body MITSUBISHI LANCER 2006 Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER, Model: MITSUBISHI LANCER 2006Pages: 800, PDF Size: 45.03 MB

Page 204 of 800

ON-VEHICLE SERVICE

REAR SUSPENSION34-6

ON-VEHICLE SERVICE

REAR WHEEL ALIGNMENT CHECK AND

ADJUSTMENT

M1341011000372

Measure wheel alignment with an alignment equip-

ment on level earth.

The rear suspension, wheels, and tyres should be

serviced to the normal condition prior to wheel align

-

ment measurement.

CAMBER

Standard value: −0°40' ± 0°30' (Left/right devi-

ation within 30')

CAUTION

Never subject the wheel bearings to the vehicle

load when the rear wheel hub nuts (self-locking

nuts) or special tool wheel alignment gauge

attachment (MB991014) are loosened.

NOTE:

AC001079

MB991014

AG

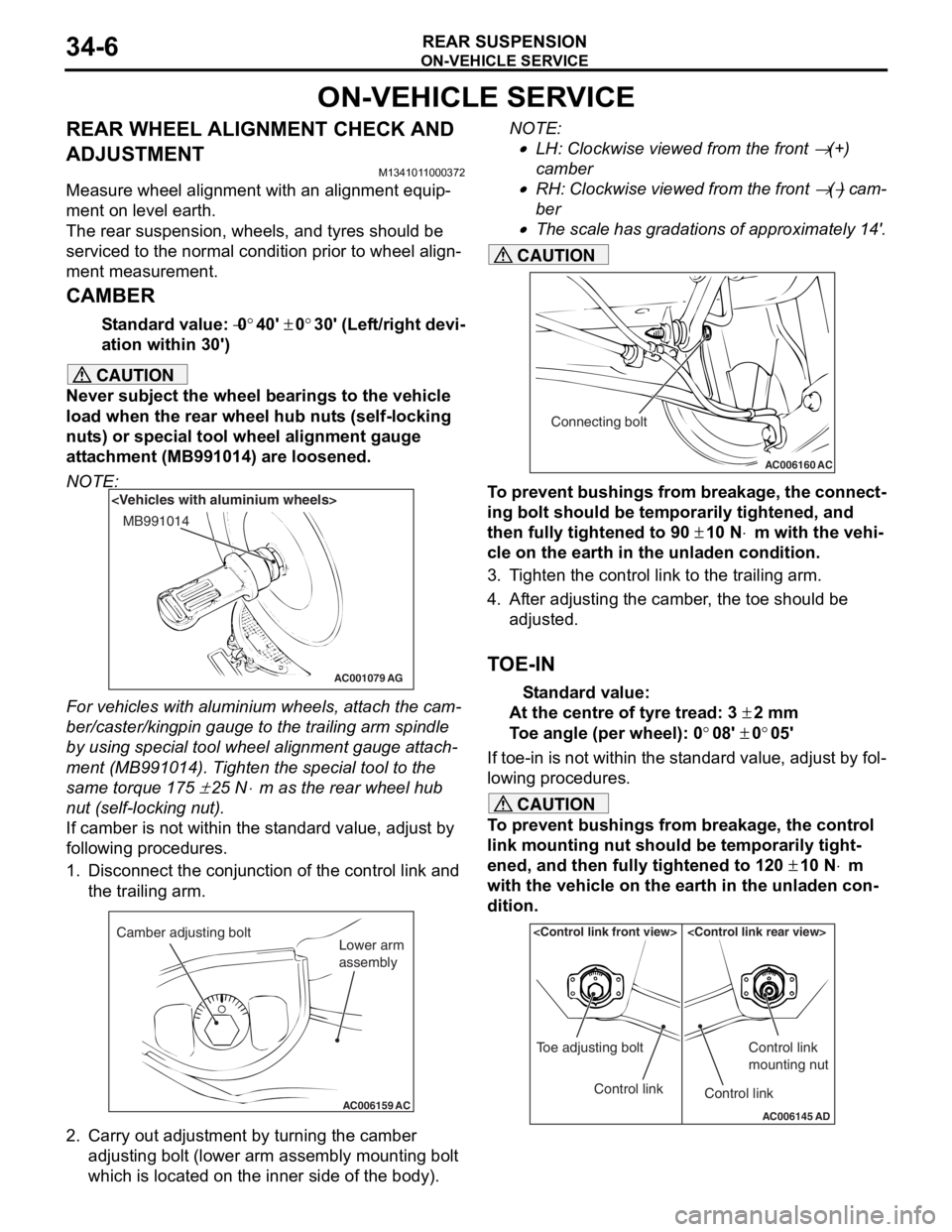

For vehicles with aluminium wheels, attach the cam-

ber/caster/kingpin gauge to the trailing arm spindle

by using special tool wheel alignment gauge attach

-

ment (MB991014). Tighten the special tool to the

same torque 175

± 25 N⋅m as the rear wheel hub

nut (self-locking nut).

If camber is not within the standard value, adjust by

following procedures.

1. Disconnect the conjunction of the control link and the trailing arm.

AC006159 AC

Camber adjusting bolt

Lower arm

assembly

2. Carry out adjustment by turning the camber

adjusting bolt (lower arm assembly mounting bolt

which is located on the inner side of the body).

NOTE: .

•LH: Clockwise viewed from the front → (+)

camber

•RH: Clockwise viewed from the front → (−) cam-

ber

•

AC006160 AC

Connecting bolt

The scale has gradations of approximately 14'.

CAUTION

To prevent bushings from breakage, the connect-

ing bolt should be temporarily tightened, and

then fully tightened to 90

± 10 N⋅m with the vehi-

cle on the earth in the unladen condition.

