body MITSUBISHI LANCER 2006 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER, Model: MITSUBISHI LANCER 2006Pages: 800, PDF Size: 45.03 MB

Page 142 of 800

FRONT AXLE HUB ASSEMBLY

FRONT AXLE26-10

<

AC100128

MB990241

MB990767

AG

AC303949

MB990244

(Three)

MB990767

MB990242

MB991354

AF

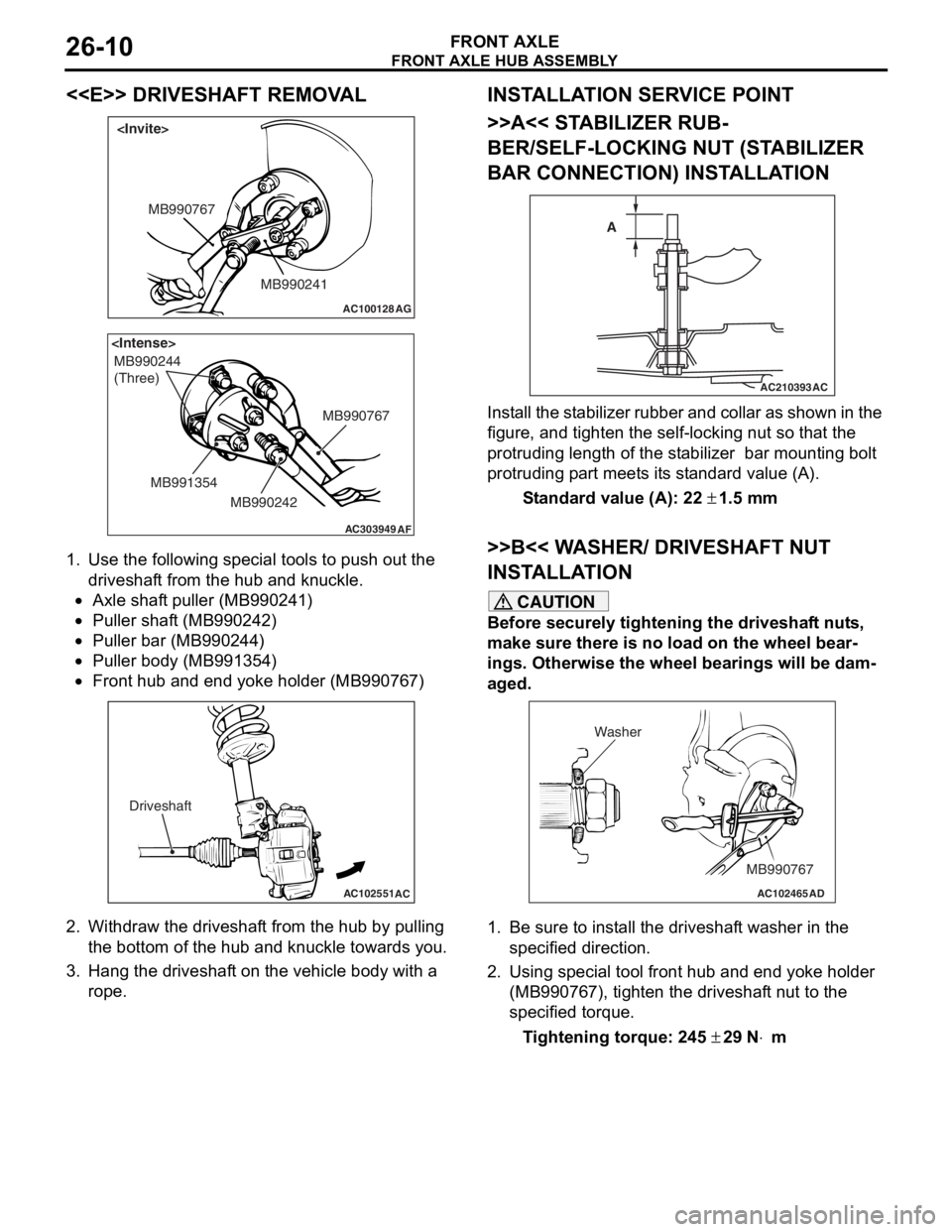

1.

Use the fo llo wing special to ols to pu sh ou t the

driveshaf t from the hub an d kn uckle.

•Axle shaf t puller (MB9 90241 )

•Puller shaft (MB990 242)

•Puller bar (MB990 244)

•Puller body (MB99135 4)

•

AC102551

AC

Driveshaft

Front hub a nd end yoke holder (MB99076 7)

2.Withdraw th e driveshaf t from the hu b by pulling

th e botto m of the hub and knuckle towards you .

3.Hang the dr ive s haf t on the vehicle b ody with a

rope.

INST ALLA T ION SER VICE POINT

>>A<< STABILIZER RUB-

BER/SELF-LOCKING NUT (ST A BILIZER

BAR CONNECTION) INST

ALLA TION

AC210393AC

A

I

n st a ll the st a b ili zer rubb er an d coll ar as sho w n in t he

figure

, and t i ghte n the self-locking nut so tha t the

protruding length

of the st abilize r bar mount ing b o lt

protruding p

a rt meet s it s st and ard value (A).

St andard va lue (A): 22 ± 1.5 m m

>>B<< W A SHER/ DRIVESHAFT NUT

INST

ALLA TION

CAUTION

Before securely tightening the driveshaft nuts,

make sure there is no load on the wheel bear

-

ings. Otherwise the wheel bearings will be dam-

aged.

AC102465AD

MB990767

Washer

1. Be sure to install the driveshaft washer in the

specified direction.

2. Using special tool front hub and end yoke holder (MB990767), tighten the driveshaft nut to the

specified torque.

Tightening torque: 245 ± 29 N⋅m

Page 147 of 800

Page 166 of 800

TROUBLESHOOTING

WHEEL AND TYRE31-4

WHEEL BALANCE ACCURACY

M1311001700247

PURPOSE

This section contains tips and procedures for achiev-

ing accurate wheel balance. Steering wheel vibration

and/or body shake can result if any of these proce

-

dures are not carefully observed.

1. Wheels and tyres must be properly mounted on a balancer in order to achieve correct balance.

Centring the wheel on the shaft of the balancer is

essential for proper mounting.

2. Off-the-car wheel balancers must be calibrated periodically to ensure good balancing results. An

inaccurately calibrated balancer could cause

unnecessary replacement of tyres, shocks,

suspension components, or steering components.

