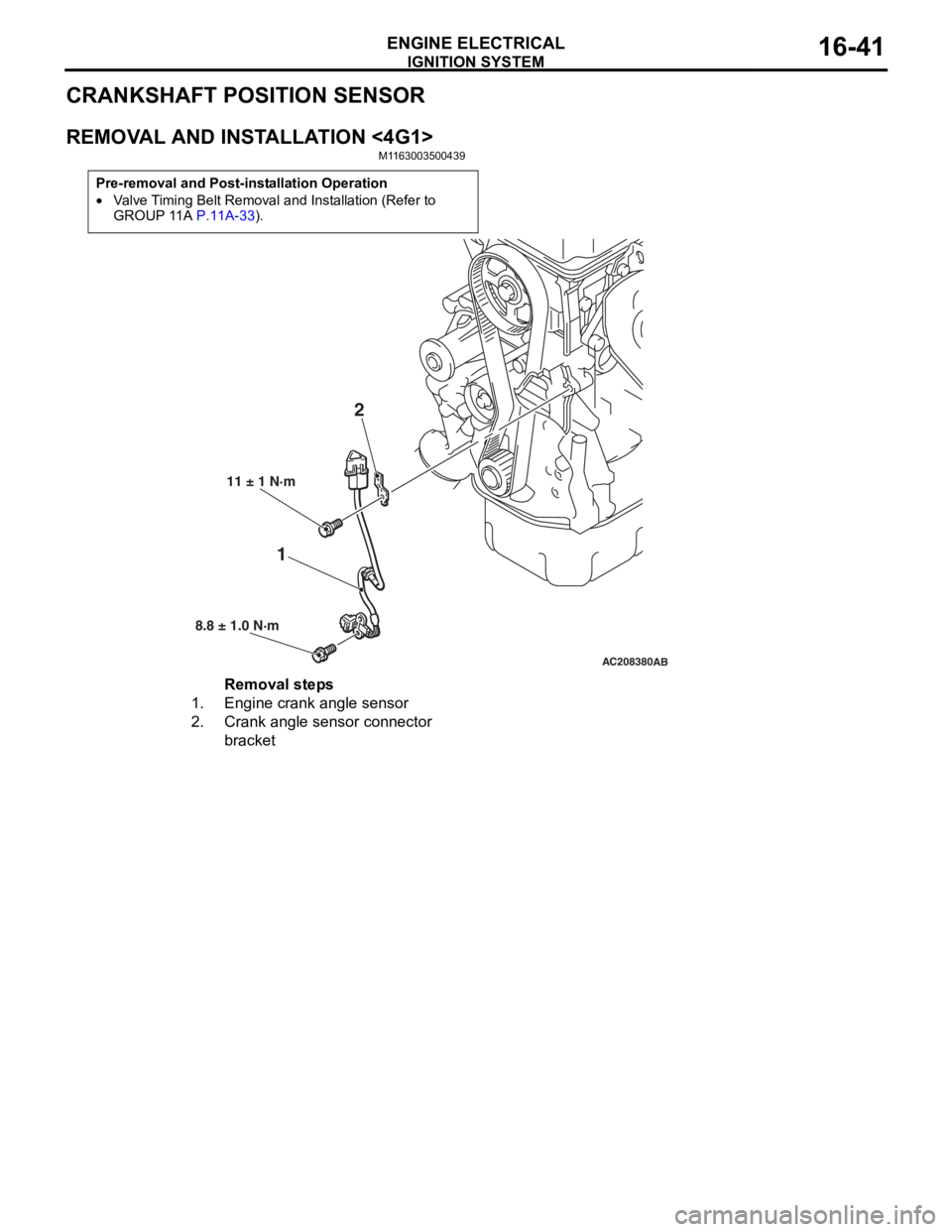

CRANKSHAFT POSITION SENSOR

REMOVAL AND INSTALLATION <4G1>

M1163003500439

Pre-removal and Post-installation Operation

•Valve Timing Belt Removal and Installation (Refer to

GROUP 11A P.11A-33).

