body MITSUBISHI LANCER 2006 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER, Model: MITSUBISHI LANCER 2006Pages: 800, PDF Size: 45.03 MB

Page 56 of 800

INLET MANIFOLD

INTAKE AND EXHAUST15-6

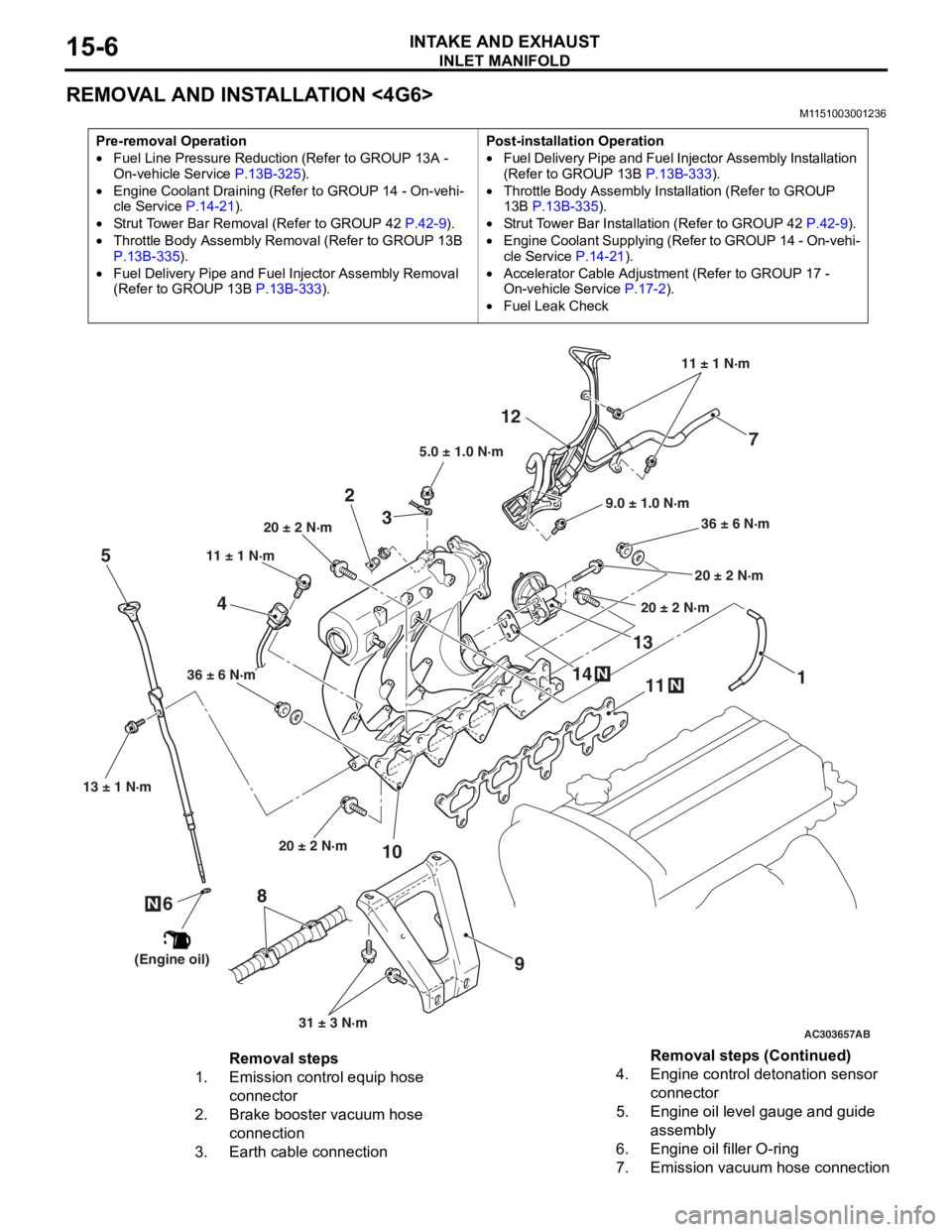

REMOVAL AND INSTALLATION <4G6>

M1151003001236

Pre-removal Operation

•Fuel Line Pressure Reduction (Refer to GROUP 13A -

On-vehicle Service P.13B-325).

•Engine Coolant Draining (Refer to GROUP 14 - On-vehi-cle Service P.14-21).

•Strut Tower Bar Removal (Refer to GROUP 42 P.42-9).

•Throttle Body Assembly Re moval (Refer to GROUP 13B

P.13B-335).

•Fuel Delivery Pipe and Fuel Injector Assembly Removal

(Refer to GROUP 13B

P.13B-333).

Post-installation Operation

•Fuel Delivery Pipe and Fuel Injector Assembly Installation

(Refer to GROUP 13B P.13B-333).

•Throttle Body Assembly Inst allation (Refer to GROUP

13B P.13B-335).

•Strut Tower Bar Installati on (Refer to GROUP 42 P.42-9).

•Engine Coolant Supplying (Refer to GROUP 14 - On-vehi-

cle Service P.14-21).

•Accelerator Cable Adjustment (Refer to GROUP 17 -

On-vehicle Service

P.17-2).

•Fuel Leak Check

AC303657

9.0 ± 1.0 N·m11 ± 1 N·m

20 ± 2 N·m 31 ± 3 N·m

36 ± 6 N·m

20 ± 2 N·m

20 ± 2 N·m

36 ± 6 N·m

20 ± 2 N·m

11

9

10

2

12

N14

13N

AB

5.0 ± 1.0 N·m

3

1

11 ± 1 N·m

4

N

13 ± 1 N·m

5

6

(Engine oil)

7

8

Removal steps

1.Emission control equip hose

connector

2.Brake booster vacuum hose

connection

3.Earth cable connection

4.Engine control detonation sensor

connector

5.Engine oil level gauge and guide

assembly

6.Engine oil filler O-ring

7.Emission vacuum hose connection

Removal steps (Continued)

Page 68 of 800

CHARGING SYSTEM

ENGINE ELECTRICAL16-6

9. Check that the reading on the voltmeter is equal

to the battery voltage.

