valve MITSUBISHI LANCER 2006 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER, Model: MITSUBISHI LANCER 2006Pages: 800, PDF Size: 45.03 MB

Page 15 of 800

14-1

GROUP 14

ENGINE COOLING

CONTENTS

GENERAL INFORMATION . . . . . . . .14-2

SERVICE SPECIFICATIONS . . . . . . .14-2

LUBRICANT . . . . . . . . . . . . . . . . . . . .14-3

SEALANTS . . . . . . . . . . . . . . . . . . . .14-3

SPECIAL TOOLS . . . . . . . . . . . . . . . .14-3

TROUBLESHOOTING . . . . . . . . . . . .14-5

INSPECTION CHART FOR TROUBLE

SYMPTOMS . . . . . . . . . . . . . . . . . . . . . . . . 14-5

INSPECTION PROCEDURE FOR

TROUBLE SYMPTOMS . . . . . . . . . . . . . . . 14-6

ON-VEHICLE SERVICE . . . . . . . . . . .14-21

ENGINE COOLANT LEAK CHECK . . . . . . 14-21

RADIATOR CAP VALVE OPENING

PRESSURE CHECK . . . . . . . . . . . . . . . . . . 14-21

ENGINE COOLANT REPLACEMENT . . . . 14-21

CONCENTRATION MEASUREMENT . . . . 14-22

COOLING FAN MOTOR DRIVE

CONTROL UNIT CHECK . . . . . . . . . . . . . . 14-22

FAN CONTROL RELAY CONTINUITY

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-23

COOLING FAN MOTOR CHECK . . . . . . . . 14-24

THERMOSTAT . . . . . . . . . . . . . . . . . .14-24

REMOVAL AND INSTALLATION . . . . . . . . 14-24

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 14-26

WATER PUMP . . . . . . . . . . . . . . . . . .14-27

REMOVAL AND INSTALLATION <4G1> . . 14-27

REMOVAL AND INSTALLATION <4G6> . . 14-28

WATER HOSE AND WATER PIPE . .14-29

REMOVAL AND INSTALLATION <4G1> . . 14-29

REMOVAL AND INSTALLATION <4G6> . . 14-31

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 14-32

RADIATOR . . . . . . . . . . . . . . . . . . . . .14-33

REMOVAL AND INSTALLATION <4G1> . . 14-33

REMOVAL AND INSTALLATION <4G6> . . 14-35

Page 16 of 800

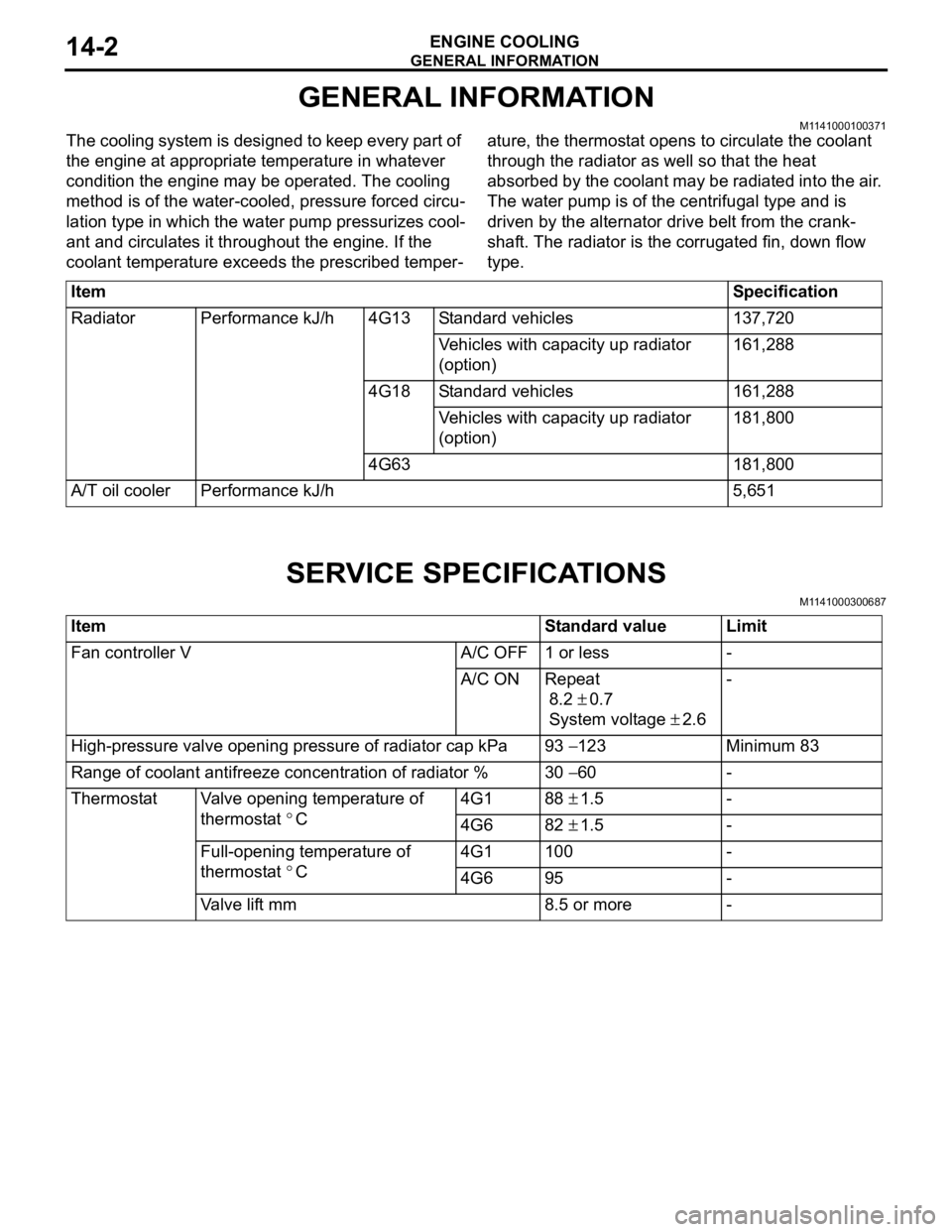

GENERAL INFORMATION

ENGINE COOLING14-2

GENERAL INFORMATION

M1141000100371

The cooling system is designed to keep every part of

the engine at appropriate temperature in whatever

condition the engine may be operated. The cooling

method is of the water-cooled, pressure forced circu

-

lation type in which the water pump pressurizes cool-

ant and circulates it throughout the engine. If the

coolant temperature exceeds the prescribed temper

-

ature, the thermostat opens to circulate the coolant

through the radiator as well so that the heat

absorbed by the coolant may be radiated into the air.

