engine MITSUBISHI LANCER 2006 Manual Online

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER, Model: MITSUBISHI LANCER 2006Pages: 800, PDF Size: 45.03 MB

Page 91 of 800

AK202734

STARTING SYSTEM

ENGINE ELECTRICAL16-29

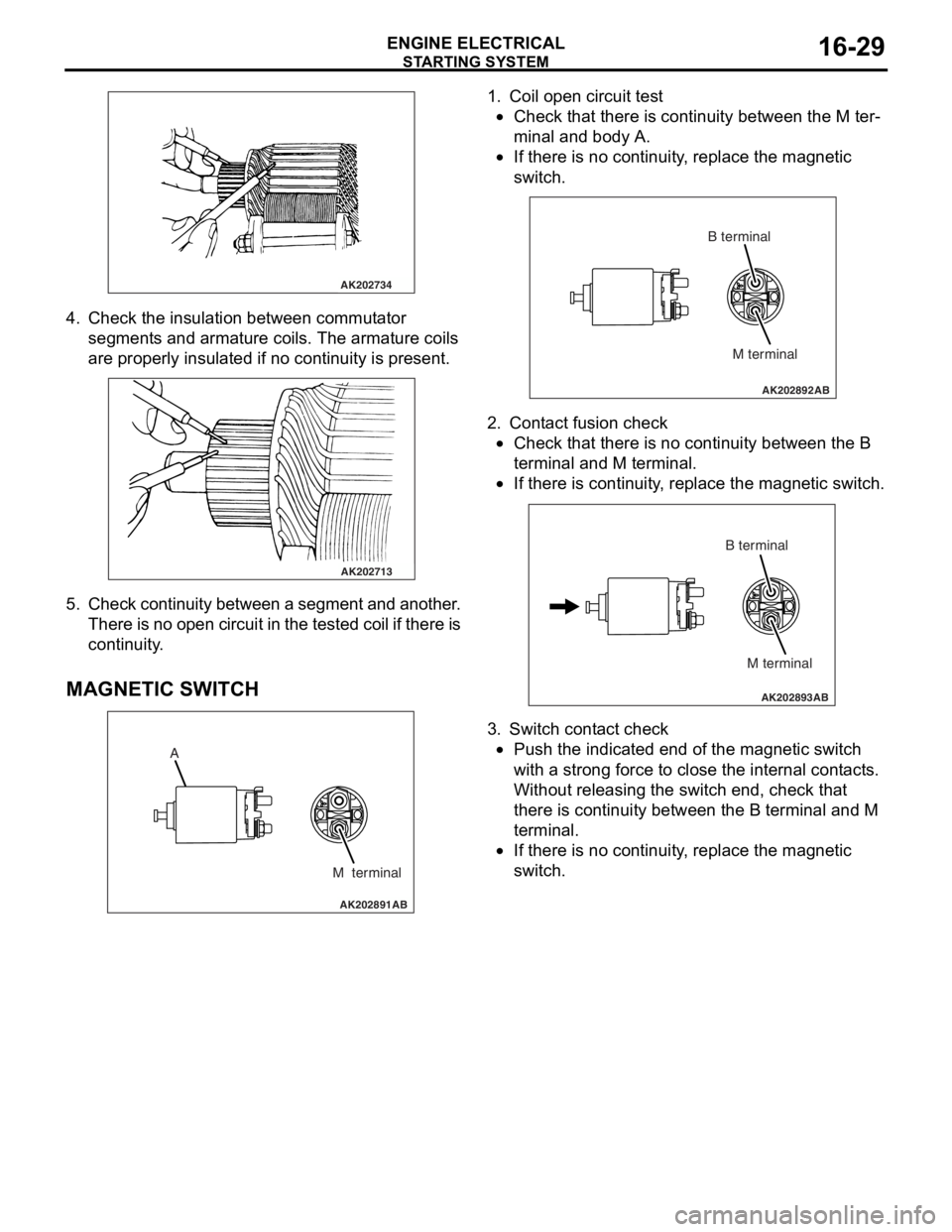

4. Check t he in sulation between commut ator

segment s an d arma ture coils. Th e armature coils

are prope rly insu lated if no con t inuity is pre s ent .

AK202713

5. Check continuit y bet ween a segment and another .

Th ere is n o ope n circui t in th e t e s t e d c o il if t h e r e is

continuity .

MA GNETIC SW ITCH

AK202891

A

M terminal

AB

1.Coil ope n circuit test

•Check that there is continuity be twe en the M te r-

minal and body A.

•

AK202892

M terminal

B terminal

AB

If th

ere is no continuit y , replace t he ma gnetic

sw

itc h .

2.Cont act fusion check

•Check that there is no co ntinu i ty between the B

termina

l and M te rmin al.

•

AK202893

M terminal

B terminal

AB

If th

ere is co ntinu i ty , re place the magn etic switch.

3.Switch cont act check

•Push the indicated end o f the magne tic switch

with

a stro ng force to close th e inte rnal cont act s .

Without re

leasing the switch end, check tha t

the

r e is con t inuity b e tween th e B terminal and M

termina

l .

•If there is no continuit y , replace t he ma gnetic

sw

itc h .

