wheel MITSUBISHI LANCER EVOLUTION 2007 Service Owners Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 969 of 1449

REAR AXLE -On-vehicle Service27B-23

3. If the limit value is exceeded, loosen the flange nut and

then tighten it to the specified torque 225±25 N·m and

check the rear hub rotary sliding resistance again.

4. Replace the rear hub assembly if an adjustment cannot

be made to within the limit.

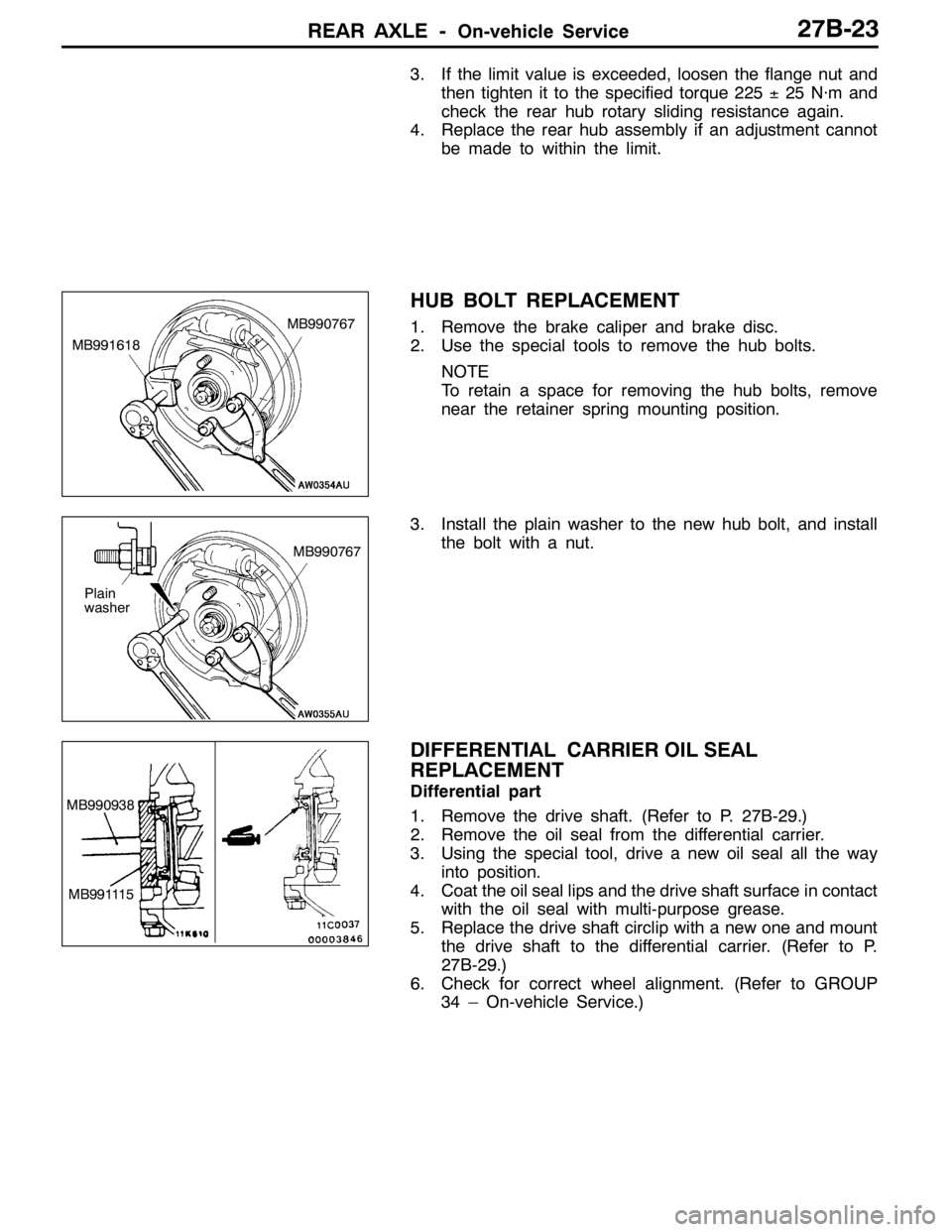

HUB BOLT REPLACEMENT

1. Remove the brake caliper and brake disc.

2. Use the special tools to remove the hub bolts.

NOTE

To retain a space for removing the hub bolts, remove

near the retainer spring mounting position.

3. Install the plain washer to the new hub bolt, and install

the bolt with a nut.

DIFFERENTIAL CARRIER OIL SEAL

REPLACEMENT

Differential part

1. Remove the drive shaft. (Refer to P. 27B-29.)

2. Remove the oil seal from the differential carrier.

3. Using the special tool, drive a new oil seal all the way

into position.

4. Coat the oil seal lips and the drive shaft surface in contact

with the oil seal with multi-purpose grease.

5. Replace the drive shaft circlip with a new one and mount

the drive shaft to the differential carrier. (Refer to P.

27B-29.)

6. Check for correct wheel alignment. (Refer to GROUP

34 – On-vehicle Service.)