NOTE: If the voltage is 0 V, the cause is probably

an open circuit in the wire or fusible link between

the alternator "B" terminal and the battery (+) ter

-

minal.

10.Turn the light switch on to turn on headlamps and

then start the engine.

11.Immediately after setting the headlamps to high

beam and turning the heater blower switch to the

high revolution position, increase the engine

speed to 2,500 r/min and read the maximum

current output value displayed on the ammeter.

Limit: 70 % of normal current output

NOTE: .

•For the nominal current output, refer to the

Alternator Specifications.

•Because the current from the battery will soon

drop after the engine is started, the above step

should be carried out as quickly as possible in

order to obtain the maximum current output

value.

•The current output value will depend on the

electrical load and the temperature of the

alternator body.

•If the electrical load is small while testing, the

specified level of current may not be output

even though the alternator is normal. In such

cases, increase the electrical load by leaving

the headlamps turned on for some time to dis

-

charge the battery or by using the lighting sys-

tem in another vehicle, and then test again.

•The specified level of current also may not be

output if the temperature of the alternator body

or the ambient temperature is too high. In such

cases, cool the alternator and then test again.

12.The reading on the ammeter should be above the

limit value. If the reading is below the limit value

and the alternator output wire is normal, remove

the alternator from the engine and check the

alternator.

13.Run the engine at idle after the test.

14.Turn the ignition switch to the "LOCK" (OFF)

position.

15.Remove the tachometer or the M.U.T.-II/III.

16.Disconnect the negative battery cable.

17.Disconnect the ammeter and voltmeter.

18.Connect the negative battery cable.

Page 86 of 800

STARTING SYSTEM

ENGINE ELECTRICAL16-24

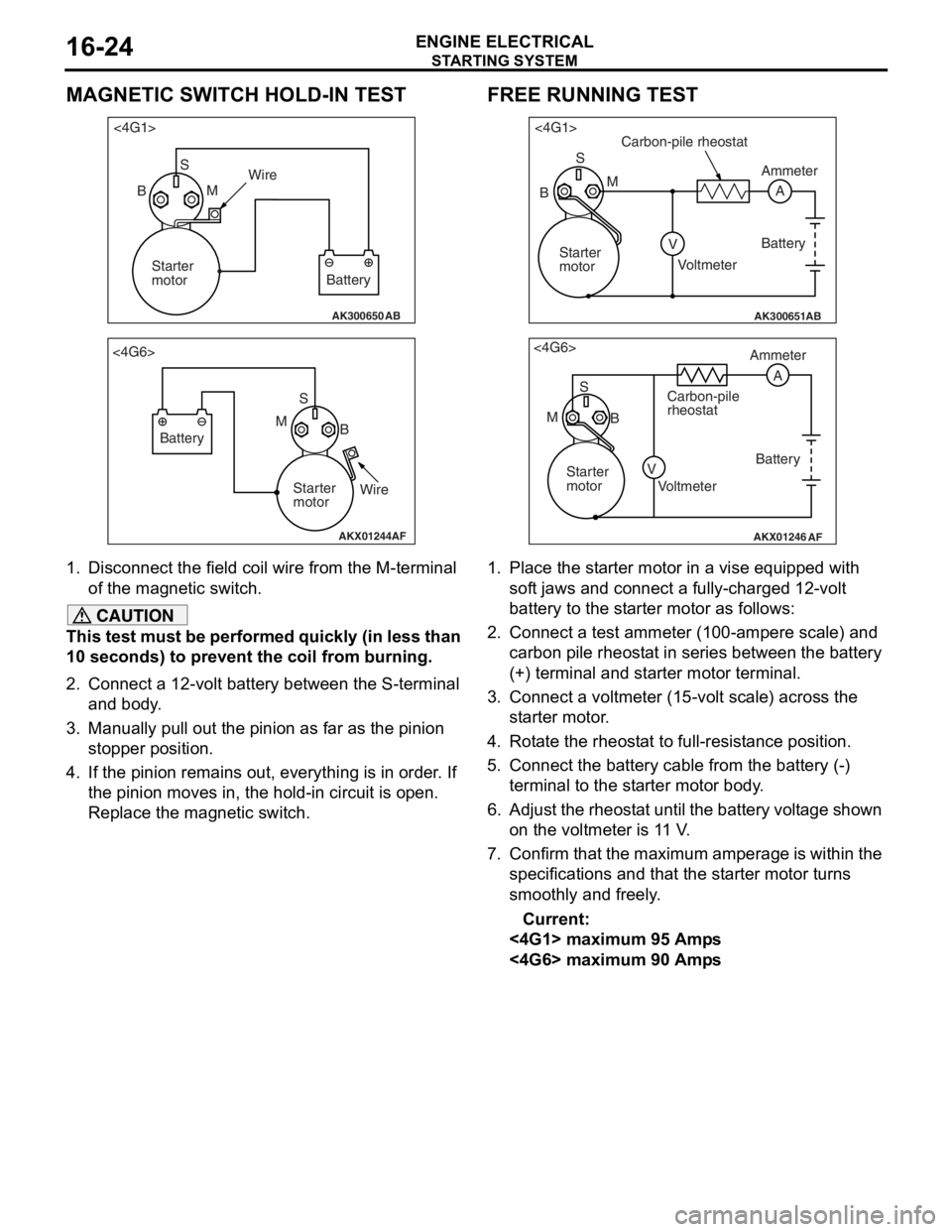

MAGNETIC SWITCH HOLD-IN TEST

AK300650AB

<4G1>S

B MWire

Battery

Starter

motor

AKX01244

<4G6>

SB

M

Battery

Starter

motorWire

AF

1.

Disco nnect the field coil wire f r om th e M-te rmin al

of the magnet ic switch.

CAUTION

This test must be performed quickly (in less than

10 seconds) to prevent the coil from burning.

2. Connect a 12-volt battery between the S-terminal and body.

3. Manually pull out the pinion as far as the pinion stopper position.

4. If the pinion remains out, everything is in order. If

the pinion moves in, the hold-in circuit is open.