AC208380AB

12

11 ± 1 N·m

8.8 ± 1.0 N·m

Removal steps

1.Engine crank angle sensor

2.Crank angle sensor connector

bracket

Page 104 of 800

IGNITION SYSTEM

ENGINE ELECTRICAL16-42

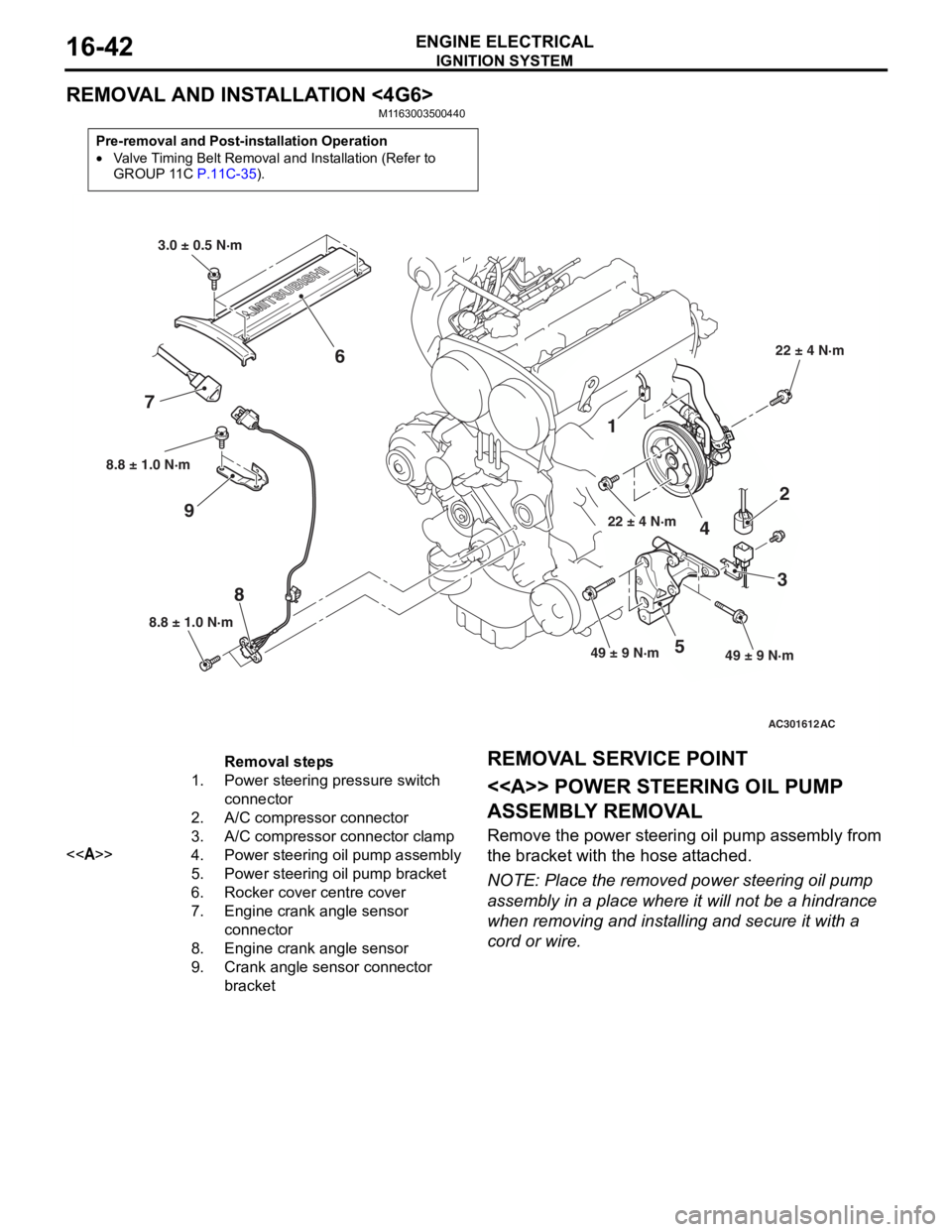

REMOVAL AND INSTALLATION <4G6>

M1163003500440

Pre-removal and Post-installation Operation

•Valve Timing Belt Removal and Installation (Refer to

GROUP 11C P.11C-35).

AC301612

8.8 ± 1.0 N·m

8

8.8 ± 1.0 N·m

9

1

22 ± 4 N·m

4

2

3

49 ± 9 N·m49 ± 9 N·m5

22 ± 4 N·m

3.0 ± 0.5 N·m

6

7

AC

Removal steps

1.Power steering pressure switch

connector

2.A/C compressor connector

3.A/C compressor connector clamp

<>4.Power steering oil pump assembly

5.Power steering oil pump bracket

6.Rocker cover centre cover

7.Engine crank angle sensor

connector

8.Engine crank angle sensor

9.Crank angle sensor connector

bracket

REMOV A L SER VICE POINT

<> POWE R STEERING OIL PUMP

ASSEMBL

Y REMOV A L

Remove the p o wer st eering oil pump assembly from

the bra

cke t with th e hose att a ched.

NOTE: Place the remo ved power st eering oil pump

assembly in a place where it will not be a hindrance

wh

en removing an d inst a lling an d secure it with a

cord or wire.

