service MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 1 of 1449

00

11

12

13

14

15

16

17

21

22

25

26

27

31

32

33

34

35

36

37

42

51

52

54

55

General........................

Engine .........................

Engine Lubrication .............

Fuel ...........................

Engine Cooling .................

Intake and Exhaust ............

Engine Electrical ...............

Engine and Emission Control ....

Clutch .........................

Manual Transmission ...........

Propeller Shaft .................

Front Axle ......................

Rear Axle ......................

Wheel and Tyre .................

Power Plant Mount ..............

Front Suspension ...............

Rear Suspension ...............

Service Brakes .................

Parking Brakes .................

Steering ........................

Body ...........................

Exterior ........................

Chassis Electrical ..............

Electrical Wiring ................

Body Repair ....................

WORKSHOP

MANUAL

FOREWORD

This Workshop Manual contains procedures for

service mechanics, including removal, disassembly,

inspection, adjustment, reassembly and

installation. Use the following manuals in

combination with this manual as required.

TECHNICAL INFORMATION MANUAL N0104CT9A

All information, illustrations and product

descriptions contained in this manual are current

as at the time of publication. We, however, reserve

the right to make changes at any time without prior

notice or obligation.

The EVOLUTION-VII is sold exclusively through

RALLIART Inc. Since the EVOLUTION-VII is a

rally-based model, it will not be warranted and will

not be homologated for general production.

Therefore, any service matters on the

EVOLUTION-VII should be inquired to RALLIART

Inc. as usual.

EMitsubishi Motors Corporation May 2001

Interior and Supplemental

Restraint System (SRS) ........

Heater, Air Conditioner and

Ventilation .....................

Page 2 of 1449

WARNING REGARDING SERVICING OF SUPPLEMENTAL

RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLE

WARNING!

(1) Improper service or maintenance of any component of the SRS, or any SRS-related component,

can lead to personal injury or death to service personnel (from inadvertent firing of the air

bag) or to the driver and passenger (from rendering the SRS inoperative).

(2) The SRS components should not be subjected to temperature of 93_C or more. So, remove

the SRS-ECU, driver’s and front passenger’s air bag modules and clock spring before drying

or baking the vehicle after painting.

(3) Service or maintenance of any SRS component or SRS-related component must be performed

only at an authorized MITSUBISHI dealer.

(4) MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP

52B - Supplemental Restraint System (SRS), before beginning any service or maintenance

of any SRS component or any SRS-related component.

NOTE

Section titles with asterisks (*) in the table of contents in each group indicate operations requiring warnings.

Page 3 of 1449

A-1

BODY

CONSTRUCTION

CONTENTS

BODY COMPONENTS 2...................

BODY MAIN CROSS-SECTIONAL VIEWS 4.

MAINTENANCE, SERVICEABILITY 6........

BODY CONSTRUCTION

CHARACTERISTICS 8.....................

FRONT BODY 8...........................

SIDE BODY 13.............................

REAR BODY 15............................

ROOF 16...................................UNDER BODY 17...........................

DOOR 20..................................

SILENCER APPLICATION LOCATIONS 21..

LOCATIONS USING URETHANE FOAM

AND FOAM

MATERIAL 22.............................

STIFFENER AND DUMP SHEET

APPLICATION

LOCATIONS 24............................