MB991618MB990767

Plain

washerMB990767

MB990938

MB991115

Page 970 of 1449

REAR AXLE -On-vehicle Service27B-24

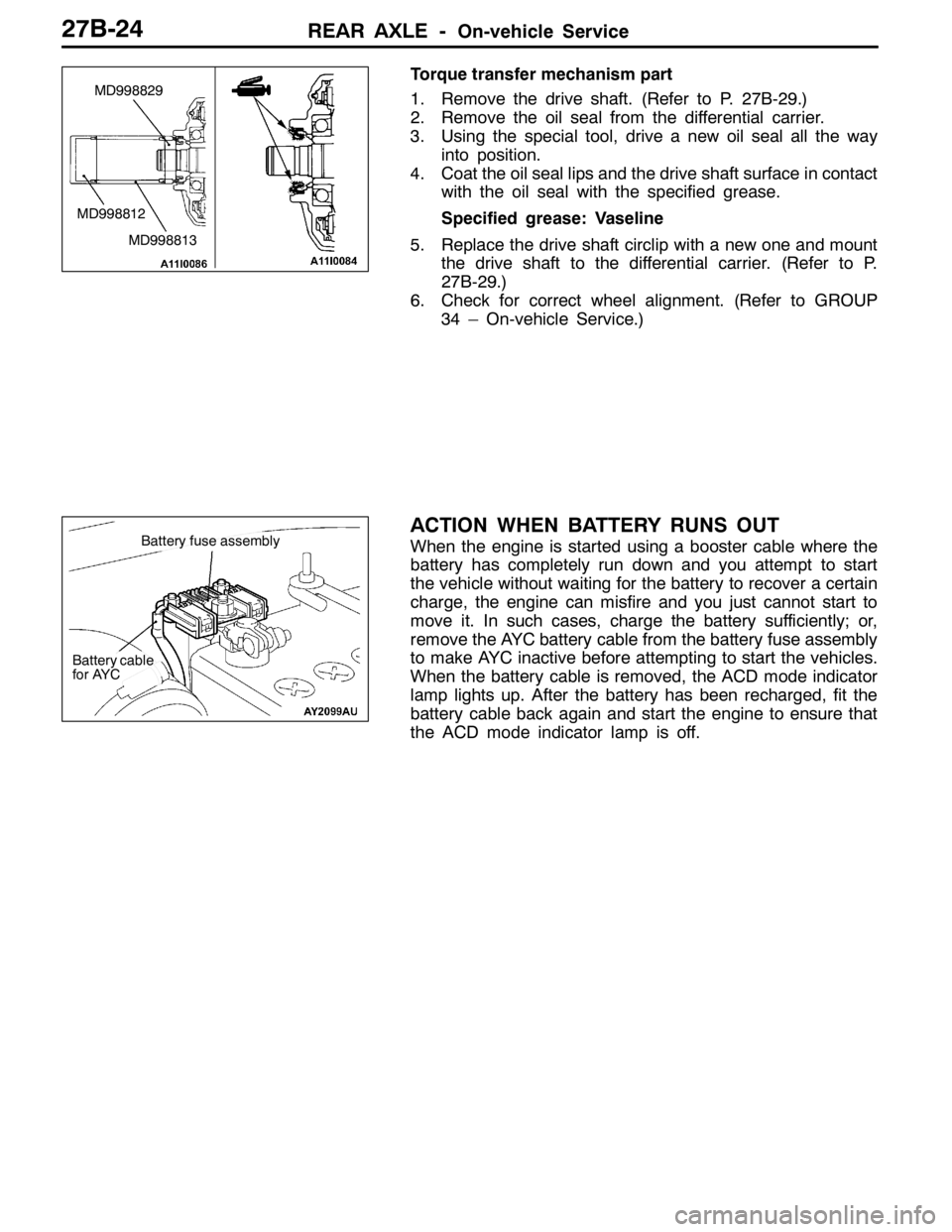

Torque transfer mechanism part

1. Remove the drive shaft. (Refer to P. 27B-29.)

2. Remove the oil seal from the differential carrier.

3. Using the special tool, drive a new oil seal all the way

into position.

4. Coat the oil seal lips and the drive shaft surface in contact

with the oil seal with the specified grease.

Specified grease: Vaseline

5. Replace the drive shaft circlip with a new one and mount

the drive shaft to the differential carrier. (Refer to P.

27B-29.)

6. Check for correct wheel alignment. (Refer to GROUP

34 – On-vehicle Service.)

ACTION WHEN BATTERY RUNS OUT

When the engine is started using a booster cable where the

battery has completely run down and you attempt to start

the vehicle without waiting for the battery to recover a certain

charge, the engine can misfire and you just cannot start to

move it. In such cases, charge the battery sufficiently; or,

remove the AYC battery cable from the battery fuse assembly

to make AYC inactive before attempting to start the vehicles.

When the battery cable is removed, the ACD mode indicator

lamp lights up. After the battery has been recharged, fit the

battery cable back again and start the engine to ensure that

the ACD mode indicator lamp is off.