Check your balancer's calibration approximately

every 100 balances. Your wheel balancer's instruc

-

tion manual should include calibration procedures. If

the calibration procedures specifically for your bal

-

ancer are missing, use the generic steps in this sec-

tion for zero calibration, static balance, and dynamic

balance checks. The wheel balancer calibration

checks are also described in the flowchart. (Refer to

P.31-6).

PROCEDURE

1. Confirm that the balancer's cone and the wheel

mounting cone are undamaged and free of dirt

and rust.

2. On this vehicle, the wheel's centre hole on the hub side has a chamfered edge. Use a

back-mounting cone on your wheel balancer to

centre the wheel on the balancer shaft.

3. Install a wheel mounting cone. The appropriate size cone for this vehicle is 67.0 mm.

4. Before balancing the wheel, remove any wheel weights from both sides. Also check both sides for

any damage.

5. When installing wheel weights, hammer them at a straight (not diagonal) angle.

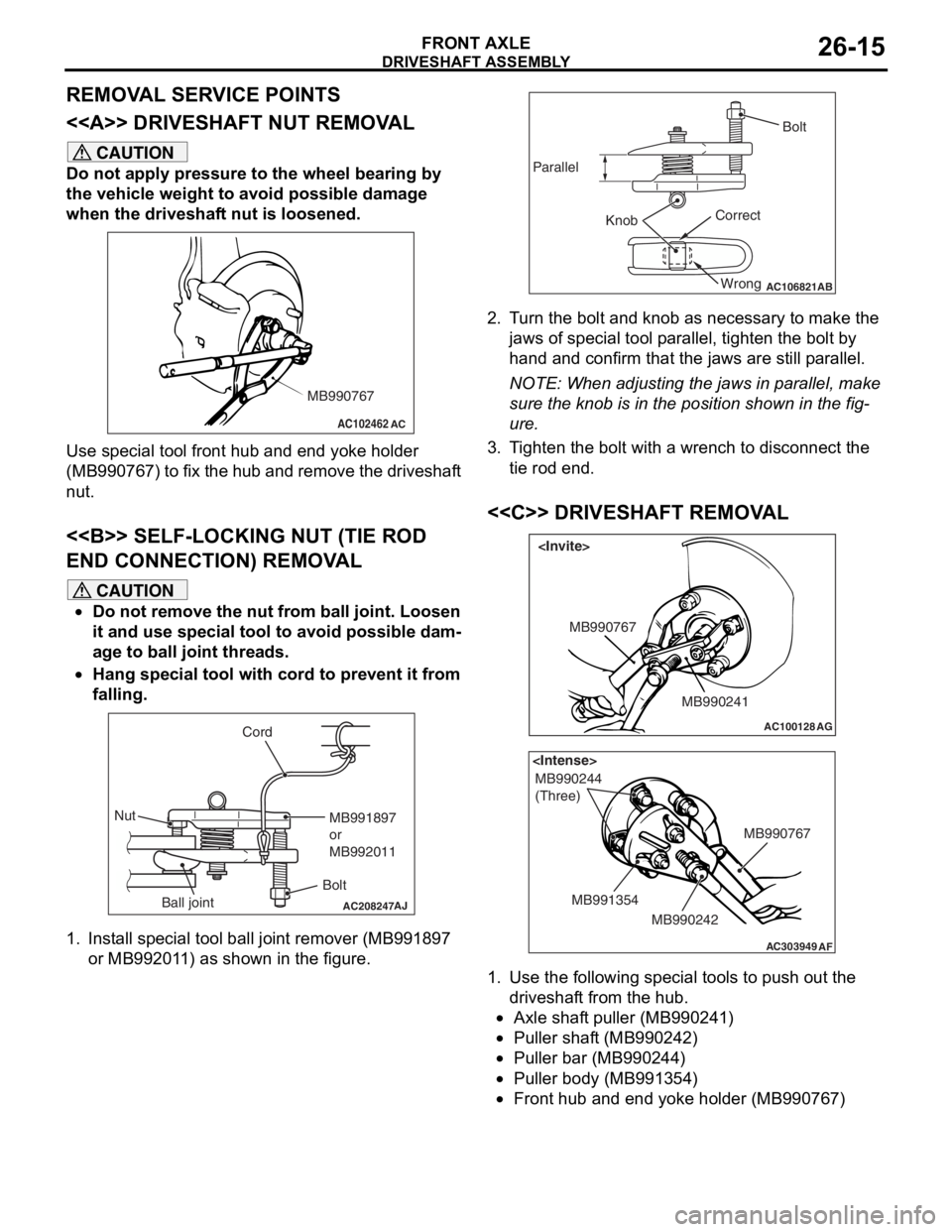

Scalloped

wear

ACX00934

Lack of rot a tio n of tyres or worn

or out-of-a

lign m ent suspensionRota te th e tyre s, an d

check the f

r ont or

rea

r suspension

alignment

s.

Refer to GROUP

33

, On -vehicle

serv

ic e

− Front

whee

l alignment

check and

ad

justmen t

P.33-6.

Refer to GROUP

34

, On -vehicle

serv

ic e

− Rear

whee

l alignment

check and

ad

justmen t

P.34-6.