3. Tighten the control link to the trailing arm.

4. After adjusting the camber, the toe should be

adjusted.

TOE-IN

Standard value:

At the centre of tyre tread: 3 ± 2 mm

Toe angle (per wheel): 0°08' ± 0°05'

If toe-in is not within the standard value, adjust by fol-

lowing procedures.

CAUTION

To prevent bushings from breakage, the control

link mounting nut should be temporarily tight

-

ened, and then fully tightened to 120 ± 10 N⋅m

with the vehicle on the earth in the unladen con

-

dition.

AC006145 AD

Control link

Toe adjusting boltControl link

Control link

mounting nut

Page 205 of 800

ON-VEHICLE SERVICE

REAR SUSPENSION34-7

Carry out adjustment by turning the toe adjusting bolt

(control link mounting bolt which is located on the

inner side of the body).

NOTE: .

•LH: Clockwise viewed from the front → To e - i n

•RH: Clockwise viewed from the front → Toe-out

•Turning the toe adjusting bolt by one groove of

the scale, toe can be changed approximately 2.6

mm (single side toe angle equivalent to 16').

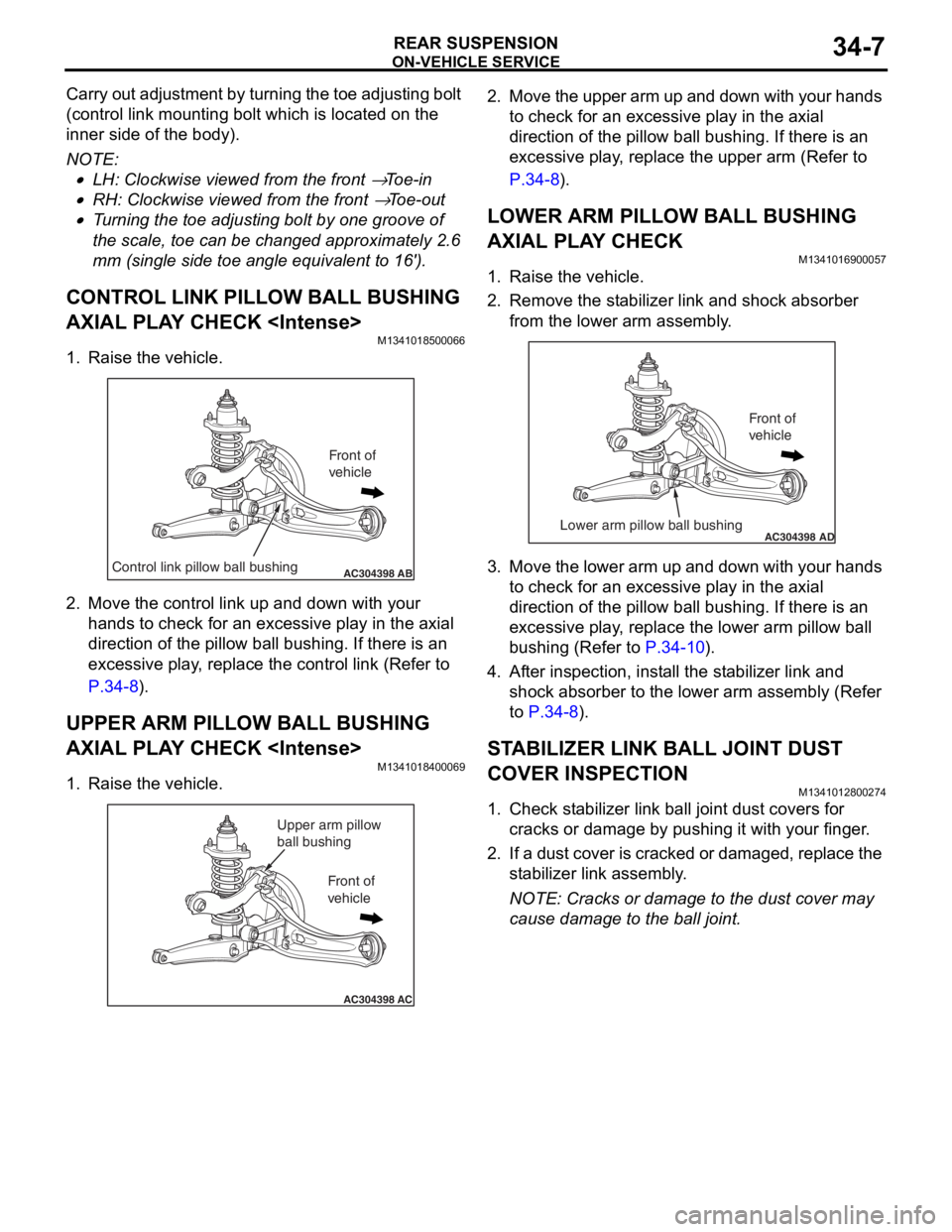

CONTROL LINK PILLOW BALL BUSHING

AXIAL PLAY CHECK

M1341018500066

1. Raise the vehicle.

AC304398ABControl link pillow ball bushing

Front of

vehicle

2.Move the control link up and d o wn with your

ha nds to ch eck for an excessive pla y in the a x ia l

direct ion o f the p illow ball bushing . If the r e is an

exce ssive play , re place the cont rol link (Re f er to

P.34-8).

UPPER ARM PILLOW BALL BUSHING

AXIAL PLAY CHECK

M13410184 0006 9

1.Raise th e ve hicle.

AC304398AC

Upper arm pillow

ball bushing

Front of

vehicle

2. Move the up per arm up and down with you r hand s

to che ck for an e xce ssive play in the axial

d i rection o f the p illow ball bushing . If the r e is an

e xce ssive play , re place the upper arm (Refe r to

P.34-8).