Page 8 of 1449

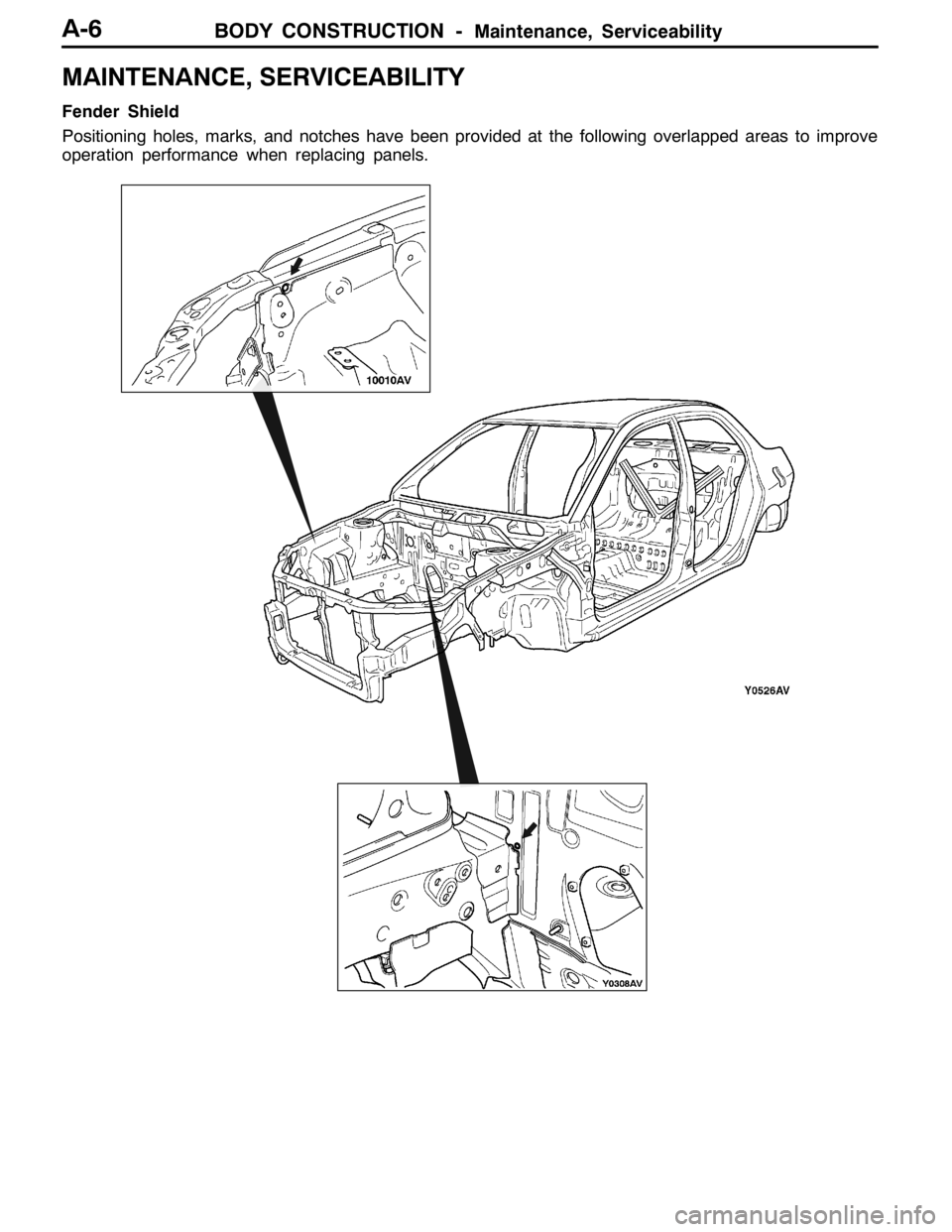

BODY CONSTRUCTION -Maintenance, ServiceabilityA-6

MAINTENANCE, SERVICEABILITY

Fender Shield

Positioning holes, marks, and notches have been provided at the following overlapped areas to improve

operation performance when replacing panels.