Replace the magnetic switch.

FREE RUNNING TEST

AK300651AB

<4G1>

S

A

M

V

B

Carbon-pile rheostat

Battery

Voltmeter Ammeter

Starter

motor

AKX01246

<4G6> S

M B Ammeter

Carbon-pile

rheostat

Battery

Starter

motor Voltmeter

AF

A

V

1. Place the starter motor in a vise equipped with soft jaws and connect a fully-charged 12-volt

battery to the starter motor as follows:

2. Connect a test ammeter (100-ampere scale) and carbon pile rheostat in series between the battery

(+) terminal and starter motor terminal.

3. Connect a voltmeter (15-volt scale) across the starter motor.

4. Rotate the rheostat to full-resistance position.

5. Connect the battery c able from the battery (-)

terminal to the starter motor body.

6. Adjust the rheostat until the battery voltage shown

on the voltmeter is 11 V.

7. Confirm that the maximum amperage is within the specifications and that the starter motor turns

smoothly and freely.

Current:

<4G1> maximum 95 Amps

<4G6> maximum 90 Amps

Page 87 of 800

STARTING SYSTEM

ENGINE ELECTRICAL16-25

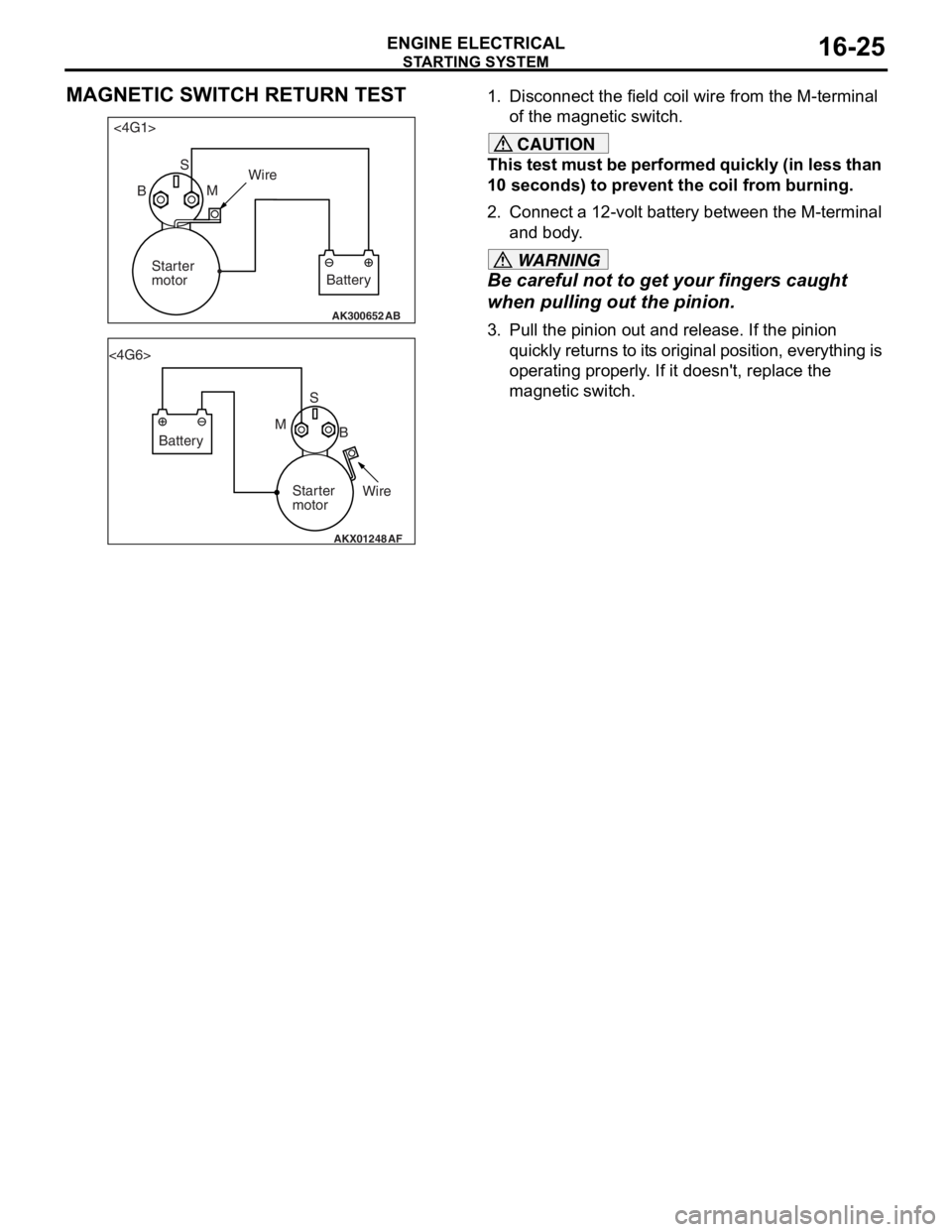

MAGNETIC SWITCH RETURN TEST

AK300652AB

<4G1>S

B MWire

Battery

Starter

motor

AKX01248

<4G6>

SB

M

Battery

Starter

motorWire

AF

1.

Disco nnect the field coil wire f r om th e M-te rmin al

o f the magnet ic switch.

CAUTION

This test must be performed quickly (in less than

10 seconds) to prevent the coil from burning.

2. Connect a 12-volt battery between the M-terminal and body.

WARNING

Be careful not to ge t your fingers caught

when pulling out the pinion.

3. Pull the pinion out and release. If the pinion

quickly returns to its original position, everything is

operating properly. If it doesn't, replace the

magnetic switch.