Page 92 of 800

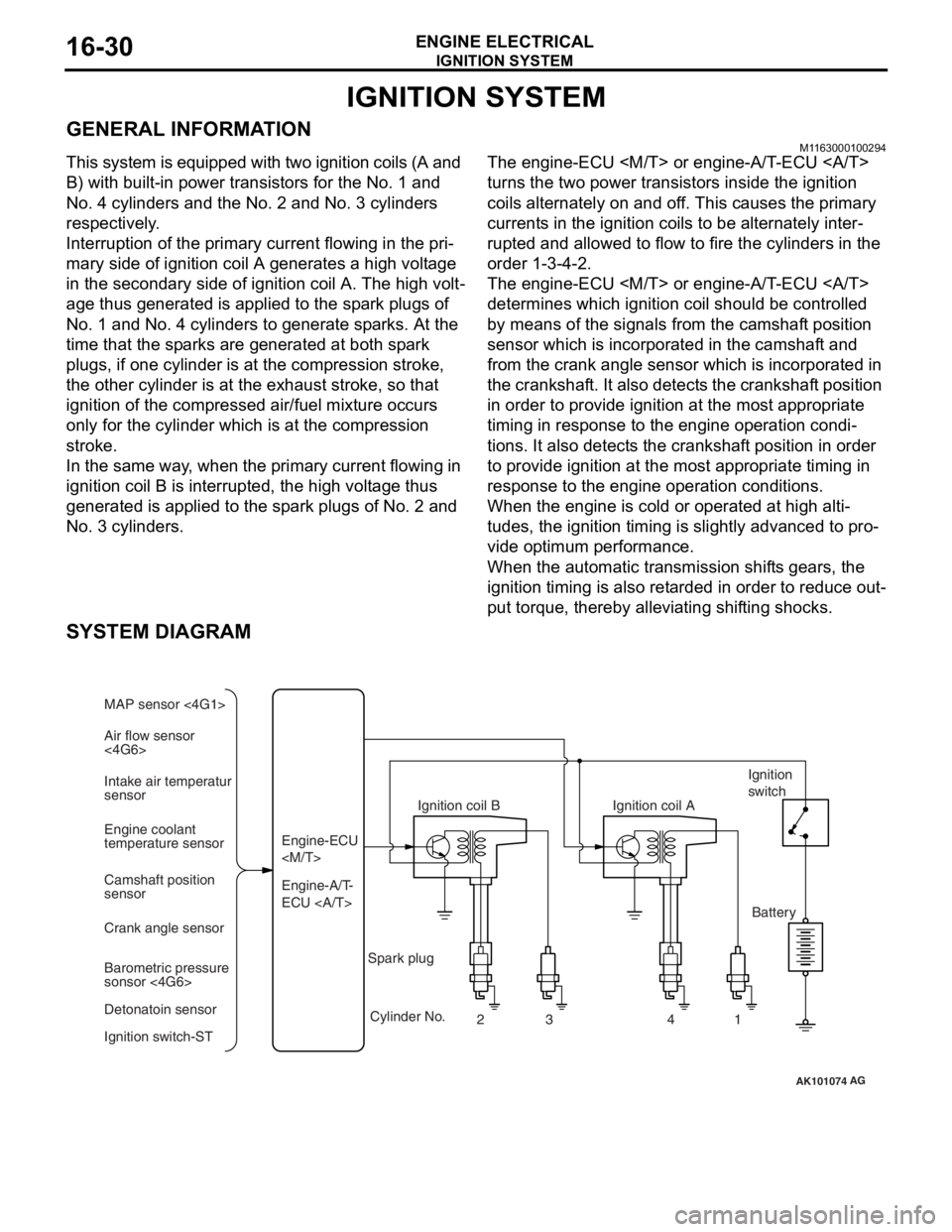

IGNITION SYSTEM

ENGINE ELECTRICAL16-30

IGNITION SYSTEM

GENERAL INFORMATIONM1163000100294

This system is equipped with two ignition coils (A and

B) with built-in power transistors for the No. 1 and

No. 4 cylinders and the No. 2 and No. 3 cylinders

respectively.

Interruption of the primary current flowing in the pri-

mary side of ignition coil A generates a high voltage

in the secondary side of ignition coil A. The high volt

-

age thus generated is applied to the spark plugs of

No. 1 and No. 4 cylinders to generate sparks. At the

time that the sparks are generated at both spark

plugs, if one cylinder is at the compression stroke,

the other cylinder is at the exhaust stroke, so that

ignition of the compressed air/fuel mixture occurs

only for the cylinder which is at the compression

stroke.

In the same way, when the primary current flowing in

ignition coil B is interrupted, the high voltage thus

generated is applied to the spark plugs of No. 2 and

No. 3 cylinders.

The engine-ECU

turns the two power transistors inside the ignition

coils alternately on and off. This causes the primary

currents in the ignition coils to be alternately inter

-

rupted and allowed to flow to fire the cylinders in the

order 1-3-4-2.

The engine-ECU

determines which ignition coil should be controlled

by means of the signals from the camshaft position

sensor which is incorporated in the camshaft and

from the crank angle sensor which is incorporated in

the crankshaft. It also detects the crankshaft position

in order to provide ignition at the most appropriate

timing in response to the engine operation condi

-

tions. It also detects the crankshaft position in order

to provide ignition at the most appropriate timing in

response to the engine operation conditions.

When the engine is cold or operated at high alti-

tudes, the ignition timing is slightly advanced to pro-

vide optimum performance.

When the automatic transmission shifts gears, the

ignition timing is also retarded in order to reduce out

-

put torque, thereby alleviating shifting shocks.

SYSTEM DIAGRAM

AK101074

Air flow sensor

<4G6> MAP sensor <4G1>

Intake air temperatur

sensor

Engine coolant

temperature sensor

Camshaft position

sensor

Crank angle sensor

Barometric pressure

sonsor <4G6>

Detonatoin sensor

Ignition switch-ST Engine-A/T-

ECU Engine-ECU

Ignition coil B

Cylinder No. 23 4

AG

1

Spark plug Ignition coil A

Ignition

switch

Battery

Page 93 of 800

IGNITION SYSTEM

ENGINE ELECTRICAL16-31

IGNITION COIL SPECIFICATION

ItemSpecification

Ty p eMolded 2-coil

SPARK PLUG SPECIFICATIONS

Items4G14G66

NGKBKR6E-11IGR6A11

DENSOK20PR-U11−

CHAMPIONRC8YC4−

SERVICE SPECIFICATIONSM1163000300180

IGNITION COIL

ItemStandard value

Secondary coil resistance kΩ8.5 − 11.5

SPARK PLUG

ItemsStandard valueLimit

Spark plug gap mm4G11.0 − 1.1−

4G61.0 − 1.11.3

RESISTIVE CORD

ItemStandard valueLimit

Resistance kΩ−Maximum 19

SPECIAL TOOL

M1163000600288

ToolNumberNameUse

MD998773Detonation sensor

wrenchDetonation sensor

removal and installation

Page 94 of 800

IGNITION SYSTEM

ENGINE ELECTRICAL16-32

ON-VEHICLE SERVICE

IGNITION COIL (WITH BUILT-IN POWER

TRANSISTOR) CHECK

M1163001200324

Check by the following procedure, and replace if

there is a malfunction.