Page 9 of 1449

BODY CONSTRUCTION -Maintenance, ServiceabilityA-7

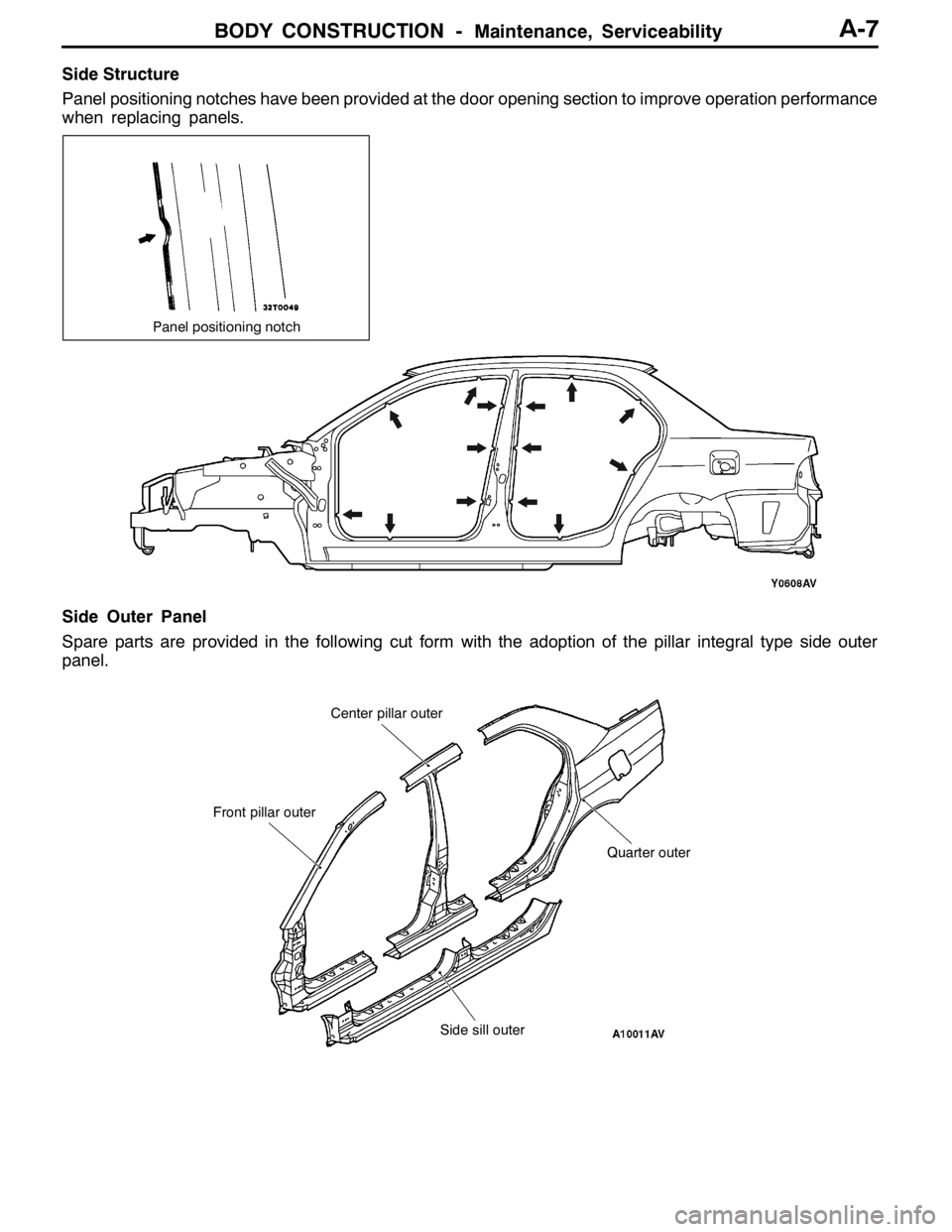

Side Structure

Panel positioning notches have been provided at the door opening section to improve operation performance

when replacing panels.

Panel positioning notch

Side Outer Panel

Spare parts are provided in the following cut form with the adoption of the pillar integral type side outer

panel.