The water pump is of the centrifugal type and is

driven by the alternator drive belt from the crank

-

shaft. The radiator is the corrugated fin, down flow

type.

ItemSpecification

RadiatorPerformance kJ/h4G13Standard vehicles137,720

Vehicles with capacity up radiator

(option)161,288

4G18Standard vehicles161,288

Vehicles with capacity up radiator

(option)181,800

4G63181,800

A/T oil coolerPerformance kJ/h5,651

SERVICE SPECIFICATIONS

M1141000300687

ItemStandard valueLimit

Fan controller VA/C OFF1 or less-

A/C ONRepeat

8.2 ± 0.7

System voltage ± 2.6

-

High-pressure valve opening pressure of radiator cap kPa93 − 123Minimum 83

Range of coolant antifreeze concentration of radiator %30 − 60-

ThermostatValve opening temperature of

thermostat

°C

4G188 ± 1.5-

4G682 ± 1.5-

Full-opening temperature of

thermostat

°C

4G1100-

4G695-

Valve lift mm8.5 or more-

Page 35 of 800

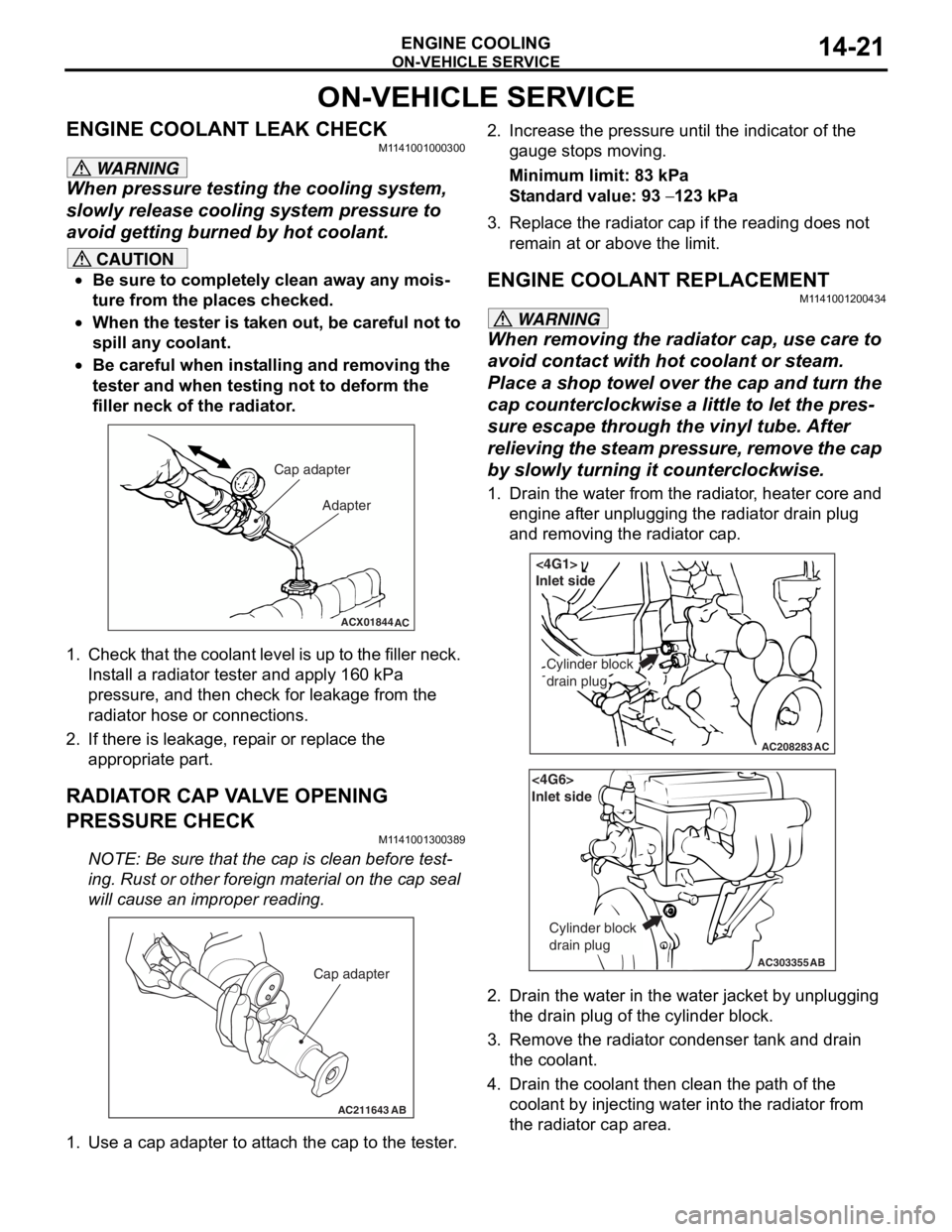

ON-VEHICLE SERVICE

ENGINE COOLING14-21

ON-VEHICLE SERVICE

ENGINE COOLANT LEAK CHECKM1141001000300

WARNING

When pressure testing the cooling system,

slowly release cooling system pressure to

avoid getting burned by hot coolant.

CAUTION

•Be sure to completely clean away any mois-

ture from the places checked.

•When the tester is taken out, be careful not to

spill any coolant.

•

ACX01844

Cap adapter

Adapter

AC

Be careful when installing and removing the

tester and when testing not to deform the

filler neck of the radiator.

1. Check that the coolant leve l is up to the filler neck.

Install a radiator tester and apply 160 kPa

pressure, and then check for leakage from the

radiator hose or connections.

2. If there is leakage, repair or replace the

appropriate part.