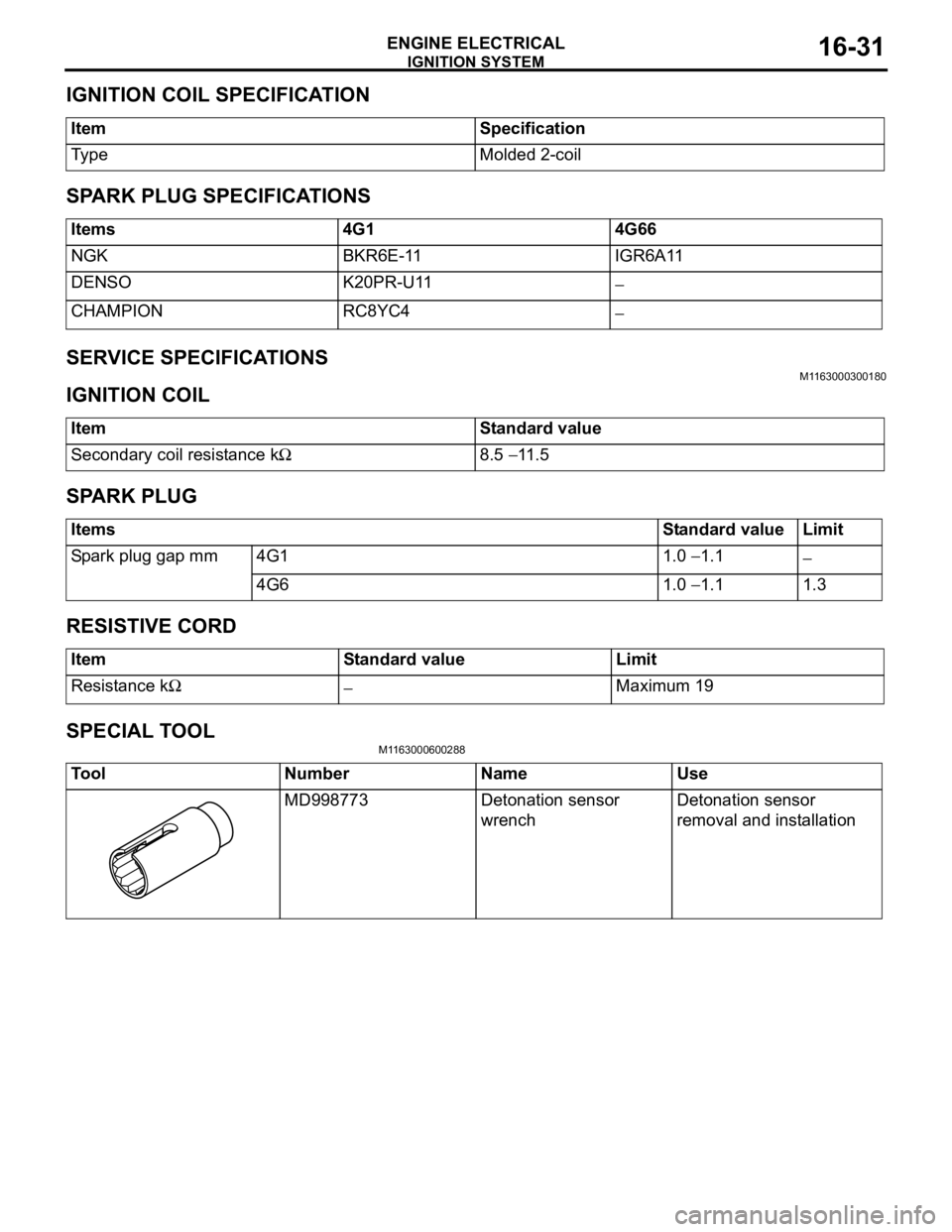

SECONDARY COIL RESISTANCE CHECK

AKX01264

Measure the resist ance bet we en the high- volt ag e

terminals of th

e ign i tio n coil.

St andard va lue: 8.5 − 11 .5 kΩ

PRIM AR Y COIL AND POWER TRANSIS-

TO R CONTINUITY CHECK

NO TE: .•

AKX01265 AD

1.5 V

1 23

+

–

An analogue-t y pe circuit t e ster shou ld be use d .

•Connect the n egative (-) pro v e of the circuit t e ster

to t

e rminal No. 1.

CAUTION

This test must be performed quickly (in less than

10 seconds) to prevent coil from burning and

power transistor from breakage.

1.5 V power supply

between 2

− 3

Continuity between 1 −

2

When current is flowingContinuity

When current is not

flowing

No continuity

RESISTIVE CORD CHECK

M1163001400124

AKX00382

Measure the resistance of the all spark plug cables.

