head lamp MITSUBISHI LANCER 2006 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER, Model: MITSUBISHI LANCER 2006Pages: 800, PDF Size: 45.03 MB

Page 57 of 800

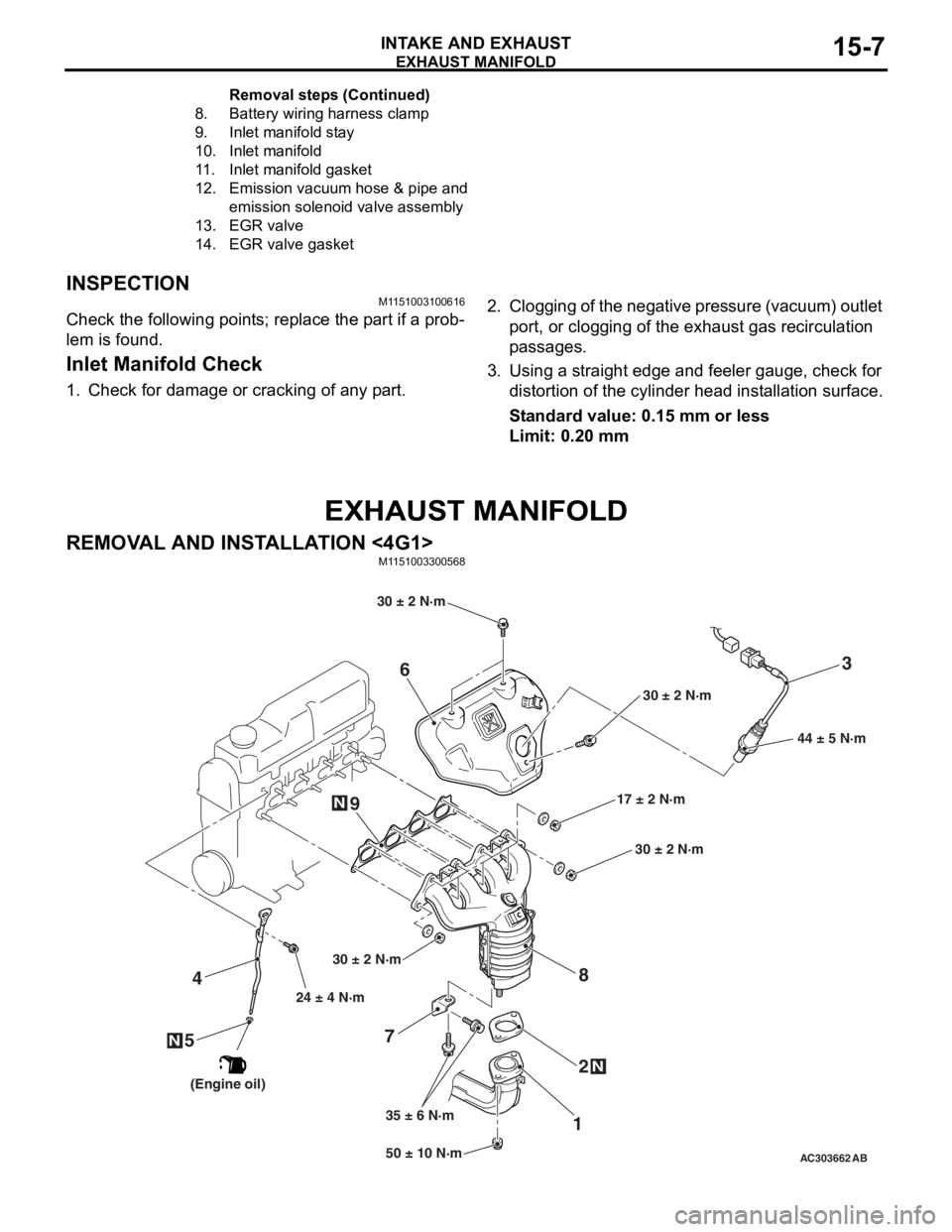

EXHAUST MANIFOLD

INTAKE AND EXHAUST15-7

INSPECTION

M1151003100616

Check the following points; replace the part if a prob-

lem is found.

Inlet Manifold Check

1. Check for damage or cracking of any part.

2. Clogging of the negative pressure (vacuum) outlet port, or clogging of the exhaust gas recirculation

passages.

3. Using a straight edge and feeler gauge, check for distortion of the cylinder head installation surface.

Standard value: 0.15 mm or less

Limit: 0.20 mm

EXHAUST MANIFOLD

REMOVAL AND INSTALLATION <4G1>

M1151003300568

AC30366250 ± 10 N·m

24 ± 4 N·m

35 ± 6 N·m 17 ± 2 N·m

30 ± 2 N·m

N

3

7 12

4

N

6

8

44 ± 5 N·m

AB

9

5N

30 ± 2 N·m

30 ± 2 N·m

30 ± 2 N·m

(Engine oil)

8.Battery wirin g ha rne s s clamp

9.Inlet manifold st ay

10.Inlet manifold

11.Inlet manifold gask et

12.Emission vacuu m hose & pipe and

emis

sion s o lenoid valve assembly

13.EGR v a lve

14.EGR v a lve gasket

Remo va l st ep s ( C o n t in u e d)

Page 66 of 800

CHARGING SYSTEM

ENGINE ELECTRICAL16-4

2. Turn the ignition switch to the "LOCK" (OFF)

position.