Page 105 of 800

IGNITION SYSTEM

ENGINE ELECTRICAL16-43

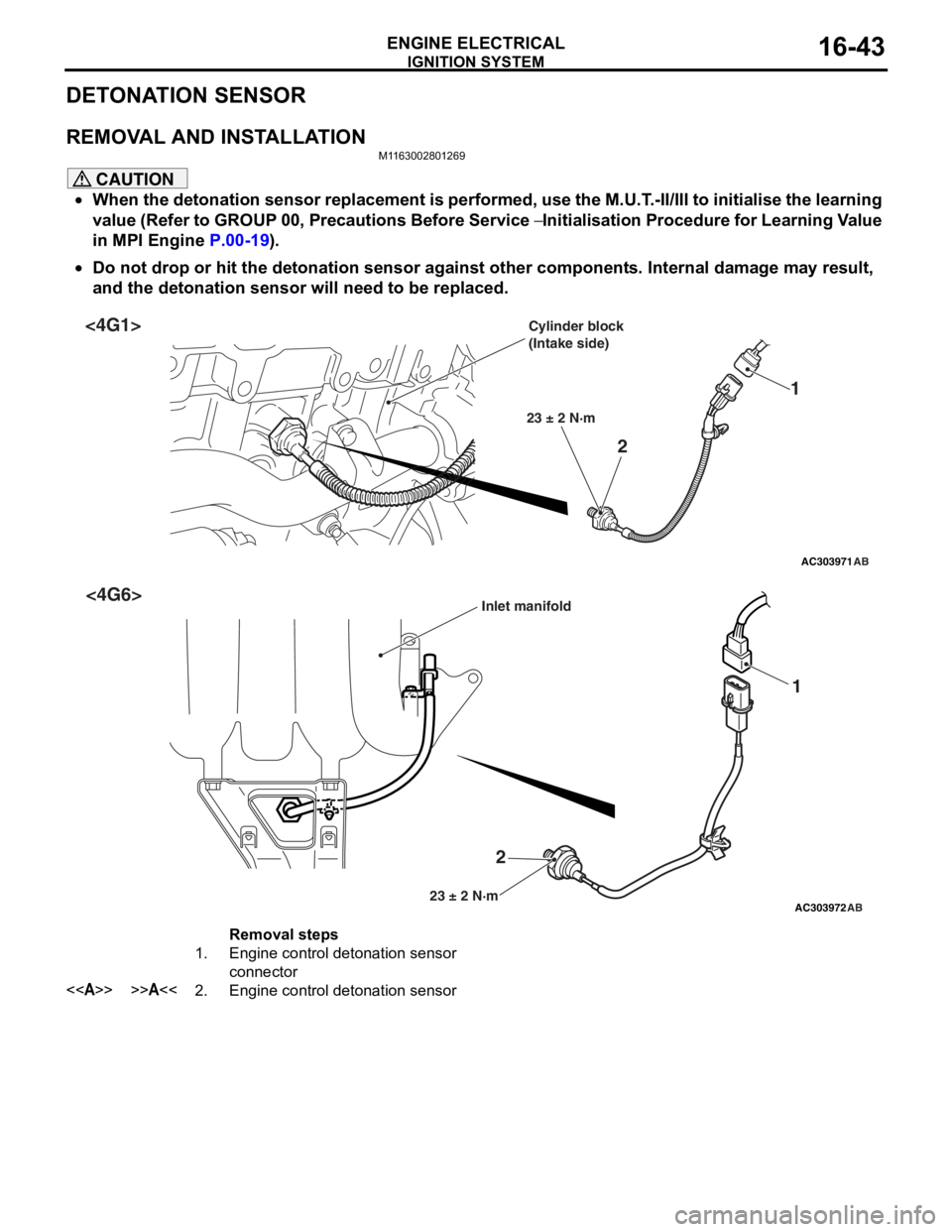

DETONATION SENSOR

REMOVAL AND INSTALLATION

M1163002801269

CAUTION

•When the detonation sensor replacement is performed, use the M.U.T.-II/III to initialise the learning

value (Refer to GROUP 00, Precautions Before Service

− Initialisation Procedure for Learning Value

in MPI Engine

P.00-19).

•

AC303971

2 1

23 ± 2 N·m

AB

<4G1>Cylinder block

(Intake side)

AC303972

2 1

23 ± 2 N·mAB

<4G6>Inlet manifold

Removal steps

1.Engine control detonation sensor

connector

<>>>A<<2.Engine control detonation sensor

Do not drop or hit the detonation sensor against other components. Internal damage may result,

and the detonation sensor will need to be replaced.