1. Check cap and coating for cracks.

2. Measure resistance.

Limit: Maximum 19 kΩ

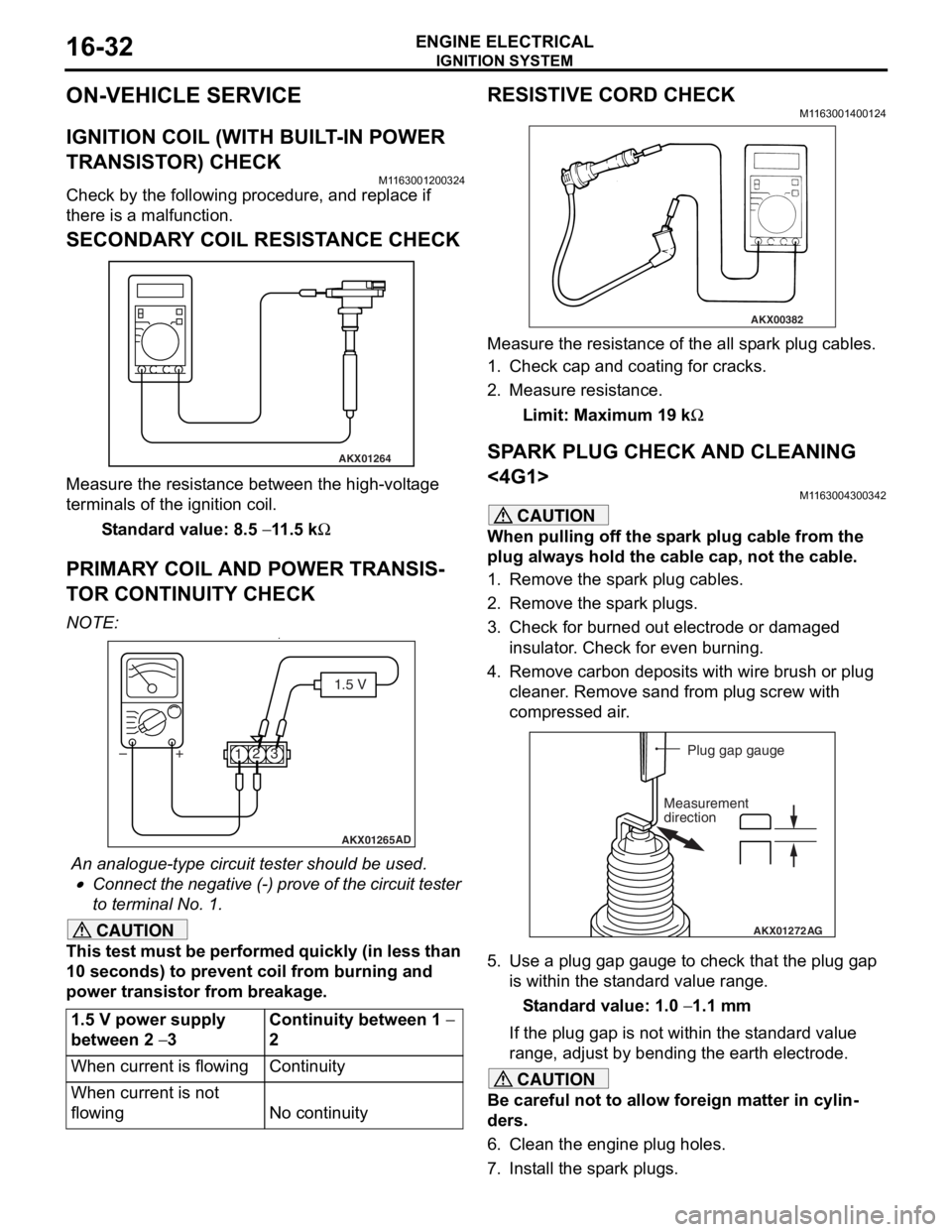

SPARK PLUG CHECK AND CLEANING

<4G1>

M1163004300342

CAUTION

When pulling off the spark plug cable from the

plug always hold the cable cap, not the cable.

1. Remove the spark plug cables.

2. Remove the spark plugs.

3. Check for burned out electrode or damaged insulator. Check for even burning.

4. Remove carbon deposits with wire brush or plug cleaner. Remove sand from plug screw with

compressed air.

AKX01272 AG

Plug gap gauge

Measurement

direction

5. Use a plug gap gauge to check that the plug gap is within the standard value range.

Standard value: 1.0 − 1.1 mm

If the plug gap is not within the standard value

range, adjust by bending the earth electrode.

CAUTION

Be careful not to allow foreign matter in cylin-

ders.

6. Clean the engine plug holes.

7. Install the spark plugs.

Page 95 of 800

IGNITION SYSTEM

ENGINE ELECTRICAL16-33

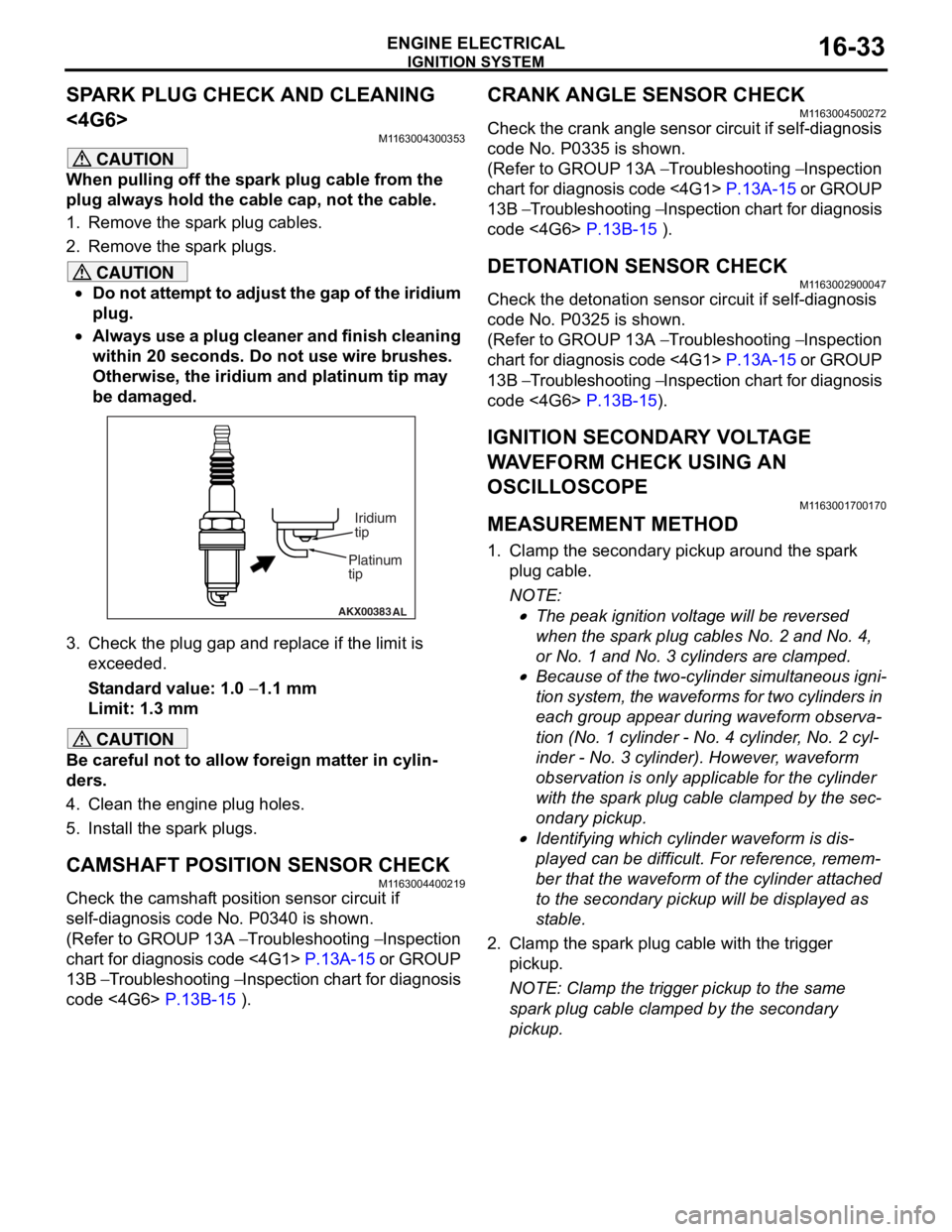

SPARK PLUG CHECK AND CLEANING

<4G6>

M1163004300353

CAUTION

When pulling off the spark plug cable from the

plug always hold the cable cap, not the cable.

1. Remove the spark plug cables.

2. Remove the spark plugs.

CAUTION

•Do not attempt to adjust the gap of the iridium

plug.

•

AKX00383 AL

Platinum

tipIridium

tip

Always use a plug cleaner and finish cleaning

within 20 seconds. Do not use wire brushes.