Page 91 of 800

AK202734

STARTING SYSTEM

ENGINE ELECTRICAL16-29

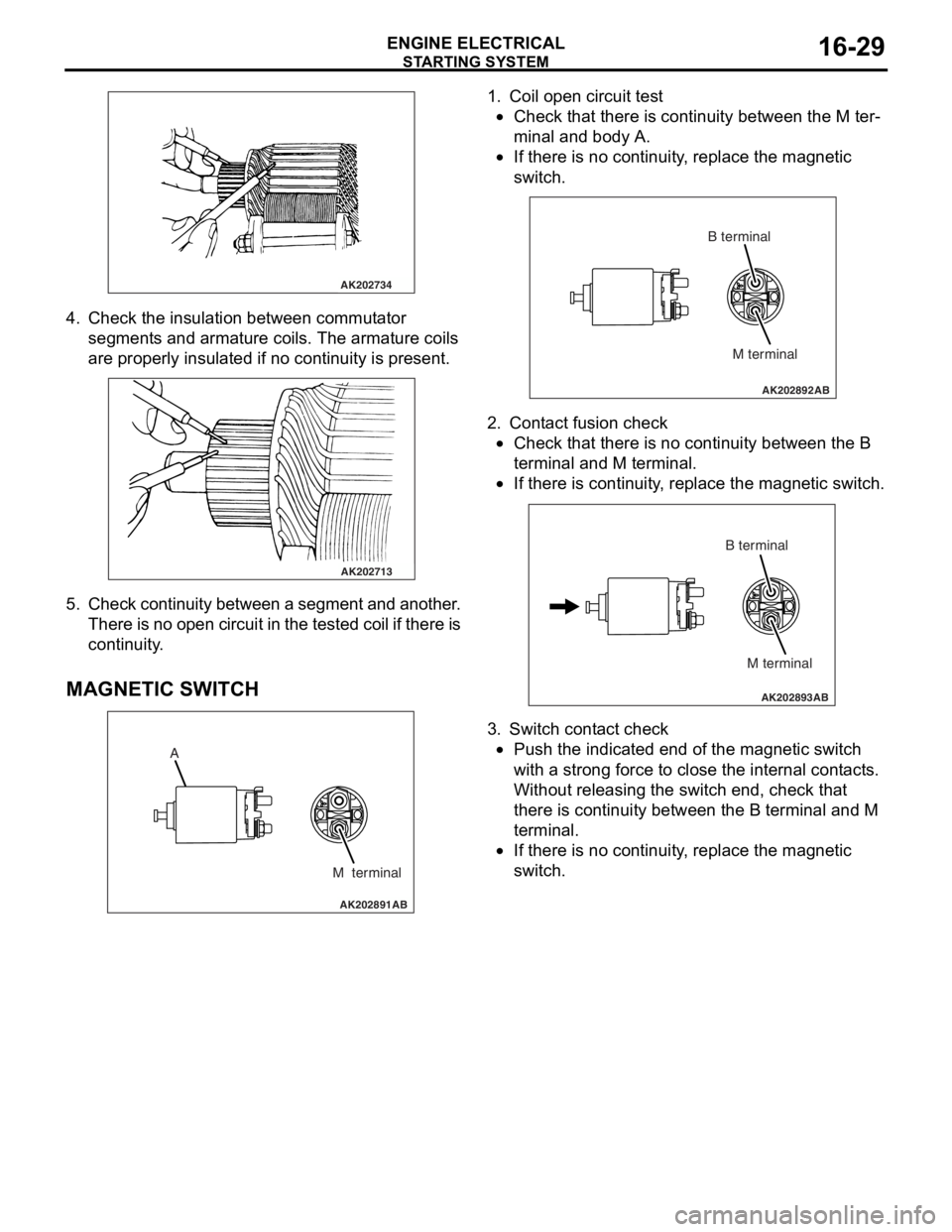

4. Check t he in sulation between commut ator

segment s an d arma ture coils. Th e armature coils

are prope rly insu lated if no con t inuity is pre s ent .

AK202713

5. Check continuit y bet ween a segment and another .

Th ere is n o ope n circui t in th e t e s t e d c o il if t h e r e is

continuity .

MA GNETIC SW ITCH

AK202891

A

M terminal

AB

1.Coil ope n circuit test

•Check that there is continuity be twe en the M te r-

minal and body A.

•

AK202892

M terminal

B terminal

AB

If th

ere is no continuit y , replace t he ma gnetic

sw

itc h .

2.Cont act fusion check

•Check that there is no co ntinu i ty between the B

termina

l and M te rmin al.

•

AK202893

M terminal

B terminal

AB

If th

ere is co ntinu i ty , re place the magn etic switch.

3.Switch cont act check

•Push the indicated end o f the magne tic switch

with

a stro ng force to close th e inte rnal cont act s .

Without re

leasing the switch end, check tha t

the

r e is con t inuity b e tween th e B terminal and M

termina

l .

•If there is no continuit y , replace t he ma gnetic

sw

itc h .