3. Disconnect the negative battery cable.

4. Connect a clamp-type DC test ammeter with a

range of 0

− 120 A to the alternator "B" terminal

output wire.

NOTE: The way of disconnecting the alternator

output wire and of connecting the ammeter is pos

-

sibly not found the problem that the output current

is dropping due to the insufficient connection

between terminal "B" and the output wire.

5. Connect a digital-type voltmeter between the

alternator "B" terminal and the battery (+)

terminal. [Connect the (+) lead of the voltmeter to

the "B" terminal and the connect the (-) lead of the

voltmeter to the battery (+) cable].

6. Reconnect the negative battery cable.

7. Connect a tachometer or the M.U.T.-II/III (Refer to

GROUP 11A

− On-vehicle Service − Idle speed

check <4G1>

P.11A-11 or GROUP 11C −

On-vehicle Service − Idle speed check <4G6>

P.11C-11).

8. Leave the hood open.

9. Start the engine.

10.With the engine running at 2,500 r/min, turn the

headlamps and other lamps on and off to adjust

the alternator load so that the value displayed on

the ammeter is slightly above 30 A.

Adjust the engine speed by gradually decreasing

it until the value displayed on the ammeter is 30

A. Take a reading of the value displayed on the

voltmeter at this time.

Limit: maximum 0.3 V

NOTE: When the alternator output is high and the

value displayed on the ammeter does not

decrease until 30 A, set the value to 40 A. Read

the value displayed on the voltmeter at this time.

When the value range is 40 A, the limit is maxi

-

mum 0.4 V.

11.If the value displayed on the voltmeter is above

the limit value, there is probably a malfunction in

the alternator output wire, so check the wiring

between the alternator "B" terminal and the

battery (+) terminal (including fusible link).

If a terminal is not sufficiently tight or if the

harness has become discolored due to

overheating, repair and then test again.

12.After the test, run the engine at idle.

13.Turn off all lamps and the ignition switch.

14.Remove the tachometer or the M.U.T.-II/III.

15.Disconnect the negative battery cable.

16.Disconnect the ammeter and voltmeter.

17.Connect the negative battery cable.

Page 68 of 800

CHARGING SYSTEM

ENGINE ELECTRICAL16-6

9. Check that the reading on the voltmeter is equal

to the battery voltage.

NOTE: If the voltage is 0 V, the cause is probably

an open circuit in the wire or fusible link between

the alternator "B" terminal and the battery (+) ter

-

minal.

10.Turn the light switch on to turn on headlamps and

then start the engine.

11.Immediately after setting the headlamps to high

beam and turning the heater blower switch to the

high revolution position, increase the engine

speed to 2,500 r/min and read the maximum

current output value displayed on the ammeter.

Limit: 70 % of normal current output

NOTE: .

•For the nominal current output, refer to the

Alternator Specifications.

•Because the current from the battery will soon

drop after the engine is started, the above step

should be carried out as quickly as possible in

order to obtain the maximum current output

value.

•The current output value will depend on the

electrical load and the temperature of the

alternator body.

•If the electrical load is small while testing, the

specified level of current may not be output

even though the alternator is normal. In such

cases, increase the electrical load by leaving

the headlamps turned on for some time to dis

-

charge the battery or by using the lighting sys-

tem in another vehicle, and then test again.

•The specified level of current also may not be

output if the temperature of the alternator body

or the ambient temperature is too high. In such

cases, cool the alternator and then test again.

12.The reading on the ammeter should be above the

limit value. If the reading is below the limit value

and the alternator output wire is normal, remove

the alternator from the engine and check the

alternator.

13.Run the engine at idle after the test.

14.Turn the ignition switch to the "LOCK" (OFF)

position.

15.Remove the tachometer or the M.U.T.-II/III.

16.Disconnect the negative battery cable.

17.Disconnect the ammeter and voltmeter.

18.Connect the negative battery cable.