RADIATOR CAP VALVE OPENING

PRESSURE CHECK

M1141001300389

NOTE: Be sure that the cap is clean before test-

ing. Rust or other foreign material on the cap seal

will cause an improper reading.

AC211643AB

Cap adapter

1. Use a cap adapter to attach the cap to the tester.

2. Increase the pressure until the indicator of the gauge stops moving.

Minimum limit: 83 kPa

Standard value: 93 − 123 kPa

3. Replace the radiator cap if the reading does not remain at or above the limit.

ENGINE COOLANT REPLACEMENT

M1141001200434

WARNING

When removing the radiator cap, use care to

avoid contact with hot coolant or steam.

Place a shop towel over the cap and turn the

cap counterclockwise a little to let the pres

-

sure escape through the vinyl tube. After

relieving the steam pres sure, remove the cap

by slowly turning it counterclockwise.

1. Drain the water from the radiator, heater core and

engine after unplugging the radiator drain plug

and removing the radiator cap.

AC208283AC

Cylinder block

drain plug

<4G1>

Inlet side

AC303355

<4G6>

Inlet side

Cylinder block

drain plug

AB

2. Drain the water in the water jacket by unplugging the drain plug of the cylinder block.

3. Remove the radiator condenser tank and drain

the coolant.

4. Drain the coolant then clean the path of the coolant by injecting water into the radiator from

the radiator cap area.

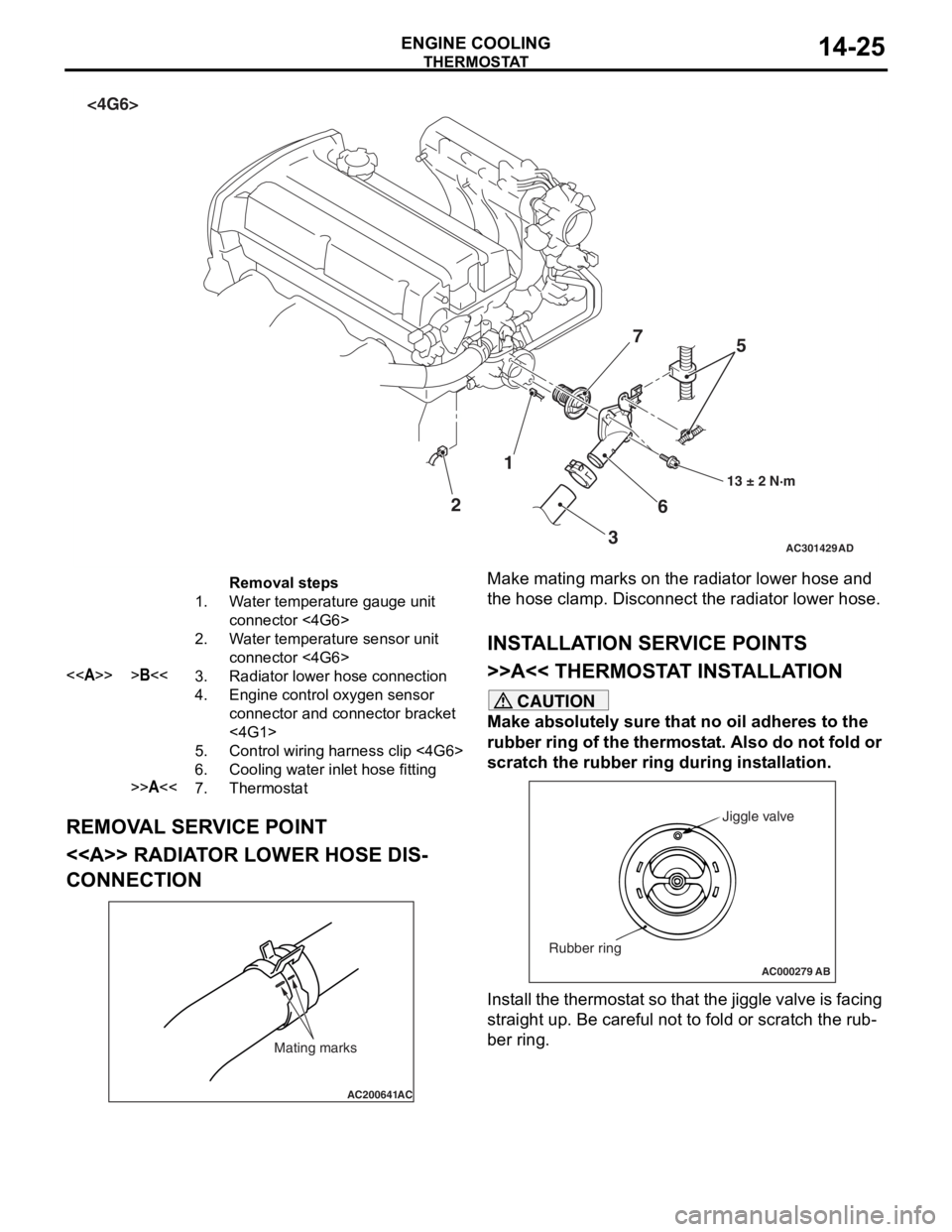

Page 39 of 800

AC301429

1

2 36

7

13 ± 2 N·m

AD

5

<4G6>

Removal steps

1.Water temperature gauge unit

connector <4G6>

2.Water temperature sensor unit

connector <4G6>

<>>B<<3.Radiator lower hose connection

4.Engine control oxygen sensor

connector and connector bracket

<4G1>

5.Control wiring harness clip <4G6>

6.Cooling water inlet hose fitting

>>A<<7.Thermostat

THERMOST

A T

ENGINE COOLING14-25

REMOV A L SER V ICE POINT

<> RADIAT OR LOW E R HOSE DIS-

CONNECTION

AC200641AC

Mating marks

Make mating marks on the rad i ator lower ho se an d

the hose clamp. Disconn

ect t he radiator lower hose.

INSTALLA T ION SER VICE POINTS

>>A<< THERMOSTA T INST ALLA TION

CAUTION

Make absolutely sure that no oil adheres to the

rubber ring of the thermostat. Also do not fold or

scratch the rubber ring during installation.