MD998829

MD998813 MD998812

Battery fuse assembly

Battery cable

for AYC

Page 972 of 1449

REAR AXLE -Rear Hub Assembly27B-26

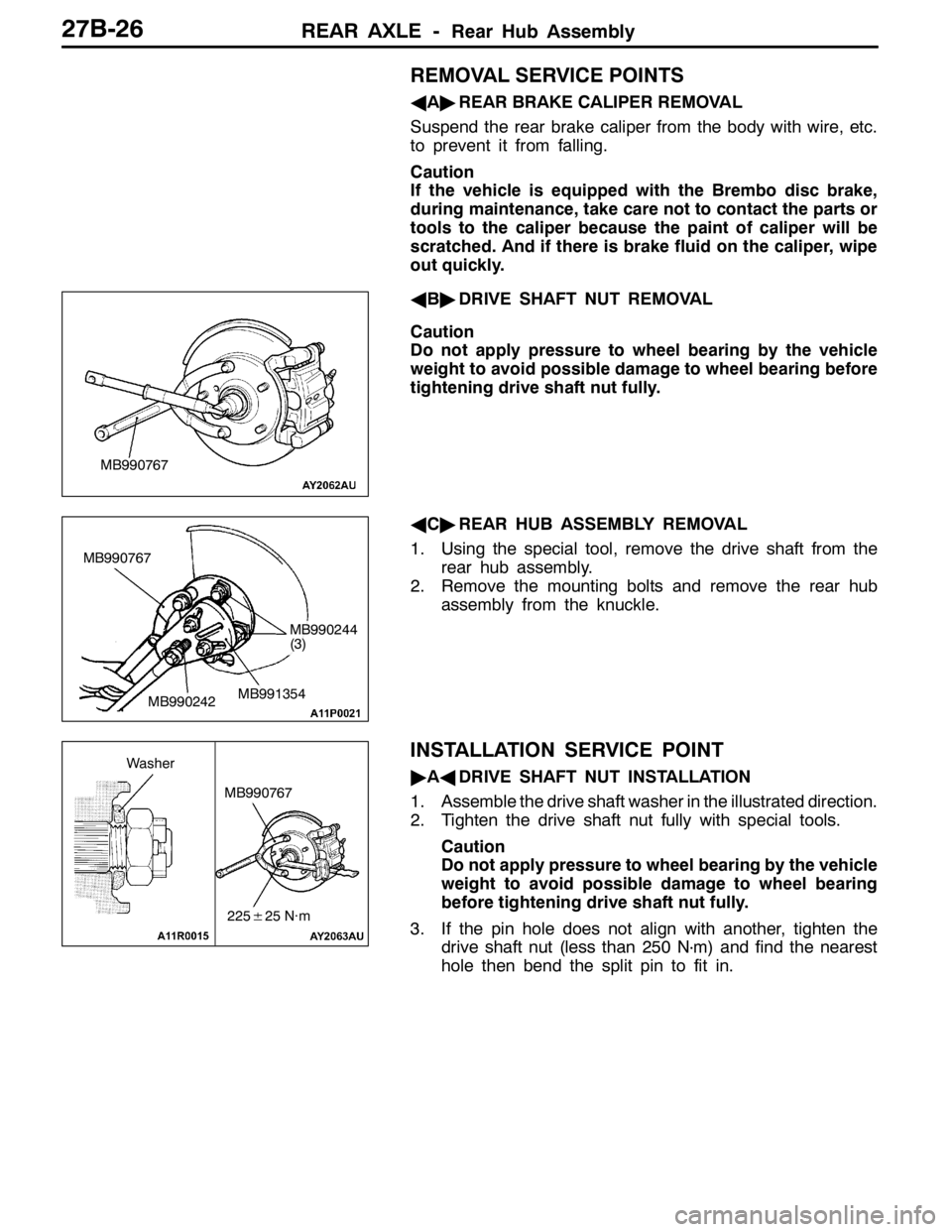

REMOVAL SERVICE POINTS

AA"REAR BRAKE CALIPER REMOVAL

Suspend the rear brake caliper from the body with wire, etc.

to prevent it from falling.

Caution

If the vehicle is equipped with the Brembo disc brake,

during maintenance, take care not to contact the parts or

tools to the caliper because the paint of caliper will be

scratched. And if there is brake fluid on the caliper, wipe

out quickly.

AB"DRIVE SHAFT NUT REMOVAL

Caution

Do not apply pressure to wheel bearing by the vehicle

weight to avoid possible damage to wheel bearing before

tightening drive shaft nut fully.

AC"REAR HUB ASSEMBLY REMOVAL

1. Using the special tool, remove the drive shaft from the

rear hub assembly.

2. Remove the mounting bolts and remove the rear hub

assembly from the knuckle.

INSTALLATION SERVICE POINT

"AADRIVE SHAFT NUT INSTALLATION

1. Assemble the drive shaft washer in the illustrated direction.

2. Tighten the drive shaft nut fully with special tools.

Caution

Do not apply pressure to wheel bearing by the vehicle

weight to avoid possible damage to wheel bearing

before tightening drive shaft nut fully.

3. If the pin hole does not align with another, tighten the

drive shaft nut (less than 250 N

·m) and find the nearest

hole then bend the split pin to fit in.

MB990767

MB990767

MB990242MB991354

MB990244

(3)