Front pillar outerCenter pillar outer

Quarter outer

Side sill outer

Page 52 of 1449

WELDED PANEL REPLACEMENT -Front PillarC-8

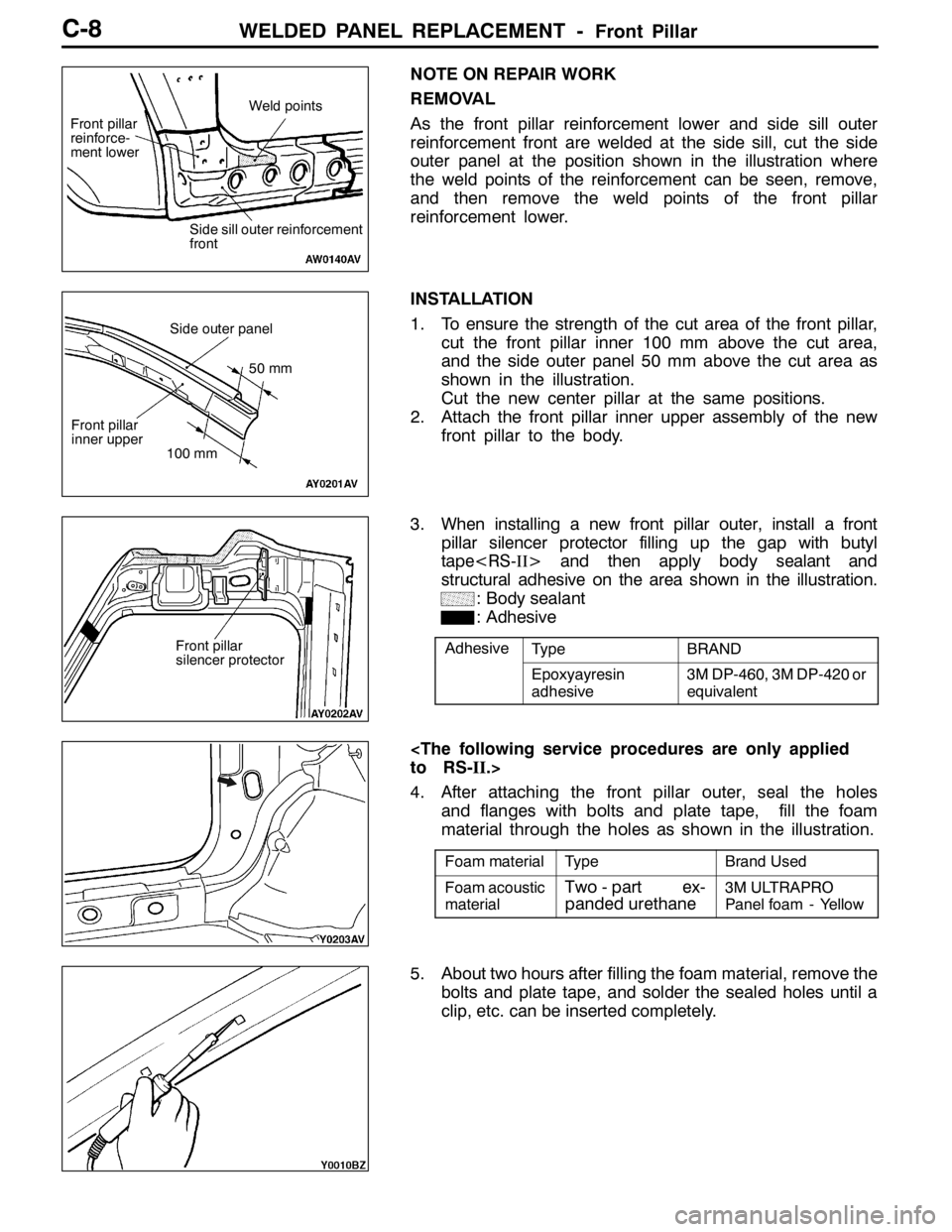

NOTE ON REPAIR WORK

REMOVAL

As the front pillar reinforcement lower and side sill outer

reinforcement front are welded at the side sill, cut the side

outer panel at the position shown in the illustration where

the weld points of the reinforcement can be seen, remove,

and then remove the weld points of the front pillar

reinforcement lower.

INSTALLATION

1. To ensure the strength of the cut area of the front pillar,

cut the front pillar inner 100 mm above the cut area,

and the side outer panel 50 mm above the cut area as

shown in the illustration.

Cut the new center pillar at the same positions.

2. Attach the front pillar inner upper assembly of the new

front pillar to the body.

3.When installing a new front pillar outer, install a front

pillar silencer protector filling up the gap with butyl

tape

structural adhesive on the area shown in the illustration.

: Body sealant

: Adhesive

AdhesiveTypeBRAND

Epoxyayresin

adhesive3M DP-460, 3M DP-420 or

equivalent

4.After attaching the front pillar outer, seal the holes

and flanges with bolts and plate tape, fill the foam

material through the holes as shown in the illustration.

Foam materialTypeBrand Used

Foam acoustic

materialTwo - part ex-

panded urethane3M ULTRAPRO

Panel foam - Yellow

5. About two hours after filling the foam material, remove the

bolts and plate tape, and solder the sealed holes until a

clip, etc. can be inserted completely.