Page 72 of 800

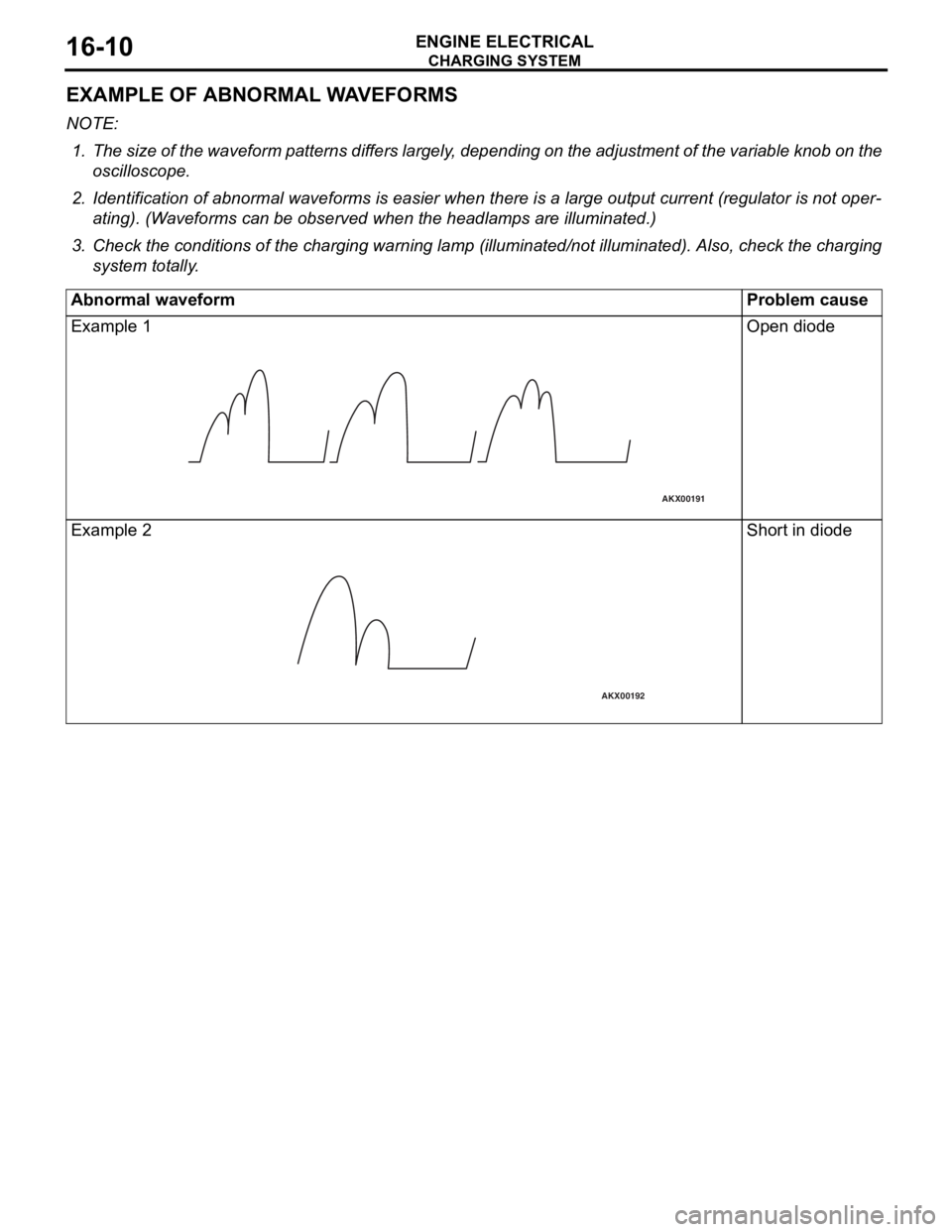

CHARGING SYSTEM

ENGINE ELECTRICAL16-10

EXAMPLE OF ABNORMAL WAVEFORMS

NOTE: .

1. The size of the waveform patterns differs largely, depending on the adjustment of the variable knob on the

oscilloscope.

2. Identification of abnormal waveforms is easier when th ere is a large output current (regulator is not oper-

ating). (Waveforms can be observed when the headlamps are illuminated.)

3. Check the conditions of the charging warning lamp (illuminated/not illum inated). Also, check the charging

system totally.