LOWER ARM PILLOW BALL BUSHING

AXIAL PLAY CHECK

M13410169 0005 7

1.Raise th e ve hicle.

2.Remove the st a b ilizer link and shock a b sorb er

f r om t h e l o we r arm a s s e mb l y .

AC304398ADLower arm pillow ball bushing

Front of

vehicle

3.Move the lower a r m u p and down with your h ands

to che ck for an e xce ssive play in the axial

d i rection o f the p illow ball bushing . If the r e is an

e xce ssive play , re place the lower a r m pillo w b a ll

b u shing (Refer to

P.34-10).

4.Af ter inspe c tio n , in st all the st a b ilizer link and

shock a b sorb er to the lower arm assembly (Refer

to

P.34-8).

STABILIZER LINK BALL JOINT DUST

COVER INSPECTION

M1341 0128 0027 4

1.Check st abilize r lin k ba ll joint dust covers f o r

cracks o r damage by pushing it wit h you r fing er .

2. If a du st cove r is crack ed or da mag ed, rep l ace t he

st a b ili zer link assembly .

NOTE: Cracks or dama ge to t he dust co ver may

cause damage to the b a ll join t.

Page 211 of 800

Page 214 of 800

SHOCK ABSORBER ASSEMBLY

REAR SUSPENSION34-16

DISASSEMBLY AND REASSEMBLY

M1341005300460

AC304156AE

25 ± 5 N·m

1

2

4

5

3

6

7

8

9

11

13

12

10

8

Wagon

(Invite)

Sedan,

Wagon

(Intense)

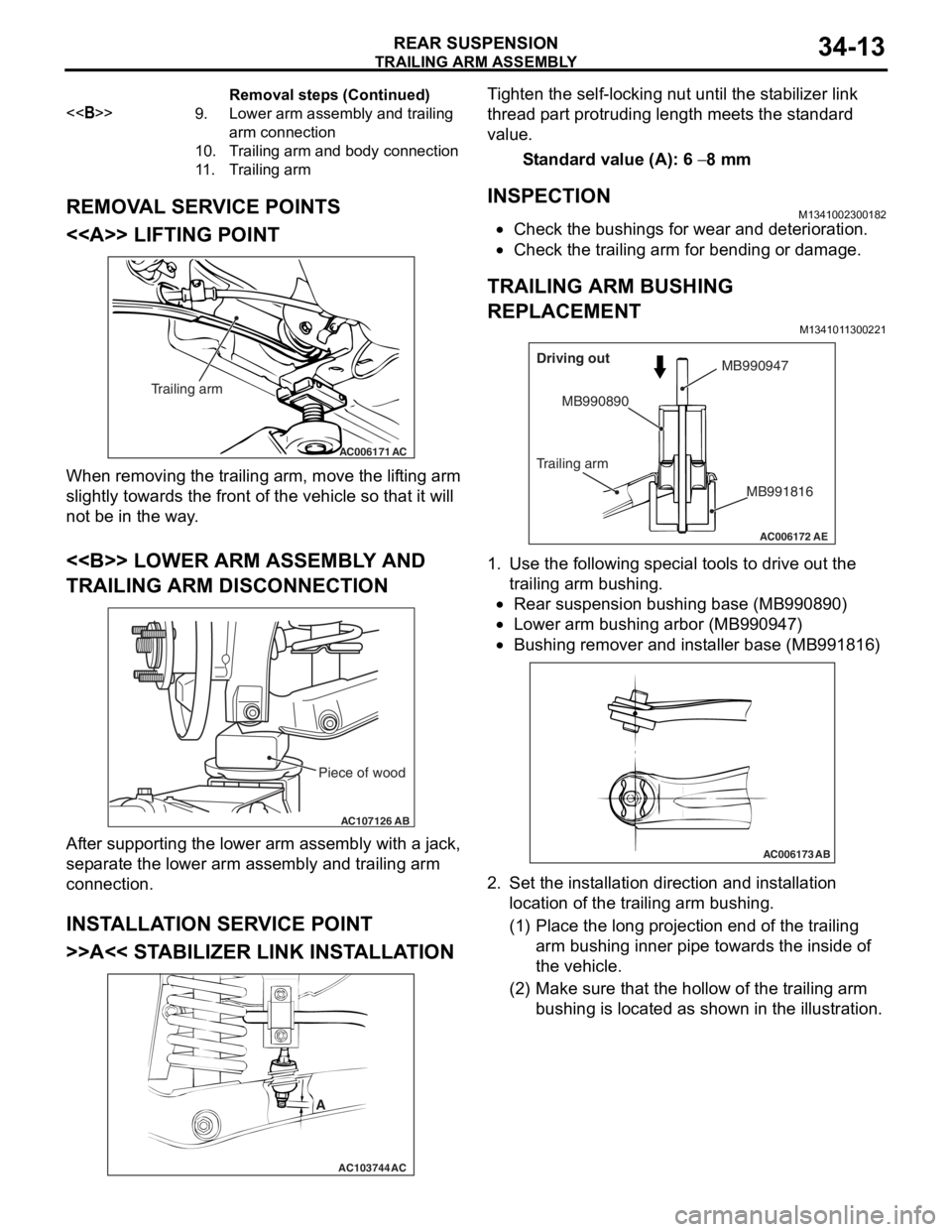

Disassembly steps

<>>>E<<1.Rear suspension coil spring nut

(self-locking nut)

2.Rear suspension coil spring washer

3.Rear suspension coil spring bushing

4.Rear suspension coil spring collar

>>D<<5.Rear shock absorber insulator

6.Rear suspension coil spring bushing

7.Rear suspension spring damper plate

8.Rear shock absorber damper

9.Rear shock absorber cover

>>C<<10.Rear suspension spring upper pad

>>B<<11 .Rear suspension coil spring

>>A<<12.Rear suspension spring lower pad

<>13.Rear suspension shock absorber

DISASSEMBL

Y SER V ICE POINTS

<> REAR SUSPENSION COIL SPRING

NUT (SELF-LOCKING NUT) REMOV

A L

CAUTION

•To hold the coil spring securely, install spe-

cial tool arm set (MB991239) evenly, and so

that the space between both arms of the spe

-

cial tool will be maximum within the installa-

tion range.