MB990767

225±25 N·m

Washer

Page 973 of 1449

REAR AXLE -Rear Hub Assembly27B-27

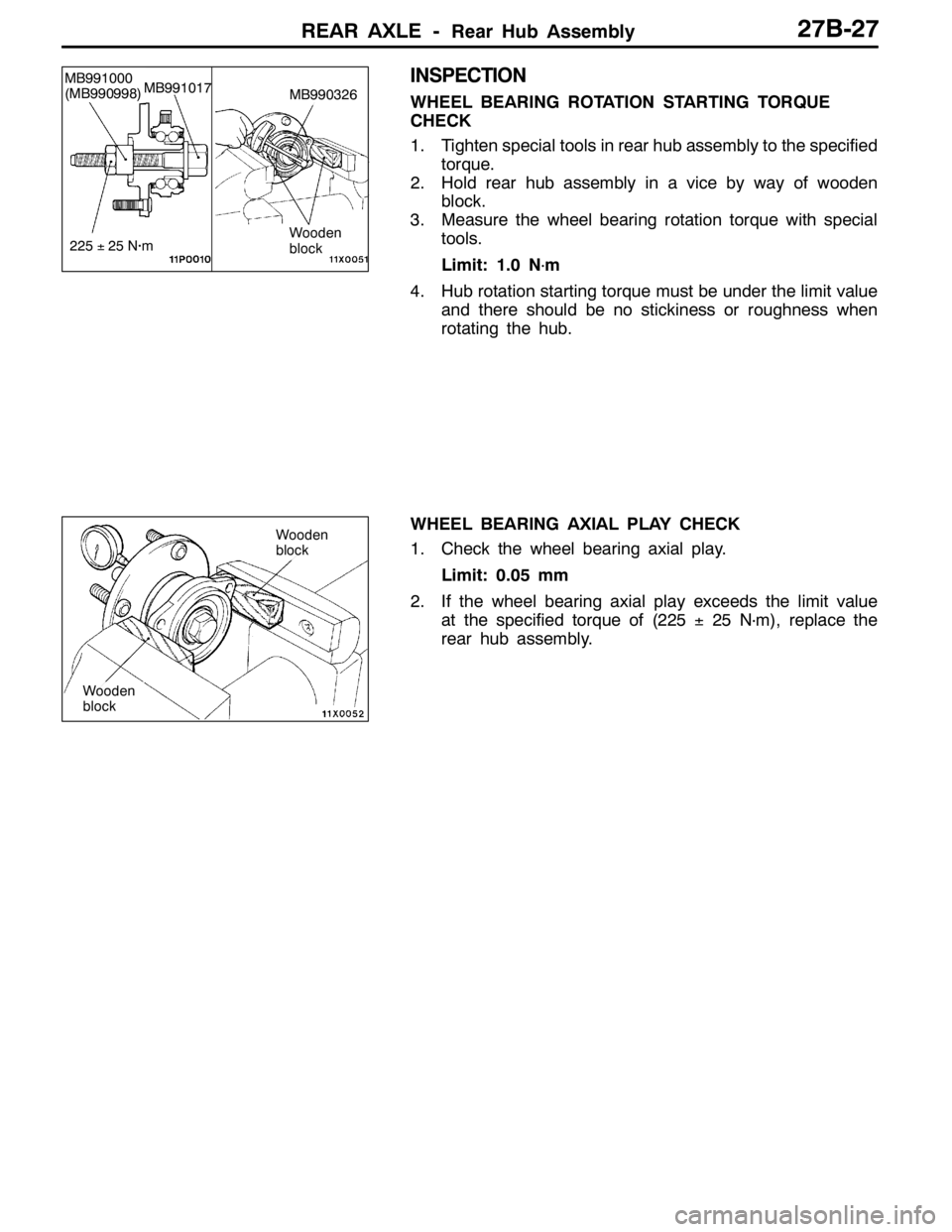

INSPECTION

WHEEL BEARING ROTATION STARTING TORQUE

CHECK

1. Tighten special tools in rear hub assembly to the specified

torque.

2. Hold rear hub assembly in a vice by way of wooden

block.

3. Measure the wheel bearing rotation torque with special

tools.

Limit: 1.0 N

·m

4. Hub rotation starting torque must be under the limit value

and there should be no stickiness or roughness when

rotating the hub.

WHEEL BEARING AXIAL PLAY CHECK

1. Check the wheel bearing axial play.

Limit: 0.05 mm

2. If the wheel bearing axial play exceeds the limit value

at the specified torque of (225±25 N

·m), replace the

rear hub assembly.