AC000279

Jiggle valve

Rubber ring

AB

Install the thermostat so that the jiggle valve is facing

straight up. Be careful not to fold or scratch the rub

-

ber ring.

Page 40 of 800

THERMOSTAT

ENGINE COOLING14-26

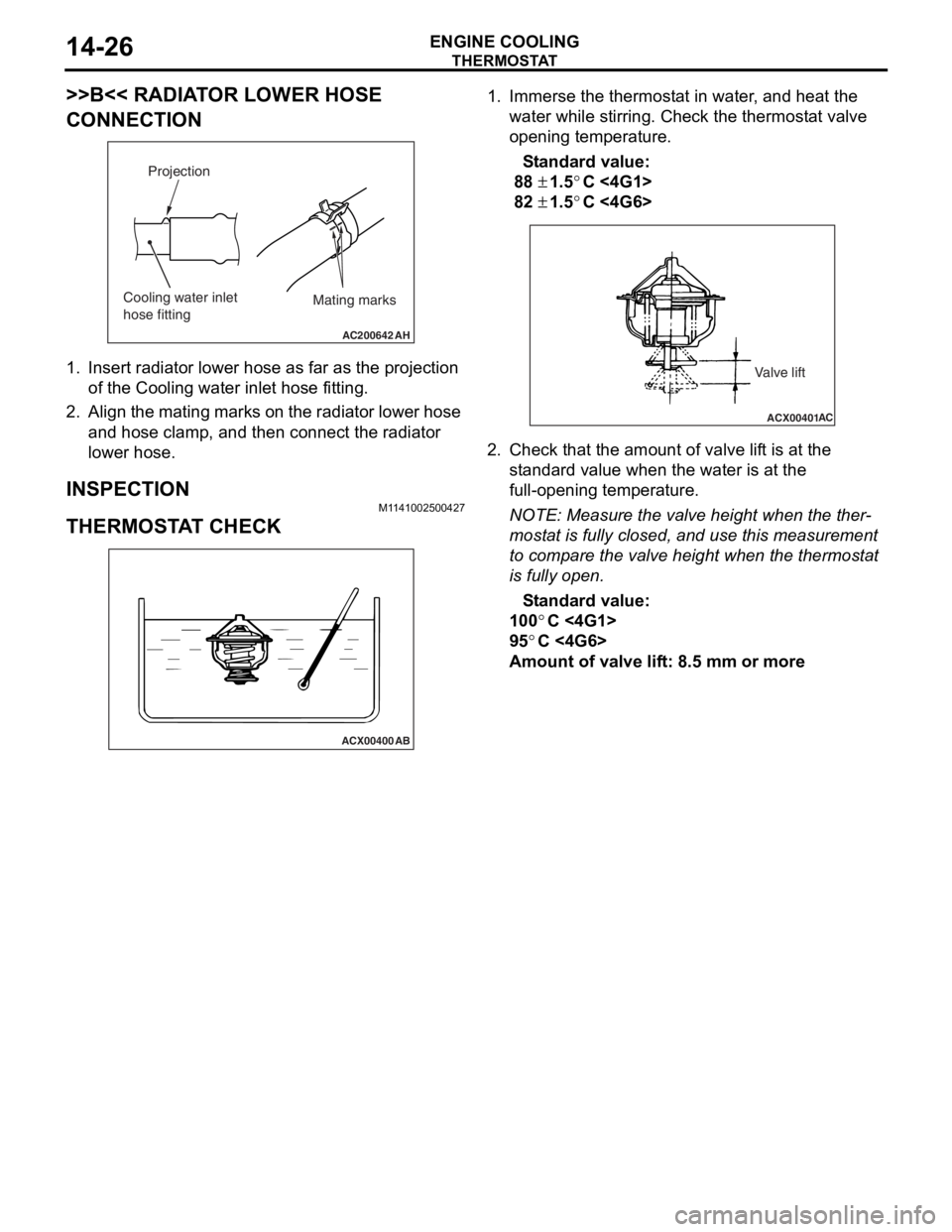

>>B<< RADIATOR LOWER HOSE

CONNECTION

AC200642

Mating marks

Projection

Cooling water inlet

hose fitting

AH

1.In sert ra diato r lower h o se a s fa r as th e projection

of the Cooling wa ter inlet ho se fitting .

2.Align the mating marks on the radiator lower hose

an d hose clamp, and then connect the radia t or

lower hose.

INSPECTION

M1 141 0025 0042 7

THERMOSTA T CHECK

ACX00400

AB

1.Imme rse th e thermost at in water , and h eat the

wate r wh ile stirring. Ch eck the th ermost a t va lve

o penin g temperatu r e.

St andard va lue:

88 ± 1.5°C <4G1 >

82 ± 1.5°C <4G6 >

ACX00401 AC

Valve lift

2.

Check t hat the amo unt of valve lif t is at the

st a ndard valu e when th e water is at the

fu ll-o penin g temperatu r e.

NOTE: Meas ure the valve height when the the r-

mostat is fu lly closed , and use t h is measurement

to

comp are the valve h e ight wh en the thermost at

is fully open.

St andard va lue:

100°C <4G1>

95°C <4G6>

Amou nt of val ve lif t: 8 . 5 mm or more

Page 41 of 800

WATE R P U M P

ENGINE COOLING14-27

WAT E R P U M P

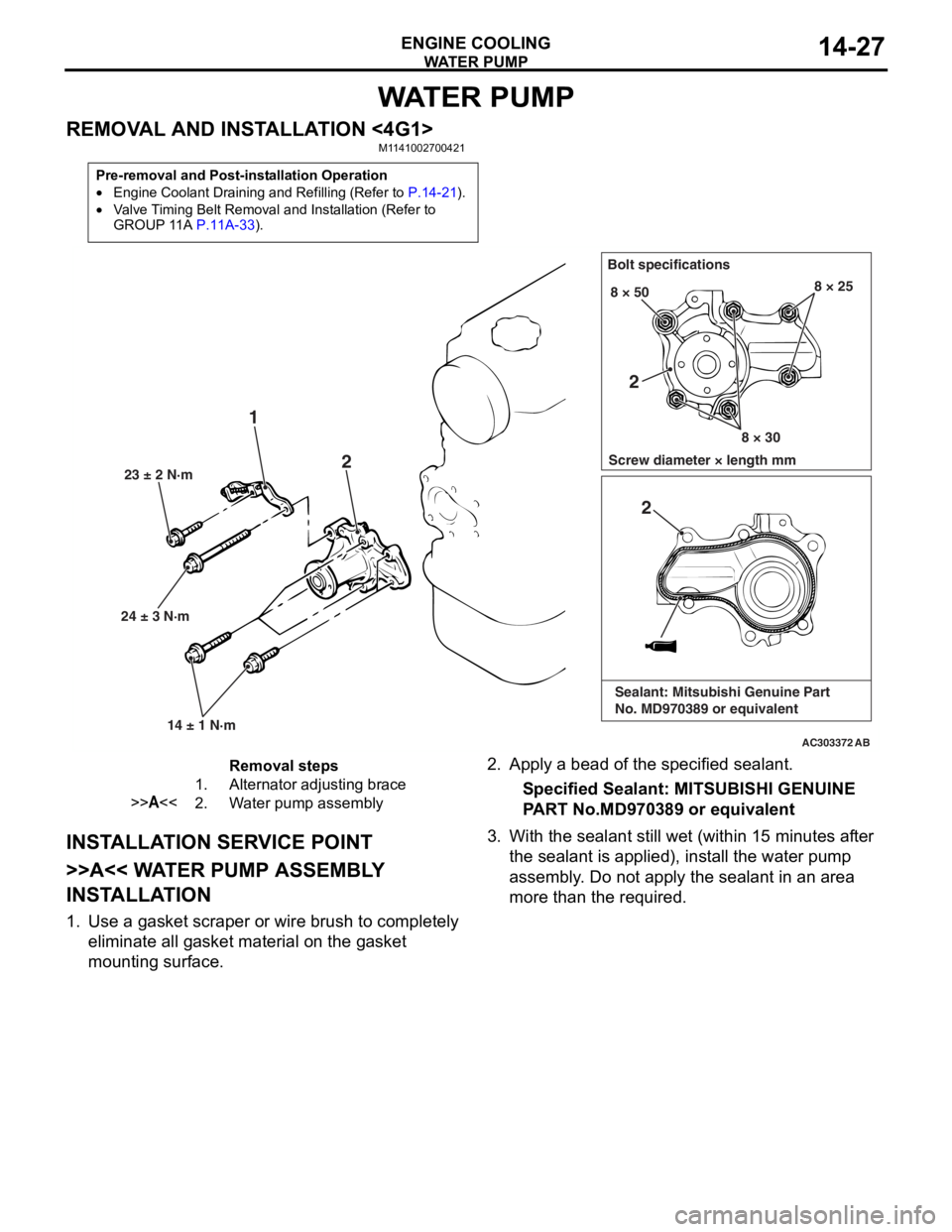

REMOVAL AND INSTALLATION <4G1>M1141002700421

Pre-removal and Post-installation Operation

•Engine Coolant Draining and Refilling (Refer to P.14-21).

•Valve Timing Belt Removal and Installation (Refer to

GROUP 11A P.11A-33).

AC303372

24 ± 3 N·m23 ± 2 N·m

14 ± 1 N·m

1 2

Bolt specifications

Screw diameter × length mm 8 × 50

8 × 308 × 25

AB

2

2

Sealant: Mitsubishi Genuine Part

No. MD970389 or equivalent

Removal steps

1.Alternator adjusting brace

>>A<<2.Water pump assembly

INST ALLA T ION SER VICE POINT

>>A<< WA TER PUMP ASSEMBL Y

INST

ALLA TION

1.Use a gaske t scraper o r wire brush to complet e ly

eliminate all gasket material o n the g a sket

mounting surface.

2. App l y a bead of the specified sealan t.

Specified Sealant: MITSUBISHI GENUINE

P

ART No.MD970 389 or eq uivalen t

3.With the sea l ant still wet (within 1 5 minutes af ter

th e se alant is applied), inst all the wa ter pump

a sse mbly . Do not a pply the sealant in an are a

more th an the required.