Otherwise, the iridium and platinum tip may

be damaged.

3. Check the plug gap and re

place if the limit is

exceeded.

Standard value: 1.0 − 1.1 mm

Limit: 1.3 mm

CAUTION

Be careful not to allow foreign matter in cylin-

ders.

4. Clean the engine plug holes.

5. Install the spark plugs.

CAMSHAFT POSITION SENSOR CHECK

M1163004400219

Check the camshaft position sensor circuit if

self-diagnosis code No. P0340 is shown.

(Refer to GROUP 13A − Troubleshooting − Inspection

chart for diagnosis code <4G1>

P.13A-15 or GROUP

13B − Troubleshooting − Inspection chart for diagnosis

code <4G6>

P.13B-15 ).

CRANK ANGLE SENSOR CHECK

M1163004500272

Check the crank angle sensor circuit if self-diagnosis

code No. P0335 is shown.

(Refer to GROUP 13A − Troubleshooting − Inspection

chart for diagnosis code <4G1>

P.13A-15 or GROUP

13B − Troubleshooting − Inspection chart for diagnosis

code <4G6>

P.13B-15 ).

DETONATION SENSOR CHECKM1163002900047

Check the detonation sensor circuit if self-diagnosis

code No. P0325 is shown.

(Refer to GROUP 13A − Troubleshooting − Inspection

chart for diagnosis code <4G1>

P.13A-15 or GROUP

13B − Troubleshooting − Inspection chart for diagnosis

code <4G6>

P.13B-15).

IGNITION SECONDARY VOLTAGE

WAVEFORM CHECK USING AN

OSCILLOSCOPE

M1163001700170

MEASUREMENT METHOD

1. Clamp the secondary pickup around the spark

plug cable.

NOTE: .

•The peak ignition voltage will be reversed

when the spark plug cables No. 2 and No. 4,

or No. 1 and No. 3 cylinders are clamped.

•Because of the two-cylinder simultaneous igni-

tion system, the waveforms for two cylinders in

each group appear during waveform observa

-

tion (No. 1 cylinder - No. 4 cylinder, No. 2 cyl-

inder - No. 3 cylinder). However, waveform

observation is only applicable for the cylinder

with the spark plug cable clamped by the sec

-

ondary pickup.

•Identifying which cylinder waveform is dis-

played can be difficult. For reference, remem-

ber that the waveform of the cylinder attached

to the secondary pickup will be displayed as

stable.

2. Clamp the spark plug cable with the trigger pickup.

NOTE: Clamp the trigger pickup to the same

spark plug cable clamped by the secondary

pickup.

Page 96 of 800

IGNITION SYSTEM

ENGINE ELECTRICAL16-34

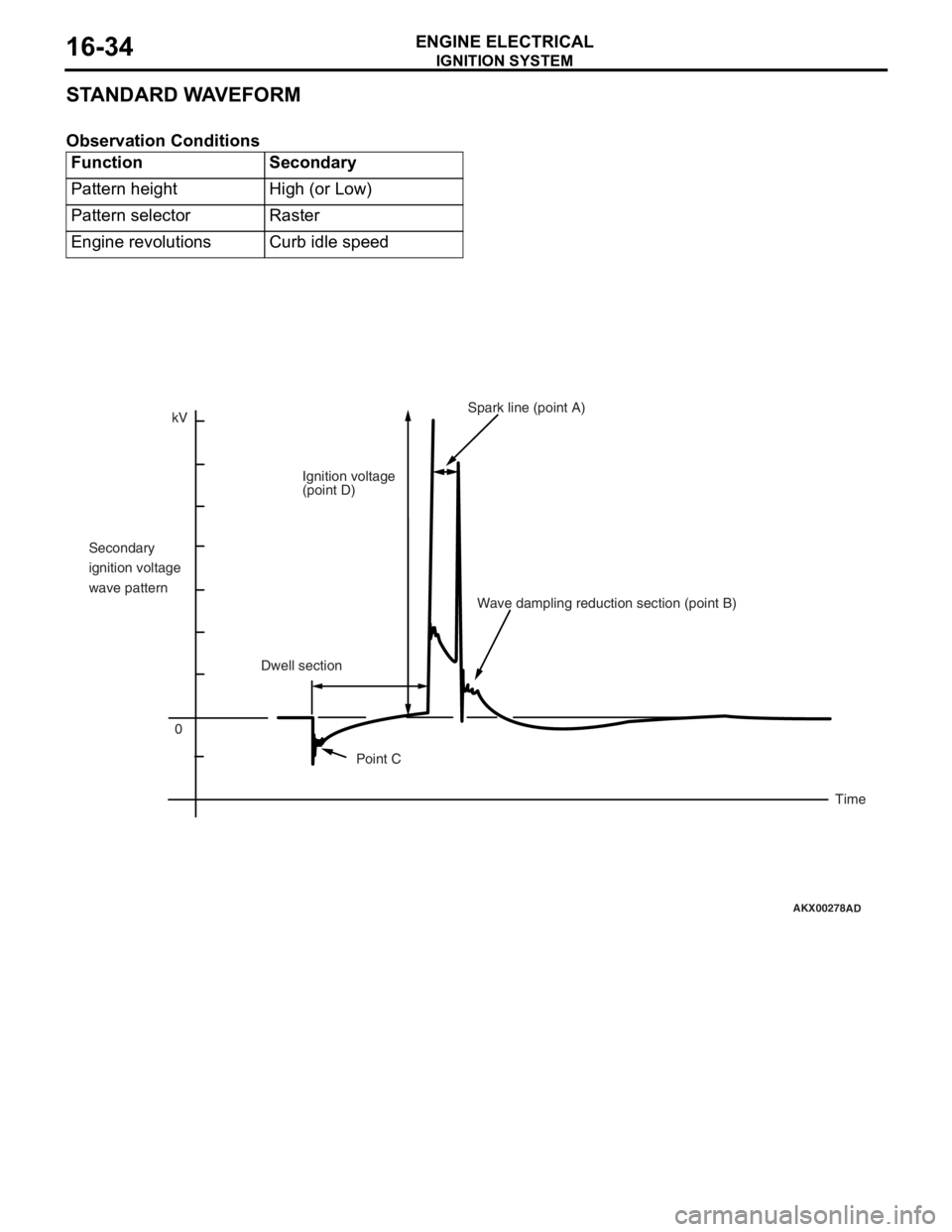

STANDARD WAVEFORM

Observation Conditions

FunctionSecondary

Pattern heightHigh (or Low)