•

AC001070

MB991237

MB991239

AB

Do not use an impact wrench to tighten the

bolt of special tool spring compressor body

(MB991237). It will break the special tool.

1. Use following special tools to compress the coil spring.

•Spring compressor body (MB991237)

•Arm set (MB991239)

Page 215 of 800

SHOCK ABSORBER ASSEMBLY

REAR SUSPENSION34-17

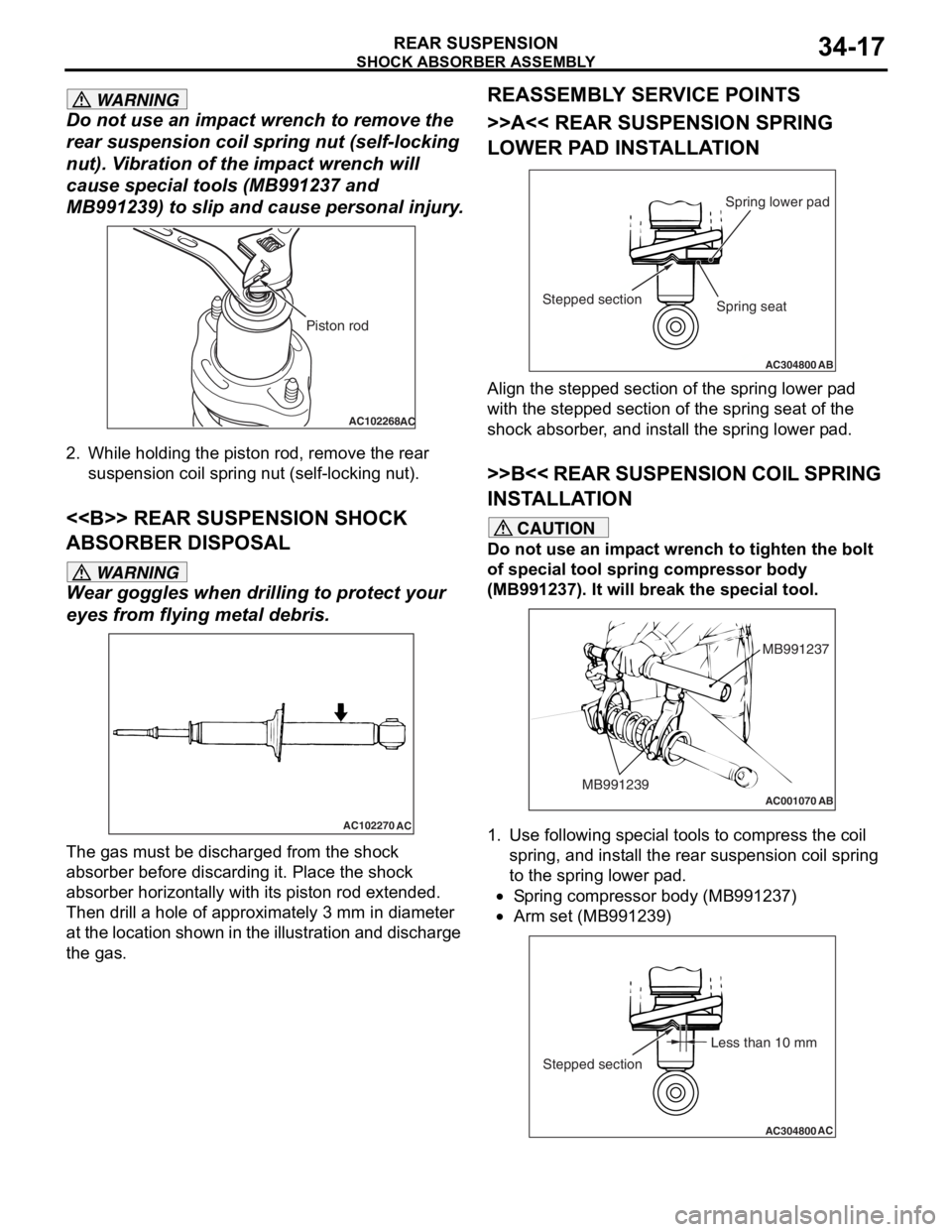

WARNING

Do not use an impact wrench to remove the

rear suspension coil spring nut (self-locking

nut). Vibration of the impact wrench will

cause special t ools (MB991237 and

MB991239) to slip and cause personal injury.

AC102268AC

Piston rod

2. While holding the piston rod, remove the rear

suspension coil spring nut (self-locking nut).

<> REAR SUSPENSION SHOCK

ABSORBER DISPOSAL

WARNING

Wear goggles when dril ling to protect your

eyes from flying metal debris.

AC102270

AC

The gas must be discharged from the shock

absorber before discarding it. Place the shock

absorber horizontally with its piston rod extended.

Then drill a hole of approximately 3 mm in diameter

at the location shown in the illustration and discharge

the gas.

REASSEMBLY SERVICE POINTS

>>A<< REAR SUSPENSION SPRING

LOWER PAD INSTALLATION

AC304800AB

Spring lower pad

Stepped section

Spring seat

Align the stepped section of the spring lower pad

with the stepped section of the spring seat of the

shock absorber, and install the spring lower pad.