Page 107 of 800

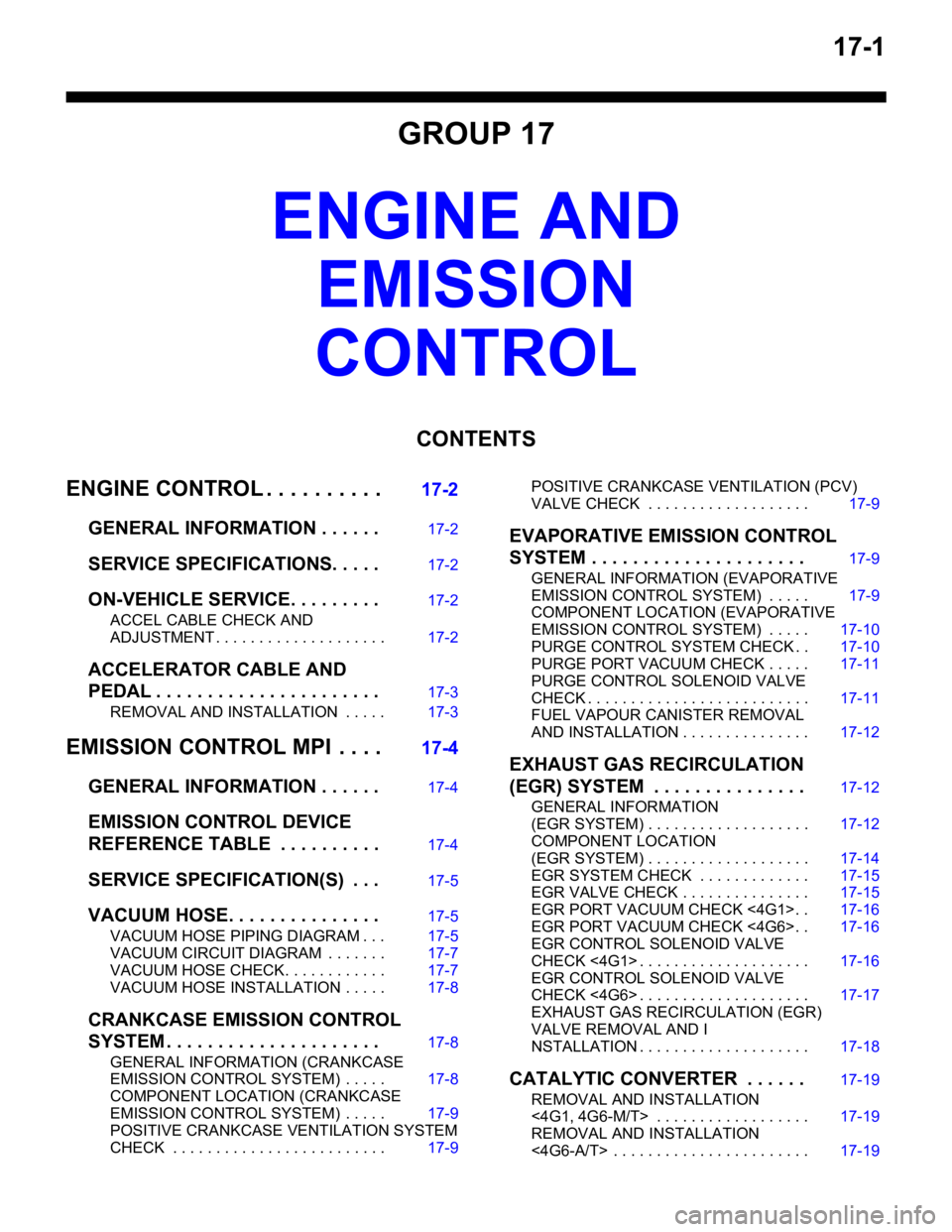

17-1

GROUP 17

ENGINE AND

EMISSION

CONTROL

CONTENTS

ENGINE CONTROL . . . . . . . . . .17-2

GENERAL INFORMATION . . . . . .17-2

SERVICE SPECIFICATIONS. . . . .17-2

ON-VEHICLE SERVICE. . . . . . . . .17-2

ACCEL CABLE CHECK AND

ADJUSTMENT . . . . . . . . . . . . . . . . . . . . 17-2

ACCELERATOR CABLE AND

PEDAL . . . . . . . . . . . . . . . . . . . . . .17-3

REMOVAL AND INSTALLATION . . . . . 17-3

EMISSION CONTROL MPI . . . .17-4

GENERAL INFORMATION . . . . . .17-4

EMISSION CONTROL DEVICE

REFERENCE TABLE . . . . . . . . . .17-4

SERVICE SPECIFICATION(S) . . .17-5

VACUUM HOSE. . . . . . . . . . . . . . .17-5

VACUUM HOSE PIPING DIAGRAM . . . 17-5

VACUUM CIRCUIT DIAGRAM . . . . . . . 17-7

VACUUM HOSE CHECK. . . . . . . . . . . . 17-7

VACUUM HOSE INSTALLATION . . . . . 17-8

CRANKCASE EMISSION CONTROL

SYSTEM . . . . . . . . . . . . . . . . . . . . .17-8

GENERAL INFORMATION (CRANKCASE

EMISSION CONTROL SYSTEM) . . . . . 17-8

COMPONENT LOCATI ON (CRANKCASE

EMISSION CONTROL SYSTEM) . . . . . 17-9

POSITIVE CRANKCASE VENTILATION SYSTEM

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . 17-9

POSITIVE CRANKCASE VENTILATION (PCV)

VALVE CHECK . . . . . . . . . . . . . . . . . . . 17-9

EVAPORATIVE EMISSION CONTROL

SYSTEM . . . . . . . . . . . . . . . . . . . . .17-9

GENERAL INFORMATION (EVAPORATIVE

EMISSION CONTROL SYSTEM) . . . . . 17-9

COMPONENT LOCATION (EVAPORATIVE