Page 109 of 800

ENGINE CONTROL

ENGINE AND EMISSION CONTROL17-3

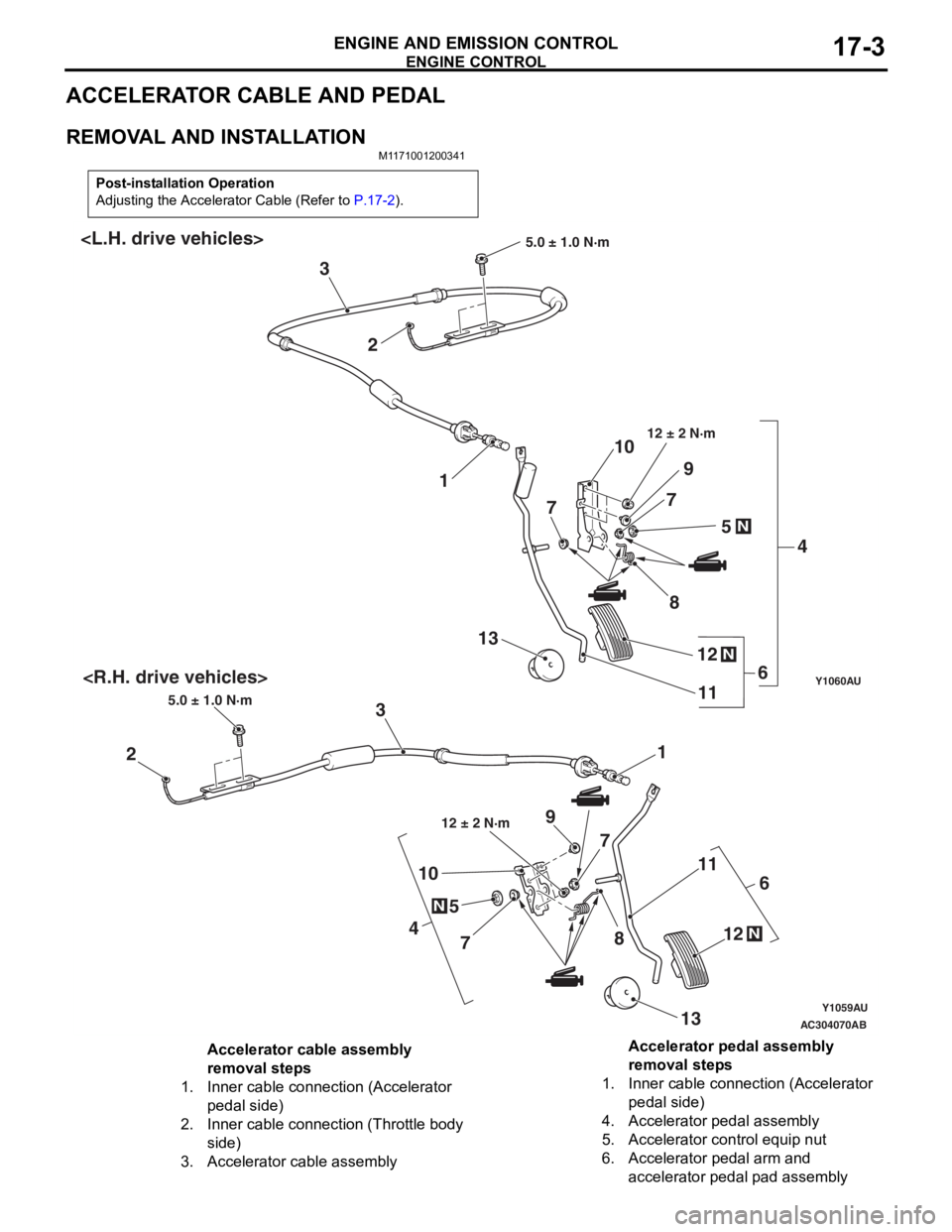

ACCELERATOR CABLE AND PEDAL

REMOVAL AND INSTALLATION

M1171001200341

Post-installation Operation

Adjusting the Accelerator Cable (Refer to P.17-2).

Y1059AU

Y1060AU

AC304070

N

4

5 7 8

10

11

N12

13

AB

1

2 3

5.0 ± 1.0 N·m

6

12 ± 2 N·m9

7

1

2

3

5.0 ± 1.0 N·m

N

4

5

7

8

10

11

N12

13

6

12 ± 2 N·m

9

7

Accelerator cable assembly

removal steps

1.Inner cable connection (Accelerator

pedal side)

2.Inner cable connection (Throttle body

side)

3.Accelerator cable assembly

Accelerator pedal assembly

removal steps

1.Inner cable connection (Accelerator

pedal side)