Abnormal waveformProblem cause

Example 1

AKX00191

Open diod e

Exampl e 2

AKX00192

Shor t in diode

Page 253 of 800

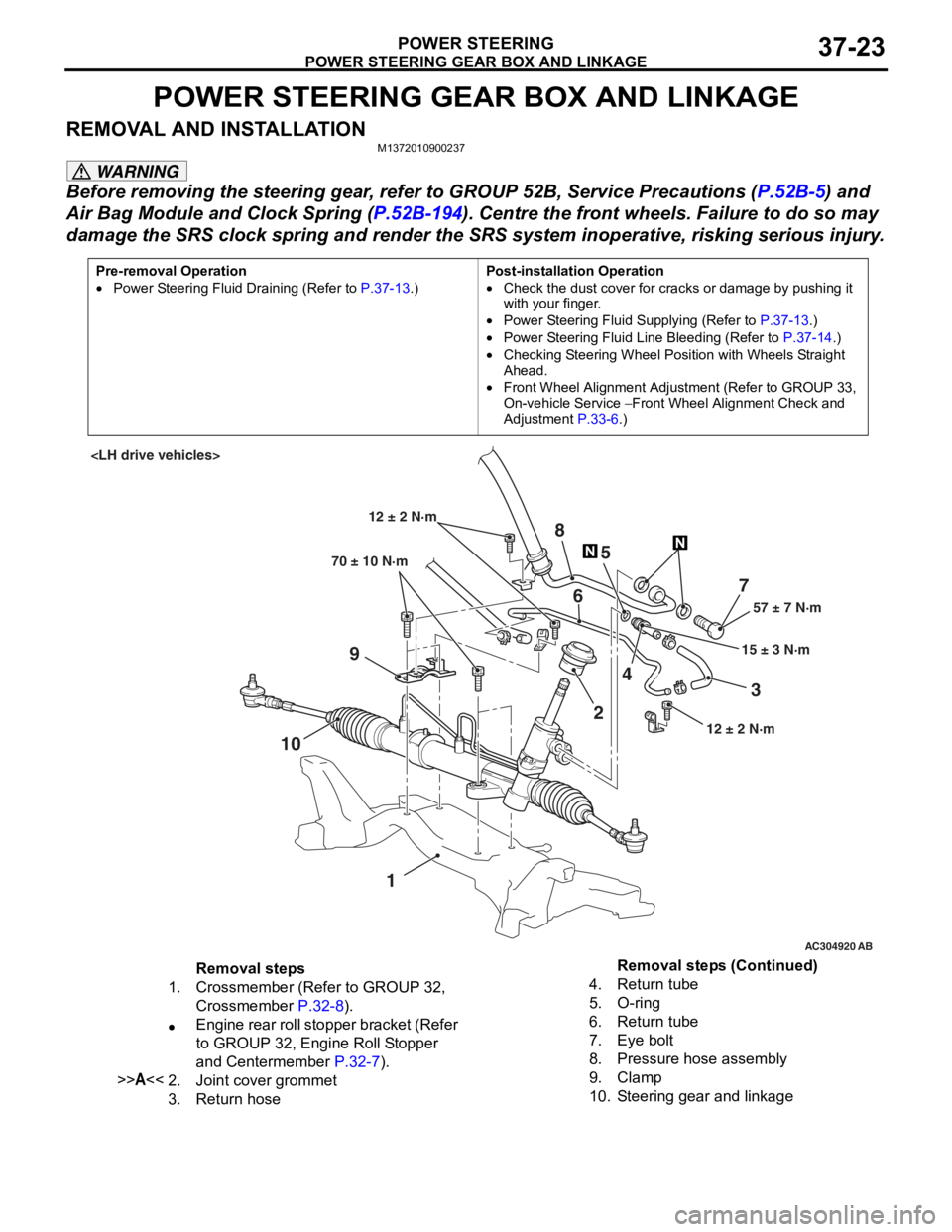

POWER STEERING GEAR BOX AND LINKAGE

POWER STEERING37-23

POWER STEERING GEAR BOX AND LINKAGE

REMOVAL AND INSTALLATIONM1372010900237

WARNING

Before removing the steering gear, refer to GROUP 52B, Service Precautions (P.52B-5) and

Air Bag Module and Clock Spring (P.52B-194). Centre the front wheels. Failure to do so may

damage the SRS clock spring and render the SRS system inoperative, risking serious injury.

Pre-removal Operation

•Power Steering Fluid Draining (Refer to P.37-13.)

Post-installation Operation

•Check the dust cover for cracks or damage by pushing it

with your finger.

•Power Steering Fluid Supplying (Refer to P.37-13.)

•Power Steering Fluid Line Bleeding (Refer to P.37-14.)

•Checking Steering Wheel Position with Wheels Straight

Ahead.

•Front Wheel Alignment Adjustment (Refer to GROUP 33,

On-vehicle Service

− Front Wheel Alignment Check and

Adjustment

P.33-6.)

AC304920 AB

57 ± 7 N·m

15 ± 3 N·m

70 ± 10 N·m

7

3

8

5

6

9

10 24

1

12 ± 2 N·m

12 ± 2 N·m

Removal steps

1.Crossmember (Refer to GROUP 32,

Crossmember

P.32-8).

•Engine rear roll stopper bracket (Refer

to GROUP 32, Engine Roll Stopper

and Centermember

P.32-7).

>>A<<2.Joint cover grommet

3.Return hose

4.Return tube

5.O-ring

6.Return tube

7.Eye bolt

8.Pressure hose assembly

9.Clamp

10.Steering gear and linkage

Removal steps (Continued)