>>B<< REAR SUSPENSION COIL SPRING

INSTALLATION

CAUTION

Do not use an impact wrench to tighten the bolt

of special tool spring compressor body

(MB991237). It will break the special tool.

AC001070

MB991237

MB991239

AB

1. Use following special tools to compress the coil spring, and install the rear suspension coil spring

to the spring lower pad.

•Spring compressor body (MB991237)

•

AC304800AC

Less than 10 mm

Stepped section

Arm set (MB991239)

Page 246 of 800

ON-VEHICLE SERVICE

POWER STEERING37-16

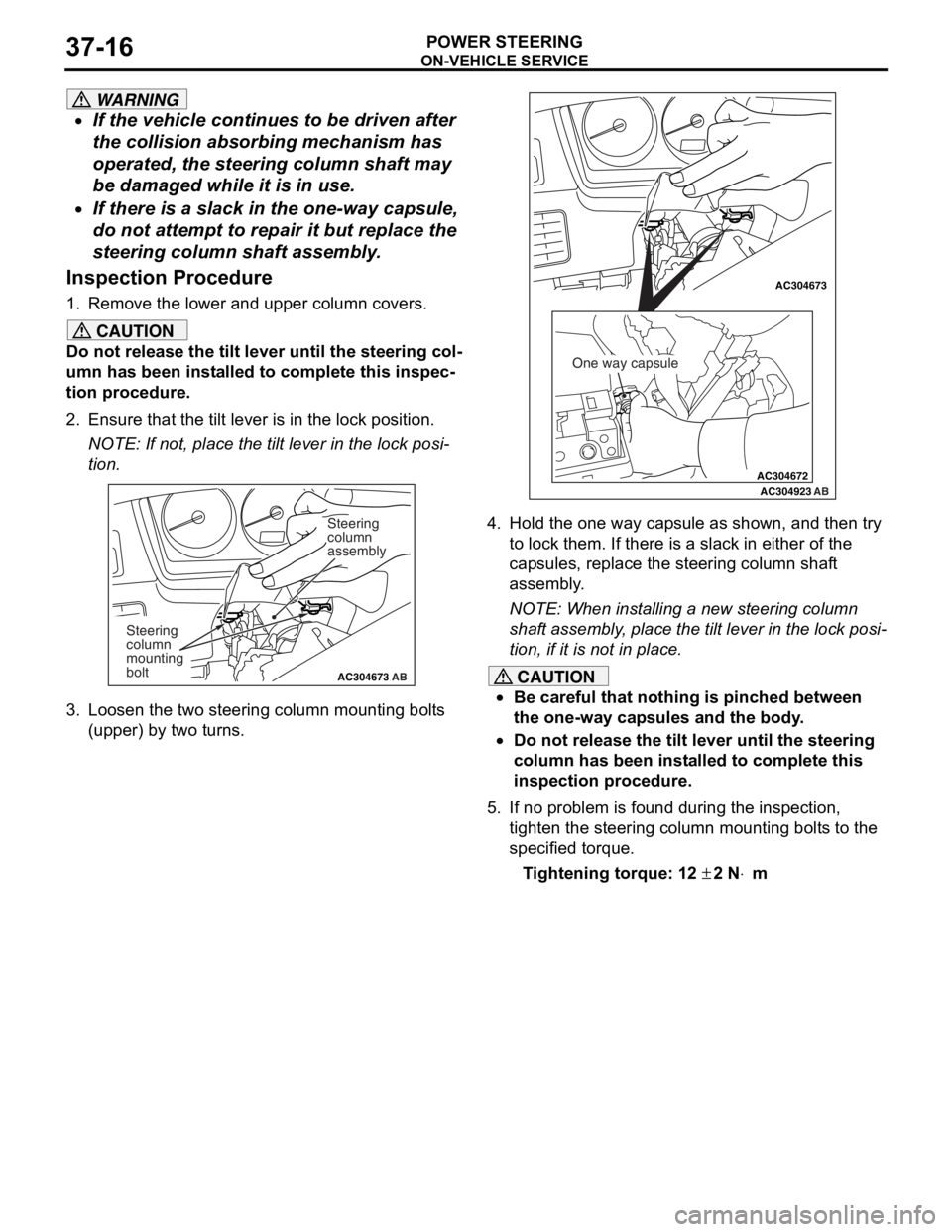

WARNING

•If the vehicle continues to be driven after

the collision absorbing mechanism has

operated, the steering column shaft may

be damaged while it is in use.

•If there is a slack in the one-way capsule,

do not attempt to repa ir it but replace the

steering column shaft assembly.

Inspection Procedure

1. Remove the lower and upper column covers.

CAUTION

Do not release the tilt lever until the steering col-

umn has been installed to complete this inspec-

tion procedure.

2. Ensure that the tilt lever is in the lock position.

NOTE: If not, place the tilt lever in the lock posi-

tion.

AC304673AC304673

Steering

column

assembly

AB

Steering

column

mounting

bolt

3. Loosen the two steering column mounting bolts

(upper) by two turns.

AC304672

AC304673AC304673

AC304923 AB

One way capsule

4. Hold the one way capsule as shown, and then try

to lock them. If there is a slack in either of the

capsules, replace the steering column shaft

assembly.

NOTE: When installing a new steering column

shaft assembly, place the tilt lever in the lock posi

-

tion, if it is not in place.

CAUTION

•Be careful that nothing is pinched between

the one-way capsules and the body.

•Do not release the tilt lever until the steering

column has been installed to complete this

inspection procedure.

5. If no problem is found during the inspection, tighten the steering column mounting bolts to the

specified torque.