4.Accelerator pedal assembly

5.Accelerator control equip nut

6.Accelerator pedal arm and

accelerator pedal pad assembly

Page 113 of 800

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-7

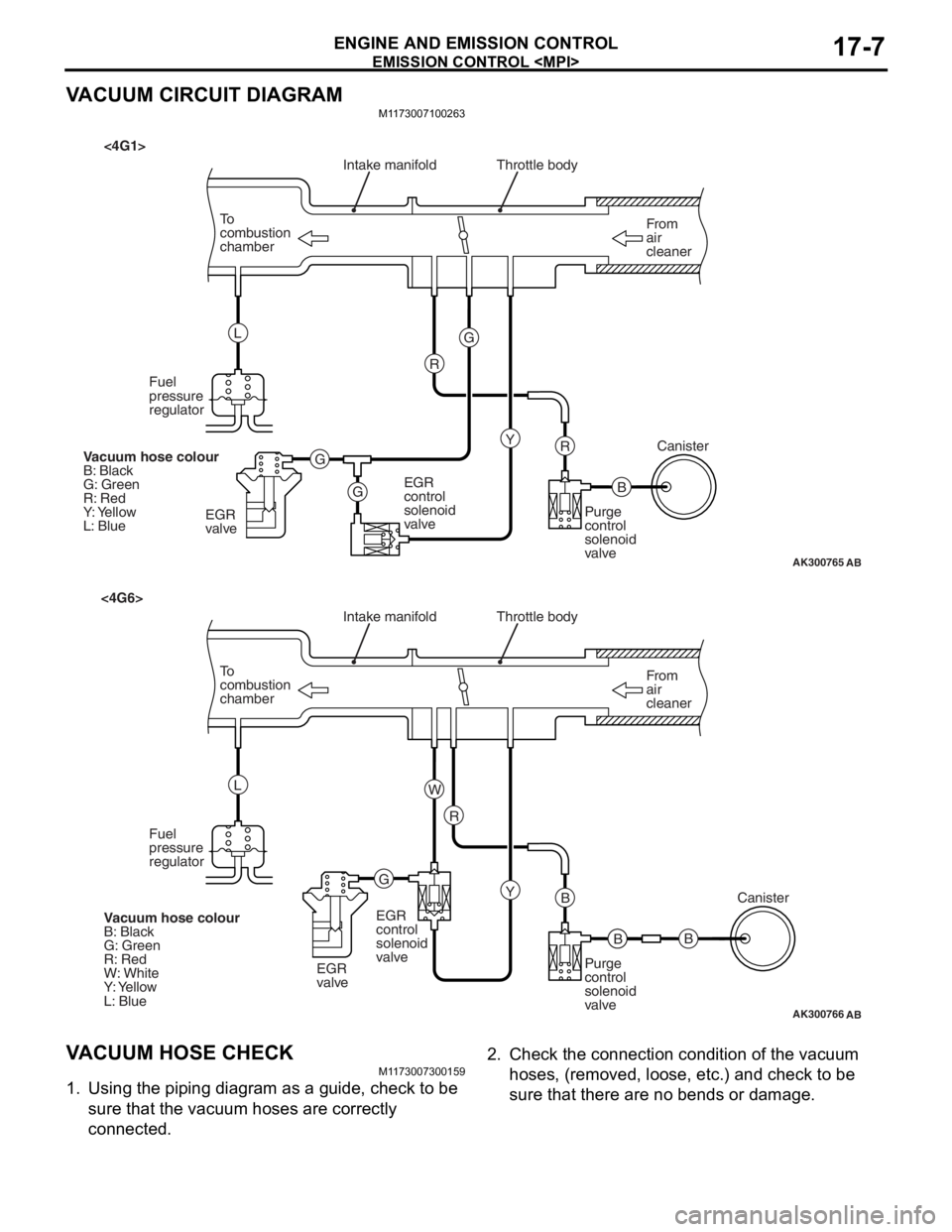

VACUUM CIRCUIT DIAGRAM

M1173007100263

AK300765

From

air

cleaner

To

combustion

chamber Throttle body

B

R

AB

Intake manifold

Y

G

G G R

L

Fuel

pressure

regulator

EGR

valve EGR

control

solenoid

valve

Purge

control

solenoid

valveCanister

Vacuum hose colour

B: Black

G: Green

R: Red

Y: Yellow

L: Blue

<4G1>

AK300766

From

air

cleaner

To

combustion

chamber Throttle body

B

B

AB

Intake manifold

Y

R

G W

L

Fuel

pressure

regulator

EGR

valveEGR

control

solenoid

valve

Purge

control

solenoid

valveCanister

Vacuum hose colour

B: Black

G: Green

R: Red

W: White

Y: Yellow

L: Blue

<4G6>

B

V ACUUM HOSE CHECK

M1 173 0073 0015 9

1.Using th e pip i ng d i agra m as a gu ide, check to be

sure th at the vacuum h o ses are correctly

connected.

2. Check t he co nnection cond itio n of th e vacuum

ho s e s, (re mo v e d, l o os e , et c . ) an d c h e c k t o b e

sure th at there are no bends or da mage .

Page 116 of 800

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-10

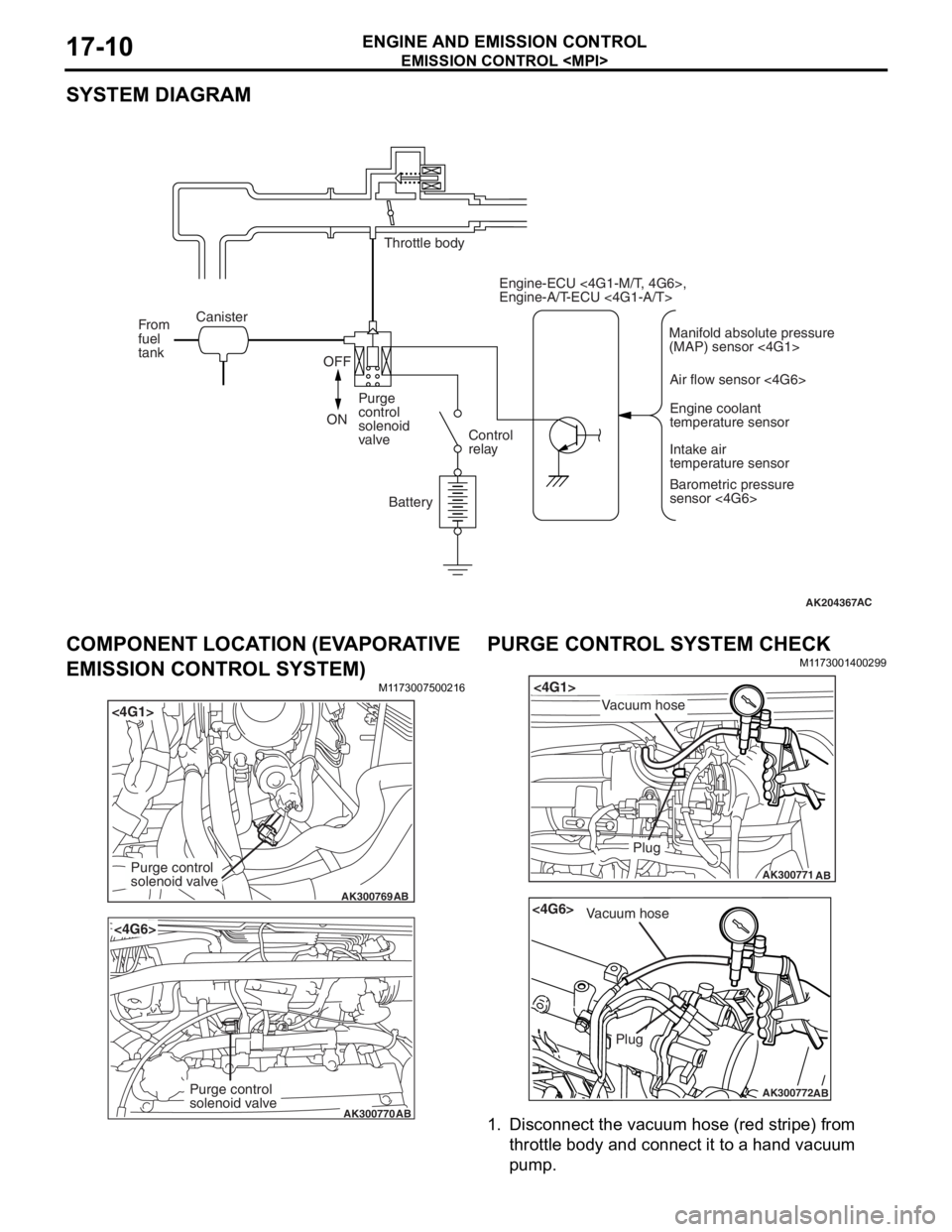

SYSTEM DIAGRAM

AK204367AC

Throttle body

Canister

From

fuel

tank

OFF

ON Purge

control

solenoid

valve

Control

relay

Battery Engine-ECU <4G1-M/T, 4G6>,

Engine-A/T-ECU <4G1-A/T>

Air flow sensor <4G6>Engine coolant

temperature sensor

Intake air

temperature sensor

Barometric pressure

sensor <4G6>

Manifold absolute pressure

(MAP) sensor <4G1>

COMPONENT LOCA

TION (EV A PORA TIVE

EMISSION CONTROL SYSTEM)