Weld points

Side sill outer reinforcement

front Front pillar

reinforce-

ment lower

50 mm

100 mm

Side outer panel

Front pillar

inner upper

Front pillar

silencer protector

Page 55 of 1449

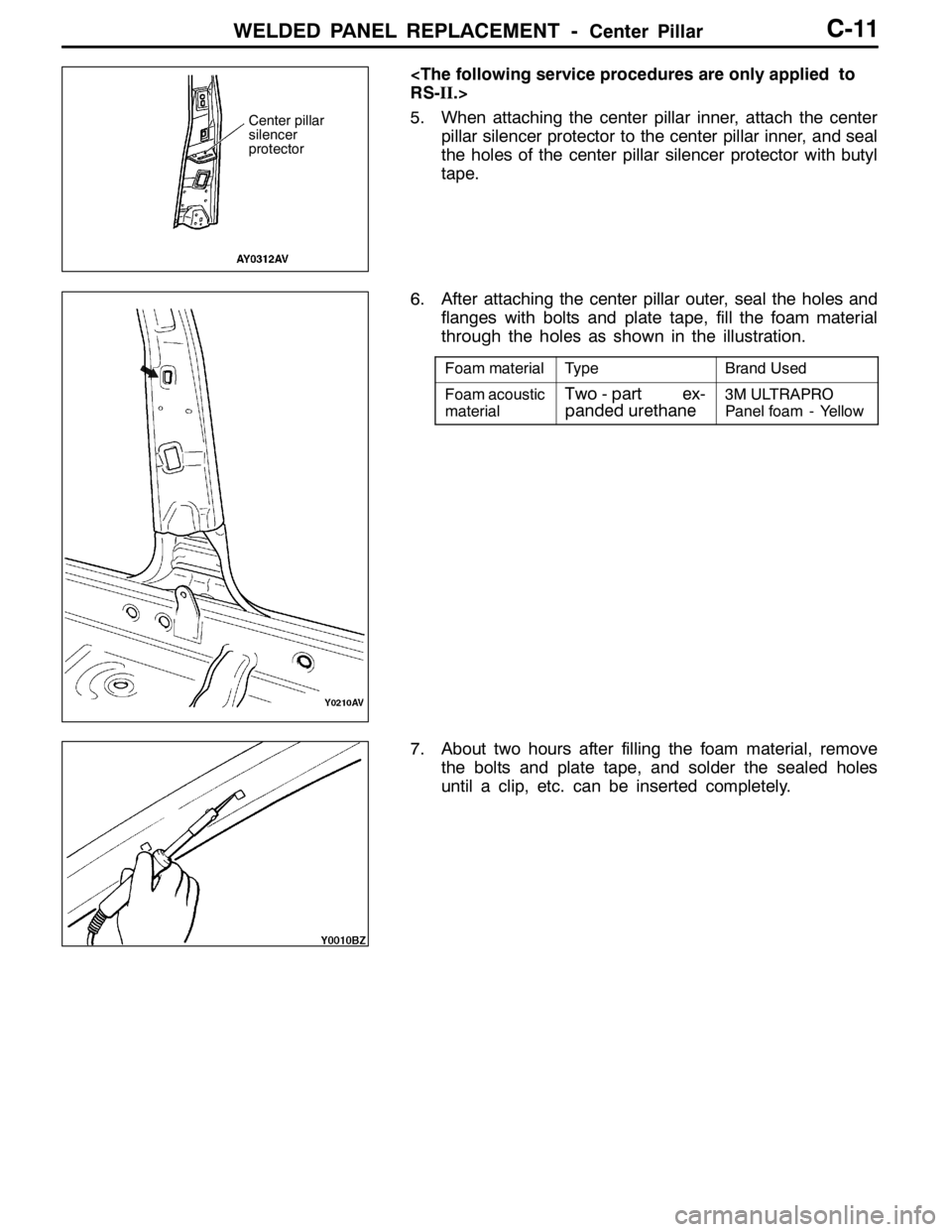

WELDED PANEL REPLACEMENT -Center PillarC-11

5. When attaching the center pillar inner, attach the center

pillar silencer protector to the center pillar inner, and seal

the holes of the center pillar silencer protector with butyl

tape.

6. After attaching the center pillar outer, seal the holes and

flanges with bolts and plate tape,fill the foam material

through the holes as shown in the illustration.

Foam materialTypeBrand Used

Foam acoustic

materialTwo - part ex-

panded urethane3M ULTRAPRO

Panel foam - Yellow

7. About two hours after filling the foam material, remove

the bolts and plate tape, and solder the sealed holes

until a clip, etc. can be inserted completely.