EMISSION CONTROL SYSTEM) . . . . . 17-10

PURGE CONTROL SYSTEM CHECK . . 17-10

PURGE PORT VACUUM CHECK . . . . . 17-11

PURGE CONTROL SOLENOID VALVE

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . 17-11

FUEL VAPOUR CANISTER REMOVAL

AND INSTALLATION . . . . . . . . . . . . . . . 17-12

EXHAUST GAS RECIRCULATION

(EGR) SYSTEM . . . . . . . . . . . . . . .17-12

GENERAL INFORMATION

(EGR SYSTEM) . . . . . . . . . . . . . . . . . . . 17-12

COMPONENT LOCATION

(EGR SYSTEM) . . . . . . . . . . . . . . . . . . . 17-14

EGR SYSTEM CHECK . . . . . . . . . . . . . 17-15

EGR VALVE CHECK . . . . . . . . . . . . . . . 17-15

EGR PORT VACUUM CHECK <4G1>. . 17-16

EGR PORT VACUUM CHECK <4G6>. . 17-16

EGR CONTROL SOLENOID VALVE

CHECK <4G1> . . . . . . . . . . . . . . . . . . . . 17-16

EGR CONTROL SOLENOID VALVE

CHECK <4G6> . . . . . . . . . . . . . . . . . . . . 17-17

EXHAUST GAS RECIRCULATION (EGR)

VALVE REMOVAL AND I

NSTALLATION . . . . . . . . . . . . . . . . . . . . 17-18

CATALYTIC CONVERTER . . . . . .17-19

REMOVAL AND INSTALLATION

<4G1, 4G6-M/T> . . . . . . . . . . . . . . . . . . 17-19

REMOVAL AND INSTALLATION

<4G6-A/T> . . . . . . . . . . . . . . . . . . . . . . . 17-19

Page 118 of 800

Battery voltageNormal condition

AppliedVacuum leaks

Not appliedVacuum maintained

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-12

5. Measure the resistance between the terminals of the solenoid valve.

Standard value: 30 − 34 Ω (at 20°C)