M1173 0075 0021 6

AK300769

<4G1>

AB

Purge control

solenoid valve

AK300770

<4G6>

AB

Purge control

solenoid valve

PURGE CONTROL SYSTEM CHECK

M1173 0014 0029 9

AK300771

<4G1>

AB

Plug

Vacuum hose

AK300772

<4G6>

AB

Plug

Vacuum hose

1.Disco nnect the vacu um h o se (re d str i pe) fro m

th rottle body and conne ct it to a h and vacu um

pu m p .

Page 117 of 800

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-11

2. Plug the nipple from which the vacuum hose was removed.

3. When the engine is cold or hot, apply a vacuum of 53 kPa, and check the condition of the vacuum.

When engine is cold

(Engine coolant temperature: 40°C or less)

Engine conditionNormal condition

At idleVacuum is maintained.

3,000 r/min

When engine is hot

(Engine coolant temperature: 80°C or higher)

Engine conditionNormal condition

At idleVacuum is maintained.

3,000 r/min (within 3

minutes after engine

starts)Vacuum will leak.

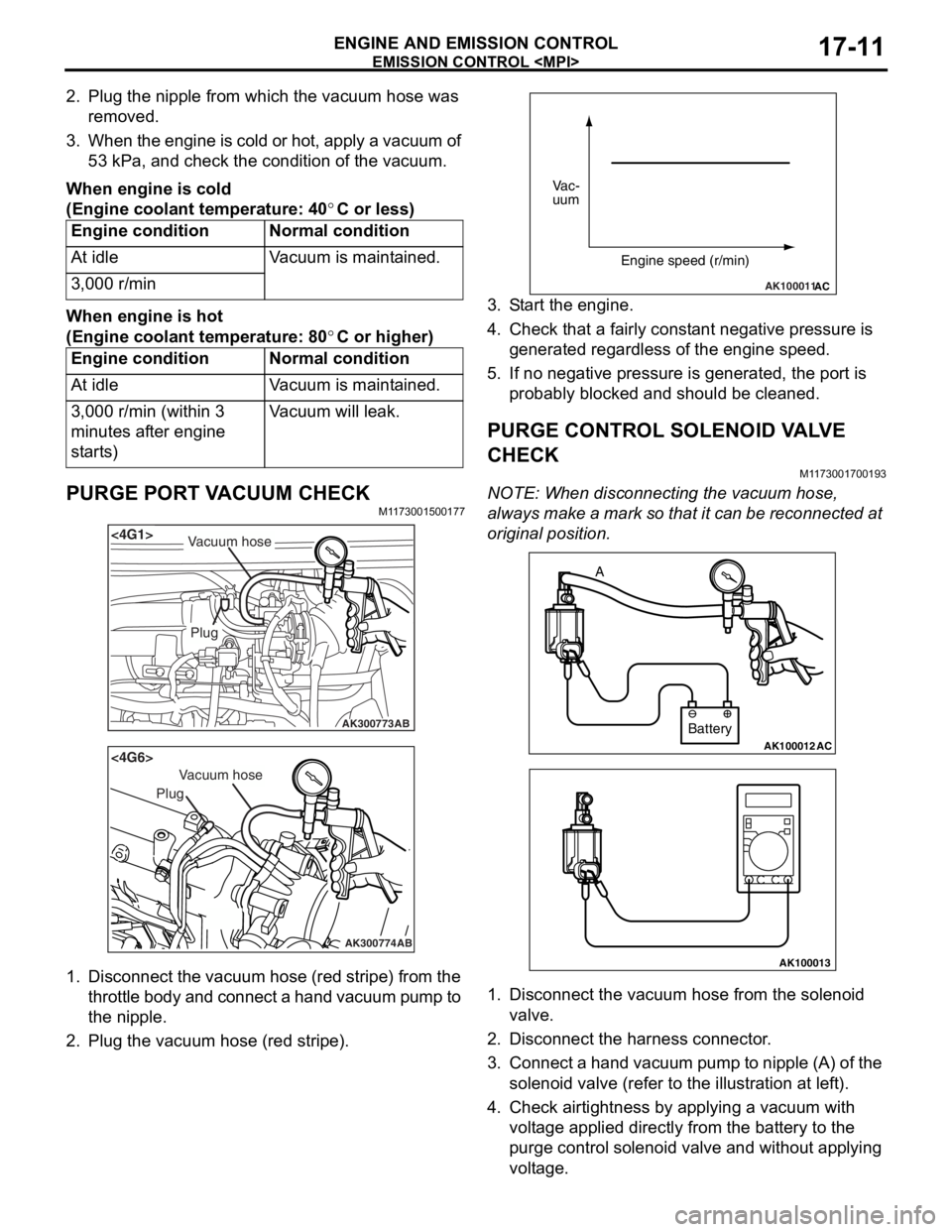

PURGE PORT VACUUM CHECKM1173001500177

AK300773

<4G1>

AB

Plug

Vacuum hose

AK300774

<4G6>

AB

Plug

Vacuum hose

1.Disco nnect th e vacuum ho se (red st ripe) from the

throttle body and connect a hand vacuum pump to

th e nip p le.

2.Plu g the vacuum hose (red stripe).

AK100011AC

Vac-

uum

Engine speed (r/min)

3.S t art the engine.

4.Check t hat a f a irly co nst ant n egative p r essure is

g enerate d regard l ess of the en gine spee d.