Page 289 of 800

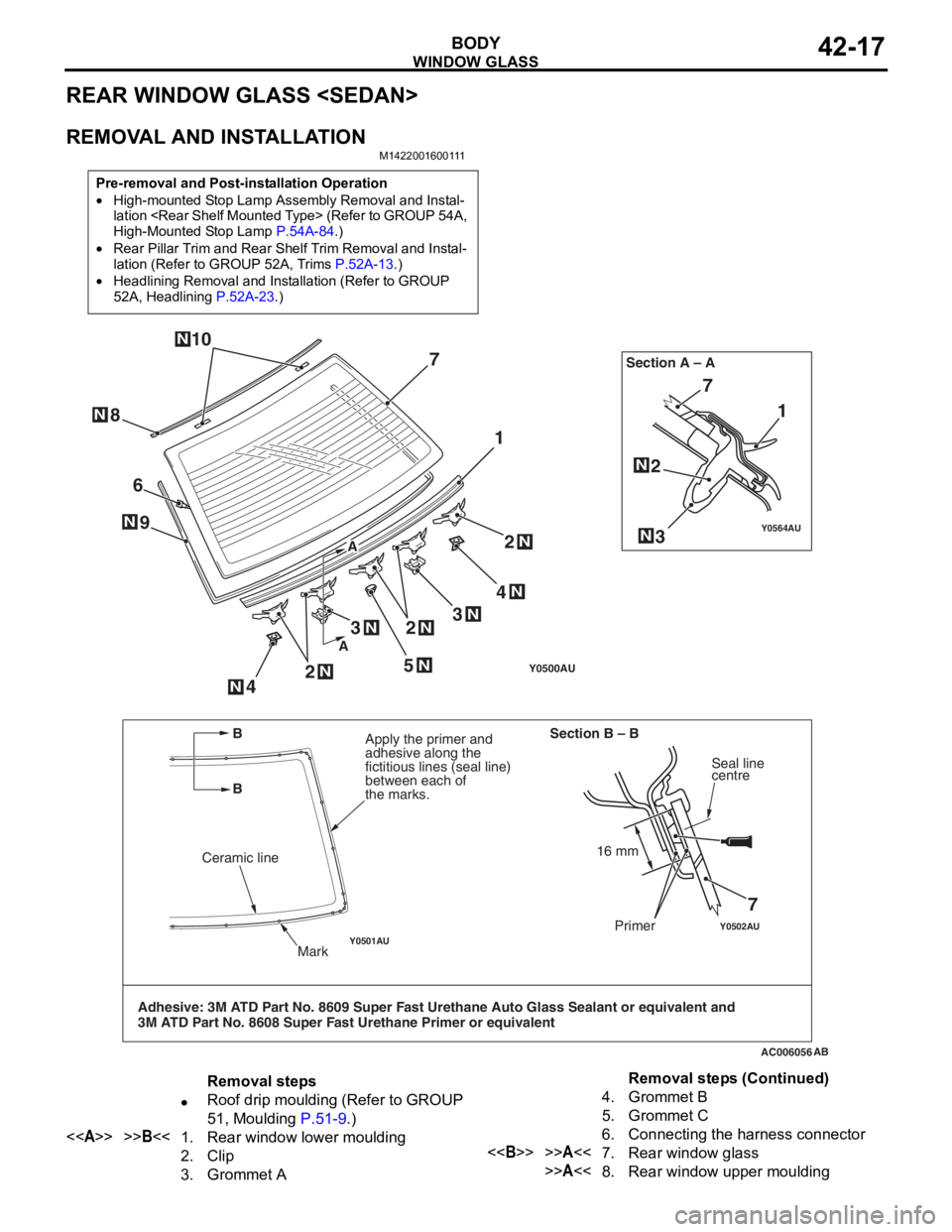

WINDOW GLASS

BODY42-17

REAR WINDOW GLASS

REMOVAL AND INSTALLATION

M1422001600111

Pre-removal and Post-installation Operation

•High-mounted Stop Lamp Assembly Removal and Instal-lation

High-Mounted Stop Lamp

P.54A-84.)

•Rear Pillar Trim and Rear Shelf Trim Removal and Instal-

lation (Refer to GROUP 52A, Trims P.52A-13.)

•Headlining Removal and Installation (Refer to GROUP

52A, Headlining

P.52A-23.)

Y0500AU

Y0502AUY0501AU

Y0564AU

AC006056

1 1

7

7

AB

6

25

4

9

7

3

N

2N

2N

N

4N

N

3N3N

NN

2N

Ceramic line

Mark

Apply the primer and

adhesive along the

fictitious lines (seal line)

between each of

the marks. Section A – A

Section B – B

Seal line

centre

Primer

8N

10N

Adhesive: 3M ATD Part No. 8609 Super Fast Urethane Auto Glass Sealant or equivalent and

3M ATD Part No. 8608 Super Fast Urethane Primer or equivalent

16 mm

A

A

B

B

Removal steps

•Roof drip moulding (Refer to GROUP

51, Moulding

P.51-9.)

<>>>B<<1.Rear window lower moulding

2.Clip

3.Grommet A

4.Grommet B

5.Grommet C

6.Connecting the harness connector

<>>>A<<7.Rear window glass

>>A<<8.Rear window upper moulding

Removal steps (Continued)