Page 42 of 800

WATE R P U M P

ENGINE COOLING14-28

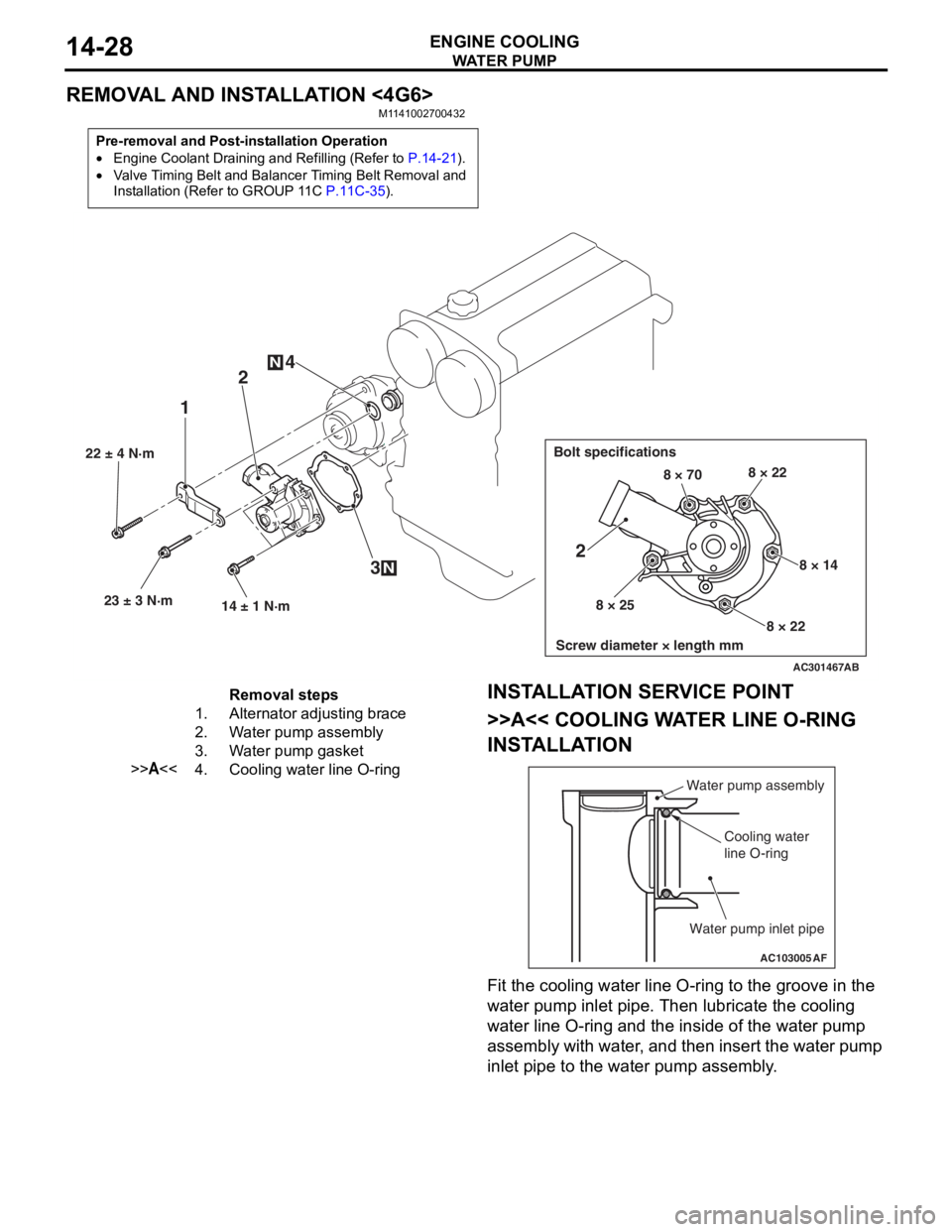

REMOVAL AND INSTALLATION <4G6>

M1141002700432

Pre-removal and Post-installation Operation

•Engine Coolant Draining and Refilling (Refer to P.14-21).

•Valve Timing Belt and Balancer Timing Belt Removal and

Installation (Refer to GROUP 11C

P.11C-35).

AC301467

22 ± 4 N·m23 ± 3 N·m 14 ± 1 N·m

12

3

4

N

N

Bolt specifications

Screw diameter × length mm

8 × 70 8 × 22

8 × 14

8 × 22

8 × 25

2

AB

Removal steps

1.Alternator adjusting brace

2.Water pump assembly

3.Water pump gasket

>>A<<4.Cooling water line O-ring

INST

ALLA T ION SER VICE POINT

>>A<< COOLING WA TER LINE O-RING

INST

ALLA TION

AC103005

Water pump assembly

Cooling water

line O-ring

Water pump inlet pipe

AF

Fit the coo ling water line O-ring to the groove in the

wa

ter pump in let p i pe. T hen lubricate th e co olin g

wa

ter line O-ring and the inside of the wat e r pump

assembly with wa

ter , and then insert the wa ter pu mp

inle

t pip e to the water pu mp asse mbly .