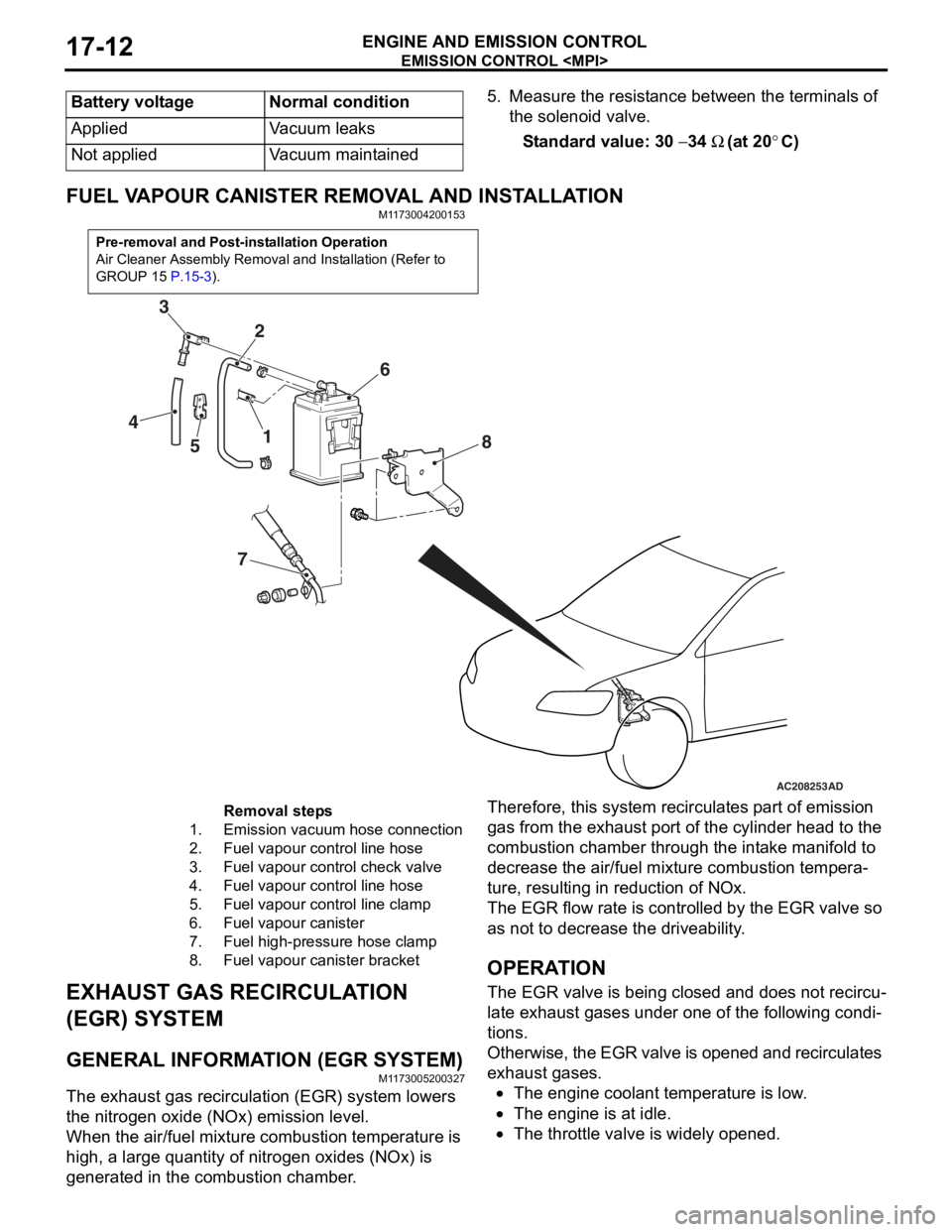

FUEL VAPOUR CANISTER RE MOVAL AND INSTALLATION

M1173004200153

Pre-removal and Post-installation Operation

Air Cleaner Assembly Removal and Installation (Refer to

GROUP 15

P.15-3).

AC208253

1

2

3

4 5 6

7 8

AD

Removal steps

1.Emission vacuum hose connection

2.Fuel vapour control line hose

3.Fuel vapour control check valve

4.Fuel vapour control line hose

5.Fuel vapour control line clamp

6.Fuel vapour canister

7.Fuel high-pressure hose clamp

8.Fuel vapour canister bracket

EXHAUST GAS RECIRCULA

T ION

(EGR) SYSTEM

GENERAL INFORMAT ION (EGR SYSTEM)

M1173 0052 0032 7

The exhaust gas recircu l atio n (EGR) system lowers

the nitrogen

oxide (NOx) emission level.

When the air/fuel mixture combus tio n temp erature is

high,

a larg e qua ntity of nitrogen oxides (NOx) is

generat

ed in the comb ustion chamb e r .

Therefor e, this syst em re circulat es p a rt o f emission

gas fro

m the e x ha ust po rt of the cylinder h ead to th e

combust

i on chamber thro ugh th e int a ke ma nifold to

decre

ase the air/fuel mixture combust i on te mpera

-

ture, resulting in redu ctio n of NOx.

The EGR flow rate is cont rolle d by the EGR valve so

as no

t to de crease the driveability .

OPERAT ION

The EGR valve is being clos ed an d does not re circu-

late ex hau st ga ses unde r one o f the fo llo wing condi-

tions.

Otherwise, th e EGR va lve is opene d an d recircul ates

exha

ust g a ses.

•The engine coolan t temperature is low .

•The engine is at idle.

•The throttle va lve is widely ope ned.