Page 334 of 800

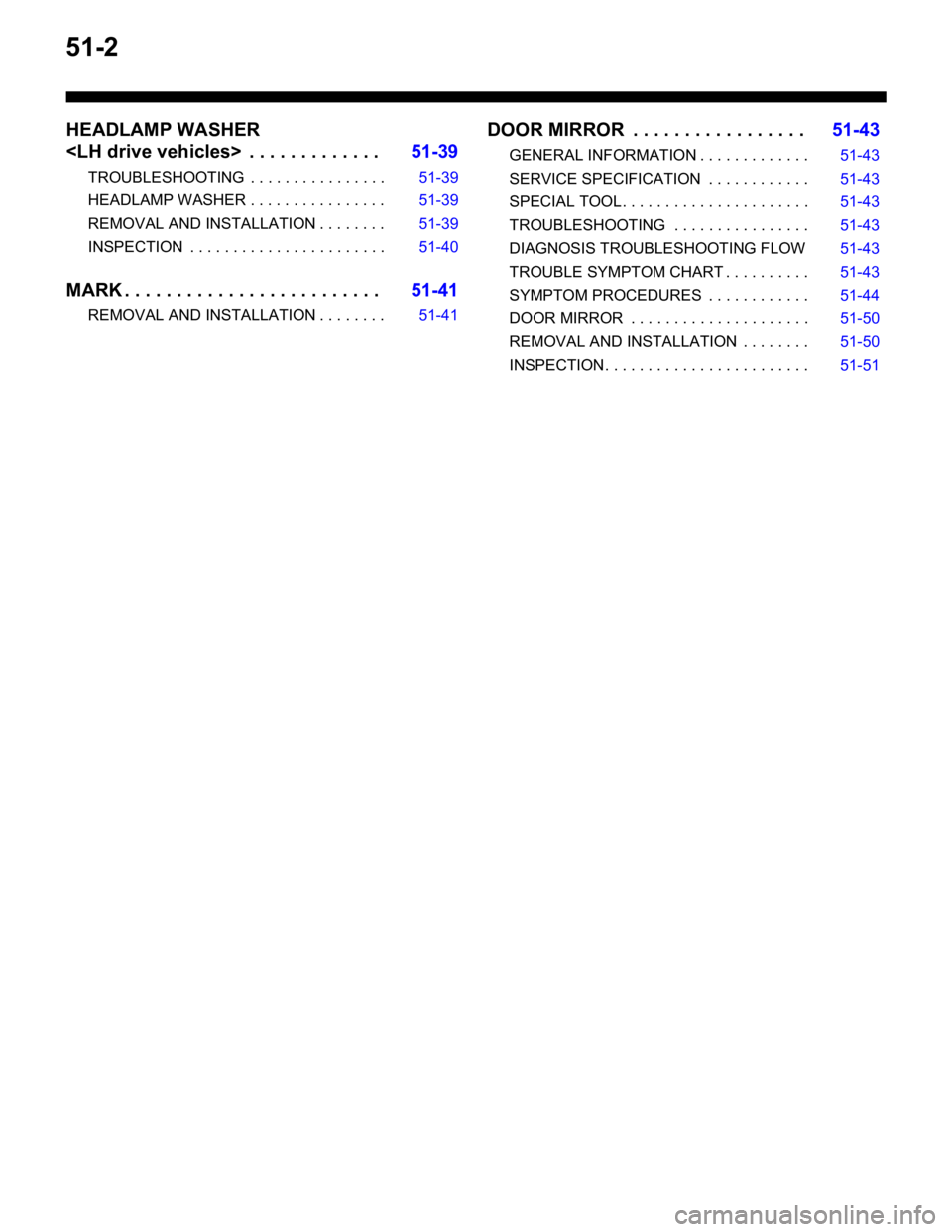

51-2

HEADLAMP WASHER

TROUBLESHOOTING . . . . . . . . . . . . . . . . 51-39

HEADLAMP WASHER . . . . . . . . . . . . . . . . 51-39

REMOVAL AND INSTALLATION . . . . . . . . 51-39

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . 51-40

MARK . . . . . . . . . . . . . . . . . . . . . . . . .51-41

REMOVAL AND INSTALLATION . . . . . . . . 51-41

DOOR MIRROR . . . . . . . . . . . . . . . . .51-43

GENERAL INFORMATION . . . . . . . . . . . . . 51-43

SERVICE SPECIFICATION . . . . . . . . . . . . 51-43

SPECIAL TOOL. . . . . . . . . . . . . . . . . . . . . . 51-43

TROUBLESHOOTING . . . . . . . . . . . . . . . . 51-43

DIAGNOSIS TROUBLESHOOTING FLOW 51-43

TROUBLE SYMPTOM CHART . . . . . . . . . . 51-43

SYMPTOM PROCEDURES . . . . . . . . . . . . 51-44

DOOR MIRROR . . . . . . . . . . . . . . . . . . . . . 51-50

REMOVAL AND INSTALLATION . . . . . . . . 51-50

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 51-51