Wooden

block

MB991000

(MB990998)MB991017

225±25 N·m

MB990326

Wooden

block

Wooden

block

Page 975 of 1449

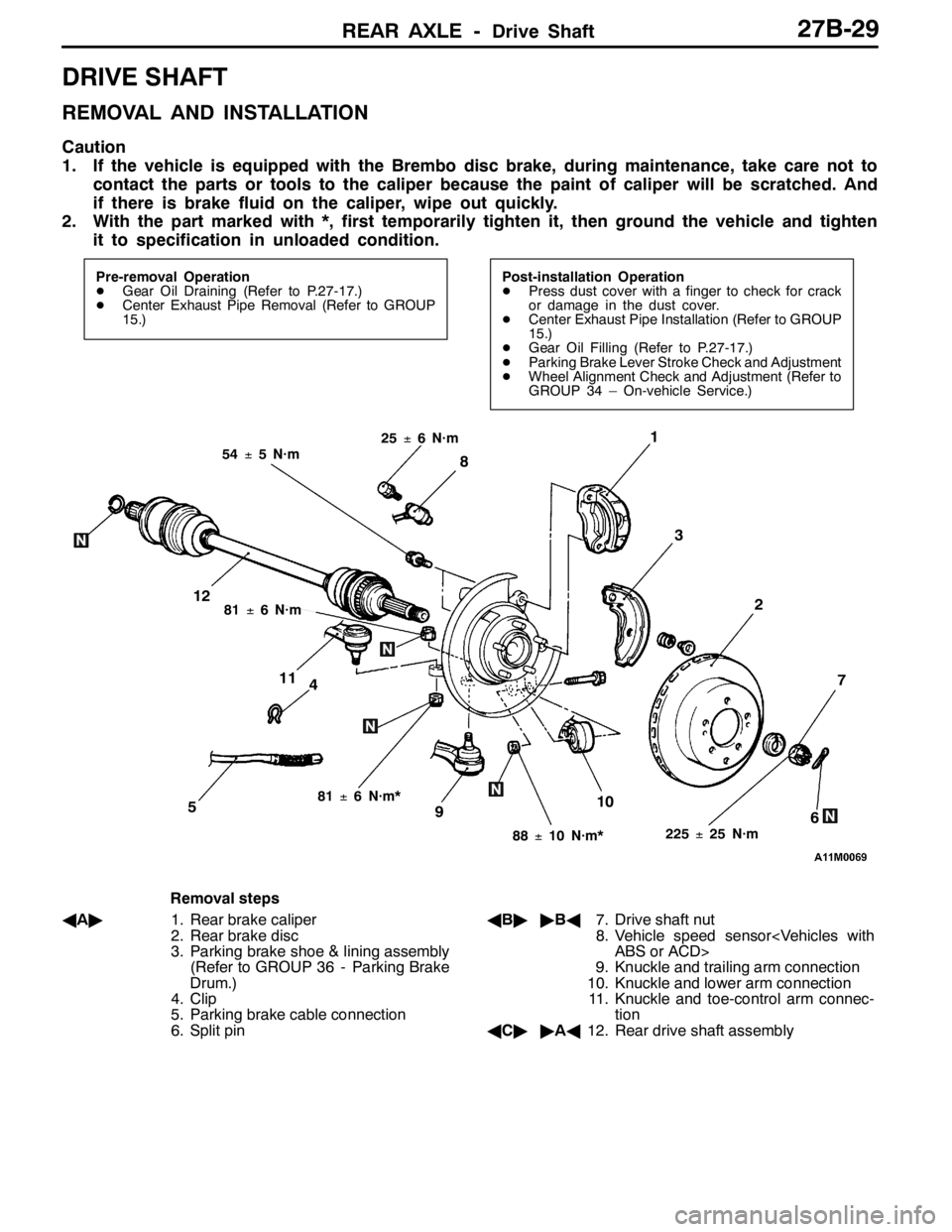

REAR AXLE -Drive Shaft27B-29

DRIVE SHAFT

REMOVAL AND INSTALLATION

Caution

1. If the vehicle is equipped with the Brembo disc brake, during maintenance, take care not to

contact the parts or tools to the caliper because the paint of caliper will be scratched. And

if there is brake fluid on the caliper, wipe out quickly.

2. With the part marked with *, first temporarily tighten it, then ground the vehicle and tighten

it to specification in unloaded condition.

Pre-removal Operation

DGear Oil Draining (Refer to P.27-17.)

DCenter Exhaust Pipe Removal (Refer to GROUP

15.)Post-installation Operation

DPress dust cover with a finger to check for crack

or damage in the dust cover.

DCenter Exhaust Pipe Installation (Refer to GROUP

15.)

DGear Oil Filling (Refer to P.27-17.)

DParking Brake Lever Stroke Check and Adjustment

DWheel Alignment Check and Adjustment (Refer to

GROUP 34 – On-vehicle Service.)

4

1

3

7

6510

2

8

9

11

12

225±25 N·m

54±5 N·m

88±10 N·m*

81±6 N·m*

81±6 N·m

25±6 N·m

Removal steps

AA"1. Rear brake caliper

2. Rear brake disc

3. Parking brake shoe & lining assembly

(Refer to GROUP 36 - Parking Brake

Drum.)