Pattern selectorRaster

Engine revolutionsCurb idle speed

AKX00278

kV0

Secondary

ignition voltage

wave pattern

Ignition voltage

(point D)

Spark line (point A)

Dwell section Wave dampling reduction section (point B)

Point C Time

AD

Page 97 of 800

IGNITION SYSTEM

ENGINE ELECTRICAL16-35

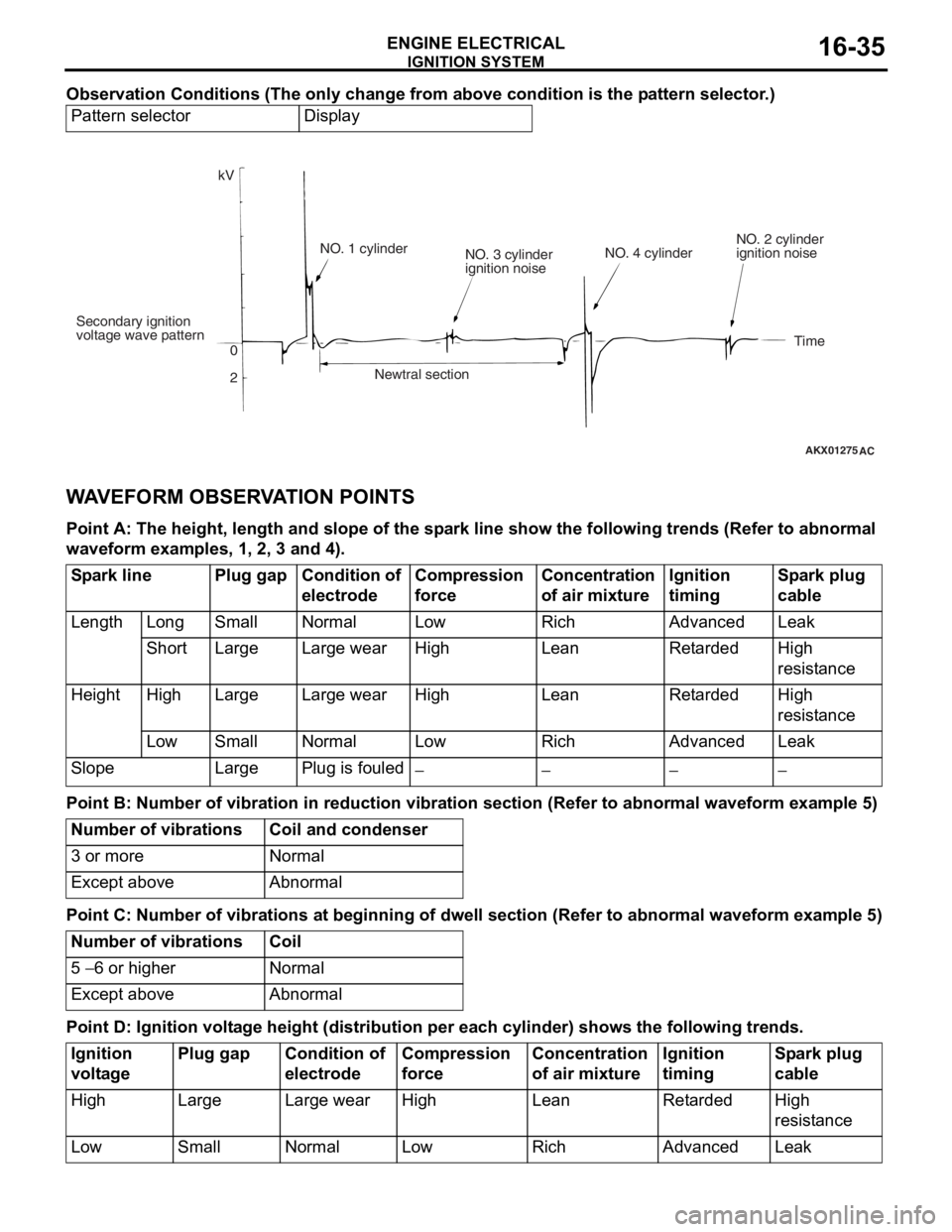

Observation Conditions (The only change from above condition is the pattern selector.)

Pattern selectorDisplay

AKX01275

kV

Secondary ignition

voltage wave pattern 0

2NO. 1 cylinder

NO. 3 cylinder

ignition noise

Newtral section NO. 4 cylinder

NO. 2 cylinder

ignition noise

Time

AC

WA VEFORM OBSER V A T ION POINTS

Point A: The he ight, len g th and s l ope of th e sp a r k line sho w the following trends (Re f er to abnorma l

wave

form exam ples, 1 , 2, 3 a nd 4).

Spark linePlug gapCondition of

electrodeCompression

force Concentration

of air mixtureIgnition

timingSpark plug

cable

LengthLongSmallNormalLowRichAdvancedLeak

ShortLargeLarge wearHigh LeanRetardedHigh

resistance

HeightHighLargeLarge wearHighLeanRetardedHigh

resistance

LowSmallNormalLow RichAdvancedLeak

SlopeLargePlug is fouled−−−−

Point B: Number of v i bra t ion in red uction vi bra t ion sec tion (Refer to a bnormal wavefo r m examp l e 5)

Number of vibrationsCoil and condenser

3 or moreNormal

Except aboveAbnormal

Point C: Number of v i bra t ions a t beginnin g of dwell se ction (Refer to a bnormal wave form exam ple 5)

Number of vibrationsCoil

5 − 6 or higherNormal

Except aboveAbnormal

Point D: Ignition volt a g e height (distribution per each cylinder) s hows the follo wing tren ds.