Page 124 of 800

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-18

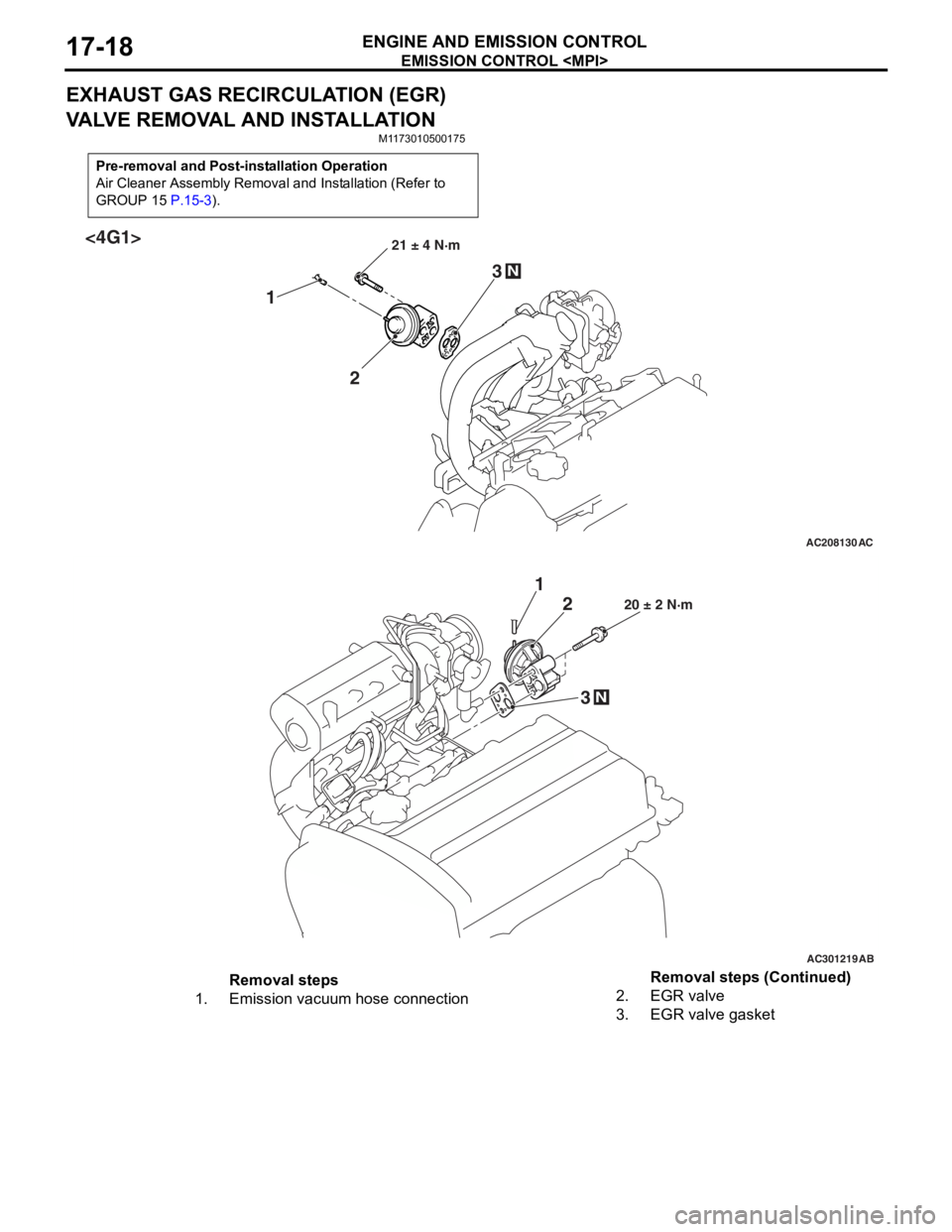

EXHAUST GAS RECIRCULATION (EGR)

VALVE REMOVAL AND INSTALLATION

M1173010500175

Pre-removal and Post-installation Operation

Air Cleaner Assembly Removal and Installation (Refer to

GROUP 15

P.15-3).

AC208130

21 ± 4 N·m

2

1

3

N

AC

<4G1>

AC301219

20 ± 2 N·m2

1

3

N

AB

Removal steps

1.Emission vacuum hose connection2.EGR valve

3.EGR valve gasket

Removal steps (Continued)