Sy mptom P robable cause Reme dy Referen ce p a g e

Page 174 of 800

ENGINE MOUNTING

POWER PLANT MOUNT32-4

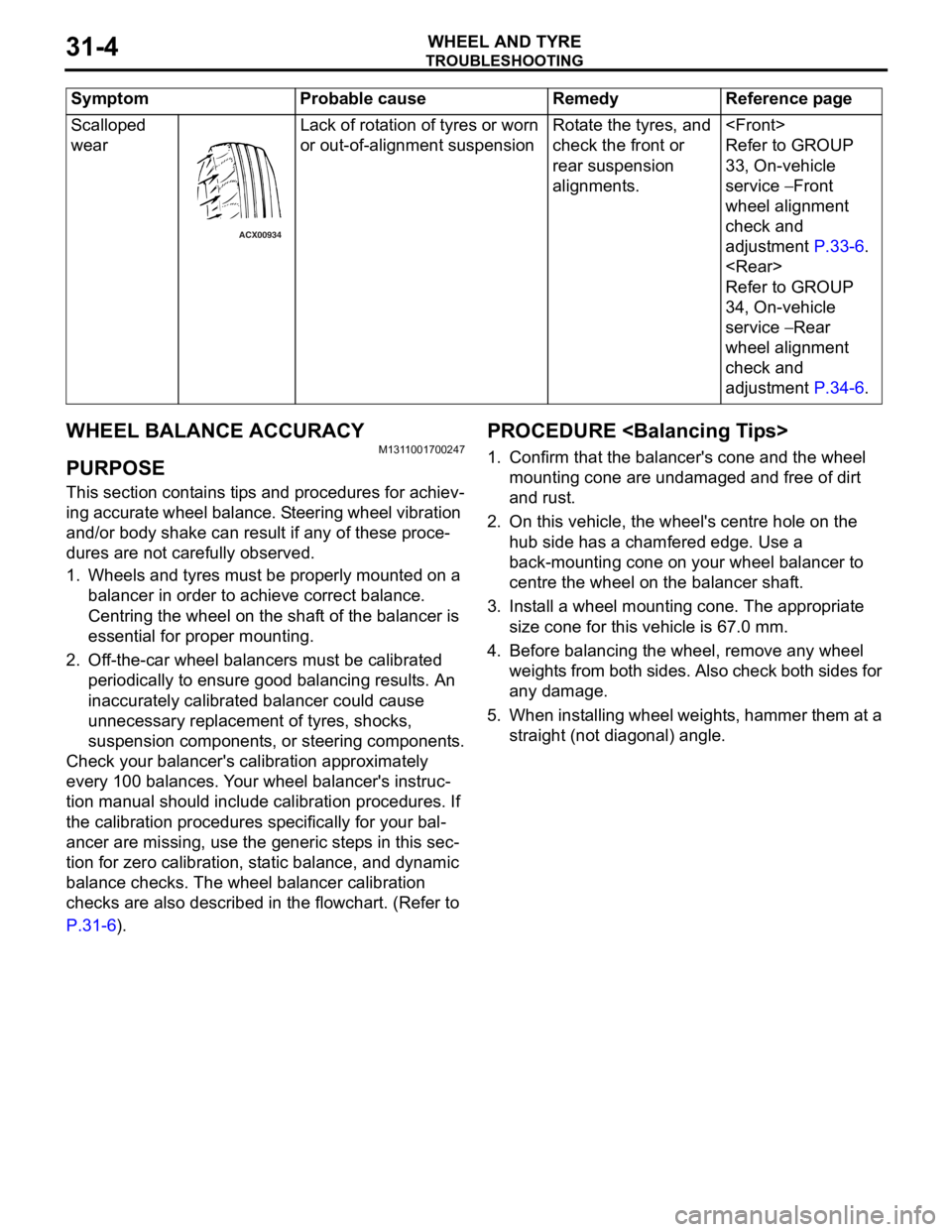

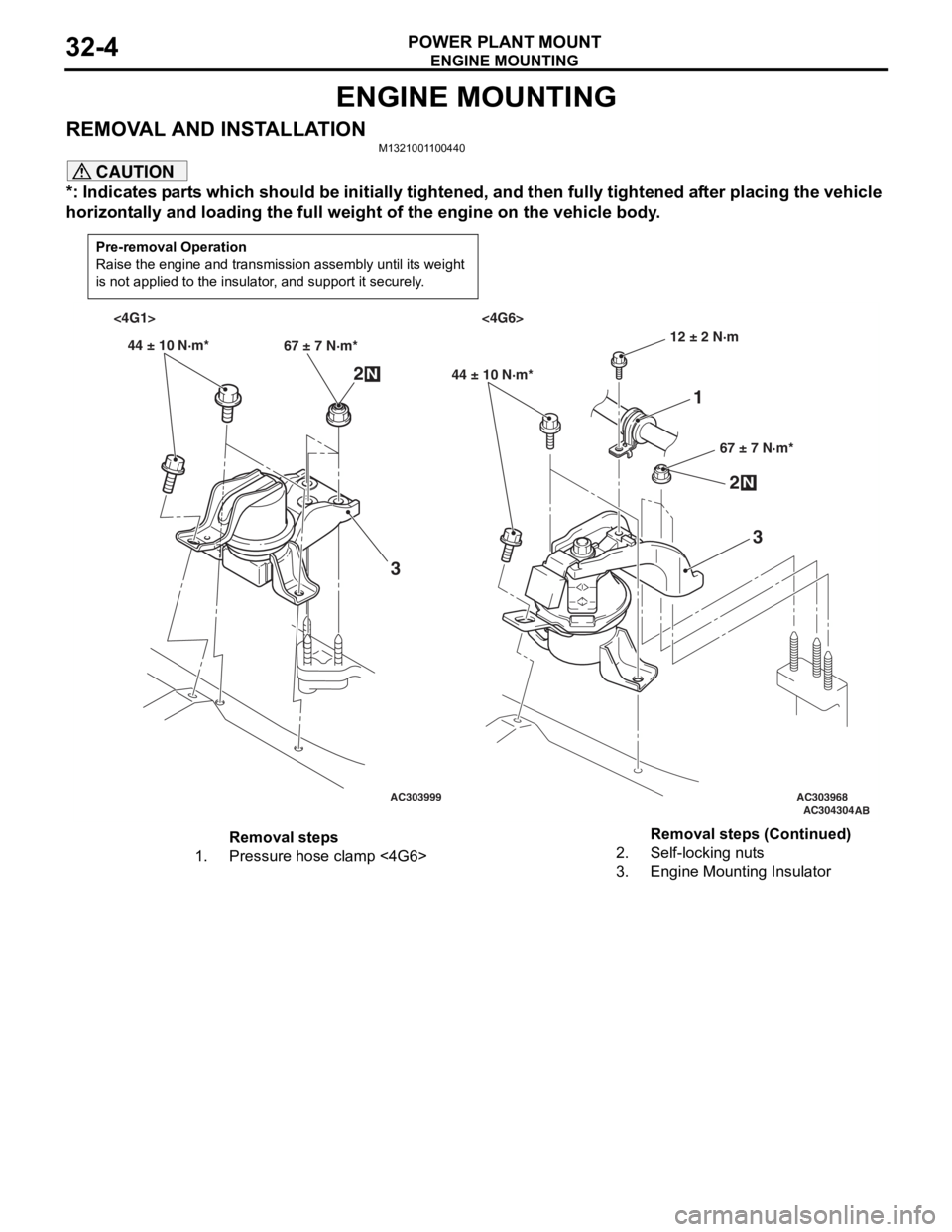

ENGINE MOUNTING

REMOVAL AND INSTALLATIONM1321001100440

CAUTION

*: Indicates parts which should be initially tightened, and then fully tightened after placing the vehicle

horizontally and loading the full weight of the engine on the vehicle body.