4. Clip

5. Parking brake cable connection

6. Split pinAB""BA7. Drive shaft nut

8. Vehicle speed sensor

9. Knuckle and trailing arm connection

10. Knuckle and lower arm connection

11. Knuckle and toe-control arm connec-

tion

AC""AA12. Rear drive shaft assembly

Page 976 of 1449

REAR AXLE -Drive Shaft27B-30

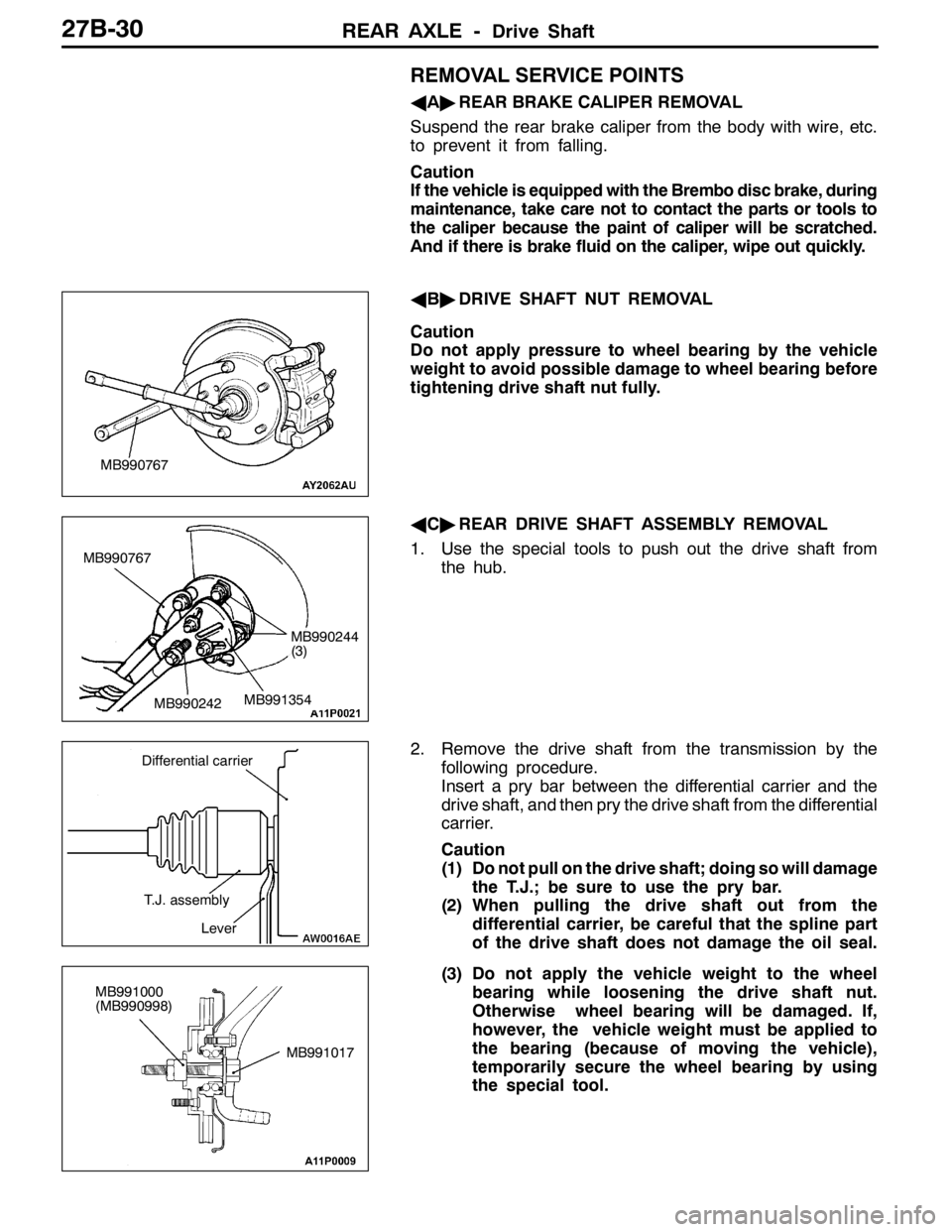

REMOVAL SERVICE POINTS

AA"REAR BRAKE CALIPER REMOVAL

Suspend the rear brake caliper from the body with wire, etc.

to prevent it from falling.

Caution

If the vehicle is equipped with the Brembo disc brake, during

maintenance, take care not to contact the parts or tools to

the caliper because the paint of caliper will be scratched.

And if there is brake fluid on the caliper, wipe out quickly.

AB"DRIVE SHAFT NUT REMOVAL

Caution

Do not apply pressure to wheel bearing by the vehicle

weight to avoid possible damage to wheel bearing before

tightening drive shaft nut fully.

AC"REAR DRIVE SHAFT ASSEMBLY REMOVAL

1. Use the special tools to push out the drive shaft from

the hub.

2. Remove the drive shaft from the transmission by the

following procedure.

Insert a pry bar between the differential carrier and the

drive shaft, and then pry the drive shaft from the differential

carrier.

Caution

(1) Do not pull on the drive shaft; doing so will damage

the T.J.; be sure to use the pry bar.

(2) When pulling the drive shaft out from the

differential carrier, be careful that the spline part

of the drive shaft does not damage the oil seal.

(3) Do not apply the vehicle weight to the wheel

bearing while loosening the drive shaft nut.

Otherwise wheel bearing will be damaged. If,

however, the vehicle weight must be applied to

the bearing (because of moving the vehicle),

temporarily secure the wheel bearing by using

the special tool.

MB990767

MB990767

MB990242MB991354

MB990244

(3)

Differential carrier

T.J. assembly

Lever

MB991017 MB991000

(MB990998)

Page 977 of 1449

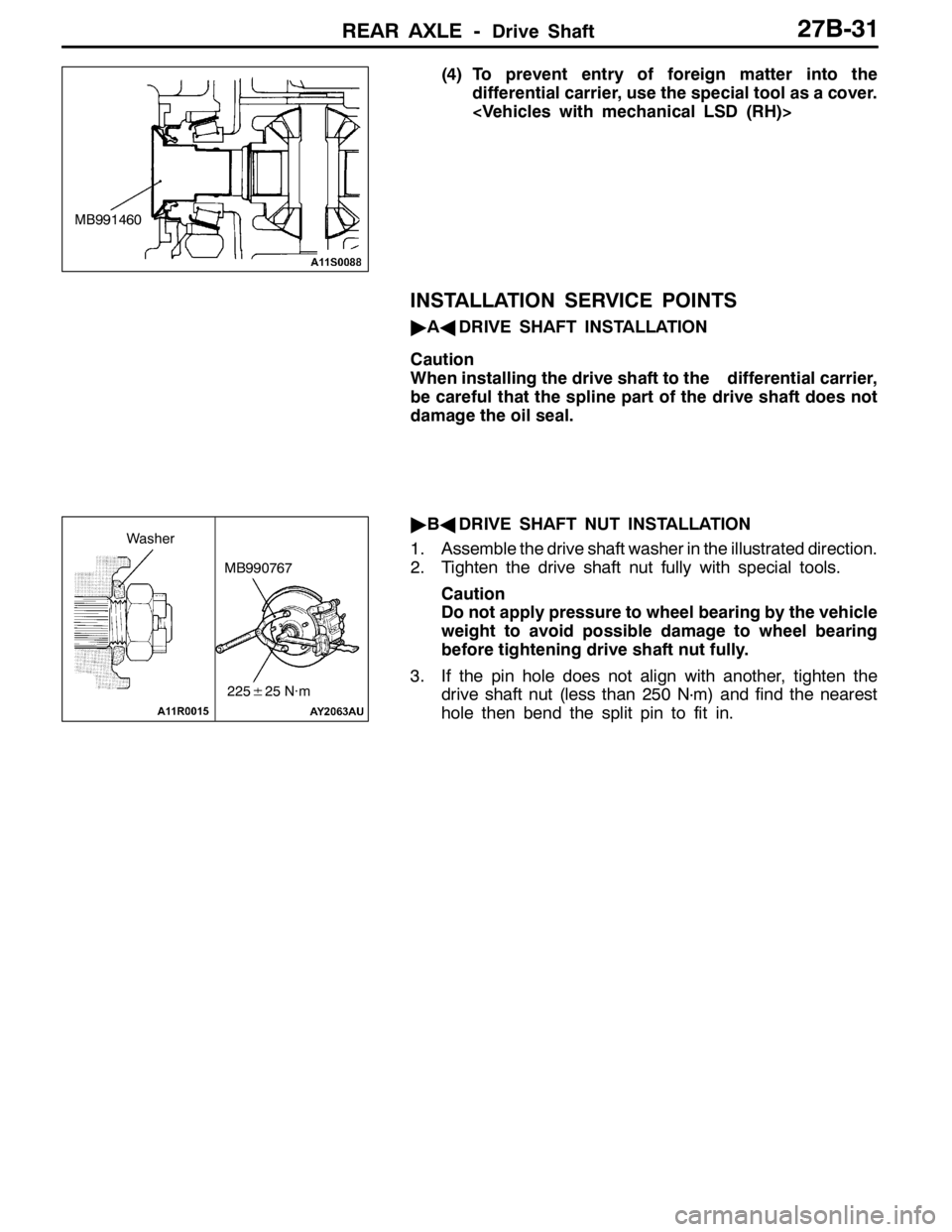

REAR AXLE -Drive Shaft27B-31

(4) To prevent entry of foreign matter into the

differential carrier, use the special tool as a cover.