5.If no neg ative pressur e is genera t ed, th e port is

p r obably blocked an d sh ould be cleane d.

PURGE CONTROL SOLENOID VA L V E

CHECK

M1173 0017 0019 3

NOTE: Whe n discon nect i ng th e va cuum hose,

always make a mark so th at it can be reconnected at

original p o sition.

AK100012AC

Battery

A

AK100013

1.

Disco nnect the vacu um h o se f r om th e solenoid

valve.

2.Disco nnect the ha rness connector .

3.Con nect a ha nd vacu um pump to nipp le (A) of the

solen o id valve (ref e r to th e ill ust r ation at le f t ).

4.Check a i rtig htness b y app lying a vacuum with

volt age applied d i rectly from t he batt e ry to the

p u rge con t rol so leno id valve an d without app lying

volt age .

Page 136 of 800

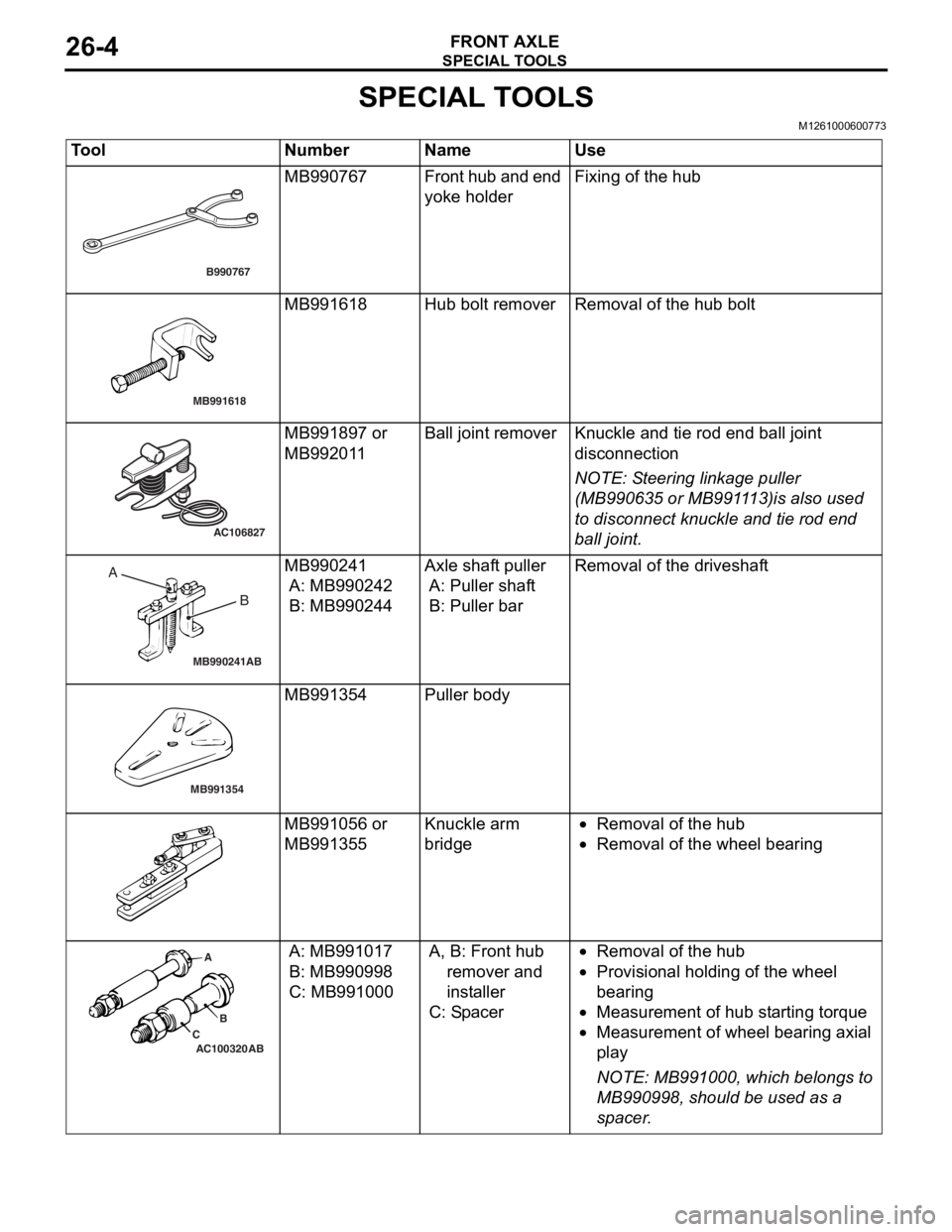

SPECIAL TOOLS

FRONT AXLE26-4

SPECIAL TOOLS

M1261000600773

ToolNumberNameUse

B990767

MB990767Fr o n t hu b a n d en d

yoke holderFixing of the h u b

MB991618

MB991618Hub bolt remo verRemoval of the h ub bolt

AC106827

MB991897 or

MB992

01 1Ball j o int remo verKnuckle and tie rod e nd ball joint

discon

nection

NOTE: St eering linkage pu lle r

(MB990 635 or MB991 1 13)is also u s ed

to disconnect kn uckle an d tie rod en d

bal

l j

o

int.

MB990241AB

A BMB990241

A: MB9902 42

B: MB990244

Axle shaft pu ller

A: Puller shaf t

B: Puller bar

Rem o va l of t h e dri v es h a f t

MB991354

MB991354Pulle r body

MB991 056 or

MB991

355Knuckle a r m

bridg

e•Removal of the hu b

•Removal of the whee l bea ring

AC100320 ABA

B

C

A: MB9910 17

B: MB990998

C: MB99100 0

A, B: Fr ont hu b

remover and

ins t all e r

C: Sp acer

•Removal of the hu b

•Prov ision a l ho ldin g of th e wheel

b

earin g

•Measurement of hub st a r ting t o rque

•Measurement of wh eel b earin g axial

pl

a y

NOTE: MB9 91000, which b e lon g s to

MB9909 98, should be used a s a

sp

acer

.