Page 125 of 800

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-19

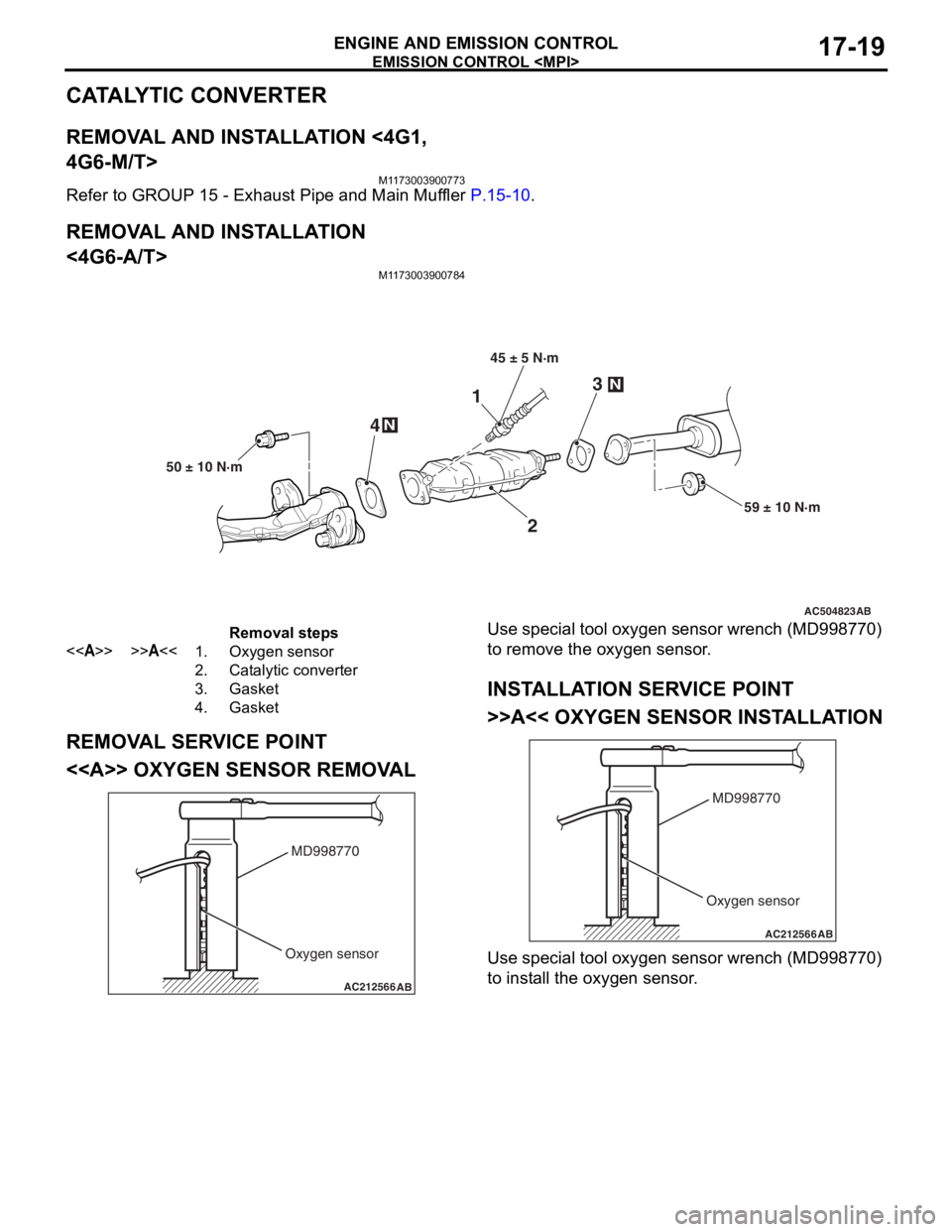

CATALYTIC CONVERTER

REMOVAL AND INSTALLATION <4G1,

4G6-M/T>

M1173003900773

Refer to GROUP 15 - Exhaust Pipe and Main Muffler P.15-10.

REMOVAL AND INSTALLATION

<4G6-A/T>

M1173003900784

AC504823

2

3N

N4

59 ± 10 N·m

50 ± 10 N·m

1

45 ± 5 N·m

AB

Removal steps

<>>>A<<1.Oxygen sensor

2.Catalytic converter

3.Gasket

4.Gasket

REMOVA L SER V ICE POINT

<> OXYGEN SENSOR REMOV A L

AC212566AB

MD998770

Oxygen sensor

Use spec ia l tool oxyg en sen s or wrench (MD9987 70)

to remove

the oxyge n sen s or .

INSTALLA T ION SER VICE POINT

>>A<< OXYGEN SENSOR INST ALL A TION

AC212566AB

MD998770

Oxygen sensor

Use spec ia l tool oxyg en sen s or wrench (MD9987 70)

to inst

all the oxyge n sen s or .

Page 127 of 800

21-1

GROUP 21

CLUTCH

CONTENTS

CLUTCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21A

CLUTCH OVERHAUL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21B