Pre-removal Operation

Raise the engine and transmission assembly until its weight

is not applied to the insulator, and support it securely.

AC303999AC303968AC304304AB

<4G1> <4G6>

44 ± 10 N·m* 67 ± 7 N·m*

2N

3

44 ± 10 N·m*

67 ± 7 N·m*

2N

3

12 ± 2 N·m

1

Removal steps

1.Pressure hose clamp <4G6>2.Self-locking nuts

3.Engine Mounting Insulator

Removal steps (Continued)

Page 175 of 800

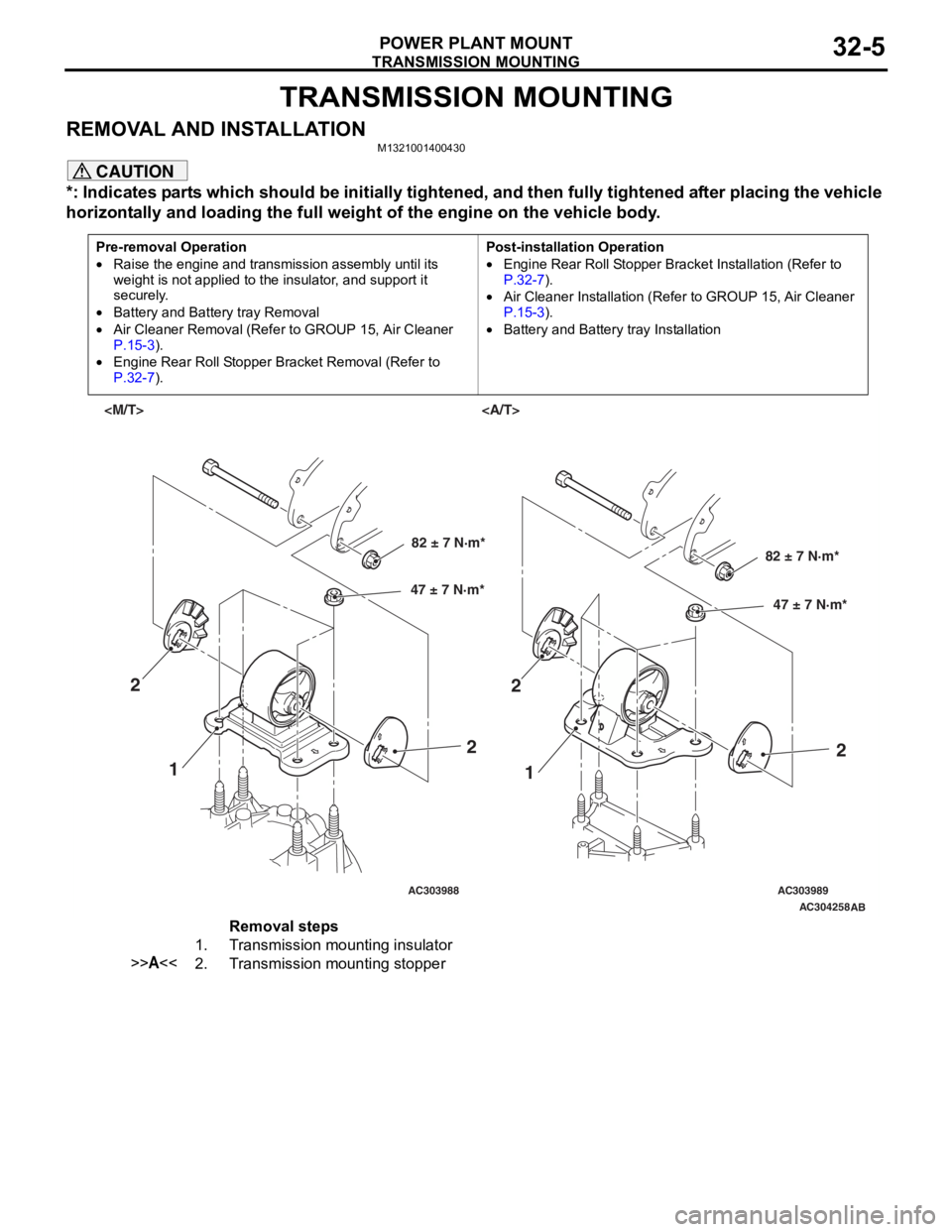

TRANSMISSION MOUNTING

POWER PLANT MOUNT32-5

TRANSMISSION MOUNTING

REMOVAL AND INSTALLATIONM1321001400430

CAUTION

*: Indicates parts which should be initially tightened, and then fully tightened after placing the vehicle

horizontally and loading the full weight of the engine on the vehicle body.

Pre-removal Operation

•Raise the engine and transmission assembly until its

weight is not applied to the insulator, and support it

securely.

•Battery and Battery tray Removal

•Air Cleaner Removal (Refer to GROUP 15, Air Cleaner

P.15-3).

•Engine Rear Roll Stopper Bracket Removal (Refer to

P.32-7).

Post-installation Operation

•Engine Rear Roll Stopper Bracket Installation (Refer to

P.32-7).

•Air Cleaner Installation (Refer to GROUP 15, Air Cleaner

P.15-3).