Tightening torque: 12 ± 2 N⋅m

Page 269 of 800

POWER STEERING OIL PUMP ASSEMBLY

POWER STEERING37-39

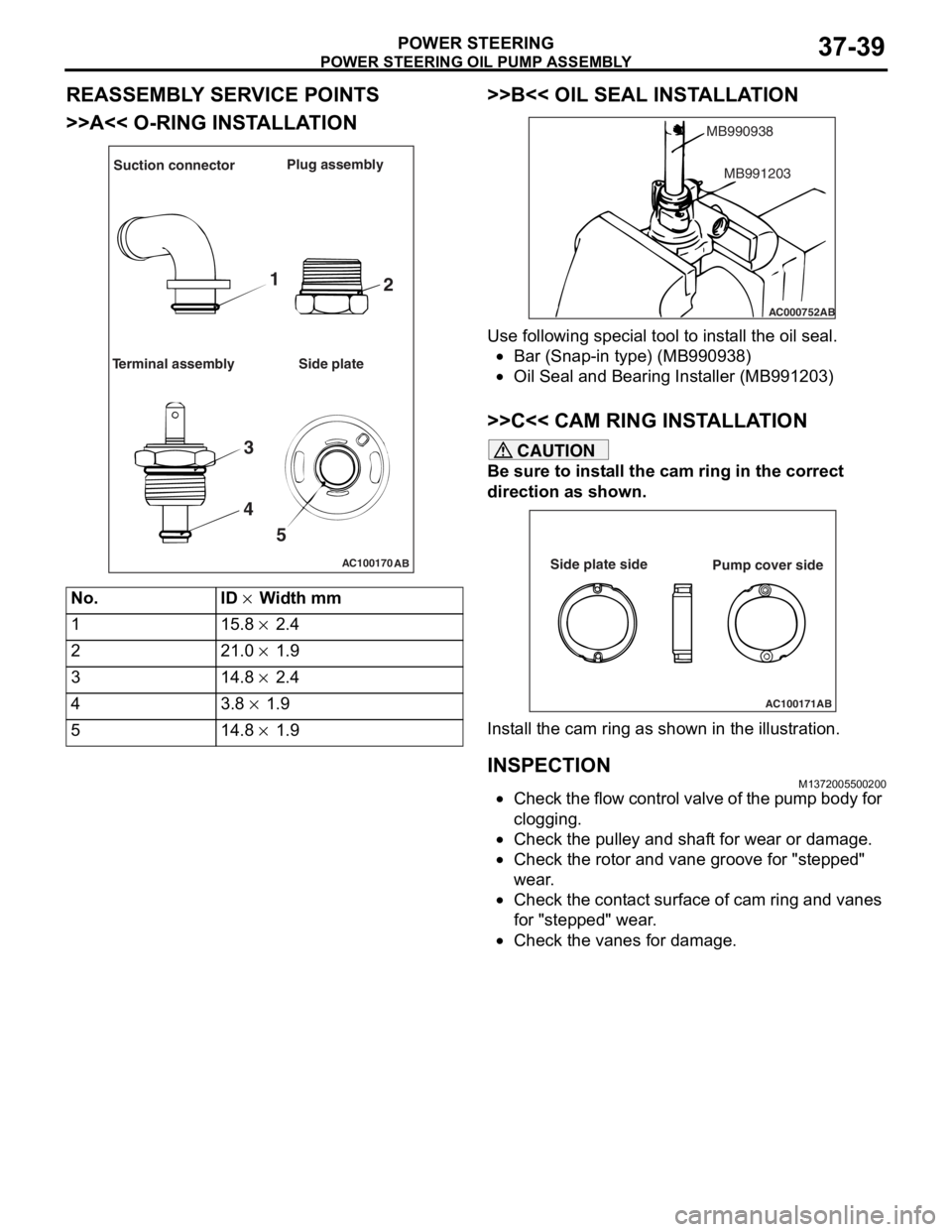

REASSEMBLY SERVICE POINTS

>>A<< O-RING INSTALLATION

AC100170AB

Suction connector Plug assembly

Terminal assembly Side plate

1 2

3

4 5

No.ID × Width mm

115.8 × 2.4

221.0 × 1.9

314.8 × 2.4

43.8 × 1.9

514.8 × 1.9

>>B<< OIL SEAL INST ALLA TION

AC000752

MB990938

AB

MB991203

Use following spe c ia l too l to inst all the oil seal.

•Bar (Snap-in type) (MB9909 38)

•Oil Seal and Bearin g Inst aller (MB9912 03)

>>C<< CAM RING INSTALLA TION

CAUTION

Be sure to install the cam ring in the correct

direction as shown.

AC100171AB

Side plate side

Pump cover side

Install the cam ring as shown in the illustration.

INSPECTION

M1372005500200

•Check the flow control valve of the pump body for

clogging.

•Check the pulley and shaft for wear or damage.

•Check the rotor and vane groove for "stepped"

wear.

•Check the contact surface of cam ring and vanes

for "stepped" wear.

•Check the vanes for damage.