Page 371 of 800

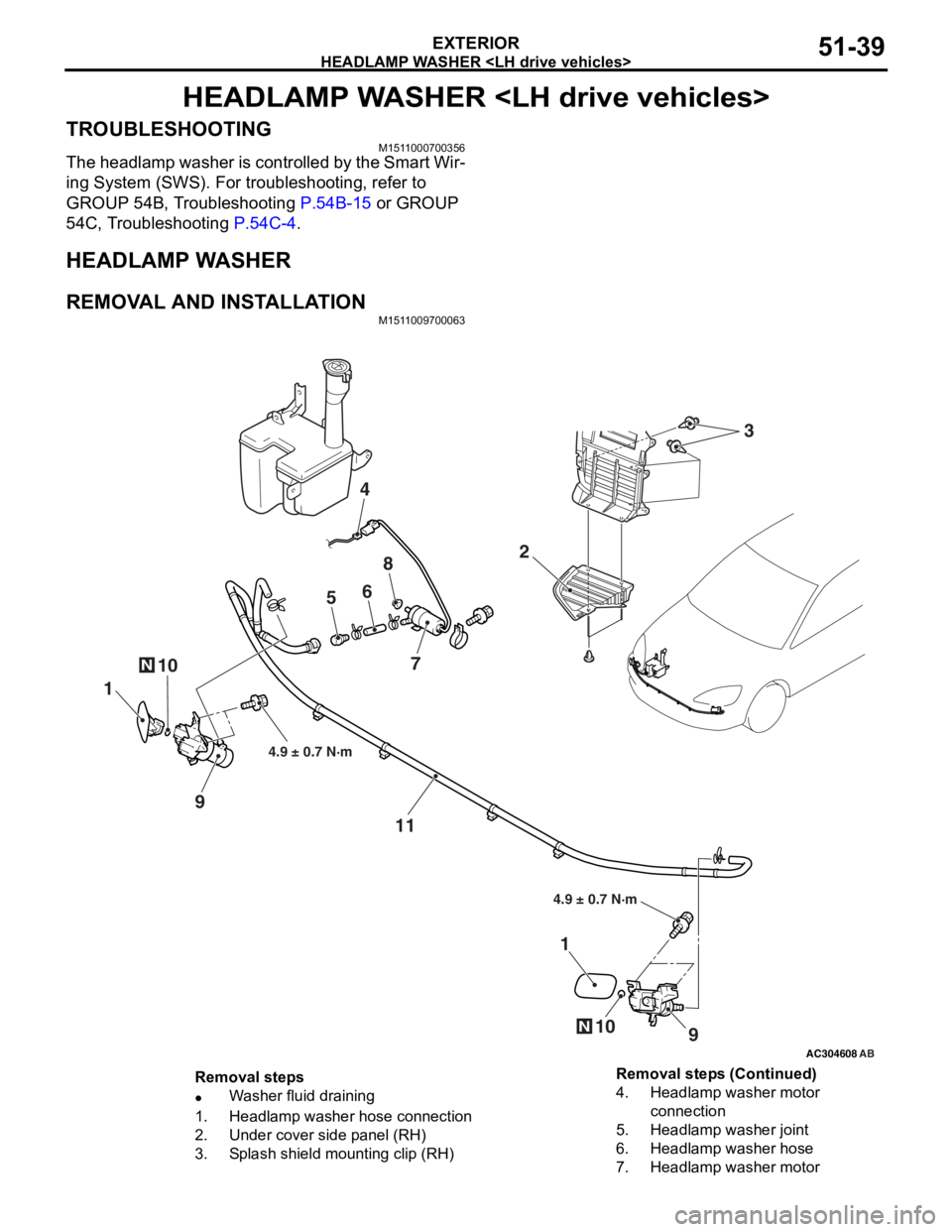

HEADLAMP WASHER

EXTERIOR51-39

HEADLAMP WASHER

TROUBLESHOOTINGM1511000700356

The headlamp washer is controlled by the Smart Wir-

ing System (SWS). For troubleshooting, refer to

GROUP 54B, Troubleshooting

P.54B-15 or GROUP

54C, Troubleshooting P.54C-4.

HEADLAMP WASHER

REMOVAL AND INSTALLATION

M1511009700063

AC304608AB

10N

2

4

56

8

7

1

9

11

9

1

10N

4.9 ± 0.7 N·m

4.9 ± 0.7 N·m

3

Removal steps

•Washer fluid draining

1.Headlamp washer hose connection

2.Under cover side panel (RH)

3.Splash shield mounting clip (RH)

4.Headlamp washer motor

connection

5.Headlamp washer joint

6.Headlamp washer hose

7.Headlamp washer motor

Removal steps (Continued)

Page 372 of 800

HEADLAMP WASHER

EXTERIOR51-40

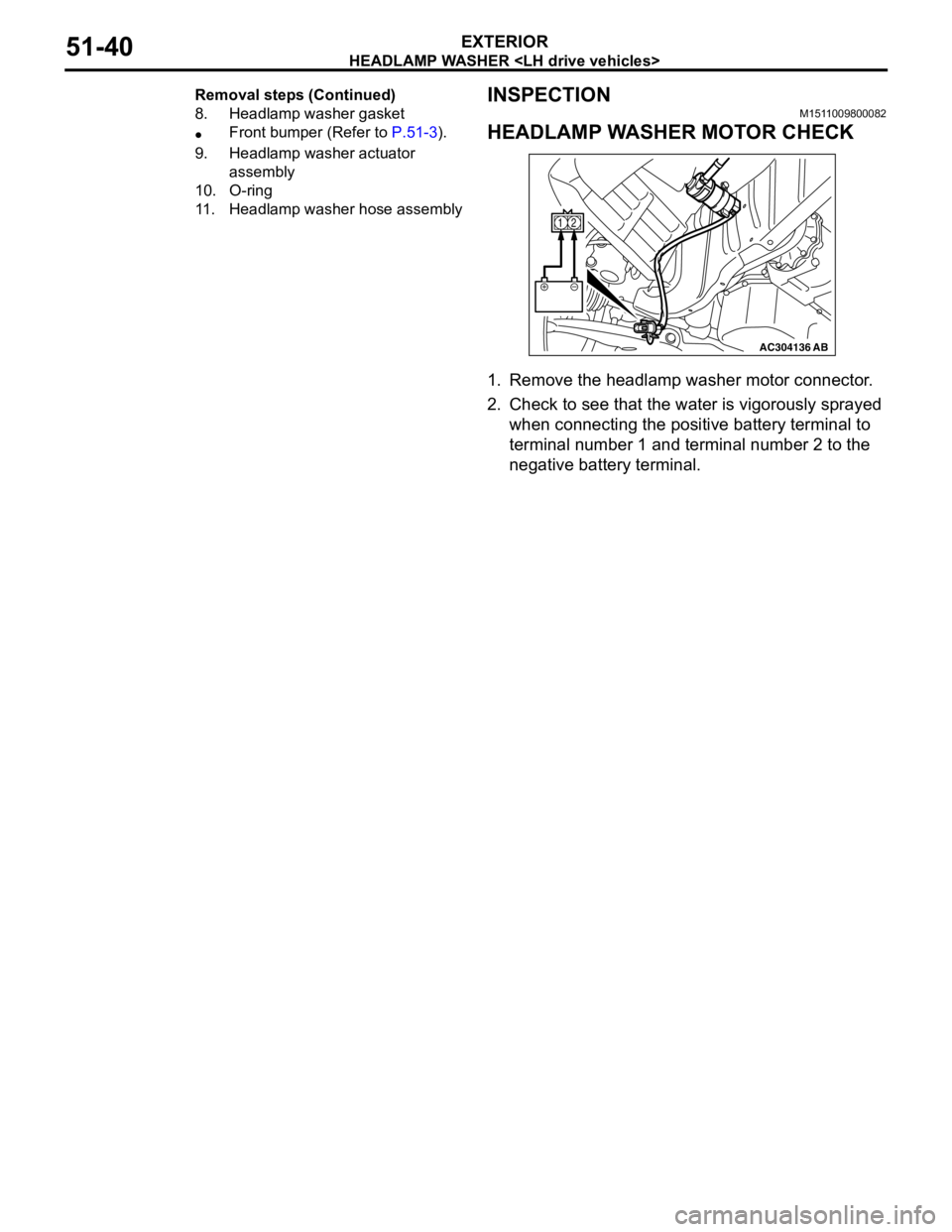

INSPECTION

M1511009800082

HEADLAMP WASHER MOTOR CHECK

AC304136AB

12

1.Remove the he adla m p washer motor connector .