•Battery and Battery tray Installation

AC303988AC303989AC304258

AB

82 ± 7 N·m*

47 ± 7 N·m*82 ± 7 N·m*

47 ± 7 N·m*

1 1

2

22

2

Removal steps

1.Transmission mounting insulator

>>A<<2.Transmission mounting stopper

Page 177 of 800

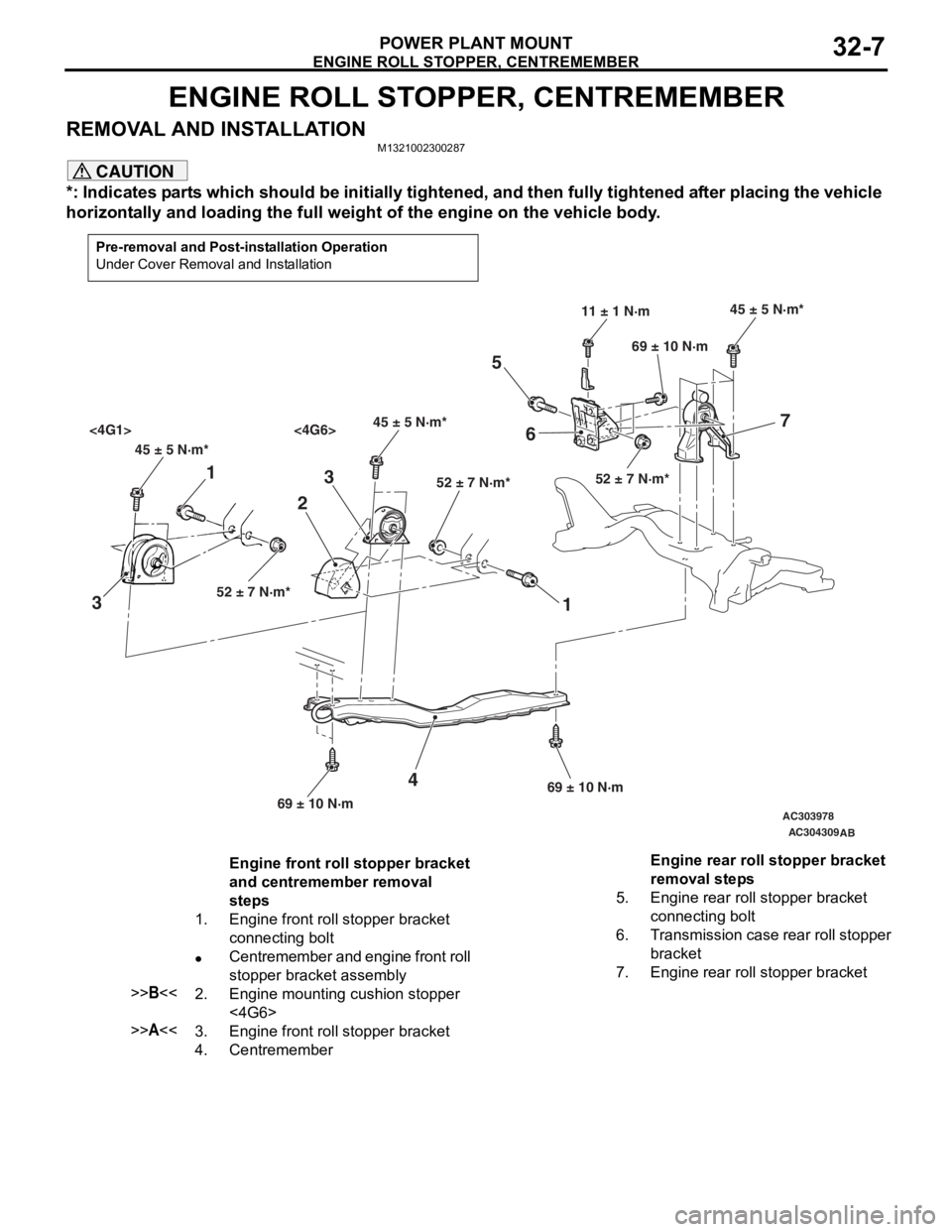

ENGINE ROLL STOPPER, CENTREMEMBER

POWER PLANT MOUNT32-7

ENGINE ROLL STOPPER, CENTREMEMBER

REMOVAL AND INSTALLATIONM1321002300287

CAUTION

*: Indicates parts which should be initially tightened, and then fully tightened after placing the vehicle

horizontally and loading the full weight of the engine on the vehicle body.