Page 270 of 800

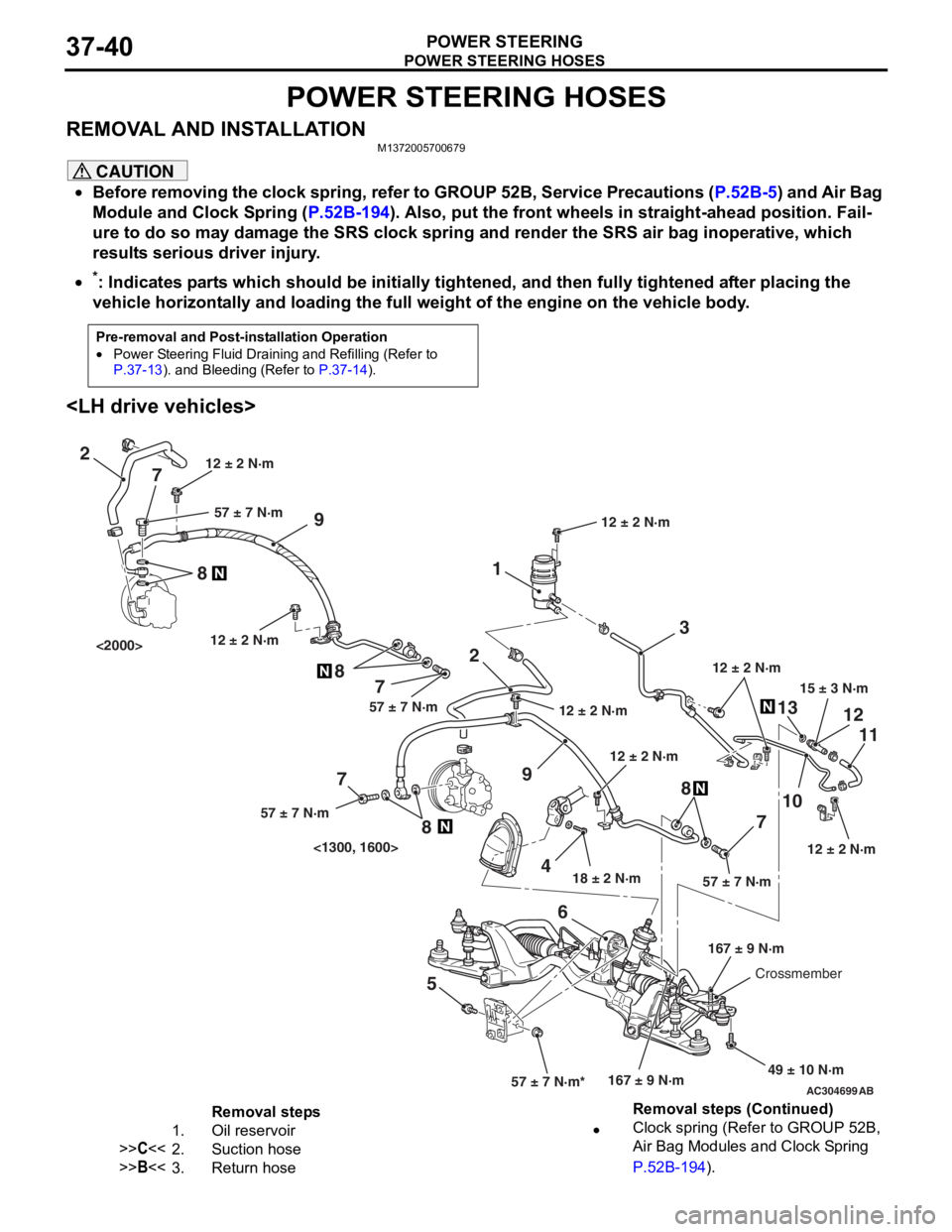

POWER STEERING HOSES

POWER STEERING37-40

POWER STEERING HOSES

REMOVAL AND INSTALLATIONM1372005700679

CAUTION

•Before removing the clock spring, refer to GROUP 52B, Service Precautions (P.52B-5) and Air Bag

Module and Clock Spring (P.52B-194). Also, put the front wheels in straight-ahead position. Fail-

ure to do so may damage the SRS clock spring and render the SRS air bag inoperative, which

results serious driver injury.

•

Pre-removal and Post-installation Operation

•Power Steering Fluid Draining and Refilling (Refer to P.37-13). and Bleeding (Refer to P.37-14).

*: Indicates parts which should be initially tightened, and then fully tightened after placing the

vehicle horizontally and loading the full weight of the engine on the vehicle body.

AC304699AB

15 ± 3 N·m

18 ± 2 N·m

167 ± 9 N·m

12 ± 2 N·m

49 ± 10 N·m

12 ± 2 N·m

57 ± 7 N·m*57 ± 7 N·m

3

1

2

9

1310

7 11

12

5 68

12 ± 2 N·m

12 ± 2 N·m

2

9

4

7

8

7

8

7

8

57 ± 7 N·m57 ± 7 N·m

57 ± 7 N·m

12 ± 2 N·m

167 ± 9 N·mCrossmember

12 ± 2 N·m

<1300, 1600>

<2000>

12 ± 2 N·m

Removal steps

1.Oil reservoir

>>C<<2.Suction hose

>>B<<3.Return hose

•Clock spring (Refer to GROUP 52B,

Air Bag Modules and Clock Spring

P.52B-194).

Removal steps (Continued)