2.Check to se e tha t the wat e r is vigorou sly sp rayed

when con nect i ng th e positive ba ttery terminal to

te rmin al nu mber 1 and terminal n u mb er 2 to the

n egative ba ttery terminal.

8.Headlamp wa s h er gasket

•Fr o n t b u m p er ( R ef er to P.51-3).

9.Head lam p wa sh er a c tu ator

assembly

10.O-rin g

11.Headlamp w a s h er hose assembly

Remo val st ep s ( C o n tinue d)

Page 416 of 800

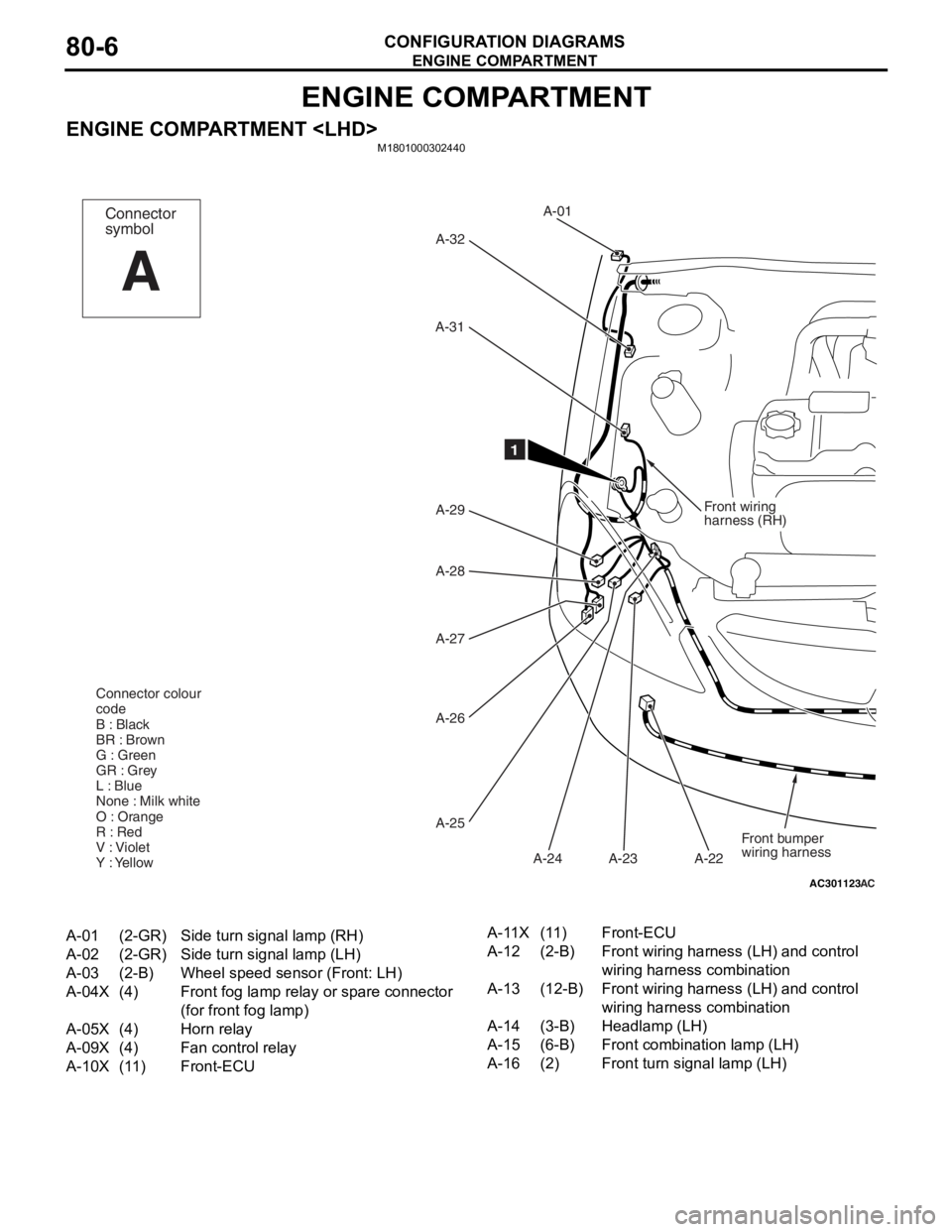

ENGINE COMPARTMENT

CONFIGURATION DIAGRAMS80-6

ENGINE COMPARTMENT

ENGINE COMPARTMENT

AC301123

Front wiring

harness (RH)

A-01

A-32

A-31

A-29

A-28

A-27

A-26

A-25 A-23

A-24 A-22

AC

1

Front bumper

wiring harness

Connector colour

code

B : Black

BR : Brown

G : Green

GR : Grey

L : Blue

None : Milk white

O : Orange

R : Red

V : Violet

Y : Yellow

Connector

symbol

A

A-01(2-GR)Side turn signal lamp (RH)

A-02(2-GR)Side turn signal lamp (LH)

A-03(2-B)Wheel speed sensor (Front: LH)

A-04X(4)Front fog lamp relay or spare connector

(for front fog lamp)

A-05X(4)Horn relay

A-09X(4)Fan control relay

A-10X(11)Front-ECU

A-11X(11)Front-ECU

A-12(2-B)Front wiring harness (LH) and control

wiring harness combination

A-13(12-B)Front wiring harness (LH) and control

wiring harness combination

A-14(3-B)Headlamp (LH)

A-15(6-B)Front combination lamp (LH)

A-16(2)Front turn signal lamp (LH)