Pre-removal and Post-installation Operation

Under Cover Removal and Installation

AC303978

AC304309

45 ± 5 N·m*45 ± 5 N·m*

<4G1> <4G6>

52 ± 7 N·m* 52 ± 7 N·m*

45 ± 5 N·m*

52 ± 7 N·m*

11 ± 1 N·m

69 ± 10 N·m

69 ± 10 N·m 69 ± 10 N·m

1

3 2

1

3

4

56 7

AB

Engine front roll stopper bracket

and centremember removal

steps

1.Engine front roll stopper bracket

connecting bolt

•Centremember and engine front roll

stopper bracket assembly

>>B<<2.Engine mounting cushion stopper

<4G6>

>>A<<3.Engine front roll stopper bracket

4.Centremember

Engine rear roll stopper bracket

removal steps

5.Engine rear roll stopper bracket

connecting bolt

6.Transmission case rear roll stopper

bracket

7.Engine rear roll stopper bracket

Page 178 of 800

CROSSMEMBER

POWER PLANT MOUNT32-8

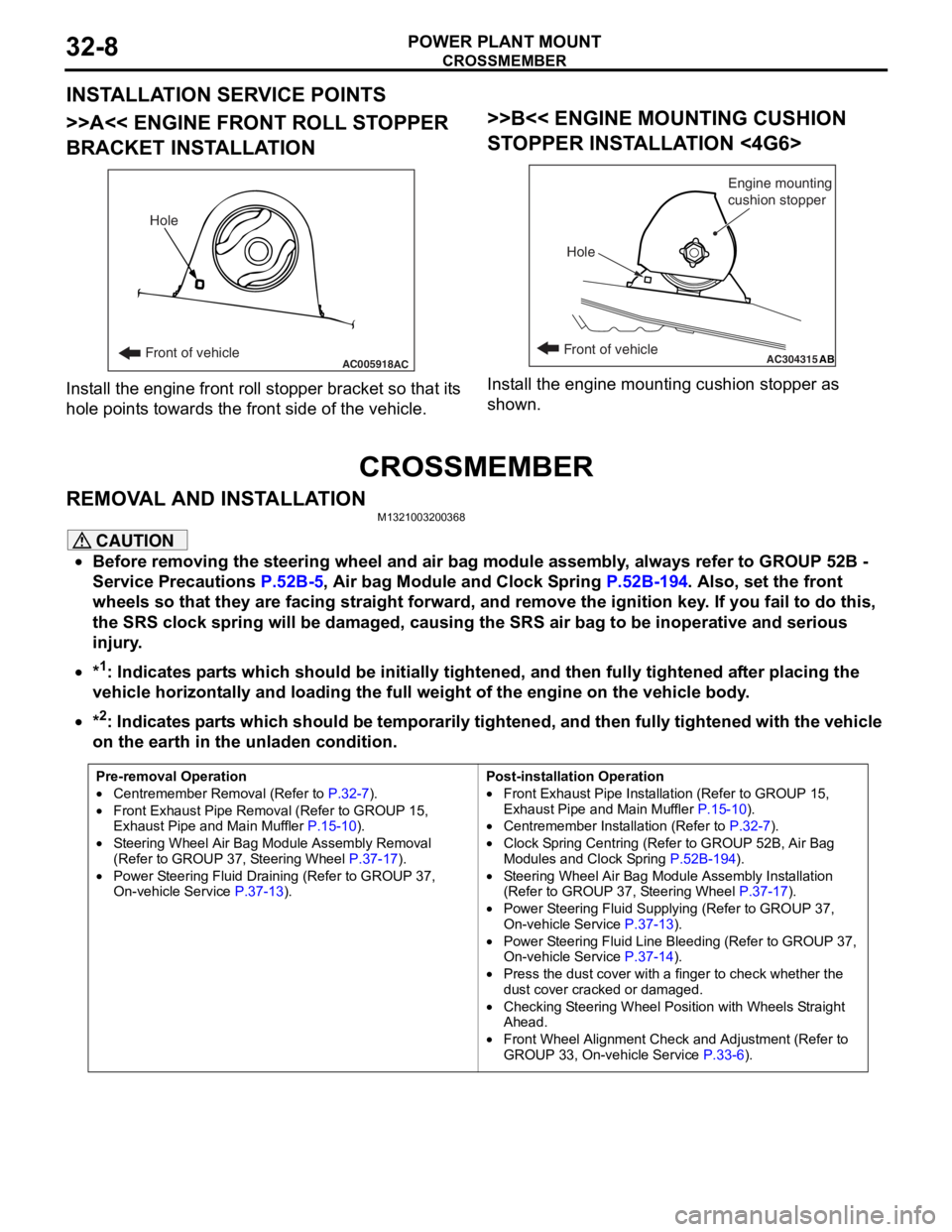

INSTALLATION SERVICE POINTS

>>A<< ENGINE FRONT ROLL STOPPER

BRACKET INSTALLATION

AC005918Front of vehicleHoleAC

Inst

all th e en gine fron t roll stop per b r acket so that it s

hole

point s towards the fro n t side of the vehicle.

>>B<< ENGINE MOUNTING CUSHION

ST

OPPER INST ALLA TION <4G6>

AC304315ABFront of vehicle

Hole Engine mounting

cushion stopper

Inst

all the e ngin e mo untin g cushio n sto pper a s

shown.

CROSSMEMBER

REMOVA L AND INST ALLA TIONM13210032 0036 8

CAUTION

•Before removing the steering wheel and air bag module assembly, always refer to GROUP 52B -

Service Precautions

P.52B-5, Air bag Module and Clock Spring P.52B-194. Also, set the front

wheels so that they are facing straight forward, and remove the ignition key. If you fail to do this,

the SRS clock spring will be damaged, causing the SRS air bag to be inoperative and serious

injury.

•*1: Indicates parts which should be initially tightened, and then fully tightened after placing the

vehicle horizontally and loading the full weight of the engine on the vehicle body.

•

Pre-removal Operation

•Centremember Removal (Refer to P.32-7).

•Front Exhaust Pipe Remova l (Refer to GROUP 15,

Exhaust Pipe and Main Muffler P.15-10).

•Steering Wheel Air Bag Mo dule Assembly Removal

(Refer to GROUP 37, Steering Wheel P.37-17).

•Power Steering Fluid Draining (Refer to GROUP 37,

On-vehicle Service P.37-13).

Post-installation Operation

•Front Exhaust Pipe Installation (Refer to GROUP 15,

Exhaust Pipe and Main Muffler

P.15-10).

•Centremember Installation (Refer to P.32-7).

•Clock Spring Centring (Refer to GROUP 52B, Air Bag

Modules and Clock Spring P.52B-194).

•Steering Wheel Air Bag Module Assembly Installation

(Refer to GROUP 37, Steering Wheel P.37-17).

•Power Steering Fluid Supplying (Refer to GROUP 37,

On-vehicle Service P.37-13).

•Power Steering Fluid Line Bleeding (Refer to GROUP 37,

On-vehicle Service P.37-14).

•Press the dust cover with a finger to check whether the

dust cover cracked or damaged.

•Checking Steering Wheel Position with Wheels Straight

Ahead.

•Front Wheel Alignment Check and Adjustment (Refer to

GROUP 33, On-vehicle Service P.33-6).

*2: Indicates parts which should be temporarily tightened, and then fully tightened with the vehicle

on the earth in the unladen condition.