Center pillar

silencer

protector

Page 60 of 1449

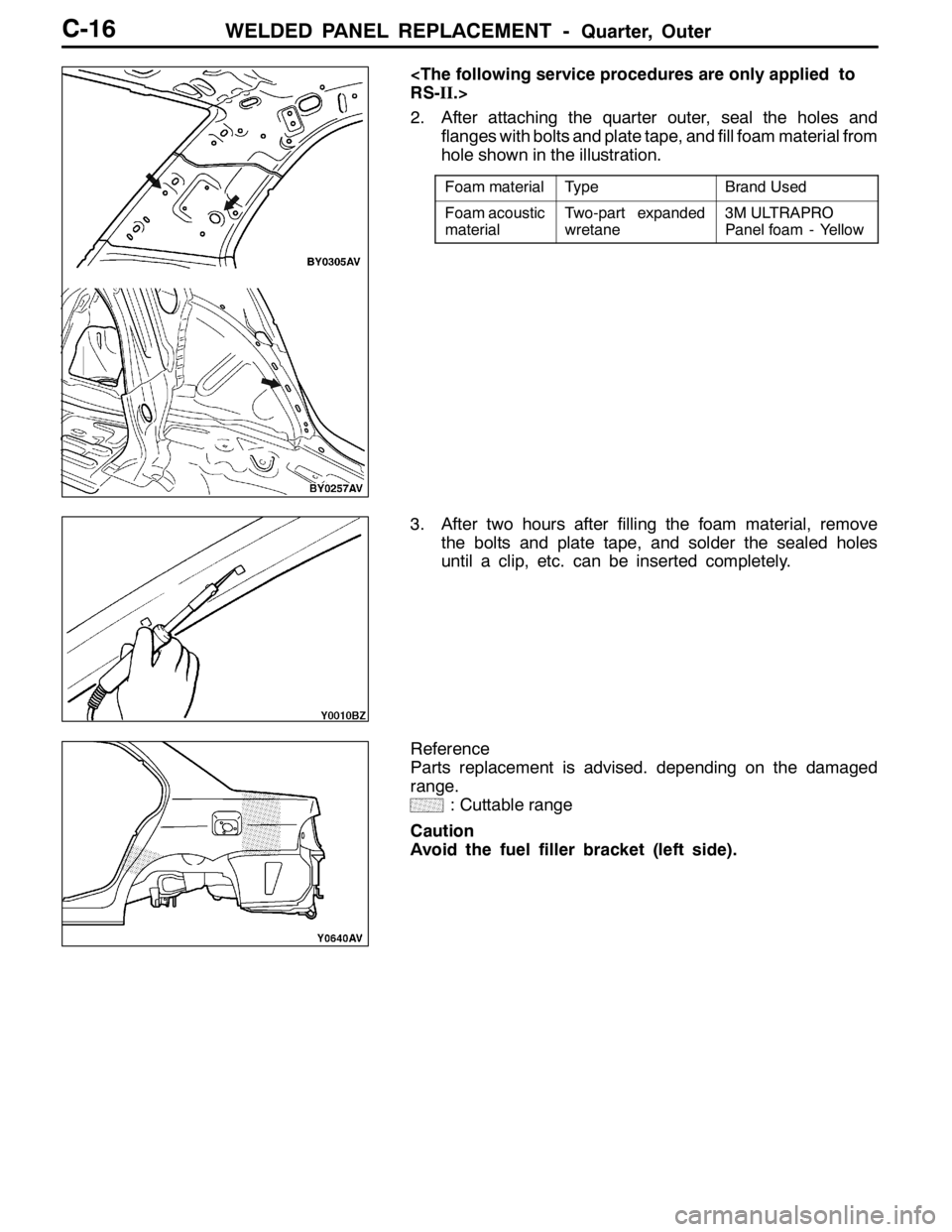

WELDED PANEL REPLACEMENT -Quarter, OuterC-16

2. After attaching the quarter outer, seal the holes and

flanges with bolts and plate tape, and fill foam material from

hole shown in the illustration.

Foam materialTypeBrand Used

Foam acoustic

materialTwo-part expanded

wretane3M ULTRAPRO

Panel foam - Yellow

3. After two hours after filling the foam material, remove

the bolts and plate tape, and solder the sealed holes

until a clip, etc. can be inserted completely.

Reference

Parts replacement is advised. depending on the damaged

range.