Ignition

voltagePlug gapCondition of

electrodeCompression

forceConcentration

of air mixtureIgnition

timingSpark plug

cable

HighLargeLarge wearHighLeanRetardedHigh

resistance

LowSmallNormalLowRichAdvancedLeak

Page 98 of 800

IGNITION SYSTEM

ENGINE ELECTRICAL16-36

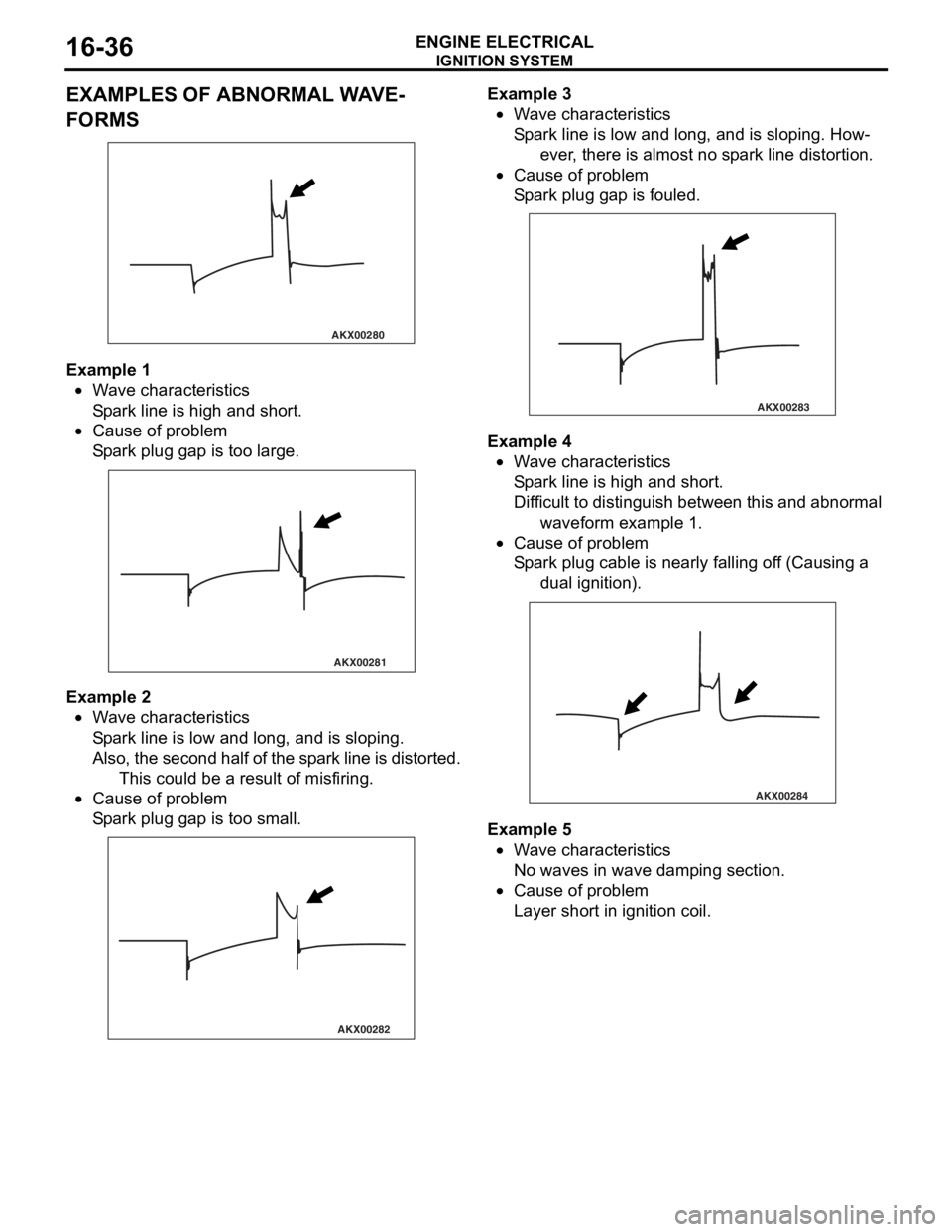

EXAMPLES OF ABNORMAL WAVE-

FORMS

AKX00280

Example 1

•Wa ve ch aracte rist ics

Sp a r k line is high an d sh ort.

•Cause of pr oblem

Sp a r k plug ga p is too large.

AKX00281

Example 2

•Wa ve ch aracte rist ics

Sp a r k line is low and long, a nd is sloping.

Also, the secon d half of the sp ark line is distorted.

This cou l d be a result o f misfiring.

•Cause of pr oblem

Sp a r k plug ga p is too small.

AKX00282

Example 3

•Wa ve ch aracte rist ics

Sp a r k line is low and long, a nd is sloping. How-

ever, there is a l mo st no sp ark lin e distortion.

•Cause of pr oblem

Sp a r k plug ga p is fouled.

AKX00283

Example 4

•Wa ve ch aracte rist ics

Sp a r k line is high an d sh ort.

Diff icu l t to distingu ish be twe en this an d a bnormal

wa vefor m examp l e 1.

•Cause of pr oblem

Sp a r k plug cable is nearly fallin g of f (Ca u sing a

dual ignition ).

AKX00284

Example 5

•Wa ve ch aracte rist ics

No waves in wave damp i ng section.

•Cause of pr oblem

Layer short in ign i tio n coil.