Page 191 of 800

Page 192 of 800

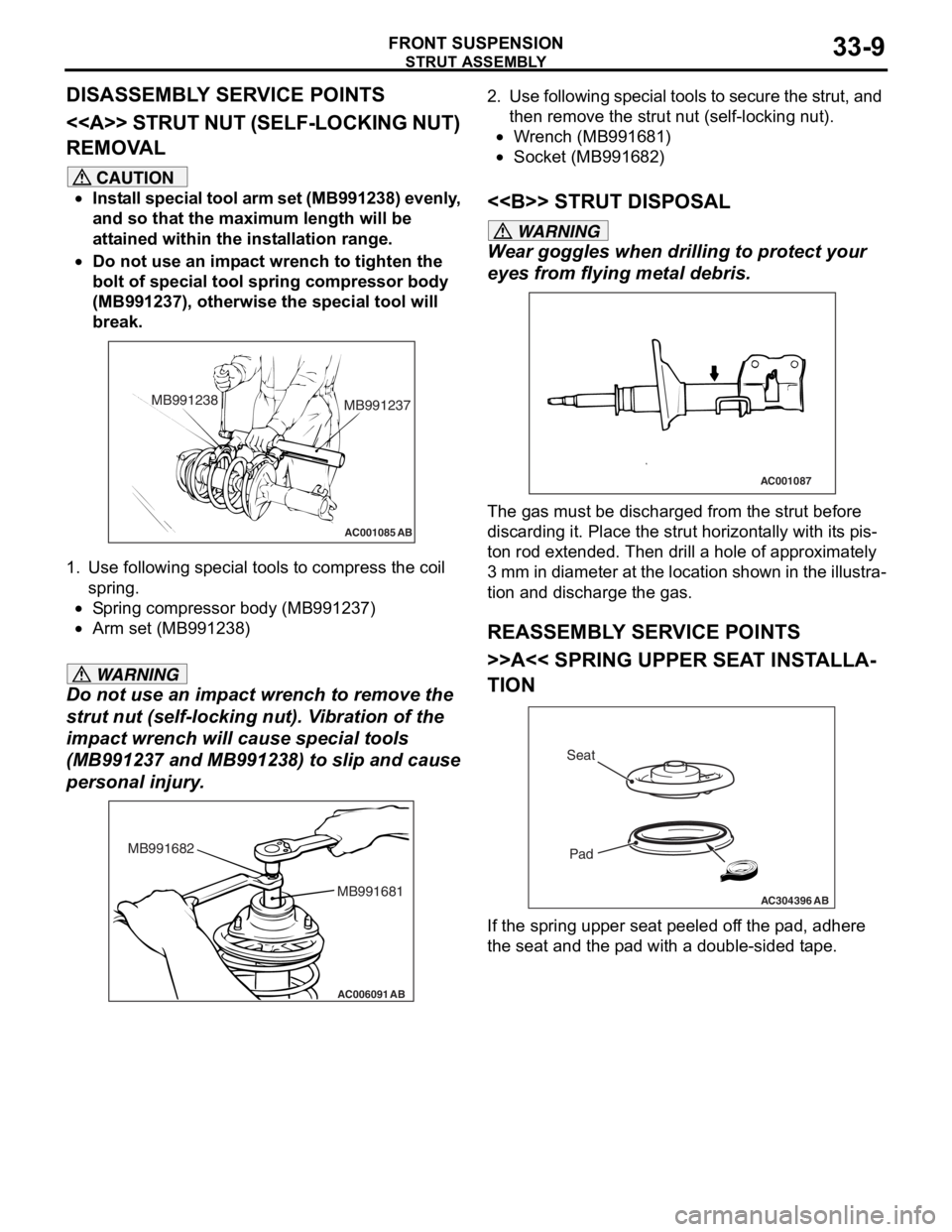

STRUT ASSEMBLY

FRONT SUSPENSION33-10

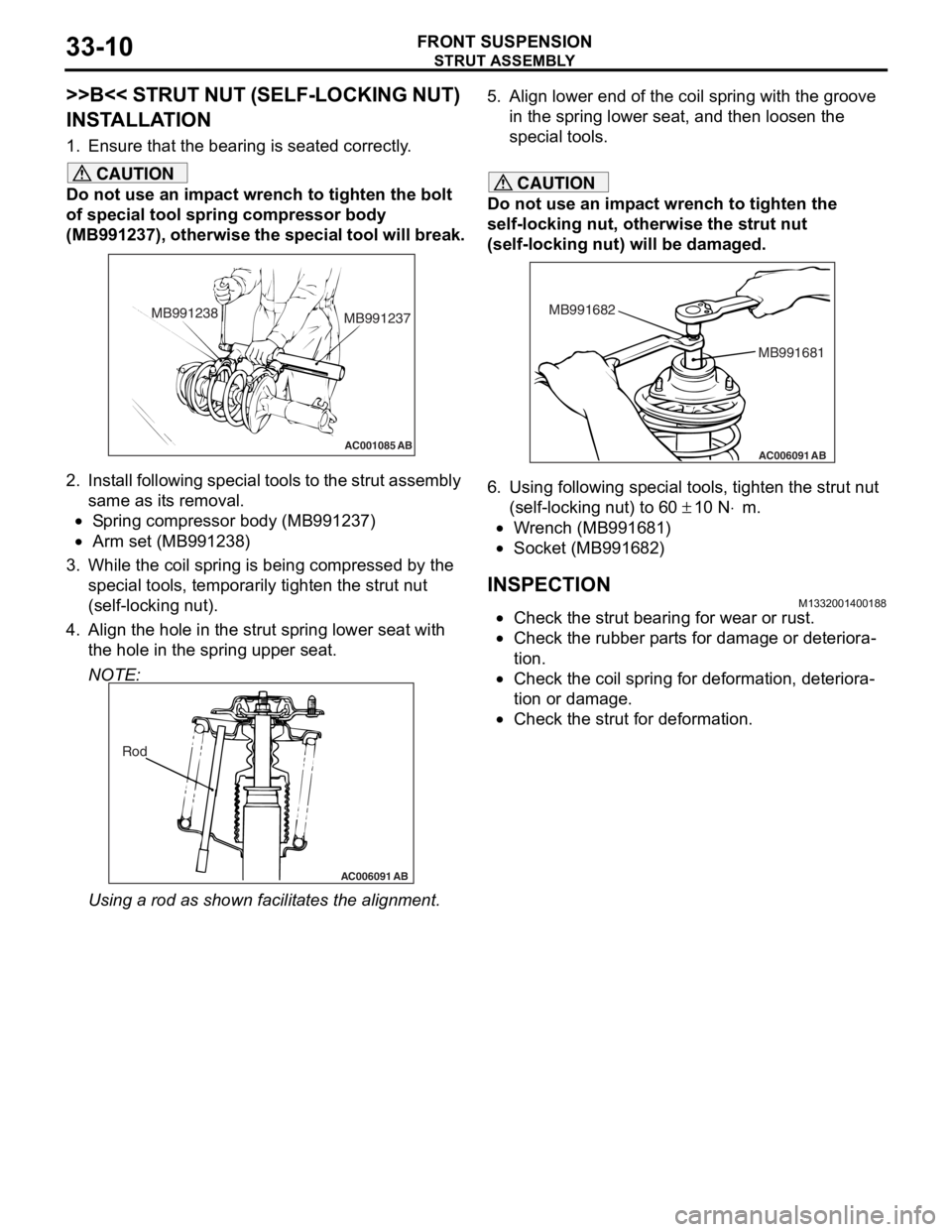

>>B<< STRUT NUT (SELF-LOCKING NUT)

INSTALLATION

1. Ensure that the bearing is seated correctly.

CAUTION

Do not use an impact wrench to tighten the bolt

of special tool spring compressor body

(MB991237), otherwise the special tool will break.

AC001085 AB

MB991238MB991237

2. Install following special tools to the strut assembly

same as its removal.

•Spring compressor body (MB991237)

•Arm set (MB991238)

3. While the coil spring is being compressed by the

special tools, temporarily tighten the strut nut

(self-locking nut).

4. Align the hole in the strut spring lower seat with the hole in the spring upper seat.

NOTE:

AC006091 AB

Rod

Using a rod as shown fa cilitates the alignment.

5. Align lower end of the coil spring with the groove

in the spring lower seat, and then loosen the

special tools.

CAUTION

Do not use an impact wrench to tighten the

self-locking nut, otherwise the strut nut

(self-locking nut) will be damaged.