INSTALLATION SERVICE POINTS

"AADRIVE SHAFT INSTALLATION

Caution

When installing the drive shaft to the differential carrier,

be careful that the spline part of the drive shaft does not

damage the oil seal.

"BADRIVE SHAFT NUT INSTALLATION

1. Assemble the drive shaft washer in the illustrated direction.

2. Tighten the drive shaft nut fully with special tools.

Caution

Do not apply pressure to wheel bearing by the vehicle

weight to avoid possible damage to wheel bearing

before tightening drive shaft nut fully.

3. If the pin hole does not align with another, tighten the

drive shaft nut (less than 250 N

·m) and find the nearest

hole then bend the split pin to fit in.

MB991460

MB990767

225±25 N·m

Washer

Page 978 of 1449

REAR AXLE -Drive Shaft27B-32

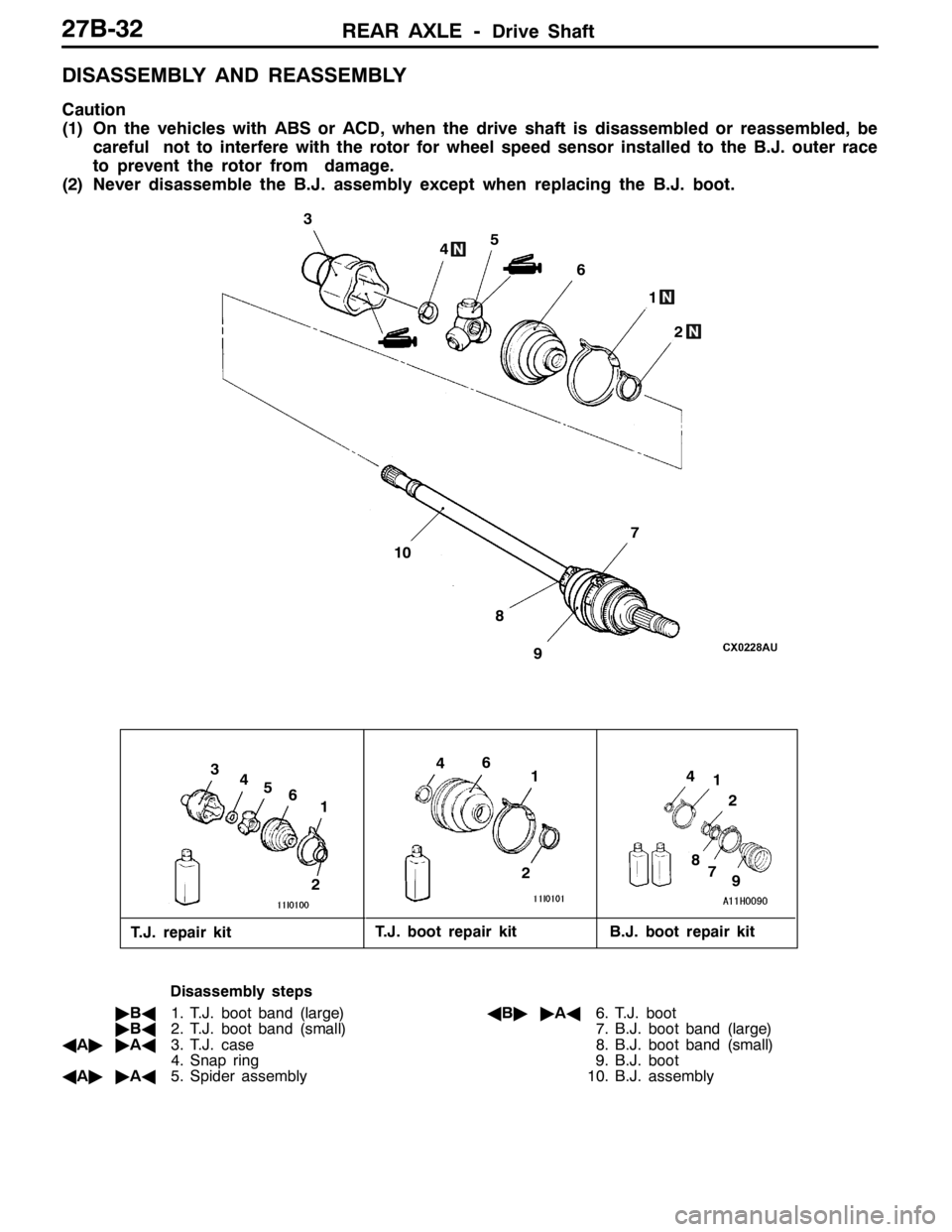

DISASSEMBLY AND REASSEMBLY

Caution

(1) On the vehicles with ABS or ACD, when the drive shaft is disassembled or reassembled, be

careful not to interfere with the rotor for wheel speed sensor installed to the B.J. outer race

to prevent the rotor from damage.

(2) Never disassemble the B.J. assembly except when replacing the B.J. boot.