Page 99 of 800

IGNITION SYSTEM

ENGINE ELECTRICAL16-37

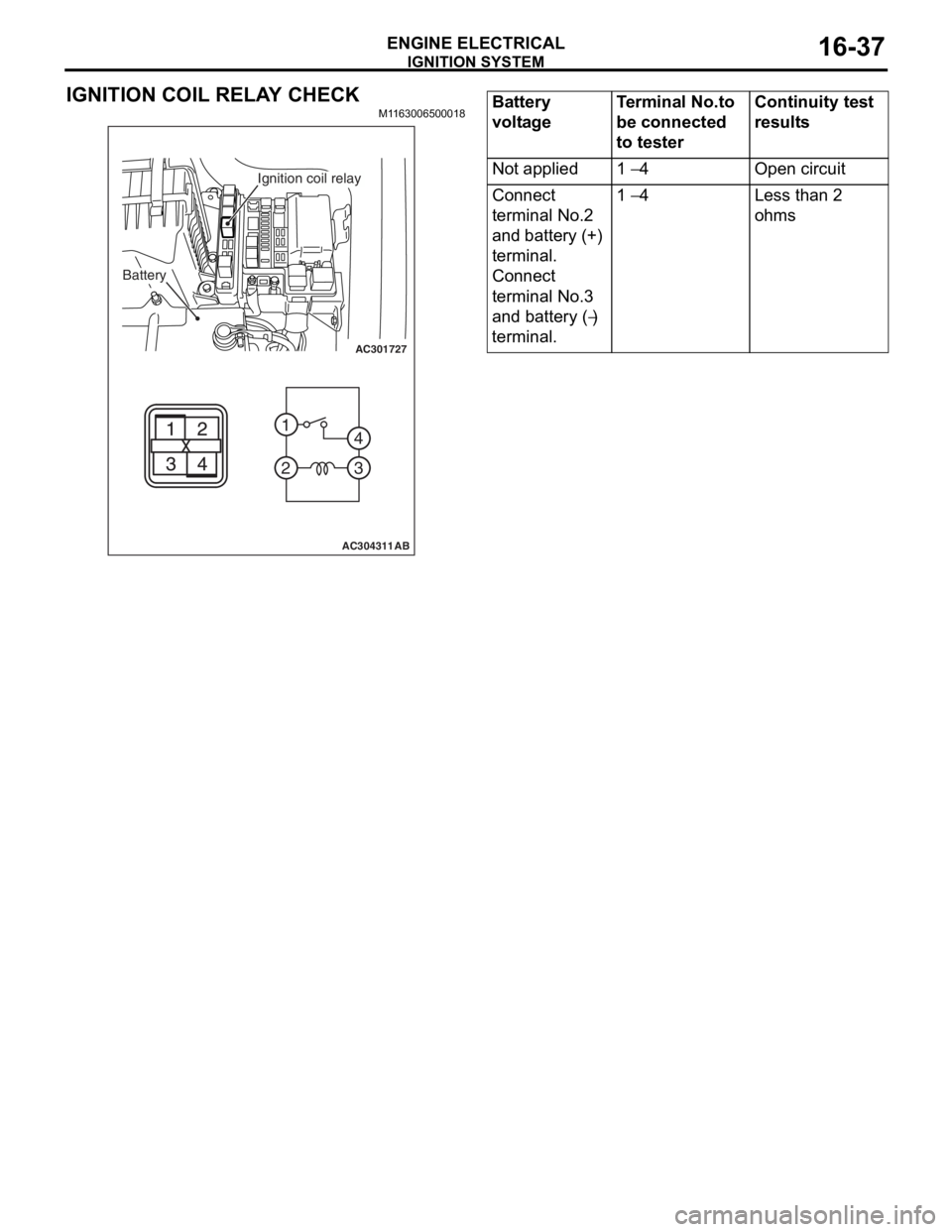

IGNITION COIL RELAY CHECK

M1163006500018

AC301727

2 1

3

4

AC304311AB

Battery

Ignition coil relay

Battery

voltageTerminal No.to

be connected

to testerContinuity test

results

Not applied1 − 4Open circuit

Connect

terminal No.2

and battery (+)

terminal.

Connect

terminal No.3

and battery (

−)

terminal.

1 − 4Less than 2

ohms

Page 100 of 800

IGNITION SYSTEM

ENGINE ELECTRICAL16-38

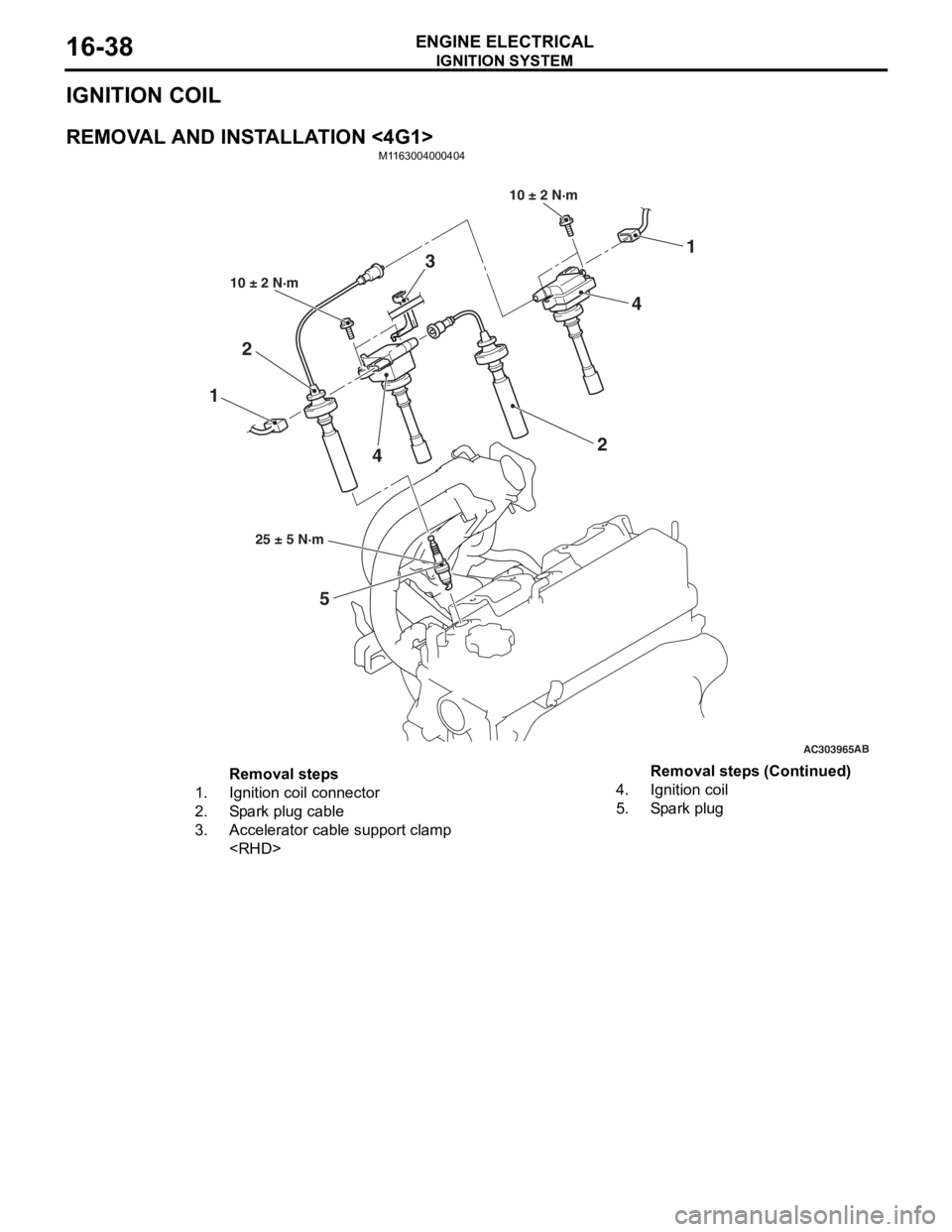

IGNITION COIL

REMOVAL AND INSTALLATION <4G1>

M1163004000404

AC303965AB

11

5

2

2

10 ± 2 N·m

10 ± 2 N·m

25 ± 5 N·m

3

4

4

Removal steps

1.Ignition coil connector

2.Spark plug cable

3.Accelerator cable support clamp

4.Ignition coil

5.Spark plug

Removal steps (Continued)