AC006091 AB

MB991681

MB991682

6. Using following special tools, tighten the strut nut

(self-locking nut) to 60

± 10 N⋅m.

•Wrench (MB991681)

•Socket (MB991682)

INSPECTIONM1332001400188

•Check the strut bearing for wear or rust.

•Check the rubber parts for damage or deteriora-

tion.

•Check the coil spring for deformation, deteriora-

tion or damage.

•Check the strut for deformation.

Page 196 of 800

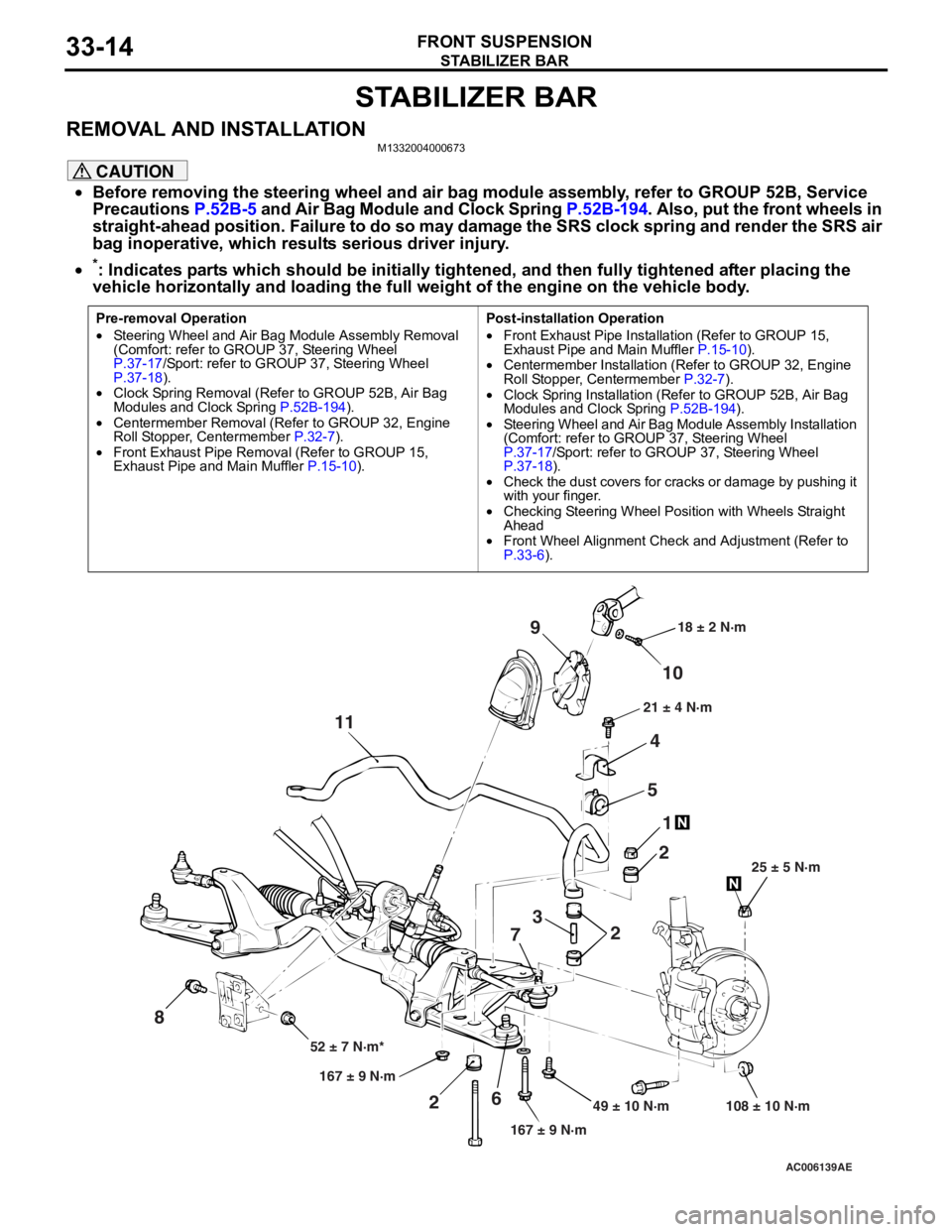

STABILIZER BAR

FRONT SUSPENSION33-14

STABILIZER BAR

REMOVAL AND INSTALLATIONM1332004000673

CAUTION

•Before removing the steering wheel and air bag module assembly, refer to GROUP 52B, Service

Precautions

P.52B-5 and Air Bag Module and Clock Spring P.52B-194. Also, put the front wheels in

straight-ahead position. Failure to do so may damage the SRS clock spring and render the SRS air

bag inoperative, which results serious driver injury.

•

Pre-removal Operation

•Steering Wheel and Air Bag Module Assembly Removal

(Comfort: refer to GROUP 37, Steering Wheel

P.37-17/Sport: refer to GROUP 37, Steering Wheel P.37-18).•Clock Spring Removal (Refer to GROUP 52B, Air Bag

Modules and Clock Spring P.52B-194).

•Centermember Removal (Ref er to GROUP 32, Engine

Roll Stopper, Centermember P.32-7).

•Front Exhaust Pipe Remova l (Refer to GROUP 15,

Exhaust Pipe and Main Muffler P.15-10).

Post-installation Operation

•Front Exhaust Pipe Installation (Refer to GROUP 15,

Exhaust Pipe and Main Muffler P.15-10).•Centermember Installation (Refer to GROUP 32, Engine

Roll Stopper, Centermember P.32-7).

•Clock Spring Installation (Refer to GROUP 52B, Air Bag

Modules and Clock Spring P.52B-194).

•Steering Wheel and Air Bag Module Assembly Installation

(Comfort: refer to GROUP 37, Steering Wheel

P.37-17/Sport: refer to GROUP 37, Steering Wheel P.37-18).•Check the dust covers for cracks or damage by pushing it

with your finger.

•Checking Steering Wheel Position with Wheels Straight

Ahead

•Front Wheel Alignment Check and Adjustment (Refer to P.33-6).

AC006139 AE

49 ± 10 N·m 108 ± 10 N·m

167 ± 9 N·m

167 ± 9 N·m

52 ± 7 N·m* 25 ± 5 N·m

21 ± 4 N·m

18 ± 2 N·m

10

9

4

5 1

2

2

3

7

6

2

11

8

*: Indicates parts which should be initially tightened, and then fully tightened after placing the

vehicle horizontally and loading the full weight of the engine on the vehicle body.