2

6

4

3

5

7

1

4

2

43

61

2

4

51

2

9

10

1

8

8

97

6

T.J. repair kitT.J. boot repair kit B.J. boot repair kit

Disassembly steps

"BA1. T.J. boot band (large)

"BA2. T.J. boot band (small)

AA""AA3. T.J. case

4. Snap ring

AA""AA5. Spider assemblyAB""AA6. T.J. boot

7. B.J. boot band (large)

8. B.J. boot band (small)

9. B.J. boot

10. B.J. assembly

Page 1009 of 1449

31-1

WHEEL AND TYRE

CONTENTS

GENERAL INFORMATION 2..................

SERVICE SPECIFICATIONS 2.................

TROUBLESHOOTING 3.......................ON-VEHICLE SERVICE 6.....................

Tyre Inflation Pressure Check 6.................

Tyre Wear Check 6............................

Wheel Runout Check 6.........................

WHEEL AND TYRE 6........................

Page 1010 of 1449

WHEEL AND TYRE -General Information/Service Specifications31-2

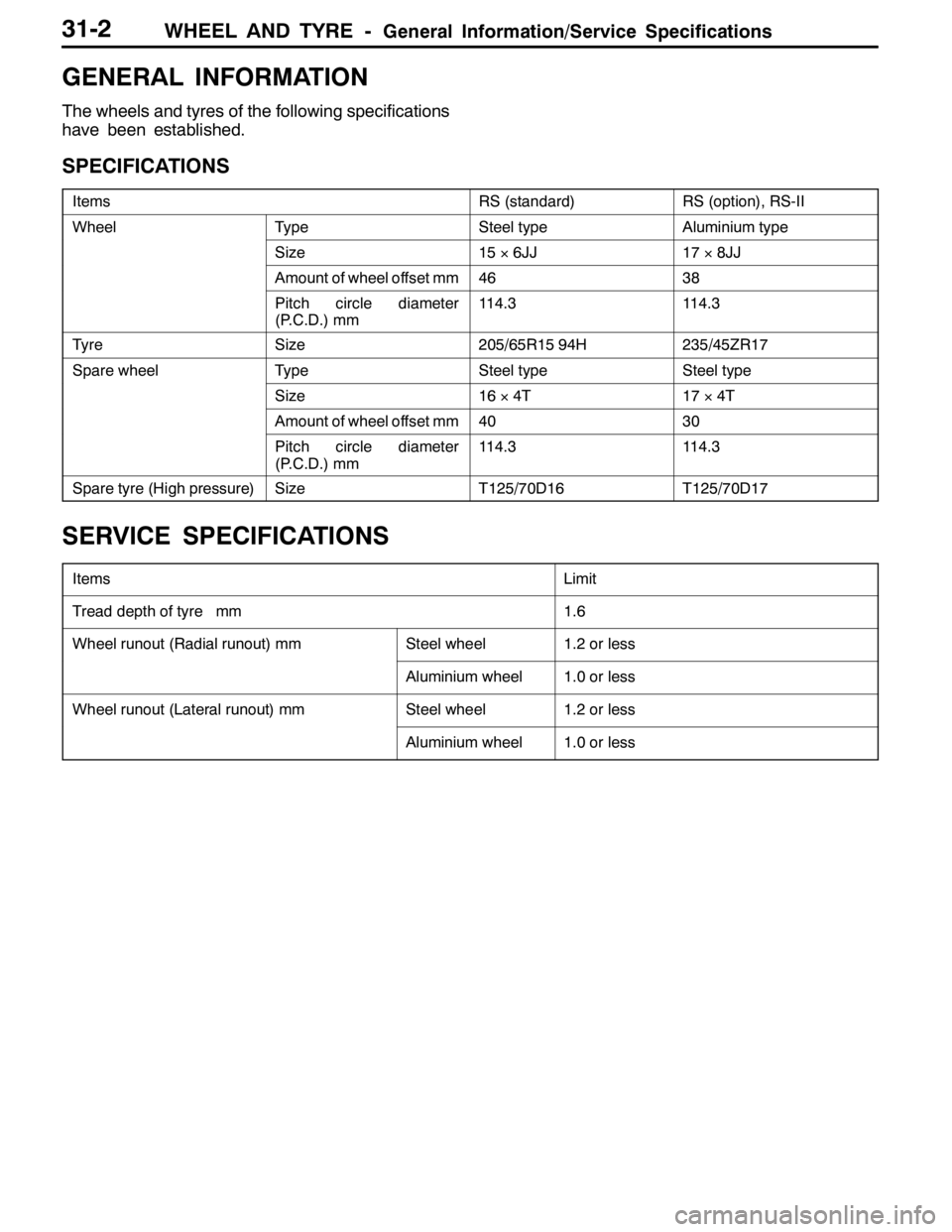

GENERAL INFORMATION

The wheels and tyres of the following specifications

have been established.

SPECIFICATIONS

ItemsRS (standard)RS (option), RS-II

WheelTypeSteel typeAluminium type

Size15×6JJ17×8JJ

Amount of wheel offset mm4638

Pitch circle diameter

(P.C.D.) mm114.3114.3

TyreSize205/65R15 94H235/45ZR17

Spare wheelTypeSteel typeSteel typep

Size16×4T17×4T

Amount of wheel offset mm4030

Pitch circle diameter

(P.C.D.) mm114.3114.3

Spare tyre (High pressure)SizeT125/70D16T125/70D17

SERVICE SPECIFICATIONS

ItemsLimit

Tread depth of tyre mm1.6

Wheel runout (Radial runout) mmSteel wheel1.2 or less

Aluminium wheel1.0 or less

Wheel runout (Lateral runout) mmSteel wheel1.2 or less

Aluminium wheel1.0 or less