: Cuttable range

Caution

Avoid the fuel filler bracket (left side).

Page 379 of 1449

00-1

GENERAL

CONTENTS

HOW TO USE THIS MANUAL 2..............

Scope of Maintenance, Repair and Servicing

Explanations 2.................................

Indication of Destination 2......................

Definition of Terms 2...........................

Indication of Tightening Torque 2................

Model Indications 3............................

Explanation of Manual Contents 4...............

HOW TO USE

TROUBLESHOOTING/INSPECTION SERVICE

POINTS 6....................................

Troubleshooting Contents 6.....................

Diagnosis Function 7...........................

How to Use the Inspection Procedures 10........

Connector Measurement Service Points 11.......

Connector Inspection 12........................

Inspection Service Points for a Blown Fuse 13...

Points to Note for Intermittent Malfunctions 13....

VEHICLE IDENTIFICATION 14.................

Vehicle Information Code Plate 14...............Models 14.....................................

Model Code 15................................

Chassis Number 16............................

Engine Model Number 16.......................

MAJOR SPECIFICATIONS 17.................

PRECAUTIONS BEFORE SERVICE 18.........

SUPPLEMENTAL RESTRAINT SYSTEM

(SRS) 21...................................

SRS SERVICE PRECAUTIONS 22.............

SUPPORT LOCATIONS FOR LIFTING AND

JACKING 24.................................

Support Positions for a Garage Jack and Axle

Stands 24.....................................

Support Positions for a Single-Post Lift or

Double-Post Lift 25.............................

Support Positions and Support Method for an

H-Bar Lift 26..................................

STANDARD PART/TIGHTENING-TORQUE

TABLE 28....................................

Page 380 of 1449

GENERAL -How to Use This Manual00-2

HOW TO USE THIS MANUAL

SCOPE OF MAINTENANCE, REPAIR

AND SERVICING EXPLANATIONS

This manual provides explanations, etc. concerning

procedures for the inspection, maintenance, repair

and servicing of the subject model. Note, however,

that for engine and transmission-related component

parts, this manual covers only on-vehicle

inspections, adjustments, and the removal and

installation procedures for major components.

For detailed information concerning the inspection,

checking, adjustment, disassembly and reassembly

of the engine, transmission and major components

after they have been removed from the vehicle,

please refer to separate manuals covering the

engine and the transmission.

ON-VEHICLE SERVICE

“On-vehicle Service” is procedures for performing

inspections and adjustments of particularly

important locations with regard to the construction

and for maintenance and servicing, but other

inspection (for looseness, play, cracking, damage,

etc.) must also be performed.

INSPECTION

Under this title are presented inspection and

checking procedures to be performed by using

special tools and measuring instruments and by

feeling, but, for actual maintenance and servicing

procedures, visual inspections should always be

performed as well.

INDICATION OF DESTINATION

General Export and GCC are used for convenience

to indicate destination.

NOTE

(1) “General Export” means territories other than

Europe, GCC, Australia, New Zealand, the

U.S.A. and Canada.

(2) “GCC” indicates countries that are members

of the (Persian) Gulf Cooperation Council of

nations.

(3) In some instances, vehicles with other

specifications may be shipped to some

countries.

DEFINITION OF TERMS

STANDARD VALUE

Indicates the value used as the standard for judging

the quality of a part or assembly on inspection

or the value to which the part or assembly is

corrected and adjusted. It is given by tolerance.

LIMIT

Shows the standard for judging the quality of a

part or assembly on inspection and means the

maximum or minimum value within which the part

or assembly must be kept functionally or in strength.

It is a value established outside the range of

standard value.

REFERENCE VALUE

Indicates the adjustment value prior to starting the

work (presented in order to facilitate assembly and

adjustment procedures, and so they can be

completed in a shorter time).

CAUTION

Indicates the presentation of information particularly

vital to the worker during the performance of

maintenance and servicing procedures in order to

avoid the possibility of injury to the worker, or

damage to component parts, or a reduction of

component or vehicle function or performance, etc.

INDICATION OF TIGHTENING TORQUE

Tightening torques (units: N·m) are set to take into

account the central value and the allowable

tolerance. The central value is the target value,

and the allowable tolerance provides the checking

range for tightening torques. If bolts and nuts are

not provided with tightening torques, refer to

P.00-28.