Page 55 of 800

INLET MANIFOLD

INTAKE AND EXHAUST15-5

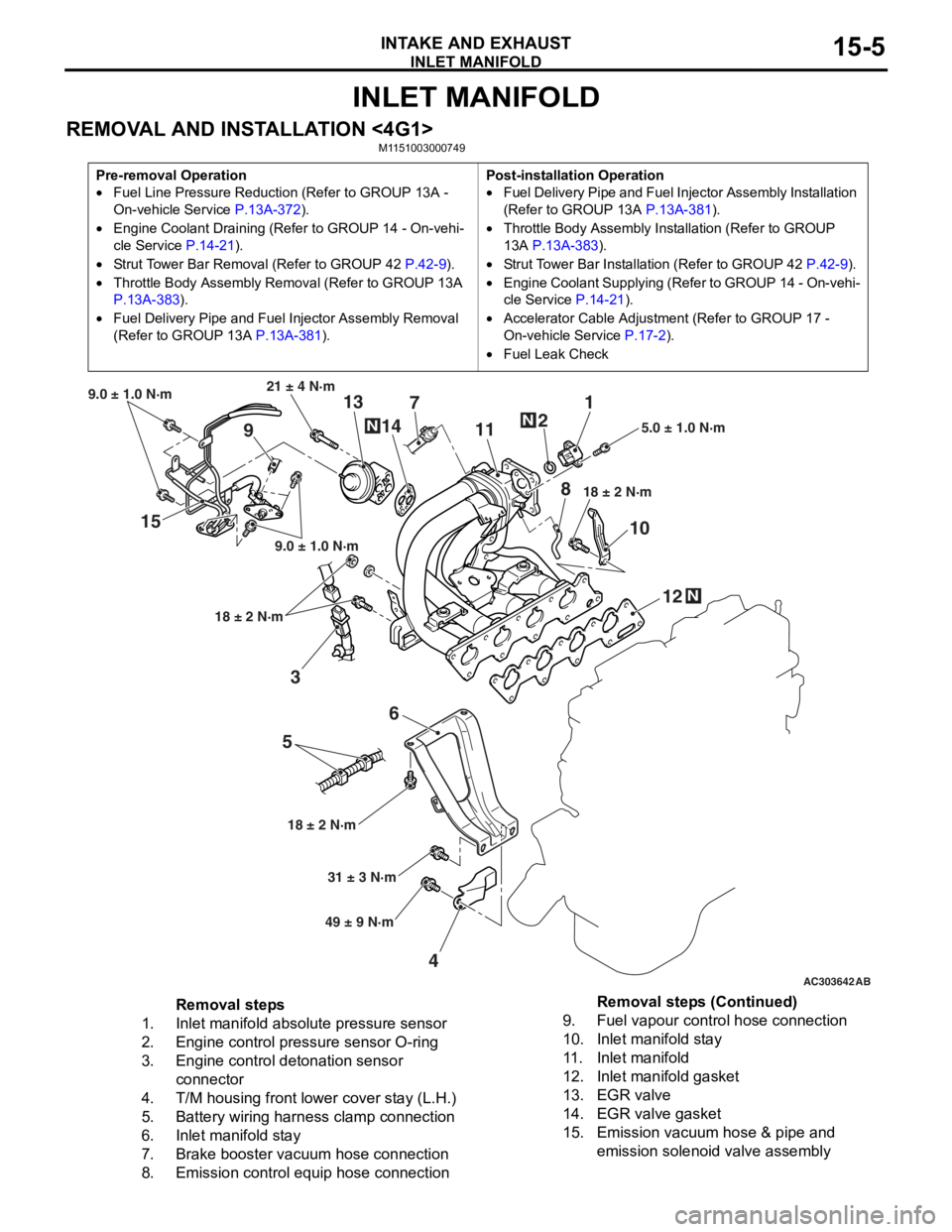

INLET MANIFOLD

REMOVAL AND INSTALLATION <4G1>M1151003000749

Pre-removal Operation

•Fuel Line Pressure Reduction (Refer to GROUP 13A -

On-vehicle Service

P.13A-372).

•Engine Coolant Draining (Refer to GROUP 14 - On-vehi-

cle Service P.14-21).

•Strut Tower Bar Removal (Refer to GROUP 42 P.42-9).

•Throttle Body Assembly Re moval (Refer to GROUP 13A

P.13A-383).

•Fuel Delivery Pipe and Fuel Injector Assembly Removal

(Refer to GROUP 13A

P.13A-381).

Post-installation Operation

•Fuel Delivery Pipe and Fuel Injector Assembly Installation

(Refer to GROUP 13A

P.13A-381).

•Throttle Body Assembly Inst allation (Refer to GROUP

13A

P.13A-383).

•Strut Tower Bar Installati on (Refer to GROUP 42 P.42-9).

•Engine Coolant Supplying (Refer to GROUP 14 - On-vehi-

cle Service P.14-21).

•Accelerator Cable Adjustment (Refer to GROUP 17 -

On-vehicle Service

P.17-2).

•Fuel Leak Check

AC303642AB

15

36

5

4 12

10

7

1

2

11

9 13

14

21 ± 4 N·m

9.0 ± 1.0 N·m

9.0 ± 1.0 N·m

18 ± 2 N·m

18 ± 2 N·m 18 ± 2 N·m

5.0 ± 1.0 N·m

31 ± 3 N·m

49 ± 9 N·m

N

N

N

8

Removal steps

1.Inlet manifold absolute pressure sensor

2.Engine control pressure sensor O-ring

3.Engine control detonation sensor

connector

4.T/M housing front lower cover stay (L.H.)

5.Battery wiring harness clamp connection

6.Inlet manifold stay

7.Brake booster vacuum hose connection

8.Emission control equip hose connection

9.Fuel vapour control hose connection

10.Inlet manifold stay

11 .Inlet manifold

12.Inlet manifold gasket

13.EGR valve

14.EGR valve gasket

15.Emission vacuum hose & pipe and

emission solenoid valve assembly

Removal steps (Continued)

Page 57 of 800

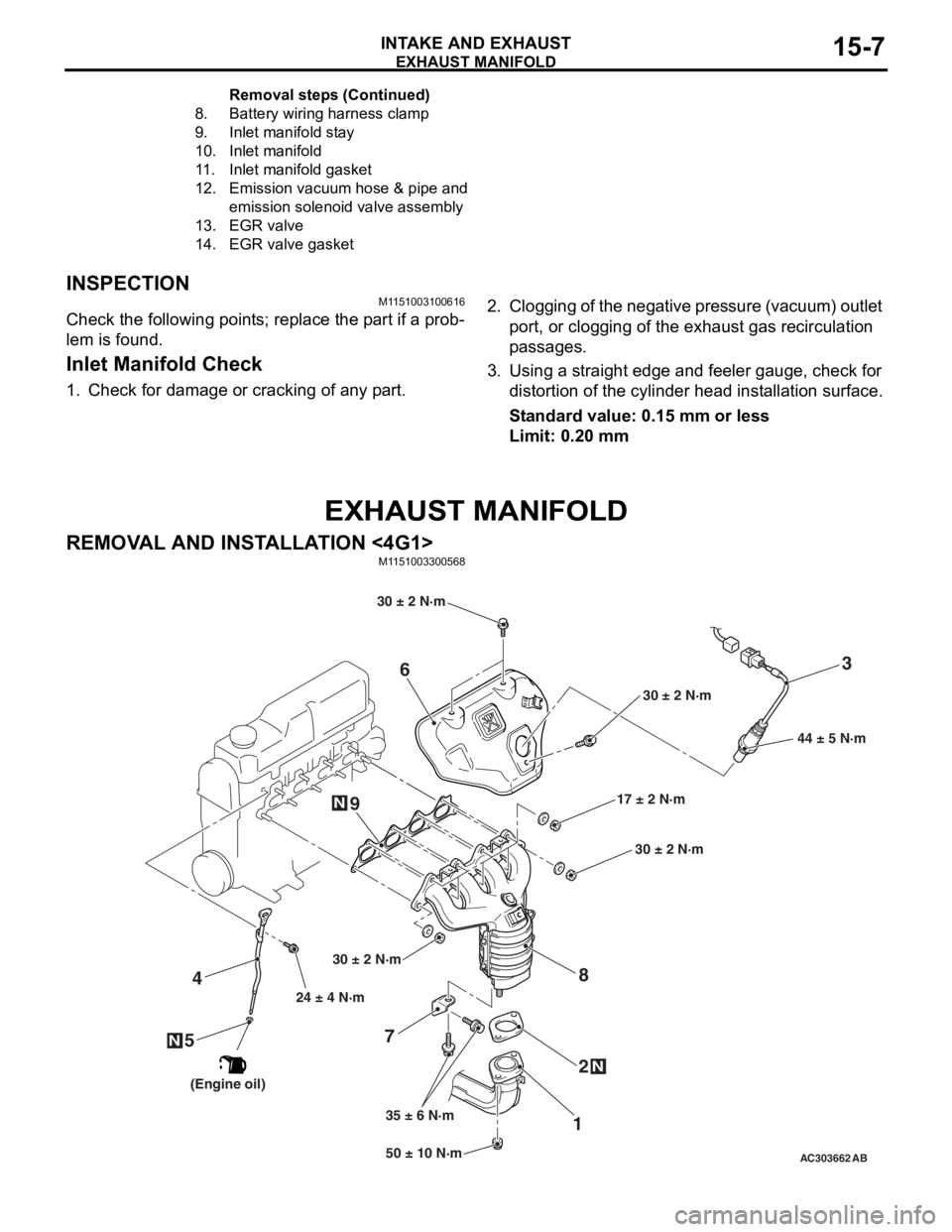

EXHAUST MANIFOLD

INTAKE AND EXHAUST15-7

INSPECTION

M1151003100616

Check the following points; replace the part if a prob-

lem is found.