Page 273 of 800

42-1

GROUP 42

BODY

CONTENTS

HOOD . . . . . . . . . . . . . . . . . . . . .42-3

ON-VEHICLE SERVICE. . . . . . . . .42-3

ADJUSTMENT OF CLEARANCE

AROUND HOOD . . . . . . . . . . . . . . . . . . 42-3

ADJUSTMENT OF ALIGNMENT OF

HOOD STEPPED PORTION AND

HOOD STRIKER . . . . . . . . . . . . . . . . . . 42-3

ADJUSTMENT OF HOOD HEIGHT . . . 42-3

HOOD . . . . . . . . . . . . . . . . . . . . . . .42-4

REMOVAL AND INSTALLATION . . . . . 42-4

FENDER . . . . . . . . . . . . . . . . . . .42-5

SPECIAL TOOL . . . . . . . . . . . . . . .42-5

FENDER . . . . . . . . . . . . . . . . . . . . .42-6

REMOVAL AND INSTALLATION . . . . . 42-6

FUEL FILLER LID . . . . . . . . . . .42-8

REMOVAL AND INSTALLATION .42-8

STRUT TOWER BAR . . . . . . . .42-9

REMOVAL AND INSTALLATION .42-9

WINDOW GLASS . . . . . . . . . . . 42-10

ADHESIVE . . . . . . . . . . . . . . . . . . .42-10

SPECIAL TOOLS . . . . . . . . . . . . . .42-10

WINDOW REPAIR . . . . . . . . . . . . .42-10

WINDSHIELD . . . . . . . . . . . . . . . . .42-12

REMOVAL AND INSTALLATION . . . . . . 42-12

REAR WINDOW GLASS

REMOVAL AND INSTALLATION . . . . . . 42-17

QUARTER WINDOW GLASS

REMOVAL AND INSTALLATION . . . . . . 42-20

TAILGATE WINDOW GLASS

REMOVAL AND INSTALLATION . . . . . . 42-23

DOOR . . . . . . . . . . . . . . . . . . . . 42-25

SERVICE SPECIFICA TIONS . . . . .42-25

SEALANT . . . . . . . . . . . . . . . . . . . .42-25

SPECIAL TOOLS . . . . . . . . . . . . . .42-26

Continued on next page

Page 275 of 800

HOOD

BODY42-3

HOOD

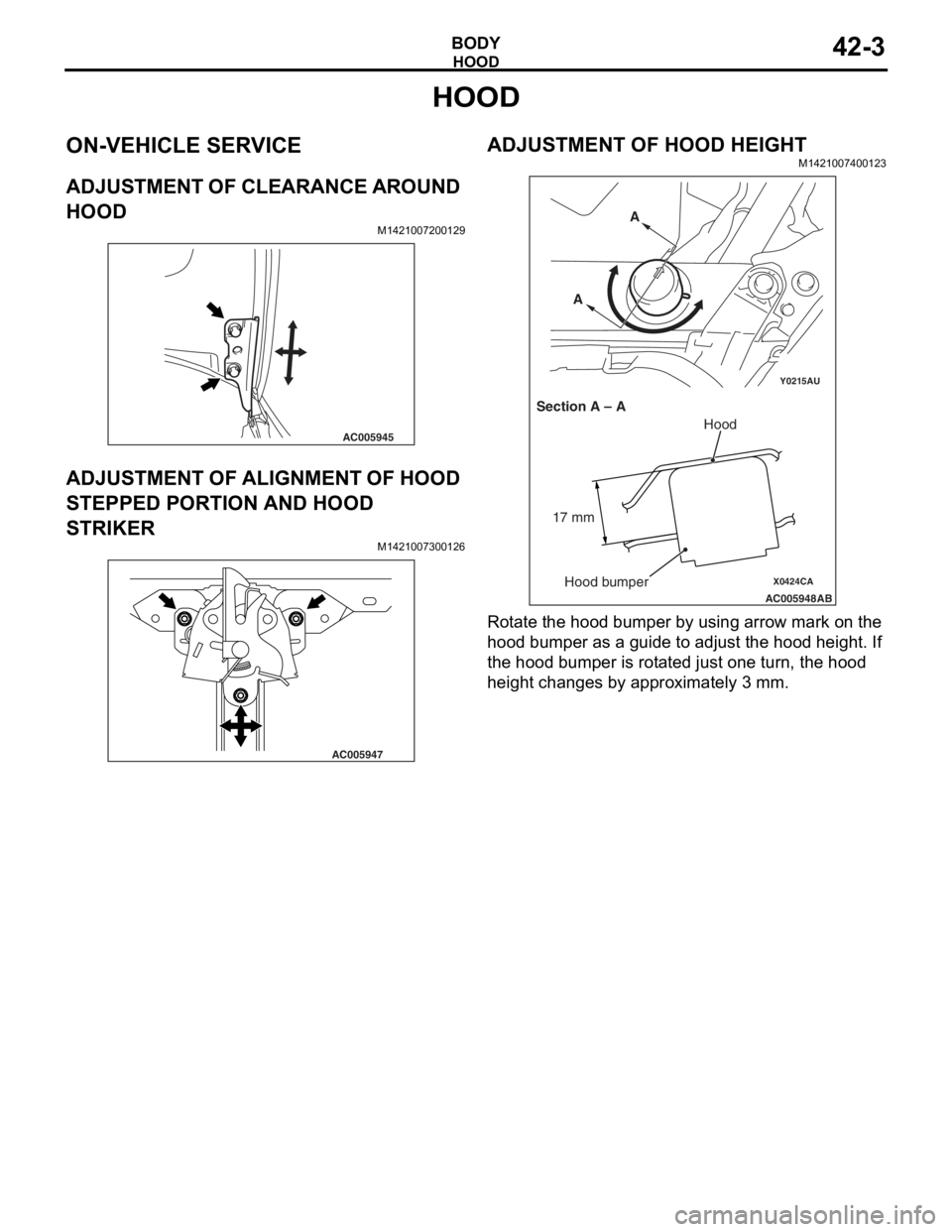

ON-VEHICLE SERVICE

ADJUSTMENT OF CLEARANCE AROUND

HOOD

M1421007200129

AC005945

ADJUSTMENT OF ALIGNMENT OF HOOD

STEPPED PORTION AND HOOD

STRIKER

M14210073 0012 6

AC005947

ADJUSTMENT OF HOOD HEIGHT

M14210074 0012 3

Y0215AU

X0424CA

AC005948

AB

Section A – A A

A

Hood

Hood bumper

17 mm

Ro

t a te t he hood bu mper by using arrow mark o n the

hood bu

mpe r as a g u ide t o adju s t the hood h e ight . If

the hoo

d bumper is rot a te d just one turn, th e hood

heigh

t cha nges by approximately 3 mm.