Inlet Manifold Check

1. Check for damage or cracking of any part.

2. Clogging of the negative pressure (vacuum) outlet port, or clogging of the exhaust gas recirculation

passages.

3. Using a straight edge and feeler gauge, check for distortion of the cylinder head installation surface.

Standard value: 0.15 mm or less

Limit: 0.20 mm

EXHAUST MANIFOLD

REMOVAL AND INSTALLATION <4G1>

M1151003300568

AC30366250 ± 10 N·m

24 ± 4 N·m

35 ± 6 N·m 17 ± 2 N·m

30 ± 2 N·m

N

3

7 12

4

N

6

8

44 ± 5 N·m

AB

9

5N

30 ± 2 N·m

30 ± 2 N·m

30 ± 2 N·m

(Engine oil)

8.Battery wirin g ha rne s s clamp

9.Inlet manifold st ay

10.Inlet manifold

11.Inlet manifold gask et

12.Emission vacuu m hose & pipe and

emis

sion s o lenoid valve assembly

13.EGR v a lve

14.EGR v a lve gasket

Remo va l st ep s ( C o n t in u e d)

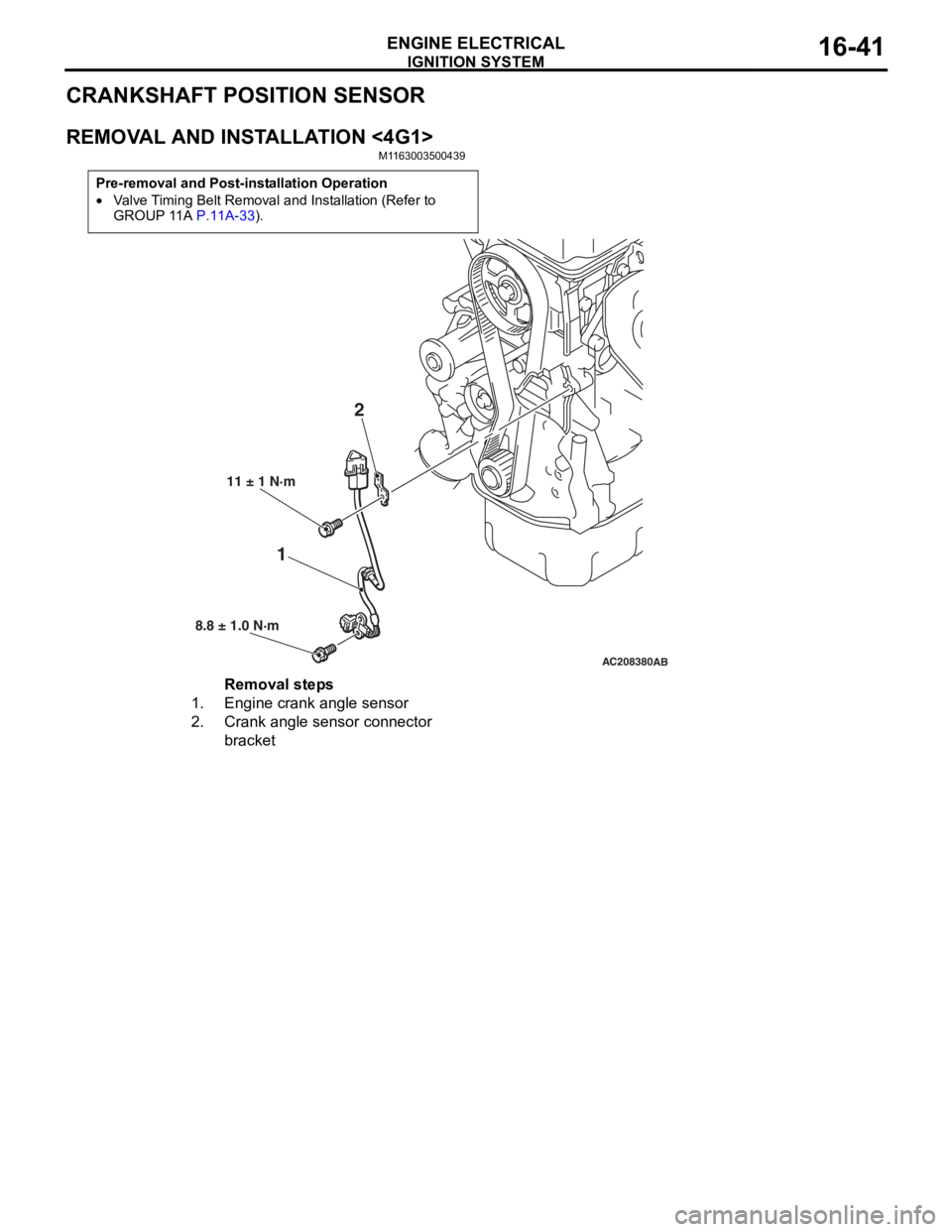

Page 103 of 800

IGNITION SYSTEM

ENGINE ELECTRICAL16-41

CRANKSHAFT POSITION SENSOR

REMOVAL AND INSTALLATION <4G1>

M1163003500439

Pre-removal and Post-installation Operation

•Valve Timing Belt Removal and Installation (Refer to

GROUP 11A P.11A-33).

AC208380AB

12

11 ± 1 N·m

8.8 ± 1.0 N·m

Removal steps

1.Engine crank angle sensor

2.Crank angle sensor connector

bracket